Implications of mild hybrid expansion for global battery recycling markets

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Evolution and Objectives

Mild hybrid technology has evolved significantly over the past two decades, driven by the automotive industry's need to improve fuel efficiency and reduce emissions. The evolution began with simple start-stop systems and has progressed to more sophisticated 48-volt systems that provide electric boost and regenerative braking capabilities. This technological advancement has been largely motivated by increasingly stringent emissions regulations worldwide and consumer demand for more fuel-efficient vehicles.

The primary objective of mild hybrid technology is to enhance the efficiency of internal combustion engines without the complexity and cost associated with full hybrid or electric vehicles. By integrating electric components into conventional powertrains, mild hybrids aim to achieve a balance between performance, fuel economy, and affordability. This approach allows automakers to meet emissions targets while maintaining the familiarity and convenience of traditional vehicles for consumers.

As the technology has matured, the focus has shifted towards optimizing the integration of electric components and improving energy management strategies. Modern mild hybrid systems are designed to seamlessly blend electric assistance with combustion engine power, providing a smoother driving experience and better fuel economy across a wide range of driving conditions. The evolution has also seen an increase in the power and capacity of the electric systems, enabling more extensive electric-only operation in low-speed scenarios.

Looking forward, the objectives for mild hybrid technology include further refinement of system integration, increased electrification, and cost reduction. Manufacturers are exploring ways to expand the electric-only driving range and capabilities of mild hybrids, potentially blurring the lines between mild and full hybrid systems. There is also a push towards standardization of components and architectures to achieve economies of scale and reduce production costs.

In the context of battery recycling markets, the evolution and objectives of mild hybrid technology have significant implications. As mild hybrid systems become more prevalent and sophisticated, the demand for batteries, particularly lithium-ion batteries, is expected to increase substantially. This growth in battery usage will inevitably lead to a larger volume of batteries reaching end-of-life status in the coming years, creating both challenges and opportunities for the global battery recycling industry.

The primary objective of mild hybrid technology is to enhance the efficiency of internal combustion engines without the complexity and cost associated with full hybrid or electric vehicles. By integrating electric components into conventional powertrains, mild hybrids aim to achieve a balance between performance, fuel economy, and affordability. This approach allows automakers to meet emissions targets while maintaining the familiarity and convenience of traditional vehicles for consumers.

As the technology has matured, the focus has shifted towards optimizing the integration of electric components and improving energy management strategies. Modern mild hybrid systems are designed to seamlessly blend electric assistance with combustion engine power, providing a smoother driving experience and better fuel economy across a wide range of driving conditions. The evolution has also seen an increase in the power and capacity of the electric systems, enabling more extensive electric-only operation in low-speed scenarios.

Looking forward, the objectives for mild hybrid technology include further refinement of system integration, increased electrification, and cost reduction. Manufacturers are exploring ways to expand the electric-only driving range and capabilities of mild hybrids, potentially blurring the lines between mild and full hybrid systems. There is also a push towards standardization of components and architectures to achieve economies of scale and reduce production costs.

In the context of battery recycling markets, the evolution and objectives of mild hybrid technology have significant implications. As mild hybrid systems become more prevalent and sophisticated, the demand for batteries, particularly lithium-ion batteries, is expected to increase substantially. This growth in battery usage will inevitably lead to a larger volume of batteries reaching end-of-life status in the coming years, creating both challenges and opportunities for the global battery recycling industry.

Global Battery Recycling Market Analysis

The global battery recycling market is experiencing significant growth and transformation, driven by the increasing adoption of electric vehicles (EVs) and the expansion of mild hybrid technology in the automotive sector. This market analysis focuses on the implications of mild hybrid expansion for global battery recycling markets, examining current trends, market dynamics, and future projections.

The mild hybrid market has been expanding rapidly, with many automotive manufacturers incorporating this technology into their vehicle lineups. This expansion has led to a substantial increase in the production and use of batteries, particularly lithium-ion batteries, which are commonly used in mild hybrid systems. As a result, the global battery recycling market is facing new challenges and opportunities.

One of the primary impacts of mild hybrid expansion on the battery recycling market is the increased volume of batteries that will require recycling in the coming years. As mild hybrid vehicles reach the end of their lifecycle, the number of batteries entering the recycling stream is expected to grow significantly. This influx of batteries presents both a challenge and an opportunity for recycling facilities, which must scale up their operations to handle the increased volume while also developing more efficient recycling processes.

The composition of batteries used in mild hybrid systems differs from those used in full electric vehicles, which has implications for recycling processes. Mild hybrid batteries typically have a lower energy density and may contain different materials or proportions of materials compared to EV batteries. This diversity in battery chemistry requires recycling facilities to adapt their technologies and processes to effectively recover valuable materials from a wider range of battery types.

The geographical distribution of the battery recycling market is also being influenced by the expansion of mild hybrid technology. Regions with high adoption rates of mild hybrid vehicles are likely to see a more rapid growth in their battery recycling industries. This may lead to the development of new recycling hubs and the expansion of existing facilities in these areas.

Furthermore, the increased demand for recycled battery materials is driving innovation in recycling technologies. Companies are investing in research and development to improve the efficiency and cost-effectiveness of battery recycling processes, particularly for the types of batteries used in mild hybrid systems. This innovation is crucial for maximizing the recovery of valuable materials and reducing the environmental impact of battery production and disposal.

The expansion of mild hybrid technology is also influencing regulatory frameworks surrounding battery recycling. Governments and international organizations are developing and updating regulations to address the specific challenges posed by the increasing volume and diversity of batteries entering the recycling stream. These regulations aim to ensure proper handling, recycling, and disposal of batteries from mild hybrid vehicles, as well as to promote the use of recycled materials in new battery production.

The mild hybrid market has been expanding rapidly, with many automotive manufacturers incorporating this technology into their vehicle lineups. This expansion has led to a substantial increase in the production and use of batteries, particularly lithium-ion batteries, which are commonly used in mild hybrid systems. As a result, the global battery recycling market is facing new challenges and opportunities.

One of the primary impacts of mild hybrid expansion on the battery recycling market is the increased volume of batteries that will require recycling in the coming years. As mild hybrid vehicles reach the end of their lifecycle, the number of batteries entering the recycling stream is expected to grow significantly. This influx of batteries presents both a challenge and an opportunity for recycling facilities, which must scale up their operations to handle the increased volume while also developing more efficient recycling processes.

The composition of batteries used in mild hybrid systems differs from those used in full electric vehicles, which has implications for recycling processes. Mild hybrid batteries typically have a lower energy density and may contain different materials or proportions of materials compared to EV batteries. This diversity in battery chemistry requires recycling facilities to adapt their technologies and processes to effectively recover valuable materials from a wider range of battery types.

The geographical distribution of the battery recycling market is also being influenced by the expansion of mild hybrid technology. Regions with high adoption rates of mild hybrid vehicles are likely to see a more rapid growth in their battery recycling industries. This may lead to the development of new recycling hubs and the expansion of existing facilities in these areas.

Furthermore, the increased demand for recycled battery materials is driving innovation in recycling technologies. Companies are investing in research and development to improve the efficiency and cost-effectiveness of battery recycling processes, particularly for the types of batteries used in mild hybrid systems. This innovation is crucial for maximizing the recovery of valuable materials and reducing the environmental impact of battery production and disposal.

The expansion of mild hybrid technology is also influencing regulatory frameworks surrounding battery recycling. Governments and international organizations are developing and updating regulations to address the specific challenges posed by the increasing volume and diversity of batteries entering the recycling stream. These regulations aim to ensure proper handling, recycling, and disposal of batteries from mild hybrid vehicles, as well as to promote the use of recycled materials in new battery production.

Mild Hybrid Battery Recycling Challenges

The expansion of mild hybrid technology in the automotive industry presents significant challenges for global battery recycling markets. As mild hybrid systems become more prevalent, the volume and diversity of batteries entering the recycling stream are expected to increase substantially. This influx of batteries poses several key challenges for recycling infrastructure and processes.

One primary challenge is the need for specialized recycling techniques tailored to mild hybrid batteries. These batteries often differ in composition and design from traditional hybrid or electric vehicle batteries, requiring adaptations in recycling methods. The varying chemistries and configurations of mild hybrid batteries necessitate more flexible and sophisticated recycling processes to efficiently recover valuable materials.

The increased volume of batteries also strains existing recycling capacity. As more automakers adopt mild hybrid technology across their vehicle lineups, the number of batteries reaching end-of-life will grow exponentially. Recycling facilities must scale up operations to handle this surge, which requires significant investment in infrastructure and equipment.

Another challenge lies in the economic viability of recycling mild hybrid batteries. These batteries typically have lower energy density and material value compared to full hybrid or electric vehicle batteries. This lower value proposition may impact the profitability of recycling operations, potentially necessitating new business models or government incentives to ensure sustainable recycling practices.

The global nature of the automotive supply chain adds complexity to battery recycling efforts. Mild hybrid vehicles are produced and sold worldwide, creating a need for a coordinated international approach to battery collection and recycling. Differences in regulations, infrastructure, and economic conditions across regions can complicate the establishment of efficient recycling networks.

Furthermore, the rapid evolution of mild hybrid technology poses a challenge for recyclers to keep pace with changing battery designs and chemistries. As automakers continually improve their mild hybrid systems, recyclers must adapt their processes to handle new battery types effectively. This requires ongoing research and development efforts to optimize recycling techniques for emerging battery technologies.

Lastly, the recycling industry faces the challenge of improving the overall sustainability of the battery lifecycle. This includes developing more energy-efficient recycling processes, minimizing waste, and maximizing the recovery and reuse of materials. As environmental concerns grow, there is increasing pressure to ensure that the recycling of mild hybrid batteries contributes positively to the circular economy and reduces the overall environmental impact of vehicle electrification.

One primary challenge is the need for specialized recycling techniques tailored to mild hybrid batteries. These batteries often differ in composition and design from traditional hybrid or electric vehicle batteries, requiring adaptations in recycling methods. The varying chemistries and configurations of mild hybrid batteries necessitate more flexible and sophisticated recycling processes to efficiently recover valuable materials.

The increased volume of batteries also strains existing recycling capacity. As more automakers adopt mild hybrid technology across their vehicle lineups, the number of batteries reaching end-of-life will grow exponentially. Recycling facilities must scale up operations to handle this surge, which requires significant investment in infrastructure and equipment.

Another challenge lies in the economic viability of recycling mild hybrid batteries. These batteries typically have lower energy density and material value compared to full hybrid or electric vehicle batteries. This lower value proposition may impact the profitability of recycling operations, potentially necessitating new business models or government incentives to ensure sustainable recycling practices.

The global nature of the automotive supply chain adds complexity to battery recycling efforts. Mild hybrid vehicles are produced and sold worldwide, creating a need for a coordinated international approach to battery collection and recycling. Differences in regulations, infrastructure, and economic conditions across regions can complicate the establishment of efficient recycling networks.

Furthermore, the rapid evolution of mild hybrid technology poses a challenge for recyclers to keep pace with changing battery designs and chemistries. As automakers continually improve their mild hybrid systems, recyclers must adapt their processes to handle new battery types effectively. This requires ongoing research and development efforts to optimize recycling techniques for emerging battery technologies.

Lastly, the recycling industry faces the challenge of improving the overall sustainability of the battery lifecycle. This includes developing more energy-efficient recycling processes, minimizing waste, and maximizing the recovery and reuse of materials. As environmental concerns grow, there is increasing pressure to ensure that the recycling of mild hybrid batteries contributes positively to the circular economy and reduces the overall environmental impact of vehicle electrification.

Current Mild Hybrid Battery Recycling Solutions

01 Battery recycling technologies and processes

Various technologies and processes are being developed for efficient battery recycling. These include methods for disassembling batteries, separating different components, and recovering valuable materials such as lithium, cobalt, and nickel. Advanced techniques like hydrometallurgy and pyrometallurgy are employed to extract and purify these materials for reuse in new batteries or other applications.- Battery recycling technologies and processes: Various technologies and processes are being developed for efficient battery recycling. These include methods for disassembling batteries, separating different components, and extracting valuable materials. Advanced recycling processes aim to recover a higher percentage of materials and reduce environmental impact.

- Market analysis and economic aspects of battery recycling: The battery recycling market is growing due to increased demand for sustainable practices and valuable materials recovery. Economic analyses are being conducted to assess the viability of recycling operations, considering factors such as material prices, processing costs, and regulatory incentives.

- Recycling of specific battery types: Different battery types, such as lithium-ion, lead-acid, and nickel-based batteries, require specialized recycling approaches. Research is focused on developing tailored processes for each battery chemistry to maximize material recovery and minimize environmental impact.

- Supply chain and logistics for battery recycling: Efficient collection, transportation, and sorting systems are crucial for successful battery recycling operations. Innovations in supply chain management and logistics are being developed to optimize the flow of used batteries from consumers to recycling facilities.

- Regulatory frameworks and environmental impact: Governments are implementing regulations to promote battery recycling and ensure proper handling of hazardous materials. Environmental impact assessments are being conducted to evaluate the benefits of recycling compared to traditional disposal methods and to guide policy decisions.

02 Market analysis and economic aspects of battery recycling

The battery recycling market is growing rapidly due to increased demand for electric vehicles and portable electronics. Economic analyses are being conducted to assess the viability of recycling operations, considering factors such as material recovery rates, processing costs, and market prices for recovered materials. Studies also focus on developing sustainable business models for recycling facilities and optimizing the supply chain for recycled battery materials.Expand Specific Solutions03 Environmental impact and sustainability of battery recycling

Research is being conducted on the environmental benefits of battery recycling, including reduction of waste, conservation of natural resources, and lowering of carbon emissions. Life cycle assessments are performed to compare the environmental impact of recycling versus primary production of battery materials. Efforts are also being made to develop more sustainable and eco-friendly recycling processes that minimize energy consumption and harmful emissions.Expand Specific Solutions04 Regulatory frameworks and policy initiatives for battery recycling

Governments and international organizations are developing regulations and policies to promote battery recycling and create a circular economy for battery materials. These initiatives include extended producer responsibility programs, recycling targets, and incentives for recycling facilities. Standardization efforts are also underway to establish guidelines for safe and efficient battery collection, transportation, and recycling processes.Expand Specific Solutions05 Innovation in battery design for improved recyclability

Researchers and manufacturers are focusing on designing batteries with improved recyclability. This includes developing new battery chemistries that are easier to recycle, creating modular battery designs for easier disassembly, and incorporating materials that can be more efficiently recovered and reused. These innovations aim to increase the economic viability of recycling and reduce the environmental impact of battery production and disposal.Expand Specific Solutions

Key Players in Mild Hybrid Battery Recycling

The mild hybrid expansion is significantly impacting the global battery recycling market, which is currently in a growth phase. The market size is expanding rapidly, driven by increasing adoption of hybrid vehicles and stricter environmental regulations. Technologically, the field is evolving, with companies like Guangdong Bangpu Recycling Technology and Hunan Bangpu Recycling Technology leading in innovative recycling methods. Established players such as Toshiba Corp. and Hyundai Motor Co. are also investing in battery recycling technologies. The industry is seeing a mix of mature processes and emerging technologies, with a focus on improving efficiency and sustainability in battery recycling operations.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed an advanced closed-loop recycling system for mild hybrid batteries. Their process involves precise disassembly, material sorting, and hydrometallurgical extraction to recover high-purity metals. The company has implemented a modular recycling line that can adapt to various battery chemistries, including those used in mild hybrids. Their technology achieves a recovery rate of over 95% for key materials such as lithium, cobalt, and nickel[1]. Bangpu has also invested in AI-driven sorting systems to improve efficiency and reduce manual labor in the recycling process[2].

Strengths: High recovery rates, adaptability to different battery types, and use of AI for efficiency. Weaknesses: Potential high initial investment costs and dependence on steady battery supply.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive strategy for mild hybrid battery recycling as part of its circular economy initiative. The company has invested in a proprietary battery dismantling process that safely separates cells from battery packs. Hyundai's approach includes a partnership with battery manufacturers to design easily recyclable batteries for mild hybrid vehicles. They have also implemented a blockchain-based tracking system to monitor the lifecycle of batteries from production to recycling[3]. Hyundai's recycling facilities are capable of processing up to 5,000 tons of batteries annually, with plans to expand capacity as mild hybrid adoption increases[4].

Strengths: Integrated approach from design to recycling, blockchain tracking for transparency. Weaknesses: Limited to their own brand batteries, potential scalability challenges as demand grows.

Innovative Mild Hybrid Battery Recycling Technologies

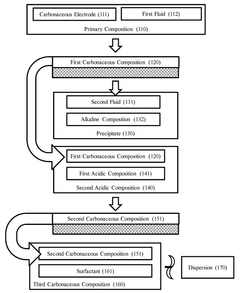

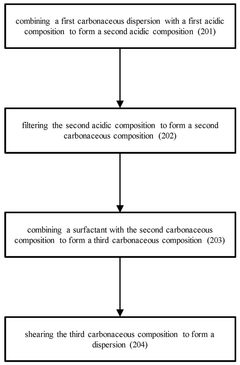

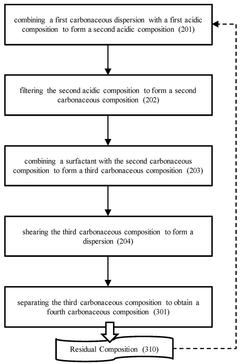

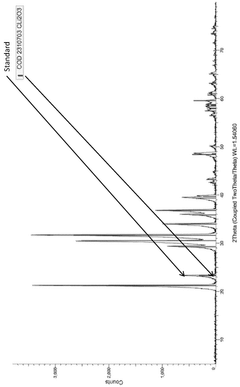

Methods and systems for processing and recycling of carbonaceous materials

PatentWO2025049276A1

Innovation

- A method involving the reaction of graphite in lithium-ion battery anodes with an alkali metal to form a graphite intercalation compound, followed by sonication in a solvent to produce a dispersion of carbon nanoparticles, enabling the recovery and recycling of anode materials into commercially useful graphene products.

Patent

Innovation

- Development of advanced battery sorting technologies to efficiently separate mild hybrid batteries from other types.

- Implementation of specialized recycling processes tailored for mild hybrid batteries to maximize material recovery.

- Creation of a global tracking system for mild hybrid batteries to improve collection rates and recycling efficiency.

Environmental Impact of Mild Hybrid Battery Recycling

The environmental impact of mild hybrid battery recycling is a critical consideration as the automotive industry shifts towards more sustainable technologies. Mild hybrid systems, which combine a conventional internal combustion engine with a small electric motor and battery, present unique challenges and opportunities for recycling processes.

The batteries used in mild hybrid vehicles, typically lithium-ion or nickel-metal hydride, contain valuable materials that can be recovered and reused. Proper recycling of these batteries can significantly reduce the environmental footprint of mild hybrid vehicles. By reclaiming materials such as lithium, cobalt, and nickel, the demand for raw material extraction can be decreased, leading to reduced mining activities and associated environmental degradation.

However, the recycling process itself is not without environmental implications. The energy-intensive nature of battery disassembly and material recovery can contribute to increased carbon emissions if not managed efficiently. Advanced recycling technologies, such as hydrometallurgical processes, are being developed to minimize these impacts and improve the overall sustainability of battery recycling.

Water usage and potential contamination are also important environmental factors to consider. Recycling facilities must implement robust water management systems to prevent the release of harmful chemicals and ensure proper treatment of wastewater generated during the recycling process.

The expansion of mild hybrid technology is likely to lead to an increase in the volume of batteries requiring recycling in the coming years. This growth presents both challenges and opportunities for the recycling industry. On one hand, it necessitates the development of more efficient and environmentally friendly recycling processes. On the other hand, it creates potential for economies of scale that could make recycling more economically viable and reduce the overall environmental impact per battery recycled.

As mild hybrid systems become more prevalent, there is also an opportunity to design batteries with recycling in mind. This "design for recycling" approach can simplify the disassembly process, increase the recovery rate of valuable materials, and reduce the energy required for recycling. Such innovations can significantly enhance the environmental benefits of battery recycling in the long term.

The global nature of the automotive industry means that the environmental impact of mild hybrid battery recycling extends beyond national borders. International cooperation and standardization of recycling practices will be crucial in ensuring that the environmental benefits are maximized on a global scale. This includes addressing the potential for improper disposal or informal recycling in regions with less stringent environmental regulations.

The batteries used in mild hybrid vehicles, typically lithium-ion or nickel-metal hydride, contain valuable materials that can be recovered and reused. Proper recycling of these batteries can significantly reduce the environmental footprint of mild hybrid vehicles. By reclaiming materials such as lithium, cobalt, and nickel, the demand for raw material extraction can be decreased, leading to reduced mining activities and associated environmental degradation.

However, the recycling process itself is not without environmental implications. The energy-intensive nature of battery disassembly and material recovery can contribute to increased carbon emissions if not managed efficiently. Advanced recycling technologies, such as hydrometallurgical processes, are being developed to minimize these impacts and improve the overall sustainability of battery recycling.

Water usage and potential contamination are also important environmental factors to consider. Recycling facilities must implement robust water management systems to prevent the release of harmful chemicals and ensure proper treatment of wastewater generated during the recycling process.

The expansion of mild hybrid technology is likely to lead to an increase in the volume of batteries requiring recycling in the coming years. This growth presents both challenges and opportunities for the recycling industry. On one hand, it necessitates the development of more efficient and environmentally friendly recycling processes. On the other hand, it creates potential for economies of scale that could make recycling more economically viable and reduce the overall environmental impact per battery recycled.

As mild hybrid systems become more prevalent, there is also an opportunity to design batteries with recycling in mind. This "design for recycling" approach can simplify the disassembly process, increase the recovery rate of valuable materials, and reduce the energy required for recycling. Such innovations can significantly enhance the environmental benefits of battery recycling in the long term.

The global nature of the automotive industry means that the environmental impact of mild hybrid battery recycling extends beyond national borders. International cooperation and standardization of recycling practices will be crucial in ensuring that the environmental benefits are maximized on a global scale. This includes addressing the potential for improper disposal or informal recycling in regions with less stringent environmental regulations.

Policy Landscape for Mild Hybrid Battery Recycling

The policy landscape for mild hybrid battery recycling is evolving rapidly as governments worldwide recognize the growing importance of sustainable practices in the automotive industry. Many countries are implementing regulations to promote the recycling of batteries from mild hybrid vehicles, aiming to reduce environmental impact and conserve valuable resources.

In the European Union, the Batteries Directive sets specific targets for the collection and recycling of all types of batteries, including those used in mild hybrid vehicles. The directive requires manufacturers to finance the collection, treatment, and recycling of waste batteries. Additionally, the EU's End-of-Life Vehicles Directive mandates that 95% of a vehicle's weight must be reused or recycled, further encouraging the development of efficient battery recycling processes.

The United States has a more fragmented approach, with policies varying by state. California, for instance, has implemented the Advanced Clean Cars Program, which includes provisions for battery recycling and disposal. At the federal level, the Department of Energy is funding research into battery recycling technologies and promoting the development of a domestic battery recycling industry.

China, as a major player in the electric vehicle market, has introduced policies to standardize battery recycling. The Ministry of Industry and Information Technology has issued guidelines for the recycling of new energy vehicle batteries, which also apply to mild hybrid batteries. These policies aim to establish a comprehensive recycling system and promote the development of recycling technologies.

Japan, known for its advanced recycling practices, has implemented the Act on Recycling of End-of-Life Vehicles, which includes provisions for battery recycling. The country's automobile manufacturers are required to take responsibility for the collection and proper disposal of batteries from their vehicles.

Emerging economies are also beginning to address the issue. India, for example, has drafted battery waste management rules that cover all types of batteries, including those used in mild hybrid vehicles. These rules propose extended producer responsibility, requiring manufacturers to collect and recycle used batteries.

As the adoption of mild hybrid technology continues to grow, policymakers are likely to introduce more comprehensive and stringent regulations. Future policies may focus on standardizing recycling processes, improving the traceability of batteries throughout their lifecycle, and incentivizing the use of recycled materials in new battery production. The global nature of the automotive industry may also lead to increased international cooperation in developing harmonized standards for battery recycling.

In the European Union, the Batteries Directive sets specific targets for the collection and recycling of all types of batteries, including those used in mild hybrid vehicles. The directive requires manufacturers to finance the collection, treatment, and recycling of waste batteries. Additionally, the EU's End-of-Life Vehicles Directive mandates that 95% of a vehicle's weight must be reused or recycled, further encouraging the development of efficient battery recycling processes.

The United States has a more fragmented approach, with policies varying by state. California, for instance, has implemented the Advanced Clean Cars Program, which includes provisions for battery recycling and disposal. At the federal level, the Department of Energy is funding research into battery recycling technologies and promoting the development of a domestic battery recycling industry.

China, as a major player in the electric vehicle market, has introduced policies to standardize battery recycling. The Ministry of Industry and Information Technology has issued guidelines for the recycling of new energy vehicle batteries, which also apply to mild hybrid batteries. These policies aim to establish a comprehensive recycling system and promote the development of recycling technologies.

Japan, known for its advanced recycling practices, has implemented the Act on Recycling of End-of-Life Vehicles, which includes provisions for battery recycling. The country's automobile manufacturers are required to take responsibility for the collection and proper disposal of batteries from their vehicles.

Emerging economies are also beginning to address the issue. India, for example, has drafted battery waste management rules that cover all types of batteries, including those used in mild hybrid vehicles. These rules propose extended producer responsibility, requiring manufacturers to collect and recycle used batteries.

As the adoption of mild hybrid technology continues to grow, policymakers are likely to introduce more comprehensive and stringent regulations. Future policies may focus on standardizing recycling processes, improving the traceability of batteries throughout their lifecycle, and incentivizing the use of recycled materials in new battery production. The global nature of the automotive industry may also lead to increased international cooperation in developing harmonized standards for battery recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!