Microcomb Pre-Compensation Techniques For Environmental Variability

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Technology Background and Objectives

Microcombs, or optical frequency combs generated from microresonators, have emerged as a revolutionary technology in the field of photonics over the past two decades. These devices generate precisely spaced optical frequency lines through nonlinear optical processes in high-quality factor microresonators. The evolution of microcomb technology began with fundamental research in the early 2000s, progressing rapidly through laboratory demonstrations to the current phase of practical applications development.

The technological trajectory has been marked by significant breakthroughs in materials science, fabrication techniques, and control methodologies. Initially limited to specialized laboratory environments, microcombs have gradually transitioned toward integration with photonic integrated circuits, enabling miniaturization and potential mass production. This evolution reflects the broader trend in photonics toward chip-scale solutions for complex optical systems.

Environmental variability presents a critical challenge to microcomb performance and reliability. Temperature fluctuations, mechanical vibrations, and other environmental factors can significantly alter the resonance conditions of microresonators, disrupting comb formation and stability. These environmental sensitivities have historically limited the deployment of microcombs in real-world applications outside controlled laboratory settings.

Pre-compensation techniques represent a promising approach to address these environmental challenges. These methods aim to anticipate and counteract environmental disturbances before they affect comb operation, rather than merely responding to changes after they occur. The development of such techniques marks a shift from passive stability to active control paradigms in microcomb technology.

The primary technical objectives in this field include developing robust pre-compensation algorithms that can predict environmental variations with high accuracy, implementing real-time control systems with sufficient bandwidth to address rapid environmental changes, and integrating these solutions with existing microcomb platforms without compromising their performance advantages or significantly increasing system complexity.

Long-term technological goals include achieving autonomous operation of microcombs in variable environments, reducing power consumption of control systems to enable portable applications, and standardizing pre-compensation approaches to facilitate broader adoption across different application domains. The ultimate vision is to transform microcombs from sensitive laboratory instruments to reliable components in deployed photonic systems for telecommunications, spectroscopy, metrology, and quantum information processing.

The convergence of advanced control theory, machine learning techniques, and integrated photonics is expected to accelerate progress in this field, potentially enabling microcombs to fulfill their promise as versatile tools for next-generation optical technologies despite environmental challenges.

The technological trajectory has been marked by significant breakthroughs in materials science, fabrication techniques, and control methodologies. Initially limited to specialized laboratory environments, microcombs have gradually transitioned toward integration with photonic integrated circuits, enabling miniaturization and potential mass production. This evolution reflects the broader trend in photonics toward chip-scale solutions for complex optical systems.

Environmental variability presents a critical challenge to microcomb performance and reliability. Temperature fluctuations, mechanical vibrations, and other environmental factors can significantly alter the resonance conditions of microresonators, disrupting comb formation and stability. These environmental sensitivities have historically limited the deployment of microcombs in real-world applications outside controlled laboratory settings.

Pre-compensation techniques represent a promising approach to address these environmental challenges. These methods aim to anticipate and counteract environmental disturbances before they affect comb operation, rather than merely responding to changes after they occur. The development of such techniques marks a shift from passive stability to active control paradigms in microcomb technology.

The primary technical objectives in this field include developing robust pre-compensation algorithms that can predict environmental variations with high accuracy, implementing real-time control systems with sufficient bandwidth to address rapid environmental changes, and integrating these solutions with existing microcomb platforms without compromising their performance advantages or significantly increasing system complexity.

Long-term technological goals include achieving autonomous operation of microcombs in variable environments, reducing power consumption of control systems to enable portable applications, and standardizing pre-compensation approaches to facilitate broader adoption across different application domains. The ultimate vision is to transform microcombs from sensitive laboratory instruments to reliable components in deployed photonic systems for telecommunications, spectroscopy, metrology, and quantum information processing.

The convergence of advanced control theory, machine learning techniques, and integrated photonics is expected to accelerate progress in this field, potentially enabling microcombs to fulfill their promise as versatile tools for next-generation optical technologies despite environmental challenges.

Market Applications and Demand Analysis

The market for microcomb pre-compensation techniques addressing environmental variability is experiencing significant growth, driven by the increasing demand for reliable photonic integrated circuits across multiple industries. Telecommunications represents the primary market segment, where microcombs enable wavelength division multiplexing systems with unprecedented channel counts and spectral efficiency. As 5G and future 6G networks expand, the need for environmentally stable optical frequency combs becomes critical for high-capacity fiber optic communications.

Data centers constitute another substantial market, with the exponential growth in cloud computing driving demand for energy-efficient, high-bandwidth interconnects. Microcombs with robust environmental compensation techniques offer significant advantages in reducing power consumption while increasing data throughput. Industry analysts project that photonic interconnects utilizing advanced microcomb technology could reduce data center energy consumption by up to 30% compared to traditional electronic interconnects.

The test and measurement equipment sector represents a specialized but high-value market segment. Precision frequency references enabled by environmentally stable microcombs are essential for calibrating scientific and industrial equipment. This market demands the highest performance levels, with frequency stability requirements often in the sub-Hz range across varying environmental conditions.

Emerging applications in quantum computing and quantum communications are creating new market opportunities. Quantum systems require precise frequency control and environmental stability for maintaining coherence, making advanced microcomb pre-compensation techniques particularly valuable. Though currently smaller in market size, this segment shows the highest projected growth rate among all applications.

Aerospace and defense applications represent another significant market, where harsh environmental conditions necessitate robust pre-compensation techniques. Satellite communications, LIDAR systems, and advanced radar all benefit from environmentally stable frequency combs that can maintain performance across extreme temperature variations and mechanical stress.

The healthcare and biomedical sensing market is increasingly adopting microcomb technology for applications such as optical coherence tomography and spectroscopic sensing. These applications require reliable operation in clinical environments with varying conditions, driving demand for pre-compensation techniques that ensure consistent performance.

Market adoption faces challenges related to cost, integration complexity, and competition from alternative technologies. However, as manufacturing scales and integration techniques improve, the cost barriers are expected to decrease. The market is currently transitioning from research-focused applications to commercial deployment, with several companies developing proprietary pre-compensation techniques to address environmental variability challenges.

Data centers constitute another substantial market, with the exponential growth in cloud computing driving demand for energy-efficient, high-bandwidth interconnects. Microcombs with robust environmental compensation techniques offer significant advantages in reducing power consumption while increasing data throughput. Industry analysts project that photonic interconnects utilizing advanced microcomb technology could reduce data center energy consumption by up to 30% compared to traditional electronic interconnects.

The test and measurement equipment sector represents a specialized but high-value market segment. Precision frequency references enabled by environmentally stable microcombs are essential for calibrating scientific and industrial equipment. This market demands the highest performance levels, with frequency stability requirements often in the sub-Hz range across varying environmental conditions.

Emerging applications in quantum computing and quantum communications are creating new market opportunities. Quantum systems require precise frequency control and environmental stability for maintaining coherence, making advanced microcomb pre-compensation techniques particularly valuable. Though currently smaller in market size, this segment shows the highest projected growth rate among all applications.

Aerospace and defense applications represent another significant market, where harsh environmental conditions necessitate robust pre-compensation techniques. Satellite communications, LIDAR systems, and advanced radar all benefit from environmentally stable frequency combs that can maintain performance across extreme temperature variations and mechanical stress.

The healthcare and biomedical sensing market is increasingly adopting microcomb technology for applications such as optical coherence tomography and spectroscopic sensing. These applications require reliable operation in clinical environments with varying conditions, driving demand for pre-compensation techniques that ensure consistent performance.

Market adoption faces challenges related to cost, integration complexity, and competition from alternative technologies. However, as manufacturing scales and integration techniques improve, the cost barriers are expected to decrease. The market is currently transitioning from research-focused applications to commercial deployment, with several companies developing proprietary pre-compensation techniques to address environmental variability challenges.

Current Challenges in Environmental Stability

Despite significant advancements in microcomb technology, environmental stability remains one of the most critical challenges hindering widespread deployment in practical applications. Temperature fluctuations represent the primary destabilizing factor, causing thermal expansion of cavity materials and thermo-optic effects that shift resonance frequencies. Even minor temperature variations of 0.01°C can disrupt phase-matching conditions essential for soliton formation and maintenance, resulting in unpredictable comb states.

Mechanical vibrations pose another substantial challenge, particularly in field deployments outside controlled laboratory environments. These vibrations can alter cavity dimensions and coupling conditions, leading to power fluctuations and phase noise that compromise the coherence properties of the generated frequency combs. Current isolation systems remain inadequate for many real-world scenarios where equipment may be subject to transportation or installation in vibration-prone environments.

Atmospheric pressure variations, though often overlooked, significantly impact microresonator performance by altering the effective refractive index of the surrounding medium. This effect becomes particularly problematic in applications requiring long-term stability, such as optical frequency references or telecommunications systems, where drift must be minimized over extended periods.

Humidity fluctuations present unique challenges by causing material absorption and desorption processes that modify both the physical and optical properties of resonator materials. Silicon nitride and silica platforms, while offering excellent optical properties, remain susceptible to water vapor interactions that can gradually degrade performance over time, especially in unsealed environments.

Aging effects and material degradation constitute long-term stability concerns that current pre-compensation techniques struggle to address effectively. Photorefractive damage, surface contamination, and structural relaxation processes can permanently alter resonator characteristics, requiring adaptive compensation strategies that evolve with the device lifetime.

Current feedback-based stabilization approaches often introduce their own limitations, including control loop latency that prevents rapid response to sudden environmental changes. The power consumption of active stabilization systems also presents challenges for portable or space-constrained applications where energy efficiency is paramount.

The integration of pre-compensation techniques with existing photonic integrated circuit (PIC) platforms remains technically challenging, as additional control elements increase fabrication complexity and potential failure points. The trade-off between environmental robustness and device footprint continues to constrain practical implementation in compact systems where space is limited but stability requirements remain stringent.

Mechanical vibrations pose another substantial challenge, particularly in field deployments outside controlled laboratory environments. These vibrations can alter cavity dimensions and coupling conditions, leading to power fluctuations and phase noise that compromise the coherence properties of the generated frequency combs. Current isolation systems remain inadequate for many real-world scenarios where equipment may be subject to transportation or installation in vibration-prone environments.

Atmospheric pressure variations, though often overlooked, significantly impact microresonator performance by altering the effective refractive index of the surrounding medium. This effect becomes particularly problematic in applications requiring long-term stability, such as optical frequency references or telecommunications systems, where drift must be minimized over extended periods.

Humidity fluctuations present unique challenges by causing material absorption and desorption processes that modify both the physical and optical properties of resonator materials. Silicon nitride and silica platforms, while offering excellent optical properties, remain susceptible to water vapor interactions that can gradually degrade performance over time, especially in unsealed environments.

Aging effects and material degradation constitute long-term stability concerns that current pre-compensation techniques struggle to address effectively. Photorefractive damage, surface contamination, and structural relaxation processes can permanently alter resonator characteristics, requiring adaptive compensation strategies that evolve with the device lifetime.

Current feedback-based stabilization approaches often introduce their own limitations, including control loop latency that prevents rapid response to sudden environmental changes. The power consumption of active stabilization systems also presents challenges for portable or space-constrained applications where energy efficiency is paramount.

The integration of pre-compensation techniques with existing photonic integrated circuit (PIC) platforms remains technically challenging, as additional control elements increase fabrication complexity and potential failure points. The trade-off between environmental robustness and device footprint continues to constrain practical implementation in compact systems where space is limited but stability requirements remain stringent.

Existing Pre-Compensation Methodologies

01 Temperature compensation in microcombs

Temperature variations can significantly affect the performance of microcombs, causing frequency drift and instability. Pre-compensation techniques involve implementing temperature control systems or algorithms that adjust the operating parameters of the microcomb in response to environmental temperature changes. These techniques may include thermal stabilization circuits, feedback control mechanisms, or predictive models that anticipate and counteract temperature-induced variations, ensuring consistent operation across different environmental conditions.- Adaptive compensation for environmental variations in microcombs: Adaptive compensation techniques are employed to mitigate the effects of environmental variations on microcomb performance. These systems continuously monitor environmental parameters such as temperature, humidity, and mechanical vibrations, and dynamically adjust the microcomb operating parameters to maintain stability. The compensation algorithms can predict and counteract drift in frequency, phase, and amplitude caused by environmental fluctuations, ensuring consistent performance across varying conditions.

- Temperature stabilization and thermal management techniques: Temperature fluctuations significantly impact microcomb stability and performance. Advanced thermal management techniques include active temperature control systems, thermal isolation structures, and materials with low thermal expansion coefficients. These approaches minimize thermal drift and maintain precise operating conditions for microcombs. Some implementations utilize integrated temperature sensors and feedback control loops to provide real-time temperature compensation, ensuring frequency stability even in environments with variable thermal conditions.

- Digital signal processing for pre-compensation: Digital signal processing techniques are implemented to pre-compensate for environmental effects on microcombs. These methods involve sophisticated algorithms that analyze incoming signals, predict distortions, and apply corrective measures before the signal reaches the microcomb system. Machine learning approaches can be used to adapt the pre-compensation parameters based on historical performance data under various environmental conditions, improving system resilience to environmental variability.

- Mechanical isolation and vibration dampening: Mechanical vibrations can disrupt microcomb operation by affecting cavity length and coupling efficiency. Advanced isolation systems employ multi-stage vibration dampening, active cancellation technologies, and specialized mounting structures to shield microcombs from environmental mechanical disturbances. These systems can detect and counteract vibrations across multiple frequency ranges, ensuring stable operation in environments with significant mechanical noise or movement.

- Feedback-based control systems for real-time adjustment: Closed-loop feedback control systems continuously monitor microcomb output parameters and environmental conditions to make real-time adjustments. These systems compare actual performance against desired specifications and automatically implement corrective actions to maintain optimal operation. Advanced implementations may incorporate multiple feedback loops operating at different timescales to address both rapid fluctuations and slow drift, ensuring consistent microcomb performance despite changing environmental conditions.

02 Adaptive dispersion management for environmental stability

Environmental factors can alter the dispersion characteristics of microcombs, affecting their spectral output. Adaptive dispersion management techniques involve real-time monitoring and adjustment of dispersion parameters to maintain optimal comb generation despite environmental fluctuations. These methods may employ tunable dispersion compensators, phase modulators, or algorithmic approaches that dynamically modify the dispersion profile based on environmental feedback, ensuring consistent frequency spacing and power distribution across the comb spectrum.Expand Specific Solutions03 Feedback-based stabilization systems for microcombs

Feedback-based stabilization systems continuously monitor key performance parameters of microcombs and make real-time adjustments to counteract environmental disturbances. These systems typically include sensors that detect variations in output characteristics, processing units that analyze these variations, and control mechanisms that apply corrective actions. By implementing closed-loop control architectures, these systems can maintain stable operation across a range of environmental conditions, including humidity, vibration, and pressure changes.Expand Specific Solutions04 Machine learning approaches for environmental variability prediction

Advanced machine learning algorithms can be employed to predict and compensate for environmental effects on microcomb performance. These approaches involve training models on historical data that correlate environmental parameters with microcomb behavior, enabling the system to anticipate and pre-emptively adjust for environmental changes. Neural networks, regression models, or other machine learning techniques can identify complex patterns in environmental variability and generate appropriate pre-compensation signals, improving the robustness of microcombs in fluctuating conditions.Expand Specific Solutions05 Integrated photonic solutions for environmental isolation

Integrated photonic approaches focus on designing microcomb structures that are inherently less susceptible to environmental variations. These solutions may include specialized packaging techniques, material selection for reduced thermal sensitivity, or novel resonator geometries that minimize environmental coupling. By addressing environmental variability at the design level, these approaches reduce the need for active compensation while improving the overall stability and reliability of microcomb systems in diverse operating environments.Expand Specific Solutions

Leading Research Groups and Industry Players

The microcomb pre-compensation techniques for environmental variability market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size remains relatively modest, estimated below $500 million, but shows promising annual growth rates of 15-20% as applications in telecommunications, sensing, and quantum computing emerge. From a technical maturity perspective, the landscape is dominated by academic institutions like Tsinghua University, North Carolina State University, and Zhejiang University leading fundamental research, while industrial players including State Grid Corp. of China, Schlumberger, and Saudi Aramco focus on application-specific implementations. The technology remains at TRL 4-6, with significant challenges in scaling production and ensuring reliability under variable environmental conditions, indicating a 3-5 year timeline before widespread commercial adoption.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced microcomb pre-compensation techniques that address environmental variability challenges in optical frequency comb systems. Their approach combines adaptive feedback control mechanisms with machine learning algorithms to predict and counteract temperature fluctuations, mechanical vibrations, and other environmental disturbances that affect microcomb stability. The university's research team has implemented a dual-layer compensation strategy: a hardware layer utilizing piezoelectric actuators for rapid physical adjustments, and a software layer employing predictive modeling to anticipate environmental changes before they impact system performance. Their published research demonstrates successful stabilization of microcombs in varying temperature conditions (±5°C variations) while maintaining frequency stability within 10^-12 range. The team has also developed specialized integrated photonic chips with on-chip thermal stabilization elements that can respond to environmental changes within microseconds, significantly reducing the susceptibility of microcombs to ambient conditions.

Strengths: Tsinghua's approach excels in combining hardware and software solutions for comprehensive environmental compensation, particularly effective in research settings with access to sophisticated equipment. Their machine learning predictive models show exceptional adaptability to gradual environmental shifts. Weaknesses: The system's complexity requires significant computational resources and specialized hardware, potentially limiting deployment in field applications or resource-constrained environments.

Ningbo University

Technical Solution: Ningbo University has pioneered innovative microcomb pre-compensation techniques focused on addressing environmental variability through passive stabilization methods combined with active feedback systems. Their research centers on developing specialized microresonator designs with inherent resistance to environmental fluctuations. The university's approach incorporates thermally-compensated materials in the resonator structure that naturally counteract temperature-induced frequency shifts. Their published work demonstrates microresonators with negative thermo-optic coefficients that balance the positive coefficients of typical waveguide materials, creating temperature-insensitive devices. Additionally, Ningbo University researchers have developed a multi-point sensing network within their microcomb systems that monitors environmental parameters at various critical locations, enabling spatially-resolved compensation strategies. This distributed sensing approach allows for more precise compensation of non-uniform environmental effects across the photonic chip. Their latest prototypes have demonstrated frequency stability maintenance within 10^-11 range under temperature fluctuations of ±3°C without requiring active cooling systems, representing a significant advancement in practical microcomb applications.

Strengths: Ningbo University's passive stabilization approach reduces power requirements and system complexity, making their solution more suitable for field deployment and portable applications. Their multi-point sensing strategy provides superior handling of spatially non-uniform environmental effects. Weaknesses: The passive compensation has inherent limitations in extreme environmental conditions and may require supplementary active systems in highly demanding applications, potentially increasing overall system complexity.

Key Patents in Microcomb Stabilization

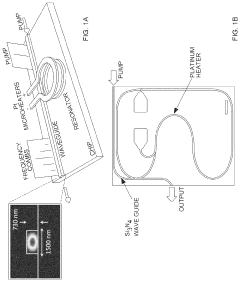

Compact microresonator frequency comb

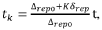

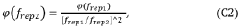

PatentWO2020076402A1

Innovation

- The use of optimized microresonator actuators and modulators, including single-sideband modulators, graphene modulators, and microheaters, allows for precise control of carrier envelope offset frequency, repetition rate, and resonance offset frequency, enabling long-term locking and reduced noise, while minimizing cross-talk between parameters.

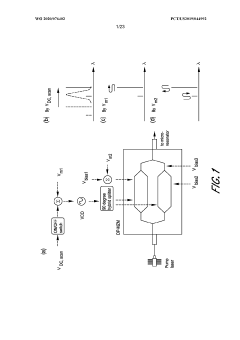

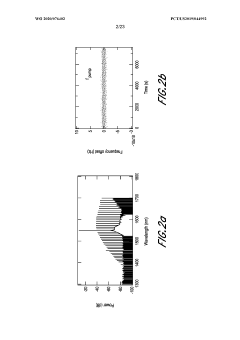

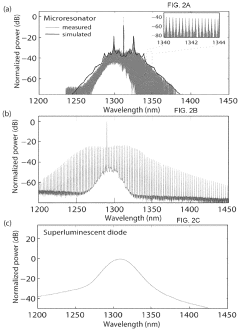

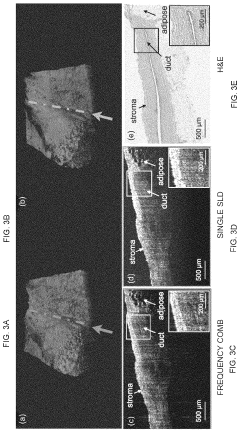

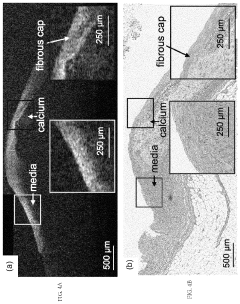

Microresonator-frequency-comb-based platform for clinical high-resolution optical coherence tomography

PatentActiveUS11859972B2

Innovation

- A microresonator-frequency-comb-based platform using high-Q silicon nitride resonators and distributed feedback lasers generates broadband frequency combs, overcoming the bandwidth-power trade-off and enabling sub-micrometer axial resolution and deeper tissue penetration, compatible with standard OCT systems.

Integration Strategies for Photonic Systems

The integration of microcomb pre-compensation techniques into photonic systems requires careful consideration of various architectural approaches. Seamless integration demands compatibility between microcombs and existing photonic components while maintaining system performance under environmental fluctuations.

Monolithic integration represents the most compact solution, where microcombs and compensation circuits are fabricated on the same substrate. This approach minimizes interconnection losses and reduces sensitivity to environmental variations by keeping critical components in close thermal proximity. Silicon photonics platforms have demonstrated particular promise for such integration, allowing for co-fabrication of microresonators alongside thermal tuning elements and phase shifters that can dynamically adjust for environmental drift.

Hybrid integration offers greater flexibility by combining different material platforms optimized for specific functions. For instance, high-Q microresonators fabricated in silicon nitride can be bonded to silicon photonic circuits containing the compensation electronics. This approach enables optimization of each subsystem independently but introduces additional interfaces that may be susceptible to environmental instability, requiring more sophisticated compensation algorithms.

Module-based integration employs discrete components packaged together with standardized interfaces. This strategy facilitates easier testing and replacement of individual elements but necessitates robust pre-compensation techniques to account for the increased vulnerability to thermal gradients across module boundaries. Hermetic packaging with active temperature control has proven effective in stabilizing such systems.

Feedback-based architectures incorporate real-time monitoring of environmental parameters and system performance metrics. Sensors distributed throughout the photonic system continuously measure temperature variations, mechanical stress, and optical performance parameters. These measurements feed into adaptive algorithms that dynamically adjust pre-compensation settings to maintain optimal microcomb operation despite changing conditions.

Hierarchical integration strategies implement multiple compensation layers operating at different time scales. Fast electronic pre-compensation addresses rapid environmental fluctuations, while slower thermal management systems handle gradual drift. This multi-tiered approach has demonstrated superior stability in field deployments of microcomb systems.

Co-design methodologies that simultaneously optimize both the microcomb and its compensation circuitry during the design phase have emerged as particularly effective. By modeling environmental sensitivity from the outset, designers can create inherently robust systems where pre-compensation requirements are minimized through careful architectural choices.

Monolithic integration represents the most compact solution, where microcombs and compensation circuits are fabricated on the same substrate. This approach minimizes interconnection losses and reduces sensitivity to environmental variations by keeping critical components in close thermal proximity. Silicon photonics platforms have demonstrated particular promise for such integration, allowing for co-fabrication of microresonators alongside thermal tuning elements and phase shifters that can dynamically adjust for environmental drift.

Hybrid integration offers greater flexibility by combining different material platforms optimized for specific functions. For instance, high-Q microresonators fabricated in silicon nitride can be bonded to silicon photonic circuits containing the compensation electronics. This approach enables optimization of each subsystem independently but introduces additional interfaces that may be susceptible to environmental instability, requiring more sophisticated compensation algorithms.

Module-based integration employs discrete components packaged together with standardized interfaces. This strategy facilitates easier testing and replacement of individual elements but necessitates robust pre-compensation techniques to account for the increased vulnerability to thermal gradients across module boundaries. Hermetic packaging with active temperature control has proven effective in stabilizing such systems.

Feedback-based architectures incorporate real-time monitoring of environmental parameters and system performance metrics. Sensors distributed throughout the photonic system continuously measure temperature variations, mechanical stress, and optical performance parameters. These measurements feed into adaptive algorithms that dynamically adjust pre-compensation settings to maintain optimal microcomb operation despite changing conditions.

Hierarchical integration strategies implement multiple compensation layers operating at different time scales. Fast electronic pre-compensation addresses rapid environmental fluctuations, while slower thermal management systems handle gradual drift. This multi-tiered approach has demonstrated superior stability in field deployments of microcomb systems.

Co-design methodologies that simultaneously optimize both the microcomb and its compensation circuitry during the design phase have emerged as particularly effective. By modeling environmental sensitivity from the outset, designers can create inherently robust systems where pre-compensation requirements are minimized through careful architectural choices.

Standardization Efforts and Benchmarking

In the rapidly evolving field of microcombs, standardization efforts and benchmarking methodologies are becoming increasingly critical for ensuring consistent performance across different environmental conditions. Currently, several international organizations including IEEE, ITU-T, and the Optical Internetworking Forum (OIF) are developing standards specifically addressing pre-compensation techniques for environmental variability in microcomb systems.

The IEEE P1918.1 working group has recently established a task force focused on standardizing testing protocols for temperature-dependent microcomb stability, with particular emphasis on pre-compensation algorithm validation. These standards aim to create uniform metrics for evaluating how effectively different pre-compensation techniques mitigate thermal and mechanical perturbations in integrated photonic platforms.

Similarly, the OIF has published implementation agreements that include specifications for environmental testing of microcomb-based systems, establishing minimum performance requirements for pre-compensation techniques across temperature ranges from -5°C to 70°C and relative humidity variations between 10% and 90%.

Benchmarking frameworks have emerged to quantitatively compare different pre-compensation approaches. The Microcomb Environmental Resilience Index (MERI) has gained industry acceptance as a composite metric that evaluates frequency stability, power consistency, and noise characteristics under standardized environmental stress tests. This index allows for objective comparison between different pre-compensation techniques across multiple operational scenarios.

Academic institutions including MIT, Caltech, and EPFL have collaborated to develop the Open Microcomb Benchmark Suite (OMBS), which provides standardized datasets representing various environmental perturbations. These datasets enable researchers and industry practitioners to evaluate their pre-compensation algorithms against common reference scenarios, facilitating more meaningful comparisons between different approaches.

Industry consortia have also established reference implementations for pre-compensation techniques, with companies like Intel, Cisco, and NTT contributing to open-source libraries of environmental compensation algorithms. These reference implementations serve as baseline comparisons for evaluating novel approaches and accelerating industry adoption of proven techniques.

The standardization landscape continues to evolve, with recent efforts focusing on establishing metrics for real-time adaptation capabilities and energy efficiency of pre-compensation techniques. As microcomb technology moves toward commercial deployment in telecommunications and sensing applications, these standardization and benchmarking initiatives will play a crucial role in ensuring interoperability and performance consistency across diverse environmental conditions.

The IEEE P1918.1 working group has recently established a task force focused on standardizing testing protocols for temperature-dependent microcomb stability, with particular emphasis on pre-compensation algorithm validation. These standards aim to create uniform metrics for evaluating how effectively different pre-compensation techniques mitigate thermal and mechanical perturbations in integrated photonic platforms.

Similarly, the OIF has published implementation agreements that include specifications for environmental testing of microcomb-based systems, establishing minimum performance requirements for pre-compensation techniques across temperature ranges from -5°C to 70°C and relative humidity variations between 10% and 90%.

Benchmarking frameworks have emerged to quantitatively compare different pre-compensation approaches. The Microcomb Environmental Resilience Index (MERI) has gained industry acceptance as a composite metric that evaluates frequency stability, power consistency, and noise characteristics under standardized environmental stress tests. This index allows for objective comparison between different pre-compensation techniques across multiple operational scenarios.

Academic institutions including MIT, Caltech, and EPFL have collaborated to develop the Open Microcomb Benchmark Suite (OMBS), which provides standardized datasets representing various environmental perturbations. These datasets enable researchers and industry practitioners to evaluate their pre-compensation algorithms against common reference scenarios, facilitating more meaningful comparisons between different approaches.

Industry consortia have also established reference implementations for pre-compensation techniques, with companies like Intel, Cisco, and NTT contributing to open-source libraries of environmental compensation algorithms. These reference implementations serve as baseline comparisons for evaluating novel approaches and accelerating industry adoption of proven techniques.

The standardization landscape continues to evolve, with recent efforts focusing on establishing metrics for real-time adaptation capabilities and energy efficiency of pre-compensation techniques. As microcomb technology moves toward commercial deployment in telecommunications and sensing applications, these standardization and benchmarking initiatives will play a crucial role in ensuring interoperability and performance consistency across diverse environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!