Testing And Characterization Suites For Microcomb Performance Claims

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Testing Background and Objectives

Microcombs, or optical frequency combs generated in microresonators, have emerged as a revolutionary technology in the field of photonics over the past two decades. These devices generate precisely spaced optical frequency lines through nonlinear optical processes in microscale resonators, offering unprecedented capabilities for applications ranging from telecommunications to precision metrology. The evolution of microcomb technology has progressed from fundamental demonstrations in the early 2000s to increasingly sophisticated implementations with enhanced performance characteristics and functionality.

The development trajectory of microcombs has been marked by significant milestones, including the first demonstration of Kerr frequency combs in microresonators, the achievement of soliton states for low-noise operation, and the integration of these devices with photonic integrated circuits. Recent advances have focused on expanding the spectral coverage, improving power efficiency, and enhancing the stability and coherence properties of these devices.

Despite the rapid progress in microcomb technology, a critical challenge facing the field is the lack of standardized testing and characterization methodologies. This absence of uniform measurement protocols has led to inconsistent performance claims across research groups and commercial entities, making it difficult to objectively compare different microcomb implementations and assess their suitability for specific applications.

The primary objective of this technical research is to establish a comprehensive framework for testing and characterizing microcomb performance. This framework aims to provide standardized methodologies for evaluating key performance metrics such as spectral bandwidth, line spacing uniformity, power per comb line, phase noise, and long-term stability. By developing these standardized testing protocols, we seek to enable meaningful comparisons between different microcomb technologies and facilitate their adoption in practical applications.

Additionally, this research aims to identify the critical parameters that define microcomb performance for specific application domains, recognizing that different use cases may prioritize different performance metrics. For telecommunications applications, for instance, channel spacing uniformity and power equalization may be paramount, while quantum information processing may prioritize phase coherence and stability.

The ultimate goal is to accelerate the maturation of microcomb technology by providing the research community and industry with reliable benchmarking tools. These tools will not only facilitate technology development but also help establish performance standards that can guide future research directions and commercial implementations, thereby bridging the gap between laboratory demonstrations and real-world applications of this transformative photonic technology.

The development trajectory of microcombs has been marked by significant milestones, including the first demonstration of Kerr frequency combs in microresonators, the achievement of soliton states for low-noise operation, and the integration of these devices with photonic integrated circuits. Recent advances have focused on expanding the spectral coverage, improving power efficiency, and enhancing the stability and coherence properties of these devices.

Despite the rapid progress in microcomb technology, a critical challenge facing the field is the lack of standardized testing and characterization methodologies. This absence of uniform measurement protocols has led to inconsistent performance claims across research groups and commercial entities, making it difficult to objectively compare different microcomb implementations and assess their suitability for specific applications.

The primary objective of this technical research is to establish a comprehensive framework for testing and characterizing microcomb performance. This framework aims to provide standardized methodologies for evaluating key performance metrics such as spectral bandwidth, line spacing uniformity, power per comb line, phase noise, and long-term stability. By developing these standardized testing protocols, we seek to enable meaningful comparisons between different microcomb technologies and facilitate their adoption in practical applications.

Additionally, this research aims to identify the critical parameters that define microcomb performance for specific application domains, recognizing that different use cases may prioritize different performance metrics. For telecommunications applications, for instance, channel spacing uniformity and power equalization may be paramount, while quantum information processing may prioritize phase coherence and stability.

The ultimate goal is to accelerate the maturation of microcomb technology by providing the research community and industry with reliable benchmarking tools. These tools will not only facilitate technology development but also help establish performance standards that can guide future research directions and commercial implementations, thereby bridging the gap between laboratory demonstrations and real-world applications of this transformative photonic technology.

Market Analysis for Microcomb Characterization Tools

The global market for microcomb characterization tools is experiencing significant growth, driven by the increasing adoption of microcombs in various applications such as telecommunications, spectroscopy, metrology, and quantum computing. Current market estimates suggest that the overall photonic integrated circuit (PIC) testing equipment market, which includes microcomb characterization tools, is valued at approximately $500 million and is projected to grow at a compound annual growth rate of 20% through 2028.

The demand for specialized microcomb testing equipment stems from the unique challenges associated with accurately characterizing these complex devices. Traditional optical spectrum analyzers and other photonic test equipment often lack the precision, bandwidth, and specialized features required for comprehensive microcomb performance evaluation.

Market segmentation reveals distinct customer groups with varying needs. Research institutions and universities currently represent the largest market segment, accounting for roughly 45% of the total market share. These customers typically require high-precision, customizable solutions with comprehensive data analysis capabilities. Commercial entities in telecommunications and data centers form the second-largest segment at approximately 30%, prioritizing reliability, standardization, and integration with existing systems.

Emerging applications in quantum technologies, precision timing, and LiDAR systems are creating new market opportunities, with this segment growing at nearly 35% annually—significantly faster than the overall market. This rapid growth is attracting new entrants and driving innovation in testing methodologies.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate due to increasing investments in photonic technologies in China, Japan, and South Korea.

The competitive landscape features both established test and measurement companies expanding their portfolios to include microcomb-specific solutions and specialized startups developing novel characterization techniques. Key market drivers include the growing complexity of integrated photonic circuits, increasing data rates in telecommunications, and the push toward standardization in the industry.

Pricing models vary significantly, with high-end, comprehensive characterization suites commanding prices between $200,000 and $500,000, while more specialized or limited-function tools are available in the $50,000 to $150,000 range. The market is witnessing a trend toward modular systems that allow customers to scale their testing capabilities as needed.

Customer feedback indicates growing demand for automated testing solutions, cloud-based data analysis, and tools that can characterize not only spectral properties but also phase stability, noise characteristics, and power efficiency—all critical parameters for practical microcomb applications.

The demand for specialized microcomb testing equipment stems from the unique challenges associated with accurately characterizing these complex devices. Traditional optical spectrum analyzers and other photonic test equipment often lack the precision, bandwidth, and specialized features required for comprehensive microcomb performance evaluation.

Market segmentation reveals distinct customer groups with varying needs. Research institutions and universities currently represent the largest market segment, accounting for roughly 45% of the total market share. These customers typically require high-precision, customizable solutions with comprehensive data analysis capabilities. Commercial entities in telecommunications and data centers form the second-largest segment at approximately 30%, prioritizing reliability, standardization, and integration with existing systems.

Emerging applications in quantum technologies, precision timing, and LiDAR systems are creating new market opportunities, with this segment growing at nearly 35% annually—significantly faster than the overall market. This rapid growth is attracting new entrants and driving innovation in testing methodologies.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate due to increasing investments in photonic technologies in China, Japan, and South Korea.

The competitive landscape features both established test and measurement companies expanding their portfolios to include microcomb-specific solutions and specialized startups developing novel characterization techniques. Key market drivers include the growing complexity of integrated photonic circuits, increasing data rates in telecommunications, and the push toward standardization in the industry.

Pricing models vary significantly, with high-end, comprehensive characterization suites commanding prices between $200,000 and $500,000, while more specialized or limited-function tools are available in the $50,000 to $150,000 range. The market is witnessing a trend toward modular systems that allow customers to scale their testing capabilities as needed.

Customer feedback indicates growing demand for automated testing solutions, cloud-based data analysis, and tools that can characterize not only spectral properties but also phase stability, noise characteristics, and power efficiency—all critical parameters for practical microcomb applications.

Current Challenges in Microcomb Performance Validation

Despite significant advancements in microcomb technology, the field currently faces substantial challenges in standardizing performance validation methodologies. The absence of universally accepted testing protocols creates inconsistencies in how researchers and manufacturers characterize and report microcomb performance metrics. This fragmentation hampers meaningful comparison between different devices and impedes broader adoption across industries.

One critical challenge is the multidimensional nature of microcomb performance parameters. Researchers must simultaneously evaluate spectral bandwidth, frequency stability, power consumption, noise characteristics, and coherence properties. However, the relative importance of these parameters varies significantly depending on the intended application, making it difficult to establish a one-size-fits-all validation framework.

Measurement reproducibility presents another significant obstacle. Environmental factors such as temperature fluctuations, mechanical vibrations, and electromagnetic interference can dramatically affect microcomb performance. Many research groups employ custom-built characterization setups with varying degrees of environmental isolation, leading to discrepancies in reported results even for nominally identical devices.

The rapid evolution of microcomb technology further complicates validation efforts. As new materials, fabrication techniques, and operational regimes emerge, existing characterization methods may become inadequate or irrelevant. This creates a moving target for standardization bodies attempting to establish enduring validation protocols.

Calibration traceability represents a fundamental challenge in the field. While national metrology institutes maintain primary frequency standards, translating these references to on-chip microcomb validation requires sophisticated transfer techniques. Many research facilities lack direct access to these reference standards, resulting in validation measurements with uncertain absolute accuracy.

Cross-platform compatibility issues also hinder comprehensive performance validation. Microcombs developed on different material platforms (silicon nitride, lithium niobate, aluminum nitride, etc.) exhibit distinct characteristics that may require tailored testing approaches. This diversity complicates efforts to develop universal benchmarking methodologies applicable across the entire technology landscape.

Finally, there exists a significant gap between laboratory characterization and real-world performance validation. Many reported microcomb metrics derive from idealized testing environments that poorly represent actual deployment conditions. Developing robust validation protocols that accurately predict field performance remains an unsolved challenge for the microcomb community.

One critical challenge is the multidimensional nature of microcomb performance parameters. Researchers must simultaneously evaluate spectral bandwidth, frequency stability, power consumption, noise characteristics, and coherence properties. However, the relative importance of these parameters varies significantly depending on the intended application, making it difficult to establish a one-size-fits-all validation framework.

Measurement reproducibility presents another significant obstacle. Environmental factors such as temperature fluctuations, mechanical vibrations, and electromagnetic interference can dramatically affect microcomb performance. Many research groups employ custom-built characterization setups with varying degrees of environmental isolation, leading to discrepancies in reported results even for nominally identical devices.

The rapid evolution of microcomb technology further complicates validation efforts. As new materials, fabrication techniques, and operational regimes emerge, existing characterization methods may become inadequate or irrelevant. This creates a moving target for standardization bodies attempting to establish enduring validation protocols.

Calibration traceability represents a fundamental challenge in the field. While national metrology institutes maintain primary frequency standards, translating these references to on-chip microcomb validation requires sophisticated transfer techniques. Many research facilities lack direct access to these reference standards, resulting in validation measurements with uncertain absolute accuracy.

Cross-platform compatibility issues also hinder comprehensive performance validation. Microcombs developed on different material platforms (silicon nitride, lithium niobate, aluminum nitride, etc.) exhibit distinct characteristics that may require tailored testing approaches. This diversity complicates efforts to develop universal benchmarking methodologies applicable across the entire technology landscape.

Finally, there exists a significant gap between laboratory characterization and real-world performance validation. Many reported microcomb metrics derive from idealized testing environments that poorly represent actual deployment conditions. Developing robust validation protocols that accurately predict field performance remains an unsolved challenge for the microcomb community.

Established Microcomb Characterization Techniques

01 Optical characterization techniques for microcombs

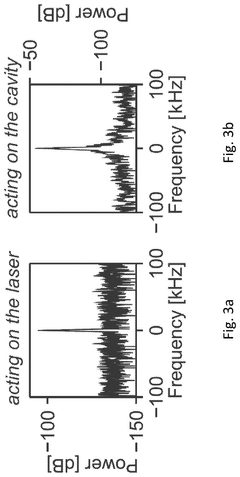

Various optical characterization techniques are employed to evaluate the performance of microcombs. These include spectral analysis to measure frequency spacing, stability, and power distribution across comb lines. Advanced optical measurement systems can characterize phase noise, coherence properties, and spectral purity of the generated comb lines. These techniques are essential for validating microcomb performance in applications requiring high precision frequency references.- Optical characterization techniques for microcombs: Various optical characterization techniques are employed to evaluate the performance of microcombs. These include spectral analysis to measure frequency spacing and stability, phase noise measurements to assess coherence properties, and optical power measurements to determine efficiency. Advanced optical testing suites incorporate interferometric methods and high-resolution spectroscopy to characterize the quality and stability of the generated comb lines across the spectrum.

- Electrical performance testing systems: Electrical testing systems for microcombs focus on measuring power consumption, thermal performance, and electronic control response. These systems typically include precision current sources, voltage monitors, and thermal sensors to characterize the electrical-to-optical conversion efficiency. Testing suites incorporate automated measurement capabilities to evaluate stability under varying electrical conditions and to optimize driving parameters for improved microcomb performance.

- Network and telecommunications testing frameworks: Specialized testing frameworks evaluate microcomb performance in telecommunications applications. These characterization suites measure data transmission rates, signal-to-noise ratios, and channel spacing accuracy. The testing systems simulate real-world network conditions to assess the reliability of microcombs in wavelength division multiplexing systems and high-bandwidth communications. Performance metrics include bit error rates, modulation efficiency, and stability under varying transmission loads.

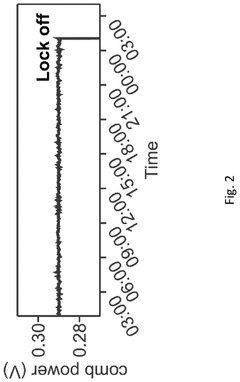

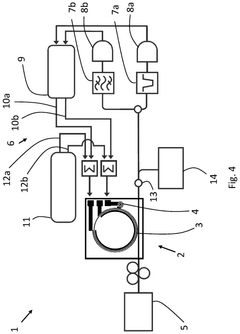

- Integrated testing platforms for microcomb stability: Integrated testing platforms combine multiple measurement techniques to comprehensively evaluate microcomb stability. These systems simultaneously monitor frequency drift, phase coherence, and amplitude stability over extended periods. Advanced characterization suites incorporate environmental controls to assess performance under varying temperature, humidity, and vibration conditions. The platforms enable automated long-term stability testing with high-precision measurement capabilities for quality control and reliability assessment.

- Error detection and performance validation methods: Specialized methods for error detection and performance validation ensure microcomb reliability in practical applications. These testing approaches include comparative analysis against reference standards, statistical evaluation of comb line stability, and automated detection of mode-hopping or phase slips. Characterization suites implement machine learning algorithms to identify performance degradation patterns and predict potential failures. These methods enable comprehensive quality assurance and certification of microcomb devices for critical applications.

02 Electrical testing methods for microcomb systems

Electrical testing methods are crucial for evaluating microcomb performance parameters such as power consumption, thermal stability, and electronic control response. These methods include measuring electrical-to-optical conversion efficiency, characterizing the electronic driving circuits, and testing the stability of control systems. Specialized test equipment can monitor the electrical performance under various operating conditions to ensure reliable operation in practical applications.Expand Specific Solutions03 Performance metrics and benchmarking frameworks

Standardized performance metrics and benchmarking frameworks have been developed to evaluate and compare different microcomb technologies. These frameworks assess key parameters including frequency stability, noise characteristics, power efficiency, and operational temperature range. Comprehensive testing suites enable systematic evaluation across multiple performance dimensions, allowing for objective comparison between different microcomb designs and implementations.Expand Specific Solutions04 Integration testing for microcomb-based systems

Integration testing methodologies evaluate how microcombs perform when incorporated into larger systems. These tests assess compatibility with other components, system-level performance, and reliability under real-world operating conditions. Testing protocols examine signal integrity across interfaces, timing synchronization, and overall system stability. These integration tests are particularly important for telecommunications, sensing, and computing applications where microcombs must function reliably within complex systems.Expand Specific Solutions05 Environmental and reliability testing

Environmental and reliability testing evaluates microcomb performance under various environmental conditions and over extended periods. These tests include temperature cycling, humidity exposure, mechanical shock, and long-term stability analysis. Accelerated aging tests help predict the operational lifetime and identify potential failure modes. These testing methodologies are critical for ensuring that microcomb devices can maintain their performance specifications in practical deployment scenarios across different application environments.Expand Specific Solutions

Leading Organizations in Microcomb Testing Standards

The microcomb testing and characterization market is currently in its growth phase, with increasing demand driven by advancements in integrated photonics and telecommunications. The global market size is expanding rapidly as microcombs find applications in precision metrology, telecommunications, and quantum technologies. From a technological maturity perspective, the landscape shows varying degrees of development across key players. Academic institutions like Tsinghua University and Beijing University of Technology are conducting foundational research, while established corporations including Corning, Applied Materials, and TSMC are leveraging their semiconductor expertise to develop standardized testing solutions. Emerging players such as FormFactor and Synopsys are creating specialized characterization tools, while telecommunications giants like Texas Instruments are focusing on application-specific testing methodologies. The industry is moving toward establishing unified performance metrics and validation protocols to support commercial deployment.

Corning, Inc.

Technical Solution: Corning has developed comprehensive testing and characterization suites for microcomb performance evaluation, leveraging their expertise in optical materials and photonics. Their approach integrates advanced spectral analysis systems with phase noise measurement capabilities to characterize microcomb stability and coherence. Corning's test suites employ high-precision wavelength meters and optical spectrum analyzers capable of sub-picometer resolution to evaluate comb line spacing uniformity and power distribution. Their characterization methodology includes automated measurement of key performance indicators such as conversion efficiency, threshold power, and free spectral range variations across different operational conditions. Additionally, Corning has implemented temperature-controlled test environments to assess thermal stability and drift characteristics of microcombs, critical for telecommunications and sensing applications.

Strengths: Exceptional optical materials expertise and vertical integration capabilities allow for comprehensive testing across the entire photonic system chain. Weaknesses: Their test suites may be optimized primarily for telecom applications rather than emerging quantum technology applications of microcombs.

Tsinghua University

Technical Solution: Tsinghua University has pioneered advanced microcomb characterization techniques through their Integrated Photonics Laboratory. Their testing suite incorporates multi-parameter analysis systems that simultaneously evaluate spectral purity, phase noise, and power efficiency of microcombs. The university has developed proprietary algorithms for automated comb state identification that can distinguish between various operational regimes including chaotic, breather soliton, and stable soliton states. Their characterization methodology includes comprehensive stability analysis across environmental variations, with particular focus on evaluating comb resilience to temperature fluctuations and mechanical vibrations. Tsinghua's test suite features custom-designed heterodyne detection systems for ultra-precise frequency stability measurements down to sub-Hz levels, enabling detailed characterization of microcomb noise properties across different timescales. Their approach integrates both time and frequency domain measurements to provide complete performance profiles for different microcomb architectures.

Strengths: Cutting-edge research capabilities with strong theoretical foundations and algorithm development for automated characterization. Weaknesses: Academic focus may result in characterization systems that prioritize research flexibility over industrial standardization and throughput requirements.

Critical Patents in Microcomb Testing Technologies

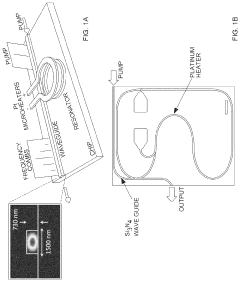

Optical devices comprising a micro-resonator frequency comb

PatentPendingUS20250246866A1

Innovation

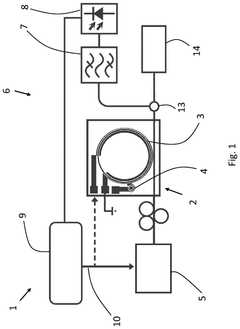

- A micro-resonator frequency comb with a feedback control loop and control circuit stabilizes optical power and detuning by using a photo detector and control circuit to adjust the pump laser or resonator cavities, allowing for stable operation and tuning of the center frequency.

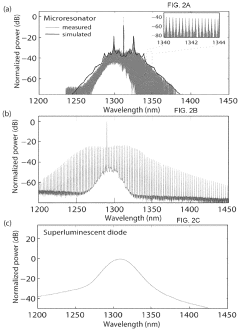

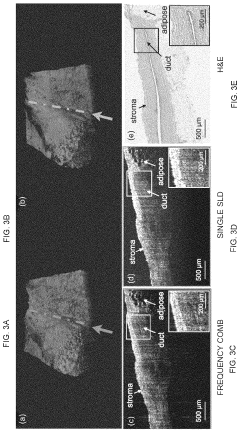

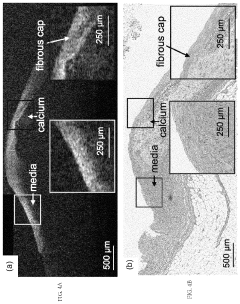

Microresonator-frequency-comb-based platform for clinical high-resolution optical coherence tomography

PatentActiveUS11859972B2

Innovation

- A microresonator-frequency-comb-based platform using high-Q silicon nitride resonators and distributed feedback lasers generates broadband frequency combs, overcoming the bandwidth-power trade-off and enabling sub-micrometer axial resolution and deeper tissue penetration, compatible with standard OCT systems.

Standardization Efforts for Microcomb Performance Metrics

The standardization of microcomb performance metrics represents a critical step toward enabling reliable comparison and evaluation of different microcomb technologies across the research community and industry. Currently, several international organizations are spearheading efforts to establish comprehensive standards for characterizing microcombs, including the IEEE Photonics Society, the Optical Society (OSA), and the International Electrotechnical Commission (IEC).

These standardization initiatives primarily focus on defining uniform measurement protocols and performance benchmarks for key microcomb parameters. These include spectral bandwidth, comb line spacing uniformity, power per comb line, phase noise characteristics, and conversion efficiency. The IEEE P1918.1 working group has recently initiated a task force specifically dedicated to microcomb standardization, with participation from both academic institutions and industry stakeholders.

One significant advancement in standardization has been the development of reference architectures for testing setups. These architectures specify the required equipment configuration, calibration procedures, and environmental conditions necessary for consistent and reproducible measurements. For instance, the proposed standard testing suite for phase noise characterization includes specifications for reference oscillators, phase-locked loops, and spectrum analyzer configurations.

The National Institute of Standards and Technology (NIST) has contributed substantially by developing calibrated reference microcombs that serve as benchmarks against which other devices can be measured. These reference devices, with thoroughly characterized performance metrics, enable cross-platform comparisons and validation of measurement techniques across different laboratories.

Industry consortia have also emerged to accelerate standardization efforts. The Integrated Photonics Systems Roadmap (IPSR) has established a special interest group focused on microcomb metrics, bringing together manufacturers, end-users, and researchers to define application-specific performance requirements and corresponding test methodologies.

Challenges in standardization persist, particularly regarding the diverse application requirements for microcombs. Standards must accommodate the varying performance priorities across applications ranging from telecommunications to quantum computing. Additionally, the rapid pace of technological advancement in microcombs necessitates flexible standards that can evolve alongside the technology.

Recent progress includes the publication of draft measurement guidelines for frequency stability and noise characterization, which are currently undergoing community review. These guidelines represent an important step toward establishing globally accepted standards that will facilitate technology transfer, commercialization, and broader adoption of microcomb technology across multiple industries.

These standardization initiatives primarily focus on defining uniform measurement protocols and performance benchmarks for key microcomb parameters. These include spectral bandwidth, comb line spacing uniformity, power per comb line, phase noise characteristics, and conversion efficiency. The IEEE P1918.1 working group has recently initiated a task force specifically dedicated to microcomb standardization, with participation from both academic institutions and industry stakeholders.

One significant advancement in standardization has been the development of reference architectures for testing setups. These architectures specify the required equipment configuration, calibration procedures, and environmental conditions necessary for consistent and reproducible measurements. For instance, the proposed standard testing suite for phase noise characterization includes specifications for reference oscillators, phase-locked loops, and spectrum analyzer configurations.

The National Institute of Standards and Technology (NIST) has contributed substantially by developing calibrated reference microcombs that serve as benchmarks against which other devices can be measured. These reference devices, with thoroughly characterized performance metrics, enable cross-platform comparisons and validation of measurement techniques across different laboratories.

Industry consortia have also emerged to accelerate standardization efforts. The Integrated Photonics Systems Roadmap (IPSR) has established a special interest group focused on microcomb metrics, bringing together manufacturers, end-users, and researchers to define application-specific performance requirements and corresponding test methodologies.

Challenges in standardization persist, particularly regarding the diverse application requirements for microcombs. Standards must accommodate the varying performance priorities across applications ranging from telecommunications to quantum computing. Additionally, the rapid pace of technological advancement in microcombs necessitates flexible standards that can evolve alongside the technology.

Recent progress includes the publication of draft measurement guidelines for frequency stability and noise characterization, which are currently undergoing community review. These guidelines represent an important step toward establishing globally accepted standards that will facilitate technology transfer, commercialization, and broader adoption of microcomb technology across multiple industries.

Reliability and Reproducibility Considerations in Testing

Reliability and reproducibility represent critical dimensions in the evaluation of microcomb technologies, particularly as these devices transition from laboratory demonstrations to commercial applications. The testing methodologies employed must ensure consistent performance across multiple fabrication runs and operating conditions. Current testing protocols often lack standardization, leading to challenges in comparing results across different research groups and manufacturers.

A fundamental consideration in microcomb testing reliability involves environmental stability assessment. Microcombs must demonstrate consistent performance across temperature variations, mechanical vibrations, and humidity changes. Testing suites should incorporate controlled environmental chambers capable of simulating these conditions while monitoring key performance metrics such as frequency stability, power consumption, and spectral purity.

Long-term drift characterization constitutes another essential aspect of reliability testing. Microcombs intended for deployment in precision measurement systems or telecommunications infrastructure must maintain calibrated performance over extended periods. Testing protocols should include continuous operation assessments spanning weeks or months, with automated data collection systems tracking performance degradation patterns.

Statistical validation frameworks represent a critical yet often overlooked component of microcomb testing. Single-device measurements provide limited insight into manufacturing variability. Robust characterization requires testing multiple devices from different fabrication batches to establish performance distributions and yield metrics. This approach enables meaningful confidence intervals for performance claims and supports quality control processes.

Measurement uncertainty quantification demands particular attention in microcomb testing. Each measurement instrument introduces its own error sources, which must be systematically documented and incorporated into performance claims. Testing suites should include calibration verification procedures and uncertainty budgets for all critical measurements, particularly for frequency accuracy, power stability, and noise floor determinations.

Round-robin testing between independent laboratories offers a powerful approach to validate reproducibility. When multiple facilities test identical devices using standardized protocols, systematic biases in measurement approaches can be identified and eliminated. Several international metrology institutes have initiated such programs for microcomb technologies, though broader industry participation remains limited.

Documentation standards for testing procedures require significant improvement across the field. Comprehensive test reports should include detailed descriptions of experimental setups, calibration procedures, environmental conditions, and data processing methodologies. This level of documentation enables meaningful peer review and supports technology transfer between research and manufacturing environments.

A fundamental consideration in microcomb testing reliability involves environmental stability assessment. Microcombs must demonstrate consistent performance across temperature variations, mechanical vibrations, and humidity changes. Testing suites should incorporate controlled environmental chambers capable of simulating these conditions while monitoring key performance metrics such as frequency stability, power consumption, and spectral purity.

Long-term drift characterization constitutes another essential aspect of reliability testing. Microcombs intended for deployment in precision measurement systems or telecommunications infrastructure must maintain calibrated performance over extended periods. Testing protocols should include continuous operation assessments spanning weeks or months, with automated data collection systems tracking performance degradation patterns.

Statistical validation frameworks represent a critical yet often overlooked component of microcomb testing. Single-device measurements provide limited insight into manufacturing variability. Robust characterization requires testing multiple devices from different fabrication batches to establish performance distributions and yield metrics. This approach enables meaningful confidence intervals for performance claims and supports quality control processes.

Measurement uncertainty quantification demands particular attention in microcomb testing. Each measurement instrument introduces its own error sources, which must be systematically documented and incorporated into performance claims. Testing suites should include calibration verification procedures and uncertainty budgets for all critical measurements, particularly for frequency accuracy, power stability, and noise floor determinations.

Round-robin testing between independent laboratories offers a powerful approach to validate reproducibility. When multiple facilities test identical devices using standardized protocols, systematic biases in measurement approaches can be identified and eliminated. Several international metrology institutes have initiated such programs for microcomb technologies, though broader industry participation remains limited.

Documentation standards for testing procedures require significant improvement across the field. Comprehensive test reports should include detailed descriptions of experimental setups, calibration procedures, environmental conditions, and data processing methodologies. This level of documentation enables meaningful peer review and supports technology transfer between research and manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!