K24 Engine Impact: Off-Road Vehicle Transformations

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine has undergone significant evolution since its introduction, marking key milestones in off-road vehicle technology. Initially developed by Honda in the late 1990s, the K24 engine was designed to provide a balance of power, efficiency, and reliability for various vehicle applications.

In its early iterations, the K24 engine featured a 2.4-liter displacement with a dual overhead camshaft (DOHC) design and Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This configuration allowed for improved performance across a wide range of engine speeds, making it suitable for both on-road and off-road applications.

As off-road enthusiasts began to recognize the potential of the K24 engine, aftermarket modifications and upgrades became increasingly popular. This led to the development of specialized components designed to enhance the engine's performance in rugged terrain and extreme conditions.

One significant evolution in the K24 engine's off-road application was the introduction of forced induction systems. Turbocharging and supercharging kits specifically designed for the K24 engine emerged, allowing for substantial increases in power output while maintaining reliability. These modifications enabled off-road vehicles to tackle more challenging terrains and compete in high-performance off-road events.

Another key development in the K24 engine's evolution was the integration of advanced engine management systems. These electronic control units (ECUs) allowed for precise tuning of fuel injection, ignition timing, and other parameters, optimizing performance for off-road conditions. This advancement significantly improved the engine's adaptability to various terrains and driving styles.

The K24 engine also saw improvements in materials and construction techniques over time. Stronger internal components, such as forged pistons and connecting rods, were introduced to withstand the increased stresses of off-road use. Additionally, enhanced cooling systems were developed to maintain optimal operating temperatures in harsh environments.

As environmental concerns grew, the K24 engine evolved to meet stricter emissions standards while maintaining its performance characteristics. This led to the incorporation of more efficient fuel injection systems and improved exhaust gas recirculation (EGR) technologies, ensuring that off-road vehicles powered by the K24 engine could comply with regulations without sacrificing capability.

The latest iterations of the K24 engine have seen further refinements in combustion efficiency and power delivery. Direct injection technology has been implemented in some variants, providing more precise fuel control and improved fuel economy. These advancements have allowed the K24 engine to remain competitive in the off-road market, even as newer engine designs have emerged.

In its early iterations, the K24 engine featured a 2.4-liter displacement with a dual overhead camshaft (DOHC) design and Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This configuration allowed for improved performance across a wide range of engine speeds, making it suitable for both on-road and off-road applications.

As off-road enthusiasts began to recognize the potential of the K24 engine, aftermarket modifications and upgrades became increasingly popular. This led to the development of specialized components designed to enhance the engine's performance in rugged terrain and extreme conditions.

One significant evolution in the K24 engine's off-road application was the introduction of forced induction systems. Turbocharging and supercharging kits specifically designed for the K24 engine emerged, allowing for substantial increases in power output while maintaining reliability. These modifications enabled off-road vehicles to tackle more challenging terrains and compete in high-performance off-road events.

Another key development in the K24 engine's evolution was the integration of advanced engine management systems. These electronic control units (ECUs) allowed for precise tuning of fuel injection, ignition timing, and other parameters, optimizing performance for off-road conditions. This advancement significantly improved the engine's adaptability to various terrains and driving styles.

The K24 engine also saw improvements in materials and construction techniques over time. Stronger internal components, such as forged pistons and connecting rods, were introduced to withstand the increased stresses of off-road use. Additionally, enhanced cooling systems were developed to maintain optimal operating temperatures in harsh environments.

As environmental concerns grew, the K24 engine evolved to meet stricter emissions standards while maintaining its performance characteristics. This led to the incorporation of more efficient fuel injection systems and improved exhaust gas recirculation (EGR) technologies, ensuring that off-road vehicles powered by the K24 engine could comply with regulations without sacrificing capability.

The latest iterations of the K24 engine have seen further refinements in combustion efficiency and power delivery. Direct injection technology has been implemented in some variants, providing more precise fuel control and improved fuel economy. These advancements have allowed the K24 engine to remain competitive in the off-road market, even as newer engine designs have emerged.

Off-Road Market Trends

The off-road vehicle market has been experiencing significant growth and transformation in recent years, driven by increasing consumer interest in outdoor activities, adventure tourism, and recreational off-roading. This trend has been further accelerated by the global pandemic, which has led to a surge in demand for outdoor recreational vehicles as people seek safer, socially-distanced leisure activities.

The market for off-road vehicles encompasses a wide range of products, including all-terrain vehicles (ATVs), utility task vehicles (UTVs), off-road motorcycles, and modified 4x4 trucks and SUVs. Each segment has shown robust growth, with UTVs and modified 4x4 vehicles particularly gaining traction among enthusiasts and casual users alike.

One of the key drivers of this market growth is the increasing disposable income in many regions, coupled with a growing interest in outdoor adventures and extreme sports. This has led to a rise in off-road parks and dedicated trails, further fueling the demand for capable off-road vehicles. Additionally, technological advancements in vehicle design, suspension systems, and powertrain technologies have made off-road vehicles more accessible and appealing to a broader consumer base.

The introduction of electric powertrains in the off-road vehicle segment is another significant trend shaping the market. Major manufacturers are investing heavily in electric off-road vehicles, addressing both environmental concerns and the demand for quieter operation in natural settings. This shift towards electrification is expected to open up new opportunities and reshape the competitive landscape in the coming years.

Geographically, North America continues to dominate the off-road vehicle market, with strong sales in the United States and Canada. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth, driven by increasing urbanization, rising disposable incomes, and growing interest in outdoor recreational activities.

The COVID-19 pandemic has had a mixed impact on the off-road vehicle market. While initial lockdowns and supply chain disruptions caused temporary setbacks, the subsequent increase in outdoor activities and desire for socially-distanced recreation has led to a surge in demand for off-road vehicles. This trend is expected to continue in the post-pandemic era, as more people discover the appeal of off-road adventures and outdoor lifestyles.

Looking ahead, the off-road vehicle market is poised for continued growth, with innovations in vehicle technology, increasing focus on sustainability, and expanding consumer base driving the industry forward. The integration of advanced features such as GPS navigation, telematics, and enhanced safety systems is likely to further boost the appeal of off-road vehicles to both enthusiasts and casual users.

The market for off-road vehicles encompasses a wide range of products, including all-terrain vehicles (ATVs), utility task vehicles (UTVs), off-road motorcycles, and modified 4x4 trucks and SUVs. Each segment has shown robust growth, with UTVs and modified 4x4 vehicles particularly gaining traction among enthusiasts and casual users alike.

One of the key drivers of this market growth is the increasing disposable income in many regions, coupled with a growing interest in outdoor adventures and extreme sports. This has led to a rise in off-road parks and dedicated trails, further fueling the demand for capable off-road vehicles. Additionally, technological advancements in vehicle design, suspension systems, and powertrain technologies have made off-road vehicles more accessible and appealing to a broader consumer base.

The introduction of electric powertrains in the off-road vehicle segment is another significant trend shaping the market. Major manufacturers are investing heavily in electric off-road vehicles, addressing both environmental concerns and the demand for quieter operation in natural settings. This shift towards electrification is expected to open up new opportunities and reshape the competitive landscape in the coming years.

Geographically, North America continues to dominate the off-road vehicle market, with strong sales in the United States and Canada. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth, driven by increasing urbanization, rising disposable incomes, and growing interest in outdoor recreational activities.

The COVID-19 pandemic has had a mixed impact on the off-road vehicle market. While initial lockdowns and supply chain disruptions caused temporary setbacks, the subsequent increase in outdoor activities and desire for socially-distanced recreation has led to a surge in demand for off-road vehicles. This trend is expected to continue in the post-pandemic era, as more people discover the appeal of off-road adventures and outdoor lifestyles.

Looking ahead, the off-road vehicle market is poised for continued growth, with innovations in vehicle technology, increasing focus on sustainability, and expanding consumer base driving the industry forward. The integration of advanced features such as GPS navigation, telematics, and enhanced safety systems is likely to further boost the appeal of off-road vehicles to both enthusiasts and casual users.

K24 Challenges in Off-Road

The K24 engine, renowned for its reliability and performance in on-road vehicles, faces unique challenges when adapted for off-road use. The primary obstacle lies in the engine's durability under extreme conditions. Off-road environments subject engines to intense vibrations, dust, and temperature fluctuations, which can accelerate wear and tear on components designed primarily for paved road use.

One significant challenge is the engine's cooling system. The K24's stock cooling setup may struggle to maintain optimal operating temperatures in the demanding off-road scenarios, where sustained high-load operation and limited airflow are common. This necessitates modifications to the radiator, oil cooler, and potentially the addition of auxiliary cooling systems to prevent overheating and ensure consistent performance.

Another critical issue is the engine's air intake system. Off-road vehicles frequently encounter dusty and muddy conditions, which can quickly clog standard air filters and potentially damage the engine. Developing a robust air filtration system that can handle these harsh environments without restricting airflow is crucial for maintaining engine health and performance.

The K24's lubrication system also requires attention when adapting for off-road use. Steep inclines and uneven terrain can cause oil starvation in certain engine areas, leading to increased wear and potential failure. Modifying the oil pan design and implementing a dry sump system may be necessary to ensure consistent oil pressure and distribution across all driving conditions.

Vibration and impact resistance present another set of challenges. Off-road driving subjects the engine to significantly more shock and vibration than typical road use. Strengthening engine mounts, reinforcing critical components, and potentially adding additional bracing to the engine bay may be required to prevent damage and maintain alignment of crucial parts.

Lastly, the engine management system needs recalibration to accommodate the different power delivery requirements of off-road driving. This includes adjusting fuel mapping, ignition timing, and throttle response to provide optimal performance across a wider range of RPMs and load conditions encountered in off-road scenarios. Additionally, implementing safeguards against sudden impacts and potential rollovers, such as an automatic engine cut-off system, is crucial for safety in extreme off-road situations.

One significant challenge is the engine's cooling system. The K24's stock cooling setup may struggle to maintain optimal operating temperatures in the demanding off-road scenarios, where sustained high-load operation and limited airflow are common. This necessitates modifications to the radiator, oil cooler, and potentially the addition of auxiliary cooling systems to prevent overheating and ensure consistent performance.

Another critical issue is the engine's air intake system. Off-road vehicles frequently encounter dusty and muddy conditions, which can quickly clog standard air filters and potentially damage the engine. Developing a robust air filtration system that can handle these harsh environments without restricting airflow is crucial for maintaining engine health and performance.

The K24's lubrication system also requires attention when adapting for off-road use. Steep inclines and uneven terrain can cause oil starvation in certain engine areas, leading to increased wear and potential failure. Modifying the oil pan design and implementing a dry sump system may be necessary to ensure consistent oil pressure and distribution across all driving conditions.

Vibration and impact resistance present another set of challenges. Off-road driving subjects the engine to significantly more shock and vibration than typical road use. Strengthening engine mounts, reinforcing critical components, and potentially adding additional bracing to the engine bay may be required to prevent damage and maintain alignment of crucial parts.

Lastly, the engine management system needs recalibration to accommodate the different power delivery requirements of off-road driving. This includes adjusting fuel mapping, ignition timing, and throttle response to provide optimal performance across a wider range of RPMs and load conditions encountered in off-road scenarios. Additionally, implementing safeguards against sudden impacts and potential rollovers, such as an automatic engine cut-off system, is crucial for safety in extreme off-road situations.

K24 Off-Road Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and durability of the engine.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control in the engine.

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters. These systems optimize performance, fuel economy, and emissions across different operating conditions.

- Engine cooling and lubrication: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, oil circulation, and heat management techniques. These enhancements contribute to better thermal efficiency, reduced friction, and increased engine longevity.

- Engine integration and compatibility: The K24 engine is designed for integration into various vehicle platforms and compatibility with different transmission systems. This includes considerations for mounting, power transfer, and auxiliary systems. The engine's versatility allows for its use in a wide range of vehicle applications, from compact cars to SUVs.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters for optimal performance and efficiency under different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, oil circulation, and heat management techniques. These enhancements contribute to better engine durability, performance, and longevity.Expand Specific Solutions05 Engine accessories and integration

Various accessories and integration features are incorporated into the K24 engine design. This includes components such as alternators, power steering pumps, and air conditioning compressors. The integration of these accessories is optimized for space efficiency and overall engine performance.Expand Specific Solutions

Key Off-Road Manufacturers

The K24 Engine's impact on off-road vehicle transformations is shaping a competitive landscape in a rapidly evolving industry. The market is in a growth phase, with increasing demand for high-performance off-road vehicles driving innovation. Major players like Yamaha Motor Co., Arctic Cat, and Bombardier Recreational Products are investing heavily in R&D to leverage this technology. The market size is expanding, particularly in regions with diverse terrains. Technologically, while established companies like Caterpillar and Honda Motor Co. have a strong foundation, newer entrants such as Zhejiang CF Moto Power are quickly catching up, indicating a moderate level of technological maturity with room for further advancements and differentiation.

Bombardier Recreational Products, Inc.

Technical Solution: Bombardier Recreational Products (BRP) has adapted the K24 engine for use in their off-road recreational vehicles, focusing on lightweight design and high-performance output. BRP's version of the K24 engine features a redesigned cylinder head with improved port geometry to enhance airflow and combustion efficiency[13]. The company has implemented a lightweight forged crankshaft and connecting rods to reduce reciprocating mass, allowing for higher RPM operation and quicker throttle response. BRP has developed a specialized engine management system that includes multiple riding modes, optimizing power delivery for different terrains and skill levels[14]. The engine also incorporates a dry-sump lubrication system, ensuring consistent oil pressure during extreme maneuvers and allowing for a lower engine mounting position, which improves the vehicle's center of gravity[15].

Strengths: Lightweight design suitable for high-performance recreational vehicles, advanced engine management for versatile use. Weaknesses: May prioritize performance over long-term durability, potentially higher manufacturing costs due to specialized components.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a new K24 engine variant specifically for off-road vehicles, focusing on improved torque delivery and durability. The engine features a reinforced block and crankshaft, optimized camshaft profiles, and a high-flow intake system. Honda has implemented advanced fuel injection technology and a revised ECU mapping to enhance low-end torque and throttle response in challenging terrain[1]. The K24 engine's compact design allows for better weight distribution and a lower center of gravity in off-road vehicles, improving overall stability and maneuverability[2]. Honda has also incorporated a robust oil cooling system and upgraded filtration to ensure reliable performance in dusty and demanding off-road conditions[3].

Strengths: Proven reliability, excellent power-to-weight ratio, and adaptability to various off-road applications. Weaknesses: Potentially higher cost compared to simpler engines, and may require more frequent maintenance in extreme off-road use.

K24 Off-Road Innovations

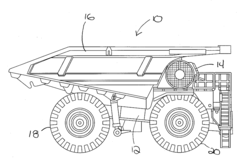

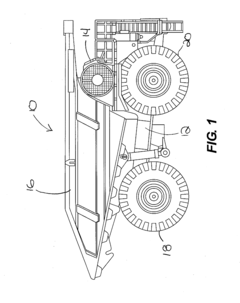

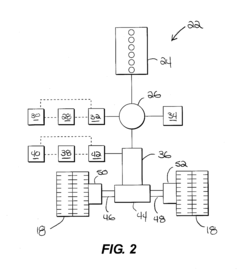

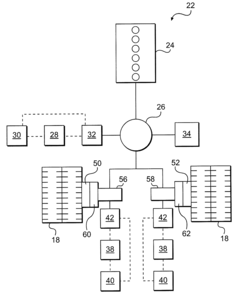

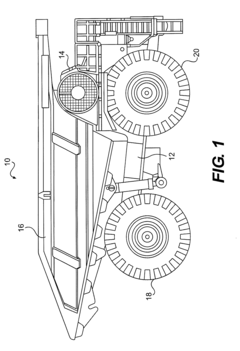

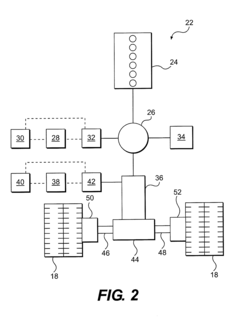

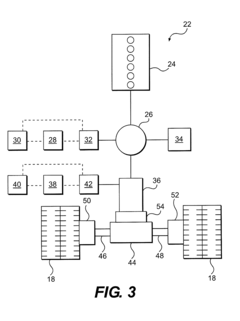

Electric powertrain for off-highway trucks

PatentInactiveUS20120018236A1

Innovation

- An electric powertrain for off-highway trucks incorporating an engine coupled with an electric power generator, electric motors, and a differential system, which allows for efficient conversion of mechanical energy into electric energy and provides infinitely variable speed control, reduced emissions, and energy storage for enhanced performance.

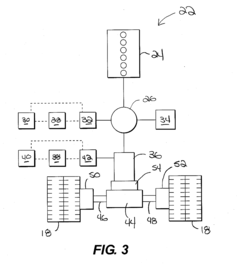

Electric powertrain for off-highway trucks

PatentInactiveUS20100065356A1

Innovation

- An electric powertrain for off-highway trucks incorporating an engine, electric power generator, electric motors, and a differential system that provides mechanical energy conversion, torque distribution, and variable speed control, utilizing a multiple range gearbox and electric energy storage for efficient propulsion and reduced emissions.

Environmental Regulations

Environmental regulations play a crucial role in shaping the off-road vehicle industry, particularly in the context of K24 engine transformations. As governments worldwide intensify their focus on reducing carbon emissions and promoting sustainable transportation, off-road vehicle manufacturers face increasing pressure to adapt their technologies and comply with stringent environmental standards.

The implementation of more rigorous emission standards has significantly impacted the development and adoption of K24 engine modifications for off-road vehicles. These regulations typically set limits on pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. Consequently, manufacturers must invest in advanced engine technologies and exhaust after-treatment systems to meet these requirements while maintaining vehicle performance.

One of the key challenges for off-road vehicle manufacturers is balancing environmental compliance with the power and durability demands of their customers. The K24 engine, known for its reliability and versatility, has undergone various modifications to improve its environmental performance. These include the integration of more efficient fuel injection systems, enhanced combustion chamber designs, and the incorporation of advanced catalytic converters.

The regulatory landscape varies across different regions, with some countries implementing stricter standards than others. For instance, the European Union's Stage V emissions standards for non-road mobile machinery have set a new benchmark for off-road vehicle emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 4 Final standards, which have driven significant technological advancements in engine design and emissions control.

These regulations have also spurred innovation in alternative powertrain technologies for off-road vehicles. While the K24 engine remains popular, there is a growing trend towards hybrid and fully electric powertrains in certain off-road applications. This shift is partly driven by the need to meet increasingly stringent emissions targets and the potential for improved energy efficiency in specific use cases.

The impact of environmental regulations extends beyond engine technology to encompass the entire vehicle lifecycle. Manufacturers must now consider factors such as recyclability, the use of sustainable materials, and the overall carbon footprint of their products. This holistic approach to environmental compliance has led to the development of more sustainable manufacturing processes and the exploration of eco-friendly materials in off-road vehicle construction.

As environmental regulations continue to evolve, the off-road vehicle industry must remain agile and innovative. The future of K24 engine transformations will likely involve a combination of advanced combustion technologies, intelligent engine management systems, and potentially the integration of hybrid-electric components to meet both performance and environmental requirements.

The implementation of more rigorous emission standards has significantly impacted the development and adoption of K24 engine modifications for off-road vehicles. These regulations typically set limits on pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. Consequently, manufacturers must invest in advanced engine technologies and exhaust after-treatment systems to meet these requirements while maintaining vehicle performance.

One of the key challenges for off-road vehicle manufacturers is balancing environmental compliance with the power and durability demands of their customers. The K24 engine, known for its reliability and versatility, has undergone various modifications to improve its environmental performance. These include the integration of more efficient fuel injection systems, enhanced combustion chamber designs, and the incorporation of advanced catalytic converters.

The regulatory landscape varies across different regions, with some countries implementing stricter standards than others. For instance, the European Union's Stage V emissions standards for non-road mobile machinery have set a new benchmark for off-road vehicle emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Tier 4 Final standards, which have driven significant technological advancements in engine design and emissions control.

These regulations have also spurred innovation in alternative powertrain technologies for off-road vehicles. While the K24 engine remains popular, there is a growing trend towards hybrid and fully electric powertrains in certain off-road applications. This shift is partly driven by the need to meet increasingly stringent emissions targets and the potential for improved energy efficiency in specific use cases.

The impact of environmental regulations extends beyond engine technology to encompass the entire vehicle lifecycle. Manufacturers must now consider factors such as recyclability, the use of sustainable materials, and the overall carbon footprint of their products. This holistic approach to environmental compliance has led to the development of more sustainable manufacturing processes and the exploration of eco-friendly materials in off-road vehicle construction.

As environmental regulations continue to evolve, the off-road vehicle industry must remain agile and innovative. The future of K24 engine transformations will likely involve a combination of advanced combustion technologies, intelligent engine management systems, and potentially the integration of hybrid-electric components to meet both performance and environmental requirements.

K24 Off-Road Performance

The K24 engine has significantly transformed off-road vehicle performance, offering a blend of power, reliability, and adaptability that has made it a popular choice among enthusiasts and manufacturers alike. This inline-four engine, originally designed for Honda's passenger cars, has found a new niche in the off-road world due to its robust construction and tuning potential.

In off-road applications, the K24 engine's performance characteristics shine through. Its high-revving nature, with a redline typically around 7,000 RPM, provides sustained power output across a wide range of engine speeds. This is particularly beneficial in off-road scenarios where maintaining momentum over varied terrain is crucial. The engine's relatively lightweight aluminum construction contributes to improved vehicle dynamics, allowing for better weight distribution and handling in challenging off-road conditions.

One of the key advantages of the K24 in off-road use is its torque curve. The engine delivers a broad, flat torque band, which translates to excellent low-end and mid-range power. This characteristic is invaluable for off-road driving, where low-speed control and the ability to climb steep inclines are essential. The K24's torque delivery allows for better traction management and reduces the need for frequent gear changes, enhancing the overall off-road experience.

Durability is another factor that has contributed to the K24's success in off-road applications. The engine's robust internals, including forged connecting rods in some variants, provide a solid foundation for withstanding the rigors of off-road use. This inherent strength also makes the K24 an excellent platform for modifications, allowing enthusiasts to extract even more performance through aftermarket upgrades.

The adaptability of the K24 engine has led to its integration into a variety of off-road vehicles, from custom-built rock crawlers to modified SUVs and even some purpose-built off-road racing vehicles. Its compact size and relatively simple design make it an ideal candidate for engine swaps in older off-road vehicles, breathing new life into classic platforms with modern performance capabilities.

Furthermore, the K24's fuel efficiency, even when tuned for higher output, is a significant advantage for off-road enthusiasts. Extended range is crucial in remote off-road environments, and the K24's ability to balance power with fuel economy enhances the overall utility of vehicles equipped with this engine. This efficiency, coupled with its reliability, makes the K24 a practical choice for long-distance off-road adventures and competitions.

In off-road applications, the K24 engine's performance characteristics shine through. Its high-revving nature, with a redline typically around 7,000 RPM, provides sustained power output across a wide range of engine speeds. This is particularly beneficial in off-road scenarios where maintaining momentum over varied terrain is crucial. The engine's relatively lightweight aluminum construction contributes to improved vehicle dynamics, allowing for better weight distribution and handling in challenging off-road conditions.

One of the key advantages of the K24 in off-road use is its torque curve. The engine delivers a broad, flat torque band, which translates to excellent low-end and mid-range power. This characteristic is invaluable for off-road driving, where low-speed control and the ability to climb steep inclines are essential. The K24's torque delivery allows for better traction management and reduces the need for frequent gear changes, enhancing the overall off-road experience.

Durability is another factor that has contributed to the K24's success in off-road applications. The engine's robust internals, including forged connecting rods in some variants, provide a solid foundation for withstanding the rigors of off-road use. This inherent strength also makes the K24 an excellent platform for modifications, allowing enthusiasts to extract even more performance through aftermarket upgrades.

The adaptability of the K24 engine has led to its integration into a variety of off-road vehicles, from custom-built rock crawlers to modified SUVs and even some purpose-built off-road racing vehicles. Its compact size and relatively simple design make it an ideal candidate for engine swaps in older off-road vehicles, breathing new life into classic platforms with modern performance capabilities.

Furthermore, the K24's fuel efficiency, even when tuned for higher output, is a significant advantage for off-road enthusiasts. Extended range is crucial in remote off-road environments, and the K24's ability to balance power with fuel economy enhances the overall utility of vehicles equipped with this engine. This efficiency, coupled with its reliability, makes the K24 a practical choice for long-distance off-road adventures and competitions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!