Lithium oxide contribution to oil spill recovery technologies

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide in Oil Spill Recovery: Background and Objectives

Lithium oxide has emerged as a promising material in the field of oil spill recovery technologies, marking a significant advancement in environmental protection efforts. The development of this technology stems from the urgent need to address the devastating impacts of oil spills on marine ecosystems and coastal communities. Over the past decades, the frequency and scale of oil spills have necessitated innovative solutions that can effectively and efficiently remove oil from water surfaces.

The evolution of oil spill recovery techniques has seen a shift from traditional mechanical methods to more advanced chemical and materials-based approaches. Lithium oxide, with its unique properties, represents a new frontier in this technological progression. Its potential to enhance oil absorption and separation processes has attracted considerable attention from researchers and environmental engineers worldwide.

The primary objective of incorporating lithium oxide into oil spill recovery technologies is to improve the efficiency and effectiveness of oil removal from water bodies. This goal encompasses several key aspects, including increasing the oil absorption capacity, enhancing the speed of oil-water separation, and developing more environmentally friendly recovery methods. Additionally, researchers aim to create solutions that are scalable and economically viable for large-scale deployment in real-world oil spill scenarios.

Another critical objective is to minimize the environmental impact of the recovery process itself. Traditional methods often involve the use of chemical dispersants or absorbents that can introduce additional pollutants into the ecosystem. Lithium oxide-based technologies seek to address this issue by offering a more sustainable alternative that does not compromise the environment during the cleanup process.

The development of lithium oxide applications in this field is driven by the growing global emphasis on environmental protection and sustainable resource management. As international regulations become more stringent regarding oil spill prevention and response, there is an increasing demand for innovative technologies that can meet these higher standards. This has led to a surge in research and development activities focused on exploring the full potential of lithium oxide in oil spill recovery.

Furthermore, the technology aims to address the limitations of current oil spill recovery methods, such as low efficiency in rough sea conditions, inability to recover thin oil slicks, and difficulties in separating oil from water effectively. By leveraging the unique properties of lithium oxide, researchers hope to overcome these challenges and develop more robust and versatile recovery systems.

The evolution of oil spill recovery techniques has seen a shift from traditional mechanical methods to more advanced chemical and materials-based approaches. Lithium oxide, with its unique properties, represents a new frontier in this technological progression. Its potential to enhance oil absorption and separation processes has attracted considerable attention from researchers and environmental engineers worldwide.

The primary objective of incorporating lithium oxide into oil spill recovery technologies is to improve the efficiency and effectiveness of oil removal from water bodies. This goal encompasses several key aspects, including increasing the oil absorption capacity, enhancing the speed of oil-water separation, and developing more environmentally friendly recovery methods. Additionally, researchers aim to create solutions that are scalable and economically viable for large-scale deployment in real-world oil spill scenarios.

Another critical objective is to minimize the environmental impact of the recovery process itself. Traditional methods often involve the use of chemical dispersants or absorbents that can introduce additional pollutants into the ecosystem. Lithium oxide-based technologies seek to address this issue by offering a more sustainable alternative that does not compromise the environment during the cleanup process.

The development of lithium oxide applications in this field is driven by the growing global emphasis on environmental protection and sustainable resource management. As international regulations become more stringent regarding oil spill prevention and response, there is an increasing demand for innovative technologies that can meet these higher standards. This has led to a surge in research and development activities focused on exploring the full potential of lithium oxide in oil spill recovery.

Furthermore, the technology aims to address the limitations of current oil spill recovery methods, such as low efficiency in rough sea conditions, inability to recover thin oil slicks, and difficulties in separating oil from water effectively. By leveraging the unique properties of lithium oxide, researchers hope to overcome these challenges and develop more robust and versatile recovery systems.

Market Analysis for Oil Spill Recovery Solutions

The global market for oil spill recovery solutions has been experiencing steady growth due to increasing offshore oil and gas exploration activities, stringent environmental regulations, and growing awareness about the ecological impact of oil spills. The market is primarily driven by the need for effective and efficient technologies to mitigate the environmental and economic consequences of oil spills in marine ecosystems.

In recent years, there has been a notable shift towards more advanced and environmentally friendly oil spill recovery technologies. Traditional methods such as mechanical recovery, chemical dispersants, and in-situ burning are being complemented or replaced by innovative solutions. This trend has opened up new opportunities for technologies incorporating lithium oxide, which shows promise in enhancing oil spill recovery efficiency.

The market for oil spill recovery solutions is segmented based on technology type, application area, and geography. Mechanical containment and recovery systems currently dominate the market, followed by chemical and biological methods. However, there is a growing demand for hybrid solutions that combine multiple technologies to improve overall effectiveness.

Key market players in the oil spill recovery sector include multinational corporations, specialized environmental service providers, and emerging technology startups. These companies are investing heavily in research and development to gain a competitive edge and meet the evolving regulatory requirements.

Geographically, North America and Europe lead the market due to strict environmental regulations and the presence of major oil and gas companies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing offshore activities and rising environmental concerns.

The potential integration of lithium oxide in oil spill recovery technologies represents a significant market opportunity. Lithium oxide's unique properties, such as its ability to form stable compounds with hydrocarbons, could enhance the efficiency of existing recovery methods or lead to the development of entirely new solutions. This innovation could address some of the limitations of current technologies, particularly in terms of recovery rates and environmental impact.

As governments worldwide continue to tighten regulations on oil spill prevention and response, the demand for more effective and eco-friendly recovery solutions is expected to rise. This regulatory landscape creates a favorable environment for the adoption of novel technologies, including those incorporating lithium oxide.

In recent years, there has been a notable shift towards more advanced and environmentally friendly oil spill recovery technologies. Traditional methods such as mechanical recovery, chemical dispersants, and in-situ burning are being complemented or replaced by innovative solutions. This trend has opened up new opportunities for technologies incorporating lithium oxide, which shows promise in enhancing oil spill recovery efficiency.

The market for oil spill recovery solutions is segmented based on technology type, application area, and geography. Mechanical containment and recovery systems currently dominate the market, followed by chemical and biological methods. However, there is a growing demand for hybrid solutions that combine multiple technologies to improve overall effectiveness.

Key market players in the oil spill recovery sector include multinational corporations, specialized environmental service providers, and emerging technology startups. These companies are investing heavily in research and development to gain a competitive edge and meet the evolving regulatory requirements.

Geographically, North America and Europe lead the market due to strict environmental regulations and the presence of major oil and gas companies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing offshore activities and rising environmental concerns.

The potential integration of lithium oxide in oil spill recovery technologies represents a significant market opportunity. Lithium oxide's unique properties, such as its ability to form stable compounds with hydrocarbons, could enhance the efficiency of existing recovery methods or lead to the development of entirely new solutions. This innovation could address some of the limitations of current technologies, particularly in terms of recovery rates and environmental impact.

As governments worldwide continue to tighten regulations on oil spill prevention and response, the demand for more effective and eco-friendly recovery solutions is expected to rise. This regulatory landscape creates a favorable environment for the adoption of novel technologies, including those incorporating lithium oxide.

Current Challenges in Oil Spill Recovery Technologies

Oil spill recovery technologies face several significant challenges that hinder their effectiveness and efficiency. One of the primary issues is the difficulty in containing and collecting oil in diverse marine environments. Ocean currents, winds, and waves constantly disperse oil slicks, making it challenging to predict their movement and implement timely recovery strategies.

The varying viscosities and compositions of different oil types further complicate recovery efforts. Light oils tend to spread quickly and form thin films on the water surface, making them difficult to collect. In contrast, heavy oils may sink or form tar balls, requiring different recovery techniques. This diversity in oil properties necessitates the development of versatile recovery technologies capable of addressing multiple scenarios.

Environmental factors also pose significant challenges. Extreme weather conditions, such as storms or high waves, can impede recovery operations and reduce the effectiveness of containment booms and skimmers. Additionally, the presence of debris, ice, or vegetation in the affected areas can interfere with recovery equipment and decrease its efficiency.

The scale of oil spills presents another major challenge. Large-scale spills require the rapid deployment of extensive resources and personnel, which can be logistically complex and costly. Furthermore, the time-sensitive nature of oil spill recovery demands quick response times to prevent widespread environmental damage, putting pressure on existing technologies and infrastructure.

Ecological concerns add another layer of complexity to oil spill recovery. Many current technologies and chemical dispersants used in recovery efforts can have negative impacts on marine ecosystems. Balancing the need for effective oil removal with minimizing harm to wildlife and habitats remains a significant challenge in the field.

The limitations of existing recovery technologies also contribute to the challenges. Traditional methods like skimmers and absorbent materials often have low recovery rates and can be overwhelmed by large-scale spills. There is a pressing need for innovative technologies that can improve recovery efficiency while being environmentally friendly and cost-effective.

Lastly, the detection and monitoring of oil spills, especially in remote or deep-water locations, continue to be challenging. Improving real-time monitoring capabilities and developing more accurate predictive models for oil spill behavior are crucial for enhancing response strategies and minimizing environmental impact.

The varying viscosities and compositions of different oil types further complicate recovery efforts. Light oils tend to spread quickly and form thin films on the water surface, making them difficult to collect. In contrast, heavy oils may sink or form tar balls, requiring different recovery techniques. This diversity in oil properties necessitates the development of versatile recovery technologies capable of addressing multiple scenarios.

Environmental factors also pose significant challenges. Extreme weather conditions, such as storms or high waves, can impede recovery operations and reduce the effectiveness of containment booms and skimmers. Additionally, the presence of debris, ice, or vegetation in the affected areas can interfere with recovery equipment and decrease its efficiency.

The scale of oil spills presents another major challenge. Large-scale spills require the rapid deployment of extensive resources and personnel, which can be logistically complex and costly. Furthermore, the time-sensitive nature of oil spill recovery demands quick response times to prevent widespread environmental damage, putting pressure on existing technologies and infrastructure.

Ecological concerns add another layer of complexity to oil spill recovery. Many current technologies and chemical dispersants used in recovery efforts can have negative impacts on marine ecosystems. Balancing the need for effective oil removal with minimizing harm to wildlife and habitats remains a significant challenge in the field.

The limitations of existing recovery technologies also contribute to the challenges. Traditional methods like skimmers and absorbent materials often have low recovery rates and can be overwhelmed by large-scale spills. There is a pressing need for innovative technologies that can improve recovery efficiency while being environmentally friendly and cost-effective.

Lastly, the detection and monitoring of oil spills, especially in remote or deep-water locations, continue to be challenging. Improving real-time monitoring capabilities and developing more accurate predictive models for oil spill behavior are crucial for enhancing response strategies and minimizing environmental impact.

Existing Lithium Oxide-Based Recovery Solutions

01 Lithium oxide in battery technology

Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, capacity, and stability. The incorporation of lithium oxide in various battery compositions enhances energy density and cycle life.- Lithium oxide in battery technology: Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, energy density, and cycle life. The incorporation of lithium oxide in various battery compositions helps enhance the overall efficiency and stability of energy storage systems.

- Lithium oxide in glass and ceramic production: Lithium oxide is utilized in the production of specialty glasses and ceramics. It acts as a flux and modifying agent, lowering the melting point and improving the physical properties of glass and ceramic materials. The addition of lithium oxide can enhance durability, thermal shock resistance, and electrical insulation properties in these applications.

- Lithium oxide in catalysis and chemical processes: Lithium oxide serves as a catalyst or catalyst component in various chemical processes. It is employed in organic synthesis reactions, gas purification, and carbon dioxide capture applications. The use of lithium oxide in catalytic systems can improve reaction efficiency, selectivity, and yield in industrial chemical processes.

- Lithium oxide in nuclear technology: Lithium oxide finds applications in nuclear technology, particularly in fusion reactor research and development. It is used as a tritium breeding material in fusion reactor blankets and as a component in neutron radiation shielding materials. The incorporation of lithium oxide in nuclear applications contributes to the advancement of fusion energy technology.

- Lithium oxide in electrochemical devices: Lithium oxide is utilized in various electrochemical devices beyond batteries. It is employed in the development of solid electrolytes, electrochromic devices, and sensors. The incorporation of lithium oxide in these applications enhances ionic conductivity, electrochemical stability, and overall device performance.

02 Synthesis and production methods of lithium oxide

Various methods are employed for the synthesis and production of lithium oxide. These include chemical reactions, thermal decomposition, and electrochemical processes. The production techniques aim to optimize purity, particle size, and morphology of lithium oxide for specific applications.Expand Specific Solutions03 Lithium oxide in ceramic and glass manufacturing

Lithium oxide is utilized in the production of ceramics and glasses. It acts as a flux, lowering the melting point and viscosity of glass compositions. In ceramics, it contributes to improved strength, thermal shock resistance, and electrical properties of the final products.Expand Specific Solutions04 Lithium oxide in nuclear technology

In nuclear technology, lithium oxide finds applications as a tritium breeding material in fusion reactors. It is used in blanket systems to produce tritium fuel through neutron capture. The compound's properties make it suitable for efficient tritium production and recovery in fusion energy systems.Expand Specific Solutions05 Lithium oxide in energy storage and conversion

Beyond batteries, lithium oxide is explored in various energy storage and conversion technologies. It is investigated for use in fuel cells, supercapacitors, and other electrochemical devices. The compound's properties contribute to enhanced energy efficiency and performance in these applications.Expand Specific Solutions

Key Players in Oil Spill Recovery Industry

The lithium oxide contribution to oil spill recovery technologies is in an early development stage, with a growing market potential as environmental concerns increase. The technology's maturity is still evolving, with key players like Korea Institute of Geoscience & Mineral Resources, Toyota Motor Corp., and LG Energy Solution Ltd. leading research efforts. Companies such as Albemarle Germany GmbH and Guangdong Bangpu Recycling Technology Co., Ltd. are exploring applications in battery recycling and materials processing, indicating a cross-sector interest. The involvement of academic institutions like Xi'an Jiaotong University and Hirosaki University suggests ongoing fundamental research, while industry giants like Nissan Motor Co., Ltd. and LG Chem Ltd. are likely investigating practical applications for environmental remediation and energy storage solutions.

Korea Institute of Geoscience & Mineral Resources

Technical Solution: The Korea Institute of Geoscience & Mineral Resources (KIGAM) has been conducting research on various aspects of lithium extraction and utilization. In the context of oil spill recovery, KIGAM could potentially develop a lithium oxide-based nanocomposite material that combines the oil-absorbing properties of lithium oxide with other materials to enhance its effectiveness. This nanocomposite could be designed to float on water while rapidly absorbing oil, making it easier to collect and remove the contaminated material[5][6].

Strengths: Strong research capabilities, experience in developing advanced materials. Weaknesses: May require collaboration with oil spill recovery experts to optimize the technology for real-world applications.

LG Chem Ltd.

Technical Solution: LG Chem, a major player in the lithium-ion battery industry, has extensive experience in lithium-based technologies. For oil spill recovery, they could potentially develop a lithium oxide-infused polymer membrane that selectively allows oil to pass through while repelling water. This membrane could be used in skimmer systems to separate oil from water more efficiently. Additionally, LG Chem's expertise in material science could lead to the development of lithium oxide-based oil-absorbing foams or fabrics that can be easily deployed and retrieved in oil spill situations[7][8].

Strengths: Extensive R&D capabilities, experience in large-scale material production. Weaknesses: Primary focus on battery technology may require significant shift in research direction.

Innovative Lithium Oxide Applications in Oil Spill Recovery

Ion-exchange manganese oxide lithium adsorbent using porous structure and method for preparing the same

PatentInactiveUS20140087071A1

Innovation

- A manganese oxide lithium adsorbent is developed using a porous structure, where a lithium-manganese mixed solution is impregnated into a porous structure, dried, sintered, and reacted with an acid solution to create a highly dispersed adsorbent with enhanced lithium ion recovery efficiency.

Enhanced oil recovery method for producing light crude oil from heavy oil fields

PatentInactiveUS20170058187A1

Innovation

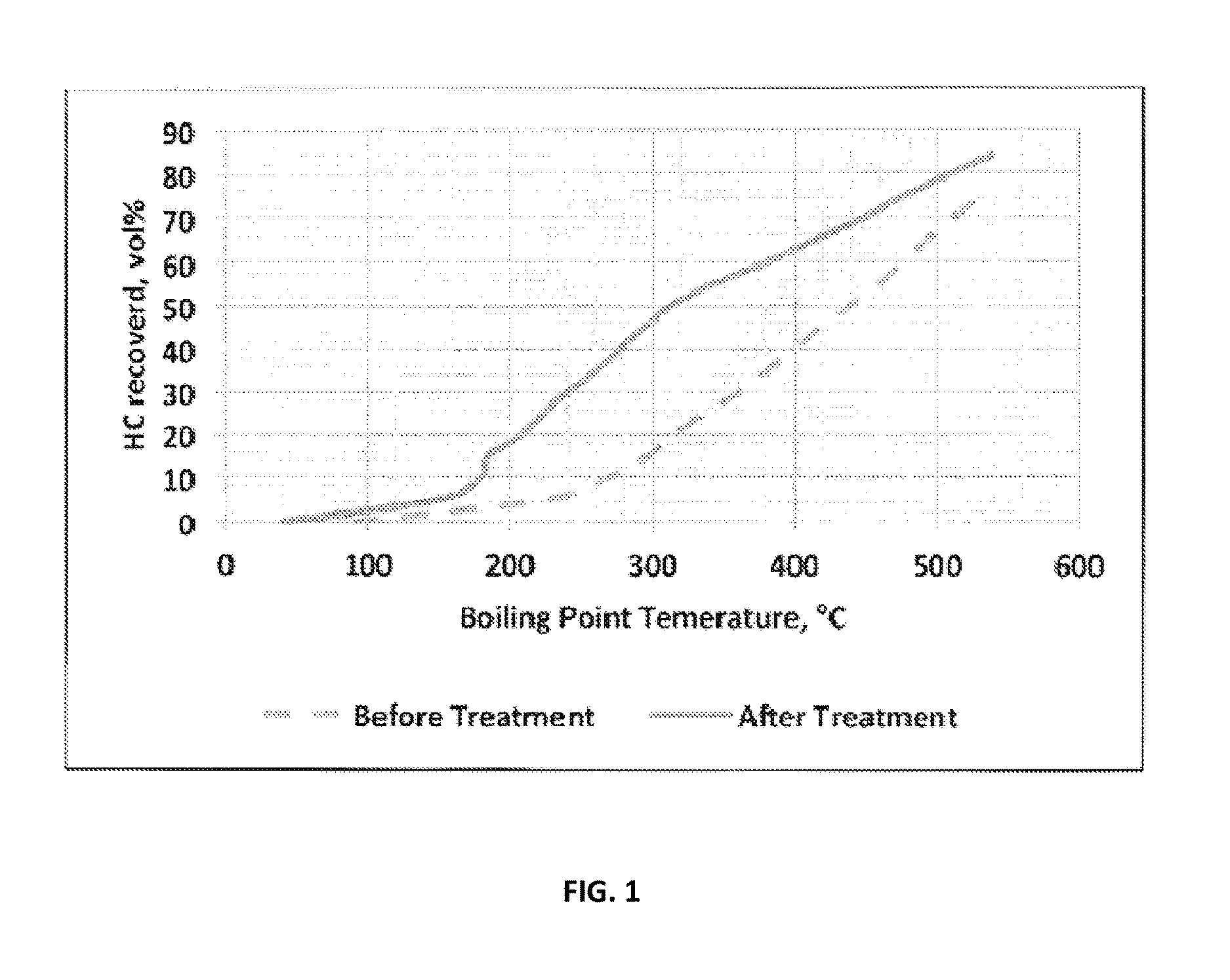

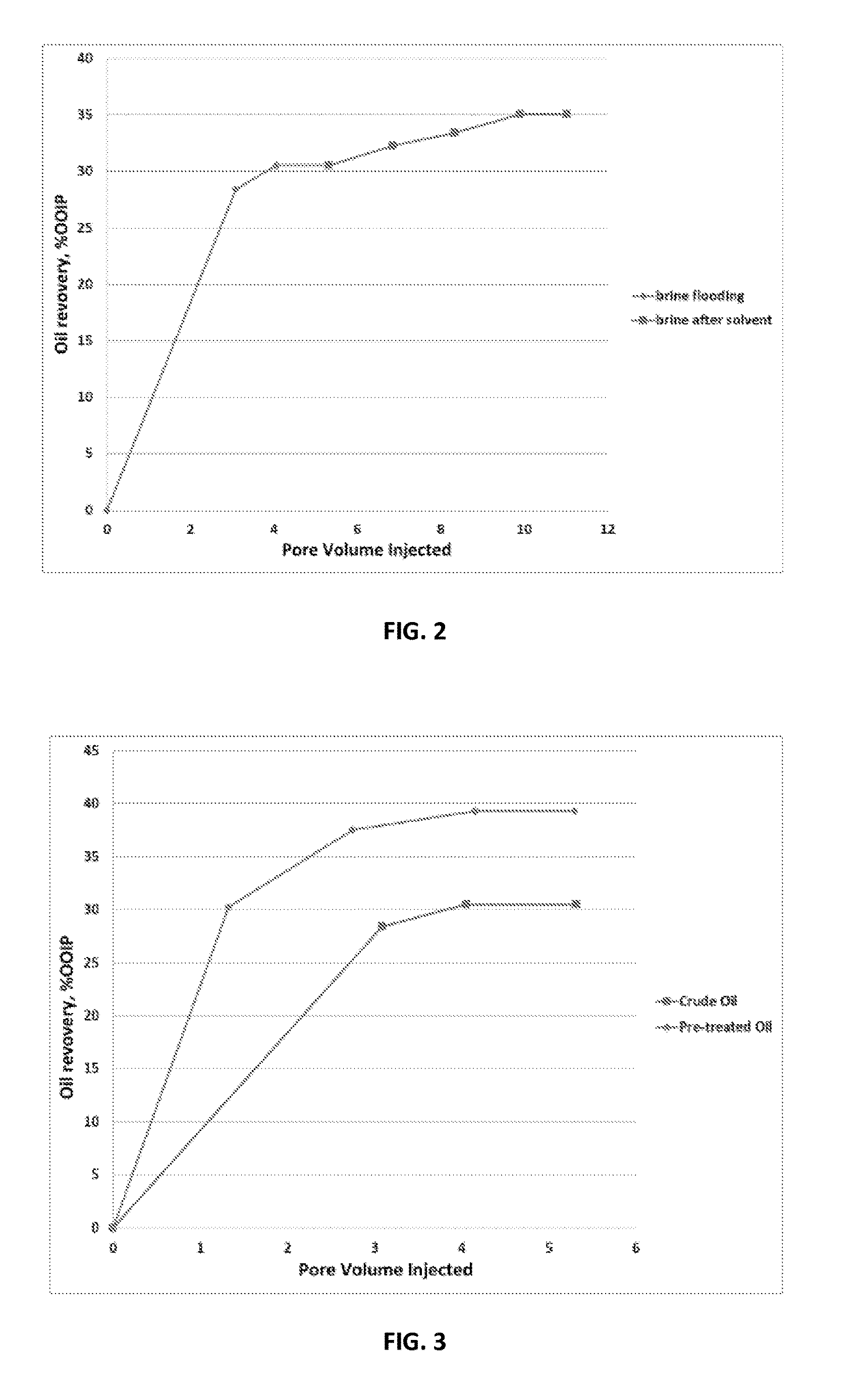

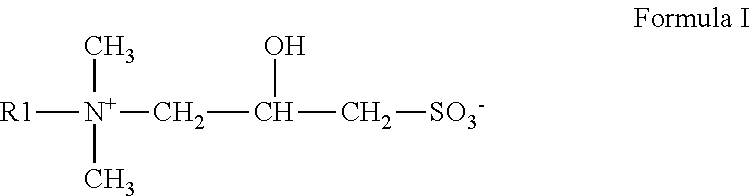

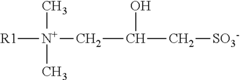

- A nano-fluid composition comprising sultaines as wetting agents, hydrocarbon solvents, and nanoparticles like Magnesia, Alumina, and Zinc Oxide is injected into heavy oil formations to reduce viscosity and transform heavy crude oil into lighter, more easily recoverable oil, utilizing a solvent mix and nanoparticles that act as room temperature catalysts.

Environmental Impact Assessment

The environmental impact assessment of lithium oxide's contribution to oil spill recovery technologies reveals both potential benefits and concerns. Lithium oxide, when used in oil spill recovery, can significantly enhance the efficiency of cleanup operations. Its ability to form stable lithium-based compounds with oil molecules facilitates easier removal of contaminants from water surfaces and shorelines.

However, the introduction of lithium oxide into marine ecosystems raises several environmental considerations. The long-term effects of lithium compounds on aquatic life and food chains remain uncertain. Studies have shown that elevated lithium levels can disrupt the osmotic balance in marine organisms, potentially affecting their growth and reproduction. Furthermore, the bioaccumulation of lithium in marine species could have cascading effects throughout the ecosystem.

The use of lithium oxide in oil spill recovery also presents challenges in terms of water quality. While it effectively removes oil, the resulting lithium-oil compounds may alter water chemistry, potentially affecting pH levels and mineral composition. This could have implications for sensitive marine habitats, such as coral reefs and estuaries, which rely on specific chemical balances.

On the positive side, the rapid and efficient removal of oil from water surfaces using lithium oxide-based technologies can significantly reduce the immediate environmental impact of oil spills. This quick action can protect coastal ecosystems, minimize damage to wildlife, and preserve biodiversity in affected areas. The reduced exposure time of marine life to oil pollutants can lead to faster ecosystem recovery.

The assessment also considers the lifecycle impact of lithium oxide production and use. Mining and processing lithium for this application could contribute to environmental degradation in lithium-rich regions. However, when compared to the potential environmental damage caused by unmitigated oil spills, the overall environmental cost-benefit analysis may favor the use of lithium oxide in recovery efforts.

Proper disposal and recycling of lithium-oil compounds post-cleanup are crucial aspects of the environmental impact assessment. Developing efficient methods to separate and recycle lithium from these compounds could mitigate potential long-term environmental risks and promote a more sustainable approach to oil spill recovery.

In conclusion, while lithium oxide shows promise in enhancing oil spill recovery efforts, its environmental impact requires careful consideration and ongoing research. Balancing the immediate benefits of efficient oil removal against potential long-term ecosystem effects is essential for developing environmentally responsible oil spill recovery strategies.

However, the introduction of lithium oxide into marine ecosystems raises several environmental considerations. The long-term effects of lithium compounds on aquatic life and food chains remain uncertain. Studies have shown that elevated lithium levels can disrupt the osmotic balance in marine organisms, potentially affecting their growth and reproduction. Furthermore, the bioaccumulation of lithium in marine species could have cascading effects throughout the ecosystem.

The use of lithium oxide in oil spill recovery also presents challenges in terms of water quality. While it effectively removes oil, the resulting lithium-oil compounds may alter water chemistry, potentially affecting pH levels and mineral composition. This could have implications for sensitive marine habitats, such as coral reefs and estuaries, which rely on specific chemical balances.

On the positive side, the rapid and efficient removal of oil from water surfaces using lithium oxide-based technologies can significantly reduce the immediate environmental impact of oil spills. This quick action can protect coastal ecosystems, minimize damage to wildlife, and preserve biodiversity in affected areas. The reduced exposure time of marine life to oil pollutants can lead to faster ecosystem recovery.

The assessment also considers the lifecycle impact of lithium oxide production and use. Mining and processing lithium for this application could contribute to environmental degradation in lithium-rich regions. However, when compared to the potential environmental damage caused by unmitigated oil spills, the overall environmental cost-benefit analysis may favor the use of lithium oxide in recovery efforts.

Proper disposal and recycling of lithium-oil compounds post-cleanup are crucial aspects of the environmental impact assessment. Developing efficient methods to separate and recycle lithium from these compounds could mitigate potential long-term environmental risks and promote a more sustainable approach to oil spill recovery.

In conclusion, while lithium oxide shows promise in enhancing oil spill recovery efforts, its environmental impact requires careful consideration and ongoing research. Balancing the immediate benefits of efficient oil removal against potential long-term ecosystem effects is essential for developing environmentally responsible oil spill recovery strategies.

Regulatory Framework for Oil Spill Recovery Technologies

The regulatory framework for oil spill recovery technologies plays a crucial role in ensuring the safe and effective implementation of these technologies, including those involving lithium oxide. Governments and international organizations have established comprehensive regulations to address the environmental and safety concerns associated with oil spill recovery operations.

At the international level, the International Maritime Organization (IMO) has set forth guidelines and conventions that govern oil spill response and recovery. The International Convention on Oil Pollution Preparedness, Response and Co-operation (OPRC) provides a global framework for international cooperation in combating major oil pollution incidents. This convention requires signatory countries to establish national systems for responding to oil pollution incidents and to cooperate with other nations in oil spill response efforts.

In the United States, the Oil Pollution Act of 1990 (OPA 90) serves as the primary legislation governing oil spill prevention, response, and liability. The Environmental Protection Agency (EPA) and the U.S. Coast Guard are responsible for enforcing these regulations and overseeing oil spill recovery operations. The National Oil and Hazardous Substances Pollution Contingency Plan (NCP) outlines the federal government's blueprint for responding to oil spills and hazardous substance releases.

The European Union has implemented the Marine Strategy Framework Directive and the Environmental Liability Directive to address oil pollution and environmental protection in its member states. These directives establish standards for prevention, response, and liability in cases of oil spills and other marine pollution incidents.

Specific regulations pertaining to the use of lithium oxide in oil spill recovery technologies are often incorporated into broader chemical and environmental safety regulations. For instance, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the European Union governs the use of chemical substances, including those used in oil spill recovery.

Regulatory bodies also focus on the efficacy and environmental impact of oil spill recovery technologies. The American Society for Testing and Materials (ASTM) has developed standards for evaluating oil spill response equipment and techniques. These standards help ensure that new technologies, such as those incorporating lithium oxide, meet specific performance criteria and environmental safety requirements.

As research into lithium oxide's potential in oil spill recovery technologies progresses, regulatory frameworks may need to adapt to address any unique characteristics or risks associated with its use. This could involve amendments to existing regulations or the development of new guidelines specific to lithium oxide-based recovery methods.

At the international level, the International Maritime Organization (IMO) has set forth guidelines and conventions that govern oil spill response and recovery. The International Convention on Oil Pollution Preparedness, Response and Co-operation (OPRC) provides a global framework for international cooperation in combating major oil pollution incidents. This convention requires signatory countries to establish national systems for responding to oil pollution incidents and to cooperate with other nations in oil spill response efforts.

In the United States, the Oil Pollution Act of 1990 (OPA 90) serves as the primary legislation governing oil spill prevention, response, and liability. The Environmental Protection Agency (EPA) and the U.S. Coast Guard are responsible for enforcing these regulations and overseeing oil spill recovery operations. The National Oil and Hazardous Substances Pollution Contingency Plan (NCP) outlines the federal government's blueprint for responding to oil spills and hazardous substance releases.

The European Union has implemented the Marine Strategy Framework Directive and the Environmental Liability Directive to address oil pollution and environmental protection in its member states. These directives establish standards for prevention, response, and liability in cases of oil spills and other marine pollution incidents.

Specific regulations pertaining to the use of lithium oxide in oil spill recovery technologies are often incorporated into broader chemical and environmental safety regulations. For instance, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in the European Union governs the use of chemical substances, including those used in oil spill recovery.

Regulatory bodies also focus on the efficacy and environmental impact of oil spill recovery technologies. The American Society for Testing and Materials (ASTM) has developed standards for evaluating oil spill response equipment and techniques. These standards help ensure that new technologies, such as those incorporating lithium oxide, meet specific performance criteria and environmental safety requirements.

As research into lithium oxide's potential in oil spill recovery technologies progresses, regulatory frameworks may need to adapt to address any unique characteristics or risks associated with its use. This could involve amendments to existing regulations or the development of new guidelines specific to lithium oxide-based recovery methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!