Lithium oxide's role in advanced chromatography techniques

AUG 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide Chromatography Background

Lithium oxide has emerged as a significant component in advanced chromatography techniques, revolutionizing the field of analytical chemistry. The journey of lithium oxide in chromatography began in the late 20th century when researchers discovered its unique properties that could enhance separation processes. As a lightweight and highly reactive compound, lithium oxide demonstrated exceptional potential in improving the efficiency and selectivity of chromatographic methods.

The evolution of lithium oxide's role in chromatography has been closely tied to the advancements in material science and nanotechnology. Initially, lithium oxide was primarily used as a modifier for stationary phases in gas chromatography. However, as research progressed, its applications expanded to liquid chromatography and other specialized chromatographic techniques.

One of the key breakthroughs came with the development of lithium oxide-based nanoparticles. These nanostructures exhibited remarkable surface area to volume ratios, allowing for enhanced interaction with analytes. This innovation led to significant improvements in separation efficiency, particularly for complex mixtures and challenging analytes that were previously difficult to resolve.

The incorporation of lithium oxide in chromatography also addressed several longstanding challenges in the field. Its ability to form stable complexes with various organic compounds made it particularly useful in the separation of isomers and structurally similar molecules. Additionally, the high thermal stability of lithium oxide-based materials extended the operational range of chromatographic systems, enabling separations at elevated temperatures without compromising column integrity.

As environmental concerns gained prominence, lithium oxide's role in green chromatography techniques became increasingly important. Its use in the development of eco-friendly stationary phases aligned with the growing demand for sustainable analytical methods. These environmentally benign chromatographic systems not only reduced the consumption of harmful solvents but also improved the overall efficiency of separations.

The integration of lithium oxide in chromatography has also paved the way for novel hybrid techniques. Combining lithium oxide-based materials with other advanced technologies, such as mass spectrometry and spectroscopic methods, has led to the creation of powerful analytical platforms. These integrated systems offer unprecedented levels of sensitivity and selectivity, pushing the boundaries of what is possible in chemical analysis.

Looking ahead, the role of lithium oxide in advanced chromatography techniques continues to evolve. Current research focuses on developing smart chromatographic materials that can respond to external stimuli, offering dynamic control over separation processes. The potential applications of these innovative systems span across various fields, from pharmaceutical analysis to environmental monitoring, promising to address complex analytical challenges in the years to come.

The evolution of lithium oxide's role in chromatography has been closely tied to the advancements in material science and nanotechnology. Initially, lithium oxide was primarily used as a modifier for stationary phases in gas chromatography. However, as research progressed, its applications expanded to liquid chromatography and other specialized chromatographic techniques.

One of the key breakthroughs came with the development of lithium oxide-based nanoparticles. These nanostructures exhibited remarkable surface area to volume ratios, allowing for enhanced interaction with analytes. This innovation led to significant improvements in separation efficiency, particularly for complex mixtures and challenging analytes that were previously difficult to resolve.

The incorporation of lithium oxide in chromatography also addressed several longstanding challenges in the field. Its ability to form stable complexes with various organic compounds made it particularly useful in the separation of isomers and structurally similar molecules. Additionally, the high thermal stability of lithium oxide-based materials extended the operational range of chromatographic systems, enabling separations at elevated temperatures without compromising column integrity.

As environmental concerns gained prominence, lithium oxide's role in green chromatography techniques became increasingly important. Its use in the development of eco-friendly stationary phases aligned with the growing demand for sustainable analytical methods. These environmentally benign chromatographic systems not only reduced the consumption of harmful solvents but also improved the overall efficiency of separations.

The integration of lithium oxide in chromatography has also paved the way for novel hybrid techniques. Combining lithium oxide-based materials with other advanced technologies, such as mass spectrometry and spectroscopic methods, has led to the creation of powerful analytical platforms. These integrated systems offer unprecedented levels of sensitivity and selectivity, pushing the boundaries of what is possible in chemical analysis.

Looking ahead, the role of lithium oxide in advanced chromatography techniques continues to evolve. Current research focuses on developing smart chromatographic materials that can respond to external stimuli, offering dynamic control over separation processes. The potential applications of these innovative systems span across various fields, from pharmaceutical analysis to environmental monitoring, promising to address complex analytical challenges in the years to come.

Market Analysis for Advanced Chromatography

The advanced chromatography market has experienced significant growth in recent years, driven by increasing demand for precise analytical techniques in various industries. The global market for advanced chromatography techniques is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other analytical instrument segments. This growth is primarily fueled by the pharmaceutical and biotechnology sectors, where the need for high-resolution separation and analysis of complex molecules is paramount.

Lithium oxide's role in advanced chromatography techniques has garnered attention due to its unique properties and potential applications. The market for lithium oxide-based chromatography materials is still emerging but shows promising growth potential. This niche market is expected to expand as research continues to unveil new applications and benefits of lithium oxide in chromatographic separations.

The pharmaceutical industry remains the largest end-user segment for advanced chromatography techniques, including those potentially incorporating lithium oxide. The increasing complexity of drug molecules and the stringent regulatory requirements for purity and characterization drive the demand for more sophisticated chromatography methods. Additionally, the food and beverage industry is becoming a significant market for advanced chromatography, particularly in quality control and safety testing applications.

Geographically, North America and Europe dominate the advanced chromatography market, owing to their well-established pharmaceutical and biotechnology industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in life sciences research and the expansion of pharmaceutical manufacturing capabilities in countries like China and India.

The market for chromatography consumables, including specialized stationary phases and columns, is growing faster than the instrument market. This trend presents an opportunity for lithium oxide-based materials to gain market share if they can demonstrate superior performance or unique separation capabilities.

Environmental concerns and the push for sustainable practices are influencing the chromatography market. There is a growing demand for green chromatography techniques that reduce solvent consumption and waste generation. Lithium oxide's potential role in enabling more efficient or environmentally friendly chromatography methods could be a significant market driver if properly developed and marketed.

As the field of personalized medicine expands, there is an increasing need for advanced chromatography techniques capable of analyzing small sample volumes with high sensitivity and specificity. This trend could open new avenues for lithium oxide-based chromatography methods, particularly if they can offer advantages in the analysis of biomarkers or other clinically relevant molecules.

Lithium oxide's role in advanced chromatography techniques has garnered attention due to its unique properties and potential applications. The market for lithium oxide-based chromatography materials is still emerging but shows promising growth potential. This niche market is expected to expand as research continues to unveil new applications and benefits of lithium oxide in chromatographic separations.

The pharmaceutical industry remains the largest end-user segment for advanced chromatography techniques, including those potentially incorporating lithium oxide. The increasing complexity of drug molecules and the stringent regulatory requirements for purity and characterization drive the demand for more sophisticated chromatography methods. Additionally, the food and beverage industry is becoming a significant market for advanced chromatography, particularly in quality control and safety testing applications.

Geographically, North America and Europe dominate the advanced chromatography market, owing to their well-established pharmaceutical and biotechnology industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by increasing investments in life sciences research and the expansion of pharmaceutical manufacturing capabilities in countries like China and India.

The market for chromatography consumables, including specialized stationary phases and columns, is growing faster than the instrument market. This trend presents an opportunity for lithium oxide-based materials to gain market share if they can demonstrate superior performance or unique separation capabilities.

Environmental concerns and the push for sustainable practices are influencing the chromatography market. There is a growing demand for green chromatography techniques that reduce solvent consumption and waste generation. Lithium oxide's potential role in enabling more efficient or environmentally friendly chromatography methods could be a significant market driver if properly developed and marketed.

As the field of personalized medicine expands, there is an increasing need for advanced chromatography techniques capable of analyzing small sample volumes with high sensitivity and specificity. This trend could open new avenues for lithium oxide-based chromatography methods, particularly if they can offer advantages in the analysis of biomarkers or other clinically relevant molecules.

Current Challenges in Lithium Oxide Chromatography

Despite the promising potential of lithium oxide in advanced chromatography techniques, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the limited stability of lithium oxide under certain chromatographic conditions. When exposed to moisture or high temperatures, lithium oxide can undergo chemical transformations, potentially altering its chromatographic properties and compromising the reliability of analytical results.

Another challenge lies in the difficulty of achieving uniform and reproducible coating of lithium oxide on chromatographic supports. The inconsistent distribution of lithium oxide can lead to variations in retention times and peak shapes, affecting the overall separation efficiency and reproducibility of chromatographic analyses. This issue is particularly pronounced when dealing with complex sample matrices or when high-resolution separations are required.

The selectivity of lithium oxide-based chromatography systems also presents challenges in certain applications. While lithium oxide exhibits unique selectivity for certain analytes, it may not provide adequate separation for closely related compounds or complex mixtures. This limitation necessitates the development of more sophisticated separation strategies or the use of complementary techniques to achieve comprehensive analytical results.

Furthermore, the relatively high cost of high-purity lithium oxide and its specialized chromatographic supports poses economic challenges for widespread implementation, especially in routine analytical laboratories. The need for specialized equipment and expertise to handle and optimize lithium oxide-based chromatography systems further compounds this issue, limiting its accessibility to a broader range of researchers and analysts.

Scaling up lithium oxide chromatography for preparative or industrial applications presents additional challenges. The behavior of lithium oxide in large-scale chromatographic systems may differ from that observed in analytical-scale setups, requiring extensive optimization and validation processes. Issues such as column loading capacity, flow rate limitations, and regeneration procedures need to be carefully addressed to ensure the feasibility and efficiency of scaled-up operations.

Lastly, the potential environmental and health impacts of lithium oxide usage in chromatography raise concerns. The proper handling, disposal, and potential recycling of lithium oxide-containing materials require careful consideration and the development of appropriate protocols to ensure safety and regulatory compliance. Addressing these environmental and safety challenges is crucial for the long-term sustainability and acceptance of lithium oxide-based chromatography techniques in various analytical and industrial settings.

Another challenge lies in the difficulty of achieving uniform and reproducible coating of lithium oxide on chromatographic supports. The inconsistent distribution of lithium oxide can lead to variations in retention times and peak shapes, affecting the overall separation efficiency and reproducibility of chromatographic analyses. This issue is particularly pronounced when dealing with complex sample matrices or when high-resolution separations are required.

The selectivity of lithium oxide-based chromatography systems also presents challenges in certain applications. While lithium oxide exhibits unique selectivity for certain analytes, it may not provide adequate separation for closely related compounds or complex mixtures. This limitation necessitates the development of more sophisticated separation strategies or the use of complementary techniques to achieve comprehensive analytical results.

Furthermore, the relatively high cost of high-purity lithium oxide and its specialized chromatographic supports poses economic challenges for widespread implementation, especially in routine analytical laboratories. The need for specialized equipment and expertise to handle and optimize lithium oxide-based chromatography systems further compounds this issue, limiting its accessibility to a broader range of researchers and analysts.

Scaling up lithium oxide chromatography for preparative or industrial applications presents additional challenges. The behavior of lithium oxide in large-scale chromatographic systems may differ from that observed in analytical-scale setups, requiring extensive optimization and validation processes. Issues such as column loading capacity, flow rate limitations, and regeneration procedures need to be carefully addressed to ensure the feasibility and efficiency of scaled-up operations.

Lastly, the potential environmental and health impacts of lithium oxide usage in chromatography raise concerns. The proper handling, disposal, and potential recycling of lithium oxide-containing materials require careful consideration and the development of appropriate protocols to ensure safety and regulatory compliance. Addressing these environmental and safety challenges is crucial for the long-term sustainability and acceptance of lithium oxide-based chromatography techniques in various analytical and industrial settings.

Lithium Oxide Chromatography Techniques

01 Lithium oxide in battery technology

Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, energy density, and cycle life. The incorporation of lithium oxide in various battery compositions helps enhance the overall efficiency and stability of energy storage systems.- Lithium oxide in battery technology: Lithium oxide is widely used in battery technology, particularly in lithium-ion batteries. It plays a crucial role in the cathode material, contributing to the battery's energy density, performance, and longevity. The compound is often incorporated into various cathode formulations to enhance the electrochemical properties of the battery.

- Synthesis and production methods of lithium oxide: Various methods are employed to synthesize and produce lithium oxide for different applications. These processes may involve chemical reactions, thermal treatments, or advanced manufacturing techniques. The synthesis methods aim to control the purity, particle size, and morphology of the lithium oxide, which are critical factors in its performance in different applications.

- Lithium oxide in ceramic and glass manufacturing: Lithium oxide is utilized in the production of ceramics and glasses. It acts as a flux, lowering the melting point of the mixture and improving the flow characteristics. In ceramics, it can enhance the strength and thermal shock resistance of the final product. In glass manufacturing, it contributes to the optical properties and durability of the glass.

- Lithium oxide in nuclear technology: Lithium oxide finds applications in nuclear technology, particularly in fusion reactors. It is used as a tritium breeding material in the blanket of fusion reactors. The compound plays a role in the production of tritium, which is essential for sustaining the fusion reaction. Research is ongoing to optimize lithium oxide's performance in this critical application.

- Lithium oxide in carbon dioxide capture: Recent research has explored the potential of lithium oxide in carbon dioxide capture and storage technologies. The compound shows promise in absorbing CO2 from gas streams, potentially contributing to efforts to mitigate greenhouse gas emissions. Studies are being conducted to enhance the efficiency and practicality of using lithium oxide in this environmental application.

02 Synthesis and production methods of lithium oxide

Various methods are employed for the synthesis and production of lithium oxide. These processes may involve chemical reactions, thermal treatments, or electrochemical techniques. The development of efficient and cost-effective production methods is essential for meeting the growing demand for lithium oxide in industrial applications.Expand Specific Solutions03 Lithium oxide in ceramic and glass manufacturing

Lithium oxide is utilized in the production of ceramics and glasses. It serves as a flux and modifier, influencing properties such as thermal expansion, strength, and chemical durability. The addition of lithium oxide to ceramic and glass formulations can result in improved material characteristics and performance in various applications.Expand Specific Solutions04 Lithium oxide in nuclear technology

Lithium oxide finds applications in nuclear technology, particularly in fusion reactor research and development. It is used as a tritium breeding material and plays a role in neutron multiplication. The properties of lithium oxide make it suitable for certain nuclear applications, contributing to advancements in fusion energy research.Expand Specific Solutions05 Lithium oxide in electrochemical devices

Beyond batteries, lithium oxide is utilized in various electrochemical devices. It can be incorporated into fuel cells, electrochromic devices, and sensors. The unique properties of lithium oxide contribute to enhanced performance, stability, and functionality in these electrochemical applications, opening up new possibilities for technological advancements.Expand Specific Solutions

Key Players in Advanced Chromatography

The lithium oxide market in advanced chromatography techniques is in a growth phase, driven by increasing demand for high-performance analytical tools in pharmaceutical and biotechnology industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Waters Technology Corp. and Biotage AB leading innovations in chromatography systems. Established chemical giants such as Sumitomo Chemical Co., Ltd. and LG Chem Ltd. are also investing in R&D to develop novel lithium-based materials for chromatography applications. The competitive landscape is diverse, with specialized chromatography firms competing alongside larger chemical conglomerates, indicating a maturing but still dynamic market.

Waters Technology Corp.

Technical Solution: Waters Technology Corp. has developed advanced chromatography techniques utilizing lithium oxide as a key component in their stationary phases. Their proprietary Li-Ox™ columns incorporate lithium oxide-modified silica particles, enhancing separation efficiency for complex mixtures. This technology allows for improved resolution of closely related compounds, particularly in the analysis of pharmaceuticals and biomolecules[1]. The company has also integrated lithium oxide into their UPLC (Ultra Performance Liquid Chromatography) systems, enabling faster analysis times and reduced solvent consumption[3]. Waters' approach combines the unique properties of lithium oxide with their expertise in chromatography instrumentation to push the boundaries of analytical capabilities.

Strengths: Enhanced separation efficiency, improved resolution for complex mixtures, faster analysis times. Weaknesses: Potentially higher cost compared to traditional columns, may require specialized training for optimal use.

Biotage AB

Technical Solution: Biotage AB has pioneered the use of lithium oxide in flash chromatography systems, particularly for the purification of organic compounds. Their SNAP Ultra cartridges incorporate lithium oxide-modified silica, providing enhanced selectivity for polar compounds[2]. This technology has been particularly beneficial in the separation of pharmaceuticals and natural products. Biotage's automated flash chromatography systems, such as the Isolera™ series, have been optimized to work with these Li-Ox cartridges, offering improved purification efficiency and reduced solvent consumption[4]. The company has also developed specialized software algorithms to optimize separation conditions when using lithium oxide-based stationary phases, further enhancing the performance of their chromatography solutions.

Strengths: Improved selectivity for polar compounds, reduced solvent consumption, integrated software optimization. Weaknesses: May be less suitable for non-polar analytes, potential for increased backpressure in some applications.

Innovations in Lithium Oxide Applications

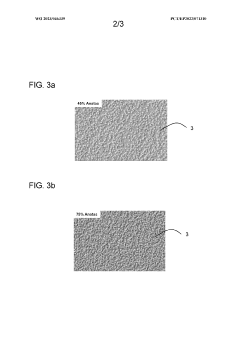

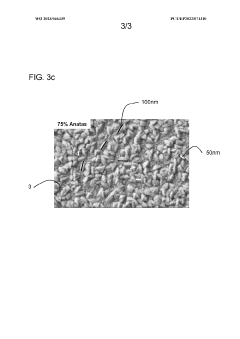

Photocatalytic layer arrangement and method for producing such a layer arrangement

PatentWO2023046339A1

Innovation

- A photocatalytic layer arrangement featuring a chromium layer with defined nitrogen content and a titanium oxide layer with a 30%-90% anatase phase, grown using reactive sputtering, providing a granular surface structure for enhanced biomolecule attachment and photocatalytic activity without the need for additional processing steps.

Lithography methods, and elements and devices obtainable by the methods

PatentWO2025093814A1

Innovation

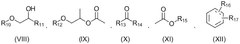

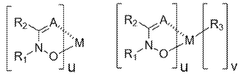

- The development of novel metal-organic complexes with a first metal chelating moiety and a second polymerizable, organic moiety, which are used to form resist films that can be patterned using electron beam or light radiation, and developed with specific developers to improve throughput.

Environmental Impact Assessment

The environmental impact of lithium oxide in advanced chromatography techniques is a crucial aspect to consider as these methods gain prominence in analytical chemistry. The use of lithium oxide as a stationary phase or modifier in chromatography can have both positive and negative effects on the environment.

One of the primary environmental benefits of using lithium oxide in chromatography is its potential to enhance separation efficiency, leading to reduced solvent consumption and waste generation. This improvement in analytical performance can result in shorter run times and decreased energy usage, contributing to a more sustainable laboratory practice.

However, the production and disposal of lithium oxide-based chromatographic materials pose environmental challenges. The mining and processing of lithium compounds can lead to habitat disruption, water pollution, and greenhouse gas emissions. Additionally, the disposal of spent chromatographic materials containing lithium oxide may contribute to soil and water contamination if not properly managed.

The use of lithium oxide in chromatography also raises concerns about the potential release of lithium ions into the environment. While lithium is generally considered to have low toxicity, its accumulation in ecosystems could have long-term effects on aquatic and terrestrial organisms. Proper handling and disposal protocols are essential to mitigate these risks.

On the other hand, the application of lithium oxide in chromatography can indirectly benefit the environment by enabling more accurate and sensitive detection of environmental pollutants. This improved analytical capability can lead to better monitoring and regulation of harmful substances, ultimately contributing to environmental protection efforts.

The environmental impact of lithium oxide in chromatography extends to the broader life cycle of analytical instruments and consumables. The production of specialized chromatographic equipment and materials incorporating lithium oxide may have a higher environmental footprint compared to conventional alternatives. However, this initial impact could be offset by the improved efficiency and longevity of these advanced systems.

As the demand for lithium-based technologies grows across various industries, including chromatography, there is an increasing need for sustainable lithium sourcing and recycling practices. The development of closed-loop systems for recovering and reusing lithium oxide from chromatographic materials could significantly reduce the environmental impact of these techniques.

In conclusion, the environmental impact of lithium oxide in advanced chromatography techniques is multifaceted, with both positive and negative aspects to consider. Balancing the analytical benefits against potential environmental risks requires ongoing research, responsible manufacturing practices, and the implementation of effective waste management strategies in laboratory settings.

One of the primary environmental benefits of using lithium oxide in chromatography is its potential to enhance separation efficiency, leading to reduced solvent consumption and waste generation. This improvement in analytical performance can result in shorter run times and decreased energy usage, contributing to a more sustainable laboratory practice.

However, the production and disposal of lithium oxide-based chromatographic materials pose environmental challenges. The mining and processing of lithium compounds can lead to habitat disruption, water pollution, and greenhouse gas emissions. Additionally, the disposal of spent chromatographic materials containing lithium oxide may contribute to soil and water contamination if not properly managed.

The use of lithium oxide in chromatography also raises concerns about the potential release of lithium ions into the environment. While lithium is generally considered to have low toxicity, its accumulation in ecosystems could have long-term effects on aquatic and terrestrial organisms. Proper handling and disposal protocols are essential to mitigate these risks.

On the other hand, the application of lithium oxide in chromatography can indirectly benefit the environment by enabling more accurate and sensitive detection of environmental pollutants. This improved analytical capability can lead to better monitoring and regulation of harmful substances, ultimately contributing to environmental protection efforts.

The environmental impact of lithium oxide in chromatography extends to the broader life cycle of analytical instruments and consumables. The production of specialized chromatographic equipment and materials incorporating lithium oxide may have a higher environmental footprint compared to conventional alternatives. However, this initial impact could be offset by the improved efficiency and longevity of these advanced systems.

As the demand for lithium-based technologies grows across various industries, including chromatography, there is an increasing need for sustainable lithium sourcing and recycling practices. The development of closed-loop systems for recovering and reusing lithium oxide from chromatographic materials could significantly reduce the environmental impact of these techniques.

In conclusion, the environmental impact of lithium oxide in advanced chromatography techniques is multifaceted, with both positive and negative aspects to consider. Balancing the analytical benefits against potential environmental risks requires ongoing research, responsible manufacturing practices, and the implementation of effective waste management strategies in laboratory settings.

Regulatory Compliance in Chromatography

Regulatory compliance in chromatography is a critical aspect of ensuring the safety, efficacy, and quality of analytical processes in various industries, including pharmaceuticals, food and beverage, environmental monitoring, and clinical diagnostics. The use of lithium oxide in advanced chromatography techniques must adhere to strict regulatory guidelines to maintain the integrity of analytical results and protect public health.

In the pharmaceutical industry, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established Good Manufacturing Practice (GMP) guidelines that directly impact chromatographic methods. These guidelines encompass the entire lifecycle of chromatographic processes, from method development to routine analysis. When incorporating lithium oxide in chromatography, manufacturers must demonstrate that the compound does not interfere with the accuracy, precision, and reproducibility of analytical results.

The International Conference on Harmonisation (ICH) has developed guidelines for analytical method validation, which are widely adopted in the pharmaceutical industry. These guidelines outline the parameters that must be evaluated when validating chromatographic methods, including specificity, linearity, range, accuracy, precision, and robustness. The use of lithium oxide in advanced chromatography techniques must be thoroughly validated according to these guidelines to ensure compliance.

Environmental regulations also play a significant role in chromatography applications involving lithium oxide. Agencies such as the U.S. Environmental Protection Agency (EPA) and the European Environment Agency (EEA) have established protocols for environmental monitoring and analysis. These regulations often specify the acceptable chromatographic methods for detecting and quantifying various pollutants and contaminants. The incorporation of lithium oxide in these methods must be validated to meet the required detection limits and accuracy standards.

In the food and beverage industry, regulatory bodies such as the FDA and the European Food Safety Authority (EFSA) have set guidelines for the analysis of food contaminants, additives, and residues. Chromatographic methods using lithium oxide must comply with these regulations to ensure the safety and quality of food products. This includes adhering to specific sample preparation procedures, method validation requirements, and reporting standards.

Regulatory compliance also extends to the documentation and record-keeping aspects of chromatography. Good Laboratory Practice (GLP) regulations require detailed documentation of all chromatographic procedures, including method development, validation, and routine analysis. When using lithium oxide in advanced chromatography techniques, laboratories must maintain comprehensive records of instrument calibration, method parameters, and quality control measures to demonstrate compliance with regulatory standards.

Furthermore, the use of lithium oxide in chromatography must comply with occupational health and safety regulations. This includes proper handling, storage, and disposal procedures to protect laboratory personnel and the environment. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for the safe use of chemicals in laboratory settings.

In the pharmaceutical industry, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established Good Manufacturing Practice (GMP) guidelines that directly impact chromatographic methods. These guidelines encompass the entire lifecycle of chromatographic processes, from method development to routine analysis. When incorporating lithium oxide in chromatography, manufacturers must demonstrate that the compound does not interfere with the accuracy, precision, and reproducibility of analytical results.

The International Conference on Harmonisation (ICH) has developed guidelines for analytical method validation, which are widely adopted in the pharmaceutical industry. These guidelines outline the parameters that must be evaluated when validating chromatographic methods, including specificity, linearity, range, accuracy, precision, and robustness. The use of lithium oxide in advanced chromatography techniques must be thoroughly validated according to these guidelines to ensure compliance.

Environmental regulations also play a significant role in chromatography applications involving lithium oxide. Agencies such as the U.S. Environmental Protection Agency (EPA) and the European Environment Agency (EEA) have established protocols for environmental monitoring and analysis. These regulations often specify the acceptable chromatographic methods for detecting and quantifying various pollutants and contaminants. The incorporation of lithium oxide in these methods must be validated to meet the required detection limits and accuracy standards.

In the food and beverage industry, regulatory bodies such as the FDA and the European Food Safety Authority (EFSA) have set guidelines for the analysis of food contaminants, additives, and residues. Chromatographic methods using lithium oxide must comply with these regulations to ensure the safety and quality of food products. This includes adhering to specific sample preparation procedures, method validation requirements, and reporting standards.

Regulatory compliance also extends to the documentation and record-keeping aspects of chromatography. Good Laboratory Practice (GLP) regulations require detailed documentation of all chromatographic procedures, including method development, validation, and routine analysis. When using lithium oxide in advanced chromatography techniques, laboratories must maintain comprehensive records of instrument calibration, method parameters, and quality control measures to demonstrate compliance with regulatory standards.

Furthermore, the use of lithium oxide in chromatography must comply with occupational health and safety regulations. This includes proper handling, storage, and disposal procedures to protect laboratory personnel and the environment. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for the safe use of chemicals in laboratory settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!