Low-Power Microcomb Generation: Device And Pump Strategies

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Technology Evolution and Objectives

Microcombs, or optical frequency combs generated in microresonators, have emerged as a revolutionary technology in the field of integrated photonics over the past two decades. The evolution of microcomb technology began with the fundamental discovery of optical Kerr frequency combs in microresonators in 2007, which demonstrated that optical frequency combs could be generated in compact chip-scale devices rather than requiring complex laboratory setups.

The early development phase (2007-2012) focused primarily on understanding the underlying physics of microcomb generation and characterizing different resonator materials and geometries. During this period, researchers explored various platforms including silica microtoroids, crystalline resonators, and integrated silicon nitride rings, establishing the fundamental requirements for quality factor, dispersion engineering, and nonlinear properties.

The middle development phase (2013-2017) witnessed significant breakthroughs in soliton microcomb generation, which provided coherent and low-noise comb spectra critical for practical applications. This period marked the transition from proof-of-concept demonstrations to engineered solutions addressing stability, repeatability, and power efficiency challenges.

In recent years (2018-present), the field has pivoted toward addressing power consumption concerns, which represent a major obstacle to widespread deployment. Traditional microcomb generation typically requires hundreds of milliwatts to several watts of pump power, making them impractical for many portable or space-constrained applications where power budgets are severely limited.

The primary technical objectives for low-power microcomb generation now focus on several key areas: reducing the threshold power required for comb initiation, improving the conversion efficiency from pump to comb lines, developing novel resonator designs with enhanced nonlinearity, and creating innovative pumping strategies that minimize energy requirements.

Specifically, researchers aim to achieve sub-milliwatt threshold powers while maintaining broad bandwidth operation (>100 nm) and ensuring phase coherence across all generated comb lines. Additional objectives include thermal stability without active control systems, compatibility with standard CMOS fabrication processes, and resilience to environmental perturbations.

The ultimate goal is to enable microcomb technology in battery-powered devices, IoT sensors, satellite communications, and portable medical diagnostics, where power constraints are particularly stringent. This requires a holistic approach combining innovations in material science, nanofabrication techniques, resonator design, and novel pumping schemes to overcome the fundamental power limitations of current technology.

The early development phase (2007-2012) focused primarily on understanding the underlying physics of microcomb generation and characterizing different resonator materials and geometries. During this period, researchers explored various platforms including silica microtoroids, crystalline resonators, and integrated silicon nitride rings, establishing the fundamental requirements for quality factor, dispersion engineering, and nonlinear properties.

The middle development phase (2013-2017) witnessed significant breakthroughs in soliton microcomb generation, which provided coherent and low-noise comb spectra critical for practical applications. This period marked the transition from proof-of-concept demonstrations to engineered solutions addressing stability, repeatability, and power efficiency challenges.

In recent years (2018-present), the field has pivoted toward addressing power consumption concerns, which represent a major obstacle to widespread deployment. Traditional microcomb generation typically requires hundreds of milliwatts to several watts of pump power, making them impractical for many portable or space-constrained applications where power budgets are severely limited.

The primary technical objectives for low-power microcomb generation now focus on several key areas: reducing the threshold power required for comb initiation, improving the conversion efficiency from pump to comb lines, developing novel resonator designs with enhanced nonlinearity, and creating innovative pumping strategies that minimize energy requirements.

Specifically, researchers aim to achieve sub-milliwatt threshold powers while maintaining broad bandwidth operation (>100 nm) and ensuring phase coherence across all generated comb lines. Additional objectives include thermal stability without active control systems, compatibility with standard CMOS fabrication processes, and resilience to environmental perturbations.

The ultimate goal is to enable microcomb technology in battery-powered devices, IoT sensors, satellite communications, and portable medical diagnostics, where power constraints are particularly stringent. This requires a holistic approach combining innovations in material science, nanofabrication techniques, resonator design, and novel pumping schemes to overcome the fundamental power limitations of current technology.

Market Applications and Demand for Low-Power Microcombs

The market for low-power microcombs is experiencing significant growth driven by the increasing demand for compact, energy-efficient photonic solutions across multiple industries. Telecommunications represents the primary market segment, where low-power microcombs enable wavelength division multiplexing (WDM) systems with reduced energy consumption. The global optical communications market, currently valued at approximately $25 billion, is projected to grow at a CAGR of 7.6% through 2028, with microcombs poised to capture an expanding share as power efficiency becomes increasingly critical.

Data centers constitute another substantial market opportunity, as they face mounting pressure to reduce energy consumption while handling exponentially growing data traffic. Low-power microcombs offer a promising solution for optical interconnects, potentially reducing power requirements by 40-60% compared to traditional approaches. With data center optical interconnect spending expected to reach $5.7 billion by 2025, the demand for energy-efficient photonic technologies continues to accelerate.

The emerging quantum technology sector represents a high-growth potential market for low-power microcombs. Quantum computing, sensing, and communications systems require precise optical frequency references and entangled photon generation, applications where microcombs excel. The quantum technology market is projected to grow from $480 million in 2022 to $1.3 billion by 2027, creating substantial opportunities for microcomb integration.

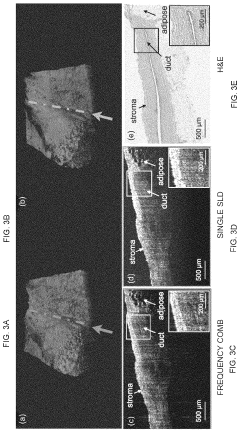

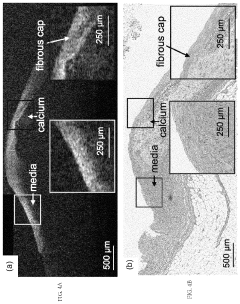

In the biomedical field, low-power microcombs are finding applications in portable spectroscopy devices, optical coherence tomography (OCT), and lab-on-chip systems. The global biomedical sensors market is expected to reach $15.3 billion by 2026, with optical sensing technologies comprising approximately 22% of this market.

Aerospace and defense applications represent another significant market segment, particularly for LiDAR systems, secure communications, and navigation technologies. The defense photonics market is projected to grow at 8.3% annually through 2027, with increasing emphasis on SWaP (Size, Weight, and Power) optimization driving demand for low-power integrated photonic solutions.

Consumer electronics represents a nascent but potentially massive market for low-power microcombs, particularly in next-generation AR/VR devices, smartphones, and wearable technology. As these devices continue to demand enhanced functionality with minimal power consumption, the integration of microcomb technology could enable new capabilities in sensing, display, and communications.

Market analysis indicates that the total addressable market for low-power photonic integrated circuits, including microcomb technology, will exceed $8 billion by 2028, representing a CAGR of 23.4% from current levels. This growth trajectory is supported by the convergence of increasing data demands, energy efficiency imperatives, and the miniaturization requirements across multiple industries.

Data centers constitute another substantial market opportunity, as they face mounting pressure to reduce energy consumption while handling exponentially growing data traffic. Low-power microcombs offer a promising solution for optical interconnects, potentially reducing power requirements by 40-60% compared to traditional approaches. With data center optical interconnect spending expected to reach $5.7 billion by 2025, the demand for energy-efficient photonic technologies continues to accelerate.

The emerging quantum technology sector represents a high-growth potential market for low-power microcombs. Quantum computing, sensing, and communications systems require precise optical frequency references and entangled photon generation, applications where microcombs excel. The quantum technology market is projected to grow from $480 million in 2022 to $1.3 billion by 2027, creating substantial opportunities for microcomb integration.

In the biomedical field, low-power microcombs are finding applications in portable spectroscopy devices, optical coherence tomography (OCT), and lab-on-chip systems. The global biomedical sensors market is expected to reach $15.3 billion by 2026, with optical sensing technologies comprising approximately 22% of this market.

Aerospace and defense applications represent another significant market segment, particularly for LiDAR systems, secure communications, and navigation technologies. The defense photonics market is projected to grow at 8.3% annually through 2027, with increasing emphasis on SWaP (Size, Weight, and Power) optimization driving demand for low-power integrated photonic solutions.

Consumer electronics represents a nascent but potentially massive market for low-power microcombs, particularly in next-generation AR/VR devices, smartphones, and wearable technology. As these devices continue to demand enhanced functionality with minimal power consumption, the integration of microcomb technology could enable new capabilities in sensing, display, and communications.

Market analysis indicates that the total addressable market for low-power photonic integrated circuits, including microcomb technology, will exceed $8 billion by 2028, representing a CAGR of 23.4% from current levels. This growth trajectory is supported by the convergence of increasing data demands, energy efficiency imperatives, and the miniaturization requirements across multiple industries.

Current Challenges in Low-Power Microcomb Generation

Despite significant advancements in microcomb technology, several critical challenges persist in achieving efficient low-power operation. The fundamental obstacle remains the high power threshold required for parametric oscillation in microresonators, typically ranging from tens to hundreds of milliwatts. This power requirement significantly limits the practical deployment of microcombs in portable or space-constrained applications where power budgets are severely restricted.

Material limitations present another significant hurdle. Current materials used in microcomb fabrication, such as silicon nitride and silica, exhibit inherent trade-offs between nonlinearity and optical loss. While highly nonlinear materials can reduce power requirements, they often introduce additional propagation losses that counteract efficiency gains. The challenge of simultaneously achieving high nonlinearity and ultra-low loss remains unresolved in current material platforms.

Thermal management issues also severely impact low-power operation. Even at moderate pump powers, thermal effects in microresonators can cause frequency shifts, mode instabilities, and degradation of comb coherence. These thermal challenges become particularly pronounced in integrated photonic platforms where heat dissipation pathways are limited by the compact device architecture.

Coupling efficiency between the pump laser and the microresonator represents another critical bottleneck. Current coupling mechanisms typically achieve only 30-70% efficiency, resulting in substantial power waste before light even enters the resonator. This inefficiency necessitates higher initial pump powers to compensate for coupling losses.

The stability and coherence of microcombs at low pump powers present additional technical difficulties. As pump power decreases, the signal-to-noise ratio deteriorates, making it challenging to maintain phase-locked comb states. Many applications require soliton states, which typically demand sophisticated power control protocols that are difficult to implement in low-power regimes.

Integration challenges further complicate low-power operation. While chip-scale integration is essential for practical applications, current integrated pump lasers often lack the spectral purity and stability required for reliable microcomb generation. The power consumption of supporting components—such as thermal controllers, modulators, and detectors—can easily exceed that of the microcomb itself, creating a system-level power bottleneck.

Fabrication inconsistencies also impede progress, as variations in resonator dimensions and material properties lead to unpredictable power thresholds and operating conditions. This lack of reproducibility necessitates individual device characterization and customization, hindering mass production and standardization efforts for low-power microcomb systems.

Material limitations present another significant hurdle. Current materials used in microcomb fabrication, such as silicon nitride and silica, exhibit inherent trade-offs between nonlinearity and optical loss. While highly nonlinear materials can reduce power requirements, they often introduce additional propagation losses that counteract efficiency gains. The challenge of simultaneously achieving high nonlinearity and ultra-low loss remains unresolved in current material platforms.

Thermal management issues also severely impact low-power operation. Even at moderate pump powers, thermal effects in microresonators can cause frequency shifts, mode instabilities, and degradation of comb coherence. These thermal challenges become particularly pronounced in integrated photonic platforms where heat dissipation pathways are limited by the compact device architecture.

Coupling efficiency between the pump laser and the microresonator represents another critical bottleneck. Current coupling mechanisms typically achieve only 30-70% efficiency, resulting in substantial power waste before light even enters the resonator. This inefficiency necessitates higher initial pump powers to compensate for coupling losses.

The stability and coherence of microcombs at low pump powers present additional technical difficulties. As pump power decreases, the signal-to-noise ratio deteriorates, making it challenging to maintain phase-locked comb states. Many applications require soliton states, which typically demand sophisticated power control protocols that are difficult to implement in low-power regimes.

Integration challenges further complicate low-power operation. While chip-scale integration is essential for practical applications, current integrated pump lasers often lack the spectral purity and stability required for reliable microcomb generation. The power consumption of supporting components—such as thermal controllers, modulators, and detectors—can easily exceed that of the microcomb itself, creating a system-level power bottleneck.

Fabrication inconsistencies also impede progress, as variations in resonator dimensions and material properties lead to unpredictable power thresholds and operating conditions. This lack of reproducibility necessitates individual device characterization and customization, hindering mass production and standardization efforts for low-power microcomb systems.

State-of-the-Art Low-Power Pump Strategies

01 Low-power microcomb generation techniques

Various techniques have been developed to generate microcombs with reduced power consumption. These include optimized resonator designs, efficient pump coupling methods, and novel materials that lower the power threshold for comb formation. By reducing the energy required to initiate and maintain the frequency comb, these approaches enable more power-efficient operation in applications ranging from telecommunications to sensing systems.- Low-power microcomb generation techniques: Various techniques have been developed to generate microcombs with reduced power consumption. These include optimized resonator designs, efficient pump coupling methods, and novel materials that lower the power threshold for comb formation. By reducing the power required for microcomb generation, these innovations enable more energy-efficient operation in various applications including telecommunications, sensing, and computing.

- Power management systems for microcomb devices: Power management systems specifically designed for microcomb devices help optimize energy usage during operation. These systems include dynamic power adjustment based on operational requirements, sleep modes during inactive periods, and intelligent control algorithms that balance performance with power consumption. Such management systems are crucial for extending battery life in portable applications and reducing overall energy costs in stationary systems.

- Integration of microcombs with energy-efficient electronics: The integration of microcombs with energy-efficient electronic components creates systems with optimized overall power consumption. This includes the development of specialized integrated circuits, low-power drivers, and efficient signal processing units designed to work with microcomb technology. Such integration enables practical applications in portable devices, telecommunications infrastructure, and sensing networks where power constraints are significant.

- Thermal management for power-efficient microcomb operation: Effective thermal management is essential for maintaining power-efficient microcomb operation. Techniques include passive and active cooling systems, thermally optimized packaging, and temperature-stabilized resonator designs. By controlling operating temperatures, these approaches prevent thermal drift, reduce power losses, and maintain stable comb generation with minimal energy input, which is particularly important for high-density photonic integrated circuits.

- Energy harvesting and sustainable power sources for microcomb systems: Research into energy harvesting and sustainable power sources aims to make microcomb systems more self-sufficient and environmentally friendly. These approaches include photovoltaic integration, ambient RF energy harvesting, and micro-scale thermal gradient utilization. By reducing dependence on external power sources, these innovations extend the operational lifetime of microcomb-based devices in remote sensing applications, IoT networks, and autonomous systems.

02 Power management systems for microcomb devices

Power management systems specifically designed for microcomb devices help optimize energy usage during operation. These systems include adaptive power control mechanisms, intelligent power distribution architectures, and sleep/wake protocols that minimize energy consumption during idle periods. Such management systems are crucial for extending battery life in portable applications and reducing overall operational costs in fixed installations.Expand Specific Solutions03 Energy-efficient microcomb integration in photonic systems

Integration approaches for incorporating microcombs into larger photonic systems with minimal power overhead have been developed. These include co-integration with electronic control circuitry, thermal management solutions, and optimized optical interfaces that reduce coupling losses. Such integration techniques enable microcombs to function efficiently within complex systems while maintaining low overall power consumption.Expand Specific Solutions04 Power consumption analysis and modeling for microcombs

Analytical frameworks and modeling approaches have been developed to accurately predict and analyze power consumption in microcomb systems. These include computational models that account for nonlinear optical effects, thermal dynamics, and electronic control overhead. Such tools enable designers to optimize microcomb architectures for specific power constraints before physical implementation.Expand Specific Solutions05 Application-specific power optimization for microcombs

Tailored power optimization strategies have been developed for microcombs in specific application domains. These include specialized operating modes for telecommunications, sensing, metrology, and computing applications that minimize power consumption while maintaining required performance metrics. By optimizing the microcomb operation for the specific requirements of each application, significant power savings can be achieved without compromising functionality.Expand Specific Solutions

Leading Institutions and Companies in Microcomb Research

The low-power microcomb generation market is currently in its early growth phase, characterized by intensive research and development activities across academic institutions and industry players. The global market size is expanding, driven by applications in telecommunications, sensing, and quantum technologies, with projections suggesting significant growth over the next decade. From a technological maturity perspective, key players demonstrate varying levels of advancement: California Institute of Technology and The Regents of the University of California lead academic research, while Industrial Technology Research Institute and O-Net Communications are developing commercial applications. Companies like Corning and United Microelectronics are leveraging their manufacturing expertise to address fabrication challenges, while research institutions such as Trinity College Dublin and Nanjing University are exploring novel pump strategies to reduce power consumption.

California Institute of Technology

Technical Solution: Caltech has pioneered integrated photonic microcombs with their revolutionary approach using high-Q silicon nitride (Si3N4) microresonators. Their technology enables microcomb generation at significantly reduced pump powers (sub-milliwatt thresholds) through precise engineering of resonator quality factors exceeding 10^7. Caltech researchers have developed proprietary dispersion engineering techniques that optimize phase-matching conditions, allowing for soliton microcomb formation at lower power requirements. Their integrated photonic platform combines low-loss waveguides with carefully designed microresonator geometries to enhance light-matter interactions while minimizing power consumption. Recent advancements include heterogeneously integrated pump lasers that reduce coupling losses and further decrease system power requirements by eliminating external bulky components.

Strengths: World-leading expertise in high-Q resonator fabrication; pioneered fundamental breakthroughs in soliton microcomb physics; strong integration capabilities with existing semiconductor manufacturing processes. Weaknesses: Complex fabrication processes may limit mass production scalability; still requires specialized equipment for optimal performance; some solutions remain at laboratory demonstration level rather than commercial readiness.

Nanjing University

Technical Solution: Nanjing University has developed an innovative approach to low-power microcomb generation utilizing lithium niobate on insulator (LNOI) platform. Their technology leverages the strong electro-optic and nonlinear optical properties of lithium niobate to achieve microcomb generation with pump powers below 5mW. The university's research team has created ultra-high Q microresonators (Q factors >5×10^6) through precision nanofabrication techniques including argon ion milling and specialized annealing processes. Their proprietary design incorporates engineered mode coupling that significantly reduces the power threshold for parametric oscillation. Additionally, they've implemented novel thermal control strategies using integrated microheaters that maintain phase-matching conditions with minimal power overhead, enabling stable soliton microcomb operation at reduced pump requirements.

Strengths: LNOI platform offers exceptional electro-optic tunability and nonlinear efficiency; demonstrated record-low threshold powers for certain microcomb configurations; technology compatible with electronic integration. Weaknesses: Lithium niobate fabrication presents challenges for mass production; thermal management remains an ongoing challenge; relatively newer platform compared to silicon photonics alternatives.

Critical Patents and Innovations in Microcomb Devices

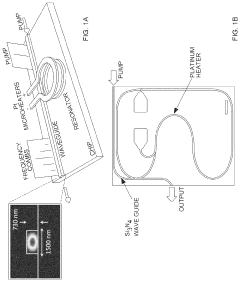

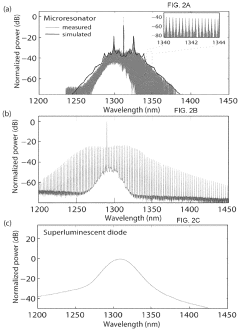

Microresonator-frequency-comb-based platform for clinical high-resolution optical coherence tomography

PatentActiveUS11859972B2

Innovation

- A microresonator-frequency-comb-based platform using high-Q silicon nitride resonators and distributed feedback lasers generates broadband frequency combs, overcoming the bandwidth-power trade-off and enabling sub-micrometer axial resolution and deeper tissue penetration, compatible with standard OCT systems.

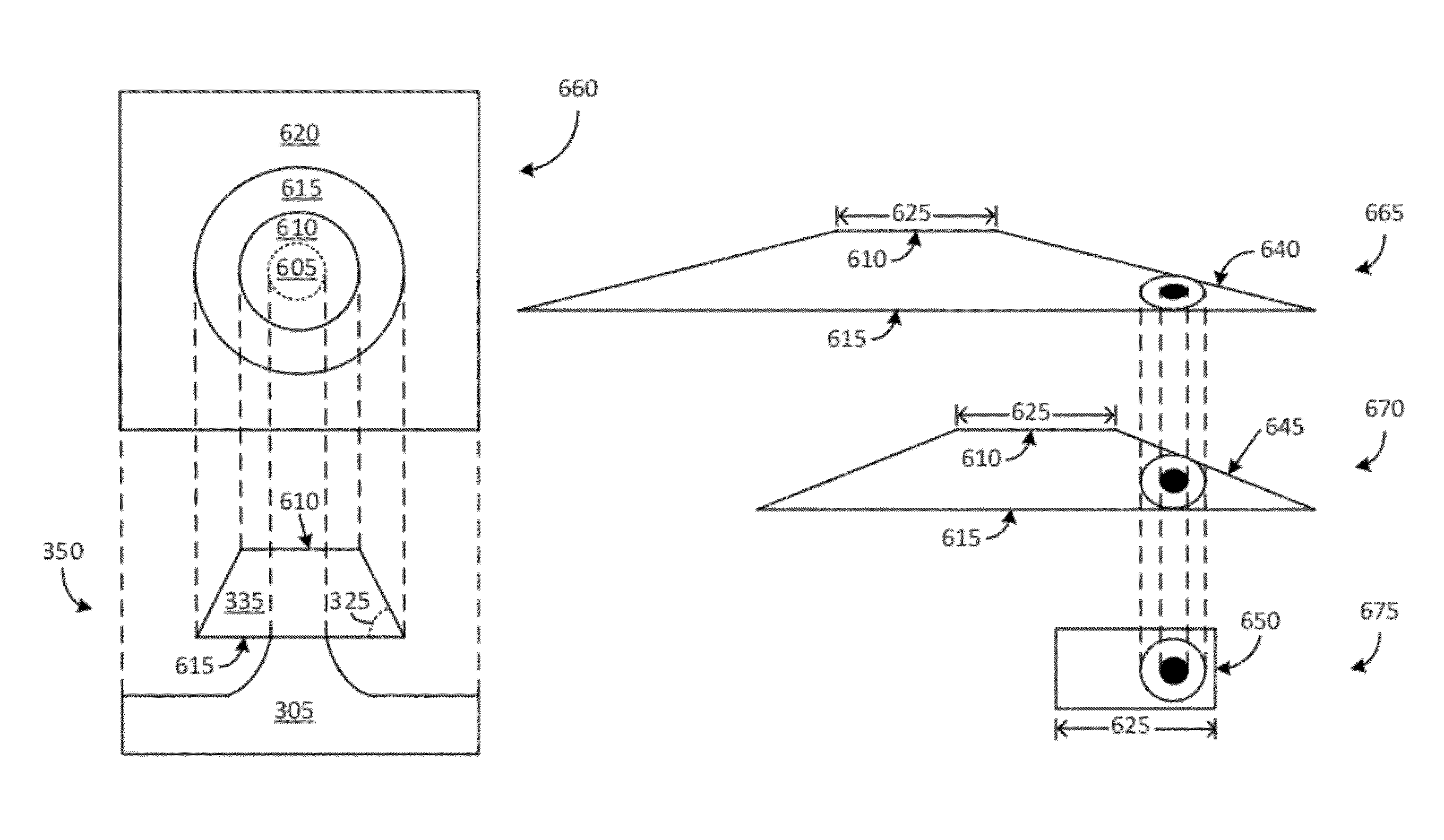

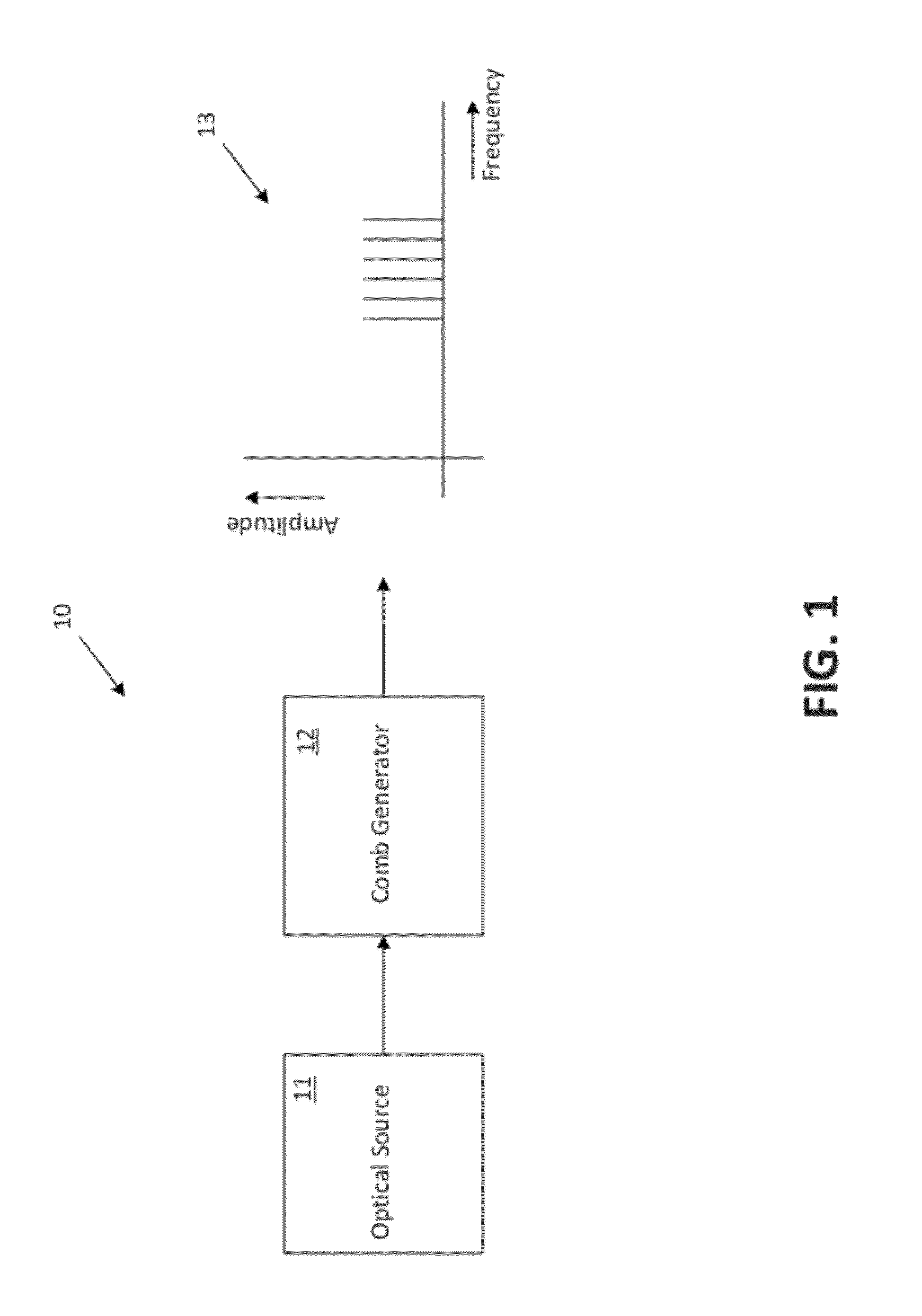

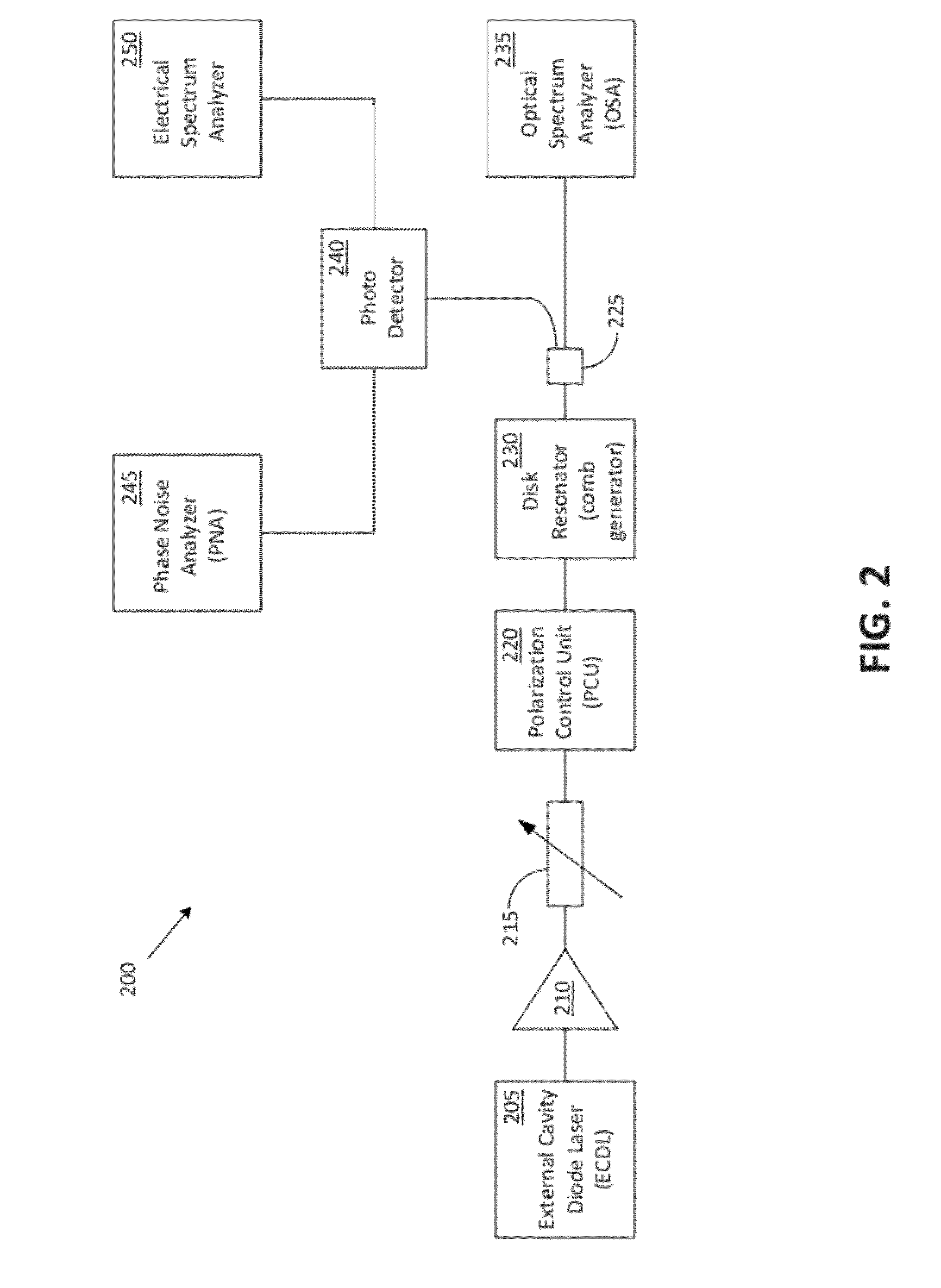

Chip-based frequency comb generator with microwave repetition rate

PatentActiveUS20120320448A1

Innovation

- A chip-based frequency comb generator with a disk resonator fabricated from a silicon dioxide layer, featuring a wedge structure that allows for low-threshold microwave to millimeter wave repetition rate control, with repetition rates ranging from 2.6 GHz to 220 GHz and a pump power threshold as low as 1 mW, utilizing a high optical Q factor and surface-loss-limited behavior to decouple the dependence on repetition rate and pumping threshold.

Materials Science Advancements for Microcomb Fabrication

Material science advancements have played a pivotal role in revolutionizing microcomb fabrication technologies, enabling significant improvements in low-power operation. Recent developments in nonlinear optical materials have dramatically enhanced the efficiency of microresonator-based frequency combs, allowing for reduced pump power requirements while maintaining stable comb generation.

Silicon nitride (Si₃N₄) has emerged as a leading platform material due to its exceptional properties, including high nonlinearity, negligible two-photon absorption at telecommunication wavelengths, and broad transparency window. Advanced deposition techniques have enabled the creation of ultra-low-loss Si₃N₄ waveguides with propagation losses below 1 dB/m, representing a critical breakthrough for power-efficient microcomb generation.

Lithium niobate on insulator (LNOI) has also demonstrated remarkable potential, leveraging its strong electro-optic effect and second-order nonlinearity. Recent fabrication advances have reduced propagation losses in LNOI microresonators to approximately 0.03 dB/cm, making it increasingly viable for low-power applications. The material's unique properties enable novel pump configurations through electro-optic modulation.

Hydex glass, aluminum nitride, and aluminum gallium arsenide represent alternative material platforms that offer complementary advantages for specific applications. Each material presents distinct trade-offs between nonlinearity, fabrication complexity, and integration potential with existing photonic and electronic systems.

Surface treatment technologies have significantly advanced, with novel annealing processes and chemical-mechanical polishing techniques reducing surface roughness to sub-nanometer levels. These improvements directly translate to higher quality factors (Q-factors) in microresonators, which proportionally reduce the power threshold for comb initiation.

Hybrid material integration approaches have emerged as promising strategies, combining the advantages of different material platforms. For example, heterogeneous integration of III-V gain materials with passive Si₃N₄ resonators enables on-chip pump lasers, dramatically reducing coupling losses and overall system power consumption.

Atomic layer deposition techniques have enabled precise control over material composition and interface quality, allowing for engineered dispersion profiles that optimize phase-matching conditions for specific comb applications. This capability is particularly valuable for tailoring comb spectra for targeted wavelength ranges while maintaining low power operation.

Looking forward, two-dimensional materials such as graphene and transition metal dichalcogenides show promise for next-generation microcomb devices, potentially offering unprecedented nonlinearities and novel operational regimes that could further reduce power requirements by orders of magnitude.

Silicon nitride (Si₃N₄) has emerged as a leading platform material due to its exceptional properties, including high nonlinearity, negligible two-photon absorption at telecommunication wavelengths, and broad transparency window. Advanced deposition techniques have enabled the creation of ultra-low-loss Si₃N₄ waveguides with propagation losses below 1 dB/m, representing a critical breakthrough for power-efficient microcomb generation.

Lithium niobate on insulator (LNOI) has also demonstrated remarkable potential, leveraging its strong electro-optic effect and second-order nonlinearity. Recent fabrication advances have reduced propagation losses in LNOI microresonators to approximately 0.03 dB/cm, making it increasingly viable for low-power applications. The material's unique properties enable novel pump configurations through electro-optic modulation.

Hydex glass, aluminum nitride, and aluminum gallium arsenide represent alternative material platforms that offer complementary advantages for specific applications. Each material presents distinct trade-offs between nonlinearity, fabrication complexity, and integration potential with existing photonic and electronic systems.

Surface treatment technologies have significantly advanced, with novel annealing processes and chemical-mechanical polishing techniques reducing surface roughness to sub-nanometer levels. These improvements directly translate to higher quality factors (Q-factors) in microresonators, which proportionally reduce the power threshold for comb initiation.

Hybrid material integration approaches have emerged as promising strategies, combining the advantages of different material platforms. For example, heterogeneous integration of III-V gain materials with passive Si₃N₄ resonators enables on-chip pump lasers, dramatically reducing coupling losses and overall system power consumption.

Atomic layer deposition techniques have enabled precise control over material composition and interface quality, allowing for engineered dispersion profiles that optimize phase-matching conditions for specific comb applications. This capability is particularly valuable for tailoring comb spectra for targeted wavelength ranges while maintaining low power operation.

Looking forward, two-dimensional materials such as graphene and transition metal dichalcogenides show promise for next-generation microcomb devices, potentially offering unprecedented nonlinearities and novel operational regimes that could further reduce power requirements by orders of magnitude.

Integration Pathways for Photonic Integrated Circuits

The integration of low-power microcombs into photonic integrated circuits (PICs) represents a critical pathway for advancing practical applications of this technology. Current integration approaches primarily follow three trajectories: hybrid integration, monolithic integration, and heterogeneous integration, each with distinct advantages for microcomb deployment.

Hybrid integration offers the most immediate path forward, allowing separately optimized microcomb resonators to be coupled with silicon photonic platforms. This approach leverages existing manufacturing infrastructure while permitting material-specific optimization of the microcomb generation components. Companies like Ligentec have demonstrated successful hybrid integration of Si3N4 microresonators with silicon photonics, achieving low-power operation while maintaining high Q-factors essential for efficient comb generation.

Monolithic integration presents a more challenging but potentially more scalable approach, where the entire microcomb system is fabricated within a single material platform. Silicon nitride has emerged as the leading candidate due to its CMOS compatibility and favorable nonlinear properties. Recent advances in ultra-high Q Si3N4 resonators by groups at EPFL and Caltech have demonstrated threshold powers below 1mW, making them viable for on-chip pump lasers.

Heterogeneous integration combines elements of both approaches, typically bonding III-V gain materials with passive photonic platforms. This method enables the co-integration of pump lasers and nonlinear resonators, addressing one of the key challenges in low-power microcomb systems. Recent demonstrations by Intel and UCSB have shown promising results with heterogeneously integrated lasers and high-Q resonators on the same chip.

The pump laser integration represents a particular challenge for low-power operation. Three strategies have emerged: external coupling of commercial lasers (simplest but least integrated), heterogeneous integration of III-V gain materials (moderate complexity with good performance), and full monolithic integration (most challenging but potentially highest volume manufacturing).

Packaging considerations also significantly impact integration pathways. Thermal management becomes critical as low-power microcombs still generate heat that can destabilize frequency combs through thermal drift. Advanced packaging solutions incorporating temperature stabilization and hermetic sealing are being developed by companies like Lionix and Ligentec to address these challenges.

Looking forward, the most promising integration pathway appears to be a hybrid approach in the near term, with heterogeneous integration gaining ground as manufacturing techniques mature. The ultimate goal of fully monolithic integration remains on the horizon, potentially enabled by emerging materials like lithium niobate on insulator (LNOI) that combine excellent nonlinear properties with electro-optic tunability.

Hybrid integration offers the most immediate path forward, allowing separately optimized microcomb resonators to be coupled with silicon photonic platforms. This approach leverages existing manufacturing infrastructure while permitting material-specific optimization of the microcomb generation components. Companies like Ligentec have demonstrated successful hybrid integration of Si3N4 microresonators with silicon photonics, achieving low-power operation while maintaining high Q-factors essential for efficient comb generation.

Monolithic integration presents a more challenging but potentially more scalable approach, where the entire microcomb system is fabricated within a single material platform. Silicon nitride has emerged as the leading candidate due to its CMOS compatibility and favorable nonlinear properties. Recent advances in ultra-high Q Si3N4 resonators by groups at EPFL and Caltech have demonstrated threshold powers below 1mW, making them viable for on-chip pump lasers.

Heterogeneous integration combines elements of both approaches, typically bonding III-V gain materials with passive photonic platforms. This method enables the co-integration of pump lasers and nonlinear resonators, addressing one of the key challenges in low-power microcomb systems. Recent demonstrations by Intel and UCSB have shown promising results with heterogeneously integrated lasers and high-Q resonators on the same chip.

The pump laser integration represents a particular challenge for low-power operation. Three strategies have emerged: external coupling of commercial lasers (simplest but least integrated), heterogeneous integration of III-V gain materials (moderate complexity with good performance), and full monolithic integration (most challenging but potentially highest volume manufacturing).

Packaging considerations also significantly impact integration pathways. Thermal management becomes critical as low-power microcombs still generate heat that can destabilize frequency combs through thermal drift. Advanced packaging solutions incorporating temperature stabilization and hermetic sealing are being developed by companies like Lionix and Ligentec to address these challenges.

Looking forward, the most promising integration pathway appears to be a hybrid approach in the near term, with heterogeneous integration gaining ground as manufacturing techniques mature. The ultimate goal of fully monolithic integration remains on the horizon, potentially enabled by emerging materials like lithium niobate on insulator (LNOI) that combine excellent nonlinear properties with electro-optic tunability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!