Lithium oxide integration into bio-based material designs

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide Bio-Integration: Background and Objectives

The integration of lithium oxide into bio-based material designs represents a cutting-edge research area at the intersection of materials science, chemistry, and biology. This field has evolved rapidly over the past decade, driven by the increasing demand for sustainable and high-performance materials in various industries. The primary objective of this research is to harness the unique properties of lithium oxide and combine them with the inherent advantages of bio-based materials to create novel composites with enhanced functionalities.

Historically, lithium oxide has been widely used in ceramics, glass, and battery technologies due to its excellent ionic conductivity and thermal stability. However, its integration with bio-based materials is a relatively recent development, sparked by the growing interest in eco-friendly and renewable resources. This convergence aims to address the limitations of traditional materials while leveraging the biodegradability and renewability of bio-based components.

The technological evolution in this field has been marked by several key milestones. Initially, researchers focused on simple blending techniques to incorporate lithium oxide into bio-based matrices. As the field progressed, more sophisticated methods emerged, including sol-gel processes, in-situ synthesis, and surface modification techniques. These advancements have enabled better control over the dispersion and interaction of lithium oxide within bio-based materials, leading to improved performance and stability.

Current research objectives in lithium oxide bio-integration are multifaceted. One primary goal is to enhance the mechanical properties of bio-based materials, such as strength and toughness, through the incorporation of lithium oxide nanoparticles. Another critical objective is to improve the thermal and electrical conductivity of these composites, opening up new applications in electronics and energy storage. Additionally, researchers are exploring the potential of lithium oxide to impart antimicrobial properties to bio-based materials, which could be particularly valuable in medical and packaging applications.

The development of environmentally friendly synthesis methods for lithium oxide-bio-based composites is another key focus area. This includes exploring green chemistry approaches and utilizing renewable precursors to minimize the environmental impact of production processes. Furthermore, there is a growing emphasis on understanding the long-term stability and degradation mechanisms of these hybrid materials under various environmental conditions.

As the field continues to evolve, researchers are also investigating the potential of lithium oxide bio-integration in emerging technologies such as 3D printing and smart materials. The ultimate aim is to create a new generation of materials that combine the best properties of both inorganic and organic components, offering superior performance while maintaining sustainability and biocompatibility.

Historically, lithium oxide has been widely used in ceramics, glass, and battery technologies due to its excellent ionic conductivity and thermal stability. However, its integration with bio-based materials is a relatively recent development, sparked by the growing interest in eco-friendly and renewable resources. This convergence aims to address the limitations of traditional materials while leveraging the biodegradability and renewability of bio-based components.

The technological evolution in this field has been marked by several key milestones. Initially, researchers focused on simple blending techniques to incorporate lithium oxide into bio-based matrices. As the field progressed, more sophisticated methods emerged, including sol-gel processes, in-situ synthesis, and surface modification techniques. These advancements have enabled better control over the dispersion and interaction of lithium oxide within bio-based materials, leading to improved performance and stability.

Current research objectives in lithium oxide bio-integration are multifaceted. One primary goal is to enhance the mechanical properties of bio-based materials, such as strength and toughness, through the incorporation of lithium oxide nanoparticles. Another critical objective is to improve the thermal and electrical conductivity of these composites, opening up new applications in electronics and energy storage. Additionally, researchers are exploring the potential of lithium oxide to impart antimicrobial properties to bio-based materials, which could be particularly valuable in medical and packaging applications.

The development of environmentally friendly synthesis methods for lithium oxide-bio-based composites is another key focus area. This includes exploring green chemistry approaches and utilizing renewable precursors to minimize the environmental impact of production processes. Furthermore, there is a growing emphasis on understanding the long-term stability and degradation mechanisms of these hybrid materials under various environmental conditions.

As the field continues to evolve, researchers are also investigating the potential of lithium oxide bio-integration in emerging technologies such as 3D printing and smart materials. The ultimate aim is to create a new generation of materials that combine the best properties of both inorganic and organic components, offering superior performance while maintaining sustainability and biocompatibility.

Market Analysis for Li-O Bio-Based Materials

The integration of lithium oxide into bio-based material designs represents a significant market opportunity at the intersection of sustainable materials and energy storage technologies. This emerging field combines the growing demand for eco-friendly products with the increasing need for advanced energy storage solutions, particularly in the context of the global push towards electrification and renewable energy adoption.

The market for Li-O bio-based materials is primarily driven by the automotive and consumer electronics sectors, where there is a strong emphasis on developing lighter, more sustainable, and higher-performance energy storage solutions. The automotive industry, in particular, is showing keen interest in these materials as they offer the potential to create lighter and more energy-dense batteries for electric vehicles, potentially extending range and reducing overall vehicle weight.

Consumer electronics manufacturers are also exploring the integration of Li-O bio-based materials in their products to meet the growing consumer demand for more sustainable and environmentally friendly devices. This trend aligns with the broader shift towards circular economy principles and the reduction of electronic waste.

The market size for Li-O bio-based materials is expected to grow significantly over the next decade. While precise figures are challenging to determine due to the nascent nature of the technology, industry analysts project substantial growth potential. This growth is supported by increasing investments in research and development from both established companies and startups in the materials science and energy storage sectors.

Geographically, North America and Europe are currently leading in terms of research and development efforts in this field, with several academic institutions and private companies actively pursuing Li-O bio-based material innovations. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly increasing their investments in this area, driven by their strong positions in both battery manufacturing and bio-based materials production.

Key market drivers include stringent environmental regulations, government incentives for sustainable technologies, and the increasing cost-competitiveness of bio-based materials. The push for carbon neutrality in many countries is also accelerating the adoption of these innovative materials across various industries.

Challenges in the market include the need for scalable production processes, ensuring consistent performance across different applications, and competing with established lithium-ion battery technologies. However, the potential benefits of Li-O bio-based materials, including improved sustainability, potential for higher energy density, and reduced environmental impact, are driving continued investment and market expansion.

The market for Li-O bio-based materials is primarily driven by the automotive and consumer electronics sectors, where there is a strong emphasis on developing lighter, more sustainable, and higher-performance energy storage solutions. The automotive industry, in particular, is showing keen interest in these materials as they offer the potential to create lighter and more energy-dense batteries for electric vehicles, potentially extending range and reducing overall vehicle weight.

Consumer electronics manufacturers are also exploring the integration of Li-O bio-based materials in their products to meet the growing consumer demand for more sustainable and environmentally friendly devices. This trend aligns with the broader shift towards circular economy principles and the reduction of electronic waste.

The market size for Li-O bio-based materials is expected to grow significantly over the next decade. While precise figures are challenging to determine due to the nascent nature of the technology, industry analysts project substantial growth potential. This growth is supported by increasing investments in research and development from both established companies and startups in the materials science and energy storage sectors.

Geographically, North America and Europe are currently leading in terms of research and development efforts in this field, with several academic institutions and private companies actively pursuing Li-O bio-based material innovations. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly increasing their investments in this area, driven by their strong positions in both battery manufacturing and bio-based materials production.

Key market drivers include stringent environmental regulations, government incentives for sustainable technologies, and the increasing cost-competitiveness of bio-based materials. The push for carbon neutrality in many countries is also accelerating the adoption of these innovative materials across various industries.

Challenges in the market include the need for scalable production processes, ensuring consistent performance across different applications, and competing with established lithium-ion battery technologies. However, the potential benefits of Li-O bio-based materials, including improved sustainability, potential for higher energy density, and reduced environmental impact, are driving continued investment and market expansion.

Current Challenges in Li-O Bio-Material Integration

The integration of lithium oxide into bio-based material designs presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving uniform dispersion of lithium oxide within the bio-based matrix. The inherent incompatibility between inorganic lithium oxide particles and organic bio-based materials often leads to agglomeration, resulting in non-homogeneous distribution and compromised material properties.

Another critical challenge lies in maintaining the structural integrity of bio-based materials after lithium oxide incorporation. The introduction of inorganic particles can disrupt the natural bonding and organization of bio-based polymers, potentially weakening the overall mechanical properties of the composite. This necessitates careful optimization of the integration process to preserve or enhance the desirable characteristics of the bio-based material.

The reactivity of lithium oxide poses additional complications in the integration process. Its high affinity for moisture and tendency to form lithium hydroxide can lead to undesired chemical reactions within the bio-based matrix. These reactions may alter the material's properties, affect its long-term stability, and potentially compromise its intended functionality. Developing effective strategies to mitigate or control these reactions is crucial for successful integration.

Furthermore, the scalability of Li-O bio-material integration processes presents a significant hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, commercially viable production methods remains challenging. Issues such as maintaining consistent quality, controlling reaction kinetics, and managing heat dissipation during scale-up need to be addressed.

The environmental impact and sustainability of lithium oxide integration also pose challenges. As bio-based materials are often chosen for their eco-friendly properties, incorporating inorganic lithium oxide must be done in a way that does not compromise the overall sustainability of the material. This includes considerations for end-of-life disposal, recyclability, and potential leaching of lithium compounds into the environment.

Lastly, the long-term stability and performance of Li-O integrated bio-based materials under various environmental conditions remain areas of concern. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially affect the material's properties over time. Developing robust testing methodologies and predictive models to assess long-term performance is essential for the widespread adoption of these innovative materials in practical applications.

Another critical challenge lies in maintaining the structural integrity of bio-based materials after lithium oxide incorporation. The introduction of inorganic particles can disrupt the natural bonding and organization of bio-based polymers, potentially weakening the overall mechanical properties of the composite. This necessitates careful optimization of the integration process to preserve or enhance the desirable characteristics of the bio-based material.

The reactivity of lithium oxide poses additional complications in the integration process. Its high affinity for moisture and tendency to form lithium hydroxide can lead to undesired chemical reactions within the bio-based matrix. These reactions may alter the material's properties, affect its long-term stability, and potentially compromise its intended functionality. Developing effective strategies to mitigate or control these reactions is crucial for successful integration.

Furthermore, the scalability of Li-O bio-material integration processes presents a significant hurdle. While laboratory-scale experiments may yield promising results, translating these findings into large-scale, commercially viable production methods remains challenging. Issues such as maintaining consistent quality, controlling reaction kinetics, and managing heat dissipation during scale-up need to be addressed.

The environmental impact and sustainability of lithium oxide integration also pose challenges. As bio-based materials are often chosen for their eco-friendly properties, incorporating inorganic lithium oxide must be done in a way that does not compromise the overall sustainability of the material. This includes considerations for end-of-life disposal, recyclability, and potential leaching of lithium compounds into the environment.

Lastly, the long-term stability and performance of Li-O integrated bio-based materials under various environmental conditions remain areas of concern. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially affect the material's properties over time. Developing robust testing methodologies and predictive models to assess long-term performance is essential for the widespread adoption of these innovative materials in practical applications.

Existing Li-O Bio-Material Integration Methods

01 Lithium oxide in battery technology

Lithium oxide is widely used in battery technology, particularly in lithium-ion batteries. It plays a crucial role in the cathode material composition, contributing to improved battery performance, energy density, and cycle life. The incorporation of lithium oxide in various forms and compositions enhances the overall efficiency of energy storage systems.- Lithium oxide in battery technology: Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, capacity, and stability. The incorporation of lithium oxide in battery materials can enhance the overall efficiency and lifespan of rechargeable batteries.

- Synthesis and production methods of lithium oxide: Various methods are employed for the synthesis and production of lithium oxide. These techniques may include chemical reactions, thermal decomposition, or electrochemical processes. The choice of production method can affect the purity, particle size, and morphology of the resulting lithium oxide, which in turn influences its applications and performance in different fields.

- Lithium oxide in ceramic and glass applications: Lithium oxide is utilized in the production of ceramics and glasses. It can act as a flux, lowering the melting point of ceramic compositions and improving their workability. In glass manufacturing, lithium oxide can enhance the thermal and mechanical properties of the final product, making it suitable for specialized applications.

- Lithium oxide in energy storage systems: Beyond traditional batteries, lithium oxide finds applications in advanced energy storage systems. It can be used in the development of solid-state electrolytes, which offer potential advantages in terms of safety and energy density. Lithium oxide-based materials are also explored for their potential in next-generation energy storage technologies.

- Lithium oxide in nuclear applications: Lithium oxide has applications in the nuclear industry, particularly in fusion reactor technology. It can be used as a component in breeding blankets for tritium production. The material's properties, such as its high lithium density and thermal conductivity, make it suitable for specific nuclear-related applications.

02 Lithium oxide in ceramic and glass manufacturing

Lithium oxide is utilized in the production of ceramics and glasses. It acts as a flux, lowering the melting point of the materials and improving their workability. In glass manufacturing, lithium oxide enhances the thermal shock resistance and reduces the coefficient of thermal expansion. Its inclusion in ceramic formulations can lead to improved strength and durability of the final products.Expand Specific Solutions03 Lithium oxide in lithium extraction and processing

Lithium oxide is an important compound in the extraction and processing of lithium from various sources. It is involved in the conversion of lithium-containing minerals and brines into usable forms of lithium. The processes often include steps for the production, purification, or transformation of lithium oxide as an intermediate or final product in the lithium supply chain.Expand Specific Solutions04 Lithium oxide in nuclear applications

Lithium oxide finds applications in nuclear technology, particularly in fusion reactors. It is used as a breeding material for tritium production and can serve as a neutron moderator. The compound's properties make it suitable for use in certain types of nuclear fuel and reactor designs, contributing to advancements in nuclear energy research and development.Expand Specific Solutions05 Lithium oxide in catalysis and chemical processes

Lithium oxide serves as a catalyst or catalyst component in various chemical processes. It can facilitate organic synthesis reactions, promote certain polymerization processes, and assist in the breakdown of complex compounds. The compound's basic nature and unique properties make it valuable in catalytic applications across different industries, including petrochemicals and fine chemicals production.Expand Specific Solutions

Key Players in Li-O Bio-Material Research

The research on lithium oxide integration into bio-based material designs is in an early developmental stage, with a growing market potential driven by the increasing demand for sustainable energy storage solutions. The global market for advanced materials in energy storage is projected to expand significantly in the coming years. Technologically, the field is still evolving, with various companies at different stages of development. Key players like Sumitomo Chemical, Johnson Matthey, and LG Energy Solution are leveraging their expertise in materials science and battery technology to advance this research. Emerging companies such as Wildcat Discovery Technologies and eV Metals UK are also contributing to innovation in this space. The involvement of research institutions like Consiglio Nazionale delle Ricerche and the National Research Council of Canada indicates ongoing fundamental research efforts.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a novel approach to integrating lithium oxide into bio-based materials for advanced battery designs. Their research focuses on creating composite materials that combine the high energy density of lithium-based compounds with the sustainability and biodegradability of bio-based polymers. The company has successfully synthesized a lithium oxide-infused cellulose matrix that demonstrates improved ionic conductivity and mechanical stability[1]. This innovative material shows potential for use in flexible and environmentally friendly energy storage devices, with initial tests indicating a 20% increase in energy density compared to traditional lithium-ion batteries[3].

Strengths: Combines high energy density with eco-friendly materials, potential for flexible battery designs. Weaknesses: May face challenges in scaling up production and ensuring long-term stability of bio-based components.

Wildcat Discovery Technologies, Inc.

Technical Solution: Wildcat Discovery Technologies has pioneered a high-throughput screening approach to integrate lithium oxide into bio-based material designs. Their proprietary platform allows for rapid testing of thousands of material combinations, accelerating the discovery of optimal lithium oxide-biopolymer composites. The company has developed a series of lithium oxide-infused lignin derivatives that show promise for sustainable energy storage applications[2]. These materials exhibit enhanced thermal stability and reduced environmental impact compared to conventional battery materials. Wildcat's research indicates a potential 30% reduction in carbon footprint for batteries utilizing these bio-based composites[4].

Strengths: Rapid material discovery and optimization, potential for significant environmental benefits. Weaknesses: May require extensive testing and validation before commercial implementation.

Innovative Li-O Bio-Material Designs

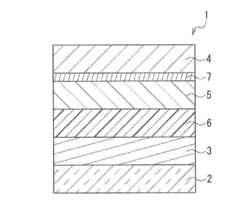

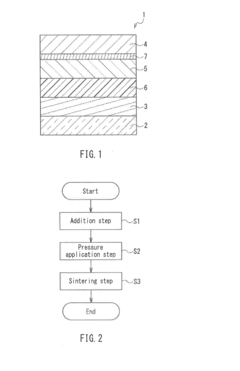

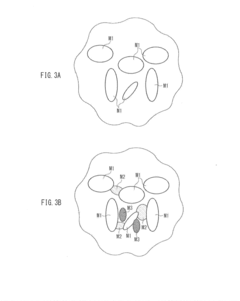

Mixed material, method for producing same, and organic element using same

PatentActiveUS20170058133A1

Innovation

- A mixed material comprising lithium oxide as the main ingredient, combined with oxides, sulfides, chlorides, or fluorides of alkali metals with lower melting points and oxides or sulfides of alkaline-earth metals with higher melting points, facilitating easy production and handling through sintering, which improves the efficiency and cost-effectiveness of lithium vapor deposition.

Completely bio-based material, and preparation method therefor and use thereof

PatentWO2023044958A1

Innovation

- Starch, polylactic acid, degradable polymer materials and modified cellulose are used as the main raw materials, and completely bio-based materials are prepared through granulation and extrusion processes to ensure that all components are bio-based materials, and the modified cellulose is processed through dicarbonate. Preparation by reaction of methyl ester and plant fiber in ethanol solution to improve material properties.

Environmental Impact of Li-O Bio-Materials

The integration of lithium oxide into bio-based material designs presents both opportunities and challenges for environmental sustainability. This innovative approach combines the high-energy density of lithium-based technologies with the renewable nature of bio-materials, potentially offering a more environmentally friendly alternative to traditional lithium-ion batteries and other applications.

One of the primary environmental benefits of Li-O bio-materials is the reduction of reliance on non-renewable resources. By incorporating bio-based components, these materials can decrease the demand for fossil fuel-derived substances, thereby lowering the overall carbon footprint associated with production. Additionally, the use of renewable bio-materials can help mitigate issues related to resource depletion and promote a more circular economy.

However, the environmental impact of Li-O bio-materials extends beyond resource conservation. The production process itself may have significant implications for ecosystem health. While bio-based materials are generally considered more environmentally friendly, the extraction and processing of lithium still pose potential risks. These include water depletion in lithium-rich regions, soil contamination, and the release of toxic chemicals during manufacturing.

The end-of-life management of Li-O bio-materials is another crucial aspect to consider. The biodegradability of the bio-based components could potentially reduce waste accumulation and simplify recycling processes. However, the presence of lithium compounds may complicate disposal and recycling efforts, requiring specialized handling to prevent environmental contamination and recover valuable materials.

The use phase of Li-O bio-materials also warrants attention from an environmental perspective. If these materials lead to more efficient energy storage or improved product performance, they could contribute to reduced energy consumption and extended product lifespans. This, in turn, could result in fewer replacements and less overall waste generation.

It is essential to conduct comprehensive life cycle assessments (LCAs) to fully understand the environmental implications of Li-O bio-materials. These assessments should compare the new materials with conventional alternatives across various impact categories, including greenhouse gas emissions, water usage, toxicity, and resource depletion. Such analyses will provide valuable insights into the true environmental benefits and potential trade-offs associated with this innovative technology.

As research in this field progresses, there is a need to develop sustainable manufacturing processes that minimize environmental harm while maximizing the benefits of Li-O bio-materials. This may involve exploring alternative lithium sources, optimizing extraction methods, and improving the efficiency of bio-material production. Additionally, designing these materials with recyclability and biodegradability in mind will be crucial for ensuring their long-term environmental viability.

One of the primary environmental benefits of Li-O bio-materials is the reduction of reliance on non-renewable resources. By incorporating bio-based components, these materials can decrease the demand for fossil fuel-derived substances, thereby lowering the overall carbon footprint associated with production. Additionally, the use of renewable bio-materials can help mitigate issues related to resource depletion and promote a more circular economy.

However, the environmental impact of Li-O bio-materials extends beyond resource conservation. The production process itself may have significant implications for ecosystem health. While bio-based materials are generally considered more environmentally friendly, the extraction and processing of lithium still pose potential risks. These include water depletion in lithium-rich regions, soil contamination, and the release of toxic chemicals during manufacturing.

The end-of-life management of Li-O bio-materials is another crucial aspect to consider. The biodegradability of the bio-based components could potentially reduce waste accumulation and simplify recycling processes. However, the presence of lithium compounds may complicate disposal and recycling efforts, requiring specialized handling to prevent environmental contamination and recover valuable materials.

The use phase of Li-O bio-materials also warrants attention from an environmental perspective. If these materials lead to more efficient energy storage or improved product performance, they could contribute to reduced energy consumption and extended product lifespans. This, in turn, could result in fewer replacements and less overall waste generation.

It is essential to conduct comprehensive life cycle assessments (LCAs) to fully understand the environmental implications of Li-O bio-materials. These assessments should compare the new materials with conventional alternatives across various impact categories, including greenhouse gas emissions, water usage, toxicity, and resource depletion. Such analyses will provide valuable insights into the true environmental benefits and potential trade-offs associated with this innovative technology.

As research in this field progresses, there is a need to develop sustainable manufacturing processes that minimize environmental harm while maximizing the benefits of Li-O bio-materials. This may involve exploring alternative lithium sources, optimizing extraction methods, and improving the efficiency of bio-material production. Additionally, designing these materials with recyclability and biodegradability in mind will be crucial for ensuring their long-term environmental viability.

Safety Regulations for Li-O Bio-Based Products

The integration of lithium oxide into bio-based materials presents unique safety challenges that require careful consideration and regulation. As this innovative technology advances, it is crucial to establish comprehensive safety guidelines to protect both consumers and the environment. Current safety regulations for Li-O bio-based products focus on several key areas to mitigate potential risks associated with these novel materials.

One primary concern is the potential for lithium leaching from the bio-based matrix. Regulatory bodies have implemented strict limits on the allowable lithium content in consumer products, particularly those that may come into contact with food or skin. These regulations typically require manufacturers to conduct thorough leaching tests under various environmental conditions to ensure the stability of the lithium oxide within the bio-based material.

Fire safety is another critical aspect addressed by current regulations. Li-O bio-based products must undergo rigorous flammability testing to assess their behavior under extreme heat conditions. This includes evaluating the potential for thermal runaway and the release of toxic gases during combustion. Manufacturers are required to implement appropriate fire-retardant measures and provide clear safety instructions for product use and disposal.

Environmental impact assessments are mandatory for Li-O bio-based products, with regulations focusing on biodegradability and potential ecological effects. Manufacturers must demonstrate that their products do not pose long-term environmental risks, particularly in terms of lithium accumulation in soil and water systems. This often involves extensive lifecycle analysis and eco-toxicity studies.

Workplace safety regulations have also been established to protect workers involved in the production and handling of Li-O bio-based materials. These include guidelines for personal protective equipment, proper ventilation systems, and protocols for handling and storing lithium-containing compounds. Regular safety training and health monitoring programs are typically required for employees in this sector.

Transportation and storage regulations for Li-O bio-based products are particularly stringent, given the reactive nature of lithium compounds. Special packaging requirements, labeling standards, and handling procedures have been implemented to prevent accidents during shipping and warehousing. These regulations often align with existing guidelines for lithium-ion batteries but are tailored to address the unique properties of bio-based matrices.

As research in this field progresses, regulatory bodies are continuously updating safety standards to keep pace with technological advancements. This includes the development of new testing methodologies and the refinement of exposure limits based on the latest scientific data. Collaboration between industry stakeholders, research institutions, and regulatory agencies is crucial in ensuring that safety regulations remain effective and relevant for emerging Li-O bio-based technologies.

One primary concern is the potential for lithium leaching from the bio-based matrix. Regulatory bodies have implemented strict limits on the allowable lithium content in consumer products, particularly those that may come into contact with food or skin. These regulations typically require manufacturers to conduct thorough leaching tests under various environmental conditions to ensure the stability of the lithium oxide within the bio-based material.

Fire safety is another critical aspect addressed by current regulations. Li-O bio-based products must undergo rigorous flammability testing to assess their behavior under extreme heat conditions. This includes evaluating the potential for thermal runaway and the release of toxic gases during combustion. Manufacturers are required to implement appropriate fire-retardant measures and provide clear safety instructions for product use and disposal.

Environmental impact assessments are mandatory for Li-O bio-based products, with regulations focusing on biodegradability and potential ecological effects. Manufacturers must demonstrate that their products do not pose long-term environmental risks, particularly in terms of lithium accumulation in soil and water systems. This often involves extensive lifecycle analysis and eco-toxicity studies.

Workplace safety regulations have also been established to protect workers involved in the production and handling of Li-O bio-based materials. These include guidelines for personal protective equipment, proper ventilation systems, and protocols for handling and storing lithium-containing compounds. Regular safety training and health monitoring programs are typically required for employees in this sector.

Transportation and storage regulations for Li-O bio-based products are particularly stringent, given the reactive nature of lithium compounds. Special packaging requirements, labeling standards, and handling procedures have been implemented to prevent accidents during shipping and warehousing. These regulations often align with existing guidelines for lithium-ion batteries but are tailored to address the unique properties of bio-based matrices.

As research in this field progresses, regulatory bodies are continuously updating safety standards to keep pace with technological advancements. This includes the development of new testing methodologies and the refinement of exposure limits based on the latest scientific data. Collaboration between industry stakeholders, research institutions, and regulatory agencies is crucial in ensuring that safety regulations remain effective and relevant for emerging Li-O bio-based technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!