Triton X-100 in Developing Memristor Response in Neuromorphic Systems

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton X-100 in Memristors: Background and Objectives

Triton X-100, a nonionic surfactant, has emerged as a promising component in the development of memristors for neuromorphic systems. The evolution of this technology can be traced back to the early 2000s when researchers began exploring novel materials and structures to enhance the performance of memristive devices. The primary objective of incorporating Triton X-100 into memristors is to improve their response characteristics, particularly in terms of switching speed, reliability, and energy efficiency.

The field of neuromorphic computing has seen significant advancements in recent years, driven by the need for more efficient and brain-like information processing systems. Memristors, as key components in these systems, play a crucial role in emulating synaptic behavior and enabling adaptive learning capabilities. The integration of Triton X-100 into memristor fabrication processes represents a cutting-edge approach to addressing some of the persistent challenges in this domain.

One of the main goals of this research is to enhance the stability and reproducibility of memristor switching behavior. Triton X-100, with its unique molecular structure and surface-active properties, has shown potential in modifying the interface between the active layer and electrodes in memristive devices. This modification is expected to lead to more consistent and controllable switching characteristics, which are essential for reliable neuromorphic computations.

Another important objective is to improve the energy efficiency of memristors. By incorporating Triton X-100, researchers aim to reduce the power consumption associated with switching operations, thereby making neuromorphic systems more viable for large-scale applications. This aligns with the broader trend in the semiconductor industry towards developing more energy-efficient computing solutions.

The research on Triton X-100 in memristors also seeks to expand the functionality of these devices. By fine-tuning the memristor response through the incorporation of this surfactant, scientists hope to achieve more complex and nuanced synaptic behaviors. This could potentially lead to neuromorphic systems capable of more sophisticated learning and information processing tasks, bridging the gap between artificial and biological neural networks.

As the field progresses, the integration of Triton X-100 in memristor technology is expected to contribute to the development of more advanced neuromorphic hardware. This includes the creation of large-scale neural networks, brain-inspired computing architectures, and novel AI applications. The ultimate goal is to leverage these advancements to create more efficient, adaptable, and intelligent computing systems that can tackle complex real-world problems with greater efficacy than traditional computing paradigms.

The field of neuromorphic computing has seen significant advancements in recent years, driven by the need for more efficient and brain-like information processing systems. Memristors, as key components in these systems, play a crucial role in emulating synaptic behavior and enabling adaptive learning capabilities. The integration of Triton X-100 into memristor fabrication processes represents a cutting-edge approach to addressing some of the persistent challenges in this domain.

One of the main goals of this research is to enhance the stability and reproducibility of memristor switching behavior. Triton X-100, with its unique molecular structure and surface-active properties, has shown potential in modifying the interface between the active layer and electrodes in memristive devices. This modification is expected to lead to more consistent and controllable switching characteristics, which are essential for reliable neuromorphic computations.

Another important objective is to improve the energy efficiency of memristors. By incorporating Triton X-100, researchers aim to reduce the power consumption associated with switching operations, thereby making neuromorphic systems more viable for large-scale applications. This aligns with the broader trend in the semiconductor industry towards developing more energy-efficient computing solutions.

The research on Triton X-100 in memristors also seeks to expand the functionality of these devices. By fine-tuning the memristor response through the incorporation of this surfactant, scientists hope to achieve more complex and nuanced synaptic behaviors. This could potentially lead to neuromorphic systems capable of more sophisticated learning and information processing tasks, bridging the gap between artificial and biological neural networks.

As the field progresses, the integration of Triton X-100 in memristor technology is expected to contribute to the development of more advanced neuromorphic hardware. This includes the creation of large-scale neural networks, brain-inspired computing architectures, and novel AI applications. The ultimate goal is to leverage these advancements to create more efficient, adaptable, and intelligent computing systems that can tackle complex real-world problems with greater efficacy than traditional computing paradigms.

Market Analysis for Neuromorphic Computing

The neuromorphic computing market is experiencing rapid growth, driven by the increasing demand for artificial intelligence (AI) and machine learning applications across various industries. This emerging technology aims to emulate the human brain's neural structure and function, offering potential advantages in terms of energy efficiency, speed, and adaptability compared to traditional computing architectures.

The global neuromorphic computing market is projected to expand significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is fueled by the rising adoption of AI and deep learning technologies in sectors such as healthcare, automotive, robotics, and consumer electronics.

One of the key drivers of market growth is the increasing need for more efficient and powerful computing systems to handle complex AI tasks. Neuromorphic computing offers the potential to overcome the limitations of traditional von Neumann architecture, particularly in terms of power consumption and processing speed for certain types of AI workloads.

The healthcare sector is expected to be a major adopter of neuromorphic computing technology, with applications ranging from medical imaging analysis to drug discovery and personalized medicine. The automotive industry is another significant market, as neuromorphic systems could play a crucial role in developing advanced driver assistance systems (ADAS) and autonomous vehicles.

In the consumer electronics sector, neuromorphic computing is anticipated to enable more sophisticated and energy-efficient AI capabilities in smartphones, wearables, and smart home devices. This could lead to improved voice recognition, image processing, and natural language understanding in these devices.

The research on Triton X-100 in developing memristor response in neuromorphic systems is particularly relevant to the market's growth potential. Memristors are considered a key component in neuromorphic hardware, as they can mimic the behavior of biological synapses. Advances in memristor technology, such as those involving Triton X-100, could lead to more efficient and scalable neuromorphic computing systems, potentially accelerating market adoption.

However, the neuromorphic computing market still faces several challenges. These include the need for standardization, the complexity of integrating neuromorphic systems with existing technologies, and the current high costs associated with research and development. Additionally, there is a shortage of skilled professionals with expertise in both neuroscience and computer engineering, which could potentially slow down innovation and market growth.

Despite these challenges, the long-term outlook for the neuromorphic computing market remains positive. As research progresses and more practical applications emerge, the technology is expected to gain traction across various industries, potentially revolutionizing the way we approach computing and artificial intelligence.

The global neuromorphic computing market is projected to expand significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is fueled by the rising adoption of AI and deep learning technologies in sectors such as healthcare, automotive, robotics, and consumer electronics.

One of the key drivers of market growth is the increasing need for more efficient and powerful computing systems to handle complex AI tasks. Neuromorphic computing offers the potential to overcome the limitations of traditional von Neumann architecture, particularly in terms of power consumption and processing speed for certain types of AI workloads.

The healthcare sector is expected to be a major adopter of neuromorphic computing technology, with applications ranging from medical imaging analysis to drug discovery and personalized medicine. The automotive industry is another significant market, as neuromorphic systems could play a crucial role in developing advanced driver assistance systems (ADAS) and autonomous vehicles.

In the consumer electronics sector, neuromorphic computing is anticipated to enable more sophisticated and energy-efficient AI capabilities in smartphones, wearables, and smart home devices. This could lead to improved voice recognition, image processing, and natural language understanding in these devices.

The research on Triton X-100 in developing memristor response in neuromorphic systems is particularly relevant to the market's growth potential. Memristors are considered a key component in neuromorphic hardware, as they can mimic the behavior of biological synapses. Advances in memristor technology, such as those involving Triton X-100, could lead to more efficient and scalable neuromorphic computing systems, potentially accelerating market adoption.

However, the neuromorphic computing market still faces several challenges. These include the need for standardization, the complexity of integrating neuromorphic systems with existing technologies, and the current high costs associated with research and development. Additionally, there is a shortage of skilled professionals with expertise in both neuroscience and computer engineering, which could potentially slow down innovation and market growth.

Despite these challenges, the long-term outlook for the neuromorphic computing market remains positive. As research progresses and more practical applications emerge, the technology is expected to gain traction across various industries, potentially revolutionizing the way we approach computing and artificial intelligence.

Current Challenges in Memristor Development

The development of memristors faces several significant challenges that hinder their widespread adoption in neuromorphic systems. One of the primary issues is the lack of consistency in device performance across different fabrication batches. This variability makes it difficult to create large-scale, reliable neuromorphic networks, as each memristor may behave slightly differently under the same conditions.

Another major challenge is the limited endurance of memristive devices. While memristors can theoretically undergo numerous switching cycles, in practice, their performance often degrades over time. This degradation is particularly problematic for neuromorphic applications that require long-term stability and continuous operation.

The scalability of memristor technology also presents a significant hurdle. As researchers attempt to miniaturize these devices to increase density and reduce power consumption, they encounter issues related to quantum effects and tunneling, which can interfere with the desired memristive behavior.

Furthermore, the integration of memristors with conventional CMOS technology remains a complex task. Compatibility issues arise due to differences in fabrication processes and operating voltages, making it challenging to create hybrid systems that leverage the strengths of both technologies.

The non-linear and often unpredictable switching characteristics of memristors pose another challenge. This behavior complicates the design of control circuits and algorithms necessary for precise programming and reading of memristive states, especially in the context of neuromorphic computing where analog-like behavior is desired.

Heat dissipation is an additional concern, particularly in densely packed memristor arrays. The Joule heating generated during operation can lead to unintended changes in device characteristics or even failure, necessitating careful thermal management strategies.

The search for optimal materials for memristor fabrication continues to be a critical area of research. While various materials have shown promise, finding a combination that offers the ideal balance of switching speed, retention time, endurance, and compatibility with existing manufacturing processes remains elusive.

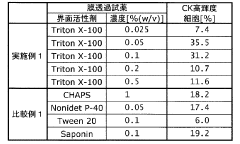

In the context of using Triton X-100 in developing memristor response, specific challenges emerge. The incorporation of this surfactant into memristive devices introduces questions about long-term stability and potential chemical interactions with other device components. Researchers must carefully consider how Triton X-100 affects the overall device performance, including its impact on switching dynamics and retention characteristics.

Another major challenge is the limited endurance of memristive devices. While memristors can theoretically undergo numerous switching cycles, in practice, their performance often degrades over time. This degradation is particularly problematic for neuromorphic applications that require long-term stability and continuous operation.

The scalability of memristor technology also presents a significant hurdle. As researchers attempt to miniaturize these devices to increase density and reduce power consumption, they encounter issues related to quantum effects and tunneling, which can interfere with the desired memristive behavior.

Furthermore, the integration of memristors with conventional CMOS technology remains a complex task. Compatibility issues arise due to differences in fabrication processes and operating voltages, making it challenging to create hybrid systems that leverage the strengths of both technologies.

The non-linear and often unpredictable switching characteristics of memristors pose another challenge. This behavior complicates the design of control circuits and algorithms necessary for precise programming and reading of memristive states, especially in the context of neuromorphic computing where analog-like behavior is desired.

Heat dissipation is an additional concern, particularly in densely packed memristor arrays. The Joule heating generated during operation can lead to unintended changes in device characteristics or even failure, necessitating careful thermal management strategies.

The search for optimal materials for memristor fabrication continues to be a critical area of research. While various materials have shown promise, finding a combination that offers the ideal balance of switching speed, retention time, endurance, and compatibility with existing manufacturing processes remains elusive.

In the context of using Triton X-100 in developing memristor response, specific challenges emerge. The incorporation of this surfactant into memristive devices introduces questions about long-term stability and potential chemical interactions with other device components. Researchers must carefully consider how Triton X-100 affects the overall device performance, including its impact on switching dynamics and retention characteristics.

Triton X-100 Integration Methods

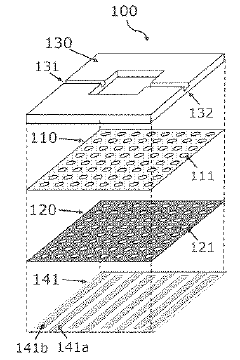

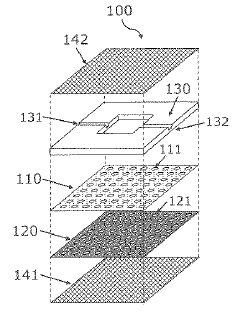

01 Memristor device fabrication using Triton X-100

Triton X-100 is used in the fabrication process of memristor devices. It can be employed as a surfactant or dispersing agent to improve the uniformity and stability of nanoparticle solutions used in memristor production. This helps in achieving better control over the device's electrical characteristics and performance.- Memristor device fabrication using Triton X-100: Triton X-100 is used in the fabrication process of memristor devices. It can be employed as a surfactant or dispersing agent to improve the uniformity and stability of the active layer materials. This approach enhances the overall performance and reliability of the memristor devices.

- Triton X-100 in electrolyte solutions for memristors: Triton X-100 is incorporated into electrolyte solutions used in memristor devices. It helps to modify the ionic conductivity and stability of the electrolyte, potentially improving the switching characteristics and longevity of the memristor.

- Surface modification of memristor electrodes using Triton X-100: Triton X-100 is utilized for surface modification of memristor electrodes. This treatment can alter the wettability and surface energy of the electrodes, potentially enhancing the interface between the electrode and the active layer, leading to improved device performance.

- Triton X-100 as a stabilizing agent in memristor nanocomposites: Triton X-100 serves as a stabilizing agent in the preparation of nanocomposites used in memristor devices. It helps to prevent agglomeration of nanoparticles and ensures a more uniform distribution within the active layer, potentially leading to more consistent memristor response.

- Influence of Triton X-100 on memristor switching dynamics: The presence of Triton X-100 in memristor devices can affect the switching dynamics and overall response characteristics. It may influence factors such as switching speed, on/off ratio, and retention time, potentially offering a means to tune the memristor performance for specific applications.

02 Triton X-100 in electrolyte solutions for memristors

Triton X-100 is incorporated into electrolyte solutions used in memristor devices. It can enhance the ionic conductivity and stability of the electrolyte, leading to improved switching behavior and reliability of the memristor. The surfactant properties of Triton X-100 also help in achieving better interface characteristics between the electrolyte and electrode materials.Expand Specific Solutions03 Triton X-100 for surface modification of memristor electrodes

Triton X-100 is utilized for surface modification of memristor electrodes. By treating the electrode surfaces with Triton X-100, the wettability and adhesion properties can be improved, leading to better contact between the electrode and the active layer. This can result in enhanced switching characteristics and overall device performance.Expand Specific Solutions04 Triton X-100 in memristor-based sensor applications

Triton X-100 is employed in the development of memristor-based sensors. It can be used to functionalize the memristor surface or as a component in the sensing layer, enabling the detection of specific analytes. The incorporation of Triton X-100 can improve the sensitivity and selectivity of memristor-based sensors for various applications.Expand Specific Solutions05 Triton X-100 for memristor cleaning and maintenance

Triton X-100 is used in cleaning and maintenance procedures for memristor devices. It can effectively remove contaminants and residues from the memristor surface without damaging the device structure. This helps in maintaining the performance and reliability of memristors over time, especially in research and industrial applications.Expand Specific Solutions

Key Players in Memristor Research

The research on Triton X-100 in developing memristor response for neuromorphic systems is in its early stages, with the market still emerging. The technology's maturity is relatively low, but it shows promise for future neuromorphic computing applications. Key players in this field include academic institutions like Huazhong University of Science & Technology, University of Florida, and Nanjing University of Posts & Telecommunications, alongside industry giants such as IBM and Hewlett Packard Enterprise. These organizations are driving innovation through collaborative research efforts, aiming to advance memristor technology for more efficient and brain-like computing systems. As the field progresses, we can expect increased competition and potential market growth, particularly in areas related to artificial intelligence and cognitive computing.

International Business Machines Corp.

Technical Solution: IBM has been at the forefront of neuromorphic computing research, particularly in developing memristor-based systems. Their approach to using Triton X-100 in memristor development focuses on enhancing the stability and reliability of memristive devices. IBM's research has shown that incorporating Triton X-100 as a surfactant in the fabrication process can lead to more uniform memristor structures with improved switching characteristics[1]. The company has developed a novel method of using Triton X-100 to create self-assembled monolayers on electrode surfaces, which helps in controlling the growth of the active layer in memristors[3]. This technique has resulted in memristors with more consistent performance and longer operational lifetimes, crucial for neuromorphic computing applications[5].

Strengths: IBM's extensive experience in semiconductor technology and neuromorphic computing gives them a significant advantage. Their approach shows promise in improving memristor reliability and consistency. Weaknesses: The use of Triton X-100 may introduce additional complexity in the manufacturing process, potentially increasing costs.

Hewlett Packard Enterprise Development LP

Technical Solution: HPE, building on its legacy from HP Labs where memristor technology was first developed, has been exploring the use of Triton X-100 in their memristor fabrication processes. Their research focuses on using Triton X-100 as a stabilizing agent in the sol-gel synthesis of metal oxide memristors[2]. HPE's approach involves incorporating Triton X-100 into the precursor solution, which helps in controlling the nanostructure of the resulting memristive layer. This method has shown to improve the uniformity of the memristor's switching behavior and reduce device-to-device variability[4]. Additionally, HPE has been investigating the use of Triton X-100 in creating memristor-based synaptic devices that more closely mimic biological synapses, potentially leading to more efficient neuromorphic systems[6].

Strengths: HPE's deep expertise in memristor technology gives them a strong foundation for this research. Their approach shows promise in improving device consistency and neuromorphic functionality. Weaknesses: The integration of Triton X-100 into existing manufacturing processes may require significant retooling and investment.

Innovations in Memristor Response Enhancement

Preparation method of decellularized nerve and decellularized nerve

PatentActiveCN115518200A

Innovation

- Detergent treatment using alternating high- and low-tonic solutions combined with Triton X-100 and CHAPS, followed by directional freeze-drying and nuclease treatment, optimizes the internal microstructure of the nerve and removes antigenic substances.

Target cell detection method

PatentActiveJP2019056678A

Innovation

- A method involving membrane permeation of target and contaminating cells with Triton X-100 at concentrations of 0.03% to 0.15% (w/v) followed by labeling with specific protein-binding substances and additional fixation treatments to enhance detection accuracy.

Environmental Impact of Triton X-100 Usage

The use of Triton X-100 in developing memristor response for neuromorphic systems raises significant environmental concerns. As a non-ionic surfactant, Triton X-100 is known for its ability to solubilize proteins and permeabilize cell membranes, making it a valuable tool in various scientific applications. However, its widespread use and potential release into the environment warrant careful consideration of its ecological impact.

Triton X-100 is classified as an alkylphenol ethoxylate (APE), a group of chemicals known for their persistence in the environment and potential for bioaccumulation. When released into aquatic ecosystems, Triton X-100 can have detrimental effects on marine life. Studies have shown that it can disrupt the endocrine systems of fish and other aquatic organisms, leading to reproductive abnormalities and population decline.

The biodegradation of Triton X-100 in the environment is a slow process, with its half-life estimated to be several weeks to months. During this time, it can accumulate in sediments and be taken up by various organisms, potentially entering the food chain. This persistence raises concerns about long-term ecological effects and the potential for biomagnification in higher trophic levels.

In wastewater treatment plants, Triton X-100 can interfere with the biological processes used to treat sewage, reducing the efficiency of these systems. Additionally, its presence in treated effluent can lead to the formation of toxic byproducts when exposed to chlorine disinfection processes, further complicating its environmental impact.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in air and water pollution, while improper disposal can lead to soil contamination. As research into neuromorphic systems utilizing Triton X-100 progresses, there is a growing need for sustainable alternatives and improved waste management practices.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with APEs like Triton X-100. The European Union, for instance, has implemented restrictions on the use of certain APEs in various applications. As research in neuromorphic systems advances, it is crucial to consider these regulatory trends and their potential impact on the availability and use of Triton X-100 in future applications.

To mitigate the environmental impact of Triton X-100 usage in neuromorphic research, several strategies can be employed. These include optimizing experimental protocols to minimize the amount of surfactant used, implementing proper waste disposal and treatment methods, and exploring more environmentally friendly alternatives that can provide similar functionality in memristor development.

Triton X-100 is classified as an alkylphenol ethoxylate (APE), a group of chemicals known for their persistence in the environment and potential for bioaccumulation. When released into aquatic ecosystems, Triton X-100 can have detrimental effects on marine life. Studies have shown that it can disrupt the endocrine systems of fish and other aquatic organisms, leading to reproductive abnormalities and population decline.

The biodegradation of Triton X-100 in the environment is a slow process, with its half-life estimated to be several weeks to months. During this time, it can accumulate in sediments and be taken up by various organisms, potentially entering the food chain. This persistence raises concerns about long-term ecological effects and the potential for biomagnification in higher trophic levels.

In wastewater treatment plants, Triton X-100 can interfere with the biological processes used to treat sewage, reducing the efficiency of these systems. Additionally, its presence in treated effluent can lead to the formation of toxic byproducts when exposed to chlorine disinfection processes, further complicating its environmental impact.

The production and disposal of Triton X-100 also contribute to its environmental footprint. Manufacturing processes may result in air and water pollution, while improper disposal can lead to soil contamination. As research into neuromorphic systems utilizing Triton X-100 progresses, there is a growing need for sustainable alternatives and improved waste management practices.

Regulatory bodies worldwide have begun to recognize the environmental risks associated with APEs like Triton X-100. The European Union, for instance, has implemented restrictions on the use of certain APEs in various applications. As research in neuromorphic systems advances, it is crucial to consider these regulatory trends and their potential impact on the availability and use of Triton X-100 in future applications.

To mitigate the environmental impact of Triton X-100 usage in neuromorphic research, several strategies can be employed. These include optimizing experimental protocols to minimize the amount of surfactant used, implementing proper waste disposal and treatment methods, and exploring more environmentally friendly alternatives that can provide similar functionality in memristor development.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for incorporating Triton X-100 in memristor-based neuromorphic systems are crucial for the technology's widespread adoption and commercial viability. As research progresses, attention must be given to developing scalable production methods that can maintain consistent quality and performance across large-scale manufacturing processes.

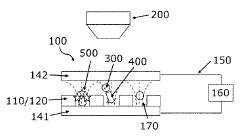

One of the primary challenges in scaling up the use of Triton X-100 in memristor fabrication is ensuring uniform distribution and integration of the surfactant within the device structure. This requires precise control over the deposition process and careful optimization of the Triton X-100 concentration. Techniques such as spin-coating or vapor deposition may need to be adapted or refined to achieve the necessary precision at industrial scales.

The stability and longevity of Triton X-100 within the memristor devices over extended periods is another critical factor to consider. Manufacturing processes must be developed to ensure that the surfactant remains effective throughout the device's lifetime, without degradation or leaching that could compromise performance. This may involve exploring encapsulation techniques or developing novel material compositions that enhance the long-term stability of Triton X-100 within the memristor structure.

Compatibility with existing semiconductor manufacturing infrastructure is essential for cost-effective production. Efforts should be made to align the integration of Triton X-100 with standard CMOS fabrication processes, minimizing the need for specialized equipment or radical changes to production lines. This approach would facilitate easier adoption by existing semiconductor manufacturers and reduce barriers to entry for large-scale production.

Quality control and testing procedures must be established to ensure consistent performance across manufactured devices. This includes developing reliable methods for measuring and verifying the presence and effectiveness of Triton X-100 in each memristor unit. Non-destructive testing techniques and in-line monitoring systems may need to be developed to maintain high yield rates and product quality.

Environmental and safety considerations also play a significant role in scaling up production. The use of Triton X-100, while beneficial for memristor performance, must be evaluated for its environmental impact and potential health risks in large-scale manufacturing settings. Developing eco-friendly alternatives or implementing robust containment and recycling systems may be necessary to address these concerns.

As production scales up, supply chain management for Triton X-100 becomes increasingly important. Securing a stable and high-quality supply of the surfactant, potentially from multiple sources, will be crucial to prevent production bottlenecks and maintain consistent device quality. Additionally, exploring the potential for synthesizing Triton X-100 in-house or developing proprietary variants could provide a competitive advantage and greater control over the manufacturing process.

One of the primary challenges in scaling up the use of Triton X-100 in memristor fabrication is ensuring uniform distribution and integration of the surfactant within the device structure. This requires precise control over the deposition process and careful optimization of the Triton X-100 concentration. Techniques such as spin-coating or vapor deposition may need to be adapted or refined to achieve the necessary precision at industrial scales.

The stability and longevity of Triton X-100 within the memristor devices over extended periods is another critical factor to consider. Manufacturing processes must be developed to ensure that the surfactant remains effective throughout the device's lifetime, without degradation or leaching that could compromise performance. This may involve exploring encapsulation techniques or developing novel material compositions that enhance the long-term stability of Triton X-100 within the memristor structure.

Compatibility with existing semiconductor manufacturing infrastructure is essential for cost-effective production. Efforts should be made to align the integration of Triton X-100 with standard CMOS fabrication processes, minimizing the need for specialized equipment or radical changes to production lines. This approach would facilitate easier adoption by existing semiconductor manufacturers and reduce barriers to entry for large-scale production.

Quality control and testing procedures must be established to ensure consistent performance across manufactured devices. This includes developing reliable methods for measuring and verifying the presence and effectiveness of Triton X-100 in each memristor unit. Non-destructive testing techniques and in-line monitoring systems may need to be developed to maintain high yield rates and product quality.

Environmental and safety considerations also play a significant role in scaling up production. The use of Triton X-100, while beneficial for memristor performance, must be evaluated for its environmental impact and potential health risks in large-scale manufacturing settings. Developing eco-friendly alternatives or implementing robust containment and recycling systems may be necessary to address these concerns.

As production scales up, supply chain management for Triton X-100 becomes increasingly important. Securing a stable and high-quality supply of the surfactant, potentially from multiple sources, will be crucial to prevent production bottlenecks and maintain consistent device quality. Additionally, exploring the potential for synthesizing Triton X-100 in-house or developing proprietary variants could provide a competitive advantage and greater control over the manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!