Lithium oxide applications in high-precision calibration equipment

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li2O in Calibration: Background and Objectives

Lithium oxide (Li2O) has emerged as a crucial material in the field of high-precision calibration equipment, marking a significant advancement in measurement technology. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the unique properties of lithium-based compounds for calibration purposes. Over the past two decades, Li2O has gained prominence due to its exceptional stability and precision in calibration applications.

The primary objective of utilizing Li2O in calibration equipment is to achieve unprecedented levels of accuracy and reliability in measurements across various industries. This technology aims to address the growing demand for ultra-precise calibration in fields such as aerospace, semiconductor manufacturing, and scientific research. By leveraging the inherent properties of Li2O, researchers and engineers seek to develop calibration systems that can maintain their accuracy over extended periods and under diverse environmental conditions.

The technological trajectory of Li2O in calibration equipment has been characterized by continuous improvements in material synthesis, integration techniques, and measurement methodologies. Initial applications focused on temperature calibration, where Li2O's stable melting point and consistent thermal properties proved invaluable. As the technology progressed, its use expanded to include pressure, force, and even electrical calibration systems.

One of the key drivers behind the development of Li2O-based calibration technology is the increasing miniaturization and complexity of electronic devices and sensors. These advancements have created a need for calibration equipment capable of providing accurate measurements at micro and nano scales. Li2O's unique atomic structure and chemical stability make it an ideal candidate for such high-precision applications.

The global push towards Industry 4.0 and smart manufacturing has further accelerated the demand for advanced calibration technologies. Li2O-based systems are expected to play a crucial role in ensuring the accuracy and reliability of automated production processes, where even minute deviations can lead to significant quality issues or safety concerns. This trend has spurred research into integrating Li2O calibration technology with IoT and AI systems for real-time monitoring and adjustment.

As we look towards the future, the objectives for Li2O in calibration equipment are becoming increasingly ambitious. Researchers are exploring ways to enhance the material's performance under extreme conditions, such as high-radiation environments or ultra-low temperatures. There is also a growing interest in developing multi-functional calibration systems that can simultaneously measure multiple parameters with Li2O as the core calibration material.

The primary objective of utilizing Li2O in calibration equipment is to achieve unprecedented levels of accuracy and reliability in measurements across various industries. This technology aims to address the growing demand for ultra-precise calibration in fields such as aerospace, semiconductor manufacturing, and scientific research. By leveraging the inherent properties of Li2O, researchers and engineers seek to develop calibration systems that can maintain their accuracy over extended periods and under diverse environmental conditions.

The technological trajectory of Li2O in calibration equipment has been characterized by continuous improvements in material synthesis, integration techniques, and measurement methodologies. Initial applications focused on temperature calibration, where Li2O's stable melting point and consistent thermal properties proved invaluable. As the technology progressed, its use expanded to include pressure, force, and even electrical calibration systems.

One of the key drivers behind the development of Li2O-based calibration technology is the increasing miniaturization and complexity of electronic devices and sensors. These advancements have created a need for calibration equipment capable of providing accurate measurements at micro and nano scales. Li2O's unique atomic structure and chemical stability make it an ideal candidate for such high-precision applications.

The global push towards Industry 4.0 and smart manufacturing has further accelerated the demand for advanced calibration technologies. Li2O-based systems are expected to play a crucial role in ensuring the accuracy and reliability of automated production processes, where even minute deviations can lead to significant quality issues or safety concerns. This trend has spurred research into integrating Li2O calibration technology with IoT and AI systems for real-time monitoring and adjustment.

As we look towards the future, the objectives for Li2O in calibration equipment are becoming increasingly ambitious. Researchers are exploring ways to enhance the material's performance under extreme conditions, such as high-radiation environments or ultra-low temperatures. There is also a growing interest in developing multi-functional calibration systems that can simultaneously measure multiple parameters with Li2O as the core calibration material.

Market Analysis for High-Precision Calibration Equipment

The market for high-precision calibration equipment has been experiencing steady growth, driven by increasing demand for accuracy and reliability across various industries. The integration of lithium oxide in these devices has opened new avenues for enhanced performance and expanded applications. Key sectors fueling this market include aerospace, semiconductor manufacturing, medical devices, and advanced manufacturing.

In the aerospace industry, the need for precise calibration of navigation systems, altimeters, and other critical instruments has led to a surge in demand for high-precision equipment. The unique properties of lithium oxide, such as its stability and low thermal expansion coefficient, make it an ideal material for calibration standards in this sector. This has resulted in a significant market share for lithium oxide-based calibration devices in aerospace applications.

The semiconductor industry, with its stringent requirements for nanometer-scale precision, has also become a major consumer of high-precision calibration equipment. As chip manufacturers push the boundaries of miniaturization, the role of lithium oxide in calibration tools has become increasingly crucial. Market analysts predict a compound annual growth rate (CAGR) of over 6% for this segment over the next five years.

In the medical device sector, the growing complexity of diagnostic and therapeutic equipment has necessitated more accurate calibration processes. Lithium oxide-based calibration tools have found particular success in applications such as MRI machine calibration and radiation therapy equipment adjustment. This has contributed to a notable expansion of the market in healthcare-related calibration equipment.

The advanced manufacturing sector, encompassing industries like robotics and automation, has also emerged as a significant market for high-precision calibration equipment. As manufacturing processes become more sophisticated and automated, the demand for highly accurate calibration tools has intensified. Lithium oxide applications in this sector have shown promising growth, particularly in the calibration of robotic assembly systems and quality control equipment.

Geographically, North America and Europe currently dominate the market for high-precision calibration equipment, owing to their advanced industrial base and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing adoption of advanced technologies in countries like China, Japan, and South Korea.

Despite the positive outlook, the market faces challenges such as high initial costs and the need for specialized expertise in handling lithium oxide-based equipment. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective and user-friendly solutions in the future.

In the aerospace industry, the need for precise calibration of navigation systems, altimeters, and other critical instruments has led to a surge in demand for high-precision equipment. The unique properties of lithium oxide, such as its stability and low thermal expansion coefficient, make it an ideal material for calibration standards in this sector. This has resulted in a significant market share for lithium oxide-based calibration devices in aerospace applications.

The semiconductor industry, with its stringent requirements for nanometer-scale precision, has also become a major consumer of high-precision calibration equipment. As chip manufacturers push the boundaries of miniaturization, the role of lithium oxide in calibration tools has become increasingly crucial. Market analysts predict a compound annual growth rate (CAGR) of over 6% for this segment over the next five years.

In the medical device sector, the growing complexity of diagnostic and therapeutic equipment has necessitated more accurate calibration processes. Lithium oxide-based calibration tools have found particular success in applications such as MRI machine calibration and radiation therapy equipment adjustment. This has contributed to a notable expansion of the market in healthcare-related calibration equipment.

The advanced manufacturing sector, encompassing industries like robotics and automation, has also emerged as a significant market for high-precision calibration equipment. As manufacturing processes become more sophisticated and automated, the demand for highly accurate calibration tools has intensified. Lithium oxide applications in this sector have shown promising growth, particularly in the calibration of robotic assembly systems and quality control equipment.

Geographically, North America and Europe currently dominate the market for high-precision calibration equipment, owing to their advanced industrial base and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing adoption of advanced technologies in countries like China, Japan, and South Korea.

Despite the positive outlook, the market faces challenges such as high initial costs and the need for specialized expertise in handling lithium oxide-based equipment. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective and user-friendly solutions in the future.

Current State and Challenges of Li2O Applications

Lithium oxide (Li2O) has emerged as a crucial material in high-precision calibration equipment, offering unique properties that enhance accuracy and reliability. Currently, Li2O applications in this field are primarily focused on its use as a reference material for calibrating instruments in nuclear and radiation detection systems. The high stability and well-defined nuclear properties of Li2O make it an ideal standard for calibrating gamma-ray spectrometers and neutron detectors.

One of the main challenges in Li2O applications is maintaining its purity and stability over extended periods. Environmental factors such as humidity and temperature fluctuations can affect the material's properties, potentially compromising calibration accuracy. Researchers are actively working on developing improved storage and handling techniques to mitigate these issues and ensure long-term stability of Li2O-based calibration standards.

Another significant challenge lies in the precise manufacturing and characterization of Li2O samples for calibration purposes. Achieving uniform composition and crystal structure across different batches of Li2O is critical for consistent calibration results. Advanced manufacturing techniques, such as controlled crystallization and isotope enrichment, are being explored to enhance the quality and reproducibility of Li2O calibration standards.

The integration of Li2O into miniaturized calibration devices presents both opportunities and challenges. As the demand for portable and compact calibration equipment grows, researchers are investigating ways to incorporate Li2O into microelectromechanical systems (MEMS) and other small-scale devices. However, maintaining the material's properties and performance at reduced scales poses significant technical hurdles that require innovative solutions.

In the field of optical calibration, Li2O is gaining attention for its potential use in high-precision wavelength standards. Its unique optical properties, including a wide transparency range and low dispersion, make it a promising candidate for next-generation optical calibration devices. However, challenges remain in optimizing the material's optical quality and developing suitable fabrication techniques for optical-grade Li2O components.

The expanding applications of Li2O in calibration equipment have also highlighted the need for improved characterization techniques. Researchers are developing advanced analytical methods, such as high-resolution spectroscopy and neutron diffraction, to better understand the material's properties and behavior under various conditions. These efforts aim to enhance the accuracy and reliability of Li2O-based calibration standards across different applications.

As the demand for higher precision in scientific and industrial measurements continues to grow, the development of Li2O applications in calibration equipment faces the challenge of meeting increasingly stringent performance requirements. This drives ongoing research into novel Li2O-based materials and composite systems that can offer enhanced stability, sensitivity, and versatility in calibration applications.

One of the main challenges in Li2O applications is maintaining its purity and stability over extended periods. Environmental factors such as humidity and temperature fluctuations can affect the material's properties, potentially compromising calibration accuracy. Researchers are actively working on developing improved storage and handling techniques to mitigate these issues and ensure long-term stability of Li2O-based calibration standards.

Another significant challenge lies in the precise manufacturing and characterization of Li2O samples for calibration purposes. Achieving uniform composition and crystal structure across different batches of Li2O is critical for consistent calibration results. Advanced manufacturing techniques, such as controlled crystallization and isotope enrichment, are being explored to enhance the quality and reproducibility of Li2O calibration standards.

The integration of Li2O into miniaturized calibration devices presents both opportunities and challenges. As the demand for portable and compact calibration equipment grows, researchers are investigating ways to incorporate Li2O into microelectromechanical systems (MEMS) and other small-scale devices. However, maintaining the material's properties and performance at reduced scales poses significant technical hurdles that require innovative solutions.

In the field of optical calibration, Li2O is gaining attention for its potential use in high-precision wavelength standards. Its unique optical properties, including a wide transparency range and low dispersion, make it a promising candidate for next-generation optical calibration devices. However, challenges remain in optimizing the material's optical quality and developing suitable fabrication techniques for optical-grade Li2O components.

The expanding applications of Li2O in calibration equipment have also highlighted the need for improved characterization techniques. Researchers are developing advanced analytical methods, such as high-resolution spectroscopy and neutron diffraction, to better understand the material's properties and behavior under various conditions. These efforts aim to enhance the accuracy and reliability of Li2O-based calibration standards across different applications.

As the demand for higher precision in scientific and industrial measurements continues to grow, the development of Li2O applications in calibration equipment faces the challenge of meeting increasingly stringent performance requirements. This drives ongoing research into novel Li2O-based materials and composite systems that can offer enhanced stability, sensitivity, and versatility in calibration applications.

Existing Li2O Solutions for Precision Calibration

01 Lithium oxide in battery technology

Lithium oxide plays a crucial role in battery technology, particularly in lithium-ion batteries. It is used as a component in cathode materials, contributing to improved battery performance, capacity, and stability. The incorporation of lithium oxide in various battery compositions enhances energy density and cycle life.- Lithium oxide in battery technology: Lithium oxide is widely used in battery technology, particularly in lithium-ion batteries. It plays a crucial role in the cathode material, contributing to the battery's energy density, performance, and longevity. The compound is often combined with other materials to create advanced cathode compositions for improved battery efficiency.

- Lithium oxide in ceramic and glass production: Lithium oxide is utilized in the production of ceramics and glass. It acts as a flux, lowering the melting point of the materials and improving their workability. In glass manufacturing, it enhances the glass's thermal shock resistance and reduces its coefficient of thermal expansion.

- Lithium oxide in nuclear applications: Lithium oxide finds applications in nuclear technology, particularly in fusion reactors. It is used as a breeding material for tritium production and as a component in neutron shielding materials. The compound's properties make it suitable for withstanding high-temperature and high-radiation environments.

- Lithium oxide in carbon dioxide capture: Lithium oxide is being researched for its potential in carbon dioxide capture and storage technologies. Its ability to react with and absorb CO2 makes it a promising material for reducing greenhouse gas emissions in industrial processes and power generation.

- Lithium oxide in surface coatings and thin films: Lithium oxide is used in the development of advanced surface coatings and thin films. These applications include protective layers for electronic devices, optical coatings, and corrosion-resistant surfaces. The compound's properties contribute to improved durability and functionality of various materials and products.

02 Synthesis and production methods of lithium oxide

Various methods are employed for the synthesis and production of lithium oxide. These include chemical reactions, thermal decomposition, and electrochemical processes. The production techniques aim to optimize the purity, particle size, and morphology of lithium oxide for specific applications.Expand Specific Solutions03 Lithium oxide in ceramic and glass manufacturing

Lithium oxide is utilized in the production of ceramics and glasses. It acts as a flux, lowering the melting point and improving the workability of ceramic and glass materials. The addition of lithium oxide can enhance the thermal and mechanical properties of these materials.Expand Specific Solutions04 Lithium oxide in nuclear technology

In nuclear technology, lithium oxide finds applications as a tritium breeding material in fusion reactors. It is used in blanket systems to produce tritium fuel through neutron capture. The development of efficient lithium oxide-based materials is crucial for sustainable fusion energy production.Expand Specific Solutions05 Lithium oxide in energy storage and conversion devices

Beyond batteries, lithium oxide is explored in various energy storage and conversion devices. It is investigated for use in supercapacitors, fuel cells, and other electrochemical systems. The unique properties of lithium oxide contribute to improved energy storage capacity and conversion efficiency in these devices.Expand Specific Solutions

Key Players in Li2O-based Calibration Industry

The lithium oxide applications in high-precision calibration equipment market is in its growth stage, with increasing demand driven by advancements in precision measurement technologies. The market size is expanding, fueled by the need for accurate calibration in various industries. Technologically, the field is progressing rapidly, with companies like Sumitomo Chemical, BASF, and Albemarle Germany leading innovation. These firms are developing advanced lithium oxide formulations and manufacturing processes to enhance calibration accuracy and stability. Emerging players such as Nivo Systems and Wildcat Discovery Technologies are also contributing to technological advancements, focusing on novel applications and improved material properties for high-precision calibration equipment.

BASF Corp.

Technical Solution: BASF has developed advanced lithium oxide-based materials for high-precision calibration equipment. Their approach involves synthesizing ultra-pure lithium oxide compounds with controlled particle size and morphology. These materials are used in the production of reference standards for calibrating analytical instruments in various industries. BASF's lithium oxide products offer exceptional purity levels, typically exceeding 99.99%, which is crucial for accurate calibration [1]. The company has also implemented innovative processing techniques to minimize contamination and ensure batch-to-batch consistency, a critical factor in calibration applications [3].

Strengths: High purity levels, consistent batch quality, and extensive experience in materials science. Weaknesses: Potentially higher production costs due to stringent quality control measures.

AGC Seimi Chemical Co. Ltd.

Technical Solution: AGC Seimi Chemical has developed a proprietary method for producing high-purity lithium oxide powders specifically tailored for calibration equipment. Their process involves a combination of sol-gel synthesis and controlled thermal decomposition, resulting in lithium oxide particles with uniform size distribution and minimal impurities. The company's lithium oxide products are used in the manufacturing of precision optical components and as reference materials for spectroscopic calibration. AGC Seimi's lithium oxide materials exhibit excellent stability under various environmental conditions, making them ideal for long-term calibration standards [2]. Additionally, they have implemented advanced characterization techniques to ensure the accuracy and reliability of their products for high-precision applications.

Strengths: Specialized production methods for high-purity materials, expertise in optical applications. Weaknesses: Limited product range compared to larger competitors.

Core Innovations in Li2O Calibration Technologies

High purity lithium oxide process

PatentInactiveUS4732751A

Innovation

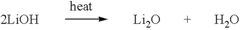

- A two-step process involving the decomposition of impure lithium peroxide at 350-450°C in an inert atmosphere to produce impure lithium oxide, followed by heating under vacuum to 900-1000°C to achieve lithium oxide with purities of 99% or greater, while minimizing sintering and corrosion by excluding active oxygen and moisture.

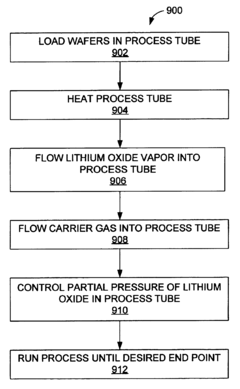

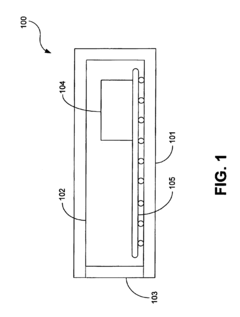

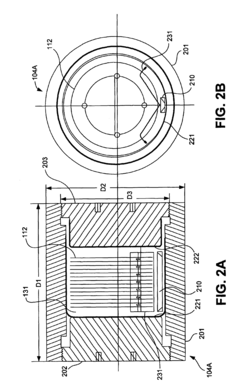

Controlled partial pressure technique for adjusting lithium oxide concentration in wafers

PatentInactiveUS6808563B1

Innovation

- A method involving a sealed vessel with a lithium oxide source and wafers, where lithium oxide vapor is absorbed to adjust the concentration, allowing for the conversion of congruent grown lithium tantalate (CLT) wafers to SLT wafers, using a controlled amount of lithium oxide powder and carrier gas to manage partial pressure, enabling efficient and cost-effective production of SLT wafers with adjustable lithium oxide concentrations.

Safety and Handling Protocols for Li2O in Calibration

Lithium oxide (Li2O) is a highly reactive compound that requires careful handling and stringent safety protocols when used in high-precision calibration equipment. The implementation of comprehensive safety measures is crucial to protect personnel, maintain equipment integrity, and ensure accurate calibration results.

Proper storage of Li2O is paramount. It must be kept in airtight, moisture-proof containers to prevent reaction with atmospheric water vapor. Storage areas should be cool, dry, and well-ventilated, with temperature and humidity controls in place. Regular inspections of storage facilities are necessary to detect any signs of container degradation or environmental changes that could compromise the integrity of the Li2O.

Personal protective equipment (PPE) is essential when handling Li2O. Workers must wear appropriate gloves, protective eyewear, and respiratory protection to prevent skin contact, eye irritation, and inhalation of Li2O dust. Full-body protective suits may be required for certain handling procedures. All PPE should be regularly inspected and replaced as needed to maintain its effectiveness.

Handling procedures for Li2O in calibration settings must be meticulously designed and followed. This includes using specialized tools and equipment that minimize the risk of spills or exposure. Transfer of Li2O should be conducted in controlled environments, preferably within a fume hood or glove box, to contain any potential release of particles.

Training programs for personnel working with Li2O are critical. These should cover the properties of Li2O, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and competency assessments should be conducted to ensure ongoing compliance with safety protocols.

Emergency response plans must be in place to address potential incidents involving Li2O. This includes procedures for dealing with spills, fires, or accidental exposure. Specialized fire extinguishing agents suitable for lithium compound fires should be readily available, and personnel must be trained in their use.

Waste management is another crucial aspect of Li2O handling protocols. Proper disposal methods must be established to prevent environmental contamination. This may involve neutralization procedures or specialized disposal services capable of handling reactive compounds.

Monitoring and documentation are essential components of safety protocols. This includes maintaining detailed logs of Li2O usage, storage conditions, and any incidents or near-misses. Regular audits of safety procedures and equipment should be conducted to identify areas for improvement and ensure ongoing compliance with safety standards.

By implementing these comprehensive safety and handling protocols, organizations can minimize risks associated with Li2O use in high-precision calibration equipment, ensuring the safety of personnel and the integrity of calibration processes.

Proper storage of Li2O is paramount. It must be kept in airtight, moisture-proof containers to prevent reaction with atmospheric water vapor. Storage areas should be cool, dry, and well-ventilated, with temperature and humidity controls in place. Regular inspections of storage facilities are necessary to detect any signs of container degradation or environmental changes that could compromise the integrity of the Li2O.

Personal protective equipment (PPE) is essential when handling Li2O. Workers must wear appropriate gloves, protective eyewear, and respiratory protection to prevent skin contact, eye irritation, and inhalation of Li2O dust. Full-body protective suits may be required for certain handling procedures. All PPE should be regularly inspected and replaced as needed to maintain its effectiveness.

Handling procedures for Li2O in calibration settings must be meticulously designed and followed. This includes using specialized tools and equipment that minimize the risk of spills or exposure. Transfer of Li2O should be conducted in controlled environments, preferably within a fume hood or glove box, to contain any potential release of particles.

Training programs for personnel working with Li2O are critical. These should cover the properties of Li2O, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and competency assessments should be conducted to ensure ongoing compliance with safety protocols.

Emergency response plans must be in place to address potential incidents involving Li2O. This includes procedures for dealing with spills, fires, or accidental exposure. Specialized fire extinguishing agents suitable for lithium compound fires should be readily available, and personnel must be trained in their use.

Waste management is another crucial aspect of Li2O handling protocols. Proper disposal methods must be established to prevent environmental contamination. This may involve neutralization procedures or specialized disposal services capable of handling reactive compounds.

Monitoring and documentation are essential components of safety protocols. This includes maintaining detailed logs of Li2O usage, storage conditions, and any incidents or near-misses. Regular audits of safety procedures and equipment should be conducted to identify areas for improvement and ensure ongoing compliance with safety standards.

By implementing these comprehensive safety and handling protocols, organizations can minimize risks associated with Li2O use in high-precision calibration equipment, ensuring the safety of personnel and the integrity of calibration processes.

Environmental Impact of Li2O in Calibration Equipment

The environmental impact of lithium oxide (Li2O) in high-precision calibration equipment is a crucial aspect to consider as the demand for such technology increases. Li2O, while essential for certain calibration processes, poses potential environmental risks throughout its lifecycle.

During the production phase, the extraction and processing of lithium can lead to significant environmental degradation. Mining operations often require large amounts of water, potentially depleting local water resources and affecting ecosystems. The extraction process may also release harmful chemicals and particulate matter into the air and surrounding soil, impacting local flora and fauna.

In the manufacturing of calibration equipment, the incorporation of Li2O may involve energy-intensive processes and the use of additional chemicals, contributing to greenhouse gas emissions and potential chemical waste. Proper handling and disposal protocols are essential to minimize environmental contamination during this stage.

The operational phase of Li2O-based calibration equipment generally has a lower environmental impact compared to production and disposal. However, the energy consumption of these devices and the potential for small-scale lithium oxide releases during use should not be overlooked. Regular maintenance and proper operating procedures can help mitigate these risks.

End-of-life disposal of calibration equipment containing Li2O presents significant environmental challenges. Improper disposal can lead to soil and water contamination, as lithium compounds can leach into the environment. Recycling of Li2O-containing devices is complex and often energy-intensive, but it is crucial for reducing the overall environmental footprint of these technologies.

To address these environmental concerns, several strategies can be implemented. Developing more efficient lithium extraction methods and exploring alternative sources, such as geothermal brines, can reduce the impact of mining. Improving manufacturing processes to minimize waste and energy consumption is also vital. Additionally, designing calibration equipment for easier disassembly and recycling can facilitate more effective end-of-life management.

Research into potential substitutes for Li2O in calibration equipment is ongoing, with a focus on materials that offer similar precision but with reduced environmental impact. However, the unique properties of Li2O make finding suitable alternatives challenging, emphasizing the need for continued improvement in lifecycle management of Li2O-based technologies.

During the production phase, the extraction and processing of lithium can lead to significant environmental degradation. Mining operations often require large amounts of water, potentially depleting local water resources and affecting ecosystems. The extraction process may also release harmful chemicals and particulate matter into the air and surrounding soil, impacting local flora and fauna.

In the manufacturing of calibration equipment, the incorporation of Li2O may involve energy-intensive processes and the use of additional chemicals, contributing to greenhouse gas emissions and potential chemical waste. Proper handling and disposal protocols are essential to minimize environmental contamination during this stage.

The operational phase of Li2O-based calibration equipment generally has a lower environmental impact compared to production and disposal. However, the energy consumption of these devices and the potential for small-scale lithium oxide releases during use should not be overlooked. Regular maintenance and proper operating procedures can help mitigate these risks.

End-of-life disposal of calibration equipment containing Li2O presents significant environmental challenges. Improper disposal can lead to soil and water contamination, as lithium compounds can leach into the environment. Recycling of Li2O-containing devices is complex and often energy-intensive, but it is crucial for reducing the overall environmental footprint of these technologies.

To address these environmental concerns, several strategies can be implemented. Developing more efficient lithium extraction methods and exploring alternative sources, such as geothermal brines, can reduce the impact of mining. Improving manufacturing processes to minimize waste and energy consumption is also vital. Additionally, designing calibration equipment for easier disassembly and recycling can facilitate more effective end-of-life management.

Research into potential substitutes for Li2O in calibration equipment is ongoing, with a focus on materials that offer similar precision but with reduced environmental impact. However, the unique properties of Li2O make finding suitable alternatives challenging, emphasizing the need for continued improvement in lifecycle management of Li2O-based technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!