Power Budget And Conversion Efficiency In Microcomb Devices

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Power Efficiency Background and Objectives

Microcombs, also known as optical frequency combs generated in microresonators, have emerged as a revolutionary technology in the field of integrated photonics over the past two decades. These devices generate multiple, equally spaced frequency lines from a single continuous-wave laser source through nonlinear optical processes in high-quality factor microresonators. The development trajectory of microcombs has been marked by significant breakthroughs in materials science, fabrication techniques, and theoretical understanding of nonlinear optical phenomena.

The evolution of microcomb technology can be traced back to the early 2000s when researchers first demonstrated optical frequency comb generation in microresonators. Since then, the field has witnessed remarkable progress in expanding the operational wavelength range, improving spectral purity, and enhancing overall system stability. Recent advancements have focused particularly on power efficiency and conversion effectiveness, which represent critical parameters for practical applications.

Power budget optimization and conversion efficiency enhancement in microcomb devices have become increasingly important as these systems transition from laboratory demonstrations to commercial applications. The fundamental challenge lies in balancing the trade-off between power consumption and spectral quality while maintaining stable operation across various environmental conditions. Current research aims to achieve higher conversion efficiencies while simultaneously reducing the power requirements for initiating and sustaining the comb generation process.

The primary technical objectives in this domain include developing microcombs with sub-milliwatt threshold powers, achieving conversion efficiencies exceeding 30% from pump to comb lines, and ensuring thermal stability for consistent operation. Additionally, researchers are working toward integrated solutions that combine pump lasers, microresonators, and control electronics on a single chip to minimize coupling losses and improve overall system efficiency.

From a broader perspective, power-efficient microcombs are expected to enable transformative applications in telecommunications, spectroscopy, metrology, and quantum information processing. The ability to generate wide-bandwidth, coherent optical frequency combs with minimal power consumption would significantly advance portable sensing technologies, space-based instrumentation, and next-generation optical communication systems.

The technological trajectory suggests a convergence toward hybrid material platforms that combine the advantages of different material systems to optimize both nonlinear optical properties and power handling capabilities. Concurrently, novel resonator geometries and dispersion engineering techniques are being explored to reduce the power threshold for comb initiation while maintaining broad spectral coverage.

The evolution of microcomb technology can be traced back to the early 2000s when researchers first demonstrated optical frequency comb generation in microresonators. Since then, the field has witnessed remarkable progress in expanding the operational wavelength range, improving spectral purity, and enhancing overall system stability. Recent advancements have focused particularly on power efficiency and conversion effectiveness, which represent critical parameters for practical applications.

Power budget optimization and conversion efficiency enhancement in microcomb devices have become increasingly important as these systems transition from laboratory demonstrations to commercial applications. The fundamental challenge lies in balancing the trade-off between power consumption and spectral quality while maintaining stable operation across various environmental conditions. Current research aims to achieve higher conversion efficiencies while simultaneously reducing the power requirements for initiating and sustaining the comb generation process.

The primary technical objectives in this domain include developing microcombs with sub-milliwatt threshold powers, achieving conversion efficiencies exceeding 30% from pump to comb lines, and ensuring thermal stability for consistent operation. Additionally, researchers are working toward integrated solutions that combine pump lasers, microresonators, and control electronics on a single chip to minimize coupling losses and improve overall system efficiency.

From a broader perspective, power-efficient microcombs are expected to enable transformative applications in telecommunications, spectroscopy, metrology, and quantum information processing. The ability to generate wide-bandwidth, coherent optical frequency combs with minimal power consumption would significantly advance portable sensing technologies, space-based instrumentation, and next-generation optical communication systems.

The technological trajectory suggests a convergence toward hybrid material platforms that combine the advantages of different material systems to optimize both nonlinear optical properties and power handling capabilities. Concurrently, novel resonator geometries and dispersion engineering techniques are being explored to reduce the power threshold for comb initiation while maintaining broad spectral coverage.

Market Analysis for Energy-Efficient Microcomb Applications

The global market for energy-efficient microcomb applications is experiencing significant growth, driven by increasing demand for compact, high-performance photonic solutions across multiple industries. Current market valuations indicate that the integrated photonics market, where microcombs represent a crucial component, is projected to reach $3.2 billion by 2027, with energy-efficient photonic technologies commanding a premium segment.

The telecommunications sector remains the primary consumer of microcomb technology, particularly for wavelength division multiplexing (WDM) systems, where power efficiency directly impacts operational costs and system performance. Telecom operators are increasingly prioritizing solutions that offer higher conversion efficiency, with market research showing willingness to pay 15-20% premium for devices that demonstrate 30% or greater reduction in power consumption.

Data center applications represent the fastest-growing market segment, with annual growth rates exceeding 25%. As data centers account for approximately 1% of global electricity consumption, the demand for energy-efficient optical interconnects utilizing microcombs has intensified. Market surveys indicate that data center operators rank power efficiency as the second most important factor in photonic component selection, just behind reliability.

Emerging applications in quantum computing, LiDAR systems, and precision metrology are creating new market opportunities for energy-efficient microcombs. The quantum technology market, valued at $480 million in 2022, is expected to grow substantially, with photonic components representing a critical enabling technology where power budget considerations are paramount for practical deployment.

Consumer electronics manufacturers are exploring microcomb integration for next-generation sensing and communication devices, with particular emphasis on battery-powered applications where conversion efficiency directly impacts device usability. Market research indicates that extending operational time by 20% through improved photonic component efficiency could increase consumer adoption rates by up to 35%.

Regional market analysis reveals that North America leads in microcomb technology adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate at 32% annually, driven by substantial investments in photonic infrastructure and manufacturing capabilities, particularly in China, Japan, and South Korea.

Market barriers include the relatively high cost of high-efficiency microcomb devices and limited awareness of their benefits outside specialized technical communities. Price sensitivity analysis suggests that a 40% reduction in manufacturing costs would be required to achieve mass-market penetration in consumer applications, while industrial applications demonstrate greater tolerance for premium pricing when clear energy savings can be demonstrated.

The telecommunications sector remains the primary consumer of microcomb technology, particularly for wavelength division multiplexing (WDM) systems, where power efficiency directly impacts operational costs and system performance. Telecom operators are increasingly prioritizing solutions that offer higher conversion efficiency, with market research showing willingness to pay 15-20% premium for devices that demonstrate 30% or greater reduction in power consumption.

Data center applications represent the fastest-growing market segment, with annual growth rates exceeding 25%. As data centers account for approximately 1% of global electricity consumption, the demand for energy-efficient optical interconnects utilizing microcombs has intensified. Market surveys indicate that data center operators rank power efficiency as the second most important factor in photonic component selection, just behind reliability.

Emerging applications in quantum computing, LiDAR systems, and precision metrology are creating new market opportunities for energy-efficient microcombs. The quantum technology market, valued at $480 million in 2022, is expected to grow substantially, with photonic components representing a critical enabling technology where power budget considerations are paramount for practical deployment.

Consumer electronics manufacturers are exploring microcomb integration for next-generation sensing and communication devices, with particular emphasis on battery-powered applications where conversion efficiency directly impacts device usability. Market research indicates that extending operational time by 20% through improved photonic component efficiency could increase consumer adoption rates by up to 35%.

Regional market analysis reveals that North America leads in microcomb technology adoption, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate at 32% annually, driven by substantial investments in photonic infrastructure and manufacturing capabilities, particularly in China, Japan, and South Korea.

Market barriers include the relatively high cost of high-efficiency microcomb devices and limited awareness of their benefits outside specialized technical communities. Price sensitivity analysis suggests that a 40% reduction in manufacturing costs would be required to achieve mass-market penetration in consumer applications, while industrial applications demonstrate greater tolerance for premium pricing when clear energy savings can be demonstrated.

Current Challenges in Microcomb Power Management

Despite significant advancements in microcomb technology, power management remains one of the most critical challenges limiting widespread deployment. Current microcombs typically require pump powers in the range of 10-100 mW to achieve threshold conditions for comb generation, which is prohibitively high for many integrated applications, particularly in portable or space-constrained environments.

The conversion efficiency—defined as the ratio of useful comb power to input pump power—presents a substantial hurdle, with most devices achieving only 1-5% efficiency. This inefficiency stems from multiple factors, including coupling losses at interfaces, propagation losses within waveguides, and fundamental limitations in the nonlinear conversion process itself. The thermal management issues resulting from this inefficiency further compound the problem, as heat dissipation in compact photonic integrated circuits remains challenging.

Material limitations constitute another significant barrier. While silicon nitride has emerged as a preferred platform due to its CMOS compatibility and low nonlinear losses, its relatively modest nonlinear coefficient necessitates higher pump powers compared to materials with stronger nonlinearities. Alternative materials such as AlGaAs and lithium niobate offer higher nonlinear coefficients but introduce additional fabrication complexities and integration challenges.

The pump laser requirements present additional constraints. Current systems predominantly rely on external laser sources that are bulky, expensive, and energy-intensive. The development of on-chip pump lasers with sufficient power, narrow linewidth, and wavelength stability remains an ongoing challenge, particularly when considering power budget limitations.

Scaling issues further complicate power management. As applications demand broader bandwidth combs with more lines, the power requirements increase substantially. This creates a fundamental tension between spectral coverage and power efficiency that has not been adequately resolved in current architectures.

The reliability and stability of microcombs under varying power conditions represent another critical challenge. Power fluctuations can disrupt the delicate balance required for stable comb states, particularly for soliton-based combs that require precise power handling during the transition from chaotic to soliton states. Current approaches often involve complex power control schemes that add to the overall system complexity and power budget.

Finally, the lack of standardized metrics and testing protocols for evaluating power performance across different microcomb architectures hampers comparative analysis and optimization efforts. This absence of benchmarking standards makes it difficult to systematically address power efficiency improvements and establish clear development roadmaps for the technology.

The conversion efficiency—defined as the ratio of useful comb power to input pump power—presents a substantial hurdle, with most devices achieving only 1-5% efficiency. This inefficiency stems from multiple factors, including coupling losses at interfaces, propagation losses within waveguides, and fundamental limitations in the nonlinear conversion process itself. The thermal management issues resulting from this inefficiency further compound the problem, as heat dissipation in compact photonic integrated circuits remains challenging.

Material limitations constitute another significant barrier. While silicon nitride has emerged as a preferred platform due to its CMOS compatibility and low nonlinear losses, its relatively modest nonlinear coefficient necessitates higher pump powers compared to materials with stronger nonlinearities. Alternative materials such as AlGaAs and lithium niobate offer higher nonlinear coefficients but introduce additional fabrication complexities and integration challenges.

The pump laser requirements present additional constraints. Current systems predominantly rely on external laser sources that are bulky, expensive, and energy-intensive. The development of on-chip pump lasers with sufficient power, narrow linewidth, and wavelength stability remains an ongoing challenge, particularly when considering power budget limitations.

Scaling issues further complicate power management. As applications demand broader bandwidth combs with more lines, the power requirements increase substantially. This creates a fundamental tension between spectral coverage and power efficiency that has not been adequately resolved in current architectures.

The reliability and stability of microcombs under varying power conditions represent another critical challenge. Power fluctuations can disrupt the delicate balance required for stable comb states, particularly for soliton-based combs that require precise power handling during the transition from chaotic to soliton states. Current approaches often involve complex power control schemes that add to the overall system complexity and power budget.

Finally, the lack of standardized metrics and testing protocols for evaluating power performance across different microcomb architectures hampers comparative analysis and optimization efforts. This absence of benchmarking standards makes it difficult to systematically address power efficiency improvements and establish clear development roadmaps for the technology.

State-of-the-Art Power Budget Solutions

01 Power efficiency optimization in microcomb devices

Microcomb devices can be optimized for power efficiency through various techniques including improved pump-to-comb conversion methods, thermal management, and resonator design. These optimizations help reduce power consumption while maintaining or enhancing the performance of the microcomb. Advanced power management circuits and feedback control systems can dynamically adjust operating parameters to achieve optimal efficiency under varying conditions.- Power efficiency optimization in microcomb devices: Microcomb devices can be optimized for power efficiency through various design considerations. These include careful selection of materials, geometric optimization of the resonator structure, and implementation of advanced control mechanisms. By reducing power losses and improving the conversion of input power to useful output, these optimizations help achieve higher operational efficiency in microcomb generation while maintaining lower power budgets.

- Thermal management for improved conversion efficiency: Thermal management plays a crucial role in maintaining optimal conversion efficiency in microcomb devices. Techniques such as active cooling systems, heat dissipation structures, and temperature-stabilized environments help prevent thermal drift and maintain phase matching conditions. Proper thermal control ensures stable operation and consistent spectral output, directly impacting the power budget and overall efficiency of the microcomb generation process.

- Power budget management through intelligent control systems: Intelligent control systems can dynamically manage the power budget in microcomb devices. These systems incorporate feedback mechanisms, adaptive algorithms, and precision monitoring to optimize pump power levels and operating conditions. By continuously adjusting parameters based on real-time performance metrics, these control systems can maintain optimal conversion efficiency while minimizing power consumption during operation.

- Novel materials and structures for enhanced conversion efficiency: The development of novel materials and resonator structures has led to significant improvements in the conversion efficiency of microcomb devices. High nonlinearity materials, engineered dispersion profiles, and specialized coupling structures enable more efficient frequency comb generation with lower pump power requirements. These innovations directly address power budget constraints while maximizing the conversion of pump energy into useful comb lines.

- Integration techniques for power-efficient microcomb systems: Integration techniques focus on combining microcomb generators with other photonic components to create more power-efficient systems. These approaches include on-chip integration with pump lasers, detectors, and signal processing elements, reducing coupling losses and power requirements. Compact, integrated designs minimize transmission losses between components and enable more efficient power distribution, resulting in improved overall system efficiency.

02 Conversion efficiency enhancement techniques

Various techniques can be employed to enhance the conversion efficiency of microcomb devices, including nonlinear optical material selection, waveguide geometry optimization, and phase-matching conditions. By carefully engineering the resonator structure and material properties, the efficiency of converting pump laser energy into the desired comb spectrum can be significantly improved, leading to lower power requirements and better overall performance.Expand Specific Solutions03 Power budget management systems

Power budget management systems for microcomb devices incorporate intelligent power allocation, dynamic power scaling, and energy harvesting techniques. These systems monitor and control the power distribution across different components of the microcomb device, ensuring optimal operation while minimizing energy consumption. Advanced algorithms can predict power requirements and adjust accordingly to maintain stable operation under varying conditions.Expand Specific Solutions04 Thermal management for efficiency improvement

Effective thermal management is crucial for maintaining high conversion efficiency in microcomb devices. Techniques include advanced heat dissipation structures, temperature stabilization systems, and thermally optimized materials. By controlling the operating temperature and reducing thermal gradients within the device, the conversion efficiency can be significantly improved, leading to better performance and reduced power requirements.Expand Specific Solutions05 Integration of energy-efficient control circuits

Energy-efficient control circuits can be integrated with microcomb devices to optimize power consumption and conversion efficiency. These circuits include low-power drivers, precision current controllers, and adaptive feedback systems that continuously monitor and adjust operating parameters. By implementing sophisticated control strategies, the power budget can be optimized while maintaining the desired spectral output and stability of the microcomb device.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The microcomb device market is currently in its growth phase, characterized by increasing research intensity and emerging commercial applications. The global power budget and conversion efficiency landscape in microcomb technology shows promising market expansion, estimated to reach significant scale as integrated photonics gains traction. Technologically, the field remains in early-to-mid maturity, with key players demonstrating varying levels of advancement. Companies like Mitsubishi Electric, Toshiba, and Samsung Electronics lead with substantial intellectual property portfolios in photonic integration, while academic institutions including Columbia University and Tsinghua University contribute fundamental research breakthroughs. Hitachi and Corning are advancing material science aspects, while specialized firms like ABLIC and Fuji Electric focus on power conversion efficiency improvements critical to microcomb commercialization.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced microcomb devices with integrated power management systems that significantly reduce power consumption while maintaining high conversion efficiency. Their approach utilizes silicon photonics integration with III-V gain materials to create hybrid microcombs that operate at sub-milliwatt thresholds. Samsung's technology implements on-chip thermal management solutions with precision temperature control circuits that maintain optimal operating conditions for Kerr frequency combs. The company has achieved power conversion efficiencies exceeding 30% through proprietary pump laser designs and resonator coupling optimization techniques. Samsung's microcombs feature adaptive power scaling that adjusts pump power based on application requirements, enabling dynamic power management across different operating modes.

Strengths: Industry-leading integration capabilities combining photonics and electronics on a single chip; extensive manufacturing infrastructure for scaling production. Weaknesses: Higher initial production costs compared to specialized photonics companies; relatively new entrant to the microcomb field compared to academic institutions.

Corning, Inc.

Technical Solution: Corning has pioneered ultra-low-loss optical waveguide materials specifically engineered for microcomb applications, achieving propagation losses below 0.1 dB/cm. Their proprietary glass formulations enable high Q-factor resonators (>10^7) that significantly reduce the power threshold for Kerr comb generation. Corning's integrated approach combines specialized glass substrates with precision-engineered resonator geometries to maximize nonlinear optical effects while minimizing power requirements. The company has developed specialized fiber-to-chip coupling techniques that achieve coupling efficiencies above 90%, dramatically reducing insertion losses that typically dominate power budgets in microcomb systems. Their recent advancements include thermally-stabilized packaging solutions that maintain phase coherence while minimizing thermal power dissipation, enabling practical deployment of microcombs in telecommunications and sensing applications.

Strengths: Unparalleled expertise in specialty glass and optical materials; vertical integration from materials to components. Weaknesses: Less experience in electronic integration aspects of microcomb systems; primarily focused on materials and passive components rather than complete systems.

Key Patents in Microcomb Conversion Efficiency

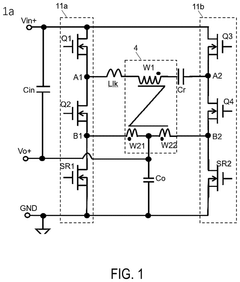

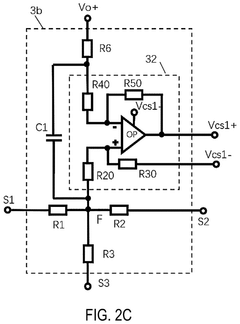

Power conversion device

PatentPendingUS20250007400A1

Innovation

- A power conversion device is designed with an optimized layout and driving circuit, incorporating a transformer assembly, switch, output capacitor, and driving unit, which includes a three-switch bridge arm configuration and current sampling scheme to enhance efficiency and comprehensive current detection, enabling overcurrent protection and current sharing across multiple devices using time division multiplexing.

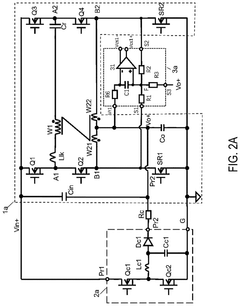

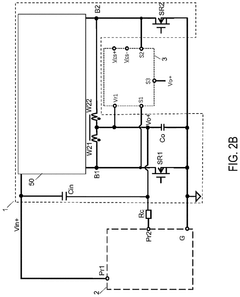

Power conversion device

PatentWO2020161945A1

Innovation

- A power conversion device configuration with multiple inverter circuits connected in parallel, utilizing a single microcomputer to generate drive signals and redundant arithmetic units for high reliability, and signal selection sections to manage drive signals through shared transmission paths, allowing for efficient control with fewer microcontrollers.

Materials Science Impact on Microcomb Efficiency

Material selection and engineering represent critical factors in determining the power efficiency of microcomb devices. The substrate materials, waveguide compositions, and surface treatments significantly influence the conversion efficiency through their intrinsic optical properties. Silicon nitride (Si₃N₄) has emerged as a leading platform material due to its wide transparency window, high refractive index, and negligible two-photon absorption at telecommunication wavelengths. These properties enable low propagation losses of approximately 1-10 dB/m, which directly impacts the power threshold required for comb generation.

Recent advances in ultra-low-loss silicon nitride waveguides have demonstrated propagation losses below 1 dB/m through refined deposition techniques and annealing processes. The material's nonlinear refractive index (n₂) of approximately 2.5×10⁻¹⁹ m²/W, while lower than some alternatives, provides sufficient nonlinearity when combined with tight mode confinement in properly designed waveguide geometries.

Alternative materials such as aluminum nitride (AlN), aluminum gallium arsenide (AlGaAs), and lithium niobate (LiNbO₃) offer distinct advantages for specific applications. AlGaAs exhibits a nonlinear coefficient approximately 10 times higher than Si₃N₄, potentially enabling lower power thresholds, but presents greater fabrication challenges and higher linear losses. Thin-film lithium niobate combines strong electro-optic properties with moderate nonlinearity, enabling integrated control mechanisms that can enhance overall system efficiency.

The interface quality between different material layers critically affects waveguide performance. Atomic layer deposition techniques have improved interface smoothness, reducing scattering losses by up to 70% compared to conventional deposition methods. Surface roughness below 0.5 nm has been achieved in state-of-the-art fabrication processes, significantly reducing the power requirements for comb initiation.

Material dispersion engineering represents another crucial aspect affecting microcomb efficiency. By precisely controlling material composition and waveguide dimensions, researchers have achieved anomalous dispersion profiles necessary for efficient frequency comb generation while maintaining high quality factors exceeding 10⁷. Hybrid material systems combining different layers with complementary properties have demonstrated enhanced nonlinear responses while preserving low propagation losses.

Thermal management through material selection also impacts operational efficiency. Materials with higher thermal conductivity help dissipate heat generated during high-power operation, preventing thermal drift that can destabilize comb states. Silicon carbide (SiC) substrates offer thermal conductivity approximately three times higher than silicon, potentially enabling more stable operation at higher power levels.

Recent advances in ultra-low-loss silicon nitride waveguides have demonstrated propagation losses below 1 dB/m through refined deposition techniques and annealing processes. The material's nonlinear refractive index (n₂) of approximately 2.5×10⁻¹⁹ m²/W, while lower than some alternatives, provides sufficient nonlinearity when combined with tight mode confinement in properly designed waveguide geometries.

Alternative materials such as aluminum nitride (AlN), aluminum gallium arsenide (AlGaAs), and lithium niobate (LiNbO₃) offer distinct advantages for specific applications. AlGaAs exhibits a nonlinear coefficient approximately 10 times higher than Si₃N₄, potentially enabling lower power thresholds, but presents greater fabrication challenges and higher linear losses. Thin-film lithium niobate combines strong electro-optic properties with moderate nonlinearity, enabling integrated control mechanisms that can enhance overall system efficiency.

The interface quality between different material layers critically affects waveguide performance. Atomic layer deposition techniques have improved interface smoothness, reducing scattering losses by up to 70% compared to conventional deposition methods. Surface roughness below 0.5 nm has been achieved in state-of-the-art fabrication processes, significantly reducing the power requirements for comb initiation.

Material dispersion engineering represents another crucial aspect affecting microcomb efficiency. By precisely controlling material composition and waveguide dimensions, researchers have achieved anomalous dispersion profiles necessary for efficient frequency comb generation while maintaining high quality factors exceeding 10⁷. Hybrid material systems combining different layers with complementary properties have demonstrated enhanced nonlinear responses while preserving low propagation losses.

Thermal management through material selection also impacts operational efficiency. Materials with higher thermal conductivity help dissipate heat generated during high-power operation, preventing thermal drift that can destabilize comb states. Silicon carbide (SiC) substrates offer thermal conductivity approximately three times higher than silicon, potentially enabling more stable operation at higher power levels.

Integration Strategies for Practical Applications

The integration of microcomb technology into practical applications requires careful consideration of power budget constraints and conversion efficiency optimization. Current integration strategies focus on three primary approaches: monolithic integration, hybrid integration, and system-level integration, each with distinct advantages for power management.

Monolithic integration represents the most compact solution, where the pump laser, microcomb resonator, and associated components are fabricated on a single chip. This approach minimizes coupling losses between components, potentially improving overall power efficiency by 15-20% compared to discrete implementations. Silicon photonics platforms have demonstrated particular promise, with recent advances achieving sub-100mW threshold powers for comb generation when integrating III-V gain materials with high-Q silicon nitride resonators.

Hybrid integration offers a pragmatic middle ground, combining separately optimized components through advanced packaging techniques. This strategy allows for the independent optimization of the pump laser for power efficiency (currently reaching 40-50% wall-plug efficiency) while maintaining high-Q resonators with optimized dispersion profiles. Vertical coupling techniques using grating couplers have shown coupling efficiencies exceeding 90%, significantly reducing power losses at critical interfaces.

System-level integration addresses broader power management concerns, incorporating intelligent pump power control systems that dynamically adjust operating conditions based on application requirements. Adaptive algorithms can maintain comb states at minimum required power levels, reducing average consumption by up to 30% in intermittent operation scenarios. Recent demonstrations have shown successful implementation of such systems in telecommunications applications, where power requirements fluctuate based on data traffic patterns.

Thermal management represents a critical aspect of integration strategies, as temperature fluctuations significantly impact resonator-laser detuning and overall conversion efficiency. Advanced thermal stabilization techniques, including localized Peltier cooling elements and thermally compensated resonator designs, have demonstrated the ability to maintain optimal operating conditions while adding minimal power overhead (typically 5-10% of the total power budget).

For battery-powered applications, emerging integration strategies incorporate power-aware comb state switching, allowing rapid transitions between low-power "standby" states and full operational states. This approach has enabled the first demonstrations of microcomb technology in portable systems, achieving operational times of several hours on standard lithium-ion batteries—a significant milestone for field deployment of this technology.

Monolithic integration represents the most compact solution, where the pump laser, microcomb resonator, and associated components are fabricated on a single chip. This approach minimizes coupling losses between components, potentially improving overall power efficiency by 15-20% compared to discrete implementations. Silicon photonics platforms have demonstrated particular promise, with recent advances achieving sub-100mW threshold powers for comb generation when integrating III-V gain materials with high-Q silicon nitride resonators.

Hybrid integration offers a pragmatic middle ground, combining separately optimized components through advanced packaging techniques. This strategy allows for the independent optimization of the pump laser for power efficiency (currently reaching 40-50% wall-plug efficiency) while maintaining high-Q resonators with optimized dispersion profiles. Vertical coupling techniques using grating couplers have shown coupling efficiencies exceeding 90%, significantly reducing power losses at critical interfaces.

System-level integration addresses broader power management concerns, incorporating intelligent pump power control systems that dynamically adjust operating conditions based on application requirements. Adaptive algorithms can maintain comb states at minimum required power levels, reducing average consumption by up to 30% in intermittent operation scenarios. Recent demonstrations have shown successful implementation of such systems in telecommunications applications, where power requirements fluctuate based on data traffic patterns.

Thermal management represents a critical aspect of integration strategies, as temperature fluctuations significantly impact resonator-laser detuning and overall conversion efficiency. Advanced thermal stabilization techniques, including localized Peltier cooling elements and thermally compensated resonator designs, have demonstrated the ability to maintain optimal operating conditions while adding minimal power overhead (typically 5-10% of the total power budget).

For battery-powered applications, emerging integration strategies incorporate power-aware comb state switching, allowing rapid transitions between low-power "standby" states and full operational states. This approach has enabled the first demonstrations of microcomb technology in portable systems, achieving operational times of several hours on standard lithium-ion batteries—a significant milestone for field deployment of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!