Influence of Triton X-100 on Reagent-Free Chemical Analysis Techniques

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 Background and Research Objectives

Triton X-100, a nonionic surfactant, has been a cornerstone in various chemical and biological applications for decades. Its unique properties, including its ability to solubilize proteins and lipids, have made it an indispensable tool in many laboratory procedures. The compound's structure, consisting of a hydrophilic polyethylene oxide chain and an aromatic hydrocarbon lipophilic group, allows it to interact with both polar and non-polar substances, making it particularly useful in membrane protein research and cell lysis protocols.

The historical development of Triton X-100 can be traced back to the mid-20th century when it was first synthesized and introduced as a detergent. Since then, its applications have expanded significantly, encompassing fields such as biochemistry, molecular biology, and analytical chemistry. The surfactant's widespread use has led to a continuous exploration of its properties and potential impacts on various analytical techniques.

In recent years, there has been a growing interest in reagent-free chemical analysis techniques, driven by the need for more environmentally friendly, cost-effective, and rapid analytical methods. These techniques aim to minimize or eliminate the use of additional chemical reagents, thereby reducing waste generation and simplifying analytical procedures. However, the presence of Triton X-100 in samples or as a residual contaminant from previous processing steps can potentially influence these reagent-free methods.

The primary objective of this research is to comprehensively investigate the influence of Triton X-100 on reagent-free chemical analysis techniques. This involves examining how the surfactant's presence affects the accuracy, sensitivity, and reliability of various analytical methods that do not rely on additional reagents. The study aims to elucidate the mechanisms by which Triton X-100 interacts with analytes and analytical instruments, potentially altering measurement outcomes.

Furthermore, this research seeks to establish guidelines for the appropriate use or removal of Triton X-100 in sample preparation stages preceding reagent-free analyses. By understanding the surfactant's effects, researchers can develop strategies to mitigate its interference or exploit its properties to enhance analytical performance. This knowledge is crucial for advancing the field of reagent-free chemical analysis and ensuring the reliability of results in various scientific and industrial applications.

The technological evolution in this area is expected to lead to more robust analytical techniques that can accurately function in the presence of surfactants like Triton X-100. This may involve the development of new instrumental designs, data processing algorithms, or sample preparation methods that can compensate for or eliminate the surfactant's influence. As such, this research not only addresses current analytical challenges but also paves the way for future innovations in chemical analysis methodologies.

The historical development of Triton X-100 can be traced back to the mid-20th century when it was first synthesized and introduced as a detergent. Since then, its applications have expanded significantly, encompassing fields such as biochemistry, molecular biology, and analytical chemistry. The surfactant's widespread use has led to a continuous exploration of its properties and potential impacts on various analytical techniques.

In recent years, there has been a growing interest in reagent-free chemical analysis techniques, driven by the need for more environmentally friendly, cost-effective, and rapid analytical methods. These techniques aim to minimize or eliminate the use of additional chemical reagents, thereby reducing waste generation and simplifying analytical procedures. However, the presence of Triton X-100 in samples or as a residual contaminant from previous processing steps can potentially influence these reagent-free methods.

The primary objective of this research is to comprehensively investigate the influence of Triton X-100 on reagent-free chemical analysis techniques. This involves examining how the surfactant's presence affects the accuracy, sensitivity, and reliability of various analytical methods that do not rely on additional reagents. The study aims to elucidate the mechanisms by which Triton X-100 interacts with analytes and analytical instruments, potentially altering measurement outcomes.

Furthermore, this research seeks to establish guidelines for the appropriate use or removal of Triton X-100 in sample preparation stages preceding reagent-free analyses. By understanding the surfactant's effects, researchers can develop strategies to mitigate its interference or exploit its properties to enhance analytical performance. This knowledge is crucial for advancing the field of reagent-free chemical analysis and ensuring the reliability of results in various scientific and industrial applications.

The technological evolution in this area is expected to lead to more robust analytical techniques that can accurately function in the presence of surfactants like Triton X-100. This may involve the development of new instrumental designs, data processing algorithms, or sample preparation methods that can compensate for or eliminate the surfactant's influence. As such, this research not only addresses current analytical challenges but also paves the way for future innovations in chemical analysis methodologies.

Market Demand for Reagent-Free Analysis

The market demand for reagent-free chemical analysis techniques has been steadily growing in recent years, driven by several key factors. Industries such as pharmaceuticals, environmental monitoring, food and beverage, and clinical diagnostics are increasingly seeking more efficient, cost-effective, and environmentally friendly analytical methods. Reagent-free techniques offer significant advantages in these areas, including reduced operational costs, minimized chemical waste, and improved process efficiency.

In the pharmaceutical sector, there is a strong push for real-time monitoring of drug manufacturing processes, where reagent-free analysis can provide rapid and continuous measurements without interfering with production. This aligns with the industry's move towards Process Analytical Technology (PAT) and Quality by Design (QbD) approaches, which emphasize in-line and on-line measurements for process control and optimization.

Environmental monitoring agencies and water treatment facilities are another major market driver for reagent-free analysis. The need for continuous monitoring of water quality parameters, such as pH, dissolved oxygen, and contaminants, without the use of chemical reagents, is becoming increasingly important for regulatory compliance and public health protection.

The food and beverage industry is also showing growing interest in reagent-free techniques for quality control and safety assurance. These methods allow for non-destructive testing of products, enabling manufacturers to maintain product integrity while ensuring compliance with stringent quality standards.

In clinical diagnostics, there is a rising demand for point-of-care testing devices that can provide rapid results without the need for complex sample preparation or reagent handling. Reagent-free analysis techniques are particularly attractive in this context, as they can simplify testing procedures and reduce the risk of errors associated with reagent management.

The global market for analytical instruments, which includes reagent-free analysis technologies, was valued at over $60 billion in 2020 and is projected to grow at a CAGR of around 6% through 2025. Within this market, the segment for reagent-free and minimal-reagent technologies is expected to show above-average growth rates, driven by the increasing adoption of spectroscopic and electrochemical techniques in various industries.

However, the market adoption of reagent-free analysis techniques faces some challenges. The initial capital investment for advanced instrumentation can be high, which may deter some smaller organizations. Additionally, there is a need for skilled operators and data analysts to interpret the results from these sophisticated systems, which could limit widespread adoption in certain sectors.

In the pharmaceutical sector, there is a strong push for real-time monitoring of drug manufacturing processes, where reagent-free analysis can provide rapid and continuous measurements without interfering with production. This aligns with the industry's move towards Process Analytical Technology (PAT) and Quality by Design (QbD) approaches, which emphasize in-line and on-line measurements for process control and optimization.

Environmental monitoring agencies and water treatment facilities are another major market driver for reagent-free analysis. The need for continuous monitoring of water quality parameters, such as pH, dissolved oxygen, and contaminants, without the use of chemical reagents, is becoming increasingly important for regulatory compliance and public health protection.

The food and beverage industry is also showing growing interest in reagent-free techniques for quality control and safety assurance. These methods allow for non-destructive testing of products, enabling manufacturers to maintain product integrity while ensuring compliance with stringent quality standards.

In clinical diagnostics, there is a rising demand for point-of-care testing devices that can provide rapid results without the need for complex sample preparation or reagent handling. Reagent-free analysis techniques are particularly attractive in this context, as they can simplify testing procedures and reduce the risk of errors associated with reagent management.

The global market for analytical instruments, which includes reagent-free analysis technologies, was valued at over $60 billion in 2020 and is projected to grow at a CAGR of around 6% through 2025. Within this market, the segment for reagent-free and minimal-reagent technologies is expected to show above-average growth rates, driven by the increasing adoption of spectroscopic and electrochemical techniques in various industries.

However, the market adoption of reagent-free analysis techniques faces some challenges. The initial capital investment for advanced instrumentation can be high, which may deter some smaller organizations. Additionally, there is a need for skilled operators and data analysts to interpret the results from these sophisticated systems, which could limit widespread adoption in certain sectors.

Current Challenges in Chemical Analysis Techniques

Chemical analysis techniques have made significant strides in recent years, yet several challenges persist in the field, particularly in reagent-free methodologies. One of the primary obstacles is achieving high sensitivity and selectivity without the use of traditional reagents. This is especially crucial when dealing with complex matrices or trace-level analytes, where interference from other compounds can significantly impact results.

The development of robust, reliable, and reproducible reagent-free techniques remains a significant challenge. Many current methods struggle with consistency across different sample types or environmental conditions, limiting their broad applicability. This variability often necessitates extensive calibration and validation processes, which can be time-consuming and resource-intensive.

Another major hurdle is the integration of real-time, in-situ analysis capabilities. While reagent-free techniques offer the potential for rapid, on-site testing, translating laboratory-based methods to field-deployable instruments presents numerous technical difficulties. These include miniaturization of equipment, ensuring stability in diverse environmental conditions, and maintaining analytical performance comparable to traditional laboratory methods.

The influence of surfactants like Triton X-100 on reagent-free chemical analysis techniques adds another layer of complexity. Surfactants can significantly alter the physicochemical properties of analytes and their surrounding medium, potentially interfering with detection mechanisms or altering signal responses. Understanding and mitigating these effects is crucial for developing reliable reagent-free methods in the presence of such compounds.

Data interpretation and analysis pose additional challenges, particularly in complex, multi-component systems. Advanced algorithms and data processing techniques are needed to extract meaningful information from spectral or signal data, especially when dealing with overlapping peaks or subtle spectral changes. The development of robust chemometric models that can account for matrix effects and interferents remains an active area of research.

Lastly, the cost and accessibility of advanced instrumentation required for many reagent-free techniques can be prohibitive, especially for smaller laboratories or field applications. Balancing analytical performance with instrument simplicity and cost-effectiveness is an ongoing challenge that requires innovative engineering solutions and novel detection principles.

The development of robust, reliable, and reproducible reagent-free techniques remains a significant challenge. Many current methods struggle with consistency across different sample types or environmental conditions, limiting their broad applicability. This variability often necessitates extensive calibration and validation processes, which can be time-consuming and resource-intensive.

Another major hurdle is the integration of real-time, in-situ analysis capabilities. While reagent-free techniques offer the potential for rapid, on-site testing, translating laboratory-based methods to field-deployable instruments presents numerous technical difficulties. These include miniaturization of equipment, ensuring stability in diverse environmental conditions, and maintaining analytical performance comparable to traditional laboratory methods.

The influence of surfactants like Triton X-100 on reagent-free chemical analysis techniques adds another layer of complexity. Surfactants can significantly alter the physicochemical properties of analytes and their surrounding medium, potentially interfering with detection mechanisms or altering signal responses. Understanding and mitigating these effects is crucial for developing reliable reagent-free methods in the presence of such compounds.

Data interpretation and analysis pose additional challenges, particularly in complex, multi-component systems. Advanced algorithms and data processing techniques are needed to extract meaningful information from spectral or signal data, especially when dealing with overlapping peaks or subtle spectral changes. The development of robust chemometric models that can account for matrix effects and interferents remains an active area of research.

Lastly, the cost and accessibility of advanced instrumentation required for many reagent-free techniques can be prohibitive, especially for smaller laboratories or field applications. Balancing analytical performance with instrument simplicity and cost-effectiveness is an ongoing challenge that requires innovative engineering solutions and novel detection principles.

Existing Triton X-100 Applications

01 Use in cell lysis and protein extraction

Triton X-100 is widely used as a detergent for cell lysis and protein extraction in biochemical research. It effectively solubilizes cell membranes and helps release intracellular proteins while maintaining their native structure. This non-ionic surfactant is particularly useful in isolating membrane-bound proteins and is often included in buffer solutions for various molecular biology techniques.- Use in protein extraction and purification: Triton X-100 is widely used in biochemistry for protein extraction and purification processes. It is effective in solubilizing membrane proteins and can be used in various extraction buffers. The non-ionic surfactant properties of Triton X-100 make it suitable for isolating proteins without denaturing them, allowing for the preservation of their biological activity.

- Application in cell lysis and membrane permeabilization: Triton X-100 is commonly employed in cell biology for cell lysis and membrane permeabilization. It can disrupt cell membranes, allowing for the release of intracellular components. This property is particularly useful in protocols for DNA and RNA extraction, as well as in immunohistochemistry and flow cytometry applications where intracellular antigens need to be accessed.

- Role in detergent formulations: Triton X-100 is utilized in various detergent formulations due to its excellent surfactant properties. It is effective in reducing surface tension and can be incorporated into cleaning solutions for industrial and laboratory use. The non-ionic nature of Triton X-100 makes it compatible with a wide range of other ingredients in detergent formulations.

- Use in pharmaceutical and cosmetic preparations: Triton X-100 finds applications in pharmaceutical and cosmetic preparations as an emulsifier and solubilizer. It can help improve the stability and bioavailability of certain active ingredients in drug formulations. In cosmetics, it may be used to enhance the texture and spreadability of products. However, its use in these applications is subject to regulatory guidelines and safety assessments.

- Application in analytical techniques: Triton X-100 is employed in various analytical techniques, particularly in biochemistry and molecular biology. It can be used in electrophoresis buffers to improve separation of proteins and nucleic acids. Additionally, it is utilized in spectrophotometric assays and enzyme-linked immunosorbent assays (ELISA) to reduce non-specific binding and improve signal-to-noise ratios.

02 Application in nucleic acid isolation

Triton X-100 plays a crucial role in nucleic acid isolation protocols. It aids in the disruption of cell membranes and nuclear envelopes, facilitating the release of DNA and RNA. The surfactant properties of Triton X-100 help to separate nucleic acids from other cellular components, improving the purity and yield of isolated genetic material. It is commonly used in combination with other reagents in DNA and RNA extraction kits.Expand Specific Solutions03 Role in enzyme assays and protein studies

Triton X-100 is utilized in various enzyme assays and protein studies. It helps maintain enzyme activity by preventing protein aggregation and non-specific binding. The detergent is often included in reaction buffers to improve the solubility of enzymes and substrates, enhancing the overall efficiency of enzymatic reactions. Additionally, it is used in protein refolding experiments and in the study of membrane-associated proteins.Expand Specific Solutions04 Use in pharmaceutical and cosmetic formulations

Triton X-100 finds applications in pharmaceutical and cosmetic formulations as an emulsifier and solubilizer. It helps to stabilize emulsions and improve the solubility of hydrophobic compounds in aqueous solutions. The surfactant properties of Triton X-100 make it useful in the formulation of topical medications, personal care products, and drug delivery systems. However, its use in these applications is subject to regulatory considerations.Expand Specific Solutions05 Application in industrial cleaning and processing

Triton X-100 is employed in various industrial cleaning and processing applications. Its excellent wetting and emulsifying properties make it effective in removing oils, greases, and other contaminants from surfaces. It is used in the manufacturing of cleaning products, as well as in textile processing, metal treatment, and as a component in pesticide formulations. The surfactant's ability to reduce surface tension contributes to its effectiveness in these applications.Expand Specific Solutions

Key Players in Chemical Analysis Industry

The influence of Triton X-100 on reagent-free chemical analysis techniques is an emerging field within the analytical chemistry sector. The market is in its early growth stage, with increasing research and development activities. While the exact market size is not readily available, it is expected to grow as the demand for more efficient and cost-effective analytical methods rises. Technologically, this area is still evolving, with companies like Eli Lilly & Co., Pfizer Inc., and Beckman Coulter, Inc. leading the way in developing innovative applications. These firms are leveraging their expertise in pharmaceutical and biomedical research to advance the use of Triton X-100 in chemical analysis, potentially revolutionizing reagent-free techniques and improving analytical efficiency across various industries.

Macherey, Nagel GmbH & Co. KG Handelsgesellschaft

Technical Solution: Macherey-Nagel has developed a novel approach to reagent-free chemical analysis in the presence of Triton X-100 using their advanced solid-phase extraction (SPE) technology. Their method employs specially designed SPE cartridges that can effectively remove Triton X-100 from samples prior to analysis, allowing for accurate quantification of target analytes without interference[4]. The company has also introduced a line of HPLC columns with unique stationary phases that are resistant to the effects of Triton X-100, enabling direct analysis of samples containing this surfactant[5]. Additionally, Macherey-Nagel has developed rapid colorimetric test kits that can detect and quantify Triton X-100 in various matrices, facilitating its removal or adjustment in analytical procedures[6].

Strengths: Versatile application across various sample types, high throughput capability, and minimal method development required. Weaknesses: Potential loss of certain analytes during Triton X-100 removal, and higher cost compared to traditional methods.

Beckman Coulter, Inc.

Technical Solution: Beckman Coulter has developed advanced reagent-free chemical analysis techniques that are influenced by Triton X-100. Their approach utilizes capillary electrophoresis (CE) systems with UV detection, which allows for the separation and quantification of various analytes without the need for additional reagents[1]. The company has optimized their CE buffers to account for the presence of Triton X-100, ensuring accurate and reproducible results even in complex sample matrices[2]. Beckman Coulter's technology also incorporates innovative surface coating methods to minimize the adsorption of Triton X-100 onto capillary walls, thereby enhancing separation efficiency and reducing interference[3].

Strengths: High sensitivity and specificity, minimal sample preparation, and reduced chemical waste. Weaknesses: Potential for micelle formation affecting separation, and limited compatibility with certain sample types.

Innovations in Surfactant-Enhanced Analysis

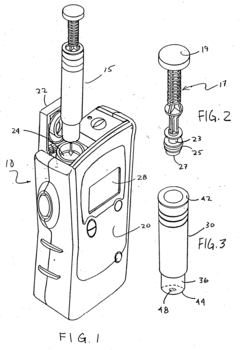

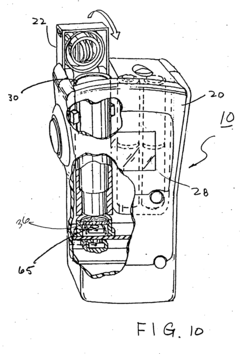

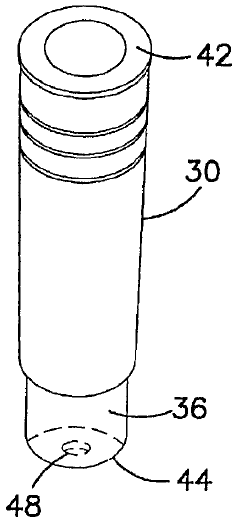

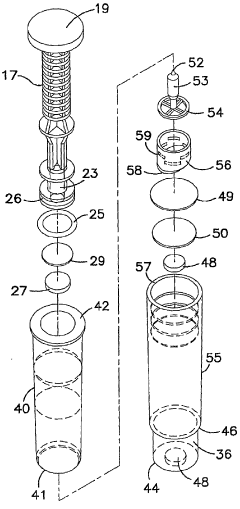

Protein assay method and test device

PatentInactiveUS20060166367A1

Innovation

- A test device design where the cupric salt is kept separate from the bicinchoninic acid or salt compound until use, utilizing a sampling wand with a bicinchoninic acid or alkali metal salt solution and a frangible seal, and a container with dried cupric sulfate pentahydrate and a non-ionic surfactant on a porous member, preventing unwanted reduction of Cu+2 to Cu+1, and allowing for a colorimetric reaction to indicate protein presence.

Protein assay method and test device

PatentWO2006081185A1

Innovation

- A test device design that separates cupric salt from bicinchoninic acid or salt until use, using a sampling wand with a frangible seal and a container with dried cupric sulfate pentahydrate and a non-ionic surfactant on a porous member, allowing for a colorimetric reaction to indicate protein presence without requiring a luminometer, and utilizing a spectrophotometer for detection.

Environmental Impact of Triton X-100 Usage

The environmental impact of Triton X-100 usage in reagent-free chemical analysis techniques is a critical consideration for researchers and industry professionals. Triton X-100, a nonionic surfactant widely used in various scientific applications, has both direct and indirect effects on the environment.

One of the primary concerns regarding Triton X-100 is its potential for bioaccumulation in aquatic ecosystems. Studies have shown that this surfactant can persist in water bodies and accumulate in the tissues of aquatic organisms, potentially disrupting their endocrine systems and reproductive processes. This bioaccumulation can lead to long-term ecological imbalances and affect biodiversity in affected areas.

Furthermore, the degradation of Triton X-100 in the environment can result in the formation of harmful byproducts. When exposed to sunlight and other environmental factors, Triton X-100 can break down into smaller molecules, some of which may have toxic properties. These degradation products can contribute to water and soil pollution, posing risks to both aquatic and terrestrial ecosystems.

The use of Triton X-100 in reagent-free chemical analysis techniques also raises concerns about its potential release into wastewater systems. Improper disposal or accidental spills can lead to the contamination of water sources, affecting drinking water quality and aquatic habitats. This is particularly problematic in areas with inadequate wastewater treatment facilities or in cases where large volumes of the surfactant are used.

Additionally, the production and transportation of Triton X-100 contribute to its overall environmental footprint. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, which can result in greenhouse gas emissions and other forms of industrial pollution. The transportation of this chemical across long distances further adds to its carbon footprint.

However, it is important to note that the use of Triton X-100 in reagent-free chemical analysis techniques can also have indirect positive environmental impacts. By enabling more efficient and accurate analytical methods, it may reduce the overall use of other, potentially more harmful chemicals in laboratory settings. This could lead to a decrease in chemical waste generation and associated environmental risks.

To mitigate the environmental impact of Triton X-100 usage, researchers and industry professionals are exploring alternative surfactants and developing more environmentally friendly formulations. Some efforts focus on creating biodegradable versions of the surfactant or finding natural compounds that can serve similar functions in chemical analysis techniques.

One of the primary concerns regarding Triton X-100 is its potential for bioaccumulation in aquatic ecosystems. Studies have shown that this surfactant can persist in water bodies and accumulate in the tissues of aquatic organisms, potentially disrupting their endocrine systems and reproductive processes. This bioaccumulation can lead to long-term ecological imbalances and affect biodiversity in affected areas.

Furthermore, the degradation of Triton X-100 in the environment can result in the formation of harmful byproducts. When exposed to sunlight and other environmental factors, Triton X-100 can break down into smaller molecules, some of which may have toxic properties. These degradation products can contribute to water and soil pollution, posing risks to both aquatic and terrestrial ecosystems.

The use of Triton X-100 in reagent-free chemical analysis techniques also raises concerns about its potential release into wastewater systems. Improper disposal or accidental spills can lead to the contamination of water sources, affecting drinking water quality and aquatic habitats. This is particularly problematic in areas with inadequate wastewater treatment facilities or in cases where large volumes of the surfactant are used.

Additionally, the production and transportation of Triton X-100 contribute to its overall environmental footprint. The manufacturing process involves the use of petrochemicals and energy-intensive procedures, which can result in greenhouse gas emissions and other forms of industrial pollution. The transportation of this chemical across long distances further adds to its carbon footprint.

However, it is important to note that the use of Triton X-100 in reagent-free chemical analysis techniques can also have indirect positive environmental impacts. By enabling more efficient and accurate analytical methods, it may reduce the overall use of other, potentially more harmful chemicals in laboratory settings. This could lead to a decrease in chemical waste generation and associated environmental risks.

To mitigate the environmental impact of Triton X-100 usage, researchers and industry professionals are exploring alternative surfactants and developing more environmentally friendly formulations. Some efforts focus on creating biodegradable versions of the surfactant or finding natural compounds that can serve similar functions in chemical analysis techniques.

Regulatory Considerations for Surfactants

The regulatory landscape for surfactants, including Triton X-100, is complex and evolving, particularly in the context of chemical analysis techniques. Regulatory bodies worldwide are increasingly scrutinizing the use of surfactants due to their potential environmental and health impacts. In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in governing the use of surfactants like Triton X-100.

Under REACH, manufacturers and importers are required to register substances, including surfactants, and provide comprehensive safety data. This regulation aims to ensure the safe use of chemicals throughout their lifecycle. For Triton X-100 and similar surfactants used in reagent-free chemical analysis techniques, compliance with REACH involves thorough documentation of their properties, potential risks, and safe handling procedures.

In the United States, the Environmental Protection Agency (EPA) regulates surfactants under various acts, including the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to report new chemical substances and significant new uses of existing chemicals, which could impact the application of Triton X-100 in novel analytical methods. Additionally, the Food and Drug Administration (FDA) may have oversight if these techniques are used in food or pharmaceutical analysis.

Globally, the Stockholm Convention on Persistent Organic Pollutants (POPs) influences the regulation of certain surfactants. While Triton X-100 is not currently listed as a POP, the convention's principles encourage the development and use of environmentally friendly alternatives, which may impact future research directions in reagent-free chemical analysis.

Water quality regulations also play a significant role in surfactant regulation. Many countries have established limits on surfactant concentrations in wastewater and environmental waters. These regulations can affect the disposal of waste from chemical analysis processes using Triton X-100, necessitating proper treatment and disposal protocols.

Occupational health and safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, mandate safe handling practices for chemicals including surfactants. This includes proper labeling, provision of safety data sheets, and implementation of exposure controls in laboratory settings where Triton X-100 is used.

As environmental concerns grow, there is an increasing trend towards green chemistry principles in regulatory frameworks. This shift may encourage the development of more sustainable alternatives to traditional surfactants like Triton X-100 in chemical analysis techniques. Researchers and manufacturers must stay abreast of these evolving regulations to ensure compliance and drive innovation in environmentally friendly analytical methods.

Under REACH, manufacturers and importers are required to register substances, including surfactants, and provide comprehensive safety data. This regulation aims to ensure the safe use of chemicals throughout their lifecycle. For Triton X-100 and similar surfactants used in reagent-free chemical analysis techniques, compliance with REACH involves thorough documentation of their properties, potential risks, and safe handling procedures.

In the United States, the Environmental Protection Agency (EPA) regulates surfactants under various acts, including the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to report new chemical substances and significant new uses of existing chemicals, which could impact the application of Triton X-100 in novel analytical methods. Additionally, the Food and Drug Administration (FDA) may have oversight if these techniques are used in food or pharmaceutical analysis.

Globally, the Stockholm Convention on Persistent Organic Pollutants (POPs) influences the regulation of certain surfactants. While Triton X-100 is not currently listed as a POP, the convention's principles encourage the development and use of environmentally friendly alternatives, which may impact future research directions in reagent-free chemical analysis.

Water quality regulations also play a significant role in surfactant regulation. Many countries have established limits on surfactant concentrations in wastewater and environmental waters. These regulations can affect the disposal of waste from chemical analysis processes using Triton X-100, necessitating proper treatment and disposal protocols.

Occupational health and safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, mandate safe handling practices for chemicals including surfactants. This includes proper labeling, provision of safety data sheets, and implementation of exposure controls in laboratory settings where Triton X-100 is used.

As environmental concerns grow, there is an increasing trend towards green chemistry principles in regulatory frameworks. This shift may encourage the development of more sustainable alternatives to traditional surfactants like Triton X-100 in chemical analysis techniques. Researchers and manufacturers must stay abreast of these evolving regulations to ensure compliance and drive innovation in environmentally friendly analytical methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!