K24 Engine Technical Advancements: Evolving Performance Standards

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, developed by Honda, has undergone significant evolution since its introduction in the early 2000s. This inline-four cylinder engine has become a cornerstone of Honda's performance lineup, powering various models across the Acura and Honda brands. The engine's evolution can be traced through several key generations, each marking substantial improvements in performance, efficiency, and technological integration.

The first generation K24A engine debuted in 2002, featuring a 2.4-liter displacement and i-VTEC technology. This initial iteration set the foundation for future advancements, offering a balance of power and fuel efficiency that would become a hallmark of the K24 series. As emissions regulations tightened and consumer demands shifted, Honda continuously refined the K24 engine to meet these changing standards.

In subsequent years, Honda introduced various iterations of the K24, including the K24A2, K24A3, and K24A4. These versions incorporated incremental improvements in areas such as valve timing, compression ratios, and intake systems. The K24A2, for instance, saw use in performance-oriented models like the Acura TSX, showcasing the engine's versatility in meeting diverse vehicle requirements.

A significant leap forward came with the introduction of the K24Z series. This generation brought about more substantial changes, including revised cylinder heads, enhanced VTEC systems, and improved fuel injection technology. The K24Z3 variant, found in vehicles like the Honda Accord, demonstrated Honda's commitment to pushing the boundaries of naturally aspirated engine performance while maintaining reliability and efficiency.

The latest evolution of the K24 engine has seen the integration of direct injection technology, further improving fuel efficiency and power output. This advancement, coupled with more sophisticated engine management systems, has allowed the K24 to remain competitive in an era increasingly dominated by turbocharged engines. The K24W, used in more recent Honda models, exemplifies this progression, offering improved low-end torque and reduced emissions without sacrificing the high-revving character that K-series engines are known for.

Throughout its evolution, the K24 engine has consistently adapted to meet changing performance standards and regulatory requirements. From its initial focus on balancing power and efficiency to later iterations emphasizing reduced emissions and enhanced drivability, the K24 has demonstrated remarkable versatility. This ongoing development process has ensured that the K24 remains a relevant and competitive option in Honda's engine lineup, even as automotive technology continues to advance rapidly.

The first generation K24A engine debuted in 2002, featuring a 2.4-liter displacement and i-VTEC technology. This initial iteration set the foundation for future advancements, offering a balance of power and fuel efficiency that would become a hallmark of the K24 series. As emissions regulations tightened and consumer demands shifted, Honda continuously refined the K24 engine to meet these changing standards.

In subsequent years, Honda introduced various iterations of the K24, including the K24A2, K24A3, and K24A4. These versions incorporated incremental improvements in areas such as valve timing, compression ratios, and intake systems. The K24A2, for instance, saw use in performance-oriented models like the Acura TSX, showcasing the engine's versatility in meeting diverse vehicle requirements.

A significant leap forward came with the introduction of the K24Z series. This generation brought about more substantial changes, including revised cylinder heads, enhanced VTEC systems, and improved fuel injection technology. The K24Z3 variant, found in vehicles like the Honda Accord, demonstrated Honda's commitment to pushing the boundaries of naturally aspirated engine performance while maintaining reliability and efficiency.

The latest evolution of the K24 engine has seen the integration of direct injection technology, further improving fuel efficiency and power output. This advancement, coupled with more sophisticated engine management systems, has allowed the K24 to remain competitive in an era increasingly dominated by turbocharged engines. The K24W, used in more recent Honda models, exemplifies this progression, offering improved low-end torque and reduced emissions without sacrificing the high-revving character that K-series engines are known for.

Throughout its evolution, the K24 engine has consistently adapted to meet changing performance standards and regulatory requirements. From its initial focus on balancing power and efficiency to later iterations emphasizing reduced emissions and enhanced drivability, the K24 has demonstrated remarkable versatility. This ongoing development process has ensured that the K24 remains a relevant and competitive option in Honda's engine lineup, even as automotive technology continues to advance rapidly.

Market Demand Analysis

The market demand for advanced engine technologies, particularly in the context of the K24 engine, has been steadily growing in recent years. This demand is driven by several factors, including stricter emissions regulations, increasing fuel efficiency requirements, and consumer preferences for high-performance vehicles with improved fuel economy.

In the automotive industry, there is a significant push towards more efficient and environmentally friendly engines. The K24 engine, known for its versatility and potential for performance enhancements, has become a focal point for manufacturers and enthusiasts alike. As governments worldwide implement more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, automakers are compelled to innovate and improve their engine technologies.

The aftermarket sector has also shown substantial interest in K24 engine advancements. Performance enthusiasts and tuning shops are constantly seeking ways to extract more power and efficiency from these engines while maintaining reliability. This has created a thriving market for aftermarket parts and performance upgrades specifically designed for the K24 platform.

In terms of market size, the global automotive engine market, which includes the segment where K24 engines compete, is projected to grow significantly. The demand for four-cylinder engines, the category to which the K24 belongs, is particularly strong due to their balance of performance and efficiency.

The trend towards vehicle electrification has not diminished the demand for advanced internal combustion engines like the K24. Instead, it has spurred development in hybrid technologies, where efficient and compact engines like the K24 can be paired with electric motors to achieve optimal performance and fuel economy.

Consumer preferences are also shaping the market demand for K24 engine advancements. There is a growing segment of buyers who desire vehicles that offer both performance and efficiency. This has led to increased interest in technologies such as variable valve timing, direct injection, and turbocharging, all of which can be applied to the K24 engine to meet these consumer expectations.

The commercial vehicle sector presents another area of potential growth for K24 engine applications. As businesses seek to reduce operating costs and meet environmental regulations, there is a rising demand for efficient, reliable engines in light commercial vehicles and small trucks.

Overall, the market demand for K24 engine technical advancements is robust and multifaceted. It spans across various automotive sectors, from personal vehicles to commercial applications, and is driven by a combination of regulatory pressures, consumer preferences, and industry trends towards improved performance and efficiency.

In the automotive industry, there is a significant push towards more efficient and environmentally friendly engines. The K24 engine, known for its versatility and potential for performance enhancements, has become a focal point for manufacturers and enthusiasts alike. As governments worldwide implement more stringent emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, automakers are compelled to innovate and improve their engine technologies.

The aftermarket sector has also shown substantial interest in K24 engine advancements. Performance enthusiasts and tuning shops are constantly seeking ways to extract more power and efficiency from these engines while maintaining reliability. This has created a thriving market for aftermarket parts and performance upgrades specifically designed for the K24 platform.

In terms of market size, the global automotive engine market, which includes the segment where K24 engines compete, is projected to grow significantly. The demand for four-cylinder engines, the category to which the K24 belongs, is particularly strong due to their balance of performance and efficiency.

The trend towards vehicle electrification has not diminished the demand for advanced internal combustion engines like the K24. Instead, it has spurred development in hybrid technologies, where efficient and compact engines like the K24 can be paired with electric motors to achieve optimal performance and fuel economy.

Consumer preferences are also shaping the market demand for K24 engine advancements. There is a growing segment of buyers who desire vehicles that offer both performance and efficiency. This has led to increased interest in technologies such as variable valve timing, direct injection, and turbocharging, all of which can be applied to the K24 engine to meet these consumer expectations.

The commercial vehicle sector presents another area of potential growth for K24 engine applications. As businesses seek to reduce operating costs and meet environmental regulations, there is a rising demand for efficient, reliable engines in light commercial vehicles and small trucks.

Overall, the market demand for K24 engine technical advancements is robust and multifaceted. It spans across various automotive sectors, from personal vehicles to commercial applications, and is driven by a combination of regulatory pressures, consumer preferences, and industry trends towards improved performance and efficiency.

Technical Challenges

The K24 engine, while renowned for its performance capabilities, faces several technical challenges in meeting evolving performance standards. One of the primary hurdles is the need for increased power output without compromising fuel efficiency. As emission regulations become more stringent globally, engineers must find innovative ways to boost performance while reducing harmful exhaust emissions.

Another significant challenge lies in the thermal management of the engine. As power output increases, so does the heat generated within the engine block. Efficient heat dissipation becomes crucial to maintain optimal performance and prevent component degradation. This necessitates advancements in cooling system design and materials technology to withstand higher operating temperatures.

The pursuit of weight reduction presents another technical obstacle. Lightweight materials must be incorporated into the engine design without sacrificing durability or increasing production costs significantly. This challenge extends to the entire powertrain system, as reducing overall vehicle weight is essential for improving performance and fuel economy.

Durability and longevity remain critical concerns, especially as consumers and manufacturers alike push for extended warranty periods and higher reliability standards. Engineers must develop solutions to mitigate wear and tear on engine components, particularly under high-stress conditions often experienced in performance applications.

The integration of advanced electronic control systems poses both an opportunity and a challenge. While these systems offer precise management of engine parameters, they also introduce complexity and potential points of failure. Ensuring robust and reliable electronic controls that can withstand harsh automotive environments is a significant technical hurdle.

Noise, vibration, and harshness (NVH) characteristics present another area of focus. As vehicles become quieter overall, engine noise becomes more noticeable. Engineers must find ways to reduce engine NVH without compromising performance or adding excessive weight through sound-dampening materials.

Lastly, the challenge of scalability and manufacturing efficiency cannot be overlooked. Any technical advancements must be designed with mass production in mind, ensuring that new technologies can be implemented across various vehicle models without significantly increasing production costs or complexity.

Another significant challenge lies in the thermal management of the engine. As power output increases, so does the heat generated within the engine block. Efficient heat dissipation becomes crucial to maintain optimal performance and prevent component degradation. This necessitates advancements in cooling system design and materials technology to withstand higher operating temperatures.

The pursuit of weight reduction presents another technical obstacle. Lightweight materials must be incorporated into the engine design without sacrificing durability or increasing production costs significantly. This challenge extends to the entire powertrain system, as reducing overall vehicle weight is essential for improving performance and fuel economy.

Durability and longevity remain critical concerns, especially as consumers and manufacturers alike push for extended warranty periods and higher reliability standards. Engineers must develop solutions to mitigate wear and tear on engine components, particularly under high-stress conditions often experienced in performance applications.

The integration of advanced electronic control systems poses both an opportunity and a challenge. While these systems offer precise management of engine parameters, they also introduce complexity and potential points of failure. Ensuring robust and reliable electronic controls that can withstand harsh automotive environments is a significant technical hurdle.

Noise, vibration, and harshness (NVH) characteristics present another area of focus. As vehicles become quieter overall, engine noise becomes more noticeable. Engineers must find ways to reduce engine NVH without compromising performance or adding excessive weight through sound-dampening materials.

Lastly, the challenge of scalability and manufacturing efficiency cannot be overlooked. Any technical advancements must be designed with mass production in mind, ensuring that new technologies can be implemented across various vehicle models without significantly increasing production costs or complexity.

Current K24 Solutions

01 Engine performance monitoring and optimization

Systems and methods for monitoring and optimizing K24 engine performance, including real-time data collection, analysis, and adjustment of engine parameters to meet performance standards. This involves the use of sensors, control units, and algorithms to ensure optimal engine operation under various conditions.- Engine performance monitoring and optimization: Systems and methods for monitoring and optimizing K24 engine performance, including real-time data collection, analysis, and adjustment of engine parameters to meet performance standards. This involves the use of sensors, control units, and algorithms to ensure optimal engine operation under various conditions.

- Emissions control and compliance: Technologies focused on ensuring K24 engines meet emissions standards while maintaining performance. This includes the development of advanced exhaust aftertreatment systems, fuel injection strategies, and engine management systems to reduce harmful emissions without compromising engine efficiency.

- Fuel efficiency improvements: Innovations aimed at enhancing the fuel efficiency of K24 engines to meet increasingly stringent performance standards. This involves optimizing combustion processes, reducing friction, improving thermal management, and implementing advanced fuel injection technologies.

- Durability and reliability testing: Methods and systems for evaluating the long-term performance and reliability of K24 engines. This includes accelerated life testing, stress analysis, and simulation techniques to ensure engines meet durability standards and maintain consistent performance over their operational lifespan.

- Performance tuning and customization: Techniques and tools for fine-tuning K24 engine performance to meet specific standards or customer requirements. This encompasses software-based engine mapping, hardware modifications, and adaptive control systems that allow for customized performance profiles while adhering to regulatory standards.

02 Emissions control and compliance

Technologies focused on ensuring K24 engines meet emissions standards while maintaining performance. This includes the development of advanced exhaust gas treatment systems, fuel injection optimization, and combustion control strategies to reduce harmful emissions without compromising engine efficiency.Expand Specific Solutions03 Fuel efficiency improvements

Innovations aimed at enhancing the fuel efficiency of K24 engines to meet increasingly stringent performance standards. This encompasses advancements in engine design, materials, and control systems to optimize fuel consumption while maintaining or improving power output.Expand Specific Solutions04 Diagnostic and maintenance systems

Development of advanced diagnostic tools and maintenance systems specifically for K24 engines. These systems are designed to detect performance issues, predict potential failures, and facilitate timely maintenance to ensure consistent adherence to performance standards throughout the engine's lifecycle.Expand Specific Solutions05 Performance testing and certification

Establishment of standardized testing procedures and certification processes for K24 engines to verify compliance with performance standards. This includes the development of specialized testing equipment, protocols, and benchmarks to accurately assess engine performance across various operational parameters.Expand Specific Solutions

Key Manufacturers

The K24 Engine Technical Advancements market is in a mature growth phase, characterized by intense competition among established players and emerging innovators. The global market size for advanced engine technologies is substantial, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. Companies like Dongfeng Motor Group, Weichai Power, and GM Global Technology Operations are at the forefront of technological maturity, investing heavily in R&D to enhance engine performance and efficiency. Other key players such as Robert Bosch GmbH, Ford Global Technologies, and Renault SA are also making significant strides in developing cutting-edge engine solutions, contributing to a highly competitive landscape.

GM Global Technology Operations LLC

Technical Solution: GM's K24 engine advancements focus on improving performance and efficiency. They have implemented variable valve timing (VVT) technology, which allows for precise control of valve opening and closing times[1]. This results in optimized engine breathing across different RPM ranges. GM has also integrated direct fuel injection, enabling more precise fuel delivery and improved combustion efficiency[2]. The K24 engine now features a higher compression ratio, typically around 11.0:1, which contributes to better thermal efficiency[3]. Additionally, GM has implemented lightweight materials and advanced manufacturing techniques to reduce overall engine weight while maintaining structural integrity[4].

Strengths: Improved fuel efficiency, enhanced power output, and reduced emissions. Weaknesses: Increased complexity and potentially higher manufacturing costs.

Robert Bosch GmbH

Technical Solution: Bosch, as a leading automotive supplier, has contributed significantly to K24 engine advancements through its component technologies. They have developed high-precision fuel injectors capable of multiple injections per cycle, improving combustion efficiency and reducing emissions[17]. Bosch has also created advanced engine control units (ECUs) that utilize artificial intelligence and machine learning algorithms to optimize engine performance in real-time[18]. The company has introduced innovative sensor technologies, such as particulate matter sensors and NOx sensors, enabling more precise emissions control[19]. Additionally, Bosch has developed a water injection system for turbocharged engines, which cools intake air and reduces knock tendency, allowing for higher compression ratios and improved efficiency[20].

Strengths: Cutting-edge component technologies that enable significant improvements in engine performance and emissions control. Weaknesses: Reliance on OEM adoption and integration of their technologies.

Core Innovations

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

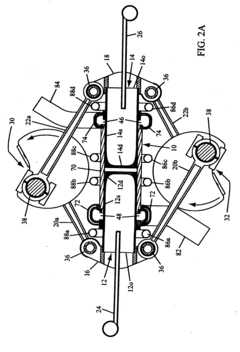

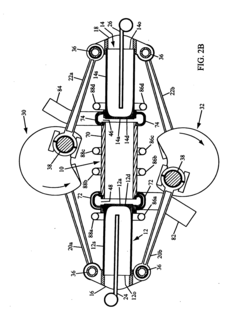

Two-Cycle, Opposed-Piston Internal Combustion Engine

PatentInactiveUS20070245892A1

Innovation

- The implementation of side-mounted crankshafts with tailored cooling systems, where liquid coolant is directed to the back surface of the piston crown and the cylinder's external surface, reducing thermal non-uniformities and mechanical stresses, and eliminating the need for piston rings by maintaining a close, uniform cylinder-to-piston clearance.

Emissions Regulations

Emissions regulations have played a pivotal role in shaping the development of the K24 engine, driving Honda to continuously innovate and improve its performance while meeting increasingly stringent environmental standards. The evolution of these regulations has been a key factor in the technical advancements of the K24 engine, pushing it to achieve higher efficiency and lower emissions without compromising power output.

Over the years, emissions standards such as the U.S. Environmental Protection Agency's (EPA) Tier 2 and Tier 3 regulations, as well as the European Union's Euro 5 and Euro 6 standards, have progressively tightened the limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). These regulations have necessitated significant improvements in engine design, fuel injection systems, and exhaust aftertreatment technologies.

In response to these challenges, Honda has implemented various technologies in the K24 engine. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) has allowed for optimized valve timing across different engine speeds and loads, improving both performance and emissions. Additionally, the integration of direct fuel injection systems has enhanced fuel atomization and combustion efficiency, leading to reduced emissions and improved fuel economy.

The K24 engine has also benefited from advancements in catalytic converter technology. The use of more efficient, three-way catalytic converters has significantly reduced the emission of harmful pollutants. Furthermore, the implementation of exhaust gas recirculation (EGR) systems has helped lower NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, reducing peak combustion temperatures.

To meet the challenges posed by particulate matter emissions, especially in direct injection variants, Honda has explored the use of gasoline particulate filters (GPFs) in some K24 engine applications. These filters trap and oxidize particulate matter, further reducing emissions and ensuring compliance with the most stringent regulations.

The ongoing development of the K24 engine in response to emissions regulations has not only resulted in cleaner operations but has also driven improvements in overall engine efficiency and performance. This has led to a generation of engines that deliver higher power outputs while consuming less fuel and producing fewer emissions, demonstrating Honda's commitment to balancing performance with environmental responsibility.

As emissions regulations continue to evolve, particularly with the increasing focus on reducing greenhouse gas emissions and the transition towards electrification, the K24 engine faces new challenges and opportunities for further advancement. Future iterations may incorporate mild hybrid technologies or more advanced combustion strategies to meet ever-tightening emissions standards while maintaining the engine's reputation for performance and reliability.

Over the years, emissions standards such as the U.S. Environmental Protection Agency's (EPA) Tier 2 and Tier 3 regulations, as well as the European Union's Euro 5 and Euro 6 standards, have progressively tightened the limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). These regulations have necessitated significant improvements in engine design, fuel injection systems, and exhaust aftertreatment technologies.

In response to these challenges, Honda has implemented various technologies in the K24 engine. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) has allowed for optimized valve timing across different engine speeds and loads, improving both performance and emissions. Additionally, the integration of direct fuel injection systems has enhanced fuel atomization and combustion efficiency, leading to reduced emissions and improved fuel economy.

The K24 engine has also benefited from advancements in catalytic converter technology. The use of more efficient, three-way catalytic converters has significantly reduced the emission of harmful pollutants. Furthermore, the implementation of exhaust gas recirculation (EGR) systems has helped lower NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, reducing peak combustion temperatures.

To meet the challenges posed by particulate matter emissions, especially in direct injection variants, Honda has explored the use of gasoline particulate filters (GPFs) in some K24 engine applications. These filters trap and oxidize particulate matter, further reducing emissions and ensuring compliance with the most stringent regulations.

The ongoing development of the K24 engine in response to emissions regulations has not only resulted in cleaner operations but has also driven improvements in overall engine efficiency and performance. This has led to a generation of engines that deliver higher power outputs while consuming less fuel and producing fewer emissions, demonstrating Honda's commitment to balancing performance with environmental responsibility.

As emissions regulations continue to evolve, particularly with the increasing focus on reducing greenhouse gas emissions and the transition towards electrification, the K24 engine faces new challenges and opportunities for further advancement. Future iterations may incorporate mild hybrid technologies or more advanced combustion strategies to meet ever-tightening emissions standards while maintaining the engine's reputation for performance and reliability.

Fuel Efficiency Trends

The K24 engine has seen significant advancements in fuel efficiency over the years, reflecting the automotive industry's growing focus on environmental sustainability and cost-effectiveness. These improvements have been driven by a combination of technological innovations, regulatory pressures, and consumer demands for more economical vehicles.

In the early stages of K24 development, fuel efficiency was primarily achieved through mechanical optimizations such as improved combustion chamber design and reduced friction between moving parts. As the engine evolved, more sophisticated technologies were incorporated to further enhance its fuel economy. Variable valve timing and lift systems, such as Honda's i-VTEC, played a crucial role in optimizing engine performance across different operating conditions, resulting in better fuel utilization.

The introduction of direct fuel injection technology marked a significant milestone in the K24's fuel efficiency journey. This system allows for more precise control over fuel delivery, leading to improved combustion efficiency and reduced fuel consumption. Additionally, the integration of advanced engine management systems and sensors has enabled real-time adjustments to engine parameters, further optimizing fuel usage based on driving conditions and load requirements.

Another notable trend in K24 fuel efficiency has been the adoption of lightweight materials and design optimizations. The use of aluminum alloys and other lightweight components has helped reduce overall engine weight, contributing to improved fuel economy without sacrificing performance. Furthermore, advancements in thermal management systems have allowed for more efficient heat dissipation, reducing energy losses and improving overall engine efficiency.

The push towards hybridization has also influenced K24 fuel efficiency trends. Some variants of the K24 engine have been adapted for use in hybrid powertrains, where they work in conjunction with electric motors to achieve even greater fuel economy. This hybrid application demonstrates the engine's versatility and its ability to meet evolving efficiency standards in the automotive industry.

Recent developments in K24 fuel efficiency have focused on fine-tuning existing technologies and exploring new avenues for improvement. These include the implementation of more advanced friction-reducing coatings, further refinements to combustion processes, and the integration of start-stop systems to eliminate fuel consumption during idle periods. Additionally, ongoing research into alternative fuels and their compatibility with K24 engines shows promise for future efficiency gains.

As environmental regulations continue to tighten globally, the K24 engine's fuel efficiency trends are expected to maintain their upward trajectory. Future iterations may incorporate even more advanced technologies, such as predictive engine management systems leveraging artificial intelligence, or further electrification to meet increasingly stringent emissions and fuel economy standards.

In the early stages of K24 development, fuel efficiency was primarily achieved through mechanical optimizations such as improved combustion chamber design and reduced friction between moving parts. As the engine evolved, more sophisticated technologies were incorporated to further enhance its fuel economy. Variable valve timing and lift systems, such as Honda's i-VTEC, played a crucial role in optimizing engine performance across different operating conditions, resulting in better fuel utilization.

The introduction of direct fuel injection technology marked a significant milestone in the K24's fuel efficiency journey. This system allows for more precise control over fuel delivery, leading to improved combustion efficiency and reduced fuel consumption. Additionally, the integration of advanced engine management systems and sensors has enabled real-time adjustments to engine parameters, further optimizing fuel usage based on driving conditions and load requirements.

Another notable trend in K24 fuel efficiency has been the adoption of lightweight materials and design optimizations. The use of aluminum alloys and other lightweight components has helped reduce overall engine weight, contributing to improved fuel economy without sacrificing performance. Furthermore, advancements in thermal management systems have allowed for more efficient heat dissipation, reducing energy losses and improving overall engine efficiency.

The push towards hybridization has also influenced K24 fuel efficiency trends. Some variants of the K24 engine have been adapted for use in hybrid powertrains, where they work in conjunction with electric motors to achieve even greater fuel economy. This hybrid application demonstrates the engine's versatility and its ability to meet evolving efficiency standards in the automotive industry.

Recent developments in K24 fuel efficiency have focused on fine-tuning existing technologies and exploring new avenues for improvement. These include the implementation of more advanced friction-reducing coatings, further refinements to combustion processes, and the integration of start-stop systems to eliminate fuel consumption during idle periods. Additionally, ongoing research into alternative fuels and their compatibility with K24 engines shows promise for future efficiency gains.

As environmental regulations continue to tighten globally, the K24 engine's fuel efficiency trends are expected to maintain their upward trajectory. Future iterations may incorporate even more advanced technologies, such as predictive engine management systems leveraging artificial intelligence, or further electrification to meet increasingly stringent emissions and fuel economy standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!