How to Leverage Silicone Rubber in Competitive Sports Gear?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Sports: Evolution and Objectives

Silicone rubber has emerged as a revolutionary material in the realm of competitive sports gear, transforming the landscape of athletic performance and protection. The evolution of this versatile substance in sports applications can be traced back to the mid-20th century, with its initial use primarily in swimming goggles and diving masks. As material science advanced, so did the understanding of silicone rubber's unique properties, leading to its expanded application across various sports disciplines.

The journey of silicone rubber in sports gear has been marked by continuous innovation and adaptation. From its early days in water sports, it quickly found its way into track and field, where it was incorporated into shoe soles to enhance cushioning and energy return. The material's flexibility, durability, and resistance to extreme temperatures made it an ideal component in outdoor sports equipment, ranging from ski boots to climbing gear.

In recent decades, the focus has shifted towards leveraging silicone rubber's shock-absorbing capabilities in contact sports. This has led to the development of advanced protective gear, including mouthguards, helmets, and padding, significantly reducing the risk of injuries in high-impact activities. Simultaneously, the material's hypoallergenic and non-toxic nature has made it a preferred choice for skin-contact applications, such as grip enhancers and compression wear.

The current technological landscape sees silicone rubber at the forefront of sports innovation, with objectives centered on enhancing athletic performance, improving safety, and pushing the boundaries of equipment design. Researchers and manufacturers are exploring ways to fine-tune the material's properties, aiming to create gear that offers optimal balance between protection and performance.

One of the primary goals in leveraging silicone rubber for competitive sports gear is to develop "smart" materials that can adapt to changing conditions. This includes creating temperature-responsive fabrics that regulate body heat, impact-sensitive protective gear that stiffens upon collision, and moisture-wicking surfaces that enhance grip and control. Additionally, there is a growing emphasis on sustainability, with efforts directed towards developing eco-friendly silicone rubber formulations and recycling processes.

As we look to the future, the objectives for silicone rubber in sports gear extend beyond mere physical enhancements. Integration with wearable technology presents exciting possibilities, such as embedding sensors within silicone-based gear to monitor athlete performance and provide real-time feedback. The ultimate aim is to create a new generation of sports equipment that not only protects and enhances performance but also actively contributes to an athlete's training and competitive edge.

The journey of silicone rubber in sports gear has been marked by continuous innovation and adaptation. From its early days in water sports, it quickly found its way into track and field, where it was incorporated into shoe soles to enhance cushioning and energy return. The material's flexibility, durability, and resistance to extreme temperatures made it an ideal component in outdoor sports equipment, ranging from ski boots to climbing gear.

In recent decades, the focus has shifted towards leveraging silicone rubber's shock-absorbing capabilities in contact sports. This has led to the development of advanced protective gear, including mouthguards, helmets, and padding, significantly reducing the risk of injuries in high-impact activities. Simultaneously, the material's hypoallergenic and non-toxic nature has made it a preferred choice for skin-contact applications, such as grip enhancers and compression wear.

The current technological landscape sees silicone rubber at the forefront of sports innovation, with objectives centered on enhancing athletic performance, improving safety, and pushing the boundaries of equipment design. Researchers and manufacturers are exploring ways to fine-tune the material's properties, aiming to create gear that offers optimal balance between protection and performance.

One of the primary goals in leveraging silicone rubber for competitive sports gear is to develop "smart" materials that can adapt to changing conditions. This includes creating temperature-responsive fabrics that regulate body heat, impact-sensitive protective gear that stiffens upon collision, and moisture-wicking surfaces that enhance grip and control. Additionally, there is a growing emphasis on sustainability, with efforts directed towards developing eco-friendly silicone rubber formulations and recycling processes.

As we look to the future, the objectives for silicone rubber in sports gear extend beyond mere physical enhancements. Integration with wearable technology presents exciting possibilities, such as embedding sensors within silicone-based gear to monitor athlete performance and provide real-time feedback. The ultimate aim is to create a new generation of sports equipment that not only protects and enhances performance but also actively contributes to an athlete's training and competitive edge.

Market Analysis for High-Performance Sports Gear

The global market for high-performance sports gear has experienced significant growth in recent years, driven by increasing participation in competitive sports and a growing emphasis on athlete performance and safety. The market for advanced sports equipment, including those incorporating silicone rubber technology, is projected to continue its upward trajectory.

Silicone rubber has emerged as a key material in the development of cutting-edge sports gear due to its unique properties. Its excellent elasticity, durability, and resistance to extreme temperatures make it ideal for various applications in competitive sports equipment. The material's ability to absorb shock, provide cushioning, and maintain its properties under stress has led to its widespread adoption in products ranging from athletic footwear to protective gear.

The demand for silicone rubber-based sports gear is particularly strong in developed markets such as North America and Europe, where athletes and sports enthusiasts are willing to invest in high-quality equipment to enhance their performance. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth potential as disposable incomes rise and sports participation increases.

Key market segments for silicone rubber in sports gear include running shoes, cycling equipment, swimming accessories, and protective gear for contact sports. The running shoe market, in particular, has seen a surge in the use of silicone-based materials for improved cushioning and energy return. Similarly, the cycling industry has embraced silicone rubber for its vibration-dampening properties in handlebar grips and saddles.

The competitive landscape of the high-performance sports gear market is characterized by a mix of established sporting goods manufacturers and innovative startups. Major players are investing heavily in research and development to incorporate advanced materials like silicone rubber into their product lines. This has led to a wave of patent filings and strategic partnerships between material suppliers and sports equipment manufacturers.

Consumer trends indicate a growing preference for customized and technologically advanced sports gear. Athletes are increasingly seeking products that offer a combination of performance enhancement, comfort, and durability. This trend aligns well with the properties of silicone rubber, positioning it as a material of choice for future product developments.

Environmental concerns are also shaping the market, with a growing demand for sustainable and eco-friendly sports equipment. Manufacturers are exploring ways to develop recyclable silicone rubber compounds or bio-based alternatives to meet this demand while maintaining performance standards.

Silicone rubber has emerged as a key material in the development of cutting-edge sports gear due to its unique properties. Its excellent elasticity, durability, and resistance to extreme temperatures make it ideal for various applications in competitive sports equipment. The material's ability to absorb shock, provide cushioning, and maintain its properties under stress has led to its widespread adoption in products ranging from athletic footwear to protective gear.

The demand for silicone rubber-based sports gear is particularly strong in developed markets such as North America and Europe, where athletes and sports enthusiasts are willing to invest in high-quality equipment to enhance their performance. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth potential as disposable incomes rise and sports participation increases.

Key market segments for silicone rubber in sports gear include running shoes, cycling equipment, swimming accessories, and protective gear for contact sports. The running shoe market, in particular, has seen a surge in the use of silicone-based materials for improved cushioning and energy return. Similarly, the cycling industry has embraced silicone rubber for its vibration-dampening properties in handlebar grips and saddles.

The competitive landscape of the high-performance sports gear market is characterized by a mix of established sporting goods manufacturers and innovative startups. Major players are investing heavily in research and development to incorporate advanced materials like silicone rubber into their product lines. This has led to a wave of patent filings and strategic partnerships between material suppliers and sports equipment manufacturers.

Consumer trends indicate a growing preference for customized and technologically advanced sports gear. Athletes are increasingly seeking products that offer a combination of performance enhancement, comfort, and durability. This trend aligns well with the properties of silicone rubber, positioning it as a material of choice for future product developments.

Environmental concerns are also shaping the market, with a growing demand for sustainable and eco-friendly sports equipment. Manufacturers are exploring ways to develop recyclable silicone rubber compounds or bio-based alternatives to meet this demand while maintaining performance standards.

Current Applications and Challenges in Sports Equipment

Silicone rubber has become increasingly prevalent in competitive sports gear, offering unique properties that enhance performance and comfort. In recent years, manufacturers have incorporated this versatile material into various sports equipment, ranging from swimwear to running shoes and protective gear.

One of the primary applications of silicone rubber in sports equipment is in the production of high-performance swimwear. Competitive swimmers benefit from silicone-based suits that reduce drag in the water, allowing for faster times and improved hydrodynamics. These suits are designed to compress the body, reducing muscle vibration and fatigue during races.

In the realm of footwear, silicone rubber has found its way into running shoes and cleats. Manufacturers utilize silicone-based materials in shoe soles to provide enhanced cushioning, shock absorption, and energy return. This application has led to improved comfort and reduced risk of injury for athletes across various sports, including track and field, soccer, and American football.

Protective gear is another area where silicone rubber has made significant inroads. Mouthguards, for instance, now often incorporate silicone components to offer better fit, comfort, and protection. Similarly, silicone-based padding in helmets and body armor provides superior impact absorption while maintaining flexibility and breathability.

Despite these advancements, several challenges persist in the application of silicone rubber in sports equipment. One major hurdle is the balance between performance enhancement and regulatory compliance. Sports governing bodies often impose strict regulations on equipment specifications, and manufacturers must navigate these rules while innovating with silicone-based materials.

Another challenge lies in the durability and longevity of silicone rubber products. While the material offers excellent initial performance, maintaining its properties over extended use and under various environmental conditions remains a concern. Manufacturers are continually working to improve the resilience of silicone-based sports gear to withstand the rigors of competitive use.

Cost-effectiveness is also a significant challenge in the widespread adoption of silicone rubber in sports equipment. The material and manufacturing processes can be more expensive compared to traditional alternatives, potentially limiting accessibility for amateur athletes and smaller sports organizations.

Lastly, the environmental impact of silicone rubber production and disposal presents a growing concern. As sustainability becomes increasingly important in the sports industry, manufacturers face the challenge of developing more eco-friendly silicone-based products and implementing effective recycling programs for used equipment.

One of the primary applications of silicone rubber in sports equipment is in the production of high-performance swimwear. Competitive swimmers benefit from silicone-based suits that reduce drag in the water, allowing for faster times and improved hydrodynamics. These suits are designed to compress the body, reducing muscle vibration and fatigue during races.

In the realm of footwear, silicone rubber has found its way into running shoes and cleats. Manufacturers utilize silicone-based materials in shoe soles to provide enhanced cushioning, shock absorption, and energy return. This application has led to improved comfort and reduced risk of injury for athletes across various sports, including track and field, soccer, and American football.

Protective gear is another area where silicone rubber has made significant inroads. Mouthguards, for instance, now often incorporate silicone components to offer better fit, comfort, and protection. Similarly, silicone-based padding in helmets and body armor provides superior impact absorption while maintaining flexibility and breathability.

Despite these advancements, several challenges persist in the application of silicone rubber in sports equipment. One major hurdle is the balance between performance enhancement and regulatory compliance. Sports governing bodies often impose strict regulations on equipment specifications, and manufacturers must navigate these rules while innovating with silicone-based materials.

Another challenge lies in the durability and longevity of silicone rubber products. While the material offers excellent initial performance, maintaining its properties over extended use and under various environmental conditions remains a concern. Manufacturers are continually working to improve the resilience of silicone-based sports gear to withstand the rigors of competitive use.

Cost-effectiveness is also a significant challenge in the widespread adoption of silicone rubber in sports equipment. The material and manufacturing processes can be more expensive compared to traditional alternatives, potentially limiting accessibility for amateur athletes and smaller sports organizations.

Lastly, the environmental impact of silicone rubber production and disposal presents a growing concern. As sustainability becomes increasingly important in the sports industry, manufacturers face the challenge of developing more eco-friendly silicone-based products and implementing effective recycling programs for used equipment.

Innovative Silicone-Based Solutions for Athletes

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.- Composition and formulation of silicone rubber: Silicone rubber compositions typically consist of silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or provide additional functionalities.

- Manufacturing processes for silicone rubber products: Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods, such as heat curing or room temperature vulcanization, are crucial steps in the production process.

- Modifications and improvements to silicone rubber properties: Researchers continually work on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of novel fillers, and the use of specialized additives. These improvements aim to address specific application requirements such as increased durability, improved chemical resistance, or enhanced electrical properties.

- Applications of silicone rubber in various industries: Silicone rubber finds extensive use across multiple industries due to its unique properties. It is commonly used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, heat resistance, and flexibility make it suitable for a wide range of applications.

- Environmental and safety considerations in silicone rubber production: The production and use of silicone rubber involve various environmental and safety considerations. This includes the development of eco-friendly formulations, reduction of volatile organic compounds, and implementation of safe handling practices. Efforts are also made to improve the recyclability and biodegradability of silicone rubber products.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating nanoparticles.Expand Specific Solutions03 Applications of silicone rubber

Silicone rubber finds wide-ranging applications due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, and consumer products. Its biocompatibility, heat resistance, and flexibility make it suitable for diverse industrial and consumer applications.Expand Specific Solutions04 Curing methods for silicone rubber

Various curing methods are employed for silicone rubber, including heat curing, room temperature vulcanization (RTV), and UV curing. Each method affects the final properties of the rubber differently. The choice of curing method depends on the specific application and desired characteristics of the final product.Expand Specific Solutions05 Silicone rubber composites and blends

Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing with fibers, blending with other elastomers, or incorporating functional fillers. These composites often exhibit improved mechanical strength, thermal properties, or specific functionalities tailored for particular applications.Expand Specific Solutions

Key Players in Sports Gear Manufacturing

The competitive landscape for leveraging silicone rubber in sports gear is characterized by a mature market with established players and ongoing innovation. The global sports equipment market, valued at over $300 billion, is in a growth phase driven by increasing health awareness and technological advancements. Major companies like Anta, Bridgestone, and Goodyear are actively developing silicone-based products, leveraging their expertise in materials science. Technological maturity varies, with firms like JSR Corp and Shin-Etsu Chemical leading in silicone rubber innovations. Emerging players such as Holmenkol and Xiamen Yuanbao are also entering the market, focusing on niche applications and specialized formulations to compete with established brands.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed advanced silicone rubber compounds specifically tailored for competitive sports gear. Their proprietary formulations offer enhanced durability and flexibility, crucial for high-performance athletic equipment. The company's silicone rubber technology incorporates nano-scale reinforcing agents, resulting in improved tear strength and abrasion resistance[1]. This allows for the creation of lightweight yet robust sports gear that can withstand intense use. Shin-Etsu's silicone rubber also exhibits excellent heat resistance and maintains its properties across a wide temperature range, making it suitable for various sporting environments[2]. The company has further innovated by developing silicone rubber with customizable hardness levels, allowing manufacturers to fine-tune the material properties for specific sports applications[3].

Strengths: Superior durability, flexibility, and customization options. Weaknesses: Potentially higher cost compared to conventional materials, may require specialized manufacturing processes.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear Tire & Rubber Co. has leveraged its expertise in rubber technology to develop silicone rubber applications for competitive sports gear. The company's approach focuses on integrating silicone rubber into high-stress areas of sports equipment to enhance performance and durability. Goodyear has developed a proprietary silicone rubber compound that offers exceptional energy return and vibration dampening properties, making it ideal for footwear and impact-absorbing components in sports gear[4]. Their silicone rubber formulations also feature advanced moisture-wicking capabilities, improving comfort for athletes during intense physical activity. Goodyear has implemented a micro-texturing process for silicone rubber surfaces, enhancing grip and control in various sporting applications[5].

Strengths: Excellent energy return and vibration dampening, advanced moisture management. Weaknesses: Limited experience in non-tire related applications, potential scalability challenges for diverse sports gear.

Breakthrough Silicone Technologies for Sports Equipment

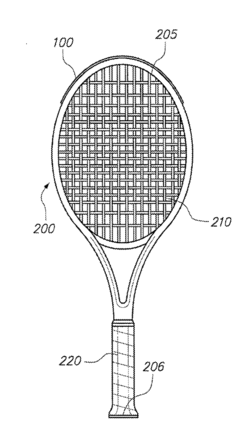

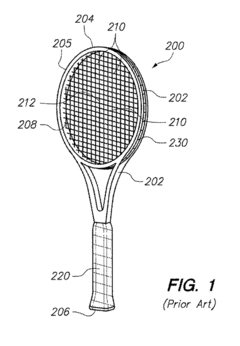

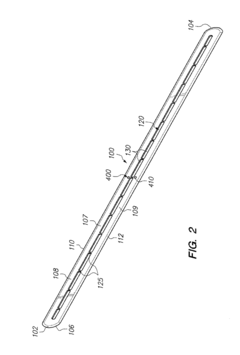

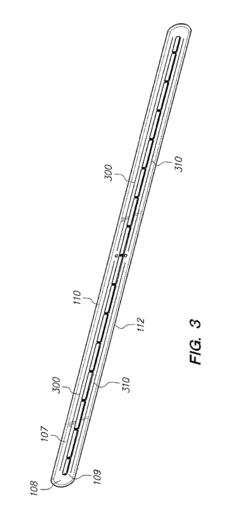

Silicone based article for use with sports equipment and other products

PatentInactiveUS20090291784A1

Innovation

- A silicone-based article with an adhesive backing, designed for easy application to sports equipment, providing protection, vibration reduction, and customization options through its durable and flexible design, which includes segmented openings for string access and customizable designs.

Rubberized fabric and sportswear

PatentWO1995019886A1

Innovation

- A rubberized cloth using zinc methacrylate-added ethylenically unsaturated nitrile-conjugated gen-based highly saturated rubber (ZSC rubber) is coated onto a soft base fabric with a urethane adhesive, providing enhanced flexibility and adhesion while maintaining wear resistance and fashionability.

Environmental Impact of Silicone in Sports Products

The environmental impact of silicone in sports products is a crucial consideration as the use of silicone rubber in competitive sports gear continues to grow. Silicone rubber, while offering numerous performance benefits, also presents environmental challenges that must be addressed throughout its lifecycle.

One of the primary environmental concerns associated with silicone in sports products is its durability and resistance to degradation. While these properties are advantageous for product longevity, they also mean that silicone-based sports gear can persist in the environment for extended periods when discarded. This persistence contributes to long-term pollution, particularly in marine ecosystems where many sports activities take place.

The production process of silicone rubber also raises environmental issues. The manufacturing of silicone involves energy-intensive processes and the use of potentially harmful chemicals. These processes can contribute to greenhouse gas emissions and the release of pollutants into the air and water if not properly managed. Additionally, the extraction of raw materials, primarily silica and hydrocarbons, can lead to habitat disruption and resource depletion.

However, it is important to note that silicone rubber does offer some environmental advantages compared to alternative materials. Its durability means that silicone-based sports products often have a longer lifespan, potentially reducing the overall consumption of resources and the frequency of product replacement. Furthermore, silicone is inert and non-toxic, which minimizes the risk of harmful chemical leaching into the environment during use.

Recycling silicone rubber presents both challenges and opportunities. While silicone can be recycled, the process is not as straightforward as with other materials like plastics. The cross-linked structure of silicone rubber makes it difficult to break down and reprocess. However, innovative recycling technologies are emerging, offering potential solutions for reducing silicone waste from sports products.

The end-of-life disposal of silicone-based sports gear is another significant environmental consideration. When incinerated, silicone produces silicon dioxide, carbon dioxide, and water vapor, with minimal toxic byproducts compared to many other synthetic materials. However, the energy required for incineration and the resulting carbon emissions remain environmental concerns.

As the sports industry continues to leverage silicone rubber in competitive gear, there is a growing emphasis on sustainable practices. Manufacturers are exploring bio-based alternatives and investigating ways to incorporate recycled silicone into new products. Additionally, efforts are being made to improve the recyclability of silicone-based sports equipment through innovative product design and material formulations.

In conclusion, while silicone rubber offers significant performance benefits in sports gear, its environmental impact requires careful consideration and ongoing efforts to mitigate negative effects throughout its lifecycle. Balancing the performance advantages with environmental responsibility will be key to the sustainable use of silicone in competitive sports equipment.

One of the primary environmental concerns associated with silicone in sports products is its durability and resistance to degradation. While these properties are advantageous for product longevity, they also mean that silicone-based sports gear can persist in the environment for extended periods when discarded. This persistence contributes to long-term pollution, particularly in marine ecosystems where many sports activities take place.

The production process of silicone rubber also raises environmental issues. The manufacturing of silicone involves energy-intensive processes and the use of potentially harmful chemicals. These processes can contribute to greenhouse gas emissions and the release of pollutants into the air and water if not properly managed. Additionally, the extraction of raw materials, primarily silica and hydrocarbons, can lead to habitat disruption and resource depletion.

However, it is important to note that silicone rubber does offer some environmental advantages compared to alternative materials. Its durability means that silicone-based sports products often have a longer lifespan, potentially reducing the overall consumption of resources and the frequency of product replacement. Furthermore, silicone is inert and non-toxic, which minimizes the risk of harmful chemical leaching into the environment during use.

Recycling silicone rubber presents both challenges and opportunities. While silicone can be recycled, the process is not as straightforward as with other materials like plastics. The cross-linked structure of silicone rubber makes it difficult to break down and reprocess. However, innovative recycling technologies are emerging, offering potential solutions for reducing silicone waste from sports products.

The end-of-life disposal of silicone-based sports gear is another significant environmental consideration. When incinerated, silicone produces silicon dioxide, carbon dioxide, and water vapor, with minimal toxic byproducts compared to many other synthetic materials. However, the energy required for incineration and the resulting carbon emissions remain environmental concerns.

As the sports industry continues to leverage silicone rubber in competitive gear, there is a growing emphasis on sustainable practices. Manufacturers are exploring bio-based alternatives and investigating ways to incorporate recycled silicone into new products. Additionally, efforts are being made to improve the recyclability of silicone-based sports equipment through innovative product design and material formulations.

In conclusion, while silicone rubber offers significant performance benefits in sports gear, its environmental impact requires careful consideration and ongoing efforts to mitigate negative effects throughout its lifecycle. Balancing the performance advantages with environmental responsibility will be key to the sustainable use of silicone in competitive sports equipment.

Regulatory Compliance for Sports Equipment Materials

Regulatory compliance is a critical aspect of developing and manufacturing sports equipment materials, including the use of silicone rubber in competitive sports gear. The sports industry is subject to various regulations and standards to ensure the safety, fairness, and performance of equipment used in competitions.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of sports equipment. They enforce regulations such as the Consumer Product Safety Act and the Federal Hazardous Substances Act, which set safety standards for materials used in sports gear. Manufacturers must ensure that silicone rubber components comply with these regulations, particularly regarding chemical composition and potential toxicity.

Internationally, the International Organization for Standardization (ISO) provides guidelines for sports equipment materials. ISO 9001 certification is often required for quality management systems in manufacturing processes. Additionally, specific ISO standards exist for various sports, such as ISO 5902 for protective equipment in combat sports, which may include silicone rubber components.

The World Anti-Doping Agency (WADA) also plays a role in regulating materials used in competitive sports. While primarily focused on performance-enhancing substances, WADA's regulations can impact the use of certain materials in sports gear if they are found to provide unfair advantages or pose health risks to athletes.

For silicone rubber specifically, manufacturers must consider regulations related to food-grade silicone when the material comes into contact with an athlete's skin or mouth. The U.S. Food and Drug Administration (FDA) provides guidelines for food-contact materials, which may apply to mouthguards or other protective gear made from silicone rubber.

Environmental regulations also impact the use of silicone rubber in sports equipment. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those in silicone rubber formulations.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct material safety assessments, performance tests, and durability evaluations to meet regulatory standards. Third-party testing laboratories are frequently employed to verify compliance and obtain necessary certifications.

As regulations evolve, manufacturers must stay informed about changes that may affect the use of silicone rubber in sports gear. This includes monitoring updates to existing standards and anticipating new regulations that may emerge in response to technological advancements or safety concerns in the sports industry.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of sports equipment. They enforce regulations such as the Consumer Product Safety Act and the Federal Hazardous Substances Act, which set safety standards for materials used in sports gear. Manufacturers must ensure that silicone rubber components comply with these regulations, particularly regarding chemical composition and potential toxicity.

Internationally, the International Organization for Standardization (ISO) provides guidelines for sports equipment materials. ISO 9001 certification is often required for quality management systems in manufacturing processes. Additionally, specific ISO standards exist for various sports, such as ISO 5902 for protective equipment in combat sports, which may include silicone rubber components.

The World Anti-Doping Agency (WADA) also plays a role in regulating materials used in competitive sports. While primarily focused on performance-enhancing substances, WADA's regulations can impact the use of certain materials in sports gear if they are found to provide unfair advantages or pose health risks to athletes.

For silicone rubber specifically, manufacturers must consider regulations related to food-grade silicone when the material comes into contact with an athlete's skin or mouth. The U.S. Food and Drug Administration (FDA) provides guidelines for food-contact materials, which may apply to mouthguards or other protective gear made from silicone rubber.

Environmental regulations also impact the use of silicone rubber in sports equipment. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to register and evaluate the safety of chemical substances used in their products, including those in silicone rubber formulations.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct material safety assessments, performance tests, and durability evaluations to meet regulatory standards. Third-party testing laboratories are frequently employed to verify compliance and obtain necessary certifications.

As regulations evolve, manufacturers must stay informed about changes that may affect the use of silicone rubber in sports gear. This includes monitoring updates to existing standards and anticipating new regulations that may emerge in response to technological advancements or safety concerns in the sports industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!