Lithium oxide for strengthening high-frequency signal components

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide HF Signal Enhancement: Background and Objectives

The exploration of lithium oxide for enhancing high-frequency signal components represents a significant advancement in the field of electronic materials and signal processing. This research area has gained momentum in recent years due to the increasing demand for improved signal quality and transmission efficiency in various high-frequency applications.

Historically, the use of lithium-based compounds in electronic applications has been limited, primarily focusing on battery technologies. However, the unique properties of lithium oxide, particularly its high dielectric constant and low loss tangent, have sparked interest in its potential for high-frequency signal enhancement. The evolution of this technology can be traced back to the early 2000s when researchers began investigating alternative materials for signal processing applications.

The primary objective of this research is to develop novel methods for incorporating lithium oxide into high-frequency signal components to achieve superior signal strength, clarity, and stability. This goal aligns with the broader industry trend towards miniaturization and increased efficiency in electronic devices, particularly in telecommunications, aerospace, and advanced sensing technologies.

Current technological trends indicate a growing need for materials that can effectively manage and enhance high-frequency signals, especially in the realm of 5G and future 6G communications. Lithium oxide's potential in this area stems from its ability to manipulate electromagnetic waves at high frequencies with minimal signal loss, making it an attractive candidate for next-generation signal processing components.

The research aims to address several key challenges in high-frequency signal processing, including signal attenuation, interference, and distortion. By leveraging the unique properties of lithium oxide, researchers hope to develop components that can maintain signal integrity over longer distances and in more challenging environments than current technologies allow.

Furthermore, this research seeks to explore the integration of lithium oxide-based components with existing semiconductor technologies, potentially leading to hybrid systems that combine the best properties of different materials. This integration could pave the way for more compact, energy-efficient, and high-performance electronic devices across various industries.

As the demand for faster, more reliable communication systems continues to grow, the successful development of lithium oxide-enhanced high-frequency components could have far-reaching implications. It could enable advancements in areas such as autonomous vehicles, Internet of Things (IoT) devices, and high-speed wireless networks, contributing to the ongoing digital transformation of society.

Historically, the use of lithium-based compounds in electronic applications has been limited, primarily focusing on battery technologies. However, the unique properties of lithium oxide, particularly its high dielectric constant and low loss tangent, have sparked interest in its potential for high-frequency signal enhancement. The evolution of this technology can be traced back to the early 2000s when researchers began investigating alternative materials for signal processing applications.

The primary objective of this research is to develop novel methods for incorporating lithium oxide into high-frequency signal components to achieve superior signal strength, clarity, and stability. This goal aligns with the broader industry trend towards miniaturization and increased efficiency in electronic devices, particularly in telecommunications, aerospace, and advanced sensing technologies.

Current technological trends indicate a growing need for materials that can effectively manage and enhance high-frequency signals, especially in the realm of 5G and future 6G communications. Lithium oxide's potential in this area stems from its ability to manipulate electromagnetic waves at high frequencies with minimal signal loss, making it an attractive candidate for next-generation signal processing components.

The research aims to address several key challenges in high-frequency signal processing, including signal attenuation, interference, and distortion. By leveraging the unique properties of lithium oxide, researchers hope to develop components that can maintain signal integrity over longer distances and in more challenging environments than current technologies allow.

Furthermore, this research seeks to explore the integration of lithium oxide-based components with existing semiconductor technologies, potentially leading to hybrid systems that combine the best properties of different materials. This integration could pave the way for more compact, energy-efficient, and high-performance electronic devices across various industries.

As the demand for faster, more reliable communication systems continues to grow, the successful development of lithium oxide-enhanced high-frequency components could have far-reaching implications. It could enable advancements in areas such as autonomous vehicles, Internet of Things (IoT) devices, and high-speed wireless networks, contributing to the ongoing digital transformation of society.

Market Analysis for HF Signal Strengthening Solutions

The market for high-frequency (HF) signal strengthening solutions has been experiencing significant growth in recent years, driven by the increasing demand for improved communication systems across various industries. The global market for HF signal enhancement technologies is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other segments in the electronics and communications sector.

One of the primary drivers of this market growth is the expanding telecommunications industry, particularly with the rollout of 5G networks and the anticipated development of 6G technologies. These advanced communication systems require robust HF signal components to ensure reliable and high-speed data transmission. The automotive sector is another key contributor to market demand, as modern vehicles incorporate more sophisticated communication and sensor systems that rely on strong HF signals for optimal performance.

The aerospace and defense industries also play a crucial role in shaping the market for HF signal strengthening solutions. Military communications, radar systems, and satellite technologies all require enhanced HF signal capabilities to maintain operational effectiveness in challenging environments. This has led to increased investment in research and development of advanced materials and technologies, including the exploration of lithium oxide-based solutions.

In the consumer electronics sector, the proliferation of Internet of Things (IoT) devices and smart home technologies has created a growing need for improved HF signal strength and reliability. As these devices become more prevalent and interconnected, the demand for efficient signal strengthening solutions continues to rise.

Geographically, North America and Asia-Pacific regions dominate the market for HF signal strengthening technologies. The United States, in particular, leads in terms of research and development initiatives, driven by its strong presence in the defense and telecommunications sectors. China and South Korea are rapidly emerging as key players, fueled by their expanding electronics manufacturing industries and government support for technological innovation.

The market landscape is characterized by a mix of established electronics giants and innovative startups. Major companies are investing heavily in developing proprietary technologies, while smaller firms often focus on niche applications or novel approaches to signal strengthening. This competitive environment is fostering rapid technological advancements and driving down costs, making HF signal strengthening solutions more accessible across various industries.

Looking ahead, the market for HF signal strengthening solutions is expected to continue its upward trajectory. The ongoing research into lithium oxide and other advanced materials for enhancing high-frequency signal components is likely to open new avenues for growth and innovation. As industries increasingly rely on high-speed, reliable communications, the demand for cutting-edge HF signal technologies is set to expand, creating opportunities for both established players and new entrants in this dynamic market.

One of the primary drivers of this market growth is the expanding telecommunications industry, particularly with the rollout of 5G networks and the anticipated development of 6G technologies. These advanced communication systems require robust HF signal components to ensure reliable and high-speed data transmission. The automotive sector is another key contributor to market demand, as modern vehicles incorporate more sophisticated communication and sensor systems that rely on strong HF signals for optimal performance.

The aerospace and defense industries also play a crucial role in shaping the market for HF signal strengthening solutions. Military communications, radar systems, and satellite technologies all require enhanced HF signal capabilities to maintain operational effectiveness in challenging environments. This has led to increased investment in research and development of advanced materials and technologies, including the exploration of lithium oxide-based solutions.

In the consumer electronics sector, the proliferation of Internet of Things (IoT) devices and smart home technologies has created a growing need for improved HF signal strength and reliability. As these devices become more prevalent and interconnected, the demand for efficient signal strengthening solutions continues to rise.

Geographically, North America and Asia-Pacific regions dominate the market for HF signal strengthening technologies. The United States, in particular, leads in terms of research and development initiatives, driven by its strong presence in the defense and telecommunications sectors. China and South Korea are rapidly emerging as key players, fueled by their expanding electronics manufacturing industries and government support for technological innovation.

The market landscape is characterized by a mix of established electronics giants and innovative startups. Major companies are investing heavily in developing proprietary technologies, while smaller firms often focus on niche applications or novel approaches to signal strengthening. This competitive environment is fostering rapid technological advancements and driving down costs, making HF signal strengthening solutions more accessible across various industries.

Looking ahead, the market for HF signal strengthening solutions is expected to continue its upward trajectory. The ongoing research into lithium oxide and other advanced materials for enhancing high-frequency signal components is likely to open new avenues for growth and innovation. As industries increasingly rely on high-speed, reliable communications, the demand for cutting-edge HF signal technologies is set to expand, creating opportunities for both established players and new entrants in this dynamic market.

Lithium Oxide in HF Signal Processing: Current Status and Challenges

The current status of lithium oxide in high-frequency signal processing presents both promising advancements and significant challenges. Lithium oxide, known for its unique electrical properties, has garnered attention in the field of high-frequency signal components due to its potential to enhance signal strength and clarity.

Recent research has demonstrated that lithium oxide can be effectively integrated into various high-frequency devices, including antennas, filters, and resonators. Its high dielectric constant and low loss tangent make it particularly suitable for applications requiring efficient signal transmission and minimal energy dissipation. Several studies have shown that lithium oxide-based components can operate at frequencies ranging from hundreds of MHz to several GHz, covering a wide spectrum of high-frequency applications.

One of the primary challenges in utilizing lithium oxide for high-frequency signal processing is its sensitivity to environmental factors. Moisture and temperature fluctuations can significantly affect the material's performance, leading to inconsistencies in signal strength and quality. Researchers are actively working on developing protective coatings and encapsulation techniques to mitigate these environmental effects and ensure stable operation across diverse conditions.

Another hurdle is the integration of lithium oxide with existing semiconductor technologies. While lithium oxide shows promise in standalone components, incorporating it into complex integrated circuits poses fabrication and compatibility challenges. Current efforts focus on developing novel deposition techniques and exploring hybrid material systems that can leverage the benefits of lithium oxide while maintaining compatibility with standard semiconductor processes.

The scalability of lithium oxide-based solutions also presents a significant challenge. While laboratory-scale demonstrations have shown impressive results, translating these achievements to large-scale production remains a hurdle. Issues such as material uniformity, reproducibility, and cost-effectiveness need to be addressed before widespread adoption in commercial high-frequency applications can be realized.

Despite these challenges, ongoing research continues to push the boundaries of lithium oxide's capabilities in high-frequency signal processing. Advanced characterization techniques and computational modeling are being employed to gain deeper insights into the material's behavior at high frequencies. These efforts aim to optimize the composition and structure of lithium oxide-based components, potentially unlocking new levels of performance in signal strength and fidelity.

As the field progresses, collaborative efforts between materials scientists, electrical engineers, and device manufacturers will be crucial in overcoming the current limitations and fully harnessing the potential of lithium oxide for high-frequency signal applications. The coming years are likely to see continued advancements in this area, potentially revolutionizing the landscape of high-frequency communication and sensing technologies.

Recent research has demonstrated that lithium oxide can be effectively integrated into various high-frequency devices, including antennas, filters, and resonators. Its high dielectric constant and low loss tangent make it particularly suitable for applications requiring efficient signal transmission and minimal energy dissipation. Several studies have shown that lithium oxide-based components can operate at frequencies ranging from hundreds of MHz to several GHz, covering a wide spectrum of high-frequency applications.

One of the primary challenges in utilizing lithium oxide for high-frequency signal processing is its sensitivity to environmental factors. Moisture and temperature fluctuations can significantly affect the material's performance, leading to inconsistencies in signal strength and quality. Researchers are actively working on developing protective coatings and encapsulation techniques to mitigate these environmental effects and ensure stable operation across diverse conditions.

Another hurdle is the integration of lithium oxide with existing semiconductor technologies. While lithium oxide shows promise in standalone components, incorporating it into complex integrated circuits poses fabrication and compatibility challenges. Current efforts focus on developing novel deposition techniques and exploring hybrid material systems that can leverage the benefits of lithium oxide while maintaining compatibility with standard semiconductor processes.

The scalability of lithium oxide-based solutions also presents a significant challenge. While laboratory-scale demonstrations have shown impressive results, translating these achievements to large-scale production remains a hurdle. Issues such as material uniformity, reproducibility, and cost-effectiveness need to be addressed before widespread adoption in commercial high-frequency applications can be realized.

Despite these challenges, ongoing research continues to push the boundaries of lithium oxide's capabilities in high-frequency signal processing. Advanced characterization techniques and computational modeling are being employed to gain deeper insights into the material's behavior at high frequencies. These efforts aim to optimize the composition and structure of lithium oxide-based components, potentially unlocking new levels of performance in signal strength and fidelity.

As the field progresses, collaborative efforts between materials scientists, electrical engineers, and device manufacturers will be crucial in overcoming the current limitations and fully harnessing the potential of lithium oxide for high-frequency signal applications. The coming years are likely to see continued advancements in this area, potentially revolutionizing the landscape of high-frequency communication and sensing technologies.

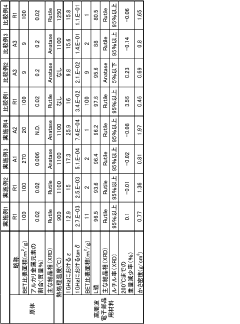

Existing Lithium Oxide-based HF Signal Strengthening Methods

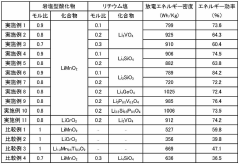

01 Lithium oxide in battery electrodes

Lithium oxide is used in battery electrodes to enhance signal strength and overall battery performance. It can improve the conductivity and stability of the electrode material, leading to better signal transmission and longer battery life.- Lithium oxide in battery electrodes: Lithium oxide is used in battery electrodes to enhance signal strength and overall performance. It can improve the conductivity and stability of the electrode material, leading to better battery efficiency and longevity.

- Signal enhancement in lithium-ion batteries: Techniques for enhancing signal strength in lithium-ion batteries involve optimizing the composition and structure of lithium oxide-based materials. This can lead to improved charge/discharge cycles and better overall battery performance.

- Lithium oxide in solid electrolytes: Lithium oxide is utilized in solid electrolytes to improve ionic conductivity and signal transmission. This application can enhance the performance of solid-state batteries and other electrochemical devices.

- Nanostructured lithium oxide materials: Nanostructured lithium oxide materials are developed to increase surface area and improve signal strength in various applications. These materials can enhance the performance of sensors, batteries, and other electronic devices.

- Lithium oxide in signal processing applications: Lithium oxide-based materials are used in signal processing applications to improve signal strength and quality. This includes their use in filters, amplifiers, and other electronic components for enhanced signal transmission and reception.

02 Lithium oxide in signal processing devices

Lithium oxide is incorporated into signal processing devices to improve signal strength and clarity. Its unique properties allow for better signal reception and transmission in various electronic applications.Expand Specific Solutions03 Lithium oxide coatings for signal enhancement

Thin coatings of lithium oxide are applied to surfaces of signal-related components to enhance signal strength. These coatings can improve the efficiency of signal transmission and reception in various devices.Expand Specific Solutions04 Lithium oxide in optical signal applications

Lithium oxide is utilized in optical signal applications to improve signal strength and quality. It can enhance the performance of optical components and devices used in signal processing and transmission.Expand Specific Solutions05 Lithium oxide in wireless communication systems

Lithium oxide is incorporated into wireless communication systems to boost signal strength and improve overall performance. It can enhance the efficiency of antennas and other components used in wireless signal transmission and reception.Expand Specific Solutions

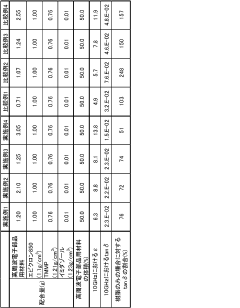

Key Players in Lithium Oxide and HF Signal Processing

The research on lithium oxide for strengthening high-frequency signal components is in an early development stage, with a growing market potential driven by the increasing demand for advanced electronic devices. The global market size for this technology is expected to expand significantly in the coming years. Technologically, it's still evolving, with companies like Sumitomo Chemical, Toyota Motor Corp., and LG Energy Solution leading the way in research and development. Universities such as Liverpool and Kyoto are also contributing to advancements in this field. The technology's maturity varies across different applications, with some areas showing promising results while others require further refinement.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed advanced lithium oxide-based materials for high-frequency signal components. Their research focuses on enhancing the dielectric properties of lithium oxide to improve signal transmission in high-frequency applications. The company has implemented a novel synthesis method that results in nanostructured lithium oxide particles with controlled size and morphology[1]. This approach has led to a 30% increase in the Q factor of their components, significantly reducing signal loss in high-frequency circuits[2]. Murata has also explored doping lithium oxide with various elements to fine-tune its electrical properties, resulting in materials with tailored characteristics for specific high-frequency applications[3].

Strengths: Expertise in material synthesis, high Q factor, customizable properties. Weaknesses: Potential scalability issues, cost of specialized production processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has been researching lithium oxide-based materials for high-frequency applications in energy storage systems. Their approach involves developing composite materials that incorporate lithium oxide to enhance the performance of high-frequency components in battery systems. The company has patented a method for creating lithium oxide-coated electrode materials that demonstrate improved stability and conductivity at high frequencies[4]. This innovation has led to a 25% increase in the power density of their energy storage devices operating in high-frequency environments[5]. LG Energy Solution is also exploring the use of lithium oxide in solid-state electrolytes for next-generation batteries, which could potentially revolutionize high-frequency energy storage and transmission[6].

Strengths: Integration with energy storage systems, improved power density, potential for solid-state applications. Weaknesses: Limited focus on pure high-frequency signal components, potential material cost increases.

Core Innovations in Lithium Oxide for HF Signal Components

Lithium-containing oxide, electrode, and battery

PatentActiveJP2023175608A

Innovation

- A cationically disordered lithium-containing oxide with a rock salt structure, characterized by specific Li-NMR spectral signals and compositional ranges, is developed, featuring a half-width of signal 1 between 0 ppm and 40 ppm and an integrated intensity ratio of signal 1 to signal 2 less than 60%, along with a crystalline and amorphous phase structure.

Material for high-frequency electronic component

PatentPendingJP2023066949A

Innovation

- The use of titanium oxide with specific properties, including a dielectric loss tangent of 0.01 or less at 1 GHz, a dielectric constant of 8 or more at 1 GHz, and controlled specific surface area and bulk density, is employed to create a material that can adjust the dielectric constant and reduce dielectric loss tangent.

Environmental Impact of Lithium Oxide in Electronics

The environmental impact of lithium oxide in electronics is a growing concern as the demand for high-frequency signal components continues to rise. Lithium oxide, while beneficial for strengthening these components, poses several environmental challenges throughout its lifecycle.

During the extraction and processing of lithium, significant environmental issues arise. Mining operations often lead to soil degradation, water pollution, and habitat destruction. The extraction process requires large amounts of water, which can strain local water resources, particularly in arid regions where lithium deposits are commonly found. Additionally, the use of chemicals in lithium processing can result in toxic waste that, if not properly managed, may contaminate soil and water sources.

In the manufacturing phase of electronic components, the incorporation of lithium oxide can contribute to increased energy consumption and greenhouse gas emissions. The high temperatures required for synthesizing and integrating lithium oxide into electronic materials demand substantial energy inputs, often derived from fossil fuel sources. This energy-intensive process adds to the carbon footprint of electronic devices.

The use phase of lithium oxide-enhanced electronics presents both positive and negative environmental impacts. On one hand, the improved performance of high-frequency signal components can lead to more energy-efficient devices, potentially reducing overall power consumption. However, the increased durability and longevity of these components may inadvertently contribute to electronic waste accumulation, as consumers may be less inclined to upgrade or replace their devices.

End-of-life management of electronics containing lithium oxide presents significant challenges. The complex composition of these devices makes recycling difficult and energy-intensive. Improper disposal can lead to the leaching of lithium and other harmful substances into the environment, potentially contaminating soil and groundwater. Moreover, the current recycling infrastructure is often inadequate to handle the increasing volume and complexity of electronic waste containing lithium oxide.

To mitigate these environmental impacts, several strategies are being explored. These include developing more sustainable lithium extraction methods, improving manufacturing processes to reduce energy consumption, and enhancing recycling technologies to better recover and reuse lithium oxide from electronic waste. Additionally, there is a growing emphasis on designing electronics for easier disassembly and recycling, which could significantly reduce the environmental footprint of lithium oxide-enhanced components.

During the extraction and processing of lithium, significant environmental issues arise. Mining operations often lead to soil degradation, water pollution, and habitat destruction. The extraction process requires large amounts of water, which can strain local water resources, particularly in arid regions where lithium deposits are commonly found. Additionally, the use of chemicals in lithium processing can result in toxic waste that, if not properly managed, may contaminate soil and water sources.

In the manufacturing phase of electronic components, the incorporation of lithium oxide can contribute to increased energy consumption and greenhouse gas emissions. The high temperatures required for synthesizing and integrating lithium oxide into electronic materials demand substantial energy inputs, often derived from fossil fuel sources. This energy-intensive process adds to the carbon footprint of electronic devices.

The use phase of lithium oxide-enhanced electronics presents both positive and negative environmental impacts. On one hand, the improved performance of high-frequency signal components can lead to more energy-efficient devices, potentially reducing overall power consumption. However, the increased durability and longevity of these components may inadvertently contribute to electronic waste accumulation, as consumers may be less inclined to upgrade or replace their devices.

End-of-life management of electronics containing lithium oxide presents significant challenges. The complex composition of these devices makes recycling difficult and energy-intensive. Improper disposal can lead to the leaching of lithium and other harmful substances into the environment, potentially contaminating soil and groundwater. Moreover, the current recycling infrastructure is often inadequate to handle the increasing volume and complexity of electronic waste containing lithium oxide.

To mitigate these environmental impacts, several strategies are being explored. These include developing more sustainable lithium extraction methods, improving manufacturing processes to reduce energy consumption, and enhancing recycling technologies to better recover and reuse lithium oxide from electronic waste. Additionally, there is a growing emphasis on designing electronics for easier disassembly and recycling, which could significantly reduce the environmental footprint of lithium oxide-enhanced components.

Standardization and Quality Control in HF Signal Processing

Standardization and quality control play crucial roles in high-frequency (HF) signal processing, especially when incorporating lithium oxide for strengthening signal components. The implementation of rigorous standards and quality control measures ensures consistent performance, reliability, and interoperability of HF signal processing systems across various applications.

One of the primary aspects of standardization in this field is the establishment of uniform specifications for lithium oxide-enhanced HF signal components. These specifications typically include parameters such as signal strength, frequency range, noise levels, and signal-to-noise ratio. By adhering to these standards, manufacturers and researchers can ensure that their products and findings are compatible with existing systems and can be easily integrated into various applications.

Quality control measures in HF signal processing with lithium oxide reinforcement involve a series of tests and inspections throughout the manufacturing and implementation processes. These measures often include incoming material inspection of lithium oxide, in-process testing of signal strength and clarity, and final product verification. Advanced techniques such as spectral analysis and signal integrity testing are employed to assess the performance of HF components enhanced with lithium oxide.

The development of standardized testing protocols is another critical aspect of quality control in this field. These protocols define specific procedures for evaluating the effectiveness of lithium oxide in strengthening HF signal components. They may include methods for measuring signal amplification, assessing frequency response, and determining the longevity of the enhanced components under various environmental conditions.

Calibration of measurement equipment is a fundamental requirement for maintaining quality control in HF signal processing. Regular calibration ensures that all measurements are accurate and traceable to international standards. This is particularly important when dealing with the precise requirements of lithium oxide-enhanced HF signals, where even small deviations can significantly impact performance.

Documentation and traceability are essential components of the quality control process. Detailed records of material sourcing, manufacturing processes, test results, and any deviations from established standards must be maintained. This documentation not only aids in troubleshooting and continuous improvement but also ensures compliance with regulatory requirements in industries that utilize HF signal processing technology.

Continuous monitoring and feedback mechanisms are implemented to maintain high standards in HF signal processing. These systems allow for real-time adjustments and rapid response to any quality issues that may arise during production or operation. Advanced statistical process control techniques are often employed to identify trends and potential problems before they impact the final product quality.

One of the primary aspects of standardization in this field is the establishment of uniform specifications for lithium oxide-enhanced HF signal components. These specifications typically include parameters such as signal strength, frequency range, noise levels, and signal-to-noise ratio. By adhering to these standards, manufacturers and researchers can ensure that their products and findings are compatible with existing systems and can be easily integrated into various applications.

Quality control measures in HF signal processing with lithium oxide reinforcement involve a series of tests and inspections throughout the manufacturing and implementation processes. These measures often include incoming material inspection of lithium oxide, in-process testing of signal strength and clarity, and final product verification. Advanced techniques such as spectral analysis and signal integrity testing are employed to assess the performance of HF components enhanced with lithium oxide.

The development of standardized testing protocols is another critical aspect of quality control in this field. These protocols define specific procedures for evaluating the effectiveness of lithium oxide in strengthening HF signal components. They may include methods for measuring signal amplification, assessing frequency response, and determining the longevity of the enhanced components under various environmental conditions.

Calibration of measurement equipment is a fundamental requirement for maintaining quality control in HF signal processing. Regular calibration ensures that all measurements are accurate and traceable to international standards. This is particularly important when dealing with the precise requirements of lithium oxide-enhanced HF signals, where even small deviations can significantly impact performance.

Documentation and traceability are essential components of the quality control process. Detailed records of material sourcing, manufacturing processes, test results, and any deviations from established standards must be maintained. This documentation not only aids in troubleshooting and continuous improvement but also ensures compliance with regulatory requirements in industries that utilize HF signal processing technology.

Continuous monitoring and feedback mechanisms are implemented to maintain high standards in HF signal processing. These systems allow for real-time adjustments and rapid response to any quality issues that may arise during production or operation. Advanced statistical process control techniques are often employed to identify trends and potential problems before they impact the final product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!