Thermal And Environmental Control For Chip-Scale Microcomb Generators

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Thermal Control Background and Objectives

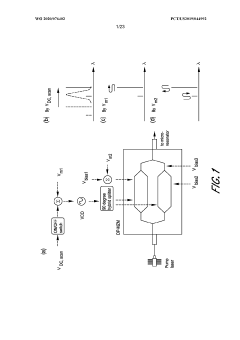

Microcomb technology has emerged as a revolutionary platform for generating optical frequency combs on integrated photonic chips. The evolution of this field traces back to the early 2000s when the first demonstrations of microresonator-based frequency combs were achieved using whispering gallery mode resonators. Since then, significant advancements have been made in materials, fabrication techniques, and control mechanisms, leading to the current generation of chip-scale microcomb generators.

The thermal management of microcombs represents a critical aspect of their operation, as these devices are highly sensitive to temperature fluctuations. Temperature variations as small as millikelvins can significantly affect the resonance conditions of microresonators, leading to instabilities in comb generation and degradation of spectral purity. The historical progression of thermal control strategies has evolved from basic passive approaches to sophisticated active feedback systems incorporating multiple control loops.

Environmental factors beyond temperature also play crucial roles in microcomb performance. Humidity, mechanical vibrations, and air pressure variations can all impact the stability and reliability of these devices. Early research focused primarily on laboratory demonstrations under controlled conditions, while recent efforts have shifted toward developing robust solutions for real-world applications outside laboratory environments.

The primary technical objectives for thermal and environmental control of chip-scale microcomb generators include achieving sub-millikelvin temperature stability, minimizing thermal gradients across the photonic chip, implementing efficient heat dissipation mechanisms, and developing compact, energy-efficient thermal management solutions compatible with portable applications.

Another key objective involves the development of integrated sensing and feedback systems that can monitor and adjust thermal conditions in real-time, ensuring stable comb operation across varying environmental conditions. This includes the integration of temperature sensors, heaters, and control electronics directly on the photonic chip to minimize size and improve response times.

Long-term stability represents another critical goal, as many applications require continuous operation over extended periods without manual intervention. This necessitates the development of adaptive control algorithms capable of compensating for environmental drift and aging effects in the materials and components.

The ultimate aim is to enable the transition of microcomb technology from laboratory demonstrations to commercially viable products that can operate reliably in diverse environments. This requires balancing competing demands for thermal stability, power consumption, size constraints, and manufacturing costs while maintaining the exceptional performance characteristics that make microcombs valuable for applications in telecommunications, spectroscopy, metrology, and quantum information processing.

The thermal management of microcombs represents a critical aspect of their operation, as these devices are highly sensitive to temperature fluctuations. Temperature variations as small as millikelvins can significantly affect the resonance conditions of microresonators, leading to instabilities in comb generation and degradation of spectral purity. The historical progression of thermal control strategies has evolved from basic passive approaches to sophisticated active feedback systems incorporating multiple control loops.

Environmental factors beyond temperature also play crucial roles in microcomb performance. Humidity, mechanical vibrations, and air pressure variations can all impact the stability and reliability of these devices. Early research focused primarily on laboratory demonstrations under controlled conditions, while recent efforts have shifted toward developing robust solutions for real-world applications outside laboratory environments.

The primary technical objectives for thermal and environmental control of chip-scale microcomb generators include achieving sub-millikelvin temperature stability, minimizing thermal gradients across the photonic chip, implementing efficient heat dissipation mechanisms, and developing compact, energy-efficient thermal management solutions compatible with portable applications.

Another key objective involves the development of integrated sensing and feedback systems that can monitor and adjust thermal conditions in real-time, ensuring stable comb operation across varying environmental conditions. This includes the integration of temperature sensors, heaters, and control electronics directly on the photonic chip to minimize size and improve response times.

Long-term stability represents another critical goal, as many applications require continuous operation over extended periods without manual intervention. This necessitates the development of adaptive control algorithms capable of compensating for environmental drift and aging effects in the materials and components.

The ultimate aim is to enable the transition of microcomb technology from laboratory demonstrations to commercially viable products that can operate reliably in diverse environments. This requires balancing competing demands for thermal stability, power consumption, size constraints, and manufacturing costs while maintaining the exceptional performance characteristics that make microcombs valuable for applications in telecommunications, spectroscopy, metrology, and quantum information processing.

Market Analysis for Chip-Scale Microcomb Applications

The global market for chip-scale microcomb applications is experiencing significant growth, driven by increasing demand for compact, high-precision frequency sources across multiple industries. Current market estimates value the integrated photonics market at approximately $3.5 billion, with microcombs representing an emerging segment projected to grow at a CAGR of 23% through 2028.

Telecommunications represents the largest application sector, where microcombs enable wavelength division multiplexing (WDM) systems with unprecedented channel counts and spectral efficiency. The deployment of 5G and future 6G networks is accelerating demand for compact, energy-efficient frequency comb sources capable of supporting high-bandwidth data transmission.

Sensing and metrology applications constitute the second-largest market segment. Chip-scale microcombs are revolutionizing precision measurement systems, offering capabilities previously available only in laboratory settings. This includes applications in LIDAR, spectroscopy, and environmental monitoring, where the market is expected to reach $1.2 billion by 2027.

Quantum computing represents a smaller but rapidly growing application area. As quantum technologies advance toward practical implementation, the need for precise optical frequency references provided by microcombs is becoming increasingly critical. Industry analysts project this segment to grow at over 30% annually as quantum computing moves from research to commercial deployment.

Healthcare and biomedical applications are emerging as promising markets for microcomb technology. Applications include optical coherence tomography, breath analysis, and portable diagnostic tools. The biomedical segment is projected to reach $800 million by 2026, with microcombs enabling miniaturization of previously bulky optical diagnostic equipment.

Aerospace and defense applications represent a specialized but high-value market segment. Here, microcombs enable advanced navigation systems, secure communications, and remote sensing capabilities. Though smaller in volume, this sector commands premium pricing due to stringent performance and reliability requirements.

Regional analysis shows North America leading in research and early commercialization, with approximately 42% market share. Asia-Pacific represents the fastest-growing region at 27% annual growth, driven by investments in telecommunications infrastructure and consumer electronics integration.

A key market challenge remains the thermal management requirements of microcomb systems, which currently limit broader commercial adoption. Industry surveys indicate that 68% of potential end-users cite thermal stability concerns as a primary barrier to implementation, highlighting the critical importance of advances in thermal and environmental control technologies to unlock the full market potential of chip-scale microcomb generators.

Telecommunications represents the largest application sector, where microcombs enable wavelength division multiplexing (WDM) systems with unprecedented channel counts and spectral efficiency. The deployment of 5G and future 6G networks is accelerating demand for compact, energy-efficient frequency comb sources capable of supporting high-bandwidth data transmission.

Sensing and metrology applications constitute the second-largest market segment. Chip-scale microcombs are revolutionizing precision measurement systems, offering capabilities previously available only in laboratory settings. This includes applications in LIDAR, spectroscopy, and environmental monitoring, where the market is expected to reach $1.2 billion by 2027.

Quantum computing represents a smaller but rapidly growing application area. As quantum technologies advance toward practical implementation, the need for precise optical frequency references provided by microcombs is becoming increasingly critical. Industry analysts project this segment to grow at over 30% annually as quantum computing moves from research to commercial deployment.

Healthcare and biomedical applications are emerging as promising markets for microcomb technology. Applications include optical coherence tomography, breath analysis, and portable diagnostic tools. The biomedical segment is projected to reach $800 million by 2026, with microcombs enabling miniaturization of previously bulky optical diagnostic equipment.

Aerospace and defense applications represent a specialized but high-value market segment. Here, microcombs enable advanced navigation systems, secure communications, and remote sensing capabilities. Though smaller in volume, this sector commands premium pricing due to stringent performance and reliability requirements.

Regional analysis shows North America leading in research and early commercialization, with approximately 42% market share. Asia-Pacific represents the fastest-growing region at 27% annual growth, driven by investments in telecommunications infrastructure and consumer electronics integration.

A key market challenge remains the thermal management requirements of microcomb systems, which currently limit broader commercial adoption. Industry surveys indicate that 68% of potential end-users cite thermal stability concerns as a primary barrier to implementation, highlighting the critical importance of advances in thermal and environmental control technologies to unlock the full market potential of chip-scale microcomb generators.

Thermal Management Challenges in Microcomb Technology

Thermal management represents one of the most critical challenges in the development and operation of chip-scale microcomb generators. These photonic devices, which produce optical frequency combs at the microscale, are highly sensitive to temperature fluctuations that can significantly impact their performance, stability, and reliability. The primary thermal challenge stems from the high optical power densities required to generate nonlinear optical effects in microresonators, which inevitably leads to heat generation through absorption processes.

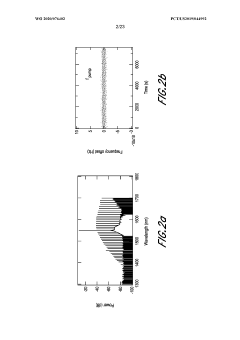

The thermal sensitivity of microcombs manifests in several ways. Temperature variations as small as 0.01°C can cause resonance wavelength shifts that exceed the resonator linewidth, disrupting the phase-matching conditions necessary for comb generation. This thermal instability directly affects frequency stability, spectral purity, and overall comb coherence—all critical parameters for applications in precision metrology, telecommunications, and quantum information processing.

Current thermal management approaches include passive techniques such as heat sinking and material selection, as well as active methods including thermoelectric cooling and feedback-controlled temperature stabilization. However, these solutions face significant limitations when scaled down to chip dimensions, where thermal gradients become more pronounced and heat dissipation pathways are constrained by the compact geometry.

The integration of thermal control systems with photonic circuits presents additional challenges related to material compatibility, fabrication processes, and power consumption. Silicon-based platforms, while offering excellent integration capabilities with electronics, suffer from relatively high thermo-optic coefficients that exacerbate thermal sensitivity. Alternative materials such as silicon nitride and silica offer improved thermal stability but present their own integration challenges.

Environmental factors further complicate thermal management in microcomb systems. Ambient temperature fluctuations, air currents, and humidity changes can all affect device performance, necessitating hermetic packaging solutions that add complexity and cost to the system. For portable or field-deployed applications, these environmental considerations become even more significant, requiring robust thermal isolation and stabilization mechanisms.

The power efficiency of thermal control systems represents another critical challenge. Active cooling methods typically consume substantial power, which contradicts the goal of developing low-power, compact photonic systems. This power-thermal management tradeoff becomes particularly acute in battery-operated devices or space-constrained applications where thermal management must be achieved within strict power budgets.

As microcomb technology advances toward commercial applications, addressing these thermal management challenges requires interdisciplinary approaches combining innovations in materials science, thermal engineering, control systems, and packaging technologies. The development of integrated, efficient thermal management solutions will be essential for realizing the full potential of chip-scale microcomb generators across diverse application domains.

The thermal sensitivity of microcombs manifests in several ways. Temperature variations as small as 0.01°C can cause resonance wavelength shifts that exceed the resonator linewidth, disrupting the phase-matching conditions necessary for comb generation. This thermal instability directly affects frequency stability, spectral purity, and overall comb coherence—all critical parameters for applications in precision metrology, telecommunications, and quantum information processing.

Current thermal management approaches include passive techniques such as heat sinking and material selection, as well as active methods including thermoelectric cooling and feedback-controlled temperature stabilization. However, these solutions face significant limitations when scaled down to chip dimensions, where thermal gradients become more pronounced and heat dissipation pathways are constrained by the compact geometry.

The integration of thermal control systems with photonic circuits presents additional challenges related to material compatibility, fabrication processes, and power consumption. Silicon-based platforms, while offering excellent integration capabilities with electronics, suffer from relatively high thermo-optic coefficients that exacerbate thermal sensitivity. Alternative materials such as silicon nitride and silica offer improved thermal stability but present their own integration challenges.

Environmental factors further complicate thermal management in microcomb systems. Ambient temperature fluctuations, air currents, and humidity changes can all affect device performance, necessitating hermetic packaging solutions that add complexity and cost to the system. For portable or field-deployed applications, these environmental considerations become even more significant, requiring robust thermal isolation and stabilization mechanisms.

The power efficiency of thermal control systems represents another critical challenge. Active cooling methods typically consume substantial power, which contradicts the goal of developing low-power, compact photonic systems. This power-thermal management tradeoff becomes particularly acute in battery-operated devices or space-constrained applications where thermal management must be achieved within strict power budgets.

As microcomb technology advances toward commercial applications, addressing these thermal management challenges requires interdisciplinary approaches combining innovations in materials science, thermal engineering, control systems, and packaging technologies. The development of integrated, efficient thermal management solutions will be essential for realizing the full potential of chip-scale microcomb generators across diverse application domains.

Current Thermal and Environmental Control Architectures

01 Thermal management systems for chip-scale microcombs

Effective thermal management is crucial for chip-scale microcomb generators to maintain stable operation. These systems include heat sinks, thermal interface materials, and active cooling mechanisms that help dissipate heat generated during operation. Proper thermal control prevents frequency drift and ensures consistent optical output from the microcomb, which is essential for applications requiring high precision and stability.- Thermal management systems for chip-scale microcombs: Effective thermal management is crucial for chip-scale microcomb generators to maintain stable operation. These systems incorporate heat sinks, thermal interface materials, and active cooling mechanisms to dissipate heat generated during operation. Temperature control helps maintain the precise resonance conditions needed for microcomb generation and ensures long-term reliability of the photonic integrated circuits. Advanced thermal management designs can include multi-layer cooling structures and thermally conductive pathways optimized for the unique requirements of microcomb devices.

- Environmental isolation and packaging for microcomb stability: Environmental factors such as humidity, vibration, and atmospheric contaminants can significantly impact microcomb performance. Specialized packaging solutions provide environmental isolation through hermetic sealing, vacuum encapsulation, or inert gas filling to protect sensitive optical components. These packaging techniques shield the microcomb resonators from external disturbances while allowing optical and electrical connections. Advanced designs incorporate vibration dampening structures and moisture barriers to ensure consistent operation across varying environmental conditions.

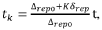

- Integrated temperature control and feedback systems: Precise temperature control is achieved through integrated feedback systems that continuously monitor and adjust operating conditions. These systems incorporate temperature sensors, microheaters, and control electronics directly on the chip to maintain optimal resonator conditions. Feedback loops enable real-time adjustment of thermal parameters to compensate for environmental variations and operational changes. Advanced implementations use machine learning algorithms to predict thermal behavior and proactively adjust settings for maximum stability of the microcomb spectrum.

- Multi-layer thermal isolation structures: Multi-layer thermal isolation structures are designed to minimize thermal crosstalk between different components of the microcomb generator. These structures use alternating layers of materials with different thermal conductivities to create controlled thermal pathways. Selective thermal isolation protects temperature-sensitive resonators while allowing heat dissipation from power-consuming components. Advanced designs incorporate suspended structures, vacuum gaps, or aerogel materials to achieve superior thermal isolation properties while maintaining mechanical stability.

- Adaptive environmental compensation techniques: Adaptive compensation techniques dynamically adjust microcomb operating parameters in response to changing environmental conditions. These systems use sensors to detect variations in temperature, pressure, or humidity and implement corrective measures to maintain stable operation. Software algorithms analyze environmental data and predict necessary adjustments to resonator tuning, pump power, or thermal controls. This approach enables microcomb generators to operate reliably across a wide range of environmental conditions without manual intervention, making them suitable for deployment in diverse applications and settings.

02 Environmental isolation and packaging techniques

Environmental factors such as humidity, dust, and mechanical vibrations can significantly impact microcomb performance. Advanced packaging solutions provide environmental isolation through hermetic sealing, vacuum packaging, and specialized encapsulation materials. These techniques protect sensitive optical components from external disturbances while maintaining optical coupling efficiency and mechanical stability of the microcomb structure.Expand Specific Solutions03 Temperature stabilization and control mechanisms

Precise temperature control is implemented through integrated thermoelectric coolers, microheaters, and temperature sensors that actively stabilize the operating conditions of microcombs. These systems can compensate for ambient temperature variations and internal heat generation, maintaining the resonator at optimal temperature for phase matching and frequency stability. Closed-loop feedback control systems continuously monitor and adjust thermal conditions to ensure consistent microcomb operation.Expand Specific Solutions04 Integration of sensing and feedback systems

Advanced microcomb generators incorporate integrated sensing elements that monitor environmental conditions and operational parameters in real-time. These sensors detect temperature fluctuations, mechanical stress, and optical performance metrics, feeding this data to control systems that make automatic adjustments. The feedback mechanisms ensure stable operation across varying environmental conditions by dynamically compensating for external disturbances and internal changes.Expand Specific Solutions05 Multi-layer substrate designs for thermal isolation

Specialized substrate architectures featuring multiple material layers provide thermal isolation between active optical components and the surrounding environment. These designs incorporate thermal barriers, suspended structures, and selective heat channeling to direct thermal energy away from sensitive components. By strategically managing heat flow paths, these multi-layer substrates minimize thermal crosstalk between different sections of the chip while maintaining mechanical integrity and optical alignment.Expand Specific Solutions

Leading Companies and Research Institutions in Microcomb Development

The thermal and environmental control for chip-scale microcomb generators market is currently in its early growth phase, characterized by significant research activity but limited commercial deployment. The global market size is estimated to be relatively modest but growing rapidly as integrated photonics applications expand. From a technical maturity perspective, this field remains in development with key players approaching the challenges from different angles. Intel, Applied Materials, and GlobalFoundries are leveraging their semiconductor manufacturing expertise to address thermal management challenges, while companies like Schneider Electric and Mitsubishi Electric focus on environmental control systems. Academic institutions including Xidian University and Waseda University are contributing fundamental research. Apple and Sony are exploring applications in consumer electronics, indicating potential future market expansion as the technology matures.

Intel Corp.

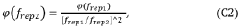

Technical Solution: Intel has developed advanced thermal management solutions for chip-scale microcomb generators that integrate both passive and active cooling technologies. Their approach combines microchannel liquid cooling with thermoelectric coolers (TECs) specifically designed for photonic integrated circuits (PICs). The system maintains temperature stability within ±0.01°C, which is critical for maintaining precise resonance conditions in microresonators[1]. Intel's solution incorporates a multi-layer thermal architecture where heat-generating components are thermally isolated from temperature-sensitive microcomb resonators. They've also implemented real-time thermal monitoring using integrated temperature sensors with sub-millikelvin resolution that feed into a closed-loop control system. This system dynamically adjusts cooling parameters based on operational conditions and environmental changes[3]. Additionally, Intel has developed specialized packaging techniques that minimize thermal expansion mismatches between different materials in the photonic-electronic integration.

Strengths: Superior temperature stability control essential for maintaining precise resonance conditions; integrated approach combining electronic and photonic components on the same platform; extensive manufacturing infrastructure. Weaknesses: Higher power consumption compared to passive-only solutions; increased system complexity requiring sophisticated control algorithms; potential reliability issues at thermal interfaces between different materials.

Applied Materials, Inc.

Technical Solution: Applied Materials has pioneered specialized deposition and etching processes specifically optimized for thermal management in chip-scale microcomb generators. Their approach focuses on material engineering solutions that address thermal challenges at the fabrication level. The company has developed proprietary thin-film deposition techniques that create thermally conductive pathways while maintaining optical isolation where needed[2]. Their thermal solution incorporates diamond-like carbon (DLC) films with thermal conductivity exceeding 1500 W/mK to efficiently dissipate heat from active regions. Applied Materials has also developed specialized atomic layer deposition (ALD) processes for creating nanoscale thermal barrier coatings that can precisely control heat flow within the device structure. These coatings can be selectively applied to create thermal "channels" that direct heat away from temperature-sensitive components[4]. Additionally, they've created advanced etching processes that enable the creation of suspended structures and air gaps that provide thermal isolation between critical components of the microcomb generator.

Strengths: Material-level approach addresses thermal issues at the fabrication stage; highly scalable solutions compatible with semiconductor manufacturing processes; excellent thermal conductivity with minimal impact on optical performance. Weaknesses: Limited active temperature control capabilities compared to TEC-based solutions; requires precise material deposition control; potential long-term reliability concerns with some advanced materials under thermal cycling.

Key Patents and Innovations in Microcomb Thermal Stabilization

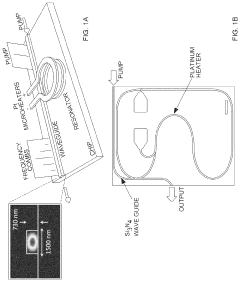

Compact microresonator frequency comb

PatentWO2020076402A1

Innovation

- The use of optimized microresonator actuators and modulators, including single-sideband modulators, graphene modulators, and microheaters, allows for precise control of carrier envelope offset frequency, repetition rate, and resonance offset frequency, enabling long-term locking and reduced noise, while minimizing cross-talk between parameters.

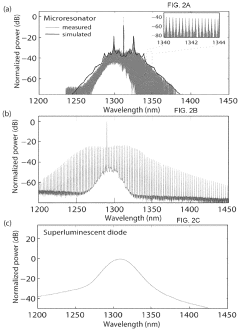

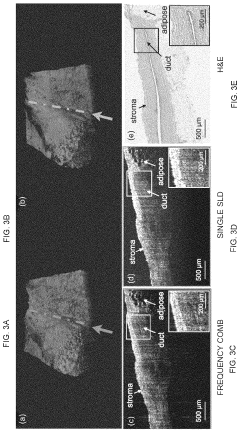

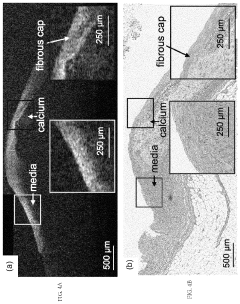

Microresonator-frequency-comb-based platform for clinical high-resolution optical coherence tomography

PatentActiveUS11859972B2

Innovation

- A microresonator-frequency-comb-based platform using high-Q silicon nitride resonators and distributed feedback lasers generates broadband frequency combs, overcoming the bandwidth-power trade-off and enabling sub-micrometer axial resolution and deeper tissue penetration, compatible with standard OCT systems.

Integration Strategies for Commercial Microcomb Systems

The successful commercialization of chip-scale microcomb generators requires comprehensive integration strategies that address thermal and environmental control challenges. Current commercial integration approaches focus on packaging solutions that maintain optimal operating conditions while ensuring scalability and cost-effectiveness.

Hermetic packaging represents a primary integration strategy, providing essential protection against environmental contaminants. Advanced hermetic sealing techniques using glass-to-silicon bonding or ceramic packages with metal lids create controlled microenvironments for microcombs. These packages typically incorporate getter materials to absorb residual gases and moisture, maintaining internal vacuum conditions critical for stable operation.

Thermal management integration has evolved toward active temperature control systems embedded within commercial packages. Thermoelectric coolers (TECs) integrated directly into microcomb packages enable precise temperature regulation within ±0.01°C, addressing the temperature sensitivity of resonance conditions. Recent commercial designs feature miniaturized temperature sensors and control circuits on the same substrate as the microcomb, creating complete thermal management subsystems.

Vibration isolation represents another crucial integration component for commercial systems. Silicon-based MEMS suspension structures and specialized polymer damping materials are being incorporated into commercial packages to isolate microcombs from environmental vibrations. Companies like NTT Electronics and Analog Photonics have developed proprietary vibration isolation platforms that maintain resonator stability in field deployments.

Electrical and optical interface standardization has emerged as a key commercial integration strategy. Industry leaders are adopting standardized fiber coupling approaches using V-groove arrays and automated alignment systems to reduce assembly costs. Electrical interfaces increasingly follow standard protocols compatible with existing photonic integrated circuit (PIC) platforms, facilitating integration with commercial electronics.

Modular design approaches are gaining traction for commercial deployment. Companies like Ligentec and LioniX International offer microcomb modules with standardized interfaces that can be integrated into larger systems. These modules incorporate all necessary thermal and environmental controls within a single package, simplifying system integration for end users.

Manufacturing scalability considerations drive integration strategies for high-volume applications. Wafer-level packaging techniques adapted from the semiconductor industry enable parallel processing of hundreds of microcomb devices simultaneously. Automated testing and calibration procedures integrated into production lines ensure consistent performance across manufactured units while maintaining thermal and environmental specifications.

Hermetic packaging represents a primary integration strategy, providing essential protection against environmental contaminants. Advanced hermetic sealing techniques using glass-to-silicon bonding or ceramic packages with metal lids create controlled microenvironments for microcombs. These packages typically incorporate getter materials to absorb residual gases and moisture, maintaining internal vacuum conditions critical for stable operation.

Thermal management integration has evolved toward active temperature control systems embedded within commercial packages. Thermoelectric coolers (TECs) integrated directly into microcomb packages enable precise temperature regulation within ±0.01°C, addressing the temperature sensitivity of resonance conditions. Recent commercial designs feature miniaturized temperature sensors and control circuits on the same substrate as the microcomb, creating complete thermal management subsystems.

Vibration isolation represents another crucial integration component for commercial systems. Silicon-based MEMS suspension structures and specialized polymer damping materials are being incorporated into commercial packages to isolate microcombs from environmental vibrations. Companies like NTT Electronics and Analog Photonics have developed proprietary vibration isolation platforms that maintain resonator stability in field deployments.

Electrical and optical interface standardization has emerged as a key commercial integration strategy. Industry leaders are adopting standardized fiber coupling approaches using V-groove arrays and automated alignment systems to reduce assembly costs. Electrical interfaces increasingly follow standard protocols compatible with existing photonic integrated circuit (PIC) platforms, facilitating integration with commercial electronics.

Modular design approaches are gaining traction for commercial deployment. Companies like Ligentec and LioniX International offer microcomb modules with standardized interfaces that can be integrated into larger systems. These modules incorporate all necessary thermal and environmental controls within a single package, simplifying system integration for end users.

Manufacturing scalability considerations drive integration strategies for high-volume applications. Wafer-level packaging techniques adapted from the semiconductor industry enable parallel processing of hundreds of microcomb devices simultaneously. Automated testing and calibration procedures integrated into production lines ensure consistent performance across manufactured units while maintaining thermal and environmental specifications.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability are critical considerations in the development and deployment of chip-scale microcomb generators. These devices, while offering revolutionary capabilities for various applications, present significant challenges in terms of power consumption and environmental impact that must be addressed for widespread adoption.

The thermal management of microcombs currently requires substantial energy input, primarily due to the need for precise temperature control to maintain phase matching conditions and resonance stability. Conventional approaches often utilize thermoelectric coolers (TECs) which, while effective, are inherently inefficient energy converters. Recent advancements have focused on reducing this energy footprint through passive cooling techniques and improved thermal isolation structures that minimize heat transfer to surrounding components.

Material selection plays a crucial role in sustainability considerations. Traditional microcomb platforms may incorporate rare earth elements or environmentally problematic materials. Research trends indicate a shift toward more abundant and environmentally benign materials, including silicon nitride and aluminum nitride platforms that offer comparable performance while reducing reliance on scarce resources.

Power consumption optimization represents another frontier in microcomb development. Current systems typically require several watts of electrical power for pump lasers and thermal control systems. Emerging approaches leverage resonant pumping schemes and advanced feedback control algorithms that can potentially reduce operational power requirements by an order of magnitude. These improvements directly translate to extended battery life in portable applications and reduced carbon footprint in fixed installations.

Lifecycle assessment of microcomb technologies reveals opportunities for improvement in manufacturing processes. The fabrication of these devices currently involves energy-intensive cleanroom processes and potentially hazardous chemicals. Innovations in nanofabrication, including additive manufacturing techniques and green chemistry approaches, show promise for reducing both energy consumption and environmental impact during production phases.

Integration with renewable energy sources represents a promising direction for sustainable microcomb deployment. The development of low-power microcombs compatible with solar or kinetic energy harvesting could enable self-powered sensing networks and communication systems with minimal environmental impact. This approach aligns with broader industry trends toward energy-autonomous microsystems.

Standardization efforts around energy efficiency metrics for integrated photonics, including microcombs, are beginning to emerge. These frameworks will enable meaningful comparisons between different technological approaches and drive competition toward more sustainable solutions. Industry consortia and academic partnerships are increasingly focusing on establishing these benchmarks to guide future development.

The thermal management of microcombs currently requires substantial energy input, primarily due to the need for precise temperature control to maintain phase matching conditions and resonance stability. Conventional approaches often utilize thermoelectric coolers (TECs) which, while effective, are inherently inefficient energy converters. Recent advancements have focused on reducing this energy footprint through passive cooling techniques and improved thermal isolation structures that minimize heat transfer to surrounding components.

Material selection plays a crucial role in sustainability considerations. Traditional microcomb platforms may incorporate rare earth elements or environmentally problematic materials. Research trends indicate a shift toward more abundant and environmentally benign materials, including silicon nitride and aluminum nitride platforms that offer comparable performance while reducing reliance on scarce resources.

Power consumption optimization represents another frontier in microcomb development. Current systems typically require several watts of electrical power for pump lasers and thermal control systems. Emerging approaches leverage resonant pumping schemes and advanced feedback control algorithms that can potentially reduce operational power requirements by an order of magnitude. These improvements directly translate to extended battery life in portable applications and reduced carbon footprint in fixed installations.

Lifecycle assessment of microcomb technologies reveals opportunities for improvement in manufacturing processes. The fabrication of these devices currently involves energy-intensive cleanroom processes and potentially hazardous chemicals. Innovations in nanofabrication, including additive manufacturing techniques and green chemistry approaches, show promise for reducing both energy consumption and environmental impact during production phases.

Integration with renewable energy sources represents a promising direction for sustainable microcomb deployment. The development of low-power microcombs compatible with solar or kinetic energy harvesting could enable self-powered sensing networks and communication systems with minimal environmental impact. This approach aligns with broader industry trends toward energy-autonomous microsystems.

Standardization efforts around energy efficiency metrics for integrated photonics, including microcombs, are beginning to emerge. These frameworks will enable meaningful comparisons between different technological approaches and drive competition toward more sustainable solutions. Industry consortia and academic partnerships are increasingly focusing on establishing these benchmarks to guide future development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!