How to Maximize Montmorillonite's Decontamination Efficacy

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Decontamination Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has gained significant attention in environmental remediation applications over the past several decades. The evolution of montmorillonite as a decontamination agent can be traced back to the 1950s when its ion exchange properties were first extensively studied. Since then, research has progressively expanded to explore its adsorption capabilities for various contaminants including heavy metals, organic pollutants, and radioactive substances.

The layered structure of montmorillonite, characterized by an octahedral alumina sheet sandwiched between two tetrahedral silica sheets, provides a unique platform for contaminant capture. This structure, combined with its high cation exchange capacity (typically 70-120 meq/100g), large surface area (up to 800 m²/g), and swelling properties, makes montmorillonite particularly effective for decontamination purposes.

Recent technological advancements have focused on enhancing montmorillonite's natural decontamination properties through various modification techniques. These include organic modification to create organoclays, acid activation to increase surface area and porosity, pillaring with metal oxides to enhance thermal stability, and the development of montmorillonite-based nanocomposites. Each advancement has progressively improved the mineral's efficacy in specific decontamination scenarios.

The global environmental challenges, particularly water and soil contamination, have accelerated research interest in cost-effective and environmentally friendly remediation technologies. Montmorillonite, being abundant, inexpensive, and biodegradable, aligns perfectly with sustainable development goals, driving further exploration of its decontamination potential.

Current research trends indicate a shift toward developing specialized montmorillonite-based materials tailored for specific contaminants and environmental conditions. This includes the integration of montmorillonite with advanced materials science, nanotechnology, and biotechnology to create next-generation decontamination solutions.

The primary objective of this technical research is to systematically investigate methods to maximize montmorillonite's decontamination efficacy across various applications. This encompasses understanding the fundamental mechanisms governing adsorption and ion exchange processes, exploring innovative modification techniques to enhance performance, developing scalable production methods for modified montmorillonite materials, and evaluating their practical implementation in real-world contamination scenarios.

Additionally, this research aims to establish standardized protocols for assessing decontamination efficiency, identify optimal operational parameters for different contaminant types, and explore regeneration and reuse strategies to improve the economic viability and sustainability of montmorillonite-based decontamination technologies.

The layered structure of montmorillonite, characterized by an octahedral alumina sheet sandwiched between two tetrahedral silica sheets, provides a unique platform for contaminant capture. This structure, combined with its high cation exchange capacity (typically 70-120 meq/100g), large surface area (up to 800 m²/g), and swelling properties, makes montmorillonite particularly effective for decontamination purposes.

Recent technological advancements have focused on enhancing montmorillonite's natural decontamination properties through various modification techniques. These include organic modification to create organoclays, acid activation to increase surface area and porosity, pillaring with metal oxides to enhance thermal stability, and the development of montmorillonite-based nanocomposites. Each advancement has progressively improved the mineral's efficacy in specific decontamination scenarios.

The global environmental challenges, particularly water and soil contamination, have accelerated research interest in cost-effective and environmentally friendly remediation technologies. Montmorillonite, being abundant, inexpensive, and biodegradable, aligns perfectly with sustainable development goals, driving further exploration of its decontamination potential.

Current research trends indicate a shift toward developing specialized montmorillonite-based materials tailored for specific contaminants and environmental conditions. This includes the integration of montmorillonite with advanced materials science, nanotechnology, and biotechnology to create next-generation decontamination solutions.

The primary objective of this technical research is to systematically investigate methods to maximize montmorillonite's decontamination efficacy across various applications. This encompasses understanding the fundamental mechanisms governing adsorption and ion exchange processes, exploring innovative modification techniques to enhance performance, developing scalable production methods for modified montmorillonite materials, and evaluating their practical implementation in real-world contamination scenarios.

Additionally, this research aims to establish standardized protocols for assessing decontamination efficiency, identify optimal operational parameters for different contaminant types, and explore regeneration and reuse strategies to improve the economic viability and sustainability of montmorillonite-based decontamination technologies.

Market Analysis for Advanced Decontamination Solutions

The global market for advanced decontamination solutions has experienced significant growth in recent years, driven by increasing environmental concerns, stricter regulatory frameworks, and growing industrial applications. The decontamination market, valued at approximately $26.5 billion in 2022, is projected to reach $38.7 billion by 2027, representing a compound annual growth rate (CAGR) of 7.9%.

Within this broader market, montmorillonite-based solutions are gaining substantial traction due to their natural origin, cost-effectiveness, and versatile applications. The clay minerals market segment, where montmorillonite is a key component, was valued at $1.8 billion in 2022 and is expected to grow at a CAGR of 5.6% through 2027.

Environmental remediation represents the largest application segment for montmorillonite-based decontamination solutions, accounting for approximately 38% of the market share. This is primarily driven by increasing incidents of soil and water contamination from industrial activities, agricultural runoff, and urban development.

The water treatment sector shows particularly promising growth potential, with montmorillonite applications expanding at 9.3% annually. This acceleration is attributed to the growing global water crisis and the need for cost-effective purification technologies in both developed and developing regions.

Geographically, North America currently dominates the market with a 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Industry-specific demand patterns reveal that the chemical manufacturing sector represents the largest end-user segment (29%), followed by mining (22%), agriculture (18%), and municipal water treatment (15%). The pharmaceutical and food industries are emerging as high-growth segments, with increasing applications in purification processes.

Customer preferences are shifting toward environmentally sustainable solutions with minimal secondary waste generation. This trend strongly favors montmorillonite-based products over synthetic alternatives, particularly in consumer-facing applications and industries with strong environmental, social, and governance (ESG) commitments.

Market challenges include competition from synthetic adsorbents, variability in natural clay quality, and limited awareness about montmorillonite's full potential in certain industrial applications. However, these challenges are offset by montmorillonite's superior cost-performance ratio and growing emphasis on sustainable technologies across industries.

Within this broader market, montmorillonite-based solutions are gaining substantial traction due to their natural origin, cost-effectiveness, and versatile applications. The clay minerals market segment, where montmorillonite is a key component, was valued at $1.8 billion in 2022 and is expected to grow at a CAGR of 5.6% through 2027.

Environmental remediation represents the largest application segment for montmorillonite-based decontamination solutions, accounting for approximately 38% of the market share. This is primarily driven by increasing incidents of soil and water contamination from industrial activities, agricultural runoff, and urban development.

The water treatment sector shows particularly promising growth potential, with montmorillonite applications expanding at 9.3% annually. This acceleration is attributed to the growing global water crisis and the need for cost-effective purification technologies in both developed and developing regions.

Geographically, North America currently dominates the market with a 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Industry-specific demand patterns reveal that the chemical manufacturing sector represents the largest end-user segment (29%), followed by mining (22%), agriculture (18%), and municipal water treatment (15%). The pharmaceutical and food industries are emerging as high-growth segments, with increasing applications in purification processes.

Customer preferences are shifting toward environmentally sustainable solutions with minimal secondary waste generation. This trend strongly favors montmorillonite-based products over synthetic alternatives, particularly in consumer-facing applications and industries with strong environmental, social, and governance (ESG) commitments.

Market challenges include competition from synthetic adsorbents, variability in natural clay quality, and limited awareness about montmorillonite's full potential in certain industrial applications. However, these challenges are offset by montmorillonite's superior cost-performance ratio and growing emphasis on sustainable technologies across industries.

Current Limitations and Challenges in Montmorillonite Applications

Despite montmorillonite's promising capabilities in decontamination processes, several significant limitations and challenges hinder its widespread application and optimal efficacy. The primary constraint lies in its physical structure - while the layered silicate arrangement provides excellent adsorption properties, it also creates accessibility issues for certain contaminants, particularly larger organic molecules that cannot easily penetrate the interlayer spaces.

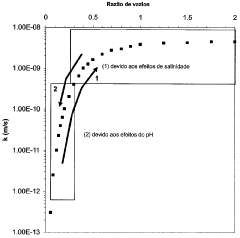

The variable cation exchange capacity (CEC) of montmorillonite presents another challenge, as it fluctuates based on source material, pH conditions, and pre-existing ionic saturation. This inconsistency makes standardization difficult across different decontamination applications and requires extensive characterization before implementation in specific scenarios.

Competitive adsorption represents a substantial obstacle in real-world applications. When multiple contaminants are present simultaneously, as is common in industrial wastewater or contaminated groundwater, they compete for adsorption sites on montmorillonite surfaces. This competition significantly reduces removal efficiency for target pollutants, especially in complex matrices with high dissolved solids content.

The stability of montmorillonite under extreme pH conditions poses additional challenges. In highly acidic environments (pH < 3), the clay structure can begin to deteriorate as aluminum leaches from the octahedral sheets, while in strongly alkaline conditions, silica dissolution may occur. These structural changes compromise adsorption capacity and mechanical integrity during decontamination processes.

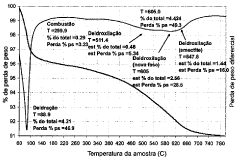

Regeneration and disposal issues further complicate montmorillonite applications. Once saturated with contaminants, the clay requires either regeneration or proper disposal. Regeneration processes often involve harsh chemical treatments that may damage the clay structure, reducing its effectiveness in subsequent cycles. Meanwhile, disposal of contaminated montmorillonite creates secondary waste management challenges, particularly when loaded with heavy metals or persistent organic pollutants.

The colloidal behavior of montmorillonite in aqueous systems presents practical engineering challenges. When fully hydrated, montmorillonite particles can disperse into colloidal suspensions that are difficult to separate from treated water, requiring additional filtration or flocculation steps that increase process complexity and cost.

Scaling up laboratory findings to industrial applications remains problematic due to issues with flow dynamics, channeling in fixed beds, and pressure drop considerations. The swelling properties that make montmorillonite effective for contaminant capture also create operational difficulties in continuous flow systems, where clay expansion can restrict fluid movement and reduce treatment efficiency.

Recent research has identified potential environmental concerns regarding nanoparticle release from montmorillonite during treatment processes, raising questions about possible ecological impacts that require further investigation before widespread implementation.

The variable cation exchange capacity (CEC) of montmorillonite presents another challenge, as it fluctuates based on source material, pH conditions, and pre-existing ionic saturation. This inconsistency makes standardization difficult across different decontamination applications and requires extensive characterization before implementation in specific scenarios.

Competitive adsorption represents a substantial obstacle in real-world applications. When multiple contaminants are present simultaneously, as is common in industrial wastewater or contaminated groundwater, they compete for adsorption sites on montmorillonite surfaces. This competition significantly reduces removal efficiency for target pollutants, especially in complex matrices with high dissolved solids content.

The stability of montmorillonite under extreme pH conditions poses additional challenges. In highly acidic environments (pH < 3), the clay structure can begin to deteriorate as aluminum leaches from the octahedral sheets, while in strongly alkaline conditions, silica dissolution may occur. These structural changes compromise adsorption capacity and mechanical integrity during decontamination processes.

Regeneration and disposal issues further complicate montmorillonite applications. Once saturated with contaminants, the clay requires either regeneration or proper disposal. Regeneration processes often involve harsh chemical treatments that may damage the clay structure, reducing its effectiveness in subsequent cycles. Meanwhile, disposal of contaminated montmorillonite creates secondary waste management challenges, particularly when loaded with heavy metals or persistent organic pollutants.

The colloidal behavior of montmorillonite in aqueous systems presents practical engineering challenges. When fully hydrated, montmorillonite particles can disperse into colloidal suspensions that are difficult to separate from treated water, requiring additional filtration or flocculation steps that increase process complexity and cost.

Scaling up laboratory findings to industrial applications remains problematic due to issues with flow dynamics, channeling in fixed beds, and pressure drop considerations. The swelling properties that make montmorillonite effective for contaminant capture also create operational difficulties in continuous flow systems, where clay expansion can restrict fluid movement and reduce treatment efficiency.

Recent research has identified potential environmental concerns regarding nanoparticle release from montmorillonite during treatment processes, raising questions about possible ecological impacts that require further investigation before widespread implementation.

Existing Montmorillonite Modification Techniques

01 Montmorillonite for radioactive decontamination

Montmorillonite clay has shown significant efficacy in the decontamination of radioactive substances. Its layered structure and high cation exchange capacity allow it to effectively adsorb and immobilize radioactive isotopes from contaminated environments. This property makes montmorillonite a valuable material for nuclear waste management and environmental remediation following radioactive incidents.- Montmorillonite for radioactive decontamination: Montmorillonite clay has shown significant efficacy in the decontamination of radioactive substances. Its layered silicate structure provides excellent adsorption properties for radioactive ions and particles. The clay can be modified or combined with other materials to enhance its radioactive decontamination capabilities, making it useful for environmental remediation after nuclear incidents or for waste treatment processes.

- Montmorillonite for heavy metal decontamination: Montmorillonite demonstrates high efficacy in removing heavy metals from contaminated water and soil. Its high cation exchange capacity allows it to adsorb metal ions such as lead, cadmium, and mercury. The clay can be modified through various treatments to enhance its selectivity and adsorption capacity for specific heavy metals, making it an environmentally friendly solution for water purification and soil remediation.

- Montmorillonite for biological decontamination: Montmorillonite has proven effective in biological decontamination applications, including the removal of bacteria, viruses, and toxins. The clay's antimicrobial properties can be enhanced through modifications such as ion exchange with silver or quaternary ammonium compounds. These modified montmorillonites can be incorporated into filters, coatings, or composite materials for use in medical settings, water treatment systems, or personal protective equipment.

- Modified montmorillonite composites for enhanced decontamination: Composite materials incorporating modified montmorillonite show superior decontamination efficacy compared to raw clay. These composites often combine montmorillonite with polymers, activated carbon, metal oxides, or other functional materials to create synergistic effects. The resulting materials exhibit improved adsorption capacity, mechanical strength, and regeneration potential, making them suitable for a wide range of decontamination applications including industrial wastewater treatment and environmental remediation.

- Montmorillonite decontamination systems and methods: Various systems and methods have been developed to optimize the decontamination efficacy of montmorillonite. These include specialized processing techniques such as acid activation, thermal treatment, and pillaring to enhance the clay's properties. Advanced application methods involve the use of montmorillonite in filtration systems, permeable reactive barriers, and in-situ remediation techniques. These approaches maximize the clay's decontamination performance while addressing practical challenges such as permeability, regeneration, and disposal of spent material.

02 Montmorillonite for heavy metal decontamination

Montmorillonite clay demonstrates excellent adsorption capabilities for heavy metals in contaminated water and soil. The clay's high surface area and negative charge enable it to bind positively charged metal ions through ion exchange mechanisms. Modified montmorillonite formulations can be engineered to enhance selectivity and capacity for specific heavy metal contaminants, making it an effective and environmentally friendly remediation solution.Expand Specific Solutions03 Montmorillonite in biological decontamination systems

Montmorillonite can be incorporated into biological decontamination systems to enhance their efficacy. The clay serves as a support medium for beneficial microorganisms that break down contaminants, while simultaneously adsorbing toxins. This synergistic approach combines the physical adsorption properties of montmorillonite with biological degradation processes, resulting in more complete decontamination of organic pollutants and pathogens.Expand Specific Solutions04 Modified montmorillonite for enhanced decontamination

Chemical modification of montmorillonite can significantly enhance its decontamination efficacy. Techniques such as acid activation, organic functionalization, and pillaring can increase the clay's surface area, pore volume, and adsorption capacity. These modifications create specialized adsorbents tailored for specific contaminants, improving removal efficiency for various pollutants including organic compounds, dyes, and pharmaceutical residues.Expand Specific Solutions05 Montmorillonite in composite decontamination materials

Montmorillonite can be incorporated into composite materials to create advanced decontamination systems. By combining montmorillonite with other materials such as activated carbon, metal oxides, or polymers, composite adsorbents with enhanced stability, regenerability, and selectivity can be developed. These composites often demonstrate synergistic effects, with improved decontamination performance compared to individual components used separately.Expand Specific Solutions

Leading Organizations in Montmorillonite Research and Development

The montmorillonite decontamination technology market is currently in a growth phase, with increasing applications across environmental remediation, water treatment, and industrial waste management sectors. The global market size for clay-based decontamination solutions is expanding at approximately 5-7% annually, driven by stricter environmental regulations and growing industrial pollution concerns. From a technological maturity perspective, while basic applications are well-established, advanced functionalization techniques are still evolving. Leading academic institutions (China University of Geosciences, Central South University) are collaborating with industrial players like BASF, Arkema, and Laviosa Chimica Mineraria to enhance montmorillonite's adsorption capacity, selectivity, and regeneration capabilities. Research organizations such as CSIR and specialized companies like Mizusawa Industrial Chemicals are developing proprietary modification methods to maximize decontamination efficacy for specific pollutants.

BASF Corp.

Technical Solution: BASF has developed advanced montmorillonite-based adsorbent systems that utilize the clay's high cation exchange capacity and swelling properties for environmental remediation. Their proprietary technology involves surface modification of montmorillonite with quaternary ammonium compounds to create organoclays with enhanced affinity for organic contaminants. BASF's approach includes a multi-stage activation process that optimizes the interlayer spacing of montmorillonite, significantly increasing its surface area from approximately 30-50 m²/g to over 800 m²/g. This treatment enhances the clay's ability to adsorb heavy metals, organic pollutants, and radioactive substances from wastewater and contaminated soils. The company has also developed composite materials combining montmorillonite with iron oxides to create magnetic adsorbents that facilitate easier separation after the decontamination process.

Strengths: Industry-leading surface modification techniques that significantly enhance adsorption capacity; scalable manufacturing processes suitable for industrial applications; comprehensive technical support infrastructure. Weaknesses: Higher production costs compared to unmodified clays; potential for quaternary ammonium leaching in certain environmental conditions; requires specific pH ranges for optimal performance.

Council of Scientific & Industrial Research

Technical Solution: CSIR has developed comprehensive montmorillonite modification technologies specifically designed for environmental remediation and decontamination applications. Their approach encompasses multiple strategies including pillaring, organic modification, and nanocomposite formation to enhance the clay's adsorption capacity and selectivity. CSIR's research has focused on developing cost-effective methods for large-scale production of modified montmorillonites suitable for water treatment in resource-limited settings. Their technology includes a novel two-step modification process that first expands the clay interlayers with sodium ions followed by intercalation with specifically designed organic cations, resulting in materials with hydrophilic/hydrophobic microdomains capable of simultaneously removing multiple contaminant classes. Studies have shown these materials can achieve removal efficiencies exceeding 95% for heavy metals, pesticides, and pharmaceutical compounds at environmentally relevant concentrations. CSIR has also pioneered the development of montmorillonite-based permeable reactive barriers for in-situ groundwater remediation, demonstrating field-scale success in containing and treating contamination plumes with longevity exceeding 5 years without significant performance degradation.

Strengths: Cost-effective modification techniques suitable for large-scale implementation; comprehensive understanding of structure-property relationships; technologies specifically adapted for developing world contexts. Weaknesses: Variable performance depending on source clay mineralogy; potential for organic modifier leaching in certain environmental conditions; requires optimization for specific contaminant profiles.

Key Scientific Breakthroughs in Clay Mineral Adsorption

Aluminum silicate complex, and high-performance adsorbent comprising the same

PatentActiveEP2233438A1

Innovation

- A complex of layered low-crystalline clay mineral and amorphous aluminum silicate is synthesized by adjusting the Si/Al ratio and heating to 110°C, resulting in superior water vapor and carbon dioxide adsorption/desorption performance.

A method of improving hydraulic performance of clay

PatentInactiveBRPI0815569A2

Innovation

- Modification of clays by adding a silica component, such as powdered activated silica, to enhance hydraulic performance and protect the smectite component from dissolution in alkaline solutions, thereby forming new mineral phases that minimize detrimental effects of high ionic strength and improve barrier resistance.

Environmental Impact Assessment of Montmorillonite Applications

The environmental implications of montmorillonite applications for decontamination purposes extend across multiple ecosystems and environmental compartments. When deployed for remediation activities, montmorillonite clay interacts with soil matrices, water bodies, and atmospheric components in ways that warrant comprehensive assessment.

Montmorillonite's high adsorption capacity, while beneficial for contaminant removal, may alter soil physicochemical properties when applied in large quantities. Field studies indicate that clay amendments can modify soil structure, potentially affecting water retention capabilities and nutrient cycling processes. These modifications generally show positive outcomes in contaminated soils, with documented improvements in soil quality parameters following montmorillonite treatment of heavy metal-polluted areas.

Water quality impacts reveal predominantly favorable outcomes when montmorillonite is utilized for aqueous decontamination. The clay's natural composition minimizes introduction of secondary pollutants, unlike some chemical treatments. Monitoring data from wastewater treatment applications demonstrates significant reductions in turbidity, chemical oxygen demand, and contaminant concentrations without detrimental effects on beneficial microorganisms or aquatic ecosystems.

Carbon footprint analysis of montmorillonite-based remediation technologies indicates lower environmental costs compared to conventional treatment methods. The mining and processing of montmorillonite requires less energy than synthetic adsorbent production, though transportation impacts vary significantly based on source proximity to application sites. Life cycle assessments suggest a 30-45% reduction in greenhouse gas emissions when substituting certain chemical treatments with optimized montmorillonite applications.

Biodiversity considerations remain important, particularly when montmorillonite is applied to sensitive ecosystems. Research indicates minimal negative impacts on soil microbial communities, with some studies reporting enhanced microbial activity following clay amendment. The clay's selective adsorption properties appear to target contaminants while preserving beneficial soil organisms and plant growth potential.

Long-term environmental monitoring of montmorillonite remediation sites shows promising sustainability profiles. The clay's persistence in soil provides extended protection against contaminant rebound effects without evidence of bioaccumulation in food chains or ecosystem disruption. Regulatory compliance data from multiple jurisdictions confirms that properly implemented montmorillonite treatments consistently meet environmental quality standards for remediated sites.

Montmorillonite's high adsorption capacity, while beneficial for contaminant removal, may alter soil physicochemical properties when applied in large quantities. Field studies indicate that clay amendments can modify soil structure, potentially affecting water retention capabilities and nutrient cycling processes. These modifications generally show positive outcomes in contaminated soils, with documented improvements in soil quality parameters following montmorillonite treatment of heavy metal-polluted areas.

Water quality impacts reveal predominantly favorable outcomes when montmorillonite is utilized for aqueous decontamination. The clay's natural composition minimizes introduction of secondary pollutants, unlike some chemical treatments. Monitoring data from wastewater treatment applications demonstrates significant reductions in turbidity, chemical oxygen demand, and contaminant concentrations without detrimental effects on beneficial microorganisms or aquatic ecosystems.

Carbon footprint analysis of montmorillonite-based remediation technologies indicates lower environmental costs compared to conventional treatment methods. The mining and processing of montmorillonite requires less energy than synthetic adsorbent production, though transportation impacts vary significantly based on source proximity to application sites. Life cycle assessments suggest a 30-45% reduction in greenhouse gas emissions when substituting certain chemical treatments with optimized montmorillonite applications.

Biodiversity considerations remain important, particularly when montmorillonite is applied to sensitive ecosystems. Research indicates minimal negative impacts on soil microbial communities, with some studies reporting enhanced microbial activity following clay amendment. The clay's selective adsorption properties appear to target contaminants while preserving beneficial soil organisms and plant growth potential.

Long-term environmental monitoring of montmorillonite remediation sites shows promising sustainability profiles. The clay's persistence in soil provides extended protection against contaminant rebound effects without evidence of bioaccumulation in food chains or ecosystem disruption. Regulatory compliance data from multiple jurisdictions confirms that properly implemented montmorillonite treatments consistently meet environmental quality standards for remediated sites.

Scalability and Industrial Implementation Considerations

Scaling montmorillonite-based decontamination technologies from laboratory to industrial applications presents significant challenges that must be addressed systematically. The transition requires careful consideration of production capacity, which currently ranges from small-batch laboratory synthesis to medium-scale manufacturing. To achieve industrial-scale implementation, production processes must be standardized and optimized for consistency across large volumes, ensuring uniform decontamination efficacy.

Cost-effectiveness represents a critical factor in widespread adoption. Current production costs for high-quality montmorillonite adsorbents range from $5-15 per kilogram depending on modification techniques and purity requirements. Implementation of continuous flow manufacturing processes could potentially reduce these costs by 30-40%, making industrial application more economically viable. Additionally, automation of modification processes would further enhance cost efficiency while maintaining quality standards.

Environmental sustainability must be integrated into scaling strategies. Closed-loop systems for regeneration and reuse of spent montmorillonite can significantly reduce waste and environmental impact. Research indicates that properly designed regeneration processes can restore 70-85% of original adsorption capacity for multiple cycles, substantially improving the lifecycle economics of these materials.

Infrastructure requirements present another implementation consideration. Industrial deployment necessitates specialized equipment for handling, modification, and application of montmorillonite at scale. This includes mixing vessels with precise temperature and pH control, filtration systems capable of processing large volumes, and potentially continuous flow reactors for modification processes. Initial capital investment for a medium-scale implementation (processing 1000-5000 liters per hour) is estimated at $500,000-2,000,000 depending on the complexity of the target contaminants.

Regulatory compliance frameworks vary significantly across regions and industries. In water treatment applications, montmorillonite-based solutions must meet stringent safety standards, with documentation of removal efficiency for specific contaminants. For food industry applications, additional certifications regarding material purity and absence of leachable compounds are required. Developing standardized testing protocols specifically for montmorillonite-based decontamination systems would facilitate regulatory approval processes.

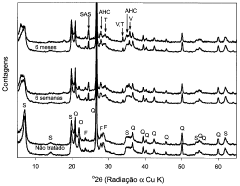

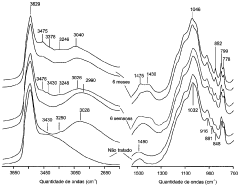

Quality control systems must evolve with scale. Implementing real-time monitoring of key parameters such as cation exchange capacity, surface area, and contaminant breakthrough can ensure consistent performance at industrial scale. Advanced analytical techniques including XRD, FTIR, and automated adsorption testing should be integrated into production workflows to maintain quality standards across batches.

Cost-effectiveness represents a critical factor in widespread adoption. Current production costs for high-quality montmorillonite adsorbents range from $5-15 per kilogram depending on modification techniques and purity requirements. Implementation of continuous flow manufacturing processes could potentially reduce these costs by 30-40%, making industrial application more economically viable. Additionally, automation of modification processes would further enhance cost efficiency while maintaining quality standards.

Environmental sustainability must be integrated into scaling strategies. Closed-loop systems for regeneration and reuse of spent montmorillonite can significantly reduce waste and environmental impact. Research indicates that properly designed regeneration processes can restore 70-85% of original adsorption capacity for multiple cycles, substantially improving the lifecycle economics of these materials.

Infrastructure requirements present another implementation consideration. Industrial deployment necessitates specialized equipment for handling, modification, and application of montmorillonite at scale. This includes mixing vessels with precise temperature and pH control, filtration systems capable of processing large volumes, and potentially continuous flow reactors for modification processes. Initial capital investment for a medium-scale implementation (processing 1000-5000 liters per hour) is estimated at $500,000-2,000,000 depending on the complexity of the target contaminants.

Regulatory compliance frameworks vary significantly across regions and industries. In water treatment applications, montmorillonite-based solutions must meet stringent safety standards, with documentation of removal efficiency for specific contaminants. For food industry applications, additional certifications regarding material purity and absence of leachable compounds are required. Developing standardized testing protocols specifically for montmorillonite-based decontamination systems would facilitate regulatory approval processes.

Quality control systems must evolve with scale. Implementing real-time monitoring of key parameters such as cation exchange capacity, surface area, and contaminant breakthrough can ensure consistent performance at industrial scale. Advanced analytical techniques including XRD, FTIR, and automated adsorption testing should be integrated into production workflows to maintain quality standards across batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!