On-Chip Microcomb Test Metrics: Standardization And Best Practices

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Technology Background and Objectives

Microcombs, or optical frequency combs generated in microresonators, have emerged as a revolutionary technology in integrated photonics over the past two decades. The evolution of this field began with the demonstration of optical frequency combs in the early 2000s, which earned John Hall and Theodor Hänsch the Nobel Prize in Physics in 2005. The subsequent miniaturization of these systems into chip-scale devices has opened unprecedented opportunities for applications ranging from telecommunications to precision metrology.

The technological trajectory of microcombs has been characterized by rapid advancement in fabrication techniques, material platforms, and control methodologies. Initially developed on specialized platforms like silicon nitride and silica, microcombs have now expanded to various material systems including lithium niobate, aluminum nitride, and diamond, each offering unique advantages for specific applications. This diversification has accelerated the technology's adoption across multiple domains.

Current research trends indicate a growing focus on enhancing the stability, efficiency, and integration capabilities of microcomb systems. The field is witnessing a transition from laboratory demonstrations to practical implementations, necessitating standardized testing protocols and performance metrics. This standardization is crucial for comparing results across different research groups and for facilitating technology transfer from academic research to commercial applications.

The primary objective of establishing standardized test metrics for on-chip microcombs is to create a common framework for evaluating and benchmarking these devices. Such standardization would enable meaningful comparisons between different microcomb architectures, accelerate technological progress through clear performance targets, and facilitate more effective communication between researchers, manufacturers, and end-users.

Key technical goals include defining universal parameters for assessing spectral purity, power efficiency, noise characteristics, and operational stability of microcombs. Additionally, there is a need to establish protocols for measuring integration compatibility, thermal management capabilities, and long-term reliability – factors critical for practical deployment in real-world systems.

The development of best practices for microcomb testing must address the multidisciplinary nature of the technology, incorporating insights from photonics, electronics, materials science, and systems engineering. These practices should be adaptable to the evolving landscape of applications, from telecommunications and quantum information processing to spectroscopy and astronomical measurements.

As the field matures, standardized metrics will play a pivotal role in guiding research priorities, informing investment decisions, and shaping regulatory frameworks. The establishment of these metrics represents a critical step in the transition of microcomb technology from promising research to transformative commercial applications.

The technological trajectory of microcombs has been characterized by rapid advancement in fabrication techniques, material platforms, and control methodologies. Initially developed on specialized platforms like silicon nitride and silica, microcombs have now expanded to various material systems including lithium niobate, aluminum nitride, and diamond, each offering unique advantages for specific applications. This diversification has accelerated the technology's adoption across multiple domains.

Current research trends indicate a growing focus on enhancing the stability, efficiency, and integration capabilities of microcomb systems. The field is witnessing a transition from laboratory demonstrations to practical implementations, necessitating standardized testing protocols and performance metrics. This standardization is crucial for comparing results across different research groups and for facilitating technology transfer from academic research to commercial applications.

The primary objective of establishing standardized test metrics for on-chip microcombs is to create a common framework for evaluating and benchmarking these devices. Such standardization would enable meaningful comparisons between different microcomb architectures, accelerate technological progress through clear performance targets, and facilitate more effective communication between researchers, manufacturers, and end-users.

Key technical goals include defining universal parameters for assessing spectral purity, power efficiency, noise characteristics, and operational stability of microcombs. Additionally, there is a need to establish protocols for measuring integration compatibility, thermal management capabilities, and long-term reliability – factors critical for practical deployment in real-world systems.

The development of best practices for microcomb testing must address the multidisciplinary nature of the technology, incorporating insights from photonics, electronics, materials science, and systems engineering. These practices should be adaptable to the evolving landscape of applications, from telecommunications and quantum information processing to spectroscopy and astronomical measurements.

As the field matures, standardized metrics will play a pivotal role in guiding research priorities, informing investment decisions, and shaping regulatory frameworks. The establishment of these metrics represents a critical step in the transition of microcomb technology from promising research to transformative commercial applications.

Market Applications and Demand Analysis for On-Chip Microcombs

The market for on-chip microcombs has witnessed significant growth in recent years, driven by increasing demand for compact, energy-efficient photonic solutions across multiple industries. The global integrated photonics market, where microcombs represent a critical component, is projected to reach $3.2 billion by 2027, with a compound annual growth rate of 21.3% from 2022 to 2027, according to recent market research.

Telecommunications represents the largest application segment for on-chip microcombs, accounting for approximately 38% of the current market share. The need for higher bandwidth in optical communication networks has created substantial demand for wavelength division multiplexing (WDM) systems, where microcombs can generate multiple wavelength channels from a single source. Major telecom operators are actively exploring microcomb technology to address the exponential growth in data traffic, particularly for 5G and future 6G networks.

Data centers constitute another significant market segment, representing about 27% of current demand. The push for higher data transmission rates while reducing power consumption has led major cloud service providers to invest in photonic integrated circuit (PIC) technologies, including microcomb-based solutions. Companies like Google, Amazon, and Microsoft have established research partnerships with photonics firms to develop microcomb-based interconnects for their next-generation data centers.

The sensing and metrology sector accounts for approximately 19% of the market. Applications include precision distance measurement, spectroscopy, and environmental monitoring. The ability of microcombs to generate precise frequency references makes them particularly valuable for applications requiring high accuracy measurements. This segment is expected to grow at 24.7% annually through 2027, outpacing the overall market growth rate.

Emerging applications in quantum computing and artificial intelligence hardware are creating new market opportunities, currently representing about 8% of the market but growing rapidly. Quantum photonic processors utilizing microcomb technology for qubit manipulation and entanglement are attracting significant venture capital investment, with funding in this specific segment exceeding $420 million in 2022 alone.

Biomedical applications, including optical coherence tomography and spectroscopic sensing for disease detection, represent approximately 6% of the current market. The non-invasive nature of these techniques, combined with the miniaturization enabled by on-chip microcombs, is driving adoption in clinical settings and research laboratories.

Geographically, North America leads the market with 41% share, followed by Europe (28%), Asia-Pacific (24%), and rest of the world (7%). However, the Asia-Pacific region is expected to exhibit the highest growth rate over the next five years, driven by substantial investments in photonics infrastructure in China, Japan, and South Korea.

Telecommunications represents the largest application segment for on-chip microcombs, accounting for approximately 38% of the current market share. The need for higher bandwidth in optical communication networks has created substantial demand for wavelength division multiplexing (WDM) systems, where microcombs can generate multiple wavelength channels from a single source. Major telecom operators are actively exploring microcomb technology to address the exponential growth in data traffic, particularly for 5G and future 6G networks.

Data centers constitute another significant market segment, representing about 27% of current demand. The push for higher data transmission rates while reducing power consumption has led major cloud service providers to invest in photonic integrated circuit (PIC) technologies, including microcomb-based solutions. Companies like Google, Amazon, and Microsoft have established research partnerships with photonics firms to develop microcomb-based interconnects for their next-generation data centers.

The sensing and metrology sector accounts for approximately 19% of the market. Applications include precision distance measurement, spectroscopy, and environmental monitoring. The ability of microcombs to generate precise frequency references makes them particularly valuable for applications requiring high accuracy measurements. This segment is expected to grow at 24.7% annually through 2027, outpacing the overall market growth rate.

Emerging applications in quantum computing and artificial intelligence hardware are creating new market opportunities, currently representing about 8% of the market but growing rapidly. Quantum photonic processors utilizing microcomb technology for qubit manipulation and entanglement are attracting significant venture capital investment, with funding in this specific segment exceeding $420 million in 2022 alone.

Biomedical applications, including optical coherence tomography and spectroscopic sensing for disease detection, represent approximately 6% of the current market. The non-invasive nature of these techniques, combined with the miniaturization enabled by on-chip microcombs, is driving adoption in clinical settings and research laboratories.

Geographically, North America leads the market with 41% share, followed by Europe (28%), Asia-Pacific (24%), and rest of the world (7%). However, the Asia-Pacific region is expected to exhibit the highest growth rate over the next five years, driven by substantial investments in photonics infrastructure in China, Japan, and South Korea.

Current Testing Challenges and Technical Limitations

Despite significant advancements in on-chip microcomb technology, the field faces substantial testing challenges that impede standardized evaluation and comparison of devices. One primary challenge is the lack of universally accepted test metrics and methodologies. Different research groups and manufacturers employ varied testing protocols, making direct performance comparisons between devices virtually impossible. This fragmentation hinders technology advancement and creates barriers to entry for new players in the field.

Measurement reproducibility presents another significant hurdle. Environmental factors such as temperature fluctuations, mechanical vibrations, and electromagnetic interference can dramatically affect microcomb performance characteristics. Even minor variations in testing conditions can lead to inconsistent results, complicating efforts to establish reliable benchmarks. The high sensitivity of microcombs to these external factors necessitates extremely controlled testing environments that many facilities struggle to maintain consistently.

The multidisciplinary nature of microcomb technology further complicates testing procedures. Comprehensive evaluation requires expertise spanning photonics, electronics, materials science, and precision measurement. Few testing facilities possess the complete suite of specialized equipment and cross-disciplinary knowledge needed for thorough characterization. This limitation often results in incomplete performance assessments that fail to capture critical operational parameters.

Technical limitations in measurement equipment also constrain testing capabilities. Current instruments often lack sufficient resolution, speed, or dynamic range to fully characterize cutting-edge microcomb devices. The detection of phase noise at extremely low levels, precise measurement of optical frequency stability, and accurate characterization of nonlinear dynamics remain particularly challenging. These instrumentation gaps create blind spots in performance evaluation that may mask critical device limitations.

Scalability of testing procedures represents another significant challenge. As microcomb technology advances toward commercial applications, testing methodologies must evolve from laboratory-scale procedures to industrial-scale quality control processes. Current testing approaches are typically time-intensive and require expert oversight, making them impractical for high-volume manufacturing environments. The development of automated, high-throughput testing solutions lags behind device innovation.

Integration testing poses additional complications. When microcombs are incorporated into larger photonic integrated circuits or systems, new performance parameters emerge that cannot be predicted from standalone device testing. Interface effects, thermal management issues, and electronic control integration can significantly impact system-level performance. Current testing methodologies often fail to adequately address these integration challenges, creating a disconnect between component-level specifications and system-level requirements.

Measurement reproducibility presents another significant hurdle. Environmental factors such as temperature fluctuations, mechanical vibrations, and electromagnetic interference can dramatically affect microcomb performance characteristics. Even minor variations in testing conditions can lead to inconsistent results, complicating efforts to establish reliable benchmarks. The high sensitivity of microcombs to these external factors necessitates extremely controlled testing environments that many facilities struggle to maintain consistently.

The multidisciplinary nature of microcomb technology further complicates testing procedures. Comprehensive evaluation requires expertise spanning photonics, electronics, materials science, and precision measurement. Few testing facilities possess the complete suite of specialized equipment and cross-disciplinary knowledge needed for thorough characterization. This limitation often results in incomplete performance assessments that fail to capture critical operational parameters.

Technical limitations in measurement equipment also constrain testing capabilities. Current instruments often lack sufficient resolution, speed, or dynamic range to fully characterize cutting-edge microcomb devices. The detection of phase noise at extremely low levels, precise measurement of optical frequency stability, and accurate characterization of nonlinear dynamics remain particularly challenging. These instrumentation gaps create blind spots in performance evaluation that may mask critical device limitations.

Scalability of testing procedures represents another significant challenge. As microcomb technology advances toward commercial applications, testing methodologies must evolve from laboratory-scale procedures to industrial-scale quality control processes. Current testing approaches are typically time-intensive and require expert oversight, making them impractical for high-volume manufacturing environments. The development of automated, high-throughput testing solutions lags behind device innovation.

Integration testing poses additional complications. When microcombs are incorporated into larger photonic integrated circuits or systems, new performance parameters emerge that cannot be predicted from standalone device testing. Interface effects, thermal management issues, and electronic control integration can significantly impact system-level performance. Current testing methodologies often fail to adequately address these integration challenges, creating a disconnect between component-level specifications and system-level requirements.

Current Test Metrics and Measurement Protocols

01 Integrated Photonic Microcomb Testing Methods

Various methods for testing integrated photonic microcombs on-chip, including optical characterization techniques to measure frequency stability, spectral purity, and power efficiency. These testing approaches enable evaluation of microcomb performance in terms of coherence, mode spacing uniformity, and phase noise, which are critical parameters for applications in optical communications and computing.- Optical microcomb testing methodologies: Testing methodologies for on-chip microcombs involve specialized metrics to evaluate their performance characteristics. These methods include measuring frequency stability, spectral purity, and power efficiency. The testing procedures often incorporate optical spectrum analyzers and phase noise measurements to assess the quality of the generated comb lines. These methodologies are essential for ensuring that microcombs meet the required specifications for various applications in integrated photonics.

- Integration of microcombs with electronic testing infrastructure: On-chip microcombs require specialized electronic testing infrastructure for comprehensive performance evaluation. This integration involves designing test circuits that can interface with both the optical and electronic components of the microcomb system. The electronic testing infrastructure typically includes signal generators, data acquisition systems, and automated test equipment that can characterize the microcomb's response under various operating conditions. This approach enables efficient validation of microcomb functionality in integrated photonic circuits.

- Quality metrics for microcomb spectral characteristics: Specific quality metrics have been developed to evaluate the spectral characteristics of on-chip microcombs. These metrics include comb line spacing uniformity, spectral flatness, and phase coherence between comb lines. The assessment typically involves measuring the optical spectrum and analyzing parameters such as the signal-to-noise ratio of individual comb lines and the overall spectral envelope. These metrics are crucial for applications requiring precise frequency control, such as optical communications and spectroscopy.

- Automated testing systems for microcomb production: Automated testing systems have been developed for efficient evaluation of microcombs in production environments. These systems incorporate machine learning algorithms to identify defects and variations in microcomb performance. The automation includes wafer-level testing capabilities that can rapidly assess multiple devices, enabling statistical process control and yield improvement. These systems typically feature programmable test sequences that can be customized for different microcomb designs and application requirements.

- Reliability and stability testing frameworks: Comprehensive frameworks for evaluating the long-term reliability and stability of on-chip microcombs have been established. These frameworks include accelerated aging tests, temperature cycling, and environmental stress screening to predict the operational lifetime of microcomb devices. The testing protocols measure parameters such as frequency drift over time, power fluctuations, and susceptibility to external perturbations. These reliability metrics are essential for qualifying microcombs for deployment in critical applications where long-term stability is required.

02 On-Chip Test Metrics for Microcomb Quality Assessment

Specific metrics developed for evaluating the quality of on-chip microcombs, including frequency comb spacing uniformity, power per comb line, conversion efficiency, and spectral coverage. These standardized measurements allow for consistent comparison between different microcomb designs and fabrication processes, enabling optimization for specific applications.Expand Specific Solutions03 Automated Testing Systems for Microcomb Characterization

Automated systems and methodologies for high-throughput testing of on-chip microcombs, incorporating machine learning algorithms for rapid analysis of test data. These systems enable efficient quality control in manufacturing environments and can identify subtle performance variations that might affect microcomb functionality in practical applications.Expand Specific Solutions04 Thermal and Environmental Stability Testing for Microcombs

Test methodologies focused on evaluating the thermal and environmental stability of on-chip microcombs, including temperature cycling, humidity exposure, and mechanical stress testing. These approaches help ensure that microcomb devices maintain consistent performance across varying operating conditions, which is essential for deployment in real-world applications.Expand Specific Solutions05 Integration of Microcomb Test Structures in Chip Design

Design approaches for incorporating dedicated test structures alongside microcombs on integrated photonic chips, enabling in-situ monitoring and characterization. These test structures can include reference resonators, photodetectors, and calibration elements that facilitate accurate measurement of microcomb parameters without requiring external equipment, streamlining both development and production testing processes.Expand Specific Solutions

Leading Research Groups and Industry Players

The on-chip microcomb test metrics field is currently in an early growth phase, characterized by increasing standardization efforts across academia and industry. The market is expanding rapidly, projected to reach significant scale as integrated photonics applications proliferate in telecommunications and computing. From a technical maturity perspective, the landscape shows varied development levels: Intel, TSMC, and GlobalFoundries lead in semiconductor integration capabilities; Tsinghua University and Xiamen University contribute fundamental research; while specialized players like Futurewei and Interuniversitair Micro-Electronica Centrum advance photonic integration techniques. The ecosystem requires further standardization of test metrics to enable consistent performance evaluation and accelerate commercial adoption across emerging applications.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed a comprehensive silicon photonics platform that includes specialized test methodologies for on-chip microcombs. Their approach integrates microcomb test structures directly into production wafers, enabling statistical process control across large manufacturing volumes. TSMC's solution features automated optical probing systems with precision alignment capabilities for coupling light into microcomb resonators. Their test metrics include standardized measurements for quality factor, threshold power, conversion efficiency, and spectral purity. The platform incorporates reference structures for calibration and implements temperature-controlled environments to characterize thermal stability of microcomb operation. TSMC's methodology enables wafer-level screening and binning based on key performance indicators, supporting high-volume manufacturing of microcomb-based devices.

Strengths: Unparalleled manufacturing scale enables comprehensive statistical analysis and process optimization. Advanced packaging capabilities support testing of integrated microcomb systems. Weaknesses: Less specialized in photonics than pure-play photonics companies. Primarily focused on manufacturing rather than end applications of microcombs.

Intel Corp.

Technical Solution: Intel has developed a comprehensive silicon photonics platform that integrates microcomb testing capabilities. Their approach utilizes automated wafer-level testing systems for on-chip microcombs with standardized metrics including quality factor (Q) measurement, frequency spacing verification, and power consumption analysis. Intel's solution incorporates reference designs for test structures alongside microcombs to enable in-situ calibration. Their methodology employs specialized grating couplers for optical input/output and implements automated resonance tracking algorithms to characterize microcomb generation thresholds and stability regions across temperature variations. The platform includes statistical process control methods specifically adapted for microcomb manufacturing variability assessment.

Strengths: Extensive manufacturing infrastructure enables high-volume testing and comprehensive statistical analysis. Integration with existing silicon photonics platform provides manufacturing maturity. Weaknesses: Proprietary test interfaces may limit cross-platform standardization efforts. Higher implementation costs compared to academic solutions.

Key Patents and Literature on Microcomb Characterization

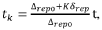

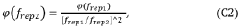

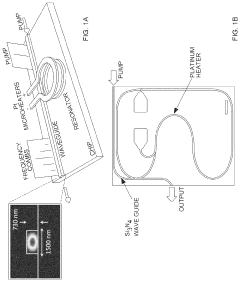

Compact microresonator frequency comb

PatentWO2020076402A1

Innovation

- The use of optimized microresonator actuators and modulators, including single-sideband modulators, graphene modulators, and microheaters, allows for precise control of carrier envelope offset frequency, repetition rate, and resonance offset frequency, enabling long-term locking and reduced noise, while minimizing cross-talk between parameters.

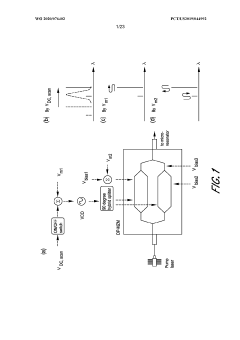

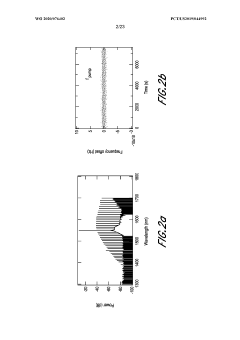

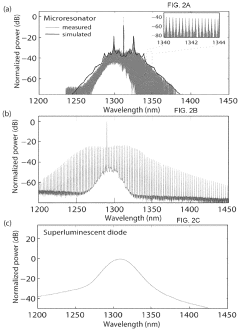

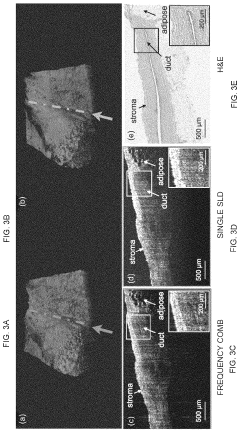

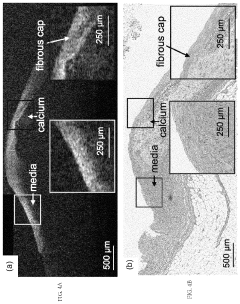

Microresonator-frequency-comb-based platform for clinical high-resolution optical coherence tomography

PatentActiveUS11859972B2

Innovation

- A microresonator-frequency-comb-based platform using high-Q silicon nitride resonators and distributed feedback lasers generates broadband frequency combs, overcoming the bandwidth-power trade-off and enabling sub-micrometer axial resolution and deeper tissue penetration, compatible with standard OCT systems.

Regulatory Framework for Photonic Integrated Circuits

The regulatory landscape for Photonic Integrated Circuits (PICs) is rapidly evolving to accommodate the emerging field of on-chip microcombs. As these devices transition from research laboratories to commercial applications, standardized regulatory frameworks become essential for ensuring consistency, safety, and interoperability across the industry. Currently, regulatory oversight for microcombs spans multiple domains including telecommunications standards (ITU-T, IEEE), safety regulations (IEC, UL), and environmental compliance (RoHS, REACH).

The development of test metrics standardization for on-chip microcombs faces unique challenges due to the interdisciplinary nature of the technology. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have begun establishing working groups specifically focused on photonic integrated circuit standards. These initiatives aim to define common terminology, measurement methodologies, and performance benchmarks that can be universally applied to microcomb devices.

Key regulatory considerations for on-chip microcombs include optical power safety thresholds, electromagnetic compatibility, thermal management requirements, and reliability standards. The IEEE P2432 working group has recently proposed draft standards for the characterization of integrated photonics, which includes specific provisions for frequency comb generation and stability metrics. Similarly, the IEC Technical Committee 86 has expanded its scope to address the unique aspects of nonlinear optical processes in integrated photonic platforms.

Regional variations in regulatory approaches present additional complexity for global deployment of microcomb technologies. While the European Union has incorporated photonic components into its broader electronic device regulatory framework through the CE marking requirements, the United States FDA has established specific guidance for optical frequency comb systems used in medical and sensing applications. Asian markets, particularly Japan and China, have developed their own certification processes for advanced photonic components, emphasizing different aspects of performance and reliability.

Industry consortia such as the Photonic Integrated Circuit Manufacturers Group (PIC-MG) and the AIM Photonics Institute have been instrumental in bridging the gap between regulatory requirements and technical capabilities. These organizations have developed voluntary best practice guidelines that often precede formal regulations, providing a pathway for standardization of test metrics for microcombs. Their recommendations typically address spectral purity, frequency stability, power efficiency, and integration compatibility – all critical parameters for establishing meaningful benchmarks.

The convergence of telecommunications standards with photonic device regulations represents a significant trend in the regulatory landscape. As microcombs find applications in optical communications, quantum computing, and sensing networks, regulatory frameworks are increasingly adopting a systems-level approach that considers the interaction between electronic and photonic components. This holistic perspective is essential for developing comprehensive test metrics that accurately reflect real-world performance requirements for on-chip microcomb technologies.

The development of test metrics standardization for on-chip microcombs faces unique challenges due to the interdisciplinary nature of the technology. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have begun establishing working groups specifically focused on photonic integrated circuit standards. These initiatives aim to define common terminology, measurement methodologies, and performance benchmarks that can be universally applied to microcomb devices.

Key regulatory considerations for on-chip microcombs include optical power safety thresholds, electromagnetic compatibility, thermal management requirements, and reliability standards. The IEEE P2432 working group has recently proposed draft standards for the characterization of integrated photonics, which includes specific provisions for frequency comb generation and stability metrics. Similarly, the IEC Technical Committee 86 has expanded its scope to address the unique aspects of nonlinear optical processes in integrated photonic platforms.

Regional variations in regulatory approaches present additional complexity for global deployment of microcomb technologies. While the European Union has incorporated photonic components into its broader electronic device regulatory framework through the CE marking requirements, the United States FDA has established specific guidance for optical frequency comb systems used in medical and sensing applications. Asian markets, particularly Japan and China, have developed their own certification processes for advanced photonic components, emphasizing different aspects of performance and reliability.

Industry consortia such as the Photonic Integrated Circuit Manufacturers Group (PIC-MG) and the AIM Photonics Institute have been instrumental in bridging the gap between regulatory requirements and technical capabilities. These organizations have developed voluntary best practice guidelines that often precede formal regulations, providing a pathway for standardization of test metrics for microcombs. Their recommendations typically address spectral purity, frequency stability, power efficiency, and integration compatibility – all critical parameters for establishing meaningful benchmarks.

The convergence of telecommunications standards with photonic device regulations represents a significant trend in the regulatory landscape. As microcombs find applications in optical communications, quantum computing, and sensing networks, regulatory frameworks are increasingly adopting a systems-level approach that considers the interaction between electronic and photonic components. This holistic perspective is essential for developing comprehensive test metrics that accurately reflect real-world performance requirements for on-chip microcomb technologies.

International Standardization Efforts and Collaborations

The global nature of microcomb technology development necessitates coordinated international standardization efforts. Currently, several major international bodies are actively working on establishing unified test metrics and protocols for on-chip microcombs. The IEEE Photonics Society has formed a specialized working group focused on integrated photonics standardization, with a dedicated subcommittee addressing microcomb characterization methodologies. This initiative brings together experts from academia, industry, and national metrology institutes to develop consensus-based standards.

Similarly, the International Electrotechnical Commission (IEC) through its Technical Committee 86 on Fibre Optics has begun incorporating microcomb-specific considerations into its standardization framework. Their recent publication IEC 63287 provides preliminary guidelines for integrated photonic devices, with plans to expand coverage specifically for microcomb testing in upcoming revisions.

The International Organization for Standardization (ISO) has also recognized the strategic importance of microcomb technology, establishing collaborative projects between its technical committees on nanotechnology and photonics. These cross-disciplinary efforts aim to address the unique challenges posed by the nanoscale features and quantum properties of advanced microcomb devices.

Regional standardization bodies have made significant contributions as well. The European Telecommunications Standards Institute (ETSI) has developed preliminary specifications for microcomb-based telecommunications systems, while the National Institute of Standards and Technology (NIST) in the United States has published comprehensive measurement guidelines that are increasingly being adopted internationally.

Collaborative international research initiatives have been instrumental in driving standardization forward. The Integrated Photonic Systems Roadmap (IPSR), supported by multiple countries, has established a dedicated technical working group on microcomb metrics. Similarly, the International Photonics Consortium has launched a cross-border certification program for microcomb testing facilities to ensure global measurement consistency.

Industry-academia partnerships have emerged as crucial vehicles for standards development. The Global Microcomb Alliance, comprising leading research institutions and technology companies from North America, Europe, and Asia-Pacific regions, meets biannually to harmonize testing approaches and share best practices. Their published recommendations have become de facto standards in many research environments.

These collaborative efforts are gradually converging toward a unified framework for microcomb characterization, though challenges remain in reconciling different regional priorities and technological approaches. The establishment of international round-robin testing programs, where identical devices are measured in different facilities worldwide, has proven particularly effective in identifying and resolving discrepancies in measurement methodologies.

Similarly, the International Electrotechnical Commission (IEC) through its Technical Committee 86 on Fibre Optics has begun incorporating microcomb-specific considerations into its standardization framework. Their recent publication IEC 63287 provides preliminary guidelines for integrated photonic devices, with plans to expand coverage specifically for microcomb testing in upcoming revisions.

The International Organization for Standardization (ISO) has also recognized the strategic importance of microcomb technology, establishing collaborative projects between its technical committees on nanotechnology and photonics. These cross-disciplinary efforts aim to address the unique challenges posed by the nanoscale features and quantum properties of advanced microcomb devices.

Regional standardization bodies have made significant contributions as well. The European Telecommunications Standards Institute (ETSI) has developed preliminary specifications for microcomb-based telecommunications systems, while the National Institute of Standards and Technology (NIST) in the United States has published comprehensive measurement guidelines that are increasingly being adopted internationally.

Collaborative international research initiatives have been instrumental in driving standardization forward. The Integrated Photonic Systems Roadmap (IPSR), supported by multiple countries, has established a dedicated technical working group on microcomb metrics. Similarly, the International Photonics Consortium has launched a cross-border certification program for microcomb testing facilities to ensure global measurement consistency.

Industry-academia partnerships have emerged as crucial vehicles for standards development. The Global Microcomb Alliance, comprising leading research institutions and technology companies from North America, Europe, and Asia-Pacific regions, meets biannually to harmonize testing approaches and share best practices. Their published recommendations have become de facto standards in many research environments.

These collaborative efforts are gradually converging toward a unified framework for microcomb characterization, though challenges remain in reconciling different regional priorities and technological approaches. The establishment of international round-robin testing programs, where identical devices are measured in different facilities worldwide, has proven particularly effective in identifying and resolving discrepancies in measurement methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!