Lithium oxide contribution to smart agriculture sensor technologies

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li2O in AgTech Sensors: Background and Objectives

Lithium oxide (Li2O) has emerged as a promising material in the development of smart agriculture sensor technologies, marking a significant advancement in precision farming practices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of lithium-based compounds in various sensing applications. As the agricultural sector faced increasing challenges related to resource management and environmental sustainability, the need for more sophisticated and accurate sensing technologies became apparent.

The primary objective of incorporating Li2O into AgTech sensors is to enhance the sensitivity, selectivity, and durability of sensing devices used in agricultural environments. These sensors are designed to monitor crucial parameters such as soil moisture, nutrient levels, pH, and various environmental factors that directly impact crop growth and yield. By leveraging the unique properties of lithium oxide, researchers aim to develop sensors that can provide real-time, accurate data to farmers and agricultural professionals, enabling them to make informed decisions about irrigation, fertilization, and pest control.

One of the key trends driving the development of Li2O-based sensors is the growing demand for precision agriculture solutions. As global food demand continues to rise and arable land becomes increasingly scarce, there is a pressing need for technologies that can optimize crop production while minimizing resource consumption. Li2O sensors are expected to play a crucial role in this paradigm shift by offering improved accuracy and reliability in data collection, which is essential for implementing data-driven farming practices.

The technical evolution of Li2O in AgTech sensors has been characterized by continuous improvements in material synthesis, sensor design, and integration with other smart farming technologies. Early research focused on understanding the fundamental properties of lithium oxide and its interactions with various agricultural analytes. This laid the groundwork for the development of prototype sensors that demonstrated enhanced sensitivity to specific soil and plant parameters.

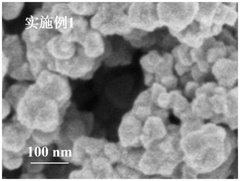

As the technology progressed, researchers began exploring novel fabrication techniques to optimize the performance of Li2O-based sensors. This included the development of nanostructured Li2O materials, which offered increased surface area and improved reactivity, leading to more sensitive and faster-responding sensors. Additionally, efforts were made to integrate Li2O sensors with wireless communication technologies and data analytics platforms, paving the way for comprehensive smart farming systems.

The current state of Li2O in AgTech sensor technologies represents a convergence of materials science, electrochemistry, and agricultural engineering. Researchers are now focusing on addressing key challenges such as long-term stability in harsh agricultural environments, cross-sensitivity to interfering compounds, and scalability of production processes. These efforts aim to transition Li2O-based sensors from laboratory prototypes to commercially viable products that can be widely adopted in the agricultural sector.

The primary objective of incorporating Li2O into AgTech sensors is to enhance the sensitivity, selectivity, and durability of sensing devices used in agricultural environments. These sensors are designed to monitor crucial parameters such as soil moisture, nutrient levels, pH, and various environmental factors that directly impact crop growth and yield. By leveraging the unique properties of lithium oxide, researchers aim to develop sensors that can provide real-time, accurate data to farmers and agricultural professionals, enabling them to make informed decisions about irrigation, fertilization, and pest control.

One of the key trends driving the development of Li2O-based sensors is the growing demand for precision agriculture solutions. As global food demand continues to rise and arable land becomes increasingly scarce, there is a pressing need for technologies that can optimize crop production while minimizing resource consumption. Li2O sensors are expected to play a crucial role in this paradigm shift by offering improved accuracy and reliability in data collection, which is essential for implementing data-driven farming practices.

The technical evolution of Li2O in AgTech sensors has been characterized by continuous improvements in material synthesis, sensor design, and integration with other smart farming technologies. Early research focused on understanding the fundamental properties of lithium oxide and its interactions with various agricultural analytes. This laid the groundwork for the development of prototype sensors that demonstrated enhanced sensitivity to specific soil and plant parameters.

As the technology progressed, researchers began exploring novel fabrication techniques to optimize the performance of Li2O-based sensors. This included the development of nanostructured Li2O materials, which offered increased surface area and improved reactivity, leading to more sensitive and faster-responding sensors. Additionally, efforts were made to integrate Li2O sensors with wireless communication technologies and data analytics platforms, paving the way for comprehensive smart farming systems.

The current state of Li2O in AgTech sensor technologies represents a convergence of materials science, electrochemistry, and agricultural engineering. Researchers are now focusing on addressing key challenges such as long-term stability in harsh agricultural environments, cross-sensitivity to interfering compounds, and scalability of production processes. These efforts aim to transition Li2O-based sensors from laboratory prototypes to commercially viable products that can be widely adopted in the agricultural sector.

Smart Agriculture Market Demand Analysis

The smart agriculture market has been experiencing significant growth in recent years, driven by the increasing global population, rising food demand, and the need for sustainable farming practices. The integration of advanced technologies, including lithium oxide-based sensors, is playing a crucial role in revolutionizing agricultural processes and enhancing productivity.

Market research indicates that the global smart agriculture market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is primarily attributed to the adoption of precision farming techniques, which rely heavily on sensor technologies for data collection and analysis.

The demand for lithium oxide-based sensors in smart agriculture is particularly strong due to their unique properties and versatility. These sensors offer high sensitivity, stability, and reliability in detecting various environmental parameters crucial for crop management. Farmers and agricultural businesses are increasingly recognizing the value of real-time data provided by these sensors in optimizing resource utilization and improving crop yields.

One of the key drivers of market demand is the growing emphasis on water conservation in agriculture. Lithium oxide sensors are being widely employed in soil moisture monitoring systems, enabling precise irrigation scheduling and reducing water waste. This application is especially critical in regions facing water scarcity and drought conditions.

Furthermore, the rising awareness of climate change impacts on agriculture has led to increased demand for weather monitoring systems. Lithium oxide-based sensors are integral components in these systems, providing accurate measurements of temperature, humidity, and atmospheric pressure. This data helps farmers make informed decisions regarding crop selection, planting times, and pest management strategies.

The market for nutrient management solutions in smart agriculture is also expanding rapidly. Lithium oxide sensors are being utilized in soil nutrient analysis systems, allowing farmers to optimize fertilizer application and reduce environmental impact. This trend aligns with the growing consumer preference for sustainably produced food and stricter regulations on agricultural practices.

In the livestock sector, lithium oxide sensors are gaining traction for animal health monitoring applications. These sensors can detect early signs of diseases, monitor vital signs, and track animal behavior, leading to improved herd management and increased productivity.

The adoption of smart agriculture technologies, including lithium oxide sensors, is not limited to large-scale commercial farms. Small and medium-sized farms are also recognizing the benefits of these technologies in improving efficiency and profitability. This trend is expected to drive further market growth and innovation in sensor technologies.

As the smart agriculture market continues to evolve, the demand for more sophisticated and integrated sensor solutions is likely to increase. This presents significant opportunities for further development and application of lithium oxide-based sensor technologies in the agricultural sector.

Market research indicates that the global smart agriculture market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is primarily attributed to the adoption of precision farming techniques, which rely heavily on sensor technologies for data collection and analysis.

The demand for lithium oxide-based sensors in smart agriculture is particularly strong due to their unique properties and versatility. These sensors offer high sensitivity, stability, and reliability in detecting various environmental parameters crucial for crop management. Farmers and agricultural businesses are increasingly recognizing the value of real-time data provided by these sensors in optimizing resource utilization and improving crop yields.

One of the key drivers of market demand is the growing emphasis on water conservation in agriculture. Lithium oxide sensors are being widely employed in soil moisture monitoring systems, enabling precise irrigation scheduling and reducing water waste. This application is especially critical in regions facing water scarcity and drought conditions.

Furthermore, the rising awareness of climate change impacts on agriculture has led to increased demand for weather monitoring systems. Lithium oxide-based sensors are integral components in these systems, providing accurate measurements of temperature, humidity, and atmospheric pressure. This data helps farmers make informed decisions regarding crop selection, planting times, and pest management strategies.

The market for nutrient management solutions in smart agriculture is also expanding rapidly. Lithium oxide sensors are being utilized in soil nutrient analysis systems, allowing farmers to optimize fertilizer application and reduce environmental impact. This trend aligns with the growing consumer preference for sustainably produced food and stricter regulations on agricultural practices.

In the livestock sector, lithium oxide sensors are gaining traction for animal health monitoring applications. These sensors can detect early signs of diseases, monitor vital signs, and track animal behavior, leading to improved herd management and increased productivity.

The adoption of smart agriculture technologies, including lithium oxide sensors, is not limited to large-scale commercial farms. Small and medium-sized farms are also recognizing the benefits of these technologies in improving efficiency and profitability. This trend is expected to drive further market growth and innovation in sensor technologies.

As the smart agriculture market continues to evolve, the demand for more sophisticated and integrated sensor solutions is likely to increase. This presents significant opportunities for further development and application of lithium oxide-based sensor technologies in the agricultural sector.

Current State of Li2O-based Sensor Technologies

Lithium oxide (Li2O) has emerged as a promising material for sensor technologies in smart agriculture, offering unique properties that enhance the capabilities of various sensing devices. The current state of Li2O-based sensor technologies reflects significant advancements in sensitivity, selectivity, and durability, making them increasingly valuable for agricultural applications.

One of the primary areas where Li2O-based sensors have shown remarkable progress is in soil moisture sensing. These sensors utilize the high ionic conductivity of Li2O to accurately measure soil water content, providing farmers with crucial data for irrigation management. The integration of Li2O into capacitive and resistive soil moisture sensors has resulted in improved accuracy and longevity compared to traditional sensor materials.

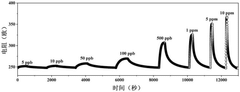

In the realm of gas sensing, Li2O-based sensors have demonstrated exceptional performance in detecting various gases relevant to agriculture. These sensors excel in monitoring atmospheric conditions, including CO2 levels, which is vital for optimizing greenhouse environments and assessing plant health. The high surface area and catalytic properties of Li2O nanostructures contribute to enhanced sensitivity and faster response times in gas detection.

Li2O-based sensors have also made significant strides in pH measurement, a critical parameter for soil and water quality assessment in agriculture. The incorporation of Li2O in ion-selective electrodes has led to more stable and accurate pH sensors, capable of withstanding harsh agricultural environments while maintaining long-term reliability.

Another area of notable progress is in the development of Li2O-based biosensors for detecting plant pathogens and monitoring crop health. These sensors leverage the unique electrochemical properties of Li2O to create highly sensitive platforms for detecting specific biomolecules associated with plant diseases or stress responses.

The current state of Li2O-based sensor technologies also includes advancements in wearable and flexible sensors for plant monitoring. By incorporating Li2O into flexible substrates, researchers have developed sensors that can be directly attached to plant leaves or stems, enabling real-time monitoring of physiological parameters such as water content, temperature, and nutrient levels.

Furthermore, Li2O has shown promise in the development of multi-parameter sensing platforms. These integrated sensor arrays combine multiple Li2O-based sensing elements to simultaneously measure various agricultural parameters, providing a comprehensive view of crop and soil conditions.

While Li2O-based sensors have demonstrated significant potential, challenges remain in scaling up production and ensuring long-term stability in diverse agricultural environments. Ongoing research focuses on optimizing Li2O nanostructures, improving sensor packaging, and developing more robust signal processing algorithms to enhance overall sensor performance and reliability.

One of the primary areas where Li2O-based sensors have shown remarkable progress is in soil moisture sensing. These sensors utilize the high ionic conductivity of Li2O to accurately measure soil water content, providing farmers with crucial data for irrigation management. The integration of Li2O into capacitive and resistive soil moisture sensors has resulted in improved accuracy and longevity compared to traditional sensor materials.

In the realm of gas sensing, Li2O-based sensors have demonstrated exceptional performance in detecting various gases relevant to agriculture. These sensors excel in monitoring atmospheric conditions, including CO2 levels, which is vital for optimizing greenhouse environments and assessing plant health. The high surface area and catalytic properties of Li2O nanostructures contribute to enhanced sensitivity and faster response times in gas detection.

Li2O-based sensors have also made significant strides in pH measurement, a critical parameter for soil and water quality assessment in agriculture. The incorporation of Li2O in ion-selective electrodes has led to more stable and accurate pH sensors, capable of withstanding harsh agricultural environments while maintaining long-term reliability.

Another area of notable progress is in the development of Li2O-based biosensors for detecting plant pathogens and monitoring crop health. These sensors leverage the unique electrochemical properties of Li2O to create highly sensitive platforms for detecting specific biomolecules associated with plant diseases or stress responses.

The current state of Li2O-based sensor technologies also includes advancements in wearable and flexible sensors for plant monitoring. By incorporating Li2O into flexible substrates, researchers have developed sensors that can be directly attached to plant leaves or stems, enabling real-time monitoring of physiological parameters such as water content, temperature, and nutrient levels.

Furthermore, Li2O has shown promise in the development of multi-parameter sensing platforms. These integrated sensor arrays combine multiple Li2O-based sensing elements to simultaneously measure various agricultural parameters, providing a comprehensive view of crop and soil conditions.

While Li2O-based sensors have demonstrated significant potential, challenges remain in scaling up production and ensuring long-term stability in diverse agricultural environments. Ongoing research focuses on optimizing Li2O nanostructures, improving sensor packaging, and developing more robust signal processing algorithms to enhance overall sensor performance and reliability.

Existing Li2O Sensor Solutions for Agriculture

01 Lithium oxide in battery technology

Lithium oxide is widely used in battery technology, particularly in lithium-ion batteries. It serves as a crucial component in the cathode material, contributing to improved battery performance, energy density, and cycle life. The incorporation of lithium oxide in various battery compositions enhances the overall efficiency and stability of energy storage systems.- Lithium oxide in battery technology: Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, capacity, and stability. The incorporation of lithium oxide in battery materials can enhance the overall efficiency and lifespan of rechargeable batteries.

- Synthesis and production methods of lithium oxide: Various methods are employed for the synthesis and production of lithium oxide. These may include chemical reactions, thermal decomposition, or electrochemical processes. The choice of production method can affect the purity, particle size, and morphology of the resulting lithium oxide, which in turn influences its properties and applications.

- Lithium oxide in ceramic and glass applications: Lithium oxide is utilized in ceramic and glass industries as a flux and modifier. It can lower the melting point of glass and improve its chemical durability. In ceramics, lithium oxide can enhance the strength and thermal shock resistance of the final product. Its incorporation in these materials can lead to improved properties and expanded applications.

- Lithium oxide in energy storage systems: Beyond traditional batteries, lithium oxide finds applications in various energy storage systems. It can be used in thermal energy storage, fuel cells, and other advanced energy technologies. The unique properties of lithium oxide make it a valuable component in developing more efficient and sustainable energy storage solutions.

- Lithium oxide in material science and engineering: In material science and engineering, lithium oxide serves as a precursor for the synthesis of other lithium-containing compounds. It is also used in the development of advanced materials with specific properties, such as high-temperature superconductors or specialized optical materials. The versatility of lithium oxide in materials engineering opens up possibilities for innovative applications across various industries.

02 Synthesis and production methods of lithium oxide

Various methods for synthesizing and producing lithium oxide have been developed. These processes often involve chemical reactions, high-temperature treatments, or electrochemical techniques. The synthesis methods aim to control the purity, particle size, and morphology of lithium oxide, which are crucial factors in determining its performance in different applications.Expand Specific Solutions03 Lithium oxide in ceramic and glass manufacturing

Lithium oxide is utilized in the production of ceramics and glasses. It acts as a flux, lowering the melting point of the mixture and improving the workability of the materials. In ceramics, lithium oxide can enhance the strength and thermal shock resistance of the final product. In glass manufacturing, it contributes to the optical properties and durability of the glass.Expand Specific Solutions04 Lithium oxide in nuclear technology

Lithium oxide plays a role in nuclear technology, particularly in fusion reactor research. It is considered as a potential material for tritium breeding blankets in fusion reactors. The compound's ability to produce tritium when bombarded with neutrons makes it valuable in the development of sustainable fusion energy systems.Expand Specific Solutions05 Lithium oxide in environmental applications

Lithium oxide has applications in environmental technologies. It can be used in carbon dioxide capture systems, where it reacts with CO2 to form lithium carbonate. This property makes it potentially useful in reducing greenhouse gas emissions. Additionally, lithium oxide may have applications in water treatment processes and as a component in certain catalytic systems for environmental remediation.Expand Specific Solutions

Key Players in AgTech Sensor Industry

The lithium oxide contribution to smart agriculture sensor technologies is in an early development stage, with a growing market potential as the agricultural sector increasingly adopts IoT and precision farming techniques. The technology's maturity is still evolving, with major players like Sumitomo Chemical, LG Energy Solution, and Solvay SA leading research efforts. These companies are leveraging their expertise in battery technologies and chemical engineering to develop innovative sensor solutions. Emerging players such as SK On and Toda Kogyo Corp are also making significant strides in this field, focusing on high-performance materials for sensor applications. The competitive landscape is characterized by a mix of established chemical conglomerates and specialized technology firms, indicating a dynamic and rapidly evolving market.

Sensirion AG

Technical Solution: Sensirion AG has developed advanced lithium oxide-based sensors for smart agriculture applications. Their technology utilizes miniaturized lithium oxide membranes to detect soil moisture, nutrient levels, and pH with high precision. The sensors employ a unique electrochemical sensing principle, where lithium oxide acts as both an electrolyte and a sensing material. This allows for real-time, in-situ measurements of key soil parameters[1]. The company has also integrated these sensors with wireless communication modules, enabling seamless data transmission to cloud-based analytics platforms for comprehensive farm management[2]. Sensirion's sensors boast low power consumption and long-term stability, making them suitable for extended deployment in agricultural fields[3].

Strengths: High precision, real-time measurements, and low power consumption. Weaknesses: May require periodic calibration and could be sensitive to extreme environmental conditions.

Rural Development Administration

Technical Solution: The Rural Development Administration has pioneered the use of lithium oxide-based sensors in smart agriculture systems. Their approach involves embedding lithium oxide nanoparticles into polymer matrices to create flexible, large-area sensor arrays. These arrays can be deployed across vast agricultural lands to monitor soil conditions, crop health, and environmental factors. The lithium oxide sensors are particularly effective in detecting minute changes in soil moisture and nutrient levels, enabling precise irrigation and fertilization strategies[4]. The administration has also developed AI-powered data analysis tools that interpret sensor data to provide actionable insights for farmers, optimizing resource use and crop yields[5].

Strengths: Large-scale deployment capability and integration with AI for data analysis. Weaknesses: Higher initial implementation costs and potential complexity for small-scale farmers.

Core Innovations in Li2O Sensor Technologies

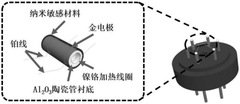

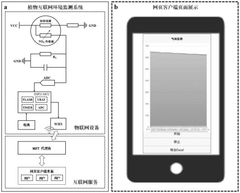

Nitrogen oxide sensor based on Ag2Te/CeO2 sensitive material, preparation method and internet environment monitoring system

PatentPendingCN119804576A

Innovation

- Ag2Te/CeO2 is used as the sensitive material, and a nitrogen oxide sensor is constructed by coating the Al2O3 ceramic tube substrate and combining a nickel-chromium heating coil. Sensitive materials are prepared by hydrothermal method and room temperature solution method to reduce the impact of H2O adsorption.

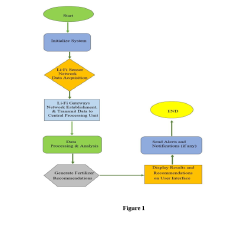

Li-fi enabled smart agriculture system with real time data for farmers

PatentPendingIN202411039196A

Innovation

- A Li-Fi-enhanced smart agriculture system integrating advanced sensor technologies with Li-Fi communication for real-time data transmission, AI, and IoT, providing precise monitoring and control of soil conditions and environmental factors, and generating tailored recommendations for fertilization, irrigation, and crop management.

Environmental Impact of Li2O-based Sensors

The environmental impact of Li2O-based sensors in smart agriculture is a critical consideration as these technologies become more prevalent. These sensors offer significant benefits in terms of precision farming and resource management, but their production and disposal can have notable environmental implications.

The manufacturing process of Li2O-based sensors involves the extraction and processing of lithium, which can lead to habitat disruption and water pollution in mining areas. The energy-intensive production of these sensors also contributes to greenhouse gas emissions. However, advancements in manufacturing techniques are gradually reducing the environmental footprint of sensor production.

In agricultural applications, Li2O-based sensors contribute to more efficient use of resources such as water and fertilizers. By providing accurate, real-time data on soil moisture, nutrient levels, and crop health, these sensors enable farmers to optimize irrigation and fertilizer application. This precision approach reduces water waste and minimizes the runoff of excess nutrients, which can otherwise lead to eutrophication in nearby water bodies.

The long lifespan and durability of Li2O-based sensors contribute to their environmental sustainability. Many of these sensors can operate effectively for several years, reducing the need for frequent replacements and the associated waste. However, the eventual disposal of these sensors presents environmental challenges due to the presence of lithium and other electronic components.

Proper recycling and disposal protocols are essential to mitigate the end-of-life environmental impact of Li2O-based sensors. Recycling facilities can recover valuable materials, including lithium, reducing the demand for new raw material extraction. However, the current recycling infrastructure for these specialized sensors is limited in many regions, highlighting the need for improved waste management strategies.

The use of Li2O-based sensors in smart agriculture also indirectly impacts the environment through changes in farming practices. By enabling more efficient resource use, these sensors can lead to reduced carbon emissions from agricultural machinery and decreased use of chemical inputs. This contributes to overall improvements in soil health and biodiversity on farmlands.

As the adoption of Li2O-based sensors in agriculture continues to grow, ongoing research is focused on further improving their environmental performance. This includes developing more eco-friendly manufacturing processes, enhancing sensor longevity, and designing sensors with easier recyclability. These efforts aim to maximize the environmental benefits of smart agriculture while minimizing the negative impacts associated with sensor production and disposal.

The manufacturing process of Li2O-based sensors involves the extraction and processing of lithium, which can lead to habitat disruption and water pollution in mining areas. The energy-intensive production of these sensors also contributes to greenhouse gas emissions. However, advancements in manufacturing techniques are gradually reducing the environmental footprint of sensor production.

In agricultural applications, Li2O-based sensors contribute to more efficient use of resources such as water and fertilizers. By providing accurate, real-time data on soil moisture, nutrient levels, and crop health, these sensors enable farmers to optimize irrigation and fertilizer application. This precision approach reduces water waste and minimizes the runoff of excess nutrients, which can otherwise lead to eutrophication in nearby water bodies.

The long lifespan and durability of Li2O-based sensors contribute to their environmental sustainability. Many of these sensors can operate effectively for several years, reducing the need for frequent replacements and the associated waste. However, the eventual disposal of these sensors presents environmental challenges due to the presence of lithium and other electronic components.

Proper recycling and disposal protocols are essential to mitigate the end-of-life environmental impact of Li2O-based sensors. Recycling facilities can recover valuable materials, including lithium, reducing the demand for new raw material extraction. However, the current recycling infrastructure for these specialized sensors is limited in many regions, highlighting the need for improved waste management strategies.

The use of Li2O-based sensors in smart agriculture also indirectly impacts the environment through changes in farming practices. By enabling more efficient resource use, these sensors can lead to reduced carbon emissions from agricultural machinery and decreased use of chemical inputs. This contributes to overall improvements in soil health and biodiversity on farmlands.

As the adoption of Li2O-based sensors in agriculture continues to grow, ongoing research is focused on further improving their environmental performance. This includes developing more eco-friendly manufacturing processes, enhancing sensor longevity, and designing sensors with easier recyclability. These efforts aim to maximize the environmental benefits of smart agriculture while minimizing the negative impacts associated with sensor production and disposal.

Standardization and Certification Processes

The standardization and certification processes for lithium oxide-based smart agriculture sensor technologies are crucial for ensuring reliability, interoperability, and widespread adoption. These processes involve multiple stakeholders, including industry leaders, regulatory bodies, and research institutions.

International organizations such as ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) play a pivotal role in developing global standards for sensor technologies. They have established technical committees focused on agricultural electronics and IoT devices, which are working towards creating unified standards for lithium oxide sensors in smart agriculture applications.

The certification process typically involves rigorous testing of sensor performance, durability, and safety. Accredited laboratories conduct these tests to verify compliance with established standards. For lithium oxide sensors in agriculture, key parameters such as sensitivity, selectivity, response time, and long-term stability are evaluated under various environmental conditions.

Regulatory bodies in different countries also contribute to the standardization process. In the United States, the FDA and USDA have guidelines for agricultural sensors that come into contact with food products. The European Union has established the CE marking system, which includes specific requirements for electronic devices used in agriculture.

Industry consortia and alliances, such as the AgGateway and the Industrial Internet Consortium, are actively working on developing best practices and interoperability standards for smart agriculture technologies. These efforts aim to ensure seamless integration of lithium oxide sensors with other components of smart farming systems.

The standardization process also addresses data formats and communication protocols. This is essential for enabling data exchange between different sensor systems and agricultural management platforms. Efforts are underway to establish common data models and APIs that facilitate the integration of lithium oxide sensor data with big data analytics and decision support systems in agriculture.

As the technology evolves, standards and certification processes are continuously updated. This iterative process involves feedback from early adopters, research findings, and technological advancements. Regular revisions ensure that standards remain relevant and continue to drive innovation in lithium oxide sensor technologies for smart agriculture.

Certification programs are being developed to validate the performance and reliability of lithium oxide sensors in specific agricultural applications. These programs aim to provide farmers and agribusinesses with confidence in the quality and effectiveness of sensor-based solutions, ultimately accelerating the adoption of smart agriculture practices.

International organizations such as ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) play a pivotal role in developing global standards for sensor technologies. They have established technical committees focused on agricultural electronics and IoT devices, which are working towards creating unified standards for lithium oxide sensors in smart agriculture applications.

The certification process typically involves rigorous testing of sensor performance, durability, and safety. Accredited laboratories conduct these tests to verify compliance with established standards. For lithium oxide sensors in agriculture, key parameters such as sensitivity, selectivity, response time, and long-term stability are evaluated under various environmental conditions.

Regulatory bodies in different countries also contribute to the standardization process. In the United States, the FDA and USDA have guidelines for agricultural sensors that come into contact with food products. The European Union has established the CE marking system, which includes specific requirements for electronic devices used in agriculture.

Industry consortia and alliances, such as the AgGateway and the Industrial Internet Consortium, are actively working on developing best practices and interoperability standards for smart agriculture technologies. These efforts aim to ensure seamless integration of lithium oxide sensors with other components of smart farming systems.

The standardization process also addresses data formats and communication protocols. This is essential for enabling data exchange between different sensor systems and agricultural management platforms. Efforts are underway to establish common data models and APIs that facilitate the integration of lithium oxide sensor data with big data analytics and decision support systems in agriculture.

As the technology evolves, standards and certification processes are continuously updated. This iterative process involves feedback from early adopters, research findings, and technological advancements. Regular revisions ensure that standards remain relevant and continue to drive innovation in lithium oxide sensor technologies for smart agriculture.

Certification programs are being developed to validate the performance and reliability of lithium oxide sensors in specific agricultural applications. These programs aim to provide farmers and agribusinesses with confidence in the quality and effectiveness of sensor-based solutions, ultimately accelerating the adoption of smart agriculture practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!