Lithium oxide stabilization techniques for integrated circuits

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IC Lithium Oxide Challenges

The integration of lithium oxide in integrated circuits (ICs) presents significant challenges that have hindered its widespread adoption despite its potential benefits. One of the primary obstacles is the inherent instability of lithium oxide in typical IC environments. This instability manifests as a tendency for lithium ions to migrate under the influence of electric fields, leading to unpredictable changes in device characteristics over time.

Another major challenge is the reactivity of lithium oxide with common materials used in IC fabrication. This reactivity can result in the formation of undesired compounds at interfaces, potentially compromising the integrity and performance of the device. The high sensitivity of lithium oxide to moisture and atmospheric contaminants further complicates its integration, necessitating stringent environmental controls during manufacturing and packaging processes.

The thermal behavior of lithium oxide in IC applications also poses significant challenges. The material's thermal expansion coefficient often differs substantially from that of silicon and other IC materials, leading to mechanical stress and potential delamination or cracking during thermal cycling. This mismatch in thermal properties can severely impact the reliability and lifespan of devices incorporating lithium oxide.

Furthermore, the incorporation of lithium oxide into existing IC fabrication processes requires substantial modifications to established manufacturing techniques. The need for specialized deposition methods, precise control of stoichiometry, and the development of compatible etching processes adds complexity and cost to production. These factors have slowed the adoption of lithium oxide in mainstream IC manufacturing.

The challenge of achieving uniform and controlled doping of lithium oxide layers presents another hurdle. The high mobility of lithium ions makes it difficult to maintain stable doping profiles, which are crucial for consistent device performance. This issue is particularly pronounced in nanoscale devices where even small variations in doping concentration can have significant impacts on functionality.

Lastly, the long-term reliability and aging characteristics of lithium oxide in IC applications remain areas of concern. The potential for gradual degradation of material properties over time, especially under operational stresses, raises questions about the viability of lithium oxide in applications requiring extended service life or high reliability. Addressing these challenges requires innovative approaches to material engineering, process integration, and device design, making the stabilization of lithium oxide a critical focus area for advancing its use in integrated circuits.

Another major challenge is the reactivity of lithium oxide with common materials used in IC fabrication. This reactivity can result in the formation of undesired compounds at interfaces, potentially compromising the integrity and performance of the device. The high sensitivity of lithium oxide to moisture and atmospheric contaminants further complicates its integration, necessitating stringent environmental controls during manufacturing and packaging processes.

The thermal behavior of lithium oxide in IC applications also poses significant challenges. The material's thermal expansion coefficient often differs substantially from that of silicon and other IC materials, leading to mechanical stress and potential delamination or cracking during thermal cycling. This mismatch in thermal properties can severely impact the reliability and lifespan of devices incorporating lithium oxide.

Furthermore, the incorporation of lithium oxide into existing IC fabrication processes requires substantial modifications to established manufacturing techniques. The need for specialized deposition methods, precise control of stoichiometry, and the development of compatible etching processes adds complexity and cost to production. These factors have slowed the adoption of lithium oxide in mainstream IC manufacturing.

The challenge of achieving uniform and controlled doping of lithium oxide layers presents another hurdle. The high mobility of lithium ions makes it difficult to maintain stable doping profiles, which are crucial for consistent device performance. This issue is particularly pronounced in nanoscale devices where even small variations in doping concentration can have significant impacts on functionality.

Lastly, the long-term reliability and aging characteristics of lithium oxide in IC applications remain areas of concern. The potential for gradual degradation of material properties over time, especially under operational stresses, raises questions about the viability of lithium oxide in applications requiring extended service life or high reliability. Addressing these challenges requires innovative approaches to material engineering, process integration, and device design, making the stabilization of lithium oxide a critical focus area for advancing its use in integrated circuits.

Market for Stable ICs

The market for stable integrated circuits (ICs) has been experiencing significant growth due to the increasing demand for reliable electronic components across various industries. As lithium oxide stabilization techniques continue to advance, the potential for more robust and long-lasting ICs has expanded, driving market interest and investment.

In the consumer electronics sector, stable ICs are crucial for smartphones, tablets, and wearable devices. These devices require components that can withstand daily use and environmental stressors while maintaining consistent performance. The automotive industry has also become a major driver for stable IC demand, particularly with the rise of electric vehicles and advanced driver assistance systems (ADAS). These applications require ICs that can operate reliably under extreme temperature conditions and withstand vibrations and electromagnetic interference.

The industrial and manufacturing sectors are increasingly adopting automation and IoT technologies, creating a growing need for stable ICs in sensors, controllers, and communication modules. These components must function reliably in harsh industrial environments, often for extended periods without maintenance. Similarly, the aerospace and defense industries demand highly stable ICs for mission-critical systems where failure is not an option.

The healthcare sector represents another significant market for stable ICs, with applications in medical devices, diagnostic equipment, and implantable technologies. These ICs must meet stringent reliability and longevity requirements to ensure patient safety and reduce the need for invasive replacement procedures.

Market analysts project that the global stable IC market will continue to expand at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is driven not only by increasing demand from established sectors but also by emerging applications in fields such as renewable energy, smart cities, and edge computing.

Geographically, Asia-Pacific remains the largest market for stable ICs, driven by the region's dominant position in electronics manufacturing. However, North America and Europe are showing strong growth, particularly in high-value applications such as automotive and aerospace. Emerging markets in Latin America and Africa are also contributing to the expanding demand, albeit at a slower pace.

As the market for stable ICs grows, so does the competition among manufacturers. Companies are investing heavily in research and development to improve lithium oxide stabilization techniques and other methods to enhance IC reliability. This competitive landscape is driving innovation and pushing the boundaries of what's possible in IC stability, ultimately benefiting end-users across all industries.

In the consumer electronics sector, stable ICs are crucial for smartphones, tablets, and wearable devices. These devices require components that can withstand daily use and environmental stressors while maintaining consistent performance. The automotive industry has also become a major driver for stable IC demand, particularly with the rise of electric vehicles and advanced driver assistance systems (ADAS). These applications require ICs that can operate reliably under extreme temperature conditions and withstand vibrations and electromagnetic interference.

The industrial and manufacturing sectors are increasingly adopting automation and IoT technologies, creating a growing need for stable ICs in sensors, controllers, and communication modules. These components must function reliably in harsh industrial environments, often for extended periods without maintenance. Similarly, the aerospace and defense industries demand highly stable ICs for mission-critical systems where failure is not an option.

The healthcare sector represents another significant market for stable ICs, with applications in medical devices, diagnostic equipment, and implantable technologies. These ICs must meet stringent reliability and longevity requirements to ensure patient safety and reduce the need for invasive replacement procedures.

Market analysts project that the global stable IC market will continue to expand at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is driven not only by increasing demand from established sectors but also by emerging applications in fields such as renewable energy, smart cities, and edge computing.

Geographically, Asia-Pacific remains the largest market for stable ICs, driven by the region's dominant position in electronics manufacturing. However, North America and Europe are showing strong growth, particularly in high-value applications such as automotive and aerospace. Emerging markets in Latin America and Africa are also contributing to the expanding demand, albeit at a slower pace.

As the market for stable ICs grows, so does the competition among manufacturers. Companies are investing heavily in research and development to improve lithium oxide stabilization techniques and other methods to enhance IC reliability. This competitive landscape is driving innovation and pushing the boundaries of what's possible in IC stability, ultimately benefiting end-users across all industries.

Current Stabilization Methods

Current stabilization methods for lithium oxide in integrated circuits focus on addressing the challenges associated with its reactivity and instability. One of the primary approaches involves the use of protective coatings or encapsulation techniques. These methods aim to create a barrier between the lithium oxide and the surrounding environment, preventing unwanted reactions and degradation.

A commonly employed technique is atomic layer deposition (ALD), which allows for the precise deposition of thin, conformal layers of protective materials. Materials such as aluminum oxide (Al2O3) or titanium dioxide (TiO2) are often used due to their excellent barrier properties and compatibility with semiconductor processes. The ALD process enables the formation of uniform and pinhole-free coatings, effectively isolating the lithium oxide from moisture and other reactive species.

Another widely adopted method is the incorporation of stabilizing additives into the lithium oxide matrix. These additives, typically metal oxides or dopants, help to enhance the structural stability and chemical resistance of the lithium oxide layer. For instance, the addition of small amounts of magnesium oxide (MgO) or yttrium oxide (Y2O3) has been shown to improve the thermal and chemical stability of lithium oxide films.

Surface modification techniques are also employed to enhance the stability of lithium oxide in integrated circuits. These methods involve altering the surface properties of the lithium oxide layer to reduce its reactivity. One approach is the use of plasma treatments to create a passivation layer on the surface, which can significantly improve the material's resistance to environmental factors.

Researchers have also explored the use of composite structures to stabilize lithium oxide. By combining lithium oxide with other materials, such as silicon dioxide (SiO2) or silicon nitride (Si3N4), it is possible to create hybrid structures that exhibit improved stability while maintaining the desired electrical properties. These composite materials often demonstrate enhanced resistance to moisture and thermal cycling.

In recent years, advanced deposition techniques have been developed to improve the quality and stability of lithium oxide films. Pulsed laser deposition (PLD) and radio frequency (RF) sputtering have shown promise in producing high-quality, dense lithium oxide layers with improved stability. These techniques allow for better control over the film composition and microstructure, resulting in more robust and reliable lithium oxide-based devices.

Lastly, post-deposition treatments have gained attention as effective stabilization methods. Annealing processes, conducted under controlled atmospheres, can help to reduce defects and improve the crystallinity of lithium oxide films. Additionally, ion implantation techniques have been explored to modify the surface properties and enhance the overall stability of the material.

A commonly employed technique is atomic layer deposition (ALD), which allows for the precise deposition of thin, conformal layers of protective materials. Materials such as aluminum oxide (Al2O3) or titanium dioxide (TiO2) are often used due to their excellent barrier properties and compatibility with semiconductor processes. The ALD process enables the formation of uniform and pinhole-free coatings, effectively isolating the lithium oxide from moisture and other reactive species.

Another widely adopted method is the incorporation of stabilizing additives into the lithium oxide matrix. These additives, typically metal oxides or dopants, help to enhance the structural stability and chemical resistance of the lithium oxide layer. For instance, the addition of small amounts of magnesium oxide (MgO) or yttrium oxide (Y2O3) has been shown to improve the thermal and chemical stability of lithium oxide films.

Surface modification techniques are also employed to enhance the stability of lithium oxide in integrated circuits. These methods involve altering the surface properties of the lithium oxide layer to reduce its reactivity. One approach is the use of plasma treatments to create a passivation layer on the surface, which can significantly improve the material's resistance to environmental factors.

Researchers have also explored the use of composite structures to stabilize lithium oxide. By combining lithium oxide with other materials, such as silicon dioxide (SiO2) or silicon nitride (Si3N4), it is possible to create hybrid structures that exhibit improved stability while maintaining the desired electrical properties. These composite materials often demonstrate enhanced resistance to moisture and thermal cycling.

In recent years, advanced deposition techniques have been developed to improve the quality and stability of lithium oxide films. Pulsed laser deposition (PLD) and radio frequency (RF) sputtering have shown promise in producing high-quality, dense lithium oxide layers with improved stability. These techniques allow for better control over the film composition and microstructure, resulting in more robust and reliable lithium oxide-based devices.

Lastly, post-deposition treatments have gained attention as effective stabilization methods. Annealing processes, conducted under controlled atmospheres, can help to reduce defects and improve the crystallinity of lithium oxide films. Additionally, ion implantation techniques have been explored to modify the surface properties and enhance the overall stability of the material.

Existing Stabilization Solutions

01 Coating and encapsulation techniques

Various coating and encapsulation methods are employed to stabilize lithium oxide particles. These techniques involve creating protective layers around the lithium oxide to prevent degradation and improve its stability. Common materials used for coating include carbon, metal oxides, and polymers. These methods help to maintain the structural integrity of lithium oxide and enhance its performance in various applications.- Coating and encapsulation techniques: Various coating and encapsulation methods are employed to stabilize lithium oxide particles. These techniques involve creating protective layers around the lithium oxide to prevent degradation and improve its stability. Common materials used for coating include carbon, metal oxides, and polymers. These methods help to maintain the structural integrity of lithium oxide and enhance its performance in various applications.

- Doping and elemental modification: Introducing dopants or modifying the elemental composition of lithium oxide can significantly improve its stability. This approach involves adding small amounts of other elements or compounds to the lithium oxide structure. These modifications can enhance the material's resistance to degradation, improve its electrochemical properties, and extend its lifespan in various applications, such as batteries and catalysts.

- Surface treatment and functionalization: Surface treatment and functionalization techniques are used to stabilize lithium oxide by modifying its surface properties. These methods involve chemical or physical treatments that alter the surface characteristics of lithium oxide particles. Such treatments can improve the material's resistance to moisture, enhance its compatibility with other materials, and prevent unwanted reactions that may lead to degradation.

- Composite formation and matrix incorporation: Stabilization of lithium oxide can be achieved by incorporating it into composite materials or matrices. This approach involves dispersing lithium oxide particles within a host material, such as polymers, ceramics, or other inorganic compounds. The resulting composites can provide enhanced stability, improved mechanical properties, and better control over the reactivity of lithium oxide in various applications.

- Environmental control and packaging: Controlling the environment in which lithium oxide is stored, handled, and used is crucial for its stabilization. This includes using specialized packaging materials, inert atmospheres, and moisture-free conditions to prevent degradation. Advanced packaging techniques and environmental control systems are employed to maintain the stability of lithium oxide during storage, transportation, and application in various industrial processes.

02 Doping and elemental modification

Introducing dopants or modifying the elemental composition of lithium oxide can significantly improve its stability. This approach involves adding small amounts of other elements or compounds to the lithium oxide structure. These modifications can enhance the material's resistance to degradation, improve its electrochemical properties, and extend its lifespan in various applications, particularly in battery technologies.Expand Specific Solutions03 Surface treatment and functionalization

Surface treatment and functionalization techniques are used to stabilize lithium oxide by modifying its surface properties. These methods involve chemical or physical treatments that alter the surface characteristics of lithium oxide particles. Such treatments can improve the material's resistance to moisture, enhance its compatibility with other materials, and prevent unwanted reactions that may lead to degradation.Expand Specific Solutions04 Composite formation and matrix incorporation

Lithium oxide stability can be enhanced by incorporating it into composite materials or embedding it within a stable matrix. This approach involves combining lithium oxide with other materials to create a composite structure that provides protection and stability. The matrix material can act as a barrier against environmental factors and help maintain the structural integrity of the lithium oxide.Expand Specific Solutions05 Environmental control and packaging

Controlling the environment in which lithium oxide is stored, handled, or used is crucial for its stabilization. This includes managing factors such as humidity, temperature, and exposure to reactive substances. Advanced packaging techniques and storage solutions are developed to create optimal conditions for maintaining the stability of lithium oxide, particularly in applications where long-term stability is critical.Expand Specific Solutions

Key IC Manufacturers

The lithium oxide stabilization techniques for integrated circuits market is in a growth phase, driven by increasing demand for high-performance, energy-efficient electronic devices. The market size is expanding rapidly, with major players like Samsung Electronics, LG Chem, and ON Semiconductor (Semiconductor Components Industries LLC) investing heavily in research and development. The technology is approaching maturity, with companies like Zhuhai CosMX Battery and Ionblox making significant advancements in lithium-ion battery technologies. Academic institutions such as Zhejiang University and Beijing Institute of Technology are also contributing to the field, fostering innovation and pushing the boundaries of lithium oxide stabilization techniques.

Uchicago Argonne LLC

Technical Solution: Uchicago Argonne LLC, in collaboration with Argonne National Laboratory, has developed cutting-edge lithium oxide stabilization techniques for integrated circuits. Their approach focuses on the atomic-scale engineering of lithium oxide interfaces to enhance stability and performance in advanced semiconductor devices[1]. The team has pioneered the use of in situ characterization techniques, such as synchrotron X-ray diffraction and spectroscopy, to study the evolution of lithium oxide structures during device operation[2]. This has led to the development of novel doping strategies and defect engineering methods to optimize the electrical properties of lithium oxide layers in integrated circuits. Additionally, Argonne has created advanced computational models to predict and optimize the behavior of lithium oxide interfaces under various operating conditions, enabling more efficient design of stable and high-performance integrated circuits[3].

Strengths: Advanced characterization capabilities, strong fundamental understanding of lithium oxide behavior, and innovative computational modeling approaches. Weaknesses: Potential challenges in scaling up from laboratory research to industrial production.

Semiconductor Components Industries LLC

Technical Solution: Semiconductor Components Industries LLC, also known as ON Semiconductor, has developed lithium oxide stabilization techniques for integrated circuits, focusing on power management and sensor applications. Their approach involves the integration of lithium oxide-based materials into advanced packaging solutions for power semiconductors, improving thermal stability and reliability[1]. The company has also implemented novel lithium oxide-based passivation layers in their sensor technologies, enhancing sensitivity and reducing drift in environmental and industrial sensing applications[2]. Additionally, ON Semiconductor has developed a proprietary lithium oxide doping process for silicon carbide (SiC) power devices, which significantly improves the interface quality and reduces on-resistance in high-voltage applications[3].

Strengths: Wide range of applications in power management and sensing, improved device performance, and enhanced reliability. Weaknesses: Potential increased production costs and challenges in maintaining consistent quality across large-scale production.

Core Lithium Oxide Patents

Surface stabilized electrodes for lithium batteries

PatentActiveUS20120141860A1

Innovation

- Preconditioning electrode particles with aqueous or non-aqueous solutions containing stabilizing cations and anions, such as ammonium, phosphorus, titanium, silicon, zirconium, aluminum, and boron cations, and fluoride anions to form a protective surface layer, improving the electrochemical properties and stability of the electrodes.

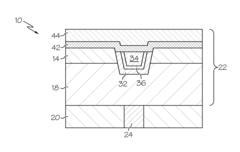

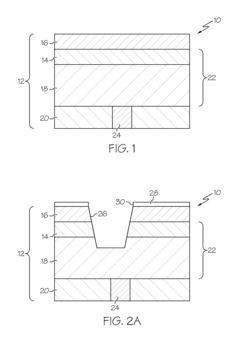

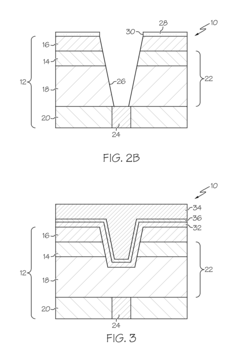

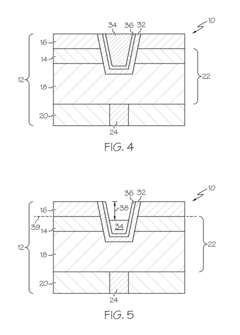

Integrated circuits and processes for forming integrated circuits having an embedded electrical interconnect within a substrate

PatentActiveUS8871635B2

Innovation

- A process involving a protecting layer is used to shield the oxide layer during recessing of the embedded electrical interconnect and barrier layer, allowing for selective etching of the barrier layer without significantly etching the oxide layer, ensuring both the interconnect and barrier layer are recessed to a common plane, thereby promoting electrical insulation and minimizing oxide layer degradation.

Material Compatibility Issues

The integration of lithium oxide in integrated circuits presents significant material compatibility challenges that must be carefully addressed. Lithium oxide, while offering promising properties for certain applications, can react aggressively with many common materials used in semiconductor fabrication. This reactivity can lead to degradation of circuit components and compromise the overall integrity of the integrated circuit.

One of the primary concerns is the interaction between lithium oxide and silicon dioxide, a fundamental material in integrated circuit construction. The high reactivity of lithium can lead to the formation of lithium silicates, which can alter the electrical properties of the insulating layers and potentially create short circuits. This reaction is particularly problematic in high-temperature environments, which are common during various stages of semiconductor processing.

Additionally, lithium oxide can react with metals used for interconnects and electrodes, such as aluminum, copper, and titanium. These reactions can result in the formation of intermetallic compounds, leading to increased resistivity, reduced conductivity, and potential mechanical stress within the circuit structure. The migration of lithium ions through metal layers can also cause reliability issues over time, potentially leading to device failure.

The presence of moisture in the manufacturing environment or during device operation poses another significant challenge. Lithium oxide is highly hygroscopic, readily absorbing water from the atmosphere to form lithium hydroxide. This transformation can cause volume expansion, leading to mechanical stress and potential delamination of layers within the integrated circuit.

To address these compatibility issues, several strategies have been developed. One approach involves the use of barrier layers to isolate lithium oxide from reactive materials. Materials such as silicon nitride or tantalum nitride have shown promise in preventing lithium diffusion and reactions with adjacent layers. However, the integration of these barrier layers adds complexity to the fabrication process and may impact the overall performance of the device.

Another strategy focuses on modifying the composition of lithium oxide to enhance its stability. Doping with other elements or creating composite materials can reduce reactivity while maintaining desired electrical properties. For instance, the incorporation of aluminum or yttrium into lithium oxide has been explored to improve its chemical stability and reduce interactions with other circuit materials.

Careful control of processing conditions, including temperature, atmosphere, and exposure time, is crucial in managing material compatibility issues. Low-temperature deposition techniques and rapid thermal processing have been investigated to minimize unwanted reactions during fabrication. Additionally, advanced encapsulation methods are being developed to protect lithium oxide-containing components from environmental factors that could trigger degradation.

One of the primary concerns is the interaction between lithium oxide and silicon dioxide, a fundamental material in integrated circuit construction. The high reactivity of lithium can lead to the formation of lithium silicates, which can alter the electrical properties of the insulating layers and potentially create short circuits. This reaction is particularly problematic in high-temperature environments, which are common during various stages of semiconductor processing.

Additionally, lithium oxide can react with metals used for interconnects and electrodes, such as aluminum, copper, and titanium. These reactions can result in the formation of intermetallic compounds, leading to increased resistivity, reduced conductivity, and potential mechanical stress within the circuit structure. The migration of lithium ions through metal layers can also cause reliability issues over time, potentially leading to device failure.

The presence of moisture in the manufacturing environment or during device operation poses another significant challenge. Lithium oxide is highly hygroscopic, readily absorbing water from the atmosphere to form lithium hydroxide. This transformation can cause volume expansion, leading to mechanical stress and potential delamination of layers within the integrated circuit.

To address these compatibility issues, several strategies have been developed. One approach involves the use of barrier layers to isolate lithium oxide from reactive materials. Materials such as silicon nitride or tantalum nitride have shown promise in preventing lithium diffusion and reactions with adjacent layers. However, the integration of these barrier layers adds complexity to the fabrication process and may impact the overall performance of the device.

Another strategy focuses on modifying the composition of lithium oxide to enhance its stability. Doping with other elements or creating composite materials can reduce reactivity while maintaining desired electrical properties. For instance, the incorporation of aluminum or yttrium into lithium oxide has been explored to improve its chemical stability and reduce interactions with other circuit materials.

Careful control of processing conditions, including temperature, atmosphere, and exposure time, is crucial in managing material compatibility issues. Low-temperature deposition techniques and rapid thermal processing have been investigated to minimize unwanted reactions during fabrication. Additionally, advanced encapsulation methods are being developed to protect lithium oxide-containing components from environmental factors that could trigger degradation.

Reliability Testing Standards

Reliability testing standards play a crucial role in ensuring the long-term stability and performance of lithium oxide stabilization techniques for integrated circuits. These standards provide a systematic approach to evaluate the robustness and durability of lithium oxide layers under various environmental conditions and operational stresses.

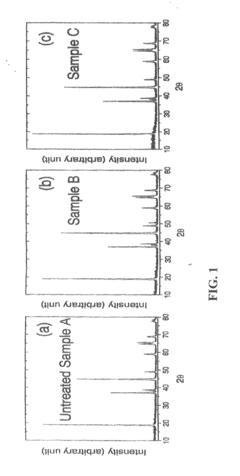

The primary focus of reliability testing for lithium oxide stabilization techniques is to assess the material's resistance to degradation over time. This includes evaluating the oxide layer's ability to maintain its protective properties against lithium diffusion and prevent potential short circuits or device failures. Standard tests typically involve accelerated aging processes, thermal cycling, and electrical stress tests to simulate real-world operating conditions.

One key aspect of reliability testing is the assessment of lithium oxide layer thickness consistency and uniformity across the integrated circuit. Variations in thickness can lead to localized weak points, compromising the overall effectiveness of the stabilization technique. Advanced imaging techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are employed to measure and analyze the oxide layer's morphology and thickness distribution.

Electrical characterization forms another critical component of reliability testing standards. This involves measuring parameters such as leakage current, breakdown voltage, and capacitance-voltage characteristics before and after stress tests. These measurements provide insights into the oxide layer's ability to maintain its insulating properties and prevent lithium ion migration under various operating conditions.

Environmental stress testing is also a fundamental part of reliability standards for lithium oxide stabilization techniques. This includes subjecting the integrated circuits to extreme temperature cycles, high humidity, and mechanical stresses to evaluate the oxide layer's resistance to cracking, delamination, or other forms of physical degradation. The ability of the lithium oxide layer to withstand these environmental challenges is crucial for ensuring long-term device reliability.

Standardized accelerated life testing protocols are employed to predict the long-term performance and reliability of lithium oxide stabilization techniques. These tests typically involve exposing the integrated circuits to elevated temperatures and voltages for extended periods, simulating years of operation in a compressed timeframe. The results of these tests are used to estimate the mean time to failure (MTTF) and other reliability metrics.

Reliability testing standards also encompass statistical analysis methods to interpret test results and establish confidence levels in the performance of lithium oxide stabilization techniques. This includes defining acceptable failure rates, determining sample sizes for testing, and applying statistical models to predict long-term reliability based on accelerated test data.

As the semiconductor industry continues to advance, reliability testing standards for lithium oxide stabilization techniques are evolving to address new challenges. This includes developing more sophisticated test methodologies to evaluate the performance of ultra-thin oxide layers in advanced node technologies and assessing the impact of new manufacturing processes on long-term stability.

The primary focus of reliability testing for lithium oxide stabilization techniques is to assess the material's resistance to degradation over time. This includes evaluating the oxide layer's ability to maintain its protective properties against lithium diffusion and prevent potential short circuits or device failures. Standard tests typically involve accelerated aging processes, thermal cycling, and electrical stress tests to simulate real-world operating conditions.

One key aspect of reliability testing is the assessment of lithium oxide layer thickness consistency and uniformity across the integrated circuit. Variations in thickness can lead to localized weak points, compromising the overall effectiveness of the stabilization technique. Advanced imaging techniques, such as scanning electron microscopy (SEM) and atomic force microscopy (AFM), are employed to measure and analyze the oxide layer's morphology and thickness distribution.

Electrical characterization forms another critical component of reliability testing standards. This involves measuring parameters such as leakage current, breakdown voltage, and capacitance-voltage characteristics before and after stress tests. These measurements provide insights into the oxide layer's ability to maintain its insulating properties and prevent lithium ion migration under various operating conditions.

Environmental stress testing is also a fundamental part of reliability standards for lithium oxide stabilization techniques. This includes subjecting the integrated circuits to extreme temperature cycles, high humidity, and mechanical stresses to evaluate the oxide layer's resistance to cracking, delamination, or other forms of physical degradation. The ability of the lithium oxide layer to withstand these environmental challenges is crucial for ensuring long-term device reliability.

Standardized accelerated life testing protocols are employed to predict the long-term performance and reliability of lithium oxide stabilization techniques. These tests typically involve exposing the integrated circuits to elevated temperatures and voltages for extended periods, simulating years of operation in a compressed timeframe. The results of these tests are used to estimate the mean time to failure (MTTF) and other reliability metrics.

Reliability testing standards also encompass statistical analysis methods to interpret test results and establish confidence levels in the performance of lithium oxide stabilization techniques. This includes defining acceptable failure rates, determining sample sizes for testing, and applying statistical models to predict long-term reliability based on accelerated test data.

As the semiconductor industry continues to advance, reliability testing standards for lithium oxide stabilization techniques are evolving to address new challenges. This includes developing more sophisticated test methodologies to evaluate the performance of ultra-thin oxide layers in advanced node technologies and assessing the impact of new manufacturing processes on long-term stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!