How to Maximize Silicone Rubber's Abrasion Resistance?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Abrasion Resistance Overview

Silicone rubber, a versatile elastomer known for its exceptional properties, has gained significant attention in various industries due to its unique combination of characteristics. Among these, abrasion resistance stands out as a critical factor in determining the material's durability and longevity in applications where wear and tear are prevalent. The quest to maximize silicone rubber's abrasion resistance has been a focal point of research and development efforts in recent years.

Abrasion resistance refers to the ability of a material to withstand mechanical action on its surface that progressively removes material. For silicone rubber, this property is particularly important in applications such as seals, gaskets, conveyor belts, and protective coatings, where the material is subjected to constant friction and wear. The challenge lies in enhancing this property without compromising other desirable characteristics of silicone rubber, such as flexibility, thermal stability, and chemical resistance.

The current state of silicone rubber's abrasion resistance varies depending on the specific formulation and manufacturing process. Standard silicone rubber compounds typically exhibit moderate abrasion resistance, which may be insufficient for high-wear applications. This limitation has driven the development of advanced silicone formulations and surface treatment techniques aimed at improving wear resistance.

Several factors influence the abrasion resistance of silicone rubber, including the molecular structure of the polymer, the type and amount of fillers used, the degree of crosslinking, and the presence of additives. Researchers and manufacturers have been exploring various approaches to optimize these factors and achieve superior abrasion resistance.

One promising avenue of research involves the incorporation of reinforcing fillers such as silica, carbon black, or more recently, nanoparticles. These fillers can significantly enhance the mechanical properties of silicone rubber, including its resistance to abrasion. The challenge lies in achieving a uniform dispersion of these fillers within the silicone matrix to ensure consistent performance.

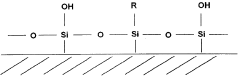

Surface modification techniques have also shown potential in improving the abrasion resistance of silicone rubber. Methods such as plasma treatment, UV irradiation, and chemical grafting can alter the surface properties of the material, creating a more wear-resistant outer layer while maintaining the bulk properties of the silicone rubber.

As the demand for high-performance materials continues to grow across industries, the importance of maximizing silicone rubber's abrasion resistance cannot be overstated. The ongoing research and development in this area promise to unlock new possibilities for silicone rubber applications, potentially expanding its use in more demanding environments and extending the lifespan of silicone rubber products.

Abrasion resistance refers to the ability of a material to withstand mechanical action on its surface that progressively removes material. For silicone rubber, this property is particularly important in applications such as seals, gaskets, conveyor belts, and protective coatings, where the material is subjected to constant friction and wear. The challenge lies in enhancing this property without compromising other desirable characteristics of silicone rubber, such as flexibility, thermal stability, and chemical resistance.

The current state of silicone rubber's abrasion resistance varies depending on the specific formulation and manufacturing process. Standard silicone rubber compounds typically exhibit moderate abrasion resistance, which may be insufficient for high-wear applications. This limitation has driven the development of advanced silicone formulations and surface treatment techniques aimed at improving wear resistance.

Several factors influence the abrasion resistance of silicone rubber, including the molecular structure of the polymer, the type and amount of fillers used, the degree of crosslinking, and the presence of additives. Researchers and manufacturers have been exploring various approaches to optimize these factors and achieve superior abrasion resistance.

One promising avenue of research involves the incorporation of reinforcing fillers such as silica, carbon black, or more recently, nanoparticles. These fillers can significantly enhance the mechanical properties of silicone rubber, including its resistance to abrasion. The challenge lies in achieving a uniform dispersion of these fillers within the silicone matrix to ensure consistent performance.

Surface modification techniques have also shown potential in improving the abrasion resistance of silicone rubber. Methods such as plasma treatment, UV irradiation, and chemical grafting can alter the surface properties of the material, creating a more wear-resistant outer layer while maintaining the bulk properties of the silicone rubber.

As the demand for high-performance materials continues to grow across industries, the importance of maximizing silicone rubber's abrasion resistance cannot be overstated. The ongoing research and development in this area promise to unlock new possibilities for silicone rubber applications, potentially expanding its use in more demanding environments and extending the lifespan of silicone rubber products.

Market Demand Analysis

The market demand for silicone rubber with enhanced abrasion resistance continues to grow across various industries. This demand is primarily driven by the need for durable and long-lasting materials in applications where wear and tear are significant concerns. The automotive sector, in particular, shows a strong interest in abrasion-resistant silicone rubber for use in seals, gaskets, and hoses that are subjected to constant friction and environmental stresses.

In the medical and healthcare industry, there is an increasing demand for silicone rubber with improved abrasion resistance for use in prosthetics, implants, and medical devices. These applications require materials that can withstand prolonged contact with body fluids and tissues without degrading or releasing particles. The growing aging population and advancements in medical technologies are expected to further boost this demand.

The consumer electronics market also presents significant opportunities for abrasion-resistant silicone rubber. With the rise of wearable technology and smart devices, there is a need for materials that can withstand daily wear and tear while maintaining their protective and aesthetic properties. This includes applications in smartwatch straps, protective cases for mobile devices, and other electronic accessories.

In the industrial sector, the demand for abrasion-resistant silicone rubber is driven by the need for improved performance in seals, conveyor belts, and protective coatings. Industries such as mining, oil and gas, and manufacturing require materials that can withstand harsh environments and prolonged mechanical stress.

The construction industry is another key market for abrasion-resistant silicone rubber, particularly in applications such as expansion joints, weather seals, and protective coatings for building materials. The growing focus on sustainable and long-lasting construction materials is expected to drive further demand in this sector.

Market analysts project a steady growth in the global silicone rubber market, with a significant portion attributed to the demand for abrasion-resistant variants. The Asia-Pacific region is expected to lead this growth, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

As environmental concerns and regulations become more stringent, there is also a growing demand for eco-friendly and recyclable silicone rubber materials with enhanced abrasion resistance. This trend is likely to shape product development and market strategies in the coming years, opening up new opportunities for innovation and market expansion.

In the medical and healthcare industry, there is an increasing demand for silicone rubber with improved abrasion resistance for use in prosthetics, implants, and medical devices. These applications require materials that can withstand prolonged contact with body fluids and tissues without degrading or releasing particles. The growing aging population and advancements in medical technologies are expected to further boost this demand.

The consumer electronics market also presents significant opportunities for abrasion-resistant silicone rubber. With the rise of wearable technology and smart devices, there is a need for materials that can withstand daily wear and tear while maintaining their protective and aesthetic properties. This includes applications in smartwatch straps, protective cases for mobile devices, and other electronic accessories.

In the industrial sector, the demand for abrasion-resistant silicone rubber is driven by the need for improved performance in seals, conveyor belts, and protective coatings. Industries such as mining, oil and gas, and manufacturing require materials that can withstand harsh environments and prolonged mechanical stress.

The construction industry is another key market for abrasion-resistant silicone rubber, particularly in applications such as expansion joints, weather seals, and protective coatings for building materials. The growing focus on sustainable and long-lasting construction materials is expected to drive further demand in this sector.

Market analysts project a steady growth in the global silicone rubber market, with a significant portion attributed to the demand for abrasion-resistant variants. The Asia-Pacific region is expected to lead this growth, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

As environmental concerns and regulations become more stringent, there is also a growing demand for eco-friendly and recyclable silicone rubber materials with enhanced abrasion resistance. This trend is likely to shape product development and market strategies in the coming years, opening up new opportunities for innovation and market expansion.

Current Challenges in Abrasion Resistance

Despite significant advancements in silicone rubber technology, enhancing its abrasion resistance remains a persistent challenge for manufacturers and researchers. The primary obstacle lies in the inherent molecular structure of silicone rubber, which provides excellent flexibility and heat resistance but lacks the toughness required for high abrasion resistance. This fundamental trade-off between flexibility and wear resistance continues to be a key focus area for material scientists.

One of the main challenges is maintaining the desirable properties of silicone rubber while improving its abrasion resistance. Attempts to enhance wear resistance often lead to a compromise in other critical characteristics such as elasticity, thermal stability, or chemical resistance. This delicate balance makes it difficult to develop a one-size-fits-all solution for various industrial applications.

The incorporation of reinforcing fillers, such as silica or carbon black, has been a common approach to improve abrasion resistance. However, achieving uniform dispersion of these fillers within the silicone matrix remains problematic. Agglomeration of filler particles can lead to inconsistent material properties and potential weak points in the rubber structure, ultimately limiting the effectiveness of this method.

Another significant challenge is the development of cost-effective solutions for large-scale production. While some laboratory-scale techniques have shown promise in enhancing abrasion resistance, translating these methods to industrial-scale manufacturing processes without substantially increasing production costs has proven difficult. This economic constraint often hinders the adoption of novel abrasion-resistant silicone rubber formulations in price-sensitive markets.

The environmental impact of additives used to improve abrasion resistance is also a growing concern. As sustainability becomes increasingly important in material science, finding eco-friendly solutions that do not compromise performance or introduce potential health risks is a complex challenge. This includes developing alternatives to traditional reinforcing agents that may have negative environmental implications.

Furthermore, the diverse range of applications for silicone rubber, each with its specific abrasion requirements, complicates the development of universally applicable solutions. For instance, the abrasion resistance needed for automotive seals differs significantly from that required for medical implants or industrial conveyor belts. This variability necessitates tailored approaches, making it challenging to develop a single, widely applicable method for maximizing abrasion resistance across all use cases.

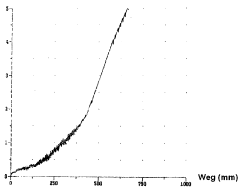

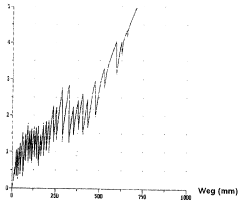

Lastly, the lack of standardized testing methods for abrasion resistance specific to silicone rubber compounds hinders comparative analysis and benchmarking. This absence of uniform evaluation criteria makes it difficult for researchers and manufacturers to accurately assess and compare the effectiveness of different abrasion resistance enhancement techniques, slowing down the overall progress in this field.

One of the main challenges is maintaining the desirable properties of silicone rubber while improving its abrasion resistance. Attempts to enhance wear resistance often lead to a compromise in other critical characteristics such as elasticity, thermal stability, or chemical resistance. This delicate balance makes it difficult to develop a one-size-fits-all solution for various industrial applications.

The incorporation of reinforcing fillers, such as silica or carbon black, has been a common approach to improve abrasion resistance. However, achieving uniform dispersion of these fillers within the silicone matrix remains problematic. Agglomeration of filler particles can lead to inconsistent material properties and potential weak points in the rubber structure, ultimately limiting the effectiveness of this method.

Another significant challenge is the development of cost-effective solutions for large-scale production. While some laboratory-scale techniques have shown promise in enhancing abrasion resistance, translating these methods to industrial-scale manufacturing processes without substantially increasing production costs has proven difficult. This economic constraint often hinders the adoption of novel abrasion-resistant silicone rubber formulations in price-sensitive markets.

The environmental impact of additives used to improve abrasion resistance is also a growing concern. As sustainability becomes increasingly important in material science, finding eco-friendly solutions that do not compromise performance or introduce potential health risks is a complex challenge. This includes developing alternatives to traditional reinforcing agents that may have negative environmental implications.

Furthermore, the diverse range of applications for silicone rubber, each with its specific abrasion requirements, complicates the development of universally applicable solutions. For instance, the abrasion resistance needed for automotive seals differs significantly from that required for medical implants or industrial conveyor belts. This variability necessitates tailored approaches, making it challenging to develop a single, widely applicable method for maximizing abrasion resistance across all use cases.

Lastly, the lack of standardized testing methods for abrasion resistance specific to silicone rubber compounds hinders comparative analysis and benchmarking. This absence of uniform evaluation criteria makes it difficult for researchers and manufacturers to accurately assess and compare the effectiveness of different abrasion resistance enhancement techniques, slowing down the overall progress in this field.

Existing Abrasion Resistance Solutions

01 Incorporation of reinforcing fillers

Adding reinforcing fillers such as silica, carbon black, or other inorganic particles to silicone rubber compositions can significantly improve their abrasion resistance. These fillers enhance the mechanical properties of the rubber, making it more durable and resistant to wear.- Incorporation of reinforcing fillers: Adding reinforcing fillers such as silica, carbon black, or other inorganic particles to silicone rubber compositions can significantly improve their abrasion resistance. These fillers enhance the mechanical properties of the rubber, making it more durable and resistant to wear.

- Surface modification techniques: Various surface modification techniques can be applied to silicone rubber to enhance its abrasion resistance. These may include plasma treatment, chemical etching, or the application of protective coatings. Such modifications can create a harder, more wear-resistant surface layer.

- Crosslinking and curing optimization: Optimizing the crosslinking and curing processes of silicone rubber can lead to improved abrasion resistance. This may involve adjusting curing temperatures, times, or using specific catalysts to achieve a more tightly crosslinked structure that is more resistant to wear.

- Blending with other polymers: Blending silicone rubber with other polymers or elastomers can create composite materials with enhanced abrasion resistance. This approach combines the beneficial properties of multiple materials to achieve improved wear characteristics.

- Incorporation of nanoparticles: Adding nanoparticles, such as nano-silica or carbon nanotubes, to silicone rubber formulations can significantly improve abrasion resistance. These nanoparticles can enhance the overall mechanical properties and create a more durable material at the nanoscale level.

02 Surface modification techniques

Various surface modification techniques can be applied to silicone rubber to enhance its abrasion resistance. These may include plasma treatment, chemical etching, or the application of protective coatings. Such treatments can alter the surface properties of the rubber, making it more resistant to wear and tear.Expand Specific Solutions03 Crosslinking and curing optimization

Optimizing the crosslinking and curing processes of silicone rubber can lead to improved abrasion resistance. This may involve adjusting curing temperatures, times, and the use of specific catalysts or crosslinking agents to achieve a more tightly bound molecular structure.Expand Specific Solutions04 Blending with other polymers

Blending silicone rubber with other polymers or elastomers can create composite materials with enhanced abrasion resistance. This approach combines the beneficial properties of multiple materials to achieve improved wear resistance while maintaining other desirable characteristics of silicone rubber.Expand Specific Solutions05 Incorporation of nanoparticles

Adding nanoparticles to silicone rubber formulations can significantly improve abrasion resistance. Nanoparticles such as nano-silica, carbon nanotubes, or graphene can enhance the mechanical properties and wear resistance of the rubber at very low loading levels, due to their high surface area and strong interactions with the polymer matrix.Expand Specific Solutions

Key Industry Players

The abrasion resistance of silicone rubber is a critical area of focus in the advanced materials industry, currently in a mature growth phase. The global silicone rubber market size is projected to reach $9.34 billion by 2027, driven by demand in automotive, electronics, and healthcare sectors. Technologically, companies like Shin-Etsu Chemical, Wacker Chemie, and Momentive Performance Materials are at the forefront, developing innovative formulations and manufacturing processes to enhance silicone rubber's abrasion resistance. These industry leaders are investing in R&D to create high-performance silicone compounds that meet the increasing demands for durability and longevity in various applications.

Shin-Etsu Chemical Co., Ltd.

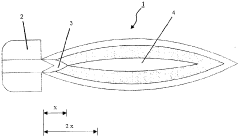

Technical Solution: Shin-Etsu Chemical has developed a proprietary silicone rubber formulation with enhanced abrasion resistance. Their approach involves incorporating specially engineered silica fillers and optimizing the cross-linking density of the silicone polymer network. The company has also introduced a surface treatment process that creates a hardened outer layer on the silicone rubber, significantly improving its abrasion resistance without compromising flexibility[1]. This technology has been successfully applied in various industries, including automotive and industrial equipment, where the silicone parts are exposed to high wear conditions[3].

Strengths: Improved durability in high-wear applications, maintains flexibility. Weaknesses: Potentially higher production costs, may require specialized manufacturing processes.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a novel silicone rubber compound that exhibits exceptional abrasion resistance. Their approach involves the use of advanced silicone-organic hybrid polymers and the incorporation of nano-scale reinforcing agents. This technology, known as SILPURAN®, combines the elasticity of silicone rubber with the abrasion resistance typically associated with thermoplastic elastomers[2]. The company has also implemented a proprietary vulcanization process that enhances the cross-linking density and uniformity of the silicone network, further improving its mechanical properties and wear resistance[4]. This advanced silicone rubber has found applications in medical devices, automotive components, and industrial seals where high abrasion resistance is critical.

Strengths: Excellent abrasion resistance while maintaining silicone's beneficial properties, versatile applications. Weaknesses: Higher cost compared to standard silicone rubbers, may require specialized processing equipment.

Innovative Approaches in Material Science

Method for modifying a silicone rubber surface

PatentWO2006122744A1

Innovation

- A pyrolytic method deposits a 40-100 nm thick silanol/siloxane layer on silicone rubber surfaces using a silicon-organic compound under atmospheric pressure, reducing adhesion and stickiness, suitable for both profiles and molded parts, and can be integrated into production lines.

Addition reaction-curable liquid silicone rubber compositions and process of preparing same

PatentActiveUS20050277725A1

Innovation

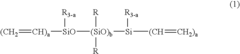

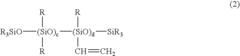

- An addition reaction-curable liquid silicone rubber composition comprising specific organopolysiloxanes, finely divided silica, hexamethyldisilazane, water, and an organohydrogenpolysiloxane, along with a hydrosilation catalyst, is developed, allowing for a cured product with a hardness of at least 75 and an elongation at break of at least 200%, enabling broader application beyond insulation potting.

Environmental Impact Assessment

The environmental impact assessment of maximizing silicone rubber's abrasion resistance is a crucial aspect to consider in the development and application of this technology. Silicone rubber, known for its versatility and durability, is widely used in various industries. However, enhancing its abrasion resistance may have both positive and negative environmental implications.

One of the primary environmental benefits of improving silicone rubber's abrasion resistance is the potential reduction in material consumption. More durable silicone rubber products would have longer lifespans, reducing the need for frequent replacements. This, in turn, could lead to a decrease in raw material extraction, manufacturing processes, and waste generation associated with silicone rubber production.

However, the methods used to enhance abrasion resistance may introduce new environmental concerns. For instance, the incorporation of certain additives or surface treatments might increase the complexity of the material's composition. This could potentially make the silicone rubber more challenging to recycle or dispose of at the end of its life cycle, potentially leading to increased environmental pollution if not managed properly.

The manufacturing processes required to achieve enhanced abrasion resistance may also have environmental implications. These processes might require additional energy consumption or the use of chemicals that could have negative impacts on air and water quality if not properly controlled. It is essential to assess and mitigate these potential risks through the implementation of advanced pollution control technologies and sustainable manufacturing practices.

From a lifecycle perspective, the improved durability of silicone rubber products could contribute to reduced environmental impact in the long term. By extending the service life of products, fewer resources would be required for replacements, potentially offsetting the initial environmental costs associated with producing more abrasion-resistant silicone rubber.

The disposal and end-of-life management of abrasion-resistant silicone rubber products also warrant careful consideration. While the extended lifespan is beneficial, it is crucial to develop effective recycling or safe disposal methods to prevent these materials from accumulating in landfills or natural environments. Research into biodegradable additives or environmentally friendly decomposition methods could be valuable in addressing this concern.

In conclusion, while maximizing silicone rubber's abrasion resistance offers potential environmental benefits through reduced material consumption and extended product lifespans, it also presents challenges in terms of manufacturing processes, material complexity, and end-of-life management. A comprehensive environmental impact assessment should consider these factors to ensure that the development of this technology aligns with sustainable practices and minimizes negative environmental consequences.

One of the primary environmental benefits of improving silicone rubber's abrasion resistance is the potential reduction in material consumption. More durable silicone rubber products would have longer lifespans, reducing the need for frequent replacements. This, in turn, could lead to a decrease in raw material extraction, manufacturing processes, and waste generation associated with silicone rubber production.

However, the methods used to enhance abrasion resistance may introduce new environmental concerns. For instance, the incorporation of certain additives or surface treatments might increase the complexity of the material's composition. This could potentially make the silicone rubber more challenging to recycle or dispose of at the end of its life cycle, potentially leading to increased environmental pollution if not managed properly.

The manufacturing processes required to achieve enhanced abrasion resistance may also have environmental implications. These processes might require additional energy consumption or the use of chemicals that could have negative impacts on air and water quality if not properly controlled. It is essential to assess and mitigate these potential risks through the implementation of advanced pollution control technologies and sustainable manufacturing practices.

From a lifecycle perspective, the improved durability of silicone rubber products could contribute to reduced environmental impact in the long term. By extending the service life of products, fewer resources would be required for replacements, potentially offsetting the initial environmental costs associated with producing more abrasion-resistant silicone rubber.

The disposal and end-of-life management of abrasion-resistant silicone rubber products also warrant careful consideration. While the extended lifespan is beneficial, it is crucial to develop effective recycling or safe disposal methods to prevent these materials from accumulating in landfills or natural environments. Research into biodegradable additives or environmentally friendly decomposition methods could be valuable in addressing this concern.

In conclusion, while maximizing silicone rubber's abrasion resistance offers potential environmental benefits through reduced material consumption and extended product lifespans, it also presents challenges in terms of manufacturing processes, material complexity, and end-of-life management. A comprehensive environmental impact assessment should consider these factors to ensure that the development of this technology aligns with sustainable practices and minimizes negative environmental consequences.

Cost-Benefit Analysis of Enhanced Abrasion Resistance

Enhancing the abrasion resistance of silicone rubber comes with both costs and benefits that must be carefully evaluated. The primary benefit is the extended lifespan of silicone rubber products, particularly in high-wear applications. This increased durability can lead to significant cost savings over time, as replacement intervals are extended and maintenance requirements are reduced.

From a manufacturing perspective, the initial costs associated with improving abrasion resistance can be substantial. These may include investments in research and development, new equipment, and potentially more expensive raw materials. However, these upfront costs should be weighed against the long-term savings and potential market advantages.

Improved abrasion resistance can open up new market opportunities for silicone rubber products in industries where wear resistance is critical, such as automotive, aerospace, and industrial machinery. This expanded market reach can lead to increased sales and revenue, potentially offsetting the initial investment costs.

Customer satisfaction is another important factor to consider. Products with enhanced abrasion resistance are likely to perform better and last longer, leading to improved customer perception and loyalty. This can result in repeat business and positive word-of-mouth marketing, which are valuable intangible benefits.

However, it's crucial to consider the potential trade-offs. Enhancing abrasion resistance may affect other properties of silicone rubber, such as flexibility or thermal conductivity. These changes could limit the material's suitability for certain applications, potentially narrowing its market in some sectors while expanding it in others.

Environmental considerations also play a role in the cost-benefit analysis. More durable products contribute to sustainability efforts by reducing waste and the need for frequent replacements. This aligns with growing consumer and regulatory demands for environmentally friendly products, potentially leading to improved brand image and compliance with future regulations.

In conclusion, while the initial costs of maximizing silicone rubber's abrasion resistance can be significant, the long-term benefits in terms of product longevity, market expansion, customer satisfaction, and environmental impact often outweigh these costs. Companies must carefully assess their specific market needs, production capabilities, and long-term strategic goals to determine the optimal level of investment in abrasion resistance enhancement.

From a manufacturing perspective, the initial costs associated with improving abrasion resistance can be substantial. These may include investments in research and development, new equipment, and potentially more expensive raw materials. However, these upfront costs should be weighed against the long-term savings and potential market advantages.

Improved abrasion resistance can open up new market opportunities for silicone rubber products in industries where wear resistance is critical, such as automotive, aerospace, and industrial machinery. This expanded market reach can lead to increased sales and revenue, potentially offsetting the initial investment costs.

Customer satisfaction is another important factor to consider. Products with enhanced abrasion resistance are likely to perform better and last longer, leading to improved customer perception and loyalty. This can result in repeat business and positive word-of-mouth marketing, which are valuable intangible benefits.

However, it's crucial to consider the potential trade-offs. Enhancing abrasion resistance may affect other properties of silicone rubber, such as flexibility or thermal conductivity. These changes could limit the material's suitability for certain applications, potentially narrowing its market in some sectors while expanding it in others.

Environmental considerations also play a role in the cost-benefit analysis. More durable products contribute to sustainability efforts by reducing waste and the need for frequent replacements. This aligns with growing consumer and regulatory demands for environmentally friendly products, potentially leading to improved brand image and compliance with future regulations.

In conclusion, while the initial costs of maximizing silicone rubber's abrasion resistance can be significant, the long-term benefits in terms of product longevity, market expansion, customer satisfaction, and environmental impact often outweigh these costs. Companies must carefully assess their specific market needs, production capabilities, and long-term strategic goals to determine the optimal level of investment in abrasion resistance enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!