Lithium oxide as a phase change material in energy systems

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide PCM Background and Objectives

Lithium oxide (Li2O) has emerged as a promising phase change material (PCM) for energy storage systems, attracting significant attention in recent years due to its unique properties and potential applications. The development of Li2O as a PCM is rooted in the broader context of thermal energy storage technologies, which have become increasingly important in addressing the challenges of renewable energy integration and energy efficiency.

The evolution of Li2O as a PCM can be traced back to the growing interest in high-temperature thermal energy storage systems. As renewable energy sources like solar and wind power gained prominence, the need for efficient and cost-effective energy storage solutions became apparent. Traditional PCMs, such as salt hydrates and organic compounds, were limited by their operating temperature ranges and energy storage densities. This led researchers to explore alternative materials that could offer superior performance at higher temperatures.

Lithium oxide emerged as a promising candidate due to its high melting point (1570°C), substantial latent heat of fusion, and excellent thermal conductivity. These properties make Li2O particularly suitable for high-temperature applications, such as concentrated solar power plants and industrial waste heat recovery systems. The potential of Li2O to store and release large amounts of thermal energy during phase transitions opened up new possibilities for enhancing the efficiency and reliability of energy systems.

The primary objective of research on Li2O as a PCM is to develop and optimize its performance for practical applications in energy storage systems. This involves addressing several key challenges, including improving the material's cycling stability, enhancing its thermal conductivity, and developing effective containment strategies to prevent corrosion and material degradation during repeated phase changes.

Another important goal is to explore the integration of Li2O-based PCMs into various energy systems, such as solar thermal power plants, industrial processes, and advanced nuclear reactors. Researchers aim to demonstrate the feasibility and benefits of using Li2O for thermal energy storage in these applications, potentially leading to significant improvements in energy efficiency and system performance.

Furthermore, the research on Li2O as a PCM extends to understanding its fundamental properties and behavior under different operating conditions. This includes investigating the material's phase diagram, studying its interaction with containment materials, and developing accurate models to predict its performance in large-scale energy storage systems.

As the field progresses, there is also a focus on exploring potential modifications or composites based on Li2O to further enhance its properties as a PCM. This may involve the development of novel synthesis methods, the incorporation of additives to improve specific characteristics, or the creation of advanced nanostructured materials to optimize heat transfer and energy storage capabilities.

The evolution of Li2O as a PCM can be traced back to the growing interest in high-temperature thermal energy storage systems. As renewable energy sources like solar and wind power gained prominence, the need for efficient and cost-effective energy storage solutions became apparent. Traditional PCMs, such as salt hydrates and organic compounds, were limited by their operating temperature ranges and energy storage densities. This led researchers to explore alternative materials that could offer superior performance at higher temperatures.

Lithium oxide emerged as a promising candidate due to its high melting point (1570°C), substantial latent heat of fusion, and excellent thermal conductivity. These properties make Li2O particularly suitable for high-temperature applications, such as concentrated solar power plants and industrial waste heat recovery systems. The potential of Li2O to store and release large amounts of thermal energy during phase transitions opened up new possibilities for enhancing the efficiency and reliability of energy systems.

The primary objective of research on Li2O as a PCM is to develop and optimize its performance for practical applications in energy storage systems. This involves addressing several key challenges, including improving the material's cycling stability, enhancing its thermal conductivity, and developing effective containment strategies to prevent corrosion and material degradation during repeated phase changes.

Another important goal is to explore the integration of Li2O-based PCMs into various energy systems, such as solar thermal power plants, industrial processes, and advanced nuclear reactors. Researchers aim to demonstrate the feasibility and benefits of using Li2O for thermal energy storage in these applications, potentially leading to significant improvements in energy efficiency and system performance.

Furthermore, the research on Li2O as a PCM extends to understanding its fundamental properties and behavior under different operating conditions. This includes investigating the material's phase diagram, studying its interaction with containment materials, and developing accurate models to predict its performance in large-scale energy storage systems.

As the field progresses, there is also a focus on exploring potential modifications or composites based on Li2O to further enhance its properties as a PCM. This may involve the development of novel synthesis methods, the incorporation of additives to improve specific characteristics, or the creation of advanced nanostructured materials to optimize heat transfer and energy storage capabilities.

Energy Storage Market Analysis

The energy storage market has experienced significant growth in recent years, driven by the increasing demand for renewable energy integration and grid stability. As the global energy landscape shifts towards cleaner and more sustainable sources, the need for efficient and cost-effective energy storage solutions has become paramount. The market for energy storage systems is projected to expand rapidly, with lithium-based technologies playing a crucial role in this growth.

Lithium oxide, as a potential phase change material in energy systems, is positioned within a broader context of energy storage technologies. The market for thermal energy storage, which includes phase change materials, is expected to grow substantially due to its applications in various sectors such as power generation, industrial processes, and building heating and cooling systems. The integration of phase change materials like lithium oxide into energy storage systems offers promising opportunities for enhancing energy efficiency and reducing overall system costs.

The demand for energy storage solutions is being fueled by several factors, including the increasing penetration of renewable energy sources, the need for grid stabilization, and the growing electrification of transportation. As intermittent renewable energy sources such as solar and wind power continue to expand their market share, the requirement for reliable and flexible energy storage systems becomes more critical. This trend is driving innovation in thermal energy storage technologies, including the exploration of novel phase change materials like lithium oxide.

In the context of lithium oxide as a phase change material, its potential applications extend beyond traditional battery storage. The thermal energy storage market, which encompasses phase change materials, is witnessing growing interest from industries seeking to improve energy efficiency and reduce operational costs. Sectors such as concentrated solar power, industrial waste heat recovery, and building climate control systems are exploring the integration of advanced phase change materials to enhance their energy management capabilities.

The market analysis indicates that the adoption of phase change materials in energy systems is still in its early stages, presenting significant growth potential. As research and development efforts intensify, the performance and cost-effectiveness of materials like lithium oxide are expected to improve, potentially leading to wider market acceptance. The increasing focus on sustainability and energy efficiency across various industries is likely to drive further investment and innovation in this field, creating new opportunities for lithium oxide and similar phase change materials in the energy storage market.

Lithium oxide, as a potential phase change material in energy systems, is positioned within a broader context of energy storage technologies. The market for thermal energy storage, which includes phase change materials, is expected to grow substantially due to its applications in various sectors such as power generation, industrial processes, and building heating and cooling systems. The integration of phase change materials like lithium oxide into energy storage systems offers promising opportunities for enhancing energy efficiency and reducing overall system costs.

The demand for energy storage solutions is being fueled by several factors, including the increasing penetration of renewable energy sources, the need for grid stabilization, and the growing electrification of transportation. As intermittent renewable energy sources such as solar and wind power continue to expand their market share, the requirement for reliable and flexible energy storage systems becomes more critical. This trend is driving innovation in thermal energy storage technologies, including the exploration of novel phase change materials like lithium oxide.

In the context of lithium oxide as a phase change material, its potential applications extend beyond traditional battery storage. The thermal energy storage market, which encompasses phase change materials, is witnessing growing interest from industries seeking to improve energy efficiency and reduce operational costs. Sectors such as concentrated solar power, industrial waste heat recovery, and building climate control systems are exploring the integration of advanced phase change materials to enhance their energy management capabilities.

The market analysis indicates that the adoption of phase change materials in energy systems is still in its early stages, presenting significant growth potential. As research and development efforts intensify, the performance and cost-effectiveness of materials like lithium oxide are expected to improve, potentially leading to wider market acceptance. The increasing focus on sustainability and energy efficiency across various industries is likely to drive further investment and innovation in this field, creating new opportunities for lithium oxide and similar phase change materials in the energy storage market.

Lithium Oxide PCM State and Challenges

The current state of lithium oxide as a phase change material (PCM) in energy systems is characterized by both promising advancements and significant challenges. Lithium oxide, with its high melting point and substantial latent heat of fusion, has garnered attention for potential applications in high-temperature thermal energy storage systems. However, its widespread adoption faces several obstacles that researchers and engineers are actively working to overcome.

One of the primary challenges in utilizing lithium oxide as a PCM is its corrosive nature, particularly at elevated temperatures. This property poses significant material compatibility issues, limiting the selection of containment materials and heat transfer fluids. Researchers are exploring various corrosion-resistant alloys and protective coatings to mitigate this problem, but a universally effective solution remains elusive.

Another critical challenge is the relatively low thermal conductivity of lithium oxide, which hampers efficient heat transfer during the charging and discharging cycles of thermal energy storage systems. This limitation can lead to reduced system performance and longer charging times. To address this issue, scientists are investigating methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the development of composite PCMs.

The high melting temperature of lithium oxide, while advantageous for high-temperature applications, also presents challenges in terms of system design and operation. Maintaining such high temperatures requires sophisticated insulation and heat management strategies, which can increase system complexity and cost. Furthermore, the potential for thermal runaway and safety concerns at these elevated temperatures necessitate robust control systems and safety measures.

Cycling stability is another area of concern for lithium oxide PCMs. Repeated phase transitions can lead to material degradation, affecting the long-term performance and reliability of energy storage systems. Researchers are studying the mechanisms of degradation and exploring ways to improve the cyclability of lithium oxide-based PCMs through various additives and material modifications.

From a practical standpoint, the current state of lithium oxide PCM technology is primarily confined to laboratory-scale experiments and theoretical studies. While promising results have been obtained in controlled environments, scaling up to industrial applications presents additional challenges related to manufacturing processes, quality control, and economic viability.

Despite these challenges, the potential benefits of lithium oxide as a PCM continue to drive research and development efforts. Its high energy storage density and ability to operate at elevated temperatures make it an attractive option for next-generation thermal energy storage systems, particularly in concentrated solar power plants and high-temperature industrial processes. As research progresses, innovative solutions to the current limitations are expected to emerge, potentially paving the way for practical applications of lithium oxide PCMs in energy systems.

One of the primary challenges in utilizing lithium oxide as a PCM is its corrosive nature, particularly at elevated temperatures. This property poses significant material compatibility issues, limiting the selection of containment materials and heat transfer fluids. Researchers are exploring various corrosion-resistant alloys and protective coatings to mitigate this problem, but a universally effective solution remains elusive.

Another critical challenge is the relatively low thermal conductivity of lithium oxide, which hampers efficient heat transfer during the charging and discharging cycles of thermal energy storage systems. This limitation can lead to reduced system performance and longer charging times. To address this issue, scientists are investigating methods to enhance thermal conductivity, such as the incorporation of high-conductivity materials or the development of composite PCMs.

The high melting temperature of lithium oxide, while advantageous for high-temperature applications, also presents challenges in terms of system design and operation. Maintaining such high temperatures requires sophisticated insulation and heat management strategies, which can increase system complexity and cost. Furthermore, the potential for thermal runaway and safety concerns at these elevated temperatures necessitate robust control systems and safety measures.

Cycling stability is another area of concern for lithium oxide PCMs. Repeated phase transitions can lead to material degradation, affecting the long-term performance and reliability of energy storage systems. Researchers are studying the mechanisms of degradation and exploring ways to improve the cyclability of lithium oxide-based PCMs through various additives and material modifications.

From a practical standpoint, the current state of lithium oxide PCM technology is primarily confined to laboratory-scale experiments and theoretical studies. While promising results have been obtained in controlled environments, scaling up to industrial applications presents additional challenges related to manufacturing processes, quality control, and economic viability.

Despite these challenges, the potential benefits of lithium oxide as a PCM continue to drive research and development efforts. Its high energy storage density and ability to operate at elevated temperatures make it an attractive option for next-generation thermal energy storage systems, particularly in concentrated solar power plants and high-temperature industrial processes. As research progresses, innovative solutions to the current limitations are expected to emerge, potentially paving the way for practical applications of lithium oxide PCMs in energy systems.

Current Lithium Oxide PCM Solutions

01 Lithium oxide phase change materials in batteries

Lithium oxide-based materials are used as phase change materials in battery systems. These materials undergo phase transitions during charge and discharge cycles, contributing to energy storage and thermal management. The phase change properties of lithium oxides can enhance battery performance and stability.- Lithium oxide phase change materials in batteries: Lithium oxide-based materials are used as phase change materials in battery systems. These materials undergo phase transitions during charge and discharge cycles, contributing to energy storage and thermal management. The phase change properties of lithium oxides can enhance battery performance and stability.

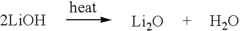

- Synthesis and preparation of lithium oxide compounds: Various methods are employed to synthesize and prepare lithium oxide compounds with specific phase change properties. These techniques may include sol-gel processes, solid-state reactions, or hydrothermal methods. The synthesis conditions are optimized to control the crystal structure and phase transition characteristics of the resulting lithium oxide materials.

- Lithium oxide in solid electrolytes: Lithium oxide-based materials are utilized in solid electrolytes for advanced battery technologies. The phase change behavior of these materials can influence ionic conductivity and electrochemical stability. Researchers explore various compositions and structures to optimize the performance of lithium oxide-based solid electrolytes.

- Thermal management applications of lithium oxide phase change materials: Lithium oxide phase change materials are employed in thermal management systems for various applications. These materials can absorb or release heat during phase transitions, helping to regulate temperature in electronic devices, energy storage systems, or industrial processes. The thermal properties of lithium oxides are tailored for specific temperature ranges and heat capacities.

- Characterization and analysis of lithium oxide phase transitions: Advanced techniques are used to characterize and analyze the phase transitions of lithium oxide materials. These methods may include X-ray diffraction, differential scanning calorimetry, or in-situ electron microscopy. Understanding the phase change mechanisms and kinetics is crucial for optimizing the performance of lithium oxide-based materials in various applications.

02 Synthesis and preparation of lithium oxide compounds

Various methods are employed to synthesize and prepare lithium oxide compounds with specific phase change properties. These techniques may include sol-gel processes, solid-state reactions, or hydrothermal methods. The synthesis conditions are optimized to control the crystal structure and phase transition characteristics of the resulting lithium oxide materials.Expand Specific Solutions03 Lithium oxide in solid electrolytes

Lithium oxide-based materials are utilized in solid electrolytes for advanced battery technologies. The phase change behavior of these materials can influence ionic conductivity and electrochemical stability. Researchers explore various compositions and structures to optimize the performance of lithium oxide-based solid electrolytes.Expand Specific Solutions04 Thermal management applications of lithium oxide phase change materials

Lithium oxide phase change materials are employed in thermal management systems for various applications. These materials can absorb or release heat during phase transitions, making them useful for temperature control in electronic devices, energy storage systems, or industrial processes. The thermal properties of lithium oxides are tailored for specific temperature ranges and heat capacities.Expand Specific Solutions05 Characterization and analysis of lithium oxide phase transitions

Advanced techniques are used to characterize and analyze the phase transitions of lithium oxide materials. These methods may include X-ray diffraction, differential scanning calorimetry, or in-situ electron microscopy. Understanding the mechanisms and kinetics of phase changes in lithium oxides is crucial for optimizing their performance in various applications.Expand Specific Solutions

Key Players in Lithium Oxide PCM Research

The research on lithium oxide as a phase change material in energy systems is in an early development stage, with growing market potential due to increasing demand for efficient energy storage solutions. The global market for phase change materials is expanding, driven by the need for sustainable energy management. Technologically, the field is still evolving, with various companies and research institutions contributing to advancements. Key players like Samsung SDI, LG Energy Solution, and BASF are investing in research and development, while academic institutions such as MIT and Tokyo Institute of Technology are conducting fundamental studies. The involvement of major battery manufacturers and chemical companies indicates the technology's potential for commercialization, although significant challenges in material optimization and system integration remain.

Massachusetts Institute of Technology

Technical Solution: MIT has been at the forefront of research on lithium oxide as a phase change material in energy systems. They have developed a novel approach using lithium oxide nanoparticles embedded in a matrix of aluminum oxide[1]. This composite material exhibits excellent thermal conductivity and high latent heat storage capacity. The nanostructured design allows for rapid phase transitions, enhancing the overall efficiency of thermal energy storage. MIT researchers have also explored the use of lithium oxide in advanced battery systems, where it serves as both an electrolyte and a phase change material for thermal management[3].

Strengths: High thermal conductivity, excellent latent heat storage, rapid phase transitions. Weaknesses: Potential high production costs, scalability challenges for large-scale energy systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has been investigating the use of lithium oxide as a phase change material in their advanced energy storage systems. Their research focuses on integrating lithium oxide into lithium-ion batteries to improve thermal management and overall battery performance[2]. By incorporating lithium oxide as a phase change material within the battery structure, Samsung aims to enhance heat dissipation during charging and discharging cycles. This approach potentially increases battery life and safety by preventing overheating issues. Samsung has also explored the use of lithium oxide in their energy storage solutions for renewable energy systems, leveraging its high latent heat capacity for efficient thermal energy storage[4].

Strengths: Improved thermal management in batteries, potential for increased battery life and safety. Weaknesses: Integration complexity, possible increase in battery production costs.

Core Lithium Oxide PCM Technologies

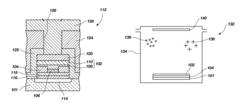

Methods of forming a phase change material

PatentActiveUS8703588B2

Innovation

- A phase change material with two portions, one having a higher percentage of nitrogen or oxygen than the other, is used to enhance adhesion to dielectric materials, with the high adhesion portion being in direct contact with the dielectric material and the low adhesion portion formed over it, ensuring sufficient adherence and allowing the material to crystallize effectively.

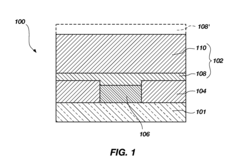

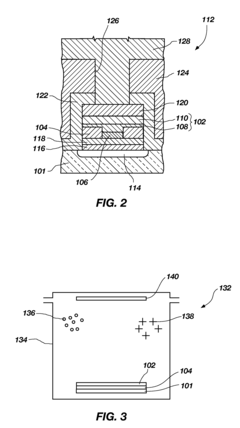

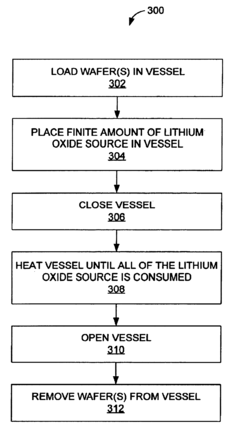

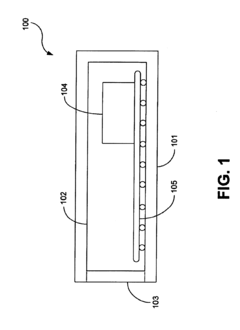

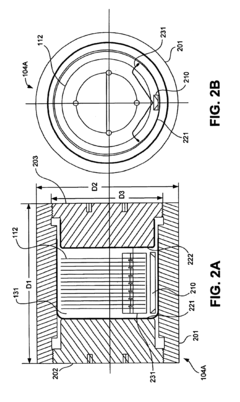

Adjusting lithium oxide concentration in wafers using a two-phase lithium-rich source

PatentInactiveUS6652644B1

Innovation

- A method involving a sealed vessel with a lithium oxide source and wafers, where lithium oxide vapor is absorbed to adjust the concentration, allowing for the conversion of congruent grown lithium tantalate (CLT) wafers to SLT wafers, with controlled partial pressure and vessel designs to optimize space and reduce contamination.

Environmental Impact of Lithium Oxide PCM

The environmental impact of lithium oxide as a phase change material (PCM) in energy systems is a critical consideration for its widespread adoption. While lithium oxide PCMs offer significant advantages in terms of energy storage and thermal management, their environmental footprint must be carefully evaluated throughout their lifecycle.

The production of lithium oxide PCMs involves the extraction and processing of lithium, which can have substantial environmental implications. Lithium mining, particularly from brine deposits, can lead to water depletion and contamination in arid regions. The extraction process may also disrupt local ecosystems and biodiversity. However, compared to traditional energy storage methods, the long-term environmental benefits of lithium oxide PCMs in reducing overall energy consumption and greenhouse gas emissions may outweigh these initial impacts.

During the operational phase, lithium oxide PCMs demonstrate excellent environmental performance. Their high thermal storage capacity and stability contribute to improved energy efficiency in various applications, such as building thermal management and industrial processes. This increased efficiency translates to reduced energy consumption and lower carbon emissions over the system's lifetime. Additionally, the non-toxic and non-flammable nature of lithium oxide minimizes the risk of environmental contamination in case of leakage or system failure.

The end-of-life management of lithium oxide PCMs presents both challenges and opportunities. While the material itself is not inherently hazardous, proper recycling and disposal procedures must be established to prevent environmental contamination and recover valuable lithium resources. The development of efficient recycling technologies for lithium oxide PCMs could significantly reduce the environmental impact associated with raw material extraction and contribute to a more circular economy.

When comparing lithium oxide PCMs to alternative energy storage technologies, their environmental impact is generally favorable. Unlike battery-based systems, lithium oxide PCMs do not require the use of heavy metals or toxic electrolytes, reducing the potential for environmental pollution. Furthermore, their longer lifespan and lower degradation rates result in less frequent replacement and disposal, minimizing waste generation over time.

However, the environmental impact of lithium oxide PCMs can vary depending on the specific application and system design. Factors such as manufacturing processes, transportation, and integration with existing infrastructure must be considered in a comprehensive life cycle assessment. Ongoing research and development efforts are focused on optimizing the production and utilization of lithium oxide PCMs to further enhance their environmental performance and sustainability.

The production of lithium oxide PCMs involves the extraction and processing of lithium, which can have substantial environmental implications. Lithium mining, particularly from brine deposits, can lead to water depletion and contamination in arid regions. The extraction process may also disrupt local ecosystems and biodiversity. However, compared to traditional energy storage methods, the long-term environmental benefits of lithium oxide PCMs in reducing overall energy consumption and greenhouse gas emissions may outweigh these initial impacts.

During the operational phase, lithium oxide PCMs demonstrate excellent environmental performance. Their high thermal storage capacity and stability contribute to improved energy efficiency in various applications, such as building thermal management and industrial processes. This increased efficiency translates to reduced energy consumption and lower carbon emissions over the system's lifetime. Additionally, the non-toxic and non-flammable nature of lithium oxide minimizes the risk of environmental contamination in case of leakage or system failure.

The end-of-life management of lithium oxide PCMs presents both challenges and opportunities. While the material itself is not inherently hazardous, proper recycling and disposal procedures must be established to prevent environmental contamination and recover valuable lithium resources. The development of efficient recycling technologies for lithium oxide PCMs could significantly reduce the environmental impact associated with raw material extraction and contribute to a more circular economy.

When comparing lithium oxide PCMs to alternative energy storage technologies, their environmental impact is generally favorable. Unlike battery-based systems, lithium oxide PCMs do not require the use of heavy metals or toxic electrolytes, reducing the potential for environmental pollution. Furthermore, their longer lifespan and lower degradation rates result in less frequent replacement and disposal, minimizing waste generation over time.

However, the environmental impact of lithium oxide PCMs can vary depending on the specific application and system design. Factors such as manufacturing processes, transportation, and integration with existing infrastructure must be considered in a comprehensive life cycle assessment. Ongoing research and development efforts are focused on optimizing the production and utilization of lithium oxide PCMs to further enhance their environmental performance and sustainability.

Lithium Oxide PCM Safety Considerations

The use of lithium oxide as a phase change material (PCM) in energy systems presents several safety considerations that must be carefully addressed. Lithium oxide, while offering promising thermal properties, is highly reactive and can pose significant risks if not properly managed.

One of the primary safety concerns is the potential for lithium oxide to react vigorously with water, producing heat and potentially leading to fire or explosion hazards. This reactivity necessitates stringent moisture control measures throughout the PCM system's lifecycle, from manufacturing to operation and maintenance. Specialized handling procedures and protective equipment are essential for personnel working with lithium oxide PCMs.

The corrosive nature of lithium oxide is another critical safety issue. It can cause severe damage to containment materials, potentially leading to system failures and leaks. This necessitates the use of corrosion-resistant materials in all components that come into contact with the PCM, as well as regular inspections and maintenance to ensure system integrity.

Thermal runaway is a significant risk associated with lithium-based materials in energy storage applications. While less prone to this phenomenon compared to other lithium compounds, lithium oxide PCMs still require careful thermal management to prevent overheating and potential system failures. This includes implementing robust temperature monitoring and control systems, as well as designing appropriate heat dissipation mechanisms.

The potential for dust formation during handling and processing of lithium oxide presents respiratory hazards to workers. Fine particles of lithium oxide can cause severe irritation to the respiratory tract and eyes. Consequently, proper ventilation systems and personal protective equipment, including respirators and eye protection, are crucial in environments where lithium oxide PCMs are handled or processed.

Environmental considerations also play a role in the safety profile of lithium oxide PCMs. Proper disposal and recycling procedures must be established to prevent environmental contamination. This includes developing protocols for the safe decommissioning of systems containing lithium oxide PCMs and ensuring that any waste materials are handled in accordance with hazardous material regulations.

Given these safety considerations, the implementation of comprehensive risk assessment and management strategies is essential for any energy system utilizing lithium oxide as a PCM. This should include detailed emergency response plans, regular safety training for personnel, and ongoing research into improving the safety profile of lithium oxide PCM systems. By addressing these safety concerns proactively, the potential benefits of lithium oxide PCMs in energy systems can be realized while minimizing risks to personnel, equipment, and the environment.

One of the primary safety concerns is the potential for lithium oxide to react vigorously with water, producing heat and potentially leading to fire or explosion hazards. This reactivity necessitates stringent moisture control measures throughout the PCM system's lifecycle, from manufacturing to operation and maintenance. Specialized handling procedures and protective equipment are essential for personnel working with lithium oxide PCMs.

The corrosive nature of lithium oxide is another critical safety issue. It can cause severe damage to containment materials, potentially leading to system failures and leaks. This necessitates the use of corrosion-resistant materials in all components that come into contact with the PCM, as well as regular inspections and maintenance to ensure system integrity.

Thermal runaway is a significant risk associated with lithium-based materials in energy storage applications. While less prone to this phenomenon compared to other lithium compounds, lithium oxide PCMs still require careful thermal management to prevent overheating and potential system failures. This includes implementing robust temperature monitoring and control systems, as well as designing appropriate heat dissipation mechanisms.

The potential for dust formation during handling and processing of lithium oxide presents respiratory hazards to workers. Fine particles of lithium oxide can cause severe irritation to the respiratory tract and eyes. Consequently, proper ventilation systems and personal protective equipment, including respirators and eye protection, are crucial in environments where lithium oxide PCMs are handled or processed.

Environmental considerations also play a role in the safety profile of lithium oxide PCMs. Proper disposal and recycling procedures must be established to prevent environmental contamination. This includes developing protocols for the safe decommissioning of systems containing lithium oxide PCMs and ensuring that any waste materials are handled in accordance with hazardous material regulations.

Given these safety considerations, the implementation of comprehensive risk assessment and management strategies is essential for any energy system utilizing lithium oxide as a PCM. This should include detailed emergency response plans, regular safety training for personnel, and ongoing research into improving the safety profile of lithium oxide PCM systems. By addressing these safety concerns proactively, the potential benefits of lithium oxide PCMs in energy systems can be realized while minimizing risks to personnel, equipment, and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!