Lithium oxide properties for optimizing smart clothing technology

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide in Smart Clothing: Background and Objectives

Smart clothing technology has been evolving rapidly in recent years, with a growing focus on integrating advanced materials to enhance functionality and performance. Lithium oxide, a compound with unique properties, has emerged as a promising material in this field. The development of smart clothing incorporating lithium oxide represents a convergence of materials science, wearable technology, and consumer electronics.

The history of smart clothing can be traced back to the late 20th century, with early experiments in wearable computing. However, it is only in the past decade that significant advancements have been made in integrating electronic components and smart materials into textiles. The incorporation of lithium oxide into smart clothing is a relatively recent development, driven by the need for more efficient and versatile wearable technologies.

Lithium oxide, with its ionic conductivity and electrochemical properties, offers several potential benefits for smart clothing applications. These include improved energy storage capabilities, enhanced thermal management, and the possibility of creating self-powered garments. The exploration of lithium oxide in this context aligns with broader trends in materials science and the ongoing quest for multifunctional textiles.

The primary objective of researching lithium oxide properties for smart clothing is to optimize its integration and performance within textile structures. This involves understanding the compound's behavior under various conditions, such as different temperatures, humidity levels, and mechanical stresses typically encountered in wearable applications. Additionally, researchers aim to develop methods for effectively incorporating lithium oxide into fibers or fabric coatings without compromising the comfort or flexibility of the garment.

Another key goal is to explore the potential of lithium oxide in enhancing the energy efficiency of smart clothing. This includes investigating its role in improving battery performance, enabling faster charging capabilities, and potentially developing new energy harvesting mechanisms. The research also seeks to address challenges related to safety, durability, and scalability of lithium oxide-based smart clothing solutions.

Furthermore, the study of lithium oxide in smart clothing aims to unlock new functionalities that were previously unattainable. This could include adaptive thermal regulation, real-time physiological monitoring, or even the ability to change color or appearance based on environmental stimuli. The ultimate vision is to create a new generation of smart clothing that seamlessly integrates advanced technology with everyday wear, offering enhanced comfort, functionality, and user experience.

The history of smart clothing can be traced back to the late 20th century, with early experiments in wearable computing. However, it is only in the past decade that significant advancements have been made in integrating electronic components and smart materials into textiles. The incorporation of lithium oxide into smart clothing is a relatively recent development, driven by the need for more efficient and versatile wearable technologies.

Lithium oxide, with its ionic conductivity and electrochemical properties, offers several potential benefits for smart clothing applications. These include improved energy storage capabilities, enhanced thermal management, and the possibility of creating self-powered garments. The exploration of lithium oxide in this context aligns with broader trends in materials science and the ongoing quest for multifunctional textiles.

The primary objective of researching lithium oxide properties for smart clothing is to optimize its integration and performance within textile structures. This involves understanding the compound's behavior under various conditions, such as different temperatures, humidity levels, and mechanical stresses typically encountered in wearable applications. Additionally, researchers aim to develop methods for effectively incorporating lithium oxide into fibers or fabric coatings without compromising the comfort or flexibility of the garment.

Another key goal is to explore the potential of lithium oxide in enhancing the energy efficiency of smart clothing. This includes investigating its role in improving battery performance, enabling faster charging capabilities, and potentially developing new energy harvesting mechanisms. The research also seeks to address challenges related to safety, durability, and scalability of lithium oxide-based smart clothing solutions.

Furthermore, the study of lithium oxide in smart clothing aims to unlock new functionalities that were previously unattainable. This could include adaptive thermal regulation, real-time physiological monitoring, or even the ability to change color or appearance based on environmental stimuli. The ultimate vision is to create a new generation of smart clothing that seamlessly integrates advanced technology with everyday wear, offering enhanced comfort, functionality, and user experience.

Market Analysis for Smart Clothing Technologies

The smart clothing market has been experiencing significant growth in recent years, driven by advancements in wearable technology and increasing consumer demand for functional and connected apparel. The global smart clothing market size was valued at approximately $1.6 billion in 2021 and is projected to reach $5.3 billion by 2027, growing at a CAGR of 21.5% during the forecast period.

The integration of lithium oxide properties in smart clothing technology presents a promising opportunity for market expansion. Lithium oxide, known for its high ionic conductivity and thermal stability, can potentially enhance the performance and functionality of smart textiles. This innovation aligns with the growing consumer interest in wearable devices that offer improved comfort, durability, and energy efficiency.

Key market segments for smart clothing include sports and fitness, healthcare monitoring, military and defense, and industrial applications. The sports and fitness sector currently dominates the market, accounting for over 40% of the total revenue share. However, the healthcare monitoring segment is expected to witness the fastest growth rate due to increasing demand for remote patient monitoring solutions.

Geographically, North America leads the smart clothing market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to early technology adoption and the presence of major players in the wearable technology industry. However, Asia-Pacific is anticipated to exhibit the highest growth rate, driven by rapid industrialization, increasing disposable income, and growing awareness of health and fitness among consumers in countries like China and India.

The market is characterized by intense competition and continuous innovation. Key players in the smart clothing industry include Adidas, Nike, Under Armour, and Hexoskin. These companies are investing heavily in research and development to incorporate advanced materials and technologies, including lithium oxide-based solutions, into their product offerings.

Consumer preferences in the smart clothing market are shifting towards more seamless integration of technology with everyday wear. There is a growing demand for smart garments that not only provide functional benefits but also maintain aesthetic appeal and comfort. The incorporation of lithium oxide properties in smart clothing aligns with this trend, potentially offering improved battery life, enhanced sensor performance, and better thermal management.

Challenges in the market include high production costs, concerns about data privacy and security, and the need for standardization in the industry. However, ongoing research in materials science, including the exploration of lithium oxide properties, is expected to address some of these challenges and drive further market growth.

The integration of lithium oxide properties in smart clothing technology presents a promising opportunity for market expansion. Lithium oxide, known for its high ionic conductivity and thermal stability, can potentially enhance the performance and functionality of smart textiles. This innovation aligns with the growing consumer interest in wearable devices that offer improved comfort, durability, and energy efficiency.

Key market segments for smart clothing include sports and fitness, healthcare monitoring, military and defense, and industrial applications. The sports and fitness sector currently dominates the market, accounting for over 40% of the total revenue share. However, the healthcare monitoring segment is expected to witness the fastest growth rate due to increasing demand for remote patient monitoring solutions.

Geographically, North America leads the smart clothing market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to early technology adoption and the presence of major players in the wearable technology industry. However, Asia-Pacific is anticipated to exhibit the highest growth rate, driven by rapid industrialization, increasing disposable income, and growing awareness of health and fitness among consumers in countries like China and India.

The market is characterized by intense competition and continuous innovation. Key players in the smart clothing industry include Adidas, Nike, Under Armour, and Hexoskin. These companies are investing heavily in research and development to incorporate advanced materials and technologies, including lithium oxide-based solutions, into their product offerings.

Consumer preferences in the smart clothing market are shifting towards more seamless integration of technology with everyday wear. There is a growing demand for smart garments that not only provide functional benefits but also maintain aesthetic appeal and comfort. The incorporation of lithium oxide properties in smart clothing aligns with this trend, potentially offering improved battery life, enhanced sensor performance, and better thermal management.

Challenges in the market include high production costs, concerns about data privacy and security, and the need for standardization in the industry. However, ongoing research in materials science, including the exploration of lithium oxide properties, is expected to address some of these challenges and drive further market growth.

Current Challenges in Lithium Oxide Integration

The integration of lithium oxide into smart clothing technology presents several significant challenges that researchers and developers must address. One of the primary obstacles is the stability of lithium oxide in various environmental conditions. Smart clothing is exposed to a wide range of temperatures, humidity levels, and physical stresses, which can potentially affect the performance and longevity of lithium oxide components. Ensuring consistent functionality across these diverse conditions remains a complex task.

Another critical challenge lies in the miniaturization of lithium oxide-based components. Smart clothing demands lightweight, flexible, and unobtrusive elements that do not compromise the wearer's comfort or mobility. Achieving the necessary level of miniaturization while maintaining the desired properties and performance of lithium oxide is a delicate balancing act that requires innovative engineering solutions.

The power management of lithium oxide-based systems in smart clothing also poses significant hurdles. Optimizing energy efficiency without sacrificing functionality is crucial, as smart clothing typically has limited space for power sources. Developing efficient power distribution and management systems that can effectively utilize the properties of lithium oxide while minimizing energy consumption is an ongoing challenge.

Durability and longevity of lithium oxide components in smart clothing applications are additional concerns. The frequent washing and wearing of smart garments subject these components to mechanical stress and potential chemical interactions. Ensuring that lithium oxide-based elements can withstand these conditions over extended periods without degradation in performance or safety is a complex engineering problem.

Furthermore, the integration of lithium oxide with other materials and components in smart clothing presents compatibility issues. Ensuring seamless interaction between lithium oxide and various sensors, conductive materials, and other smart elements while maintaining the integrity of each component is a multifaceted challenge that requires interdisciplinary expertise.

Safety considerations also play a crucial role in the integration of lithium oxide into wearable technology. Addressing potential risks associated with skin contact, heat generation, and electrical safety is paramount. Developing protective measures and fail-safe mechanisms to prevent any adverse reactions or accidents is an ongoing area of research and development.

Lastly, the scalability of lithium oxide integration in smart clothing manufacturing processes presents significant challenges. Developing cost-effective, reliable, and efficient production methods that can be scaled up for mass production while maintaining consistent quality and performance is essential for the widespread adoption of this technology in the smart clothing industry.

Another critical challenge lies in the miniaturization of lithium oxide-based components. Smart clothing demands lightweight, flexible, and unobtrusive elements that do not compromise the wearer's comfort or mobility. Achieving the necessary level of miniaturization while maintaining the desired properties and performance of lithium oxide is a delicate balancing act that requires innovative engineering solutions.

The power management of lithium oxide-based systems in smart clothing also poses significant hurdles. Optimizing energy efficiency without sacrificing functionality is crucial, as smart clothing typically has limited space for power sources. Developing efficient power distribution and management systems that can effectively utilize the properties of lithium oxide while minimizing energy consumption is an ongoing challenge.

Durability and longevity of lithium oxide components in smart clothing applications are additional concerns. The frequent washing and wearing of smart garments subject these components to mechanical stress and potential chemical interactions. Ensuring that lithium oxide-based elements can withstand these conditions over extended periods without degradation in performance or safety is a complex engineering problem.

Furthermore, the integration of lithium oxide with other materials and components in smart clothing presents compatibility issues. Ensuring seamless interaction between lithium oxide and various sensors, conductive materials, and other smart elements while maintaining the integrity of each component is a multifaceted challenge that requires interdisciplinary expertise.

Safety considerations also play a crucial role in the integration of lithium oxide into wearable technology. Addressing potential risks associated with skin contact, heat generation, and electrical safety is paramount. Developing protective measures and fail-safe mechanisms to prevent any adverse reactions or accidents is an ongoing area of research and development.

Lastly, the scalability of lithium oxide integration in smart clothing manufacturing processes presents significant challenges. Developing cost-effective, reliable, and efficient production methods that can be scaled up for mass production while maintaining consistent quality and performance is essential for the widespread adoption of this technology in the smart clothing industry.

Existing Lithium Oxide Applications in Smart Textiles

01 Chemical and physical properties of lithium oxide

Lithium oxide (Li2O) is a white, crystalline solid with a high melting point. It is highly reactive with water and air, forming lithium hydroxide. Its properties make it useful in various applications, including ceramics, glass manufacturing, and as a component in lithium-ion batteries.- Lithium oxide in battery applications: Lithium oxide is widely used in battery technologies, particularly in lithium-ion batteries. It serves as a crucial component in cathode materials, contributing to improved battery performance, capacity, and stability. The incorporation of lithium oxide in battery systems enhances energy density and cycle life.

- Synthesis and production methods of lithium oxide: Various methods are employed to synthesize and produce lithium oxide, including chemical reactions, thermal decomposition, and electrochemical processes. These techniques aim to optimize the purity, particle size, and morphology of lithium oxide for specific applications. Advanced production methods focus on enhancing the material's properties and reducing manufacturing costs.

- Lithium oxide as a precursor material: Lithium oxide serves as an important precursor material in the production of various lithium-based compounds and materials. It is used in the synthesis of lithium salts, ceramics, and other advanced materials. The reactivity and versatility of lithium oxide make it valuable in numerous industrial processes and material science applications.

- Physical and chemical properties of lithium oxide: Lithium oxide exhibits unique physical and chemical properties, including high melting point, ionic conductivity, and reactivity with water. These characteristics influence its behavior in various applications and environments. Understanding the properties of lithium oxide is crucial for its effective utilization in different fields, such as energy storage, ceramics, and chemical synthesis.

- Applications of lithium oxide in advanced materials: Lithium oxide finds applications in the development of advanced materials beyond battery technologies. It is used in the production of specialized glasses, ceramics, and optical materials. The incorporation of lithium oxide can enhance the properties of these materials, such as thermal stability, mechanical strength, and optical characteristics.

02 Use of lithium oxide in battery technology

Lithium oxide plays a crucial role in lithium-ion battery technology. It is used as a precursor for cathode materials and can enhance the performance and stability of battery electrodes. Its incorporation in battery components can lead to improved energy density, cycle life, and overall battery efficiency.Expand Specific Solutions03 Synthesis and production methods of lithium oxide

Various methods are employed to synthesize and produce lithium oxide, including thermal decomposition of lithium salts, reaction of lithium metal with oxygen, and electrochemical processes. These methods aim to control the purity, particle size, and morphology of the resulting lithium oxide, which can significantly affect its properties and performance in different applications.Expand Specific Solutions04 Applications of lithium oxide in materials science

Lithium oxide finds applications in various fields of materials science. It is used as a flux in ceramic and glass production, improving the melting characteristics and properties of the final products. Additionally, it serves as a precursor for the synthesis of other lithium compounds and as a component in specialized optical materials and nuclear applications.Expand Specific Solutions05 Environmental and safety considerations of lithium oxide

The handling and use of lithium oxide require careful consideration of environmental and safety factors. It is highly reactive with moisture and can pose health risks if inhaled or in contact with skin. Proper storage, handling, and disposal procedures are essential to mitigate potential hazards associated with its use in industrial and research settings.Expand Specific Solutions

Key Players in Smart Clothing and Lithium Technology

The research on lithium oxide properties for optimizing smart clothing technology is in its early stages, with the market still emerging and showing significant growth potential. The global smart clothing market is projected to expand rapidly, driven by increasing demand for wearable technology. Companies like LG Energy Solution, SK On, and Samsung SDI are leading the charge in battery technology development, which is crucial for smart clothing applications. However, the technology is not yet fully mature, with challenges in miniaturization and power efficiency still being addressed. Established chemical companies such as Sumitomo Chemical and BASF are also contributing to material advancements, indicating a competitive landscape that spans multiple industries.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced lithium oxide-based materials for smart clothing applications. Their research focuses on creating flexible and lightweight lithium-ion batteries that can be seamlessly integrated into textiles. The company has pioneered a unique coating technology that enhances the stability and conductivity of lithium oxide compounds, resulting in improved energy density and cycle life[1]. They have also developed a proprietary nanostructured lithium oxide material that allows for rapid ion transport, enabling fast charging capabilities in smart clothing applications[2]. Additionally, LG Energy Solution has implemented safety features such as thermal management systems to prevent overheating issues in wearable devices[3].

Strengths: High energy density, flexibility, and fast charging capabilities. Weaknesses: Potential high costs and complexity in large-scale manufacturing for textile integration.

Solvay SA

Technical Solution: Solvay has made significant contributions to lithium oxide research for smart clothing technology through their expertise in specialty polymers and advanced materials. They have developed a range of lithium-conducting polymer electrolytes that incorporate lithium oxide nanoparticles, resulting in improved ionic conductivity and mechanical flexibility[10]. This technology enables the creation of thin, flexible batteries suitable for integration into textiles. Solvay has also pioneered a process for creating lithium oxide-doped conductive fibers that can be woven directly into fabrics, serving as both power storage and distribution elements in smart clothing[11]. Furthermore, their research extends to lithium oxide-based moisture sensors that can be integrated into smart textiles for health monitoring applications[12].

Strengths: Expertise in specialty polymers, innovative conductive fibers, and multifunctional materials. Weaknesses: Potential challenges in large-scale production and ensuring long-term durability in wearable applications.

Core Innovations in Lithium Oxide Properties

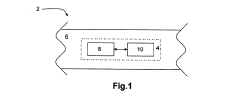

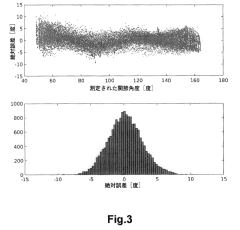

Smart textiles suitable for detecting movement and/or deformation

PatentActiveJP2022509028A

Innovation

- A stretchable conductive fabric with electrodes and a neural network inference engine to detect movements by applying Electrical Impedance Tomography (EIT) principles, using a neural network to predict joint angles with high accuracy.

Environmental Impact of Lithium-Based Smart Textiles

The environmental impact of lithium-based smart textiles is a critical consideration as this technology advances. The production and disposal of these textiles involve several environmental concerns that must be addressed for sustainable development.

Lithium extraction, a key component in smart textiles, can have significant environmental consequences. Open-pit mining, the primary method for lithium extraction, leads to habitat destruction, soil erosion, and water pollution. The process requires large amounts of water, potentially depleting local water resources in arid regions where lithium is often found. Additionally, the chemicals used in lithium processing can contaminate soil and groundwater if not properly managed.

The manufacturing of smart textiles incorporating lithium-based components also contributes to environmental issues. The production process involves energy-intensive steps and the use of various chemicals, potentially leading to air and water pollution if not properly controlled. The integration of electronic components with textiles creates complex materials that are challenging to recycle, potentially increasing electronic waste.

End-of-life management of lithium-based smart textiles presents another environmental challenge. These products often contain a mix of materials that are difficult to separate and recycle. Improper disposal can lead to the release of harmful substances into the environment, including lithium and other heavy metals used in electronic components. This can result in soil and water contamination, posing risks to ecosystems and human health.

However, the environmental impact of lithium-based smart textiles is not entirely negative. These technologies have the potential to contribute to sustainability in other ways. For instance, smart clothing with integrated temperature regulation can reduce the need for energy-intensive heating and cooling systems. Wearable health monitoring devices can lead to more efficient healthcare delivery, potentially reducing resource consumption in the medical sector.

To mitigate the environmental impact, several strategies are being explored. These include developing more efficient lithium extraction methods, improving the recyclability of smart textiles, and implementing closed-loop manufacturing processes. Research is also focused on finding alternative materials that can provide similar functionality with less environmental impact.

As the technology evolves, it is crucial to consider the entire lifecycle of lithium-based smart textiles, from raw material extraction to disposal. This holistic approach will be essential in minimizing environmental impact while maximizing the benefits of this innovative technology.

Lithium extraction, a key component in smart textiles, can have significant environmental consequences. Open-pit mining, the primary method for lithium extraction, leads to habitat destruction, soil erosion, and water pollution. The process requires large amounts of water, potentially depleting local water resources in arid regions where lithium is often found. Additionally, the chemicals used in lithium processing can contaminate soil and groundwater if not properly managed.

The manufacturing of smart textiles incorporating lithium-based components also contributes to environmental issues. The production process involves energy-intensive steps and the use of various chemicals, potentially leading to air and water pollution if not properly controlled. The integration of electronic components with textiles creates complex materials that are challenging to recycle, potentially increasing electronic waste.

End-of-life management of lithium-based smart textiles presents another environmental challenge. These products often contain a mix of materials that are difficult to separate and recycle. Improper disposal can lead to the release of harmful substances into the environment, including lithium and other heavy metals used in electronic components. This can result in soil and water contamination, posing risks to ecosystems and human health.

However, the environmental impact of lithium-based smart textiles is not entirely negative. These technologies have the potential to contribute to sustainability in other ways. For instance, smart clothing with integrated temperature regulation can reduce the need for energy-intensive heating and cooling systems. Wearable health monitoring devices can lead to more efficient healthcare delivery, potentially reducing resource consumption in the medical sector.

To mitigate the environmental impact, several strategies are being explored. These include developing more efficient lithium extraction methods, improving the recyclability of smart textiles, and implementing closed-loop manufacturing processes. Research is also focused on finding alternative materials that can provide similar functionality with less environmental impact.

As the technology evolves, it is crucial to consider the entire lifecycle of lithium-based smart textiles, from raw material extraction to disposal. This holistic approach will be essential in minimizing environmental impact while maximizing the benefits of this innovative technology.

Safety Regulations for Wearable Lithium Technologies

The integration of lithium-based technologies in smart clothing has necessitated the development of comprehensive safety regulations to ensure user protection and product reliability. These regulations address various aspects of wearable lithium technologies, including battery design, manufacturing processes, and usage guidelines.

Safety standards for lithium-based wearable devices primarily focus on preventing thermal runaway, electrical shorts, and physical damage. Manufacturers are required to implement multiple layers of protection, such as thermal management systems, overcharge protection circuits, and robust enclosures. These measures aim to minimize the risk of fire, explosion, or chemical leakage that could harm the wearer.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), have established specific standards for wearable lithium technologies. For instance, IEC 62133 outlines safety requirements for portable sealed secondary lithium cells and batteries, while UL 2054 provides standards for household and commercial batteries.

In the context of smart clothing, regulations emphasize the importance of proper integration and insulation of lithium components within the fabric. Manufacturers must ensure that the electrical connections remain stable during normal wear and tear, washing, and other typical usage scenarios. Additionally, guidelines specify maximum operating temperatures and acceptable voltage ranges to prevent overheating or electrical hazards.

Environmental considerations are also addressed in safety regulations for wearable lithium technologies. These include proper disposal and recycling procedures for lithium-containing garments, as well as guidelines for transportation and storage of smart clothing items with integrated lithium components.

User safety instructions form a crucial part of the regulatory framework. Manufacturers are required to provide clear guidelines on proper usage, charging procedures, and potential hazards associated with wearable lithium technologies. This includes warnings about exposure to extreme temperatures, physical impact, and water damage.

As the field of smart clothing continues to evolve, safety regulations are regularly updated to address new technological developments and emerging risks. Ongoing research into lithium oxide properties and their applications in wearable technologies contributes to the refinement of these regulations, ensuring that safety standards keep pace with innovation in the industry.

Safety standards for lithium-based wearable devices primarily focus on preventing thermal runaway, electrical shorts, and physical damage. Manufacturers are required to implement multiple layers of protection, such as thermal management systems, overcharge protection circuits, and robust enclosures. These measures aim to minimize the risk of fire, explosion, or chemical leakage that could harm the wearer.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), have established specific standards for wearable lithium technologies. For instance, IEC 62133 outlines safety requirements for portable sealed secondary lithium cells and batteries, while UL 2054 provides standards for household and commercial batteries.

In the context of smart clothing, regulations emphasize the importance of proper integration and insulation of lithium components within the fabric. Manufacturers must ensure that the electrical connections remain stable during normal wear and tear, washing, and other typical usage scenarios. Additionally, guidelines specify maximum operating temperatures and acceptable voltage ranges to prevent overheating or electrical hazards.

Environmental considerations are also addressed in safety regulations for wearable lithium technologies. These include proper disposal and recycling procedures for lithium-containing garments, as well as guidelines for transportation and storage of smart clothing items with integrated lithium components.

User safety instructions form a crucial part of the regulatory framework. Manufacturers are required to provide clear guidelines on proper usage, charging procedures, and potential hazards associated with wearable lithium technologies. This includes warnings about exposure to extreme temperatures, physical impact, and water damage.

As the field of smart clothing continues to evolve, safety regulations are regularly updated to address new technological developments and emerging risks. Ongoing research into lithium oxide properties and their applications in wearable technologies contributes to the refinement of these regulations, ensuring that safety standards keep pace with innovation in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!