Electro-Optic Versus Kerr Microcomb Tradeoffs For System Integration

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microcomb Technology Background and Integration Goals

Microcombs represent a revolutionary technology in integrated photonics, emerging from the convergence of nonlinear optics and precision engineering. These devices generate multiple wavelengths of light from a single laser source through nonlinear optical processes within microscale resonators. The evolution of microcomb technology began in the early 2000s with fundamental research on optical frequency combs, which earned the 2005 Nobel Prize in Physics. Since then, the field has rapidly progressed from bulky laboratory setups to chip-scale devices that can be integrated with conventional semiconductor manufacturing processes.

The technological trajectory has been marked by significant breakthroughs in materials science, nanofabrication techniques, and nonlinear optics theory. Initially, microcombs were primarily demonstrated in silica and silicon nitride platforms, but recent advances have expanded the material palette to include lithium niobate, aluminum nitride, and diamond, each offering unique advantages for specific applications.

Two primary mechanisms have emerged for microcomb generation: Kerr-based and electro-optic (EO) approaches. Kerr microcombs rely on the third-order nonlinearity of materials to generate frequency combs through parametric four-wave mixing processes. In contrast, EO microcombs utilize second-order nonlinear effects and electrical modulation to create optical frequency combs. These distinct physical mechanisms result in fundamentally different device architectures, performance characteristics, and integration challenges.

The integration goals for microcomb technology are multifaceted and ambitious. Primary objectives include achieving full photonic integration with other components such as lasers, modulators, and detectors on a single chip platform. This requires addressing challenges in material compatibility, thermal management, and coupling efficiency. Another critical goal is reducing power consumption while maintaining or improving spectral purity and stability, essential for practical deployment in portable or space-constrained applications.

System-level integration aims to incorporate microcombs into functional devices for telecommunications, spectroscopy, metrology, and quantum information processing. This necessitates the development of standardized interfaces, robust packaging solutions, and reliable manufacturing processes that can transition from laboratory demonstrations to commercial production.

The ultimate technological objective is to create fully integrated, energy-efficient microcomb systems that can operate reliably in real-world environments while meeting the stringent performance requirements of applications ranging from high-capacity optical communications to precision timing and sensing. The trade-offs between Kerr and electro-optic approaches represent a critical decision point in this technological evolution, with significant implications for the future development and commercialization of integrated photonic systems.

The technological trajectory has been marked by significant breakthroughs in materials science, nanofabrication techniques, and nonlinear optics theory. Initially, microcombs were primarily demonstrated in silica and silicon nitride platforms, but recent advances have expanded the material palette to include lithium niobate, aluminum nitride, and diamond, each offering unique advantages for specific applications.

Two primary mechanisms have emerged for microcomb generation: Kerr-based and electro-optic (EO) approaches. Kerr microcombs rely on the third-order nonlinearity of materials to generate frequency combs through parametric four-wave mixing processes. In contrast, EO microcombs utilize second-order nonlinear effects and electrical modulation to create optical frequency combs. These distinct physical mechanisms result in fundamentally different device architectures, performance characteristics, and integration challenges.

The integration goals for microcomb technology are multifaceted and ambitious. Primary objectives include achieving full photonic integration with other components such as lasers, modulators, and detectors on a single chip platform. This requires addressing challenges in material compatibility, thermal management, and coupling efficiency. Another critical goal is reducing power consumption while maintaining or improving spectral purity and stability, essential for practical deployment in portable or space-constrained applications.

System-level integration aims to incorporate microcombs into functional devices for telecommunications, spectroscopy, metrology, and quantum information processing. This necessitates the development of standardized interfaces, robust packaging solutions, and reliable manufacturing processes that can transition from laboratory demonstrations to commercial production.

The ultimate technological objective is to create fully integrated, energy-efficient microcomb systems that can operate reliably in real-world environments while meeting the stringent performance requirements of applications ranging from high-capacity optical communications to precision timing and sensing. The trade-offs between Kerr and electro-optic approaches represent a critical decision point in this technological evolution, with significant implications for the future development and commercialization of integrated photonic systems.

Market Analysis for Integrated Photonic Systems

The integrated photonics market is experiencing significant growth, with the global market valued at approximately $31.5 billion in 2022 and projected to reach $99.3 billion by 2032, representing a CAGR of 12.3%. This growth is primarily driven by increasing demand for high-speed data transmission, telecommunications infrastructure expansion, and emerging applications in quantum computing and sensing technologies.

Within this broader market, microcomb technologies—specifically Electro-Optic (EO) and Kerr-based solutions—are positioned as critical components for next-generation integrated photonic systems. The demand for these technologies is particularly strong in data centers, where bandwidth requirements continue to escalate at 25-30% annually, necessitating more efficient optical interconnects.

Telecommunications represents the largest market segment for integrated photonics, accounting for 37% of the total market share. Here, microcombs offer significant advantages for wavelength division multiplexing (WDM) systems, potentially reducing power consumption by up to 90% compared to traditional discrete laser arrays.

The emerging quantum technology sector presents another high-growth opportunity, with market forecasts suggesting a 30.2% CAGR through 2030. Both EO and Kerr microcombs serve as essential components for quantum photonic processors and quantum key distribution systems.

Regional analysis reveals North America currently leads the integrated photonics market with 42% market share, followed by Asia-Pacific at 31% and Europe at 22%. However, Asia-Pacific is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in telecommunications infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation shows varying requirements across industries. Telecommunications providers prioritize scalability and reliability, while data center operators focus on power efficiency and integration density. Defense applications emphasize performance under extreme conditions, and medical device manufacturers require biocompatibility and stability.

Market barriers include high initial manufacturing costs, with foundry services for specialized photonic integrated circuits (PICs) ranging from $15,000 to $100,000 per production run. Technical challenges in packaging and testing also contribute to higher costs, with packaging often representing 60-80% of the total device cost.

The competitive landscape is characterized by increasing consolidation, with major semiconductor companies acquiring photonics startups to secure strategic technologies. This trend is expected to continue as the market matures and applications expand beyond current use cases into consumer electronics, automotive lidar, and biomedical sensing.

Within this broader market, microcomb technologies—specifically Electro-Optic (EO) and Kerr-based solutions—are positioned as critical components for next-generation integrated photonic systems. The demand for these technologies is particularly strong in data centers, where bandwidth requirements continue to escalate at 25-30% annually, necessitating more efficient optical interconnects.

Telecommunications represents the largest market segment for integrated photonics, accounting for 37% of the total market share. Here, microcombs offer significant advantages for wavelength division multiplexing (WDM) systems, potentially reducing power consumption by up to 90% compared to traditional discrete laser arrays.

The emerging quantum technology sector presents another high-growth opportunity, with market forecasts suggesting a 30.2% CAGR through 2030. Both EO and Kerr microcombs serve as essential components for quantum photonic processors and quantum key distribution systems.

Regional analysis reveals North America currently leads the integrated photonics market with 42% market share, followed by Asia-Pacific at 31% and Europe at 22%. However, Asia-Pacific is expected to demonstrate the highest growth rate over the next decade, driven by substantial investments in telecommunications infrastructure and manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation shows varying requirements across industries. Telecommunications providers prioritize scalability and reliability, while data center operators focus on power efficiency and integration density. Defense applications emphasize performance under extreme conditions, and medical device manufacturers require biocompatibility and stability.

Market barriers include high initial manufacturing costs, with foundry services for specialized photonic integrated circuits (PICs) ranging from $15,000 to $100,000 per production run. Technical challenges in packaging and testing also contribute to higher costs, with packaging often representing 60-80% of the total device cost.

The competitive landscape is characterized by increasing consolidation, with major semiconductor companies acquiring photonics startups to secure strategic technologies. This trend is expected to continue as the market matures and applications expand beyond current use cases into consumer electronics, automotive lidar, and biomedical sensing.

Current Challenges in Microcomb Integration

Despite significant advancements in microcomb technology, several critical challenges persist in their integration into practical systems. The fundamental challenge lies in achieving stable and reliable operation of microcombs in diverse environmental conditions. Temperature fluctuations, mechanical vibrations, and other external factors can significantly impact the performance of integrated microcombs, necessitating robust stabilization mechanisms.

For Kerr microcombs, the primary integration challenge stems from their inherent nonlinear nature. The threshold power requirements for initiating the comb generation process remain relatively high, typically in the milliwatt range, which poses significant power budget constraints for integrated photonic systems. Additionally, the complex dynamics of Kerr comb formation, including chaotic regimes and multiple stability regions, complicate their reliable operation in practical applications.

Electro-optic (EO) microcombs face different integration challenges. While they offer advantages in terms of lower power consumption and deterministic operation, they typically require higher drive voltages and more complex electronic control systems. The integration of efficient RF modulators with optical microresonators presents significant fabrication challenges, particularly in maintaining high quality factors while incorporating the modulation elements.

Material compatibility issues represent another significant hurdle. Silicon nitride platforms, commonly used for Kerr combs, offer excellent nonlinear properties but present integration difficulties with active components. Conversely, lithium niobate platforms used for EO combs provide excellent electro-optic properties but face challenges in achieving the same level of integration density as silicon-based platforms.

Packaging considerations further complicate microcomb integration. Efficient fiber-to-chip coupling remains a persistent challenge, with coupling losses significantly impacting overall system efficiency. Additionally, the need for precise temperature control and mechanical isolation adds complexity to the packaging requirements, increasing both size and cost of integrated systems.

From a manufacturing perspective, yield and reproducibility issues continue to plague microcomb fabrication. Small variations in fabrication processes can lead to significant deviations in resonator properties, affecting comb generation characteristics. This variability poses substantial challenges for large-scale production and commercial deployment of microcomb-based systems.

Finally, the co-integration of microcombs with electronic control systems presents significant design challenges. The development of compact, energy-efficient feedback control mechanisms necessary for stable comb operation requires careful consideration of both optical and electronic design constraints, further complicating the system integration process.

For Kerr microcombs, the primary integration challenge stems from their inherent nonlinear nature. The threshold power requirements for initiating the comb generation process remain relatively high, typically in the milliwatt range, which poses significant power budget constraints for integrated photonic systems. Additionally, the complex dynamics of Kerr comb formation, including chaotic regimes and multiple stability regions, complicate their reliable operation in practical applications.

Electro-optic (EO) microcombs face different integration challenges. While they offer advantages in terms of lower power consumption and deterministic operation, they typically require higher drive voltages and more complex electronic control systems. The integration of efficient RF modulators with optical microresonators presents significant fabrication challenges, particularly in maintaining high quality factors while incorporating the modulation elements.

Material compatibility issues represent another significant hurdle. Silicon nitride platforms, commonly used for Kerr combs, offer excellent nonlinear properties but present integration difficulties with active components. Conversely, lithium niobate platforms used for EO combs provide excellent electro-optic properties but face challenges in achieving the same level of integration density as silicon-based platforms.

Packaging considerations further complicate microcomb integration. Efficient fiber-to-chip coupling remains a persistent challenge, with coupling losses significantly impacting overall system efficiency. Additionally, the need for precise temperature control and mechanical isolation adds complexity to the packaging requirements, increasing both size and cost of integrated systems.

From a manufacturing perspective, yield and reproducibility issues continue to plague microcomb fabrication. Small variations in fabrication processes can lead to significant deviations in resonator properties, affecting comb generation characteristics. This variability poses substantial challenges for large-scale production and commercial deployment of microcomb-based systems.

Finally, the co-integration of microcombs with electronic control systems presents significant design challenges. The development of compact, energy-efficient feedback control mechanisms necessary for stable comb operation requires careful consideration of both optical and electronic design constraints, further complicating the system integration process.

Comparative Analysis of Electro-Optic and Kerr Microcomb Solutions

01 Electro-optic microcomb generation techniques

Electro-optic microcombs utilize modulation of light in optical waveguides to generate frequency combs. These systems typically employ lithium niobate or other electro-optic materials to create phase modulation that results in multiple frequency sidebands. The advantage of electro-optic microcombs is their ability to operate at lower optical powers compared to Kerr combs, making them suitable for integration in power-sensitive applications. These systems can achieve wide frequency spans through cascaded modulation techniques while maintaining good phase coherence between comb lines.- Electro-optic microcomb generation techniques: Electro-optic microcombs utilize modulation of light in optical waveguides to generate frequency combs. These systems typically employ electro-optic modulators to create sidebands from a continuous wave laser source. The advantage of this approach is the ability to precisely control the comb spacing through the modulation frequency, offering excellent stability and tunability. However, these systems face integration challenges related to coupling efficiency, power consumption, and maintaining phase coherence across the generated comb lines.

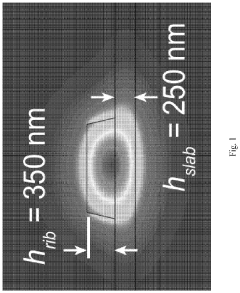

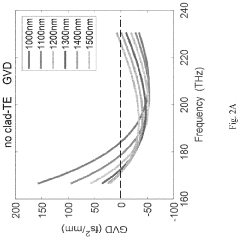

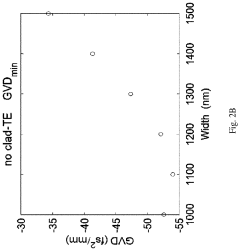

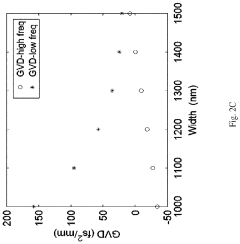

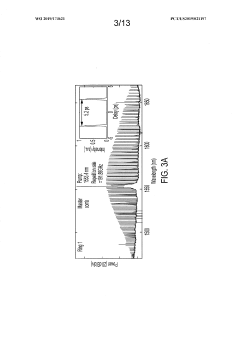

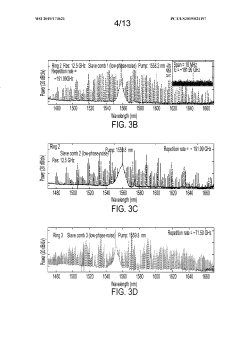

- Kerr microcomb fabrication and materials: Kerr microcombs rely on nonlinear optical effects in high-Q microresonators to generate frequency combs. The fabrication of these devices involves precise engineering of microring resonators using materials with strong Kerr nonlinearity. Integration challenges include maintaining high quality factors while ensuring compatibility with standard photonic fabrication processes. Material selection represents a critical tradeoff between nonlinear performance, optical losses, and thermal stability, with silicon nitride, silicon, and aluminum nitride being common platforms for integrated Kerr comb generation.

- System integration and packaging considerations: Integration of microcombs into practical systems presents significant tradeoffs in terms of size, power consumption, and performance. Packaging solutions must address thermal management, mechanical stability, and optical coupling efficiency. Hybrid integration approaches combining different material platforms can leverage the strengths of each technology but introduce additional manufacturing complexity. The choice between monolithic and hybrid integration depends on application requirements, with considerations for scalability, reliability, and cost effectiveness in commercial deployment scenarios.

- Power efficiency and thermal management: Power consumption represents a critical tradeoff in microcomb system design, particularly for portable or space-based applications. Kerr microcombs typically require high pump powers to initiate the comb generation process, while electro-optic approaches may consume significant RF driving power. Thermal management strategies must address both the heat generated by active components and the temperature sensitivity of the comb generation process itself. Advanced thermal design and feedback control systems can mitigate these challenges but add complexity to the overall system architecture.

- Application-specific optimization strategies: Microcomb systems must be optimized differently depending on their intended application, leading to various integration tradeoffs. For telecommunications, stability and channel spacing uniformity are prioritized, while sensing applications may emphasize spectral coverage and signal-to-noise ratio. Quantum information processing applications demand precise phase control and low noise performance. The choice between electro-optic and Kerr approaches depends on these application requirements, with hybrid solutions sometimes offering the best compromise between performance metrics such as size, power, bandwidth, and stability.

02 Kerr nonlinearity-based microcomb architectures

Kerr microcombs leverage nonlinear optical effects in high-Q microresonators to generate frequency combs. These systems rely on four-wave mixing processes that occur when high optical intensities circulate within compact resonator structures. The primary advantage of Kerr combs is their ability to generate broad spectral bandwidths with relatively simple pump configurations. However, they typically require precise control of dispersion properties and higher optical pump powers compared to electro-optic approaches. Integration challenges include thermal management and maintaining phase stability across operating conditions.Expand Specific Solutions03 Integration challenges for microcomb systems

System integration of microcombs presents several tradeoffs related to size, power consumption, and performance. Key challenges include thermal management, as both Kerr and electro-optic combs can be sensitive to temperature fluctuations that affect phase matching conditions. Packaging considerations must address optical coupling efficiency between components while maintaining mechanical stability. Integration with electronic control systems adds complexity but enables dynamic tuning capabilities. Material compatibility issues arise when combining different optical materials with semiconductor platforms, requiring careful interface design to minimize losses and reflections.Expand Specific Solutions04 Frequency stability and noise characteristics

Microcomb systems face tradeoffs between frequency span, stability, and noise performance. Electro-optic combs typically offer better frequency stability but narrower bandwidths, while Kerr combs can provide broader spectra but may exhibit higher phase noise. Stabilization techniques include optical phase-locked loops, self-referencing methods, and temperature control systems. The choice between different architectures depends on application requirements, with precision measurement applications demanding higher stability at the expense of bandwidth, while communications applications may prioritize broader frequency coverage with moderate noise performance.Expand Specific Solutions05 Application-specific optimization approaches

Microcomb systems can be optimized for specific applications by making appropriate tradeoffs in their design. For telecommunications, emphasis is placed on channel spacing uniformity and stability. For sensing applications, power efficiency and spectral coverage are prioritized. Integrated photonic circuits enable customized designs that balance performance metrics according to application needs. Hybrid approaches combining electro-optic and Kerr nonlinearities can leverage the advantages of both technologies, though at the cost of increased system complexity. Optimization strategies include dispersion engineering, resonator coupling adjustments, and pump wavelength selection.Expand Specific Solutions

Leading Companies and Research Institutions in Microcomb Development

The electro-optic versus Kerr microcomb technology landscape is currently in a transitional phase from research to early commercialization, with a global market projected to reach significant scale as integrated photonics matures. Leading academic institutions including MIT, Yale University, and Nanjing University are driving fundamental research, while companies like Huawei, IBM, and Siemens are developing practical applications. The technology maturity varies between approaches: electro-optic microcombs offer better integration potential with CMOS processes, benefiting companies like Infineon and Sharp, while Kerr microcombs deliver superior spectral purity, attracting research at institutions like UESTC and Fudan University. This competitive dynamic is shaping system integration tradeoffs as the technology advances toward commercial viability.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered significant advancements in integrated photonics, particularly in the field of microcombs. Their approach focuses on silicon nitride (Si3N4) based microresonators for Kerr frequency comb generation. MIT researchers have demonstrated ultra-low-loss Si3N4 resonators with Q factors exceeding 30 million, enabling efficient Kerr comb generation with threshold powers below 1 mW[1]. Their technology integrates these microresonators with on-chip waveguides and control electronics, creating a comprehensive platform for optical frequency comb applications. MIT has also developed novel techniques for dispersion engineering in these resonators, allowing precise control over the comb generation process and spectral characteristics. Their recent work includes demonstrating fully integrated soliton microcombs with repetition rates in the microwave domain (10-100 GHz), making them suitable for telecommunications and microwave photonics applications[2].

Strengths: Exceptional expertise in high-Q resonator fabrication, leading to ultra-low power operation; strong integration capabilities with CMOS-compatible processes; comprehensive understanding of nonlinear optical dynamics. Weaknesses: Kerr comb solutions may face challenges in power efficiency compared to electro-optic approaches; fabrication complexity may impact manufacturing scalability and cost.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a hybrid approach to microcomb technology, leveraging both electro-optic (EO) and Kerr nonlinear effects for different application scenarios. Their EO comb solution utilizes lithium niobate on insulator (LNOI) platform, achieving high modulation efficiency with Vπ values below 3V and bandwidths exceeding 70 GHz[1]. For applications requiring broader spectral coverage, Huawei employs silicon nitride-based Kerr microresonators integrated with tunable lasers and control electronics. Their proprietary "ComboNIC" technology combines these approaches with digital signal processing for telecommunications applications, enabling coherent optical communications with spectral efficiencies exceeding 10 bits/s/Hz[2]. Huawei has also demonstrated compact, energy-efficient microcomb modules for data center interconnects, with power consumption below 0.1 pJ/bit for short-reach applications. Their integration strategy includes co-packaging of photonic and electronic components using advanced 2.5D and 3D integration techniques to minimize footprint and maximize performance[3].

Strengths: Comprehensive expertise across both EO and Kerr comb technologies; strong vertical integration capabilities from materials to systems; extensive intellectual property portfolio in telecommunications applications. Weaknesses: Proprietary nature of solutions may limit ecosystem development; higher system complexity when implementing hybrid approaches may increase costs and integration challenges.

Key Patents and Breakthroughs in Microcomb Integration

Optical frequency comb generation in integrated lithium niobate devices

PatentActiveUS20230049538A1

Innovation

- The use of lithium niobate (LN) microresonators with integrated electro-optic and Kerr nonlinearities, enabling the generation of wide-spanning frequency combs through anomalous dispersion engineering and electro-optic modulation, allowing for both Kerr and electro-optic frequency comb generation on a single chip.

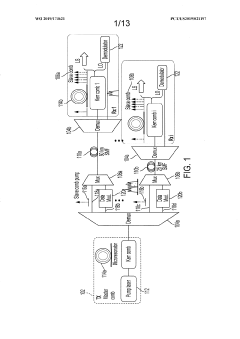

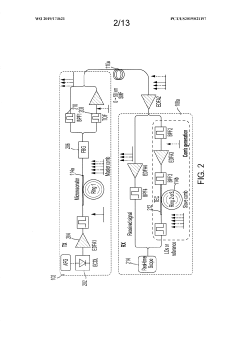

Multiple KERR-frequency-comb generation using different lines from a remote KERR comb

PatentWO2019173621A1

Innovation

- An optical communication system that generates multiple Kerr frequency combs from a single master comb by splitting and demultiplexing the master comb into multiple lines, using these lines as slave comb pumps to create coherent frequency combs at remote receivers, thereby reducing hardware complexity and phase noise.

Material Science Considerations for Microcomb Fabrication

Material selection and engineering represent critical factors in the development and performance of microcombs for integrated photonic systems. The fabrication of high-quality microcombs requires materials with specific optical, mechanical, and thermal properties that can significantly influence the trade-offs between electro-optic and Kerr-based approaches.

For Kerr microcombs, materials with high nonlinear refractive indices (n₂) are essential to achieve efficient parametric frequency conversion at reasonable power levels. Silicon nitride (Si₃N₄) has emerged as a leading platform due to its high n₂ (~2.5×10⁻¹⁹ m²/W), wide transparency window, and CMOS compatibility. However, the deposition of thick, low-loss Si₃N₄ films presents significant challenges, including film cracking and void formation during high-temperature annealing processes.

Alternative materials such as Ta₂O₅, AlN, and SiC offer promising nonlinear properties but face their own fabrication challenges. Tantalum pentoxide provides excellent optical properties but suffers from crystallization issues at high temperatures. Aluminum nitride offers piezoelectric capabilities alongside nonlinearity but requires specialized deposition techniques to achieve low optical loss.

For electro-optic microcombs, materials with strong Pockels effect such as lithium niobate (LiNbO₃) and barium titanate (BaTiO₃) are preferred. Thin-film lithium niobate on insulator (TFLN) has revolutionized this field, offering both strong electro-optic coefficients (~30 pm/V) and reduced propagation losses (<0.1 dB/cm). However, integration challenges remain due to the complex bonding and thinning processes required.

Material interfaces and heterogeneous integration present additional considerations. The quality of interfaces between different material layers significantly impacts optical losses and device performance. Advanced techniques such as wafer bonding, epitaxial growth, and atomic layer deposition are being developed to create high-quality interfaces between dissimilar materials.

Thermal management represents another critical material science consideration. Materials with high thermal conductivity and low thermo-optic coefficients are desirable to minimize thermal drift and ensure stable operation. Diamond integration has emerged as a promising approach for heat dissipation in high-power microcomb systems.

Fabrication scalability and yield also influence material selection decisions. While some materials offer superior optical properties, their processing complexity may limit large-scale manufacturing potential. Silicon nitride currently offers the best balance between performance and manufacturing scalability, though emerging techniques for lithium niobate processing are rapidly advancing.

The development of novel composite materials and engineered structures represents a frontier in microcomb fabrication. Hybrid integration approaches combining the strengths of multiple material platforms may ultimately provide the optimal solution for system-level integration of microcombs in practical applications.

For Kerr microcombs, materials with high nonlinear refractive indices (n₂) are essential to achieve efficient parametric frequency conversion at reasonable power levels. Silicon nitride (Si₃N₄) has emerged as a leading platform due to its high n₂ (~2.5×10⁻¹⁹ m²/W), wide transparency window, and CMOS compatibility. However, the deposition of thick, low-loss Si₃N₄ films presents significant challenges, including film cracking and void formation during high-temperature annealing processes.

Alternative materials such as Ta₂O₅, AlN, and SiC offer promising nonlinear properties but face their own fabrication challenges. Tantalum pentoxide provides excellent optical properties but suffers from crystallization issues at high temperatures. Aluminum nitride offers piezoelectric capabilities alongside nonlinearity but requires specialized deposition techniques to achieve low optical loss.

For electro-optic microcombs, materials with strong Pockels effect such as lithium niobate (LiNbO₃) and barium titanate (BaTiO₃) are preferred. Thin-film lithium niobate on insulator (TFLN) has revolutionized this field, offering both strong electro-optic coefficients (~30 pm/V) and reduced propagation losses (<0.1 dB/cm). However, integration challenges remain due to the complex bonding and thinning processes required.

Material interfaces and heterogeneous integration present additional considerations. The quality of interfaces between different material layers significantly impacts optical losses and device performance. Advanced techniques such as wafer bonding, epitaxial growth, and atomic layer deposition are being developed to create high-quality interfaces between dissimilar materials.

Thermal management represents another critical material science consideration. Materials with high thermal conductivity and low thermo-optic coefficients are desirable to minimize thermal drift and ensure stable operation. Diamond integration has emerged as a promising approach for heat dissipation in high-power microcomb systems.

Fabrication scalability and yield also influence material selection decisions. While some materials offer superior optical properties, their processing complexity may limit large-scale manufacturing potential. Silicon nitride currently offers the best balance between performance and manufacturing scalability, though emerging techniques for lithium niobate processing are rapidly advancing.

The development of novel composite materials and engineered structures represents a frontier in microcomb fabrication. Hybrid integration approaches combining the strengths of multiple material platforms may ultimately provide the optimal solution for system-level integration of microcombs in practical applications.

Energy Efficiency and Power Requirements for Practical Applications

Energy efficiency represents a critical factor in the practical deployment of microcomb technologies, with significant implications for system integration across various applications. When comparing Electro-Optic (EO) and Kerr microcombs, their power consumption profiles differ substantially due to fundamental operational mechanisms. Kerr microcombs typically require high optical pump powers to initiate the parametric oscillation process necessary for comb generation, often demanding tens to hundreds of milliwatts of continuous optical power.

In contrast, EO microcombs can operate at significantly lower optical power levels, as they rely on electro-optic modulation rather than nonlinear optical processes. This fundamental difference translates to potential power savings of one to two orders of magnitude in certain configurations, making EO approaches particularly attractive for power-constrained applications such as satellite communications, portable sensing devices, and battery-operated systems.

The wall-plug efficiency presents another crucial consideration. While Kerr microcombs may require less electronic control circuitry, their need for high-power laser pumps with precise wavelength control often results in substantial power conversion losses. EO systems benefit from mature electronic amplifier technology but suffer from conversion inefficiencies in the electro-optic modulation process. Recent advancements in thin-film lithium niobate platforms have significantly improved EO modulation efficiency, narrowing this gap.

Thermal management requirements also differ markedly between the two approaches. Kerr microcombs generate considerable heat due to their high optical power density, necessitating sophisticated thermal dissipation strategies that add complexity and weight to integrated systems. The lower power operation of EO microcombs generally results in reduced thermal loads, simplifying thermal management and potentially improving long-term reliability in deployed systems.

For battery-powered applications, the duty cycle capabilities become particularly relevant. EO microcombs offer superior performance in intermittent operation scenarios, as they can be rapidly activated and deactivated with minimal startup energy. Kerr systems typically require longer stabilization periods and higher initialization energy, making them less suitable for burst-mode operations where power conservation between active periods is essential.

Recent research demonstrates promising developments in hybrid approaches that leverage the advantages of both technologies. These systems utilize low-power EO seeding combined with power-efficient Kerr amplification stages, potentially offering an optimal balance between energy efficiency and spectral performance for next-generation integrated photonic systems.

In contrast, EO microcombs can operate at significantly lower optical power levels, as they rely on electro-optic modulation rather than nonlinear optical processes. This fundamental difference translates to potential power savings of one to two orders of magnitude in certain configurations, making EO approaches particularly attractive for power-constrained applications such as satellite communications, portable sensing devices, and battery-operated systems.

The wall-plug efficiency presents another crucial consideration. While Kerr microcombs may require less electronic control circuitry, their need for high-power laser pumps with precise wavelength control often results in substantial power conversion losses. EO systems benefit from mature electronic amplifier technology but suffer from conversion inefficiencies in the electro-optic modulation process. Recent advancements in thin-film lithium niobate platforms have significantly improved EO modulation efficiency, narrowing this gap.

Thermal management requirements also differ markedly between the two approaches. Kerr microcombs generate considerable heat due to their high optical power density, necessitating sophisticated thermal dissipation strategies that add complexity and weight to integrated systems. The lower power operation of EO microcombs generally results in reduced thermal loads, simplifying thermal management and potentially improving long-term reliability in deployed systems.

For battery-powered applications, the duty cycle capabilities become particularly relevant. EO microcombs offer superior performance in intermittent operation scenarios, as they can be rapidly activated and deactivated with minimal startup energy. Kerr systems typically require longer stabilization periods and higher initialization energy, making them less suitable for burst-mode operations where power conservation between active periods is essential.

Recent research demonstrates promising developments in hybrid approaches that leverage the advantages of both technologies. These systems utilize low-power EO seeding combined with power-efficient Kerr amplification stages, potentially offering an optimal balance between energy efficiency and spectral performance for next-generation integrated photonic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!