MXene Integration into Eco-Friendly Energy Solutions

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Objectives

MXene, a class of two-dimensional transition metal carbides, nitrides, and carbonitrides, has emerged as a promising material for eco-friendly energy solutions. Discovered in 2011 by researchers at Drexel University, MXenes have rapidly gained attention due to their unique combination of properties, including high electrical conductivity, mechanical strength, and surface functionality.

The evolution of MXene technology has been marked by significant advancements in synthesis methods, property characterization, and application development. Initially produced through selective etching of MAX phases, researchers have since developed various techniques to optimize MXene production, including minimally intensive layer delamination (MILD) and clay-like MXene synthesis. These innovations have paved the way for scalable production and broader application potential.

MXenes exhibit exceptional versatility in energy-related applications, particularly in energy storage and conversion systems. Their high surface area, excellent electrical conductivity, and tunable surface chemistry make them ideal candidates for supercapacitors, batteries, and electrocatalysts. As the global focus shifts towards sustainable energy solutions, MXene integration into eco-friendly technologies has become a key research objective.

The primary goals of MXene integration into eco-friendly energy solutions encompass several critical areas. Firstly, researchers aim to enhance the performance and efficiency of energy storage devices, such as supercapacitors and batteries, by leveraging MXene's unique properties. This includes improving energy density, power density, and cycle life while reducing environmental impact.

Secondly, there is a strong focus on developing MXene-based materials for renewable energy harvesting and conversion. This includes applications in solar cells, thermoelectric devices, and hydrogen evolution reactions for clean fuel production. The objective is to create more efficient and sustainable alternatives to conventional energy technologies.

Another crucial goal is to explore MXene's potential in energy-efficient electronics and sensors. By integrating MXenes into flexible and wearable devices, researchers aim to develop low-power, high-performance systems that can contribute to overall energy conservation and sustainability.

Furthermore, the environmental impact of MXene production and application is a key consideration. Objectives include developing greener synthesis methods, improving recyclability, and ensuring the long-term stability of MXene-based materials in various environmental conditions.

As research progresses, the overarching aim is to bridge the gap between laboratory discoveries and real-world applications. This involves scaling up production, optimizing integration processes, and addressing challenges related to cost-effectiveness and compatibility with existing technologies. By achieving these objectives, MXene integration into eco-friendly energy solutions has the potential to significantly contribute to global sustainability efforts and the transition towards a greener energy landscape.

The evolution of MXene technology has been marked by significant advancements in synthesis methods, property characterization, and application development. Initially produced through selective etching of MAX phases, researchers have since developed various techniques to optimize MXene production, including minimally intensive layer delamination (MILD) and clay-like MXene synthesis. These innovations have paved the way for scalable production and broader application potential.

MXenes exhibit exceptional versatility in energy-related applications, particularly in energy storage and conversion systems. Their high surface area, excellent electrical conductivity, and tunable surface chemistry make them ideal candidates for supercapacitors, batteries, and electrocatalysts. As the global focus shifts towards sustainable energy solutions, MXene integration into eco-friendly technologies has become a key research objective.

The primary goals of MXene integration into eco-friendly energy solutions encompass several critical areas. Firstly, researchers aim to enhance the performance and efficiency of energy storage devices, such as supercapacitors and batteries, by leveraging MXene's unique properties. This includes improving energy density, power density, and cycle life while reducing environmental impact.

Secondly, there is a strong focus on developing MXene-based materials for renewable energy harvesting and conversion. This includes applications in solar cells, thermoelectric devices, and hydrogen evolution reactions for clean fuel production. The objective is to create more efficient and sustainable alternatives to conventional energy technologies.

Another crucial goal is to explore MXene's potential in energy-efficient electronics and sensors. By integrating MXenes into flexible and wearable devices, researchers aim to develop low-power, high-performance systems that can contribute to overall energy conservation and sustainability.

Furthermore, the environmental impact of MXene production and application is a key consideration. Objectives include developing greener synthesis methods, improving recyclability, and ensuring the long-term stability of MXene-based materials in various environmental conditions.

As research progresses, the overarching aim is to bridge the gap between laboratory discoveries and real-world applications. This involves scaling up production, optimizing integration processes, and addressing challenges related to cost-effectiveness and compatibility with existing technologies. By achieving these objectives, MXene integration into eco-friendly energy solutions has the potential to significantly contribute to global sustainability efforts and the transition towards a greener energy landscape.

Green Energy Market Analysis

The green energy market has experienced significant growth in recent years, driven by increasing environmental concerns, government policies, and technological advancements. The integration of MXene into eco-friendly energy solutions represents a promising avenue for further market expansion and innovation.

The global renewable energy market was valued at $881.7 billion in 2020 and is projected to reach $1,977.6 billion by 2030, growing at a CAGR of 8.4% from 2021 to 2030. This growth is primarily fueled by the increasing adoption of solar, wind, and hydroelectric power generation technologies. The market for energy storage solutions, which is crucial for the integration of intermittent renewable sources, is also expanding rapidly, with a projected CAGR of 20.1% from 2021 to 2028.

MXene, as a relatively new class of two-dimensional materials, has the potential to revolutionize various aspects of the green energy sector. Its unique properties, including high electrical conductivity, large surface area, and excellent mechanical strength, make it particularly suitable for energy storage applications. The global market for advanced materials in energy storage is expected to grow from $5.1 billion in 2019 to $12.7 billion by 2024, presenting a significant opportunity for MXene-based solutions.

In the context of eco-friendly energy solutions, MXene shows promise in several key areas. For supercapacitors, MXene-based electrodes have demonstrated exceptional performance, with energy densities approaching those of batteries while maintaining the high power density characteristic of supercapacitors. This could lead to rapid charging and long-lasting energy storage devices for electric vehicles and grid-scale applications.

The hydrogen economy is another area where MXene integration could make a substantial impact. As catalysts for hydrogen evolution reactions, MXene materials have shown efficiency comparable to platinum-based catalysts but at a fraction of the cost. This could significantly reduce the production costs of green hydrogen, which is projected to become a $11 trillion market by 2050.

Furthermore, MXene's potential in improving the efficiency of solar cells and thermoelectric devices aligns well with the growing demand for more effective renewable energy harvesting technologies. The global solar energy market alone is expected to reach $223.3 billion by 2026, growing at a CAGR of 20.5% from 2019 to 2026.

However, challenges remain in scaling up MXene production and integrating it into commercial products. The market for MXene-based energy solutions is still in its infancy, with most applications currently at the research and development stage. As manufacturing processes improve and costs decrease, the adoption of MXene in eco-friendly energy solutions is expected to accelerate, potentially reshaping the competitive landscape of the green energy market.

The global renewable energy market was valued at $881.7 billion in 2020 and is projected to reach $1,977.6 billion by 2030, growing at a CAGR of 8.4% from 2021 to 2030. This growth is primarily fueled by the increasing adoption of solar, wind, and hydroelectric power generation technologies. The market for energy storage solutions, which is crucial for the integration of intermittent renewable sources, is also expanding rapidly, with a projected CAGR of 20.1% from 2021 to 2028.

MXene, as a relatively new class of two-dimensional materials, has the potential to revolutionize various aspects of the green energy sector. Its unique properties, including high electrical conductivity, large surface area, and excellent mechanical strength, make it particularly suitable for energy storage applications. The global market for advanced materials in energy storage is expected to grow from $5.1 billion in 2019 to $12.7 billion by 2024, presenting a significant opportunity for MXene-based solutions.

In the context of eco-friendly energy solutions, MXene shows promise in several key areas. For supercapacitors, MXene-based electrodes have demonstrated exceptional performance, with energy densities approaching those of batteries while maintaining the high power density characteristic of supercapacitors. This could lead to rapid charging and long-lasting energy storage devices for electric vehicles and grid-scale applications.

The hydrogen economy is another area where MXene integration could make a substantial impact. As catalysts for hydrogen evolution reactions, MXene materials have shown efficiency comparable to platinum-based catalysts but at a fraction of the cost. This could significantly reduce the production costs of green hydrogen, which is projected to become a $11 trillion market by 2050.

Furthermore, MXene's potential in improving the efficiency of solar cells and thermoelectric devices aligns well with the growing demand for more effective renewable energy harvesting technologies. The global solar energy market alone is expected to reach $223.3 billion by 2026, growing at a CAGR of 20.5% from 2019 to 2026.

However, challenges remain in scaling up MXene production and integrating it into commercial products. The market for MXene-based energy solutions is still in its infancy, with most applications currently at the research and development stage. As manufacturing processes improve and costs decrease, the adoption of MXene in eco-friendly energy solutions is expected to accelerate, potentially reshaping the competitive landscape of the green energy market.

MXene Tech Status and Challenges

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for eco-friendly energy solutions. The current technological status of MXene integration in this field is characterized by rapid advancements and significant challenges.

MXene's unique properties, including high electrical conductivity, large surface area, and excellent mechanical strength, have positioned it as a potential game-changer in energy storage and conversion applications. Researchers worldwide have successfully demonstrated MXene's efficacy in supercapacitors, batteries, and fuel cells, showcasing its versatility in addressing various energy-related challenges.

One of the primary areas of focus has been the development of MXene-based electrodes for supercapacitors. These electrodes have shown remarkable performance, exhibiting high capacitance and excellent cycling stability. The integration of MXene into lithium-ion batteries has also yielded promising results, with improved energy density and faster charging capabilities.

Despite these advancements, several challenges persist in the widespread adoption of MXene in eco-friendly energy solutions. The scalability of MXene production remains a significant hurdle. Current synthesis methods are limited to laboratory-scale production, making it difficult to meet the demands of large-scale industrial applications. Researchers are actively exploring new synthesis techniques to overcome this limitation and enable mass production of high-quality MXene materials.

Another challenge lies in the long-term stability of MXene-based devices. While initial performance metrics are impressive, maintaining these properties over extended periods and under various environmental conditions remains an area of concern. Efforts are underway to enhance the stability of MXene materials through surface modifications and composite formations.

The environmental impact of MXene production and disposal is also a critical consideration. As the field moves towards commercialization, developing sustainable and eco-friendly synthesis methods becomes paramount. Additionally, establishing effective recycling processes for MXene-based devices is crucial to ensure the material's long-term viability in eco-friendly energy solutions.

Geographically, research on MXene integration in energy solutions is distributed across various regions, with notable contributions from North America, Europe, and Asia. Collaborative efforts between academic institutions and industry partners are driving innovation and addressing the challenges associated with MXene implementation.

In conclusion, while MXene shows immense potential in revolutionizing eco-friendly energy solutions, overcoming production scalability, long-term stability, and environmental concerns are key to realizing its full potential. The coming years will likely see intensified research efforts focused on addressing these challenges and advancing MXene technology towards practical, large-scale applications in the energy sector.

MXene's unique properties, including high electrical conductivity, large surface area, and excellent mechanical strength, have positioned it as a potential game-changer in energy storage and conversion applications. Researchers worldwide have successfully demonstrated MXene's efficacy in supercapacitors, batteries, and fuel cells, showcasing its versatility in addressing various energy-related challenges.

One of the primary areas of focus has been the development of MXene-based electrodes for supercapacitors. These electrodes have shown remarkable performance, exhibiting high capacitance and excellent cycling stability. The integration of MXene into lithium-ion batteries has also yielded promising results, with improved energy density and faster charging capabilities.

Despite these advancements, several challenges persist in the widespread adoption of MXene in eco-friendly energy solutions. The scalability of MXene production remains a significant hurdle. Current synthesis methods are limited to laboratory-scale production, making it difficult to meet the demands of large-scale industrial applications. Researchers are actively exploring new synthesis techniques to overcome this limitation and enable mass production of high-quality MXene materials.

Another challenge lies in the long-term stability of MXene-based devices. While initial performance metrics are impressive, maintaining these properties over extended periods and under various environmental conditions remains an area of concern. Efforts are underway to enhance the stability of MXene materials through surface modifications and composite formations.

The environmental impact of MXene production and disposal is also a critical consideration. As the field moves towards commercialization, developing sustainable and eco-friendly synthesis methods becomes paramount. Additionally, establishing effective recycling processes for MXene-based devices is crucial to ensure the material's long-term viability in eco-friendly energy solutions.

Geographically, research on MXene integration in energy solutions is distributed across various regions, with notable contributions from North America, Europe, and Asia. Collaborative efforts between academic institutions and industry partners are driving innovation and addressing the challenges associated with MXene implementation.

In conclusion, while MXene shows immense potential in revolutionizing eco-friendly energy solutions, overcoming production scalability, long-term stability, and environmental concerns are key to realizing its full potential. The coming years will likely see intensified research efforts focused on addressing these challenges and advancing MXene technology towards practical, large-scale applications in the energy sector.

Current MXene Energy Solutions

01 MXene synthesis and composition

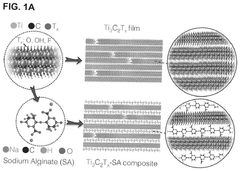

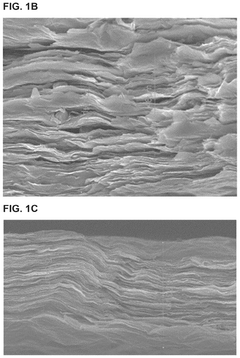

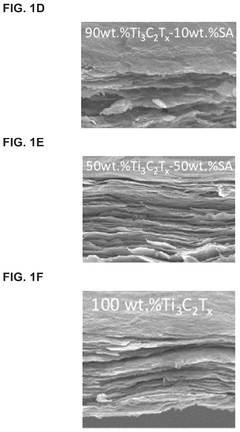

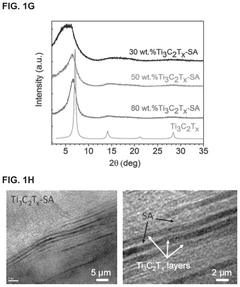

MXenes are two-dimensional transition metal carbides, nitrides, or carbonitrides with unique properties. They are typically synthesized through selective etching of MAX phases. The composition and structure of MXenes can be tailored for specific applications, offering a wide range of possibilities in material science and engineering.- MXene synthesis and composition: MXenes are a class of two-dimensional transition metal carbides, nitrides, or carbonitrides. They are synthesized by selective etching of certain atomic layers from MAX phase precursors. The resulting materials have unique properties, including high electrical conductivity, hydrophilicity, and large surface area.

- MXene-based energy storage devices: MXenes are utilized in energy storage applications, particularly in the development of high-performance electrodes for supercapacitors and batteries. Their large surface area and excellent electrical conductivity contribute to improved energy storage capacity and faster charge/discharge rates.

- MXene composites and hybrid materials: MXenes are combined with other materials to create composites and hybrid structures with enhanced properties. These composites find applications in various fields, including electromagnetic interference shielding, sensors, and catalysis.

- MXene-based water treatment and purification: MXenes are employed in water treatment and purification processes due to their adsorption capabilities and potential for removing contaminants. Their large surface area and tunable surface chemistry make them effective for removing heavy metals, organic pollutants, and other impurities from water.

- MXene applications in electronics and sensors: MXenes are utilized in electronic devices and sensors due to their unique electrical and optical properties. They are incorporated into flexible electronics, transparent conductive films, and various sensing platforms for detecting gases, biomolecules, and environmental pollutants.

02 Energy storage applications

MXenes show great potential in energy storage applications, particularly in supercapacitors and batteries. Their high electrical conductivity, large surface area, and ability to intercalate ions make them promising materials for improving energy density and charge-discharge rates in various energy storage devices.Expand Specific Solutions03 Electromagnetic interference shielding

MXenes exhibit excellent electromagnetic interference (EMI) shielding properties due to their high electrical conductivity and ability to absorb electromagnetic waves. This makes them suitable for use in electronic devices, aerospace applications, and other fields where EMI protection is crucial.Expand Specific Solutions04 Water purification and environmental applications

MXenes have shown promise in water purification and environmental remediation applications. Their large surface area and tunable surface chemistry allow for efficient adsorption of various contaminants, including heavy metals and organic pollutants, from water and other environmental matrices.Expand Specific Solutions05 Biomedical applications

MXenes are being explored for various biomedical applications, including drug delivery, biosensing, and tissue engineering. Their biocompatibility, photothermal properties, and ability to be functionalized with biomolecules make them attractive candidates for developing advanced medical technologies and treatments.Expand Specific Solutions

Key Players in MXene Energy Sector

The integration of MXene into eco-friendly energy solutions is in its early stages, with significant potential for growth. The market size is expanding rapidly as researchers and companies explore MXene's applications in energy storage, conversion, and harvesting. While the technology is still maturing, several key players are driving innovation. Universities like Shandong University, Peking University, and South China University of Technology are leading research efforts, while companies such as Suzhou Double Carbon New Material Co., Ltd. and Zhangjiagang Detai Energy Storage Equipment Co., Ltd. are working on commercialization. The competitive landscape is characterized by a mix of academic institutions and emerging startups, with collaboration between industry and academia playing a crucial role in advancing MXene-based eco-friendly energy solutions.

Peking University

Technical Solution: Peking University has made significant advancements in integrating MXenes into eco-friendly energy solutions. Their research team has developed a novel MXene-based catalyst for efficient hydrogen evolution reactions, demonstrating superior catalytic activity and stability compared to traditional noble metal catalysts[10]. This breakthrough has potential implications for clean hydrogen production. The university has also explored MXene's application in solar cells, creating a MXene-based hole transport layer that enhances the efficiency and stability of perovskite solar cells[11]. Additionally, Peking University researchers have investigated MXene's use in thermal energy harvesting, developing a MXene-based thermoelectric material with a high figure of merit, potentially revolutionizing waste heat recovery in industrial processes[12].

Strengths: Cutting-edge research in clean energy production and harvesting; focus on enhancing the efficiency of existing renewable energy technologies. Weaknesses: Limited exploration of MXene in energy storage applications; potential challenges in scaling up laboratory-scale innovations.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) has developed innovative MXene-based materials for eco-friendly energy solutions. They have created MXene/carbon nanotube hybrid aerogels for efficient solar steam generation[1]. This technology achieves a high solar-to-vapor conversion efficiency of 87.6% under 1 sun illumination. IPE has also explored MXene-based materials for supercapacitors, utilizing the material's high electrical conductivity and large surface area. Their research has shown that MXene-based electrodes can achieve capacitances as high as 1500 F/cm3, significantly outperforming many traditional materials[2]. Additionally, IPE has investigated MXene's potential in hydrogen evolution reactions, demonstrating its catalytic properties for clean hydrogen production[3].

Strengths: Cutting-edge research in multiple eco-friendly energy applications; high-performance materials with proven efficiencies. Weaknesses: Potential scalability issues for large-scale production; need for further long-term stability studies in real-world conditions.

Core MXene Energy Innovations

Antennas comprising MX-ENE films and composites

PatentActiveUS11862847B2

Innovation

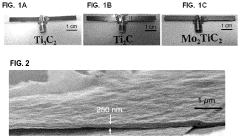

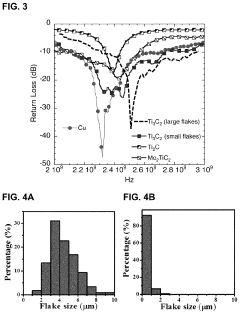

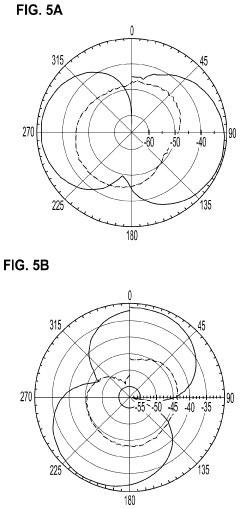

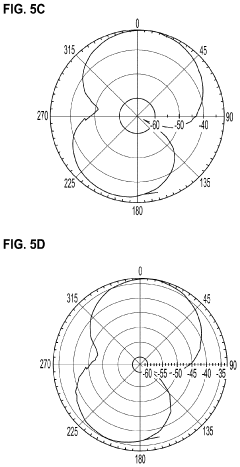

- The use of MXene films and composites as antenna materials, which can be produced as free-standing films and dispersed in various solvents, allowing for the creation of thin, flexible antennas with MXene compositions such as Ti3C2, Ti2C, and Mo2TiC2, applied to various substrates, including organic polymers and fabrics, to form monopole or dipole antennas.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact Assessment

The integration of MXene into eco-friendly energy solutions necessitates a comprehensive environmental impact assessment to ensure sustainable implementation. MXene, a two-dimensional transition metal carbide or nitride, offers promising applications in energy storage and conversion systems. However, its environmental implications must be thoroughly evaluated across its lifecycle.

During the production phase, the synthesis of MXene typically involves etching processes that use hydrofluoric acid or other strong etchants. These chemicals pose potential risks to aquatic ecosystems if not properly managed. Implementing closed-loop systems and developing less hazardous etching methods are crucial for minimizing environmental contamination. Additionally, the energy-intensive nature of MXene production requires consideration of carbon footprint reduction strategies, such as utilizing renewable energy sources in manufacturing facilities.

The application phase of MXene in energy solutions presents both positive and negative environmental impacts. On the positive side, MXene-enhanced energy storage devices, such as supercapacitors and batteries, can significantly improve energy efficiency and promote the adoption of renewable energy sources. This contributes to reduced greenhouse gas emissions and decreased reliance on fossil fuels. However, the potential release of nanomaterials into the environment during the use phase must be carefully monitored and mitigated through proper encapsulation and device design.

End-of-life considerations for MXene-based energy solutions are critical for ensuring circular economy principles. The recyclability and recoverability of MXene from spent devices should be thoroughly investigated. Developing efficient recycling processes that can separate and purify MXene from other components will be essential for minimizing waste and conserving resources. Furthermore, the potential for MXene to leach into soil or water systems during disposal must be assessed, and appropriate containment measures should be implemented.

Long-term environmental effects of MXene exposure require ongoing research. While initial studies suggest low toxicity, the persistence and bioaccumulation potential of MXene in various ecosystems need further investigation. Establishing standardized testing protocols for assessing the ecotoxicological impacts of MXene across different environmental compartments is crucial for informed decision-making and regulatory compliance.

To ensure a holistic approach to environmental impact assessment, life cycle analysis (LCA) methodologies should be applied to MXene-integrated energy solutions. This will help quantify the overall environmental footprint, including resource depletion, energy consumption, and emissions throughout the product lifecycle. By comparing these impacts with conventional energy technologies, stakeholders can make informed decisions about the sustainability of MXene-based solutions.

During the production phase, the synthesis of MXene typically involves etching processes that use hydrofluoric acid or other strong etchants. These chemicals pose potential risks to aquatic ecosystems if not properly managed. Implementing closed-loop systems and developing less hazardous etching methods are crucial for minimizing environmental contamination. Additionally, the energy-intensive nature of MXene production requires consideration of carbon footprint reduction strategies, such as utilizing renewable energy sources in manufacturing facilities.

The application phase of MXene in energy solutions presents both positive and negative environmental impacts. On the positive side, MXene-enhanced energy storage devices, such as supercapacitors and batteries, can significantly improve energy efficiency and promote the adoption of renewable energy sources. This contributes to reduced greenhouse gas emissions and decreased reliance on fossil fuels. However, the potential release of nanomaterials into the environment during the use phase must be carefully monitored and mitigated through proper encapsulation and device design.

End-of-life considerations for MXene-based energy solutions are critical for ensuring circular economy principles. The recyclability and recoverability of MXene from spent devices should be thoroughly investigated. Developing efficient recycling processes that can separate and purify MXene from other components will be essential for minimizing waste and conserving resources. Furthermore, the potential for MXene to leach into soil or water systems during disposal must be assessed, and appropriate containment measures should be implemented.

Long-term environmental effects of MXene exposure require ongoing research. While initial studies suggest low toxicity, the persistence and bioaccumulation potential of MXene in various ecosystems need further investigation. Establishing standardized testing protocols for assessing the ecotoxicological impacts of MXene across different environmental compartments is crucial for informed decision-making and regulatory compliance.

To ensure a holistic approach to environmental impact assessment, life cycle analysis (LCA) methodologies should be applied to MXene-integrated energy solutions. This will help quantify the overall environmental footprint, including resource depletion, energy consumption, and emissions throughout the product lifecycle. By comparing these impacts with conventional energy technologies, stakeholders can make informed decisions about the sustainability of MXene-based solutions.

MXene Scalability and Production

The scalability and production of MXenes present both challenges and opportunities in their integration into eco-friendly energy solutions. As a relatively new class of two-dimensional materials, MXenes have shown remarkable potential in various energy applications, including supercapacitors, batteries, and fuel cells. However, the transition from laboratory-scale synthesis to large-scale industrial production remains a significant hurdle.

Current production methods for MXenes primarily involve the selective etching of MAX phases, typically using hydrofluoric acid (HF) or other fluoride-containing etchants. While effective, these methods face limitations in terms of scalability, safety, and environmental impact. The use of hazardous chemicals like HF poses risks to workers and the environment, necessitating stringent safety protocols and waste management procedures.

To address these challenges, researchers are exploring alternative synthesis routes that are more amenable to large-scale production. One promising approach is the development of HF-free etching methods, such as using Lewis acidic molten salts or electrochemical etching techniques. These methods not only improve safety but also offer potential for continuous production processes, which are crucial for industrial-scale manufacturing.

Another critical aspect of MXene scalability is the development of efficient delamination and processing techniques. The as-synthesized multilayer MXenes need to be exfoliated into single or few-layer nanosheets to fully harness their unique properties. Current methods often involve time-consuming and low-yield processes, such as sonication or intercalation-assisted delamination. Innovations in this area, such as the use of shear mixing or electrochemical exfoliation, are showing promise for more efficient and scalable production of MXene nanosheets.

The quality control and standardization of MXene products also play a vital role in their scalability. As production scales up, maintaining consistent quality across batches becomes increasingly challenging. This includes controlling factors such as flake size, thickness, surface chemistry, and purity. Advanced characterization techniques and in-line quality monitoring systems are being developed to ensure the reproducibility and reliability of MXene materials at industrial scales.

Environmental considerations are paramount in scaling up MXene production for eco-friendly energy solutions. This involves not only the development of greener synthesis methods but also the implementation of sustainable practices throughout the production chain. Efforts are being made to minimize waste generation, recover and recycle reagents, and reduce energy consumption in the manufacturing process.

As the demand for MXenes in energy applications grows, there is an increasing focus on cost-effective production methods. This includes optimizing raw material selection, streamlining synthesis processes, and improving yield rates. The economic viability of large-scale MXene production will be crucial for their widespread adoption in commercial energy storage and conversion devices.

Current production methods for MXenes primarily involve the selective etching of MAX phases, typically using hydrofluoric acid (HF) or other fluoride-containing etchants. While effective, these methods face limitations in terms of scalability, safety, and environmental impact. The use of hazardous chemicals like HF poses risks to workers and the environment, necessitating stringent safety protocols and waste management procedures.

To address these challenges, researchers are exploring alternative synthesis routes that are more amenable to large-scale production. One promising approach is the development of HF-free etching methods, such as using Lewis acidic molten salts or electrochemical etching techniques. These methods not only improve safety but also offer potential for continuous production processes, which are crucial for industrial-scale manufacturing.

Another critical aspect of MXene scalability is the development of efficient delamination and processing techniques. The as-synthesized multilayer MXenes need to be exfoliated into single or few-layer nanosheets to fully harness their unique properties. Current methods often involve time-consuming and low-yield processes, such as sonication or intercalation-assisted delamination. Innovations in this area, such as the use of shear mixing or electrochemical exfoliation, are showing promise for more efficient and scalable production of MXene nanosheets.

The quality control and standardization of MXene products also play a vital role in their scalability. As production scales up, maintaining consistent quality across batches becomes increasingly challenging. This includes controlling factors such as flake size, thickness, surface chemistry, and purity. Advanced characterization techniques and in-line quality monitoring systems are being developed to ensure the reproducibility and reliability of MXene materials at industrial scales.

Environmental considerations are paramount in scaling up MXene production for eco-friendly energy solutions. This involves not only the development of greener synthesis methods but also the implementation of sustainable practices throughout the production chain. Efforts are being made to minimize waste generation, recover and recycle reagents, and reduce energy consumption in the manufacturing process.

As the demand for MXenes in energy applications grows, there is an increasing focus on cost-effective production methods. This includes optimizing raw material selection, streamlining synthesis processes, and improving yield rates. The economic viability of large-scale MXene production will be crucial for their widespread adoption in commercial energy storage and conversion devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!