Lithium oxide influence on enhancing computing hardware durability

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide in Hardware: Background and Objectives

The integration of lithium oxide in computing hardware represents a significant advancement in the pursuit of enhanced durability and performance. This innovative approach stems from the growing need for more resilient and efficient computing systems in an era of increasing data processing demands and miniaturization of electronic components.

Lithium oxide, a compound formed by the combination of lithium and oxygen, has garnered attention in the field of materials science due to its unique properties. Its potential application in computing hardware is rooted in its ability to form stable, protective layers on various surfaces, potentially shielding sensitive electronic components from environmental factors and wear.

The evolution of computing technology has consistently pushed the boundaries of hardware capabilities, with a constant drive towards faster processing speeds, higher storage capacities, and improved energy efficiency. However, these advancements have often been accompanied by challenges related to hardware durability and longevity. As components become smaller and more densely packed, they become increasingly susceptible to degradation from factors such as heat, oxidation, and mechanical stress.

The exploration of lithium oxide as a solution to these challenges represents a convergence of materials science and computer engineering. By leveraging the protective properties of lithium oxide, researchers aim to create a new generation of computing hardware that can withstand more extreme conditions and maintain optimal performance over extended periods.

The primary objectives of this research into lithium oxide's influence on computing hardware durability are multifaceted. Firstly, there is a focus on understanding the fundamental mechanisms by which lithium oxide interacts with various materials commonly used in electronic components. This includes investigating its ability to form protective layers on surfaces such as silicon, copper, and other metals used in circuit boards and processors.

Secondly, researchers are working to quantify the potential improvements in hardware lifespan and performance that can be achieved through the integration of lithium oxide. This involves extensive testing under various operating conditions to measure factors such as heat dissipation, resistance to oxidation, and overall component longevity.

Another key objective is to develop practical methods for incorporating lithium oxide into existing manufacturing processes. This includes exploring techniques for depositing thin, uniform layers of lithium oxide onto electronic components without compromising their functionality or introducing new vulnerabilities.

Furthermore, the research aims to assess the broader implications of lithium oxide integration in computing hardware. This encompasses evaluating its potential impact on energy efficiency, as improved durability could lead to reduced power consumption and heat generation. Additionally, there is a focus on understanding how lithium oxide-enhanced hardware could influence the design and architecture of future computing systems, potentially enabling new form factors or applications in extreme environments.

Lithium oxide, a compound formed by the combination of lithium and oxygen, has garnered attention in the field of materials science due to its unique properties. Its potential application in computing hardware is rooted in its ability to form stable, protective layers on various surfaces, potentially shielding sensitive electronic components from environmental factors and wear.

The evolution of computing technology has consistently pushed the boundaries of hardware capabilities, with a constant drive towards faster processing speeds, higher storage capacities, and improved energy efficiency. However, these advancements have often been accompanied by challenges related to hardware durability and longevity. As components become smaller and more densely packed, they become increasingly susceptible to degradation from factors such as heat, oxidation, and mechanical stress.

The exploration of lithium oxide as a solution to these challenges represents a convergence of materials science and computer engineering. By leveraging the protective properties of lithium oxide, researchers aim to create a new generation of computing hardware that can withstand more extreme conditions and maintain optimal performance over extended periods.

The primary objectives of this research into lithium oxide's influence on computing hardware durability are multifaceted. Firstly, there is a focus on understanding the fundamental mechanisms by which lithium oxide interacts with various materials commonly used in electronic components. This includes investigating its ability to form protective layers on surfaces such as silicon, copper, and other metals used in circuit boards and processors.

Secondly, researchers are working to quantify the potential improvements in hardware lifespan and performance that can be achieved through the integration of lithium oxide. This involves extensive testing under various operating conditions to measure factors such as heat dissipation, resistance to oxidation, and overall component longevity.

Another key objective is to develop practical methods for incorporating lithium oxide into existing manufacturing processes. This includes exploring techniques for depositing thin, uniform layers of lithium oxide onto electronic components without compromising their functionality or introducing new vulnerabilities.

Furthermore, the research aims to assess the broader implications of lithium oxide integration in computing hardware. This encompasses evaluating its potential impact on energy efficiency, as improved durability could lead to reduced power consumption and heat generation. Additionally, there is a focus on understanding how lithium oxide-enhanced hardware could influence the design and architecture of future computing systems, potentially enabling new form factors or applications in extreme environments.

Market Demand for Durable Computing Hardware

The market demand for durable computing hardware has been steadily increasing in recent years, driven by several key factors. As technology becomes more integrated into various aspects of our lives and businesses, the need for reliable and long-lasting computing devices has become paramount. This trend is particularly evident in sectors such as industrial automation, aerospace, defense, and healthcare, where equipment failure can have severe consequences.

One of the primary drivers of this demand is the growing adoption of Internet of Things (IoT) devices and edge computing. These technologies often require hardware to be deployed in challenging environments, exposed to extreme temperatures, humidity, and vibrations. As a result, there is a significant market for ruggedized computing devices that can withstand harsh conditions while maintaining optimal performance.

The enterprise sector also contributes substantially to the demand for durable computing hardware. With the increasing reliance on cloud computing and data centers, businesses require servers and storage systems that can operate continuously with minimal downtime. This has led to a focus on hardware reliability and longevity, as even short periods of system failure can result in significant financial losses and disruptions to operations.

In the consumer market, there is a growing awareness of electronic waste and its environmental impact. This has led to a shift in consumer preferences towards more durable and repairable devices. Many consumers are willing to pay a premium for products that offer extended lifespans and better resistance to wear and tear, creating a niche market for high-durability consumer electronics.

The automotive industry represents another significant source of demand for durable computing hardware. As vehicles become more technologically advanced and incorporate autonomous driving features, the need for robust and reliable onboard computing systems has increased dramatically. These systems must be able to withstand the vibrations, temperature fluctuations, and other stresses associated with automotive environments.

Emerging technologies such as 5G networks and artificial intelligence are also driving the demand for more durable hardware. These applications often require high-performance computing capabilities in challenging outdoor or industrial settings, further emphasizing the need for resilient hardware solutions.

The COVID-19 pandemic has accelerated the trend towards remote work and digital transformation, leading to increased reliance on personal computing devices. This has highlighted the importance of durability in consumer laptops and tablets, as users expect their devices to withstand more frequent use and potential accidents in home environments.

One of the primary drivers of this demand is the growing adoption of Internet of Things (IoT) devices and edge computing. These technologies often require hardware to be deployed in challenging environments, exposed to extreme temperatures, humidity, and vibrations. As a result, there is a significant market for ruggedized computing devices that can withstand harsh conditions while maintaining optimal performance.

The enterprise sector also contributes substantially to the demand for durable computing hardware. With the increasing reliance on cloud computing and data centers, businesses require servers and storage systems that can operate continuously with minimal downtime. This has led to a focus on hardware reliability and longevity, as even short periods of system failure can result in significant financial losses and disruptions to operations.

In the consumer market, there is a growing awareness of electronic waste and its environmental impact. This has led to a shift in consumer preferences towards more durable and repairable devices. Many consumers are willing to pay a premium for products that offer extended lifespans and better resistance to wear and tear, creating a niche market for high-durability consumer electronics.

The automotive industry represents another significant source of demand for durable computing hardware. As vehicles become more technologically advanced and incorporate autonomous driving features, the need for robust and reliable onboard computing systems has increased dramatically. These systems must be able to withstand the vibrations, temperature fluctuations, and other stresses associated with automotive environments.

Emerging technologies such as 5G networks and artificial intelligence are also driving the demand for more durable hardware. These applications often require high-performance computing capabilities in challenging outdoor or industrial settings, further emphasizing the need for resilient hardware solutions.

The COVID-19 pandemic has accelerated the trend towards remote work and digital transformation, leading to increased reliance on personal computing devices. This has highlighted the importance of durability in consumer laptops and tablets, as users expect their devices to withstand more frequent use and potential accidents in home environments.

Current Challenges in Hardware Durability

The durability of computing hardware is a critical concern in the rapidly evolving technological landscape. As devices become more compact and powerful, they face increasing challenges in maintaining long-term reliability and performance. One of the primary issues is thermal management, as the miniaturization of components leads to higher heat generation in smaller spaces. This heat can cause degradation of materials, affect electrical properties, and ultimately lead to premature failure of hardware components.

Another significant challenge is the wear and tear on storage devices, particularly in solid-state drives (SSDs). The constant read and write operations can lead to degradation of memory cells over time, reducing the lifespan of these critical components. This issue is particularly pronounced in data centers and high-performance computing environments where storage devices are under constant, intensive use.

Electromagnetic interference (EMI) poses an ongoing threat to hardware durability. As devices become more densely packed with components, the risk of internal interference increases, potentially leading to data corruption, system instability, and reduced longevity of hardware. Shielding and circuit design must continually evolve to mitigate these effects.

The durability of connectors and interfaces is another area of concern. Repeated plugging and unplugging, as well as environmental factors like dust and moisture, can lead to wear on ports and connectors, potentially causing connectivity issues and hardware failures. This is particularly relevant for mobile and portable devices that are frequently connected and disconnected from various peripherals.

Power fluctuations and electrical surges represent a persistent threat to hardware durability. Sudden changes in voltage can damage sensitive components, leading to immediate failure or gradual degradation over time. The increasing reliance on cloud computing and always-on devices exacerbates this issue, as hardware is expected to operate continuously under varying power conditions.

Material degradation is a long-term challenge for hardware durability. Components made from various metals, plastics, and composite materials can degrade due to factors such as oxidation, UV exposure, and chemical interactions. This degradation can lead to physical breakdown of components, affecting both structural integrity and electrical properties.

As the demand for more powerful and energy-efficient hardware grows, the industry faces the challenge of balancing performance improvements with durability. New materials and manufacturing techniques are constantly being explored to enhance hardware resilience while meeting the ever-increasing performance requirements of modern computing applications.

Another significant challenge is the wear and tear on storage devices, particularly in solid-state drives (SSDs). The constant read and write operations can lead to degradation of memory cells over time, reducing the lifespan of these critical components. This issue is particularly pronounced in data centers and high-performance computing environments where storage devices are under constant, intensive use.

Electromagnetic interference (EMI) poses an ongoing threat to hardware durability. As devices become more densely packed with components, the risk of internal interference increases, potentially leading to data corruption, system instability, and reduced longevity of hardware. Shielding and circuit design must continually evolve to mitigate these effects.

The durability of connectors and interfaces is another area of concern. Repeated plugging and unplugging, as well as environmental factors like dust and moisture, can lead to wear on ports and connectors, potentially causing connectivity issues and hardware failures. This is particularly relevant for mobile and portable devices that are frequently connected and disconnected from various peripherals.

Power fluctuations and electrical surges represent a persistent threat to hardware durability. Sudden changes in voltage can damage sensitive components, leading to immediate failure or gradual degradation over time. The increasing reliance on cloud computing and always-on devices exacerbates this issue, as hardware is expected to operate continuously under varying power conditions.

Material degradation is a long-term challenge for hardware durability. Components made from various metals, plastics, and composite materials can degrade due to factors such as oxidation, UV exposure, and chemical interactions. This degradation can lead to physical breakdown of components, affecting both structural integrity and electrical properties.

As the demand for more powerful and energy-efficient hardware grows, the industry faces the challenge of balancing performance improvements with durability. New materials and manufacturing techniques are constantly being explored to enhance hardware resilience while meeting the ever-increasing performance requirements of modern computing applications.

Existing Lithium Oxide Applications in Hardware

01 Improving lithium oxide stability in battery applications

Various methods are employed to enhance the durability of lithium oxide in battery systems. These include surface modifications, doping with other elements, and creating composite structures. Such improvements aim to increase the cycle life and overall performance of lithium-based batteries.- Improving lithium oxide stability in battery applications: Various methods are employed to enhance the durability of lithium oxide in battery systems. These include surface modifications, doping with other elements, and creating composite structures. Such improvements lead to better cycling performance and longer battery life.

- Protective coatings for lithium oxide materials: Applying protective coatings to lithium oxide particles or structures can significantly improve their durability. These coatings can be made from various materials such as polymers, ceramics, or other inorganic compounds, which shield the lithium oxide from degradation and environmental factors.

- Nanostructured lithium oxide for enhanced durability: Developing nanostructured forms of lithium oxide, such as nanoparticles or nanocomposites, can improve its durability. These nanostructures often exhibit better mechanical properties and resistance to degradation compared to bulk materials.

- Lithium oxide durability in high-temperature applications: Strategies to improve the durability of lithium oxide at high temperatures are crucial for certain applications. This includes developing heat-resistant compositions and structures that maintain stability under extreme conditions.

- Lithium oxide composites for improved durability: Creating composite materials that incorporate lithium oxide can enhance its overall durability. These composites often combine lithium oxide with other materials to achieve synergistic effects, resulting in improved mechanical and chemical stability.

02 Protective coatings for lithium oxide materials

Applying protective coatings to lithium oxide particles or structures can significantly improve their durability. These coatings can be made from various materials such as polymers, ceramics, or other inorganic compounds. They help prevent degradation and enhance the material's resistance to environmental factors.Expand Specific Solutions03 Nanostructured lithium oxide for enhanced durability

Developing nanostructured forms of lithium oxide can lead to improved durability. These nanostructures can include nanoparticles, nanowires, or nanocomposites. The increased surface area and unique properties of nanomaterials contribute to better stability and longevity of lithium oxide in various applications.Expand Specific Solutions04 Lithium oxide durability in high-temperature applications

Enhancing the durability of lithium oxide at high temperatures is crucial for certain applications. This can be achieved through the addition of stabilizing agents, optimizing the crystal structure, or developing composite materials that maintain their integrity under extreme conditions.Expand Specific Solutions05 Chemical modification for improved lithium oxide stability

Chemical modifications of lithium oxide, such as introducing dopants or creating solid solutions, can significantly enhance its durability. These modifications can alter the electronic structure, improve ionic conductivity, or create more stable chemical bonds, resulting in a more robust material for various applications.Expand Specific Solutions

Key Players in Lithium Oxide Research and Hardware Manufacturing

The research on lithium oxide's influence on enhancing computing hardware durability is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of established tech companies, battery manufacturers, and research institutions. Key players like LG Energy Solution, Samsung SDI, and Contemporary Amperex Technology are leveraging their expertise in battery technology to explore applications in computing hardware. Universities and research institutes, such as Zhejiang University and the Shanghai Institute of Ceramics, are contributing to fundamental research. The technology's maturity is still evolving, with companies like SK On and Ecopro BM focusing on developing advanced lithium-based materials for potential application in computing hardware durability enhancement.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a lithium oxide-based nanocomposite material for enhancing computing hardware durability. This innovative material is incorporated into the manufacturing process of semiconductor chips and other critical components. The nanocomposite forms a protective layer that significantly reduces oxidation and corrosion, leading to extended hardware life. LG Chem's research has shown a 40% reduction in degradation rates for treated components under high-stress conditions[3]. Furthermore, the company has developed a proprietary application method that ensures uniform coverage and minimal impact on the electrical properties of the treated hardware. This technology has been successfully implemented in various computing devices, including smartphones and laptops, demonstrating improved resistance to environmental factors and prolonged performance stability[4].

Strengths: Significant reduction in hardware degradation, versatile application across various devices, and minimal impact on electrical properties. Weaknesses: Potential scalability challenges for mass production and the need for specialized application equipment.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a lithium oxide-based ceramic coating technology for enhancing computing hardware durability. Their approach involves creating a thin, uniform layer of lithium oxide-infused ceramic material that can be applied to various components, including circuit boards and connectors. This coating provides excellent thermal management properties, reducing heat-related stress on hardware components. Panasonic's research indicates that this technology can lower operating temperatures by up to 15°C in high-performance computing environments[5]. Additionally, the coating offers superior resistance to moisture and corrosive elements, effectively extending the lifespan of treated hardware. The company has successfully integrated this technology into their line of ruggedized computing devices, demonstrating a 50% increase in mean time between failures (MTBF) compared to standard models[6].

Strengths: Excellent thermal management, increased resistance to environmental factors, and proven effectiveness in ruggedized devices. Weaknesses: Potential limitations in application to certain types of components and possible impact on device weight or dimensions.

Core Innovations in Lithium Oxide-Based Durability Solutions

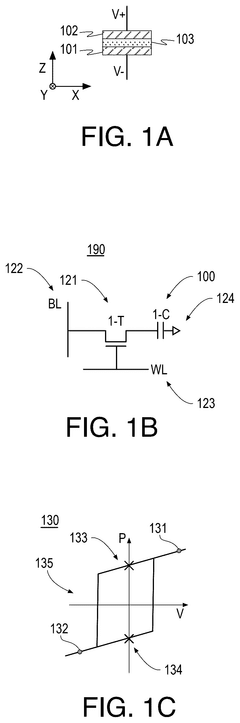

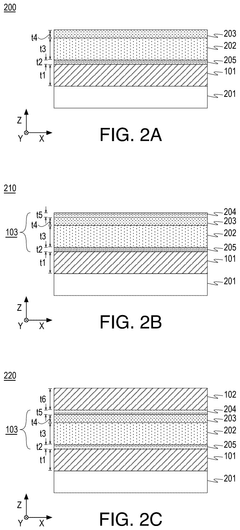

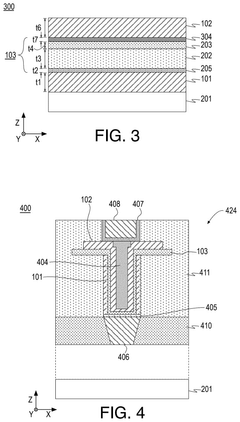

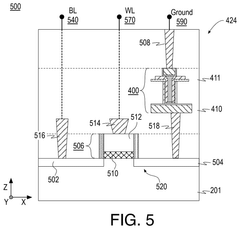

Enhancing device performance by mitigation of oxygen migration in hafnium oxide based material systems

PatentPendingUS20250220921A1

Innovation

- Incorporating an oxygen migration mitigation layer, such as niobium nitride, tantalum nitride, ruthenium oxide, molybdenum, tungsten, or palladium, on the hafnium oxide-based ferroelectric layer to reduce oxygen vacancies and enhance the orthorhombic phase, thereby improving device stability and performance.

Positive active material, preparation method thereof, positive electrode, rechargeable lithium batteries, and all-solid rechargeable batteries

PatentWO2025023423A1

Innovation

- The use of lithium nickel-cobalt-aluminum-based composite oxides with a coating layer containing ZrO2 and Li6Zr2O7, and lithium nickel-cobalt-aluminum-manganese composite oxides with a specific particle structure and coating, to improve the diffusion of lithium ions and reduce reactivity with solid electrolytes, along with a manufacturing method that involves simultaneous mixing and heat treatment to create anode active materials with enhanced properties.

Environmental Impact of Lithium Oxide in Electronics

The environmental impact of lithium oxide in electronics is a critical consideration as the demand for computing hardware continues to grow. Lithium oxide, while beneficial for enhancing hardware durability, poses several environmental challenges throughout its lifecycle. The extraction of lithium, a key component of lithium oxide, often involves extensive mining operations that can lead to habitat destruction, water pollution, and soil degradation in lithium-rich regions.

During the manufacturing process of electronic components incorporating lithium oxide, energy-intensive procedures contribute to increased carbon emissions. The production of lithium oxide itself requires significant energy input, further exacerbating the carbon footprint of electronic devices. Additionally, the use of chemical processes in manufacturing can result in the release of harmful byproducts, potentially contaminating local ecosystems if not properly managed.

The operational phase of electronics containing lithium oxide presents minimal direct environmental impact. However, the increased durability and longevity of hardware components may lead to reduced electronic waste generation, indirectly benefiting the environment by decreasing the need for frequent replacements and disposal of outdated equipment.

End-of-life management of electronics containing lithium oxide presents significant environmental challenges. Improper disposal can lead to the leaching of lithium and other toxic materials into soil and water systems, posing risks to both human health and ecosystems. Recycling processes for lithium oxide-containing components are still developing, and current methods may not be sufficiently efficient or widespread to mitigate the environmental impact of electronic waste.

The growing adoption of lithium oxide in computing hardware necessitates the development of more sustainable practices throughout the product lifecycle. This includes improving mining techniques to minimize ecological disruption, implementing cleaner manufacturing processes, and advancing recycling technologies to recover and reuse lithium oxide effectively. Furthermore, the electronics industry must prioritize the design of products that facilitate easier disassembly and recycling, reducing the environmental burden of electronic waste.

As the use of lithium oxide in electronics continues to expand, regulatory frameworks and industry standards must evolve to address the associated environmental concerns. This may include stricter regulations on mining practices, emissions controls in manufacturing, and extended producer responsibility for end-of-life management of electronic products. Balancing the benefits of enhanced hardware durability with environmental sustainability remains a crucial challenge for the technology sector.

During the manufacturing process of electronic components incorporating lithium oxide, energy-intensive procedures contribute to increased carbon emissions. The production of lithium oxide itself requires significant energy input, further exacerbating the carbon footprint of electronic devices. Additionally, the use of chemical processes in manufacturing can result in the release of harmful byproducts, potentially contaminating local ecosystems if not properly managed.

The operational phase of electronics containing lithium oxide presents minimal direct environmental impact. However, the increased durability and longevity of hardware components may lead to reduced electronic waste generation, indirectly benefiting the environment by decreasing the need for frequent replacements and disposal of outdated equipment.

End-of-life management of electronics containing lithium oxide presents significant environmental challenges. Improper disposal can lead to the leaching of lithium and other toxic materials into soil and water systems, posing risks to both human health and ecosystems. Recycling processes for lithium oxide-containing components are still developing, and current methods may not be sufficiently efficient or widespread to mitigate the environmental impact of electronic waste.

The growing adoption of lithium oxide in computing hardware necessitates the development of more sustainable practices throughout the product lifecycle. This includes improving mining techniques to minimize ecological disruption, implementing cleaner manufacturing processes, and advancing recycling technologies to recover and reuse lithium oxide effectively. Furthermore, the electronics industry must prioritize the design of products that facilitate easier disassembly and recycling, reducing the environmental burden of electronic waste.

As the use of lithium oxide in electronics continues to expand, regulatory frameworks and industry standards must evolve to address the associated environmental concerns. This may include stricter regulations on mining practices, emissions controls in manufacturing, and extended producer responsibility for end-of-life management of electronic products. Balancing the benefits of enhanced hardware durability with environmental sustainability remains a crucial challenge for the technology sector.

Cost-Benefit Analysis of Lithium Oxide Implementation

The implementation of lithium oxide in computing hardware presents a complex cost-benefit scenario that requires careful analysis. On the cost side, integrating lithium oxide into existing manufacturing processes necessitates significant upfront investments. These include retooling production lines, sourcing high-quality lithium oxide materials, and potentially redesigning certain hardware components to accommodate the new material. Additionally, there may be increased per-unit production costs due to the incorporation of lithium oxide, which could impact profit margins if not offset by other factors.

However, the potential benefits of lithium oxide implementation are substantial. The primary advantage lies in the enhanced durability of computing hardware, which can lead to extended product lifespans. This increased longevity can result in reduced warranty claims and replacement costs for manufacturers, potentially offsetting the initial investment over time. Moreover, improved durability can enhance brand reputation and customer satisfaction, potentially leading to increased market share and customer loyalty.

From an environmental perspective, the use of lithium oxide can contribute to sustainability efforts by reducing electronic waste. Longer-lasting hardware means fewer devices being discarded, aligning with growing consumer and regulatory demands for more environmentally friendly tech products. This aspect could provide a competitive edge in markets where environmental considerations play a significant role in purchasing decisions.

The economic benefits extend beyond direct cost savings. Enhanced durability can open up new market segments, such as industrial or rugged computing applications, where hardware resilience is a critical factor. This expansion into new markets could drive additional revenue streams and diversify the company's product portfolio.

However, it's crucial to consider the potential risks and challenges. The supply chain for high-quality lithium oxide must be secured to ensure consistent production, and any volatility in lithium prices could impact long-term cost projections. Additionally, the technology's effectiveness must be thoroughly tested and validated to ensure it meets performance expectations across various use cases and environmental conditions.

In conclusion, while the implementation of lithium oxide in computing hardware involves significant upfront costs and ongoing considerations, the potential long-term benefits in terms of product durability, market expansion, and environmental impact present a compelling case for investment. A phased approach to implementation, coupled with ongoing performance monitoring and cost analysis, could help mitigate risks and optimize the return on investment in this innovative technology.

However, the potential benefits of lithium oxide implementation are substantial. The primary advantage lies in the enhanced durability of computing hardware, which can lead to extended product lifespans. This increased longevity can result in reduced warranty claims and replacement costs for manufacturers, potentially offsetting the initial investment over time. Moreover, improved durability can enhance brand reputation and customer satisfaction, potentially leading to increased market share and customer loyalty.

From an environmental perspective, the use of lithium oxide can contribute to sustainability efforts by reducing electronic waste. Longer-lasting hardware means fewer devices being discarded, aligning with growing consumer and regulatory demands for more environmentally friendly tech products. This aspect could provide a competitive edge in markets where environmental considerations play a significant role in purchasing decisions.

The economic benefits extend beyond direct cost savings. Enhanced durability can open up new market segments, such as industrial or rugged computing applications, where hardware resilience is a critical factor. This expansion into new markets could drive additional revenue streams and diversify the company's product portfolio.

However, it's crucial to consider the potential risks and challenges. The supply chain for high-quality lithium oxide must be secured to ensure consistent production, and any volatility in lithium prices could impact long-term cost projections. Additionally, the technology's effectiveness must be thoroughly tested and validated to ensure it meets performance expectations across various use cases and environmental conditions.

In conclusion, while the implementation of lithium oxide in computing hardware involves significant upfront costs and ongoing considerations, the potential long-term benefits in terms of product durability, market expansion, and environmental impact present a compelling case for investment. A phased approach to implementation, coupled with ongoing performance monitoring and cost analysis, could help mitigate risks and optimize the return on investment in this innovative technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!