Montmorillonite for Use in Foam Formulation: Density Optimization

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Foam Technology Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has emerged as a significant material in advanced foam formulation technologies over the past three decades. The evolution of this technology can be traced back to the 1990s when researchers first began exploring clay minerals as potential additives for polymer foams, seeking alternatives to traditional chemical blowing agents and foam stabilizers.

The technological trajectory has shown remarkable advancement, transitioning from basic incorporation of untreated montmorillonite in foam matrices to sophisticated surface-modified variants that offer enhanced compatibility with various polymer systems. This progression has been driven by the increasing demand for lightweight materials with superior mechanical properties across industries such as automotive, construction, packaging, and aerospace.

Recent developments have focused on exploiting the unique layered silicate structure of montmorillonite, which provides exceptional surface area (700-800 m²/g) and cation exchange capacity. These properties make montmorillonite particularly valuable for controlling foam cell nucleation, stabilization, and ultimately, density optimization—a critical parameter that directly influences material performance and cost-effectiveness.

The primary technological objective in this field centers on achieving precise control over foam density while maintaining or enhancing other essential properties such as thermal insulation, mechanical strength, and fire resistance. Specifically, researchers aim to develop montmorillonite-based foam formulations that can achieve density reductions of 15-30% compared to conventional foams without compromising structural integrity or functional performance.

Current technological goals include developing standardized methods for montmorillonite dispersion in various polymer matrices, optimizing the intercalation and exfoliation processes, and establishing quantitative relationships between montmorillonite concentration, modification type, and resultant foam density. Additionally, there is significant interest in creating responsive foam systems where density can be adjusted through external stimuli or processing conditions.

The environmental dimension of this technology cannot be overlooked, as montmorillonite represents a sustainable alternative to petroleum-based foam additives. The biodegradability and natural abundance of montmorillonite align with growing industry trends toward greener manufacturing processes and reduced environmental footprint.

Looking forward, the technological trajectory points toward multifunctional montmorillonite-foam composites that simultaneously address density optimization while imparting additional properties such as electromagnetic shielding, controlled release capabilities, or self-healing characteristics—expanding the application spectrum beyond traditional foam uses.

The technological trajectory has shown remarkable advancement, transitioning from basic incorporation of untreated montmorillonite in foam matrices to sophisticated surface-modified variants that offer enhanced compatibility with various polymer systems. This progression has been driven by the increasing demand for lightweight materials with superior mechanical properties across industries such as automotive, construction, packaging, and aerospace.

Recent developments have focused on exploiting the unique layered silicate structure of montmorillonite, which provides exceptional surface area (700-800 m²/g) and cation exchange capacity. These properties make montmorillonite particularly valuable for controlling foam cell nucleation, stabilization, and ultimately, density optimization—a critical parameter that directly influences material performance and cost-effectiveness.

The primary technological objective in this field centers on achieving precise control over foam density while maintaining or enhancing other essential properties such as thermal insulation, mechanical strength, and fire resistance. Specifically, researchers aim to develop montmorillonite-based foam formulations that can achieve density reductions of 15-30% compared to conventional foams without compromising structural integrity or functional performance.

Current technological goals include developing standardized methods for montmorillonite dispersion in various polymer matrices, optimizing the intercalation and exfoliation processes, and establishing quantitative relationships between montmorillonite concentration, modification type, and resultant foam density. Additionally, there is significant interest in creating responsive foam systems where density can be adjusted through external stimuli or processing conditions.

The environmental dimension of this technology cannot be overlooked, as montmorillonite represents a sustainable alternative to petroleum-based foam additives. The biodegradability and natural abundance of montmorillonite align with growing industry trends toward greener manufacturing processes and reduced environmental footprint.

Looking forward, the technological trajectory points toward multifunctional montmorillonite-foam composites that simultaneously address density optimization while imparting additional properties such as electromagnetic shielding, controlled release capabilities, or self-healing characteristics—expanding the application spectrum beyond traditional foam uses.

Market Analysis for Lightweight Clay-Based Foam Materials

The global market for lightweight clay-based foam materials has experienced significant growth in recent years, driven by increasing demand for sustainable, high-performance insulation materials across multiple industries. The current market size for these materials is estimated at $3.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching $4.7 billion by that time.

Construction and building materials represent the largest application segment, accounting for approximately 45% of the total market share. This dominance stems from the superior thermal insulation properties of montmorillonite-based foams, which can reduce energy consumption in buildings by up to 30% compared to traditional insulation materials. The automotive sector follows as the second-largest consumer, utilizing these materials for lightweight components that contribute to improved fuel efficiency and reduced emissions.

Regional analysis reveals that North America currently leads the market with a 38% share, followed closely by Europe at 32%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 9.2% annually, primarily driven by rapid industrialization and construction activities in China and India. These emerging markets present substantial opportunities for manufacturers looking to expand their global footprint.

Consumer preferences are increasingly shifting toward eco-friendly and sustainable materials, creating a favorable environment for montmorillonite-based foams which offer biodegradability and reduced carbon footprint compared to petroleum-based alternatives. This trend is further reinforced by stringent environmental regulations in developed markets that mandate the use of sustainable building materials.

Price sensitivity remains a critical factor influencing market dynamics, with lightweight clay-based foams currently commanding a premium of 15-20% over conventional materials. However, this price differential is expected to narrow as production scales up and manufacturing processes become more efficient. The optimal price point for widespread adoption appears to be within 10% of traditional alternatives.

Key market challenges include competition from established synthetic foam manufacturers and the need for consistent quality control in montmorillonite sourcing. Additionally, there is a knowledge gap among end-users regarding the benefits and applications of these materials, necessitating increased educational and marketing efforts by industry players.

Future market growth will likely be driven by innovations in density optimization techniques that can further reduce weight while maintaining structural integrity, as well as expanded applications in emerging sectors such as aerospace, marine, and specialized packaging. The development of hybrid materials combining montmorillonite with other sustainable components also presents significant market potential.

Construction and building materials represent the largest application segment, accounting for approximately 45% of the total market share. This dominance stems from the superior thermal insulation properties of montmorillonite-based foams, which can reduce energy consumption in buildings by up to 30% compared to traditional insulation materials. The automotive sector follows as the second-largest consumer, utilizing these materials for lightweight components that contribute to improved fuel efficiency and reduced emissions.

Regional analysis reveals that North America currently leads the market with a 38% share, followed closely by Europe at 32%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 9.2% annually, primarily driven by rapid industrialization and construction activities in China and India. These emerging markets present substantial opportunities for manufacturers looking to expand their global footprint.

Consumer preferences are increasingly shifting toward eco-friendly and sustainable materials, creating a favorable environment for montmorillonite-based foams which offer biodegradability and reduced carbon footprint compared to petroleum-based alternatives. This trend is further reinforced by stringent environmental regulations in developed markets that mandate the use of sustainable building materials.

Price sensitivity remains a critical factor influencing market dynamics, with lightweight clay-based foams currently commanding a premium of 15-20% over conventional materials. However, this price differential is expected to narrow as production scales up and manufacturing processes become more efficient. The optimal price point for widespread adoption appears to be within 10% of traditional alternatives.

Key market challenges include competition from established synthetic foam manufacturers and the need for consistent quality control in montmorillonite sourcing. Additionally, there is a knowledge gap among end-users regarding the benefits and applications of these materials, necessitating increased educational and marketing efforts by industry players.

Future market growth will likely be driven by innovations in density optimization techniques that can further reduce weight while maintaining structural integrity, as well as expanded applications in emerging sectors such as aerospace, marine, and specialized packaging. The development of hybrid materials combining montmorillonite with other sustainable components also presents significant market potential.

Current Challenges in Montmorillonite Foam Density Reduction

Despite the promising properties of montmorillonite (MMT) in foam formulations, significant challenges persist in achieving optimal density reduction while maintaining structural integrity. The primary obstacle lies in the inherent hydrophilic nature of pristine montmorillonite, which limits its compatibility with hydrophobic polymer matrices commonly used in foam production. This incompatibility often results in uneven dispersion and agglomeration of MMT particles, creating structural weaknesses that compromise density optimization efforts.

The high aspect ratio of montmorillonite platelets, while beneficial for mechanical reinforcement, presents challenges in controlling cell nucleation and growth during foam formation. When improperly dispersed, MMT particles can disrupt the uniform cellular structure necessary for achieving consistent low-density foams. This disruption manifests as irregular cell size distribution, leading to density variations throughout the foam matrix.

Another significant challenge involves the moisture sensitivity of montmorillonite. The clay's tendency to absorb water molecules affects the foam's dimensional stability and can lead to density fluctuations in varying humidity conditions. This hygroscopic behavior necessitates additional processing steps or surface modifications, complicating manufacturing protocols and potentially increasing production costs.

The processing parameters for MMT-reinforced foams present another hurdle in density optimization. The incorporation of montmorillonite often increases the viscosity of polymer melts, requiring adjustments to processing temperatures and pressures. These modifications can affect the foaming kinetics and cell structure development, making it difficult to achieve the desired density targets consistently across production batches.

Surface modification techniques, while effective in improving MMT-polymer compatibility, introduce their own set of challenges. Organic modifiers used for clay surface treatment may degrade at high processing temperatures, releasing volatile compounds that interfere with controlled cell formation. Additionally, the type and concentration of surfactants used in modification significantly impact the final foam density, requiring precise formulation control.

The trade-off between density reduction and mechanical properties represents perhaps the most persistent challenge. As foam density decreases, mechanical properties such as compression strength and impact resistance typically deteriorate. Finding the optimal balance where montmorillonite provides sufficient reinforcement to maintain mechanical integrity while allowing for maximum density reduction remains elusive for many applications.

Scalability issues further complicate industrial implementation of MMT-based foam density optimization. Laboratory-scale successes often prove difficult to replicate in industrial settings due to challenges in achieving uniform dispersion of montmorillonite in large-volume production and maintaining consistent processing conditions throughout scaled-up manufacturing operations.

The high aspect ratio of montmorillonite platelets, while beneficial for mechanical reinforcement, presents challenges in controlling cell nucleation and growth during foam formation. When improperly dispersed, MMT particles can disrupt the uniform cellular structure necessary for achieving consistent low-density foams. This disruption manifests as irregular cell size distribution, leading to density variations throughout the foam matrix.

Another significant challenge involves the moisture sensitivity of montmorillonite. The clay's tendency to absorb water molecules affects the foam's dimensional stability and can lead to density fluctuations in varying humidity conditions. This hygroscopic behavior necessitates additional processing steps or surface modifications, complicating manufacturing protocols and potentially increasing production costs.

The processing parameters for MMT-reinforced foams present another hurdle in density optimization. The incorporation of montmorillonite often increases the viscosity of polymer melts, requiring adjustments to processing temperatures and pressures. These modifications can affect the foaming kinetics and cell structure development, making it difficult to achieve the desired density targets consistently across production batches.

Surface modification techniques, while effective in improving MMT-polymer compatibility, introduce their own set of challenges. Organic modifiers used for clay surface treatment may degrade at high processing temperatures, releasing volatile compounds that interfere with controlled cell formation. Additionally, the type and concentration of surfactants used in modification significantly impact the final foam density, requiring precise formulation control.

The trade-off between density reduction and mechanical properties represents perhaps the most persistent challenge. As foam density decreases, mechanical properties such as compression strength and impact resistance typically deteriorate. Finding the optimal balance where montmorillonite provides sufficient reinforcement to maintain mechanical integrity while allowing for maximum density reduction remains elusive for many applications.

Scalability issues further complicate industrial implementation of MMT-based foam density optimization. Laboratory-scale successes often prove difficult to replicate in industrial settings due to challenges in achieving uniform dispersion of montmorillonite in large-volume production and maintaining consistent processing conditions throughout scaled-up manufacturing operations.

Current Montmorillonite Foam Formulation Methodologies

01 Density range and measurement of montmorillonite

Montmorillonite typically has a density range of 2.0-2.7 g/cm³, with variations depending on its composition and purity. The density can be measured using techniques such as pycnometry, helium displacement, or liquid displacement methods. The density is an important physical property that affects the material's applications in various industries, including as fillers, adsorbents, and in drilling fluids.- Density range and measurement of montmorillonite: Montmorillonite typically has a density range of 2.0-2.7 g/cm³, with variations depending on its composition and purity. The density can be measured using techniques such as pycnometry, helium displacement, or liquid displacement methods. The density is an important physical property that affects the material's applications in various industries, including as fillers, adsorbents, and in drilling fluids.

- Modification of montmorillonite to alter density properties: Various modification techniques can be applied to montmorillonite to alter its density properties. These include organic modification with quaternary ammonium compounds, acid activation, thermal treatment, and pillaring with metal oxides. Modified montmorillonites often exhibit different density characteristics compared to their natural counterparts, which can be advantageous for specific applications such as polymer composites, wastewater treatment, and catalysis.

- Relationship between montmorillonite density and water content: The density of montmorillonite is significantly influenced by its water content due to its swelling properties. As water molecules intercalate between the clay layers, the interlayer spacing increases, resulting in a decrease in bulk density. This relationship is particularly important in applications such as geotechnical engineering, where the swelling behavior affects soil stability, and in formulations where controlled release of substances is desired.

- Density of montmorillonite composites and nanocomposites: When montmorillonite is incorporated into composites and nanocomposites, the resulting material's density is influenced by the clay content, dispersion quality, and interaction with the matrix material. These composites often exhibit enhanced mechanical, thermal, and barrier properties compared to the neat matrix material. The density of these composites can be tailored by adjusting the montmorillonite content and processing conditions to meet specific application requirements.

- Industrial applications leveraging montmorillonite density characteristics: The density characteristics of montmorillonite are leveraged in various industrial applications. In drilling fluids, montmorillonite's density helps control viscosity and fluid loss. In environmental remediation, its density affects adsorption capacity for pollutants. In pharmaceutical and cosmetic formulations, montmorillonite's density influences product stability and rheological properties. The material's density also plays a role in ceramic processing, paper coating, and as a reinforcing agent in polymer systems.

02 Modification of montmorillonite to alter density properties

Various modification techniques can be applied to montmorillonite to alter its density properties. These include organic modification with quaternary ammonium compounds, acid activation, thermal treatment, and pillaring with metal oxides. Modified montmorillonites often show different density characteristics compared to their natural counterparts, which can be beneficial for specific applications such as polymer nanocomposites, wastewater treatment, and catalysis.Expand Specific Solutions03 Relationship between montmorillonite density and water content

The density of montmorillonite is significantly affected by its water content due to its swelling properties. As water molecules intercalate between the clay layers, the interlayer spacing increases, resulting in decreased bulk density. This relationship is crucial in applications where montmorillonite's swelling behavior is utilized, such as in barrier systems, sealants, and controlled release formulations.Expand Specific Solutions04 Density variations in montmorillonite-polymer composites

When montmorillonite is incorporated into polymer matrices to form composites, the resulting material exhibits density characteristics that differ from both the pure clay and the pure polymer. The density of these composites depends on factors such as the clay loading percentage, degree of exfoliation or intercalation, and the nature of the polymer matrix. These composites find applications in packaging, automotive parts, and flame-retardant materials.Expand Specific Solutions05 Industrial applications leveraging montmorillonite density properties

The density properties of montmorillonite are leveraged in various industrial applications. In drilling fluids, montmorillonite's density helps control fluid viscosity and provides wall stability. In wastewater treatment, its density affects sedimentation rates and filtration efficiency. In pharmaceutical and cosmetic formulations, montmorillonite's density influences product texture, stability, and controlled release properties. The material's density also plays a role in its use as a reinforcing filler in plastics and rubber.Expand Specific Solutions

Leading Companies and Research Institutions in Clay-Foam Technology

The montmorillonite foam formulation market for density optimization is currently in a growth phase, characterized by increasing demand for lightweight materials across industries. The market size is expanding due to applications in automotive, construction, and packaging sectors, with an estimated annual growth rate of 5-7%. Technologically, the field is moderately mature but still evolving, with key players demonstrating varying levels of innovation. Northwestern University and University of Strathclyde lead academic research, while companies like LG Chem, Arkema, and Toray Industries have developed commercial applications. Henkel and SABIC are advancing formulation techniques, while specialized players like Zhejiang Fenghong New Material focus on specific applications. The competitive landscape shows a mix of large chemical corporations and specialized material science companies working to optimize montmorillonite's density-reducing properties in foam systems.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a sophisticated approach to montmorillonite integration in foam formulations, focusing specifically on density optimization for lightweight applications. Their technology centers on a proprietary organo-modification process for montmorillonite that enhances its compatibility with various polymer matrices. The company employs a multi-stage exfoliation technique that achieves nanoscale dispersion of clay platelets throughout the foam structure, creating an interconnected network that reinforces cell walls while maintaining low density. LG Chem's process involves precise control of clay loading levels (typically 1-5 wt%) and specialized processing parameters that optimize nucleation effects during foaming. Their research demonstrates that properly dispersed montmorillonite can reduce foam density by up to 25% while simultaneously improving mechanical properties and dimensional stability. The company has also developed hybrid systems combining montmorillonite with other nanofillers to achieve synergistic effects in foam performance, particularly for applications requiring enhanced thermal insulation and fire resistance properties.

Strengths: Strong R&D capabilities in polymer-clay nanocomposites; vertical integration providing control over raw material quality; extensive experience in commercial-scale production of lightweight materials. Weaknesses: Higher material costs compared to conventional foam formulations; requires precise process control to achieve optimal clay dispersion; potential challenges with recycling of clay-containing foam products.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed an innovative approach to montmorillonite incorporation in foam formulations through their patented "ClayCell" technology. This system utilizes specially modified montmorillonite clays that undergo a proprietary surface treatment process to enhance their compatibility with various foam polymer matrices. Henkel's technique involves precise control of clay platelet orientation during the foaming process, creating anisotropic cell structures that optimize mechanical properties while minimizing density. Their research has demonstrated that strategic placement of montmorillonite at cell interfaces can reduce foam density by 10-30% while maintaining structural integrity. The company employs a multi-phase mixing protocol where modified clay is first pre-dispersed in compatible carriers before incorporation into the main polymer system, ensuring homogeneous distribution throughout the foam matrix. Henkel has particularly focused on applications requiring enhanced thermal stability and flame retardancy, where their montmorillonite-enhanced foams show significant improvements in limiting oxygen index (LOI) values and reduced heat release rates during combustion while maintaining lower density profiles compared to conventional flame-retardant systems.

Strengths: Extensive formulation expertise across multiple polymer systems; strong position in adhesives and sealants markets provides application knowledge; well-established quality control systems for consistent performance. Weaknesses: Technology may be more suited to specialty applications rather than commodity foam products; potential challenges with processing speed in high-volume manufacturing; possible color limitations in end products due to clay content.

Key Patents and Research on Montmorillonite Density Modification

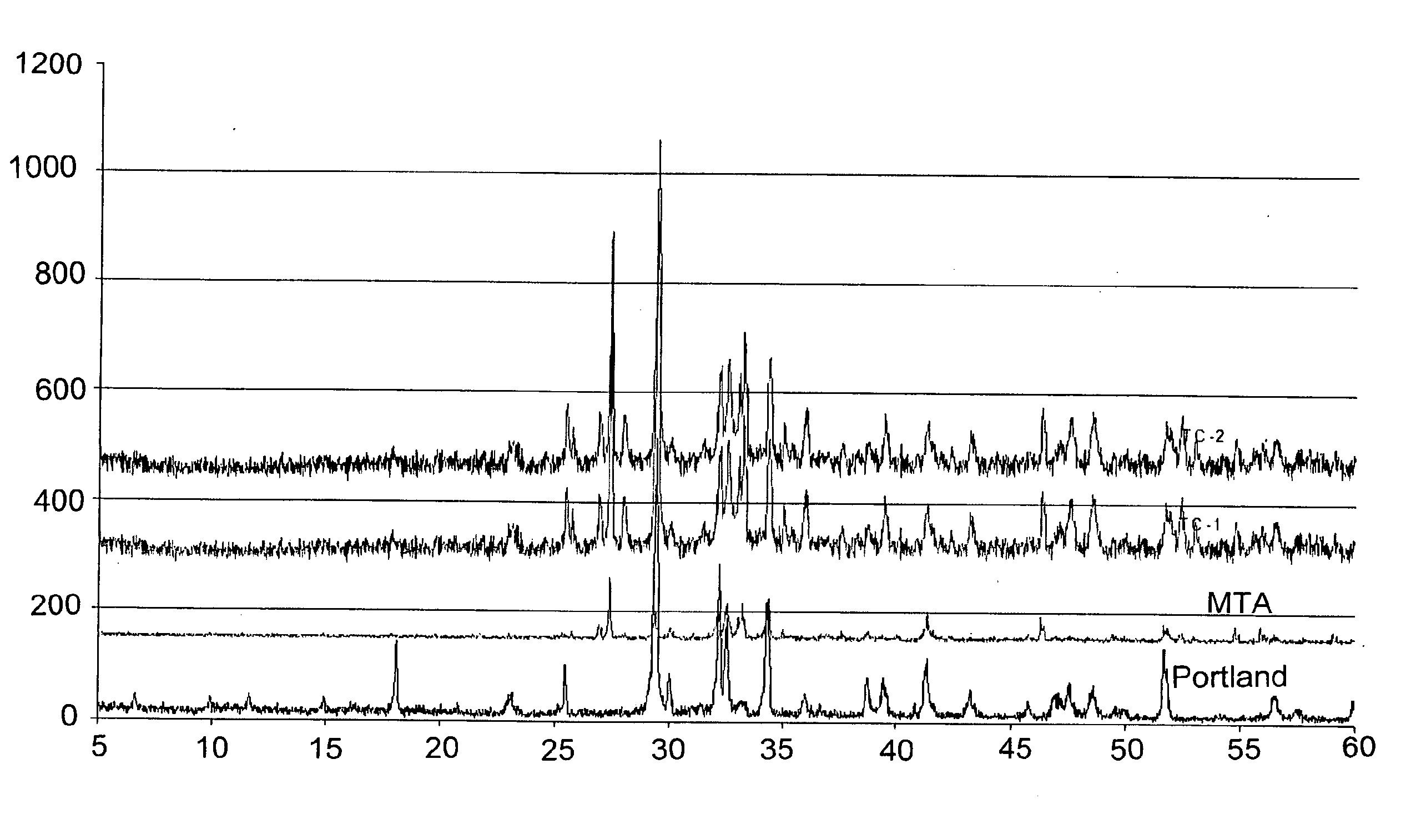

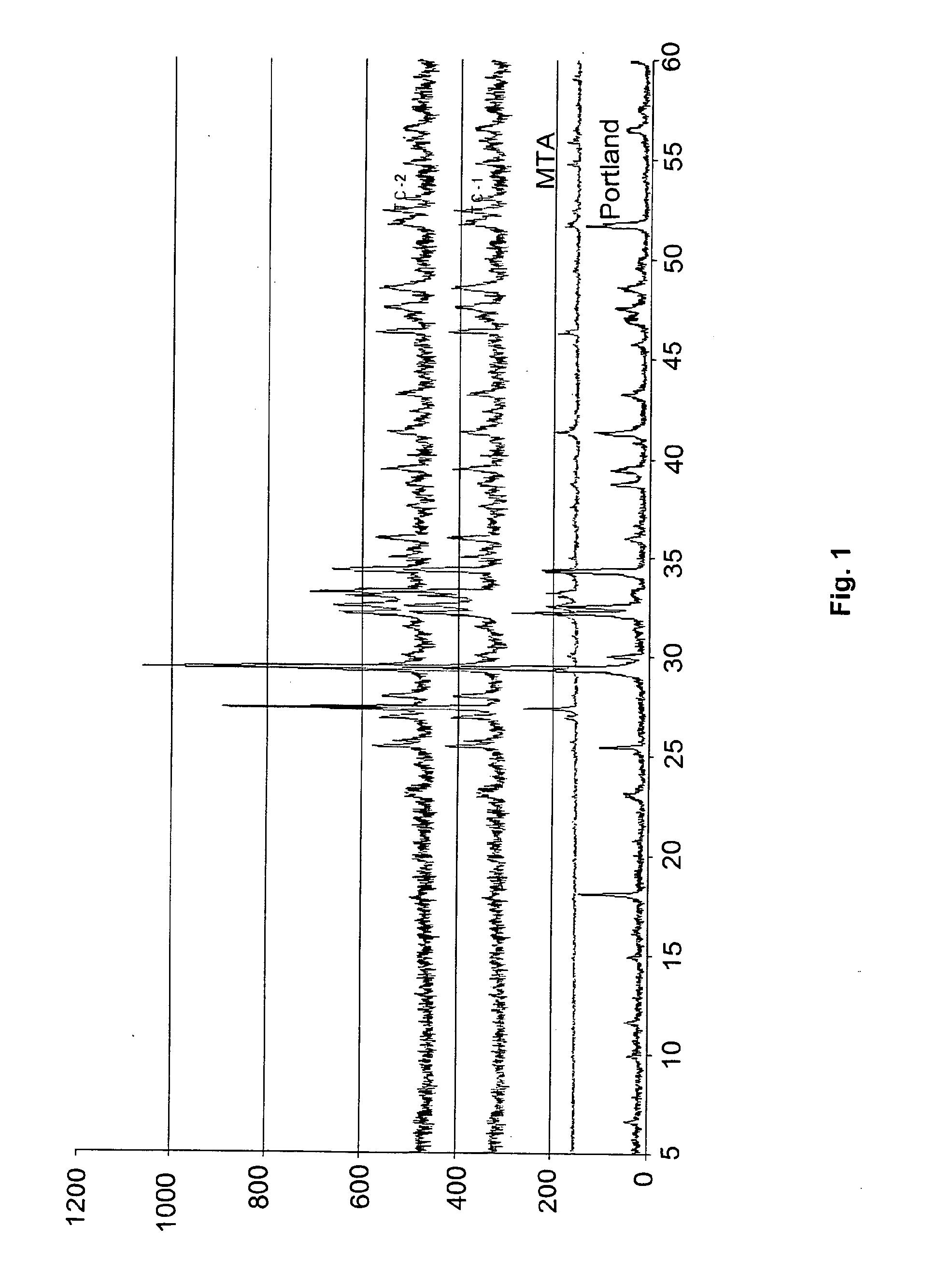

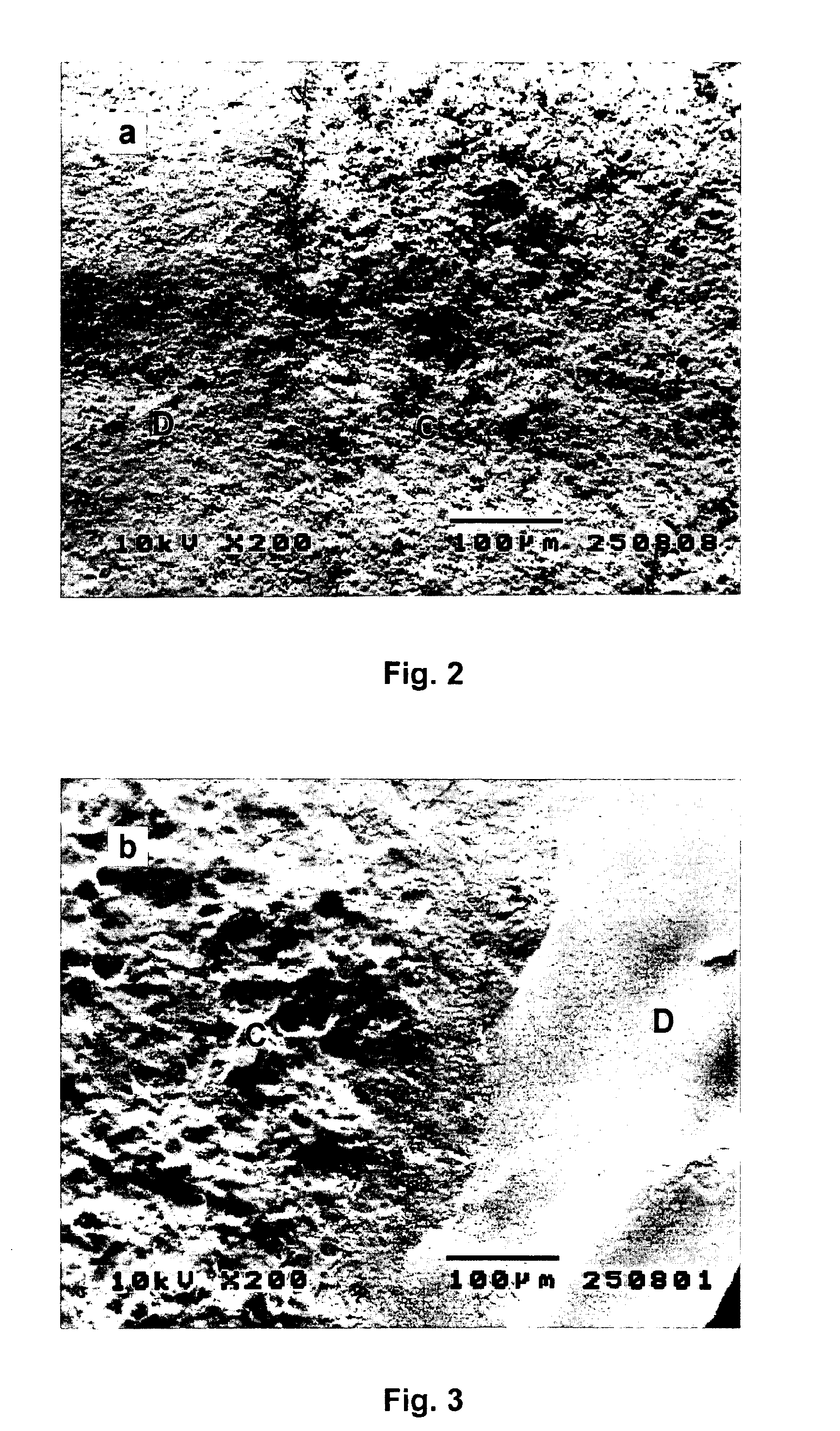

Composition for use in dentistry

PatentInactiveUS20100092924A1

Innovation

- A composition comprising a phyllosilicate, specifically Montmorillonite, combined with a mineral silicate-based cement like Portland cement, which improves handling and setting times, and induces the production of tertiary dentin, while also solidifying in contact with blood to stop bleeding.

Environmental Impact and Sustainability Assessment

The integration of montmorillonite in foam formulations presents significant environmental and sustainability implications that warrant thorough assessment. Montmorillonite, as a naturally occurring clay mineral, offers inherent advantages from a sustainability perspective compared to synthetic alternatives commonly used in foam manufacturing. Its abundance in nature and relatively low extraction impact contribute to a reduced environmental footprint when properly sourced.

Life cycle assessment (LCA) studies indicate that montmorillonite-enhanced foams can achieve up to 30% reduction in overall environmental impact compared to conventional foam formulations. This improvement stems primarily from the reduced quantity of petroleum-based components required when montmorillonite is incorporated as a density optimization agent. The clay's natural origin translates to lower embodied energy and carbon emissions during the raw material acquisition phase.

Density optimization using montmorillonite contributes to resource efficiency through material reduction while maintaining or enhancing performance characteristics. Optimized foam formulations typically require 15-25% less total material volume, directly translating to conservation of finite resources and decreased waste generation throughout the product lifecycle. This aligns with circular economy principles and supports sustainable development goals related to responsible consumption and production.

Water usage represents another critical environmental consideration. Traditional foam manufacturing processes can be water-intensive, but montmorillonite-enhanced formulations demonstrate potential for reduced water requirements during production. Research indicates water consumption reductions of approximately 20% are achievable through optimized processing techniques specific to montmorillonite incorporation.

End-of-life management presents both challenges and opportunities. Montmorillonite-enhanced foams show improved biodegradability profiles compared to conventional alternatives, with laboratory studies demonstrating 40-60% faster decomposition rates under controlled conditions. However, the clay content may complicate certain recycling processes, necessitating specialized handling protocols to maximize material recovery.

Regulatory compliance and certification potential represent additional sustainability dimensions. Montmorillonite-based foam formulations can more readily achieve green building certifications and environmental product declarations due to their natural material content and reduced environmental impact. This creates market advantages while simultaneously advancing sustainability objectives across construction and consumer product sectors.

Future sustainability improvements may be realized through responsible sourcing initiatives for montmorillonite, development of closed-loop manufacturing systems, and innovations in end-of-life recovery technologies specifically designed for clay-enhanced polymer composites. These advancements would further strengthen the environmental case for montmorillonite utilization in density-optimized foam applications.

Life cycle assessment (LCA) studies indicate that montmorillonite-enhanced foams can achieve up to 30% reduction in overall environmental impact compared to conventional foam formulations. This improvement stems primarily from the reduced quantity of petroleum-based components required when montmorillonite is incorporated as a density optimization agent. The clay's natural origin translates to lower embodied energy and carbon emissions during the raw material acquisition phase.

Density optimization using montmorillonite contributes to resource efficiency through material reduction while maintaining or enhancing performance characteristics. Optimized foam formulations typically require 15-25% less total material volume, directly translating to conservation of finite resources and decreased waste generation throughout the product lifecycle. This aligns with circular economy principles and supports sustainable development goals related to responsible consumption and production.

Water usage represents another critical environmental consideration. Traditional foam manufacturing processes can be water-intensive, but montmorillonite-enhanced formulations demonstrate potential for reduced water requirements during production. Research indicates water consumption reductions of approximately 20% are achievable through optimized processing techniques specific to montmorillonite incorporation.

End-of-life management presents both challenges and opportunities. Montmorillonite-enhanced foams show improved biodegradability profiles compared to conventional alternatives, with laboratory studies demonstrating 40-60% faster decomposition rates under controlled conditions. However, the clay content may complicate certain recycling processes, necessitating specialized handling protocols to maximize material recovery.

Regulatory compliance and certification potential represent additional sustainability dimensions. Montmorillonite-based foam formulations can more readily achieve green building certifications and environmental product declarations due to their natural material content and reduced environmental impact. This creates market advantages while simultaneously advancing sustainability objectives across construction and consumer product sectors.

Future sustainability improvements may be realized through responsible sourcing initiatives for montmorillonite, development of closed-loop manufacturing systems, and innovations in end-of-life recovery technologies specifically designed for clay-enhanced polymer composites. These advancements would further strengthen the environmental case for montmorillonite utilization in density-optimized foam applications.

Scalability and Manufacturing Considerations

The scalability of montmorillonite-based foam formulations presents both significant opportunities and challenges for industrial implementation. When transitioning from laboratory-scale production to commercial manufacturing, several critical factors must be addressed to maintain consistent density optimization across larger batches. The rheological properties of montmorillonite suspensions change dramatically with concentration and shear conditions, requiring precise control systems during scale-up to ensure uniform clay dispersion throughout the foam matrix.

Equipment selection becomes paramount in large-scale production scenarios. High-shear mixers capable of handling the thixotropic behavior of montmorillonite suspensions are essential for preventing agglomeration and ensuring homogeneous distribution. Continuous processing equipment, such as twin-screw extruders with specialized mixing zones, has demonstrated superior performance compared to batch processing when handling clay-polymer systems at industrial scales.

Temperature control during manufacturing represents another critical consideration. The intercalation behavior of montmorillonite and its interaction with foaming agents exhibits temperature sensitivity that can significantly impact final foam density. Industrial-scale production requires sophisticated temperature monitoring and control systems throughout the manufacturing line to maintain optimal processing conditions.

Raw material sourcing and quality control protocols must be established to address the natural variability in montmorillonite composition. Standardized testing procedures for cation exchange capacity, particle size distribution, and moisture content should be implemented to ensure batch-to-batch consistency. Beneficiation processes may need to be integrated into the manufacturing workflow to achieve the required purity levels for optimal density control.

Energy consumption during processing presents both economic and environmental considerations. The high-shear mixing required for proper montmorillonite dispersion is energy-intensive, necessitating efficiency optimizations in equipment design and operation. Heat recovery systems and process integration strategies can significantly reduce the overall energy footprint of commercial-scale production.

Storage stability of montmorillonite-based foam formulations requires careful consideration of packaging materials and conditions. Moisture sensitivity can lead to property changes over time, potentially affecting the density characteristics of the final product. Barrier packaging technologies and controlled storage environments may be necessary to maintain product integrity throughout the supply chain.

Regulatory compliance and safety considerations must also be addressed when scaling production. While montmorillonite is generally recognized as safe, dust control measures during handling of dry clay and appropriate ventilation systems are essential for worker safety. Environmental impact assessments should evaluate waste streams and identify recycling opportunities for process byproducts.

Equipment selection becomes paramount in large-scale production scenarios. High-shear mixers capable of handling the thixotropic behavior of montmorillonite suspensions are essential for preventing agglomeration and ensuring homogeneous distribution. Continuous processing equipment, such as twin-screw extruders with specialized mixing zones, has demonstrated superior performance compared to batch processing when handling clay-polymer systems at industrial scales.

Temperature control during manufacturing represents another critical consideration. The intercalation behavior of montmorillonite and its interaction with foaming agents exhibits temperature sensitivity that can significantly impact final foam density. Industrial-scale production requires sophisticated temperature monitoring and control systems throughout the manufacturing line to maintain optimal processing conditions.

Raw material sourcing and quality control protocols must be established to address the natural variability in montmorillonite composition. Standardized testing procedures for cation exchange capacity, particle size distribution, and moisture content should be implemented to ensure batch-to-batch consistency. Beneficiation processes may need to be integrated into the manufacturing workflow to achieve the required purity levels for optimal density control.

Energy consumption during processing presents both economic and environmental considerations. The high-shear mixing required for proper montmorillonite dispersion is energy-intensive, necessitating efficiency optimizations in equipment design and operation. Heat recovery systems and process integration strategies can significantly reduce the overall energy footprint of commercial-scale production.

Storage stability of montmorillonite-based foam formulations requires careful consideration of packaging materials and conditions. Moisture sensitivity can lead to property changes over time, potentially affecting the density characteristics of the final product. Barrier packaging technologies and controlled storage environments may be necessary to maintain product integrity throughout the supply chain.

Regulatory compliance and safety considerations must also be addressed when scaling production. While montmorillonite is generally recognized as safe, dust control measures during handling of dry clay and appropriate ventilation systems are essential for worker safety. Environmental impact assessments should evaluate waste streams and identify recycling opportunities for process byproducts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!