Lithium oxide use in increasing drone battery efficiency

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide Battery Tech Evolution and Goals

The evolution of lithium oxide battery technology for drones has been marked by significant advancements aimed at increasing energy density, reducing weight, and improving overall efficiency. Initially, drone batteries relied on traditional lithium-ion chemistries, which provided limited flight times and power output. The introduction of lithium oxide as a potential cathode material represented a pivotal moment in the quest for enhanced drone battery performance.

Early research into lithium oxide batteries focused on overcoming stability issues and improving the material's conductivity. Scientists discovered that incorporating lithium oxide into the cathode structure could potentially increase the battery's theoretical capacity, leading to longer flight times for drones. This breakthrough sparked a wave of intensive research and development efforts across academia and industry.

As the technology progressed, researchers began exploring various nanostructured lithium oxide materials to optimize electron and ion transport within the battery. These efforts resulted in improved charge-discharge cycles and higher energy densities, crucial factors for extending drone operational capabilities. Concurrently, advancements in electrolyte formulations compatible with lithium oxide cathodes further enhanced battery stability and safety.

The goals of lithium oxide battery technology for drones have evolved in tandem with the increasing demands of the unmanned aerial vehicle (UAV) industry. Primary objectives include achieving energy densities exceeding 400 Wh/kg, significantly surpassing current lithium-ion batteries. This ambitious target would potentially double flight times for many drone models, revolutionizing their applications in various sectors.

Another critical goal is to develop lithium oxide batteries with rapid charging capabilities, ideally achieving 80% charge in less than 15 minutes. This feature would dramatically reduce downtime between flights, enhancing operational efficiency for commercial and industrial drone applications. Additionally, researchers aim to improve the cycle life of lithium oxide batteries, targeting over 1000 charge-discharge cycles without significant capacity loss.

Safety remains a paramount concern, with ongoing efforts to create inherently safer lithium oxide battery designs that minimize the risk of thermal runaway and fire hazards. This is particularly crucial for drone operations in sensitive environments or populated areas. Researchers are also focusing on developing lithium oxide batteries that maintain stable performance across a wide temperature range, addressing the diverse operational conditions drones encounter.

Looking ahead, the ultimate goal is to create a new generation of drone batteries that not only surpass current performance metrics but also offer enhanced sustainability. This includes developing recyclable lithium oxide battery components and exploring environmentally friendly manufacturing processes. As the technology continues to mature, the vision is to establish lithium oxide batteries as the new standard for high-performance, long-endurance drone power systems, enabling unprecedented capabilities in aerial surveillance, delivery services, and beyond.

Early research into lithium oxide batteries focused on overcoming stability issues and improving the material's conductivity. Scientists discovered that incorporating lithium oxide into the cathode structure could potentially increase the battery's theoretical capacity, leading to longer flight times for drones. This breakthrough sparked a wave of intensive research and development efforts across academia and industry.

As the technology progressed, researchers began exploring various nanostructured lithium oxide materials to optimize electron and ion transport within the battery. These efforts resulted in improved charge-discharge cycles and higher energy densities, crucial factors for extending drone operational capabilities. Concurrently, advancements in electrolyte formulations compatible with lithium oxide cathodes further enhanced battery stability and safety.

The goals of lithium oxide battery technology for drones have evolved in tandem with the increasing demands of the unmanned aerial vehicle (UAV) industry. Primary objectives include achieving energy densities exceeding 400 Wh/kg, significantly surpassing current lithium-ion batteries. This ambitious target would potentially double flight times for many drone models, revolutionizing their applications in various sectors.

Another critical goal is to develop lithium oxide batteries with rapid charging capabilities, ideally achieving 80% charge in less than 15 minutes. This feature would dramatically reduce downtime between flights, enhancing operational efficiency for commercial and industrial drone applications. Additionally, researchers aim to improve the cycle life of lithium oxide batteries, targeting over 1000 charge-discharge cycles without significant capacity loss.

Safety remains a paramount concern, with ongoing efforts to create inherently safer lithium oxide battery designs that minimize the risk of thermal runaway and fire hazards. This is particularly crucial for drone operations in sensitive environments or populated areas. Researchers are also focusing on developing lithium oxide batteries that maintain stable performance across a wide temperature range, addressing the diverse operational conditions drones encounter.

Looking ahead, the ultimate goal is to create a new generation of drone batteries that not only surpass current performance metrics but also offer enhanced sustainability. This includes developing recyclable lithium oxide battery components and exploring environmentally friendly manufacturing processes. As the technology continues to mature, the vision is to establish lithium oxide batteries as the new standard for high-performance, long-endurance drone power systems, enabling unprecedented capabilities in aerial surveillance, delivery services, and beyond.

Drone Market Demand for High-Efficiency Batteries

The drone market has witnessed a significant surge in demand for high-efficiency batteries, driven by the rapid expansion of commercial and consumer drone applications. This growing need stems from the increasing complexity and duration of drone missions across various sectors. In the commercial realm, industries such as agriculture, construction, and logistics are leveraging drones for tasks that require extended flight times and higher payload capacities. These applications necessitate batteries that can deliver longer operational hours without compromising performance or adding excessive weight.

Consumer drones, particularly in the photography and videography segments, are also pushing the boundaries of battery technology. Enthusiasts and professionals alike seek drones capable of longer flight durations to capture more footage and explore larger areas. This demand has led to a market-wide push for batteries that offer higher energy density and improved power-to-weight ratios.

The military and defense sectors represent another crucial driver in the high-efficiency battery market for drones. Surveillance, reconnaissance, and tactical operations often require drones to remain airborne for extended periods, sometimes in challenging environmental conditions. This has spurred research into advanced battery technologies that can withstand extreme temperatures and provide reliable, long-lasting power sources.

Environmental concerns and regulatory pressures are also shaping the demand landscape. As governments worldwide implement stricter emissions regulations, there is a growing emphasis on developing eco-friendly battery solutions for drones. This trend is pushing manufacturers to explore alternative materials and chemistries that offer improved efficiency while minimizing environmental impact.

The racing drone community, though smaller, is another segment driving innovation in high-efficiency batteries. Competitive drone racing demands batteries that can deliver high burst currents for rapid acceleration while maintaining stability throughout the race. This niche market is fostering advancements in battery management systems and cell designs that could have broader applications in the drone industry.

Market analysts project substantial growth in the drone battery sector, with a particular focus on high-efficiency solutions. The increasing adoption of drones in emerging markets, coupled with ongoing technological advancements, is expected to sustain this growth trajectory. As drone capabilities continue to expand, the demand for batteries that can keep pace with these innovations will remain a critical factor in shaping the future of the drone industry.

Consumer drones, particularly in the photography and videography segments, are also pushing the boundaries of battery technology. Enthusiasts and professionals alike seek drones capable of longer flight durations to capture more footage and explore larger areas. This demand has led to a market-wide push for batteries that offer higher energy density and improved power-to-weight ratios.

The military and defense sectors represent another crucial driver in the high-efficiency battery market for drones. Surveillance, reconnaissance, and tactical operations often require drones to remain airborne for extended periods, sometimes in challenging environmental conditions. This has spurred research into advanced battery technologies that can withstand extreme temperatures and provide reliable, long-lasting power sources.

Environmental concerns and regulatory pressures are also shaping the demand landscape. As governments worldwide implement stricter emissions regulations, there is a growing emphasis on developing eco-friendly battery solutions for drones. This trend is pushing manufacturers to explore alternative materials and chemistries that offer improved efficiency while minimizing environmental impact.

The racing drone community, though smaller, is another segment driving innovation in high-efficiency batteries. Competitive drone racing demands batteries that can deliver high burst currents for rapid acceleration while maintaining stability throughout the race. This niche market is fostering advancements in battery management systems and cell designs that could have broader applications in the drone industry.

Market analysts project substantial growth in the drone battery sector, with a particular focus on high-efficiency solutions. The increasing adoption of drones in emerging markets, coupled with ongoing technological advancements, is expected to sustain this growth trajectory. As drone capabilities continue to expand, the demand for batteries that can keep pace with these innovations will remain a critical factor in shaping the future of the drone industry.

Lithium Oxide Battery Challenges and Limitations

Despite the potential of lithium oxide to enhance drone battery efficiency, several challenges and limitations hinder its widespread adoption and practical implementation. One of the primary obstacles is the inherent instability of lithium oxide when exposed to atmospheric conditions. The compound readily reacts with moisture and carbon dioxide in the air, forming lithium hydroxide and lithium carbonate, respectively. This reactivity not only compromises the battery's performance but also raises safety concerns during handling and storage.

Another significant challenge lies in the manufacturing process of lithium oxide-based batteries. The synthesis of high-purity lithium oxide requires precise control over temperature and atmospheric conditions, making large-scale production complex and costly. Additionally, the integration of lithium oxide into existing battery architectures presents technical difficulties, as it may not be directly compatible with current electrode and electrolyte designs.

The cycling stability of lithium oxide-based batteries poses another limitation. During charge and discharge cycles, the formation and decomposition of lithium oxide can lead to structural changes within the battery, potentially causing capacity fade and reduced cycle life. This issue is particularly critical for drone applications, where consistent performance over numerous cycles is essential.

Furthermore, the energy density improvements offered by lithium oxide, while promising, may not yet be sufficient to justify the additional complexities and costs associated with its implementation. The marginal gains in flight time or payload capacity need to be weighed against the increased manufacturing and maintenance expenses.

Safety considerations also present a significant hurdle. The high reactivity of lithium oxide raises concerns about thermal runaway and fire risks, especially in the context of drone operations where batteries are subjected to varying environmental conditions and potential physical impacts.

Lastly, regulatory challenges cannot be overlooked. The introduction of new battery chemistries, particularly those involving highly reactive compounds like lithium oxide, may face scrutiny from aviation authorities and safety regulators. Obtaining necessary certifications and approvals could be a time-consuming and costly process, potentially delaying the adoption of this technology in commercial drone applications.

Another significant challenge lies in the manufacturing process of lithium oxide-based batteries. The synthesis of high-purity lithium oxide requires precise control over temperature and atmospheric conditions, making large-scale production complex and costly. Additionally, the integration of lithium oxide into existing battery architectures presents technical difficulties, as it may not be directly compatible with current electrode and electrolyte designs.

The cycling stability of lithium oxide-based batteries poses another limitation. During charge and discharge cycles, the formation and decomposition of lithium oxide can lead to structural changes within the battery, potentially causing capacity fade and reduced cycle life. This issue is particularly critical for drone applications, where consistent performance over numerous cycles is essential.

Furthermore, the energy density improvements offered by lithium oxide, while promising, may not yet be sufficient to justify the additional complexities and costs associated with its implementation. The marginal gains in flight time or payload capacity need to be weighed against the increased manufacturing and maintenance expenses.

Safety considerations also present a significant hurdle. The high reactivity of lithium oxide raises concerns about thermal runaway and fire risks, especially in the context of drone operations where batteries are subjected to varying environmental conditions and potential physical impacts.

Lastly, regulatory challenges cannot be overlooked. The introduction of new battery chemistries, particularly those involving highly reactive compounds like lithium oxide, may face scrutiny from aviation authorities and safety regulators. Obtaining necessary certifications and approvals could be a time-consuming and costly process, potentially delaying the adoption of this technology in commercial drone applications.

Current Lithium Oxide Battery Solutions for Drones

01 Electrode material composition

The efficiency of lithium oxide batteries can be improved by optimizing the composition of electrode materials. This includes using specific combinations of lithium oxides, transition metals, and dopants to enhance the battery's capacity, cycling stability, and overall performance.- Electrode material composition: The efficiency of lithium oxide batteries can be improved by optimizing the composition of electrode materials. This includes using specific combinations of lithium oxides, transition metals, and dopants to enhance the battery's capacity, cycling stability, and overall performance.

- Electrolyte formulation: Developing advanced electrolyte formulations can significantly impact lithium oxide battery efficiency. This involves using novel electrolyte additives, optimizing salt concentrations, and exploring alternative solvents to improve ionic conductivity, reduce side reactions, and enhance the battery's overall performance and safety.

- Nanostructured materials: Incorporating nanostructured materials in lithium oxide batteries can lead to improved efficiency. These materials, such as nanoparticles, nanotubes, or nanosheets, can enhance the electrode's surface area, facilitate faster ion transport, and improve the overall electrochemical performance of the battery.

- Coating and surface modification: Applying protective coatings or surface modifications to electrode materials can enhance the efficiency of lithium oxide batteries. These techniques can improve the stability of the electrode-electrolyte interface, reduce side reactions, and extend the battery's cycle life and overall performance.

- Advanced manufacturing techniques: Employing advanced manufacturing techniques can improve the efficiency of lithium oxide batteries. This includes optimizing particle size distribution, developing novel synthesis methods, and utilizing innovative assembly processes to enhance the battery's structural integrity, uniformity, and overall performance.

02 Electrolyte formulation

Developing advanced electrolyte formulations can significantly impact lithium oxide battery efficiency. This involves using novel electrolyte additives, optimizing salt concentrations, and incorporating ionic liquids to improve ionic conductivity, reduce side reactions, and enhance the battery's overall performance and safety.Expand Specific Solutions03 Nanostructured materials

Incorporating nanostructured materials in lithium oxide batteries can lead to improved efficiency. These materials, such as nanoparticles, nanotubes, or nanosheets, offer increased surface area, enhanced ion diffusion, and better structural stability, resulting in higher capacity and faster charge-discharge rates.Expand Specific Solutions04 Coating and surface modification

Applying protective coatings or surface modifications to electrode materials can enhance the efficiency of lithium oxide batteries. These techniques help to stabilize the electrode-electrolyte interface, reduce side reactions, and improve the overall cycling performance and longevity of the battery.Expand Specific Solutions05 Advanced manufacturing techniques

Employing advanced manufacturing techniques can improve the efficiency of lithium oxide batteries. These methods include precision control of particle size and morphology, novel synthesis routes, and innovative assembly processes that enhance the battery's structural integrity and performance characteristics.Expand Specific Solutions

Key Players in Lithium Oxide Battery Research

The research on using lithium oxide to increase drone battery efficiency is in an early development stage, with a growing market potential as drone technology expands. The market size is expected to increase significantly due to the rising demand for longer-lasting drone batteries. Technologically, it's still evolving, with various companies and institutions at different stages of development. Samsung Electronics, Toyota Motor Corp., and Mitsubishi Heavy Industries are leading industrial players, while academic institutions like Cornell University and MIT are contributing to fundamental research. Wildcat Discovery Technologies and PolyPlus Battery Co. are specialized firms focusing on advanced battery materials, potentially accelerating the technology's maturation.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has been actively researching lithium-air battery technology as part of its efforts to develop next-generation energy storage solutions. Their approach involves the use of graphene-based cathodes with carefully engineered pore structures to facilitate efficient oxygen diffusion and lithium oxide formation [9]. Samsung's research also focuses on developing stable electrolytes that can withstand the harsh oxidative environment of lithium-air batteries. The company has demonstrated prototype cells with energy densities exceeding 1,000 Wh/kg, which is significantly higher than conventional lithium-ion batteries [10]. Samsung is exploring the potential application of this technology in various fields, including drones, where the high energy density could significantly extend flight times.

Strengths: Extensive experience in battery manufacturing and scaling, potential for rapid commercialization. Weaknesses: Challenges in adapting consumer electronics battery technology to meet the specific requirements of drone applications.

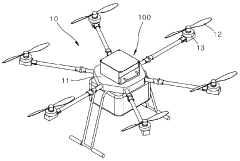

Autel Robotics Co Ltd

Technical Solution: Autel Robotics, a company specializing in drone technology, has been exploring advanced battery solutions to enhance the performance of their unmanned aerial vehicles. While specific details about their lithium oxide-based battery research are limited, the company has been investing in improving battery efficiency for their drone products. Autel's approach likely involves optimizing the integration of high-energy-density batteries, such as those utilizing lithium oxide technology, with their drone designs. This may include developing smart battery management systems that can effectively handle the unique characteristics of lithium-air or similar advanced battery chemistries [11]. The company's focus on lightweight and compact drone designs makes them well-positioned to leverage the benefits of lithium oxide-based batteries for increased flight times and improved overall performance.

Strengths: Direct application in drone products, expertise in integrating batteries with drone systems. Weaknesses: Potentially limited in-house battery research capabilities, reliance on partnerships or external technology for advanced battery development.

Core Innovations in Lithium Oxide Battery Technology

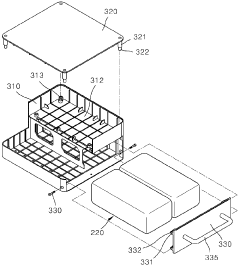

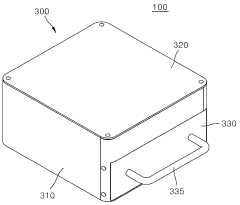

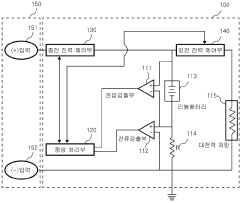

High efficiency battery for agricultural drone

PatentActiveKR1020180128683A

Innovation

- A high-efficiency battery device for agricultural drones employs a battery management module with a charge amount measuring unit, display unit, cell balancing unit, and fuzzy algorithm-based control unit to manage cell voltage balance and prevent overcharging/overdischarging, using a housing with a mounting module and rotation drive unit for stable drone operation.

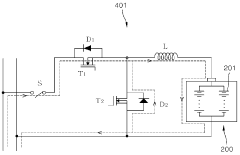

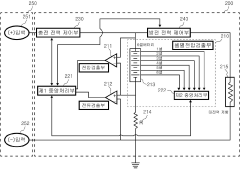

Apparatus for preventing overcharge, shortening of lifetime and explosion of lithium battery for drone and the method thereof

PatentInactiveKR1020190091037A

Innovation

- A lithium battery charging apparatus and method that includes a voltage detector, current detector, charging power controller, discharge power controller, and central processing units to monitor and control charging based on cell-specific voltages, internal resistance, and temperature to prevent overcharging and explosions by stopping or reducing charging power when threshold values are exceeded.

Environmental Impact of Lithium Oxide Batteries

The environmental impact of lithium oxide batteries in drone applications is a critical consideration as the technology advances. These batteries offer significant improvements in energy density and efficiency, potentially extending flight times and reducing the frequency of battery replacements. However, their production and disposal present unique environmental challenges that must be addressed.

The mining of lithium, a key component in lithium oxide batteries, has substantial environmental implications. Large-scale lithium extraction often occurs in ecologically sensitive areas, leading to habitat disruption and potential water pollution. The process is water-intensive, which can strain local water resources, particularly in arid regions where lithium deposits are commonly found.

During the manufacturing phase, the production of lithium oxide batteries involves energy-intensive processes and the use of various chemicals. This contributes to greenhouse gas emissions and potential chemical pollution if not properly managed. However, compared to traditional battery technologies, the longer lifespan and higher efficiency of lithium oxide batteries may offset some of these impacts over time.

In the operational phase, the use of lithium oxide batteries in drones presents a mixed environmental picture. On one hand, the increased efficiency and longer flight times reduce the need for frequent recharging or battery replacements, potentially lowering overall energy consumption. On the other hand, the increased capabilities of drones equipped with these batteries may lead to more widespread use, potentially raising concerns about noise pollution and wildlife disturbance in sensitive areas.

End-of-life management of lithium oxide batteries is a crucial environmental consideration. Improper disposal can lead to soil and water contamination due to the leaching of toxic materials. However, these batteries have high recycling potential. Effective recycling processes can recover valuable materials, reducing the need for new raw material extraction and minimizing waste.

The development of more environmentally friendly lithium oxide battery technologies is an active area of research. Efforts are being made to improve production processes, reduce the use of toxic materials, and enhance recyclability. Innovations in battery design and chemistry aim to further increase efficiency and lifespan, potentially mitigating long-term environmental impacts.

As the drone industry continues to grow, the environmental impact of lithium oxide batteries will likely become more pronounced. Balancing the benefits of improved drone performance with environmental sustainability will be crucial. This may involve developing stricter regulations for battery production and disposal, investing in more efficient recycling technologies, and promoting responsible drone usage practices to minimize ecological disturbances.

The mining of lithium, a key component in lithium oxide batteries, has substantial environmental implications. Large-scale lithium extraction often occurs in ecologically sensitive areas, leading to habitat disruption and potential water pollution. The process is water-intensive, which can strain local water resources, particularly in arid regions where lithium deposits are commonly found.

During the manufacturing phase, the production of lithium oxide batteries involves energy-intensive processes and the use of various chemicals. This contributes to greenhouse gas emissions and potential chemical pollution if not properly managed. However, compared to traditional battery technologies, the longer lifespan and higher efficiency of lithium oxide batteries may offset some of these impacts over time.

In the operational phase, the use of lithium oxide batteries in drones presents a mixed environmental picture. On one hand, the increased efficiency and longer flight times reduce the need for frequent recharging or battery replacements, potentially lowering overall energy consumption. On the other hand, the increased capabilities of drones equipped with these batteries may lead to more widespread use, potentially raising concerns about noise pollution and wildlife disturbance in sensitive areas.

End-of-life management of lithium oxide batteries is a crucial environmental consideration. Improper disposal can lead to soil and water contamination due to the leaching of toxic materials. However, these batteries have high recycling potential. Effective recycling processes can recover valuable materials, reducing the need for new raw material extraction and minimizing waste.

The development of more environmentally friendly lithium oxide battery technologies is an active area of research. Efforts are being made to improve production processes, reduce the use of toxic materials, and enhance recyclability. Innovations in battery design and chemistry aim to further increase efficiency and lifespan, potentially mitigating long-term environmental impacts.

As the drone industry continues to grow, the environmental impact of lithium oxide batteries will likely become more pronounced. Balancing the benefits of improved drone performance with environmental sustainability will be crucial. This may involve developing stricter regulations for battery production and disposal, investing in more efficient recycling technologies, and promoting responsible drone usage practices to minimize ecological disturbances.

Safety Regulations for Drone Battery Technologies

The development and implementation of safety regulations for drone battery technologies are crucial aspects of the research on using lithium oxide to increase drone battery efficiency. As the drone industry continues to expand, regulatory bodies worldwide have been working to establish comprehensive safety standards to address the unique challenges posed by lithium-based batteries in unmanned aerial vehicles.

One of the primary concerns in drone battery safety is the risk of thermal runaway, which can lead to fires or explosions. To mitigate this risk, regulations often require manufacturers to implement robust battery management systems (BMS) that monitor temperature, voltage, and current in real-time. These systems must be capable of detecting anomalies and initiating safety protocols, such as emergency shutdowns or controlled discharge procedures.

Regulatory frameworks also typically mandate specific design requirements for drone batteries. These may include the use of fire-resistant materials in battery casings, the incorporation of venting mechanisms to release pressure in case of internal failures, and the implementation of redundant safety features to prevent single-point failures from causing catastrophic events.

Testing and certification processes form another critical component of safety regulations. Manufacturers are often required to subject their battery systems to rigorous testing protocols, including simulated crash scenarios, extreme temperature conditions, and overcharge/overdischarge tests. Certification bodies may also mandate regular inspections and recertification of battery systems to ensure ongoing compliance with safety standards.

Transportation and storage of lithium-based drone batteries are subject to strict regulations as well. Many countries have implemented specific guidelines for the shipping of lithium batteries, including requirements for proper packaging, labeling, and documentation. These regulations aim to minimize the risk of incidents during transit and ensure that emergency responders are adequately informed of potential hazards.

As research into lithium oxide-based batteries for drones progresses, regulatory bodies are likely to adapt existing frameworks or develop new standards to address the specific characteristics of this technology. This may include updated safety protocols for handling and disposing of lithium oxide materials, as well as revised testing procedures to evaluate the long-term stability and performance of these advanced battery systems.

The integration of lithium oxide technology into drone batteries may also necessitate changes in operational regulations. For instance, if the new batteries significantly extend flight times, aviation authorities may need to reassess airspace management protocols and adjust flight planning requirements accordingly. Additionally, regulations may need to address potential environmental impacts associated with the production, use, and disposal of lithium oxide-based battery systems.

One of the primary concerns in drone battery safety is the risk of thermal runaway, which can lead to fires or explosions. To mitigate this risk, regulations often require manufacturers to implement robust battery management systems (BMS) that monitor temperature, voltage, and current in real-time. These systems must be capable of detecting anomalies and initiating safety protocols, such as emergency shutdowns or controlled discharge procedures.

Regulatory frameworks also typically mandate specific design requirements for drone batteries. These may include the use of fire-resistant materials in battery casings, the incorporation of venting mechanisms to release pressure in case of internal failures, and the implementation of redundant safety features to prevent single-point failures from causing catastrophic events.

Testing and certification processes form another critical component of safety regulations. Manufacturers are often required to subject their battery systems to rigorous testing protocols, including simulated crash scenarios, extreme temperature conditions, and overcharge/overdischarge tests. Certification bodies may also mandate regular inspections and recertification of battery systems to ensure ongoing compliance with safety standards.

Transportation and storage of lithium-based drone batteries are subject to strict regulations as well. Many countries have implemented specific guidelines for the shipping of lithium batteries, including requirements for proper packaging, labeling, and documentation. These regulations aim to minimize the risk of incidents during transit and ensure that emergency responders are adequately informed of potential hazards.

As research into lithium oxide-based batteries for drones progresses, regulatory bodies are likely to adapt existing frameworks or develop new standards to address the specific characteristics of this technology. This may include updated safety protocols for handling and disposing of lithium oxide materials, as well as revised testing procedures to evaluate the long-term stability and performance of these advanced battery systems.

The integration of lithium oxide technology into drone batteries may also necessitate changes in operational regulations. For instance, if the new batteries significantly extend flight times, aviation authorities may need to reassess airspace management protocols and adjust flight planning requirements accordingly. Additionally, regulations may need to address potential environmental impacts associated with the production, use, and disposal of lithium oxide-based battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!