Lithium oxide in bio-sensing technologies

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide Biosensing Background and Objectives

Lithium oxide has emerged as a promising material in the field of biosensing technologies, offering unique properties that enhance the detection and monitoring of biological analytes. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of lithium-based compounds in sensor applications. Over the past two decades, significant advancements have been made in understanding the fundamental properties of lithium oxide and its interactions with biological molecules.

The technological trajectory of lithium oxide in biosensing has been driven by the increasing demand for more sensitive, selective, and reliable biosensors in various fields, including healthcare, environmental monitoring, and food safety. As the global population continues to grow and age, there is a pressing need for rapid, accurate, and cost-effective diagnostic tools. Lithium oxide-based biosensors have shown promise in addressing these challenges, particularly in the detection of biomarkers associated with various diseases and environmental contaminants.

One of the key trends in this field is the miniaturization and integration of lithium oxide-based biosensors into portable and wearable devices. This trend aligns with the broader movement towards personalized medicine and point-of-care diagnostics. Researchers are focusing on developing novel fabrication techniques and nanostructured lithium oxide materials to enhance the performance and reduce the size of these biosensors.

Another significant trend is the exploration of lithium oxide's potential in multimodal sensing platforms. By combining lithium oxide with other materials or sensing modalities, researchers aim to create more versatile and robust biosensing systems capable of detecting multiple analytes simultaneously or providing complementary information about a single analyte.

The primary technological objectives in this field include improving the sensitivity and selectivity of lithium oxide-based biosensors, enhancing their stability and longevity in diverse environments, and developing scalable manufacturing processes for commercial applications. Researchers are also working on optimizing the surface functionalization of lithium oxide to enable more specific and efficient binding of target biomolecules.

Furthermore, there is a growing interest in leveraging the unique properties of lithium oxide for developing novel biosensing mechanisms. This includes exploring its potential in electrochemical, optical, and piezoelectric sensing modalities, as well as investigating its compatibility with emerging technologies such as microfluidics and lab-on-a-chip devices.

As the field progresses, interdisciplinary collaboration between materials scientists, chemists, biologists, and engineers will be crucial in overcoming current limitations and realizing the full potential of lithium oxide in biosensing technologies. The ultimate goal is to develop highly sensitive, specific, and reliable biosensors that can revolutionize disease diagnosis, environmental monitoring, and biomedical research.

The technological trajectory of lithium oxide in biosensing has been driven by the increasing demand for more sensitive, selective, and reliable biosensors in various fields, including healthcare, environmental monitoring, and food safety. As the global population continues to grow and age, there is a pressing need for rapid, accurate, and cost-effective diagnostic tools. Lithium oxide-based biosensors have shown promise in addressing these challenges, particularly in the detection of biomarkers associated with various diseases and environmental contaminants.

One of the key trends in this field is the miniaturization and integration of lithium oxide-based biosensors into portable and wearable devices. This trend aligns with the broader movement towards personalized medicine and point-of-care diagnostics. Researchers are focusing on developing novel fabrication techniques and nanostructured lithium oxide materials to enhance the performance and reduce the size of these biosensors.

Another significant trend is the exploration of lithium oxide's potential in multimodal sensing platforms. By combining lithium oxide with other materials or sensing modalities, researchers aim to create more versatile and robust biosensing systems capable of detecting multiple analytes simultaneously or providing complementary information about a single analyte.

The primary technological objectives in this field include improving the sensitivity and selectivity of lithium oxide-based biosensors, enhancing their stability and longevity in diverse environments, and developing scalable manufacturing processes for commercial applications. Researchers are also working on optimizing the surface functionalization of lithium oxide to enable more specific and efficient binding of target biomolecules.

Furthermore, there is a growing interest in leveraging the unique properties of lithium oxide for developing novel biosensing mechanisms. This includes exploring its potential in electrochemical, optical, and piezoelectric sensing modalities, as well as investigating its compatibility with emerging technologies such as microfluidics and lab-on-a-chip devices.

As the field progresses, interdisciplinary collaboration between materials scientists, chemists, biologists, and engineers will be crucial in overcoming current limitations and realizing the full potential of lithium oxide in biosensing technologies. The ultimate goal is to develop highly sensitive, specific, and reliable biosensors that can revolutionize disease diagnosis, environmental monitoring, and biomedical research.

Market Analysis for Lithium Oxide Biosensors

The market for lithium oxide biosensors is experiencing significant growth, driven by increasing demand for rapid, accurate, and cost-effective diagnostic tools in healthcare and environmental monitoring. This emerging technology combines the unique properties of lithium oxide with advanced biosensing techniques to create highly sensitive and selective sensors for various biomarkers and analytes.

In the healthcare sector, lithium oxide biosensors are gaining traction for point-of-care diagnostics, enabling quick and reliable detection of diseases, metabolic disorders, and drug levels in patients. The global point-of-care diagnostics market, which includes biosensors, is projected to reach substantial value in the coming years, with lithium oxide biosensors poised to capture a growing share of this market.

Environmental monitoring applications represent another key growth area for lithium oxide biosensors. These sensors are being developed for detecting pollutants, toxins, and pathogens in water and air, addressing the increasing need for real-time environmental quality assessment. The environmental sensing market is expanding rapidly, driven by stricter regulations and growing public awareness of environmental issues.

The food and beverage industry is also showing interest in lithium oxide biosensors for quality control and safety testing. These sensors can detect contaminants, allergens, and pathogens in food products, offering a faster and more cost-effective alternative to traditional laboratory testing methods. As food safety regulations become more stringent globally, the demand for such advanced sensing technologies is expected to rise.

Geographically, North America and Europe currently lead the lithium oxide biosensor market, owing to their advanced healthcare infrastructure and strong research and development capabilities. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, fueled by increasing healthcare expenditure, rapid industrialization, and growing environmental concerns in countries like China and India.

Key market drivers include the rising prevalence of chronic diseases, the need for early and accurate diagnosis, and the push for personalized medicine. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of rapid diagnostic tools, further accelerating the adoption of biosensing technologies, including those based on lithium oxide.

Despite the promising outlook, challenges remain in the widespread adoption of lithium oxide biosensors. These include the need for further miniaturization, improved stability and reliability, and reduction in production costs. Overcoming these hurdles will be crucial for the technology to reach its full market potential and compete effectively with established sensing methods.

In the healthcare sector, lithium oxide biosensors are gaining traction for point-of-care diagnostics, enabling quick and reliable detection of diseases, metabolic disorders, and drug levels in patients. The global point-of-care diagnostics market, which includes biosensors, is projected to reach substantial value in the coming years, with lithium oxide biosensors poised to capture a growing share of this market.

Environmental monitoring applications represent another key growth area for lithium oxide biosensors. These sensors are being developed for detecting pollutants, toxins, and pathogens in water and air, addressing the increasing need for real-time environmental quality assessment. The environmental sensing market is expanding rapidly, driven by stricter regulations and growing public awareness of environmental issues.

The food and beverage industry is also showing interest in lithium oxide biosensors for quality control and safety testing. These sensors can detect contaminants, allergens, and pathogens in food products, offering a faster and more cost-effective alternative to traditional laboratory testing methods. As food safety regulations become more stringent globally, the demand for such advanced sensing technologies is expected to rise.

Geographically, North America and Europe currently lead the lithium oxide biosensor market, owing to their advanced healthcare infrastructure and strong research and development capabilities. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, fueled by increasing healthcare expenditure, rapid industrialization, and growing environmental concerns in countries like China and India.

Key market drivers include the rising prevalence of chronic diseases, the need for early and accurate diagnosis, and the push for personalized medicine. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of rapid diagnostic tools, further accelerating the adoption of biosensing technologies, including those based on lithium oxide.

Despite the promising outlook, challenges remain in the widespread adoption of lithium oxide biosensors. These include the need for further miniaturization, improved stability and reliability, and reduction in production costs. Overcoming these hurdles will be crucial for the technology to reach its full market potential and compete effectively with established sensing methods.

Current Challenges in Lithium Oxide Biosensing

Despite the promising potential of lithium oxide in bio-sensing technologies, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary obstacles is the stability of lithium oxide-based sensors in complex biological environments. The reactivity of lithium oxide with various biomolecules and ions present in biological samples can lead to interference and reduced sensor accuracy over time.

Another critical challenge lies in the sensitivity and selectivity of lithium oxide biosensors. While these sensors have shown promise in detecting certain biomolecules, achieving the required level of sensitivity for trace-level detection in clinical applications remains a hurdle. Additionally, improving the selectivity to distinguish target analytes from structurally similar compounds in complex biological matrices is an ongoing area of research.

The integration of lithium oxide-based sensing elements into miniaturized, portable devices presents another set of challenges. Issues such as maintaining sensor performance during miniaturization, ensuring long-term stability in compact formats, and developing compatible read-out systems for point-of-care applications are areas that require further investigation and innovation.

Reproducibility and standardization of lithium oxide biosensors also pose significant challenges. Variations in synthesis methods, surface functionalization techniques, and sensor fabrication processes can lead to inconsistencies in sensor performance across different batches or laboratories. Establishing standardized protocols for sensor production and characterization is crucial for the widespread adoption of this technology in clinical and commercial applications.

The biocompatibility and potential toxicity of lithium oxide nanostructures used in biosensing applications are also areas of concern. While lithium oxide has shown promise in terms of sensitivity and selectivity, ensuring its long-term safety for in vivo or continuous monitoring applications requires extensive toxicological studies and careful consideration of potential biological interactions.

Lastly, the cost-effectiveness of lithium oxide biosensors compared to existing sensing technologies remains a challenge. Developing scalable and economically viable production methods for high-quality lithium oxide materials and integrating them into cost-effective sensing platforms is essential for their commercial viability and widespread adoption in various biosensing applications.

Another critical challenge lies in the sensitivity and selectivity of lithium oxide biosensors. While these sensors have shown promise in detecting certain biomolecules, achieving the required level of sensitivity for trace-level detection in clinical applications remains a hurdle. Additionally, improving the selectivity to distinguish target analytes from structurally similar compounds in complex biological matrices is an ongoing area of research.

The integration of lithium oxide-based sensing elements into miniaturized, portable devices presents another set of challenges. Issues such as maintaining sensor performance during miniaturization, ensuring long-term stability in compact formats, and developing compatible read-out systems for point-of-care applications are areas that require further investigation and innovation.

Reproducibility and standardization of lithium oxide biosensors also pose significant challenges. Variations in synthesis methods, surface functionalization techniques, and sensor fabrication processes can lead to inconsistencies in sensor performance across different batches or laboratories. Establishing standardized protocols for sensor production and characterization is crucial for the widespread adoption of this technology in clinical and commercial applications.

The biocompatibility and potential toxicity of lithium oxide nanostructures used in biosensing applications are also areas of concern. While lithium oxide has shown promise in terms of sensitivity and selectivity, ensuring its long-term safety for in vivo or continuous monitoring applications requires extensive toxicological studies and careful consideration of potential biological interactions.

Lastly, the cost-effectiveness of lithium oxide biosensors compared to existing sensing technologies remains a challenge. Developing scalable and economically viable production methods for high-quality lithium oxide materials and integrating them into cost-effective sensing platforms is essential for their commercial viability and widespread adoption in various biosensing applications.

Existing Lithium Oxide Biosensing Solutions

01 Lithium oxide in battery technology

Lithium oxide is widely used in battery technology, particularly in lithium-ion batteries. It plays a crucial role in the cathode materials, contributing to improved battery performance, energy density, and cycle life. The compound is often incorporated into various electrode compositions to enhance the overall efficiency of energy storage devices.- Lithium oxide in battery technology: Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, energy density, and cycle life. The incorporation of lithium oxide in various battery compositions helps enhance the overall efficiency and stability of energy storage systems.

- Lithium oxide in glass and ceramic production: Lithium oxide is utilized in the production of specialty glasses and ceramics. It acts as a flux, lowering the melting point of glass and improving its workability. In ceramics, lithium oxide contributes to enhanced strength, thermal shock resistance, and reduced thermal expansion. These properties make it valuable in various industrial applications.

- Lithium oxide in nuclear technology: In nuclear technology, lithium oxide finds applications as a tritium breeding material in fusion reactors. It is used to produce tritium through neutron capture, which is essential for sustaining fusion reactions. The use of lithium oxide in this context contributes to the development of advanced nuclear energy systems.

- Lithium oxide in electrochemical devices: Lithium oxide is employed in various electrochemical devices beyond batteries. It is used in fuel cells, electrochromic windows, and sensors. The compound's ionic conductivity and electrochemical properties make it suitable for applications requiring efficient ion transport and electrochemical reactions.

- Lithium oxide in materials synthesis: Lithium oxide serves as a precursor or reactant in the synthesis of advanced materials. It is used in the production of lithium-based compounds, such as lithium niobate for optical applications, and in the synthesis of complex oxides for various technological applications. The compound's reactivity and lithium content make it valuable in materials science and engineering.

02 Synthesis and production methods of lithium oxide

Various methods for synthesizing and producing lithium oxide have been developed. These processes often involve chemical reactions, high-temperature treatments, or electrochemical techniques. The focus is on creating high-purity lithium oxide with controlled particle size and morphology, which is essential for its application in advanced materials and energy storage systems.Expand Specific Solutions03 Lithium oxide in ceramic and glass applications

Lithium oxide is utilized in ceramic and glass industries as a flux and to modify material properties. It can lower the melting point of ceramics, improve the strength and durability of glass, and enhance the thermal shock resistance of ceramic products. The compound is also used in the production of specialty glasses and advanced ceramic materials.Expand Specific Solutions04 Lithium oxide in nuclear technology

In nuclear technology, lithium oxide has applications related to fusion reactors and as a potential material for tritium breeding. It is being researched for its ability to produce tritium when bombarded with neutrons, which is crucial for sustaining fusion reactions. The compound's thermal and chemical properties make it suitable for certain nuclear applications.Expand Specific Solutions05 Lithium oxide in catalysis and chemical processes

Lithium oxide serves as a catalyst or catalyst component in various chemical processes. It is used in organic synthesis reactions, CO2 capture and conversion, and as a promoter in heterogeneous catalysis. The compound's basic nature and unique properties make it valuable in catalytic applications across different industrial sectors.Expand Specific Solutions

Key Players in Lithium Oxide Biosensor Development

The research on lithium oxide in bio-sensing technologies is in an emerging stage, with a growing market driven by increasing applications in healthcare and environmental monitoring. The global biosensors market, which includes lithium oxide-based technologies, is expected to reach significant growth in the coming years. Technologically, the field is still developing, with companies like Sumitomo Chemical, LG Energy Solution, and Murata Manufacturing leading research efforts. These firms are leveraging their expertise in battery and electronic materials to explore lithium oxide's potential in bio-sensing. Universities such as Central South University and the University of Maryland are also contributing to advancements, indicating a collaborative ecosystem between industry and academia. While promising, the technology's maturity level suggests further research and development is needed before widespread commercial adoption.

University of Maryland

Technical Solution: The University of Maryland has made significant strides in the research of lithium oxide for bio-sensing technologies. Their approach focuses on developing novel lithium oxide-based nanomaterials for enhanced biosensor performance. They have successfully synthesized lithium oxide nanoparticles with controlled size and morphology, which exhibit excellent biocompatibility and high sensitivity to various biomolecules[1]. The research team has also explored the integration of these nanoparticles into electrochemical biosensors, demonstrating improved detection limits and faster response times compared to conventional materials[3]. Additionally, they have investigated the use of lithium oxide in surface-enhanced Raman spectroscopy (SERS) substrates, enabling highly sensitive and selective detection of biomarkers[5].

Strengths: High sensitivity and selectivity, improved detection limits, and versatility in biosensing applications. Weaknesses: Potential challenges in large-scale production and long-term stability of the nanomaterials.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has been at the forefront of lithium oxide research for bio-sensing applications. Their innovative approach involves the development of lithium oxide-based composite materials for enhanced biosensor performance. The research team has successfully fabricated lithium oxide/graphene nanocomposites with improved electrical conductivity and surface area, leading to higher sensitivity in electrochemical biosensors[2]. They have also explored the use of lithium oxide in conjunction with conductive polymers to create flexible and wearable biosensors for real-time health monitoring[4]. Furthermore, the university has made progress in developing lithium oxide-based optical biosensors, utilizing the material's unique optical properties for label-free detection of biomolecules[6].

Strengths: Advanced composite materials, potential for wearable biosensors, and diverse sensing modalities. Weaknesses: Complexity in fabrication processes and potential cost implications for large-scale production.

Core Innovations in Lithium Oxide Biosensing

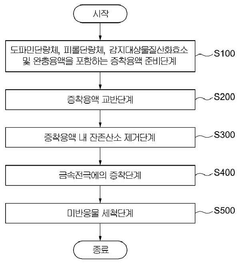

An electrochemical biosensor based on conductive polymer coated glucose oxidase nanocapsules and a preparation and application thereof

PatentActiveZA202402215A

Innovation

- Utilization of conductive polymer coated glucose oxidase nanocapsules to enhance enzyme stability in biosensors.

- Development of a preparation method for highly stable enzyme sensors based on enzyme molecule nanocapsules.

- Significant improvement in thermal stability, organic solvent tolerance, storage, and service life of the enzyme sensor.

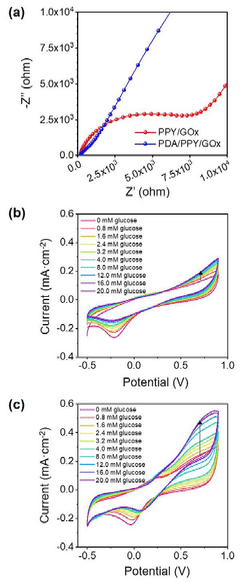

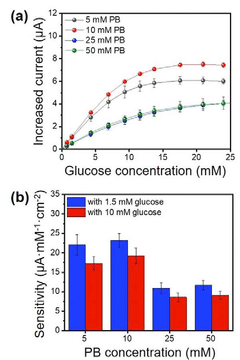

Electrochemical oxidase enzyme based biosensor containing polydopamine and method of manufacturing thereof

PatentActiveKR1020210158814A

Innovation

- The integration of polydopamine, a highly adhesive and biocompatible conductive polymer, with polypyrrole and a selective transmission layer enhances the adhesion of the sensing target material to the electrode, improving sensor stability and sensitivity through increased oxidase activity and electron transfer efficiency.

Regulatory Framework for Biosensing Technologies

The regulatory framework for biosensing technologies, particularly those involving lithium oxide, is a complex and evolving landscape. As these technologies continue to advance, regulatory bodies worldwide are working to establish comprehensive guidelines that ensure safety, efficacy, and ethical use.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing biosensing technologies. The FDA has established specific pathways for the approval of medical devices, including those utilizing lithium oxide in biosensing applications. These pathways typically involve rigorous clinical trials and extensive documentation to demonstrate safety and effectiveness.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR), which came into full effect in May 2022. This regulation sets stringent requirements for biosensing devices, including those incorporating lithium oxide. Manufacturers must comply with these regulations to obtain CE marking and market their products within the EU.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has established guidelines for the approval of biosensing technologies, while China's National Medical Products Administration (NMPA) has implemented regulations specific to innovative medical devices.

International standards, such as those developed by the International Organization for Standardization (ISO), play a crucial role in harmonizing regulatory approaches across different regions. ISO 13485, which specifies requirements for quality management systems in the medical device industry, is particularly relevant for biosensing technologies.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the Health Insurance Portability and Accountability Act (HIPAA) in the US, also impact the development and deployment of biosensing technologies. These regulations ensure the protection of sensitive health data collected by these devices.

As research on lithium oxide in biosensing technologies progresses, regulatory bodies are likely to adapt their frameworks to address specific challenges and risks associated with this emerging field. This may include the development of new guidelines for the use of lithium oxide in implantable biosensors or the establishment of specific performance standards for lithium oxide-based sensing devices.

Researchers and manufacturers in this field must stay abreast of these evolving regulations to ensure compliance and facilitate the successful development and commercialization of their technologies. Collaboration between industry stakeholders, regulatory bodies, and academic institutions will be crucial in shaping a regulatory framework that promotes innovation while safeguarding public health and safety.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing biosensing technologies. The FDA has established specific pathways for the approval of medical devices, including those utilizing lithium oxide in biosensing applications. These pathways typically involve rigorous clinical trials and extensive documentation to demonstrate safety and effectiveness.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR), which came into full effect in May 2022. This regulation sets stringent requirements for biosensing devices, including those incorporating lithium oxide. Manufacturers must comply with these regulations to obtain CE marking and market their products within the EU.

In Asia, countries like Japan and China have their own regulatory frameworks. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has established guidelines for the approval of biosensing technologies, while China's National Medical Products Administration (NMPA) has implemented regulations specific to innovative medical devices.

International standards, such as those developed by the International Organization for Standardization (ISO), play a crucial role in harmonizing regulatory approaches across different regions. ISO 13485, which specifies requirements for quality management systems in the medical device industry, is particularly relevant for biosensing technologies.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the Health Insurance Portability and Accountability Act (HIPAA) in the US, also impact the development and deployment of biosensing technologies. These regulations ensure the protection of sensitive health data collected by these devices.

As research on lithium oxide in biosensing technologies progresses, regulatory bodies are likely to adapt their frameworks to address specific challenges and risks associated with this emerging field. This may include the development of new guidelines for the use of lithium oxide in implantable biosensors or the establishment of specific performance standards for lithium oxide-based sensing devices.

Researchers and manufacturers in this field must stay abreast of these evolving regulations to ensure compliance and facilitate the successful development and commercialization of their technologies. Collaboration between industry stakeholders, regulatory bodies, and academic institutions will be crucial in shaping a regulatory framework that promotes innovation while safeguarding public health and safety.

Environmental Impact of Lithium Oxide Biosensors

The environmental impact of lithium oxide biosensors is a critical consideration in the development and deployment of these advanced sensing technologies. As these biosensors gain prominence in various applications, it is essential to assess their potential effects on ecosystems and human health throughout their lifecycle.

The production of lithium oxide biosensors involves the extraction and processing of lithium, which can have significant environmental implications. Mining operations for lithium can lead to habitat destruction, soil erosion, and water pollution in the surrounding areas. Additionally, the energy-intensive processes required for lithium extraction and refinement contribute to greenhouse gas emissions, potentially exacerbating climate change concerns.

During the operational phase, lithium oxide biosensors generally have a minimal direct environmental impact. Their small size and low power consumption make them relatively eco-friendly compared to traditional sensing technologies. However, the disposal of these biosensors at the end of their lifecycle presents environmental challenges. Improper disposal can lead to the release of lithium and other potentially harmful materials into soil and water systems, posing risks to local flora and fauna.

To mitigate these environmental concerns, researchers and manufacturers are exploring more sustainable approaches to lithium oxide biosensor production and disposal. This includes developing recycling processes to recover and reuse lithium and other valuable materials from spent biosensors. Such initiatives aim to reduce the demand for raw lithium extraction and minimize waste generation.

Furthermore, efforts are being made to enhance the longevity and durability of lithium oxide biosensors, thereby reducing the frequency of replacement and associated environmental impacts. Innovations in biosensor design are focusing on creating more robust and longer-lasting devices that can withstand harsh environmental conditions without compromising performance.

The potential for lithium oxide biosensors to contribute to environmental monitoring and protection should also be considered. These sensors can be utilized in various environmental applications, such as detecting pollutants in water bodies or monitoring air quality. In this context, the environmental benefits derived from their use may outweigh the impacts associated with their production and disposal.

As the adoption of lithium oxide biosensors continues to grow, it is crucial to implement comprehensive lifecycle assessments to fully understand and address their environmental footprint. This holistic approach will enable the development of more sustainable practices in biosensor manufacturing, use, and disposal, ensuring that the benefits of this technology are realized without compromising environmental integrity.

The production of lithium oxide biosensors involves the extraction and processing of lithium, which can have significant environmental implications. Mining operations for lithium can lead to habitat destruction, soil erosion, and water pollution in the surrounding areas. Additionally, the energy-intensive processes required for lithium extraction and refinement contribute to greenhouse gas emissions, potentially exacerbating climate change concerns.

During the operational phase, lithium oxide biosensors generally have a minimal direct environmental impact. Their small size and low power consumption make them relatively eco-friendly compared to traditional sensing technologies. However, the disposal of these biosensors at the end of their lifecycle presents environmental challenges. Improper disposal can lead to the release of lithium and other potentially harmful materials into soil and water systems, posing risks to local flora and fauna.

To mitigate these environmental concerns, researchers and manufacturers are exploring more sustainable approaches to lithium oxide biosensor production and disposal. This includes developing recycling processes to recover and reuse lithium and other valuable materials from spent biosensors. Such initiatives aim to reduce the demand for raw lithium extraction and minimize waste generation.

Furthermore, efforts are being made to enhance the longevity and durability of lithium oxide biosensors, thereby reducing the frequency of replacement and associated environmental impacts. Innovations in biosensor design are focusing on creating more robust and longer-lasting devices that can withstand harsh environmental conditions without compromising performance.

The potential for lithium oxide biosensors to contribute to environmental monitoring and protection should also be considered. These sensors can be utilized in various environmental applications, such as detecting pollutants in water bodies or monitoring air quality. In this context, the environmental benefits derived from their use may outweigh the impacts associated with their production and disposal.

As the adoption of lithium oxide biosensors continues to grow, it is crucial to implement comprehensive lifecycle assessments to fully understand and address their environmental footprint. This holistic approach will enable the development of more sustainable practices in biosensor manufacturing, use, and disposal, ensuring that the benefits of this technology are realized without compromising environmental integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!