How to Improve Silicone Rubber's Functional Wearability?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Wearability Background

Silicone rubber has emerged as a versatile material with a wide range of applications, particularly in the field of wearable technology. Its unique properties, including flexibility, durability, and biocompatibility, have made it an attractive choice for various wearable devices and applications. The journey of silicone rubber in wearable technology began in the mid-20th century, with its initial use in medical implants and prosthetics.

As technology advanced, the potential of silicone rubber in wearable applications expanded significantly. The material's ability to conform to body contours and maintain its properties under various environmental conditions made it ideal for developing comfortable and functional wearable devices. This led to its incorporation in fitness trackers, smart clothing, and medical monitoring devices.

The evolution of silicone rubber wearability has been driven by several key factors. Advancements in material science have resulted in improved formulations, enhancing the rubber's mechanical properties and durability. Concurrently, the miniaturization of electronic components has allowed for the integration of sophisticated sensors and circuitry into silicone-based wearables, expanding their functionality.

In recent years, the focus has shifted towards improving the functional aspects of silicone rubber wearables. This includes enhancing their ability to conduct electricity, improving thermal management, and increasing their responsiveness to external stimuli. Researchers and engineers are exploring various methods to modify silicone rubber at the molecular level, incorporating conductive fillers, and developing novel surface treatments to achieve these goals.

The current technological landscape presents both opportunities and challenges in improving silicone rubber's functional wearability. While the material's inherent properties provide a solid foundation, there is a growing demand for wearables that can seamlessly integrate with the human body and provide advanced functionalities. This has led to interdisciplinary collaborations between material scientists, bioengineers, and electronics experts to push the boundaries of what is possible with silicone rubber wearables.

As we look towards the future, the trajectory of silicone rubber in wearable technology is poised for significant advancements. The ongoing research in nanotechnology and smart materials is expected to yield breakthroughs in enhancing the material's sensing capabilities, self-healing properties, and adaptability to various environmental conditions. These developments aim to create wearables that are not only more comfortable and durable but also more intelligent and responsive to user needs.

As technology advanced, the potential of silicone rubber in wearable applications expanded significantly. The material's ability to conform to body contours and maintain its properties under various environmental conditions made it ideal for developing comfortable and functional wearable devices. This led to its incorporation in fitness trackers, smart clothing, and medical monitoring devices.

The evolution of silicone rubber wearability has been driven by several key factors. Advancements in material science have resulted in improved formulations, enhancing the rubber's mechanical properties and durability. Concurrently, the miniaturization of electronic components has allowed for the integration of sophisticated sensors and circuitry into silicone-based wearables, expanding their functionality.

In recent years, the focus has shifted towards improving the functional aspects of silicone rubber wearables. This includes enhancing their ability to conduct electricity, improving thermal management, and increasing their responsiveness to external stimuli. Researchers and engineers are exploring various methods to modify silicone rubber at the molecular level, incorporating conductive fillers, and developing novel surface treatments to achieve these goals.

The current technological landscape presents both opportunities and challenges in improving silicone rubber's functional wearability. While the material's inherent properties provide a solid foundation, there is a growing demand for wearables that can seamlessly integrate with the human body and provide advanced functionalities. This has led to interdisciplinary collaborations between material scientists, bioengineers, and electronics experts to push the boundaries of what is possible with silicone rubber wearables.

As we look towards the future, the trajectory of silicone rubber in wearable technology is poised for significant advancements. The ongoing research in nanotechnology and smart materials is expected to yield breakthroughs in enhancing the material's sensing capabilities, self-healing properties, and adaptability to various environmental conditions. These developments aim to create wearables that are not only more comfortable and durable but also more intelligent and responsive to user needs.

Market Analysis for Wearable Silicone Products

The wearable silicone products market has experienced significant growth in recent years, driven by increasing consumer demand for comfortable, durable, and versatile wearable devices. This market segment encompasses a wide range of products, including smartwatches, fitness trackers, medical devices, and innovative textiles incorporating silicone components.

The global wearable technology market, which includes silicone-based products, is projected to continue its upward trajectory. Key factors contributing to this growth include rising health consciousness, technological advancements in sensor technology, and the increasing adoption of Internet of Things (IoT) devices.

Silicone rubber's unique properties make it particularly suitable for wearable applications. Its flexibility, biocompatibility, and resistance to temperature extremes and chemicals have positioned it as a preferred material in the wearables industry. The medical and healthcare sectors have emerged as significant drivers of demand for wearable silicone products, with applications ranging from continuous glucose monitors to wearable drug delivery systems.

The sports and fitness segment also represents a substantial market for wearable silicone products. Silicone-based fitness trackers and smartwatches have gained popularity due to their comfort during physical activities and resistance to sweat and water. This trend is expected to continue as consumers increasingly prioritize health and wellness monitoring.

Consumer electronics manufacturers are increasingly incorporating silicone components into their wearable devices to enhance durability and user comfort. This trend is particularly evident in the smartwatch and hearables markets, where silicone straps and ear tips are becoming standard features.

The Asia-Pacific region is anticipated to witness the fastest growth in the wearable silicone products market, driven by a large consumer base, increasing disposable incomes, and rapid technological adoption. North America and Europe remain significant markets, with a focus on high-end, feature-rich wearable devices.

Challenges in the market include concerns about data privacy and security, as well as the need for improved battery life in wearable devices. Additionally, there is growing demand for more sustainable and eco-friendly silicone materials, presenting both a challenge and an opportunity for manufacturers.

As the wearable technology market continues to evolve, there is an increasing focus on developing silicone materials with enhanced properties such as improved durability, better adhesion to other materials, and advanced sensing capabilities. This trend is likely to drive innovation in silicone formulations and manufacturing processes, further expanding the potential applications for wearable silicone products.

The global wearable technology market, which includes silicone-based products, is projected to continue its upward trajectory. Key factors contributing to this growth include rising health consciousness, technological advancements in sensor technology, and the increasing adoption of Internet of Things (IoT) devices.

Silicone rubber's unique properties make it particularly suitable for wearable applications. Its flexibility, biocompatibility, and resistance to temperature extremes and chemicals have positioned it as a preferred material in the wearables industry. The medical and healthcare sectors have emerged as significant drivers of demand for wearable silicone products, with applications ranging from continuous glucose monitors to wearable drug delivery systems.

The sports and fitness segment also represents a substantial market for wearable silicone products. Silicone-based fitness trackers and smartwatches have gained popularity due to their comfort during physical activities and resistance to sweat and water. This trend is expected to continue as consumers increasingly prioritize health and wellness monitoring.

Consumer electronics manufacturers are increasingly incorporating silicone components into their wearable devices to enhance durability and user comfort. This trend is particularly evident in the smartwatch and hearables markets, where silicone straps and ear tips are becoming standard features.

The Asia-Pacific region is anticipated to witness the fastest growth in the wearable silicone products market, driven by a large consumer base, increasing disposable incomes, and rapid technological adoption. North America and Europe remain significant markets, with a focus on high-end, feature-rich wearable devices.

Challenges in the market include concerns about data privacy and security, as well as the need for improved battery life in wearable devices. Additionally, there is growing demand for more sustainable and eco-friendly silicone materials, presenting both a challenge and an opportunity for manufacturers.

As the wearable technology market continues to evolve, there is an increasing focus on developing silicone materials with enhanced properties such as improved durability, better adhesion to other materials, and advanced sensing capabilities. This trend is likely to drive innovation in silicone formulations and manufacturing processes, further expanding the potential applications for wearable silicone products.

Current Challenges in Silicone Rubber Wearability

Despite the widespread use of silicone rubber in wearable applications, several challenges persist in enhancing its functional wearability. One of the primary issues is the material's inherent hydrophobicity, which can lead to discomfort and skin irritation during prolonged contact. This property also limits the rubber's ability to effectively wick away moisture, potentially causing hygiene concerns in wearable devices.

Another significant challenge lies in achieving an optimal balance between flexibility and durability. While silicone rubber is known for its elasticity, prolonged use in wearable applications can lead to material fatigue and degradation. This is particularly problematic in areas subjected to repeated stress, such as joint regions in wearable garments or high-flex zones in medical devices.

The thermal management of silicone rubber in wearable applications presents another hurdle. The material's low thermal conductivity can result in heat accumulation, leading to user discomfort and potentially affecting the performance of integrated electronic components in smart wearables.

Adhesion to other materials, especially in multi-layered wearable structures, remains a persistent challenge. The low surface energy of silicone rubber makes it difficult to achieve strong, durable bonds with other materials commonly used in wearable technology, such as textiles or rigid components.

Biocompatibility and long-term safety are ongoing concerns, particularly for medical and continuous-wear applications. While silicone rubber is generally considered biocompatible, extended contact with skin can sometimes lead to allergic reactions or sensitization in some individuals.

The integration of functional elements, such as sensors or conductive pathways, into silicone rubber matrices without compromising the material's inherent properties is another significant challenge. This integration is crucial for developing advanced smart wearables but often requires complex manufacturing processes.

Lastly, the environmental impact and end-of-life considerations for silicone rubber wearables pose challenges. The material's durability, while beneficial for product longevity, makes it difficult to recycle or biodegrade, raising concerns about sustainable product lifecycles in the wearable technology sector.

Another significant challenge lies in achieving an optimal balance between flexibility and durability. While silicone rubber is known for its elasticity, prolonged use in wearable applications can lead to material fatigue and degradation. This is particularly problematic in areas subjected to repeated stress, such as joint regions in wearable garments or high-flex zones in medical devices.

The thermal management of silicone rubber in wearable applications presents another hurdle. The material's low thermal conductivity can result in heat accumulation, leading to user discomfort and potentially affecting the performance of integrated electronic components in smart wearables.

Adhesion to other materials, especially in multi-layered wearable structures, remains a persistent challenge. The low surface energy of silicone rubber makes it difficult to achieve strong, durable bonds with other materials commonly used in wearable technology, such as textiles or rigid components.

Biocompatibility and long-term safety are ongoing concerns, particularly for medical and continuous-wear applications. While silicone rubber is generally considered biocompatible, extended contact with skin can sometimes lead to allergic reactions or sensitization in some individuals.

The integration of functional elements, such as sensors or conductive pathways, into silicone rubber matrices without compromising the material's inherent properties is another significant challenge. This integration is crucial for developing advanced smart wearables but often requires complex manufacturing processes.

Lastly, the environmental impact and end-of-life considerations for silicone rubber wearables pose challenges. The material's durability, while beneficial for product longevity, makes it difficult to recycle or biodegrade, raising concerns about sustainable product lifecycles in the wearable technology sector.

Existing Wearability Enhancement Solutions

01 Flexible and wearable silicone rubber electronics

Silicone rubber is used as a substrate or encapsulation material for flexible and wearable electronic devices. Its elasticity and biocompatibility make it ideal for creating comfortable, skin-friendly wearable technology. These devices can include sensors, circuits, and other electronic components embedded within or attached to the silicone rubber matrix.- Flexible and wearable silicone rubber electronics: Silicone rubber is used as a substrate or encapsulation material for flexible and wearable electronic devices. Its elasticity and biocompatibility make it ideal for creating comfortable, skin-friendly wearable technology. These devices can include sensors, circuits, and other electronic components embedded within or attached to the silicone rubber material.

- Silicone rubber composites for enhanced functionality: Composite materials combining silicone rubber with other substances are developed to enhance specific properties such as conductivity, thermal management, or mechanical strength. These composites can improve the overall performance and functionality of wearable devices while maintaining the beneficial properties of silicone rubber.

- Surface modification of silicone rubber for wearables: Various surface modification techniques are applied to silicone rubber to improve its adhesion, hydrophobicity, or other surface properties. These modifications can enhance the durability, comfort, and functionality of wearable silicone rubber products, making them more suitable for long-term use in diverse environments.

- Integration of smart features in silicone rubber wearables: Silicone rubber is used as a base material for integrating smart features such as shape memory, self-healing properties, or stimuli-responsive behaviors. These advanced functionalities can create adaptive and responsive wearable devices that change their properties based on environmental conditions or user needs.

- Manufacturing processes for silicone rubber wearables: Innovative manufacturing techniques are developed to produce silicone rubber wearables with complex geometries and integrated functionalities. These processes may include 3D printing, molding techniques, or hybrid manufacturing methods that allow for the seamless integration of electronic components and other materials with silicone rubber.

02 Silicone rubber composites for enhanced functionality

Composites of silicone rubber with other materials are developed to enhance specific properties such as conductivity, thermal management, or mechanical strength. These composites can incorporate nanoparticles, conductive fillers, or other functional additives to create wearable materials with tailored characteristics for various applications.Expand Specific Solutions03 Silicone rubber coatings for textile integration

Silicone rubber coatings are applied to textiles to create functional, wearable fabrics. These coatings can provide water resistance, improved durability, or specific surface properties while maintaining the fabric's flexibility and breathability. This approach allows for the integration of silicone rubber's benefits into traditional textile-based wearables.Expand Specific Solutions04 Molding and fabrication techniques for wearable silicone rubber

Advanced molding and fabrication techniques are developed to create complex, three-dimensional silicone rubber structures for wearable applications. These methods can include 3D printing, injection molding, or multi-material molding processes to produce ergonomic, form-fitting wearable devices with integrated functionalities.Expand Specific Solutions05 Biocompatible silicone rubber formulations for medical wearables

Specialized silicone rubber formulations are developed for medical and healthcare wearables. These formulations focus on biocompatibility, long-term stability, and specific interactions with biological systems. They can be used in applications such as wearable drug delivery systems, prosthetics, or long-term health monitoring devices.Expand Specific Solutions

Key Players in Silicone Rubber Industry

The market for improving silicone rubber's functional wearability is in a growth phase, driven by increasing demand for advanced wearable technologies across industries. The global market size for functional silicone rubber is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with key players like Shin-Etsu Chemical, Dow Silicones, and Momentive Performance Materials leading innovation. These companies are developing novel formulations and manufacturing processes to enhance properties such as flexibility, durability, and biocompatibility. Academic institutions like Sichuan University and Tianjin University are also contributing to research and development, particularly in areas of material science and biomedical applications.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber formulations with enhanced functional wearability. Their approach involves incorporating specialized additives and modifying the polymer structure to improve key properties. They have introduced a series of silicone elastomers with increased elasticity and durability, achieving up to 50% improvement in tensile strength compared to conventional silicone rubbers[1]. Additionally, Shin-Etsu has developed surface modification techniques that enhance the material's hydrophilicity, resulting in improved comfort and reduced friction when in contact with skin[3]. The company has also focused on developing silicone rubbers with improved thermal management properties, incorporating phase change materials to regulate temperature and enhance wearer comfort in various environmental conditions[5].

Strengths: Industry-leading expertise in silicone chemistry, wide range of customizable formulations. Weaknesses: Higher cost compared to conventional materials, potential limitations in extreme temperature applications.

Dow Silicones Corp.

Technical Solution: Dow Silicones has made significant strides in improving silicone rubber's functional wearability through their innovative SILASTIC™ platform. They have developed a range of silicone elastomers with enhanced mechanical properties, including improved tear strength and elongation at break, which are crucial for wearable applications. Dow's approach includes the use of proprietary crosslinking technologies that allow for precise control of the material's properties[2]. They have also introduced self-healing silicone rubbers that can recover from minor damage, extending the lifespan of wearable devices. Furthermore, Dow has developed silicone composites that incorporate conductive materials, enabling the creation of stretchable electronics with up to 300% elongation while maintaining electrical performance[4]. Their latest innovations also focus on biocompatible silicone formulations with reduced skin irritation potential, making them suitable for long-term wearable medical devices[6].

Strengths: Extensive R&D capabilities, diverse product portfolio catering to various industries. Weaknesses: Potential scalability challenges for some advanced formulations, regulatory hurdles in certain applications.

Innovative Approaches in Silicone Rubber Functionality

Silicone-rubber-based curable composition, method for producing silicone rubber, silicone rubber, molding, and medical tubing

PatentWO2013042707A1

Innovation

- A curable silicone rubber composition incorporating a combination of vinyl group-containing linear and branched organopolysiloxanes, organohydrogenpolysiloxanes, silica particles, and a silane coupling agent, along with a platinum or platinum compound, is developed to enhance tensile and tear strength, ensuring improved mechanical properties without compromising usability or transparency.

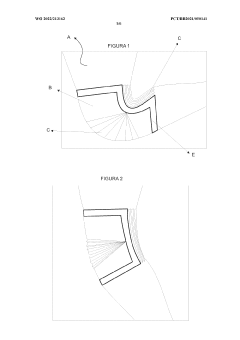

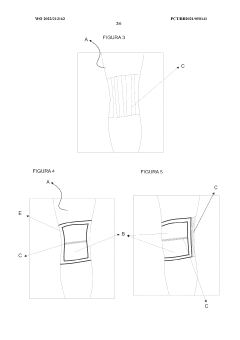

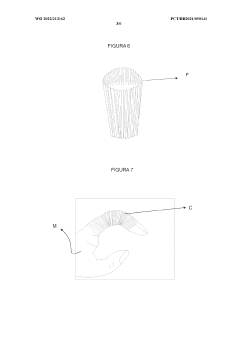

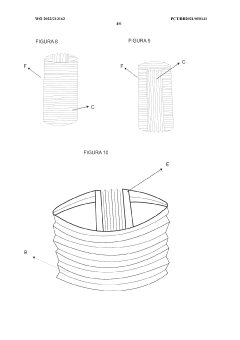

Configuration for product made of liquid silicone rubber (LSR) for providing comfort, protection, rehabilitation and bodily care

PatentWO2022213162A1

Innovation

- The use of Liquid Silicone Rubber (LSR) with pleated designs and gel inserts in products like gloves, socks, sleeves, and pads, which can be heated or cooled, providing a flexible, adherent, and protective layer that prevents friction and allows full mobility, while incorporating therapeutic benefits.

Environmental Impact of Silicone Rubber Products

The environmental impact of silicone rubber products is a critical consideration in the context of improving their functional wearability. Silicone rubber, while offering numerous advantages in wearable applications, also presents certain environmental challenges that must be addressed to ensure sustainable development and use.

One of the primary environmental concerns associated with silicone rubber products is their persistence in the environment. Unlike many organic materials, silicone rubber does not biodegrade easily, potentially leading to long-term accumulation in landfills and natural ecosystems. This persistence can contribute to pollution and habitat disruption if not properly managed.

The production process of silicone rubber also has environmental implications. The synthesis of silicone polymers typically involves energy-intensive processes and the use of various chemicals, some of which may have adverse environmental effects if not properly handled or disposed of. Additionally, the extraction of raw materials, particularly silica, can lead to habitat destruction and contribute to carbon emissions through mining and transportation activities.

However, it is important to note that silicone rubber products often have a lower environmental impact compared to some alternative materials in certain applications. Their durability and long lifespan can reduce the need for frequent replacements, potentially decreasing overall resource consumption and waste generation. Furthermore, silicone rubber's resistance to extreme temperatures and chemicals can lead to energy savings in various industrial processes.

In the context of wearable technology, the environmental impact of silicone rubber products extends to their end-of-life management. As wearable devices become more prevalent, the disposal of these products becomes a growing concern. While silicone rubber itself is not toxic, the integration of electronic components and other materials in wearable devices can complicate recycling efforts and increase the potential for electronic waste.

To mitigate these environmental impacts and improve the functional wearability of silicone rubber products, several strategies can be employed. Research into biodegradable silicone formulations or composite materials that maintain the desired properties while reducing environmental persistence is one promising avenue. Additionally, developing more efficient production processes and exploring sustainable sourcing options for raw materials can help reduce the overall environmental footprint of silicone rubber products.

Improving the recyclability of silicone rubber, particularly in wearable technology applications, is another crucial area for development. This may involve designing products with easy disassembly in mind, using modular components, or developing new recycling technologies specifically tailored for silicone-based materials. Furthermore, implementing take-back programs and promoting circular economy principles in the silicone rubber industry can help ensure proper end-of-life management and resource recovery.

One of the primary environmental concerns associated with silicone rubber products is their persistence in the environment. Unlike many organic materials, silicone rubber does not biodegrade easily, potentially leading to long-term accumulation in landfills and natural ecosystems. This persistence can contribute to pollution and habitat disruption if not properly managed.

The production process of silicone rubber also has environmental implications. The synthesis of silicone polymers typically involves energy-intensive processes and the use of various chemicals, some of which may have adverse environmental effects if not properly handled or disposed of. Additionally, the extraction of raw materials, particularly silica, can lead to habitat destruction and contribute to carbon emissions through mining and transportation activities.

However, it is important to note that silicone rubber products often have a lower environmental impact compared to some alternative materials in certain applications. Their durability and long lifespan can reduce the need for frequent replacements, potentially decreasing overall resource consumption and waste generation. Furthermore, silicone rubber's resistance to extreme temperatures and chemicals can lead to energy savings in various industrial processes.

In the context of wearable technology, the environmental impact of silicone rubber products extends to their end-of-life management. As wearable devices become more prevalent, the disposal of these products becomes a growing concern. While silicone rubber itself is not toxic, the integration of electronic components and other materials in wearable devices can complicate recycling efforts and increase the potential for electronic waste.

To mitigate these environmental impacts and improve the functional wearability of silicone rubber products, several strategies can be employed. Research into biodegradable silicone formulations or composite materials that maintain the desired properties while reducing environmental persistence is one promising avenue. Additionally, developing more efficient production processes and exploring sustainable sourcing options for raw materials can help reduce the overall environmental footprint of silicone rubber products.

Improving the recyclability of silicone rubber, particularly in wearable technology applications, is another crucial area for development. This may involve designing products with easy disassembly in mind, using modular components, or developing new recycling technologies specifically tailored for silicone-based materials. Furthermore, implementing take-back programs and promoting circular economy principles in the silicone rubber industry can help ensure proper end-of-life management and resource recovery.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount when improving silicone rubber's functional wearability. Silicone rubber has long been recognized for its excellent biocompatibility, making it a preferred material for various medical and wearable applications. However, as the demand for more advanced and integrated wearable devices increases, it is crucial to address potential safety concerns and enhance the material's biocompatibility further.

One of the primary considerations in improving silicone rubber's biocompatibility is minimizing the risk of adverse reactions when in contact with human skin or other biological tissues. This involves carefully selecting and optimizing the composition of silicone rubber formulations to reduce the presence of potentially harmful additives or residual compounds. Manufacturers must ensure that all components used in the production process meet stringent safety standards and undergo thorough testing for cytotoxicity, sensitization, and irritation.

Surface modification techniques play a vital role in enhancing the biocompatibility of silicone rubber. By altering the surface properties, it is possible to improve cell adhesion, reduce protein adsorption, and minimize the risk of bacterial colonization. Methods such as plasma treatment, chemical grafting, and nanoparticle incorporation can be employed to create functional surfaces that promote better integration with biological systems while maintaining the material's inherent properties.

The long-term stability and degradation behavior of silicone rubber in physiological environments must be carefully evaluated. While silicone rubber is generally resistant to biodegradation, prolonged exposure to bodily fluids and mechanical stress may lead to material breakdown or leaching of compounds. Developing strategies to enhance the material's durability and minimize degradation products is essential for ensuring the safety and efficacy of wearable devices over extended periods of use.

Addressing potential allergenic properties is another critical aspect of improving silicone rubber's functional wearability. Although silicone allergies are relatively rare, some individuals may experience hypersensitivity reactions. Research into hypoallergenic formulations and surface treatments that reduce the risk of allergic responses can significantly expand the user base for silicone rubber-based wearable devices.

As wearable technologies become more sophisticated, the integration of electronic components and sensors into silicone rubber matrices presents new biocompatibility challenges. Ensuring proper encapsulation and isolation of these elements is crucial to prevent potential leaching of harmful substances or electromagnetic interference with biological systems. Developing advanced manufacturing techniques and composite materials that maintain biocompatibility while enabling seamless integration of functional components is an area of ongoing research and development.

Regulatory compliance and standardization are essential considerations in the pursuit of improved biocompatibility and safety for silicone rubber wearables. Adhering to guidelines set by regulatory bodies such as the FDA and ISO ensures that new developments in silicone rubber technology meet the necessary safety requirements for human use. Establishing comprehensive testing protocols and quality control measures throughout the product development lifecycle is crucial for maintaining high standards of biocompatibility and safety in functional wearable applications.

One of the primary considerations in improving silicone rubber's biocompatibility is minimizing the risk of adverse reactions when in contact with human skin or other biological tissues. This involves carefully selecting and optimizing the composition of silicone rubber formulations to reduce the presence of potentially harmful additives or residual compounds. Manufacturers must ensure that all components used in the production process meet stringent safety standards and undergo thorough testing for cytotoxicity, sensitization, and irritation.

Surface modification techniques play a vital role in enhancing the biocompatibility of silicone rubber. By altering the surface properties, it is possible to improve cell adhesion, reduce protein adsorption, and minimize the risk of bacterial colonization. Methods such as plasma treatment, chemical grafting, and nanoparticle incorporation can be employed to create functional surfaces that promote better integration with biological systems while maintaining the material's inherent properties.

The long-term stability and degradation behavior of silicone rubber in physiological environments must be carefully evaluated. While silicone rubber is generally resistant to biodegradation, prolonged exposure to bodily fluids and mechanical stress may lead to material breakdown or leaching of compounds. Developing strategies to enhance the material's durability and minimize degradation products is essential for ensuring the safety and efficacy of wearable devices over extended periods of use.

Addressing potential allergenic properties is another critical aspect of improving silicone rubber's functional wearability. Although silicone allergies are relatively rare, some individuals may experience hypersensitivity reactions. Research into hypoallergenic formulations and surface treatments that reduce the risk of allergic responses can significantly expand the user base for silicone rubber-based wearable devices.

As wearable technologies become more sophisticated, the integration of electronic components and sensors into silicone rubber matrices presents new biocompatibility challenges. Ensuring proper encapsulation and isolation of these elements is crucial to prevent potential leaching of harmful substances or electromagnetic interference with biological systems. Developing advanced manufacturing techniques and composite materials that maintain biocompatibility while enabling seamless integration of functional components is an area of ongoing research and development.

Regulatory compliance and standardization are essential considerations in the pursuit of improved biocompatibility and safety for silicone rubber wearables. Adhering to guidelines set by regulatory bodies such as the FDA and ISO ensures that new developments in silicone rubber technology meet the necessary safety requirements for human use. Establishing comprehensive testing protocols and quality control measures throughout the product development lifecycle is crucial for maintaining high standards of biocompatibility and safety in functional wearable applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!