How to Use Microelectrode CV for High-resistance Systems — Instrument Setup and Data Examples

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microelectrode CV Technology Background and Objectives

Microelectrode cyclic voltammetry (CV) has evolved significantly since its inception in the mid-20th century, transforming from a specialized analytical technique to an essential tool in electrochemical research. The development trajectory of microelectrode CV technology has been characterized by continuous refinement in electrode fabrication, instrumentation sensitivity, and data processing capabilities. Initially limited by technological constraints, modern microelectrode systems now enable investigations at previously inaccessible scales and in challenging environments.

The evolution of microelectrode CV has been particularly impactful for high-resistance systems analysis, which traditionally posed significant measurement challenges. High-resistance systems, including non-aqueous solvents, solid electrolytes, and biological interfaces, represent critical research areas across multiple disciplines. The ability to obtain accurate electrochemical data in these environments has become increasingly important for advancing energy storage technologies, biomedical applications, and materials science.

Current technological trends in microelectrode CV focus on miniaturization, enhanced signal processing, and integration with complementary analytical techniques. The push toward nanoscale electrodes has opened new possibilities for spatial resolution and sensitivity, while advanced noise filtering algorithms have dramatically improved signal quality in challenging measurement conditions. Additionally, the integration of microelectrode CV with spectroscopic and microscopic techniques has created powerful hybrid analytical platforms.

The primary technical objectives for microelectrode CV in high-resistance systems include overcoming measurement artifacts, enhancing signal-to-noise ratios, and developing standardized protocols for reliable data acquisition and interpretation. Specifically, researchers aim to address issues such as uncompensated resistance effects, capacitive current distortions, and reference electrode stability in high-resistance environments.

Future development goals include the creation of automated calibration systems, real-time impedance compensation, and machine learning algorithms for data analysis. These advancements would significantly reduce the expertise barrier for utilizing microelectrode CV in complex systems and expand its accessibility across scientific disciplines.

The convergence of microelectrode CV technology with digital simulation tools represents another important trend, enabling researchers to model complex electrochemical processes and validate experimental results against theoretical predictions. This synergy between experimental techniques and computational methods promises to accelerate discovery in fields ranging from electrocatalysis to neurochemistry.

The evolution of microelectrode CV has been particularly impactful for high-resistance systems analysis, which traditionally posed significant measurement challenges. High-resistance systems, including non-aqueous solvents, solid electrolytes, and biological interfaces, represent critical research areas across multiple disciplines. The ability to obtain accurate electrochemical data in these environments has become increasingly important for advancing energy storage technologies, biomedical applications, and materials science.

Current technological trends in microelectrode CV focus on miniaturization, enhanced signal processing, and integration with complementary analytical techniques. The push toward nanoscale electrodes has opened new possibilities for spatial resolution and sensitivity, while advanced noise filtering algorithms have dramatically improved signal quality in challenging measurement conditions. Additionally, the integration of microelectrode CV with spectroscopic and microscopic techniques has created powerful hybrid analytical platforms.

The primary technical objectives for microelectrode CV in high-resistance systems include overcoming measurement artifacts, enhancing signal-to-noise ratios, and developing standardized protocols for reliable data acquisition and interpretation. Specifically, researchers aim to address issues such as uncompensated resistance effects, capacitive current distortions, and reference electrode stability in high-resistance environments.

Future development goals include the creation of automated calibration systems, real-time impedance compensation, and machine learning algorithms for data analysis. These advancements would significantly reduce the expertise barrier for utilizing microelectrode CV in complex systems and expand its accessibility across scientific disciplines.

The convergence of microelectrode CV technology with digital simulation tools represents another important trend, enabling researchers to model complex electrochemical processes and validate experimental results against theoretical predictions. This synergy between experimental techniques and computational methods promises to accelerate discovery in fields ranging from electrocatalysis to neurochemistry.

Market Applications for High-resistance Electrochemical Analysis

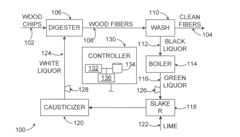

High-resistance electrochemical analysis has established itself as a critical technology across multiple industries, with market applications continuing to expand as the technology matures. The pharmaceutical sector represents one of the largest markets, where microelectrode cyclic voltammetry enables precise characterization of drug compounds in low-conductivity organic solvents. This capability is particularly valuable for analyzing the electrochemical properties of potential drug candidates during early development stages, providing insights into stability and reactivity that traditional methods cannot achieve in high-resistance environments.

The energy storage industry has embraced high-resistance electrochemical analysis for battery research and development. Manufacturers utilize this technology to study electrode-electrolyte interfaces in solid-state batteries and other advanced energy storage systems where traditional electrochemical techniques are limited by high internal resistance. The growing electric vehicle market has further accelerated demand for these analytical capabilities, as companies seek to develop safer, more efficient battery technologies with improved performance in extreme conditions.

Environmental monitoring represents another significant application area, where trace contaminant detection in low-conductivity natural waters and organic pollutants requires specialized electrochemical techniques. The ability to perform accurate measurements in high-resistance media allows for on-site analysis of environmental samples without extensive sample preparation, reducing analysis time and increasing monitoring efficiency.

The semiconductor industry leverages high-resistance electrochemical analysis for quality control of ultrapure water systems and specialized chemicals used in manufacturing processes. As chip dimensions continue to shrink, the detection of even trace electroactive impurities becomes increasingly critical, driving demand for more sensitive analytical techniques capable of operating in high-resistance media.

Materials science research constitutes a growing market segment, particularly in the development of advanced polymers, ceramics, and composite materials with specialized electrochemical properties. Researchers utilize microelectrode techniques to characterize these materials under various conditions, providing crucial data for optimizing performance characteristics.

The biomedical field has adopted high-resistance electrochemical analysis for biosensor development and neurochemical studies. The technology enables measurements in biological matrices with inherently high resistance, such as tissue samples or specialized cell culture environments, supporting advancements in personalized medicine and diagnostic technologies.

As industries continue to push technological boundaries, the market for high-resistance electrochemical analysis equipment and expertise is projected to expand, particularly in regions with strong research and manufacturing bases in pharmaceuticals, advanced materials, and energy technologies.

The energy storage industry has embraced high-resistance electrochemical analysis for battery research and development. Manufacturers utilize this technology to study electrode-electrolyte interfaces in solid-state batteries and other advanced energy storage systems where traditional electrochemical techniques are limited by high internal resistance. The growing electric vehicle market has further accelerated demand for these analytical capabilities, as companies seek to develop safer, more efficient battery technologies with improved performance in extreme conditions.

Environmental monitoring represents another significant application area, where trace contaminant detection in low-conductivity natural waters and organic pollutants requires specialized electrochemical techniques. The ability to perform accurate measurements in high-resistance media allows for on-site analysis of environmental samples without extensive sample preparation, reducing analysis time and increasing monitoring efficiency.

The semiconductor industry leverages high-resistance electrochemical analysis for quality control of ultrapure water systems and specialized chemicals used in manufacturing processes. As chip dimensions continue to shrink, the detection of even trace electroactive impurities becomes increasingly critical, driving demand for more sensitive analytical techniques capable of operating in high-resistance media.

Materials science research constitutes a growing market segment, particularly in the development of advanced polymers, ceramics, and composite materials with specialized electrochemical properties. Researchers utilize microelectrode techniques to characterize these materials under various conditions, providing crucial data for optimizing performance characteristics.

The biomedical field has adopted high-resistance electrochemical analysis for biosensor development and neurochemical studies. The technology enables measurements in biological matrices with inherently high resistance, such as tissue samples or specialized cell culture environments, supporting advancements in personalized medicine and diagnostic technologies.

As industries continue to push technological boundaries, the market for high-resistance electrochemical analysis equipment and expertise is projected to expand, particularly in regions with strong research and manufacturing bases in pharmaceuticals, advanced materials, and energy technologies.

Technical Challenges in High-resistance Systems Measurement

High-resistance systems present significant challenges for accurate electrochemical measurements using cyclic voltammetry (CV). The primary obstacle stems from the inherently low current signals generated in these systems, often in the pico to nano-ampere range, which approach the detection limits of many conventional potentiostats. This signal-to-noise ratio problem becomes particularly acute when working with microelectrodes in high-resistance media such as non-aqueous solvents, solid-state materials, or biological samples.

Electrical noise contamination represents another major technical hurdle. External electromagnetic interference, ground loops, and thermal noise can easily overwhelm the minute signals being measured. This necessitates specialized shielding techniques, including Faraday cages and careful grounding strategies, which add complexity to experimental setups and may introduce additional variables.

The uncompensated resistance (Ru) effect poses a substantial challenge in high-resistance systems. As resistance increases, the voltage drop across the solution becomes significant, leading to distorted voltammograms with shifted peak potentials and broadened features. Traditional iR compensation techniques often struggle with the extreme resistance values encountered in these systems, requiring advanced algorithms and hardware solutions.

Capacitive charging currents present another complication, as they can mask faradaic processes of interest, especially at faster scan rates. The time constants for charging the electrical double layer become prohibitively long in high-resistance media, necessitating extremely slow scan rates that may introduce additional complications such as sample degradation or electrode fouling during extended measurement periods.

Electrode stability and reproducibility become critical concerns in high-resistance environments. Surface phenomena such as adsorption, passivation, and contamination have magnified effects on the already small signals. Microelectrode fabrication must achieve exceptional dimensional precision and surface quality to ensure reliable measurements.

Temperature fluctuations introduce additional variability in high-resistance systems, as even minor changes can significantly alter resistance values and reaction kinetics. This necessitates precise temperature control systems that themselves may introduce electrical noise if not properly designed.

Data acquisition and processing present further challenges, requiring specialized amplification circuits, filtering techniques, and signal processing algorithms to extract meaningful electrochemical information from noise-dominated raw data. The integration of these components into a cohesive measurement system demands expertise across multiple disciplines including electrochemistry, electronics, and signal processing.

Electrical noise contamination represents another major technical hurdle. External electromagnetic interference, ground loops, and thermal noise can easily overwhelm the minute signals being measured. This necessitates specialized shielding techniques, including Faraday cages and careful grounding strategies, which add complexity to experimental setups and may introduce additional variables.

The uncompensated resistance (Ru) effect poses a substantial challenge in high-resistance systems. As resistance increases, the voltage drop across the solution becomes significant, leading to distorted voltammograms with shifted peak potentials and broadened features. Traditional iR compensation techniques often struggle with the extreme resistance values encountered in these systems, requiring advanced algorithms and hardware solutions.

Capacitive charging currents present another complication, as they can mask faradaic processes of interest, especially at faster scan rates. The time constants for charging the electrical double layer become prohibitively long in high-resistance media, necessitating extremely slow scan rates that may introduce additional complications such as sample degradation or electrode fouling during extended measurement periods.

Electrode stability and reproducibility become critical concerns in high-resistance environments. Surface phenomena such as adsorption, passivation, and contamination have magnified effects on the already small signals. Microelectrode fabrication must achieve exceptional dimensional precision and surface quality to ensure reliable measurements.

Temperature fluctuations introduce additional variability in high-resistance systems, as even minor changes can significantly alter resistance values and reaction kinetics. This necessitates precise temperature control systems that themselves may introduce electrical noise if not properly designed.

Data acquisition and processing present further challenges, requiring specialized amplification circuits, filtering techniques, and signal processing algorithms to extract meaningful electrochemical information from noise-dominated raw data. The integration of these components into a cohesive measurement system demands expertise across multiple disciplines including electrochemistry, electronics, and signal processing.

Current Instrument Setup Solutions for High-resistance Systems

01 Microelectrode design for high-resistance CV measurements

Specialized microelectrode designs can improve cyclic voltammetry measurements in high-resistance systems. These designs include optimized electrode geometries, materials, and surface modifications that enhance signal-to-noise ratios and measurement sensitivity. Advanced microelectrode configurations help overcome the challenges associated with high solution resistance by minimizing ohmic drop and improving current response.- Microelectrode design for high-resistance CV measurements: Specialized microelectrode designs can improve cyclic voltammetry measurements in high-resistance systems. These designs include optimized electrode geometries, materials, and surface modifications that enhance signal-to-noise ratio and measurement sensitivity. Advanced microelectrode arrays and miniaturized electrode configurations help overcome the challenges associated with high solution resistance by reducing ohmic drop and improving current distribution.

- Compensation techniques for high-resistance electrolytes: Various compensation techniques can be employed to address the challenges of high-resistance systems in cyclic voltammetry. These include IR compensation methods, feedback mechanisms, and algorithmic approaches that correct for solution resistance effects. Advanced signal processing and data correction techniques help minimize distortion in voltammograms caused by uncompensated resistance, enabling more accurate electrochemical analysis in high-resistance media.

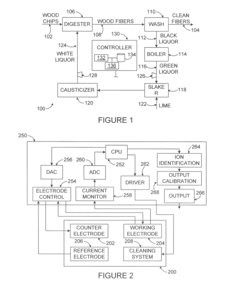

- Integrated measurement systems for high-precision CV analysis: Integrated measurement systems combine microelectrodes with specialized instrumentation for high-precision cyclic voltammetry in challenging environments. These systems incorporate advanced potentiostats, high-sensitivity current amplifiers, and noise reduction technologies specifically designed for high-resistance measurements. The integration of multiple analytical techniques with CV provides comprehensive electrochemical characterization while maintaining measurement accuracy in resistive media.

- Novel materials and coatings for enhanced electrode performance: Advanced materials and specialized coatings can significantly improve microelectrode performance in high-resistance cyclic voltammetry applications. These include conductive polymers, carbon nanomaterials, metal nanoparticles, and composite structures that enhance electron transfer kinetics and reduce interfacial resistance. Surface modifications with selective membranes or catalytic layers can improve specificity and sensitivity while maintaining performance in resistive environments.

- Microfluidic and lab-on-chip platforms for CV measurements: Microfluidic and lab-on-chip platforms integrate microelectrodes with precise fluid handling systems for cyclic voltammetry in high-resistance environments. These miniaturized systems control sample volumes, flow rates, and electrode positioning to optimize measurement conditions. The reduced dimensions minimize the effects of solution resistance while enabling multiplexed measurements and automation of analytical procedures, making them particularly suitable for high-throughput screening and point-of-care applications.

02 Compensation techniques for high-resistance systems

Various compensation techniques can be employed to address the challenges of high-resistance systems in cyclic voltammetry. These include IR compensation methods, feedback mechanisms, and algorithmic approaches that correct for resistance-induced distortions in the voltammetric response. These techniques help maintain measurement accuracy by minimizing the effects of solution resistance on potential control and current measurement.Expand Specific Solutions03 Integration of microelectrodes with advanced measurement systems

Integrating microelectrodes with advanced measurement systems enhances cyclic voltammetry performance in high-resistance environments. These systems may incorporate specialized potentiostats, signal processing units, and data analysis software specifically designed for challenging electrochemical conditions. The integration enables real-time compensation, filtering, and signal enhancement to obtain reliable voltammetric data despite high solution resistance.Expand Specific Solutions04 Miniaturized electrochemical cells for high-resistance measurements

Miniaturized electrochemical cells are designed specifically for cyclic voltammetry in high-resistance systems. These cells feature reduced inter-electrode distances, optimized geometries, and carefully selected materials to minimize solution resistance effects. The compact design helps maintain controlled diffusion conditions while reducing the impact of uncompensated resistance on the electrochemical measurements.Expand Specific Solutions05 Novel materials and surface modifications for microelectrodes

Advanced materials and surface modifications enhance microelectrode performance in high-resistance cyclic voltammetry applications. These innovations include conductive polymers, nanostructured surfaces, and composite materials that improve electron transfer kinetics and reduce interfacial resistance. Such modifications can significantly improve signal quality and measurement sensitivity in challenging electrochemical environments.Expand Specific Solutions

Leading Manufacturers and Research Groups in Microelectrode Technology

Microelectrode cyclic voltammetry (CV) for high-resistance systems is currently in a growth phase, with increasing market adoption across research and industrial applications. The market size is expanding as demand for precise electrochemical measurements in challenging environments grows. Technologically, the field shows varying maturity levels among key players. Companies like Infineon Technologies and STMicroelectronics have established strong positions in sensor technology development, while IBM and Micron Technology leverage their semiconductor expertise to address high-resistance measurement challenges. Research institutions including Lawrence Livermore National Security and the Agency for Science, Technology & Research are advancing fundamental capabilities. Fujitsu and NXP are integrating these technologies into broader system solutions, while specialized players like Physical Logic focus on niche applications requiring high precision measurements in challenging electrical environments.

Infineon Technologies AG

Technical Solution: Infineon has developed a specialized microelectrode CV measurement system designed specifically for characterizing high-resistance semiconductor materials and devices. Their approach integrates ultra-low current measurement capabilities (down to femtoampere range) with advanced signal processing to extract meaningful electrochemical data from highly resistive samples. The system employs custom-designed microelectrodes with optimized geometries to minimize capacitive effects and enhance signal-to-noise ratios. Infineon's setup includes a temperature-controlled measurement chamber that enables precise control of environmental conditions, critical for accurate characterization of temperature-dependent electrochemical processes in high-resistance systems. Their instrumentation incorporates specialized shielding and grounding techniques to minimize electromagnetic interference, which is particularly important when measuring the extremely small currents associated with high-resistance samples. Additionally, Infineon has developed proprietary algorithms for data analysis that can compensate for the non-ideal behavior often observed in high-resistance CV measurements.

Strengths: Exceptional sensitivity for detecting subtle electrochemical processes in highly resistive materials. Comprehensive environmental control capabilities allow for consistent measurements across varying conditions. Weaknesses: Complex calibration procedures required before each measurement series. Limited compatibility with third-party analysis software, creating potential workflow integration challenges.

International Business Machines Corp.

Technical Solution: IBM has developed advanced microelectrode cyclic voltammetry (CV) techniques specifically optimized for high-resistance systems. Their approach utilizes specialized potentiostats with high input impedance (>10^12 Ω) and low input current (<10 pA) capabilities to accurately measure electrochemical responses in resistive materials. IBM's setup incorporates a three-electrode configuration with carefully designed reference electrodes to minimize junction potentials and reduce noise. They've implemented digital filtering algorithms that can extract meaningful signals from high-resistance measurements while maintaining signal integrity. For semiconductor applications, IBM has pioneered the use of microelectrode arrays with precisely controlled geometries to enable spatial mapping of electrochemical properties across resistive interfaces. Their system includes automated compensation for ohmic drop effects, which are particularly problematic in high-resistance environments, using positive feedback techniques and real-time resistance monitoring.

Strengths: Superior noise rejection capabilities allowing measurements in highly resistive environments where conventional systems fail. Integrated data analysis software provides advanced interpretation of complex CV curves. Weaknesses: Requires significant expertise to properly configure and interpret results. Higher cost compared to standard CV systems, limiting accessibility for smaller research groups.

Key Innovations in Microelectrode Design and Signal Processing

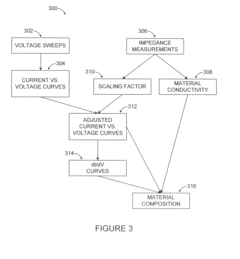

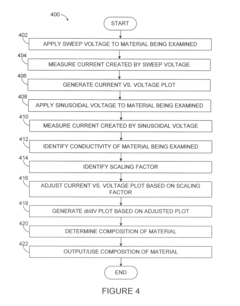

Apparatus and method for determining the composition of a material being examined

PatentInactiveUS20090255829A1

Innovation

- The method involves combining cyclic voltammetry and impedance measurements to adjust data for contamination effects, using a scaling factor derived from impedance measurements to normalize current versus voltage curves, and generate a current derivative curve for accurate material composition determination.

Electrode system with polymer electrode

PatentActiveEP3447836A1

Innovation

- A novel electrode system comprising a polymer electrode with both electron and proton conductive phases, specifically using doped poly(3,4-ethylenedioxythiophene) (PEDOT) as the electron conductor and polystyrene sulfonate (PSS) as the proton conductor, which facilitates high reversibility and efficient electrochemical conversion of molecules like benzenediols, reducing overpotential and enhancing current density.

Noise Reduction Strategies for High-resistance Measurements

Noise in high-resistance measurements presents a significant challenge when using microelectrode cyclic voltammetry (CV). The signal-to-noise ratio deteriorates substantially as resistance increases, potentially obscuring critical electrochemical data. Effective noise reduction strategies are therefore essential for obtaining meaningful results in these demanding experimental conditions.

Physical shielding represents the first line of defense against environmental noise. Faraday cages constructed from conductive materials can effectively isolate the experimental setup from external electromagnetic interference. For optimal performance, these shields should completely enclose the electrochemical cell and be properly grounded. Additionally, specialized vibration-isolation tables can minimize mechanical noise that might otherwise manifest as electrical artifacts.

Signal filtering techniques offer powerful computational approaches to noise reduction. Low-pass filters effectively remove high-frequency noise components while preserving the underlying electrochemical signal. However, filter parameters must be carefully selected to avoid distorting important features of the voltammogram. Adaptive filtering algorithms that dynamically adjust based on signal characteristics have shown particular promise for high-resistance systems.

Proper grounding and cable management significantly impact measurement quality. All system components should share a common ground point to prevent ground loops. Shielded, low-capacitance cables should be kept as short as possible, with careful routing to minimize electromagnetic pickup. Twisted-pair configurations can further reduce noise from magnetic field interference.

Advanced instrumentation designed specifically for high-resistance measurements incorporates features like current amplifiers with adjustable bandwidth, programmable filters, and high input impedance. Modern potentiostats with femtoampere-level current resolution capabilities are particularly valuable for microelectrode applications in high-resistance media.

Digital signal processing (DSP) techniques applied post-acquisition can extract meaningful data from noisy measurements. Wavelet transforms have proven especially effective for electrochemical signals, as they can separate noise from signal components across different frequency scales. Ensemble averaging of multiple voltammetric scans can also significantly improve signal quality, though care must be taken to ensure experimental stability across repeated measurements.

Temperature stabilization represents another critical factor, as thermal fluctuations can introduce significant noise in high-resistance systems. Maintaining constant temperature conditions throughout the experiment, particularly at the electrode-solution interface, helps minimize thermal noise contributions and improves measurement reproducibility.

Physical shielding represents the first line of defense against environmental noise. Faraday cages constructed from conductive materials can effectively isolate the experimental setup from external electromagnetic interference. For optimal performance, these shields should completely enclose the electrochemical cell and be properly grounded. Additionally, specialized vibration-isolation tables can minimize mechanical noise that might otherwise manifest as electrical artifacts.

Signal filtering techniques offer powerful computational approaches to noise reduction. Low-pass filters effectively remove high-frequency noise components while preserving the underlying electrochemical signal. However, filter parameters must be carefully selected to avoid distorting important features of the voltammogram. Adaptive filtering algorithms that dynamically adjust based on signal characteristics have shown particular promise for high-resistance systems.

Proper grounding and cable management significantly impact measurement quality. All system components should share a common ground point to prevent ground loops. Shielded, low-capacitance cables should be kept as short as possible, with careful routing to minimize electromagnetic pickup. Twisted-pair configurations can further reduce noise from magnetic field interference.

Advanced instrumentation designed specifically for high-resistance measurements incorporates features like current amplifiers with adjustable bandwidth, programmable filters, and high input impedance. Modern potentiostats with femtoampere-level current resolution capabilities are particularly valuable for microelectrode applications in high-resistance media.

Digital signal processing (DSP) techniques applied post-acquisition can extract meaningful data from noisy measurements. Wavelet transforms have proven especially effective for electrochemical signals, as they can separate noise from signal components across different frequency scales. Ensemble averaging of multiple voltammetric scans can also significantly improve signal quality, though care must be taken to ensure experimental stability across repeated measurements.

Temperature stabilization represents another critical factor, as thermal fluctuations can introduce significant noise in high-resistance systems. Maintaining constant temperature conditions throughout the experiment, particularly at the electrode-solution interface, helps minimize thermal noise contributions and improves measurement reproducibility.

Data Interpretation and Validation Protocols for Microelectrode CV

Establishing reliable data interpretation and validation protocols is essential for ensuring the accuracy and reproducibility of microelectrode cyclic voltammetry (CV) measurements in high-resistance systems. These protocols must address the unique challenges posed by microelectrodes when analyzing samples with limited conductivity.

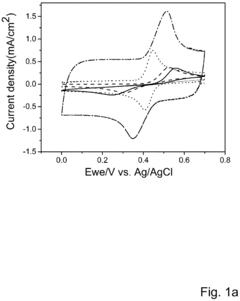

Raw data from microelectrode CV measurements requires systematic processing to extract meaningful electrochemical parameters. Initial data treatment should include baseline correction to account for capacitive currents, which are proportionally more significant in microelectrode systems than in conventional electrodes. Signal averaging techniques can be employed to improve signal-to-noise ratios without compromising the integrity of faradaic responses.

Statistical validation methods specific to microelectrode CV data should be implemented to assess measurement reliability. These include calculating confidence intervals for peak potentials and currents, as well as determining the reproducibility of measurements through multiple scan cycles. For high-resistance systems, particular attention must be paid to validating the absence of ohmic drop distortions, which can be accomplished through systematic variation of scan rates.

Internal standards with known electrochemical behaviors should be incorporated into experimental protocols. Ferrocene derivatives are particularly useful as reference redox couples due to their well-characterized reversible behavior. By comparing experimental results with theoretical responses for microelectrodes, researchers can validate their measurement systems and identify potential artifacts.

Cross-validation with complementary techniques provides additional confidence in microelectrode CV data. Techniques such as electrochemical impedance spectroscopy (EIS) can confirm resistance values independently, while scanning electrochemical microscopy (SECM) can verify local electrochemical activity at microelectrode surfaces.

Data quality indicators specific to microelectrode CV should be established, including peak-to-peak separation values, which should approach theoretical limits for microelectrodes (approximately 57 mV for one-electron transfers at room temperature). Additionally, the ratio of forward to reverse peak currents should approach unity for reversible systems, regardless of solution resistance.

Automated data analysis algorithms can be developed to standardize the interpretation process across different experimental conditions. These algorithms should incorporate microelectrode-specific theoretical models that account for hemispherical diffusion patterns rather than the planar diffusion dominant in macroelectrodes.

Documentation practices should include detailed reporting of all experimental parameters that could influence data interpretation, including microelectrode dimensions, surface preparation methods, solution composition, temperature, and instrument settings. This comprehensive approach ensures that validation protocols are transparent and reproducible across different research environments.

Raw data from microelectrode CV measurements requires systematic processing to extract meaningful electrochemical parameters. Initial data treatment should include baseline correction to account for capacitive currents, which are proportionally more significant in microelectrode systems than in conventional electrodes. Signal averaging techniques can be employed to improve signal-to-noise ratios without compromising the integrity of faradaic responses.

Statistical validation methods specific to microelectrode CV data should be implemented to assess measurement reliability. These include calculating confidence intervals for peak potentials and currents, as well as determining the reproducibility of measurements through multiple scan cycles. For high-resistance systems, particular attention must be paid to validating the absence of ohmic drop distortions, which can be accomplished through systematic variation of scan rates.

Internal standards with known electrochemical behaviors should be incorporated into experimental protocols. Ferrocene derivatives are particularly useful as reference redox couples due to their well-characterized reversible behavior. By comparing experimental results with theoretical responses for microelectrodes, researchers can validate their measurement systems and identify potential artifacts.

Cross-validation with complementary techniques provides additional confidence in microelectrode CV data. Techniques such as electrochemical impedance spectroscopy (EIS) can confirm resistance values independently, while scanning electrochemical microscopy (SECM) can verify local electrochemical activity at microelectrode surfaces.

Data quality indicators specific to microelectrode CV should be established, including peak-to-peak separation values, which should approach theoretical limits for microelectrodes (approximately 57 mV for one-electron transfers at room temperature). Additionally, the ratio of forward to reverse peak currents should approach unity for reversible systems, regardless of solution resistance.

Automated data analysis algorithms can be developed to standardize the interpretation process across different experimental conditions. These algorithms should incorporate microelectrode-specific theoretical models that account for hemispherical diffusion patterns rather than the planar diffusion dominant in macroelectrodes.

Documentation practices should include detailed reporting of all experimental parameters that could influence data interpretation, including microelectrode dimensions, surface preparation methods, solution composition, temperature, and instrument settings. This comprehensive approach ensures that validation protocols are transparent and reproducible across different research environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!