Overview of Regulatory Standards for Half Wave Rectifiers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rectifier Standards Evolution

The evolution of regulatory standards for half wave rectifiers reflects the broader progression of electrical and electronic engineering standards over the past century. In the early days of electrical power systems, there were few formal standards governing the design and operation of rectifiers. As the technology became more widespread and critical to industrial and consumer applications, the need for standardization became apparent.

The first significant standards for rectifiers emerged in the 1920s and 1930s, primarily focusing on safety aspects and basic performance metrics. These early standards were often developed by individual countries or regional bodies, leading to a fragmented landscape of regulations. The Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) began to play increasingly important roles in harmonizing these standards from the 1950s onward.

The 1960s and 1970s saw a rapid expansion of rectifier applications in power electronics, driving the development of more comprehensive standards. These new regulations addressed issues such as electromagnetic compatibility (EMC), efficiency, and reliability. The introduction of semiconductor-based rectifiers, particularly silicon diodes, necessitated updates to existing standards to account for their unique characteristics and capabilities.

In the 1980s and 1990s, environmental concerns began to influence rectifier standards. Regulations started to incorporate requirements for energy efficiency and the reduction of harmonic distortion in power systems. The European Union's introduction of the CE marking system in 1993 marked a significant step towards unified standards across multiple countries.

The turn of the millennium brought increased focus on global harmonization of standards. The IEC 60146 series, specifically addressing semiconductor converters, became a cornerstone for international rectifier standards. This period also saw the integration of rectifier standards with broader power quality and grid interconnection requirements, reflecting the growing complexity of electrical systems.

Recent developments in rectifier standards have been driven by the rapid growth of renewable energy systems and smart grid technologies. Standards now increasingly address issues such as grid stability, power factor correction, and the ability to operate under variable input conditions. The rise of high-power applications, such as electric vehicle charging and renewable energy integration, has led to the development of standards specific to these emerging fields.

Looking forward, the evolution of rectifier standards is likely to continue focusing on improved efficiency, reduced environmental impact, and enhanced integration with smart grid systems. As power electronic technologies advance, standards will need to adapt to cover new topologies and control strategies, ensuring that half wave rectifiers and other power conversion devices continue to meet the evolving needs of modern electrical systems.

The first significant standards for rectifiers emerged in the 1920s and 1930s, primarily focusing on safety aspects and basic performance metrics. These early standards were often developed by individual countries or regional bodies, leading to a fragmented landscape of regulations. The Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) began to play increasingly important roles in harmonizing these standards from the 1950s onward.

The 1960s and 1970s saw a rapid expansion of rectifier applications in power electronics, driving the development of more comprehensive standards. These new regulations addressed issues such as electromagnetic compatibility (EMC), efficiency, and reliability. The introduction of semiconductor-based rectifiers, particularly silicon diodes, necessitated updates to existing standards to account for their unique characteristics and capabilities.

In the 1980s and 1990s, environmental concerns began to influence rectifier standards. Regulations started to incorporate requirements for energy efficiency and the reduction of harmonic distortion in power systems. The European Union's introduction of the CE marking system in 1993 marked a significant step towards unified standards across multiple countries.

The turn of the millennium brought increased focus on global harmonization of standards. The IEC 60146 series, specifically addressing semiconductor converters, became a cornerstone for international rectifier standards. This period also saw the integration of rectifier standards with broader power quality and grid interconnection requirements, reflecting the growing complexity of electrical systems.

Recent developments in rectifier standards have been driven by the rapid growth of renewable energy systems and smart grid technologies. Standards now increasingly address issues such as grid stability, power factor correction, and the ability to operate under variable input conditions. The rise of high-power applications, such as electric vehicle charging and renewable energy integration, has led to the development of standards specific to these emerging fields.

Looking forward, the evolution of rectifier standards is likely to continue focusing on improved efficiency, reduced environmental impact, and enhanced integration with smart grid systems. As power electronic technologies advance, standards will need to adapt to cover new topologies and control strategies, ensuring that half wave rectifiers and other power conversion devices continue to meet the evolving needs of modern electrical systems.

Market Demand Analysis

The market demand for half wave rectifiers has been steadily growing, driven by the increasing need for power conversion and management across various industries. The global power electronics market, which includes rectifiers, is projected to reach significant market value in the coming years. This growth is primarily fueled by the rising adoption of renewable energy sources, the expansion of electric vehicle infrastructure, and the continuous development of consumer electronics.

In the renewable energy sector, half wave rectifiers play a crucial role in converting alternating current (AC) from solar panels and wind turbines into direct current (DC) for storage and distribution. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion technologies, including half wave rectifiers, is expected to surge.

The automotive industry, particularly the electric vehicle (EV) segment, represents another significant market for half wave rectifiers. These components are essential in EV charging stations and onboard power management systems. With the global shift towards electrification of transportation, the demand for reliable and efficient rectifiers is set to increase substantially.

Consumer electronics continue to be a major driver for half wave rectifier demand. Smartphones, laptops, and other portable devices require compact and efficient power conversion solutions. As these devices become more sophisticated and energy-demanding, manufacturers are seeking advanced rectifier technologies to improve power efficiency and reduce heat generation.

Industrial applications also contribute significantly to the market demand for half wave rectifiers. In sectors such as manufacturing, telecommunications, and data centers, there is a growing need for reliable power conversion and management solutions. Half wave rectifiers are utilized in various industrial equipment and power supplies, supporting the overall growth of the market.

The healthcare sector presents an emerging opportunity for half wave rectifiers. Medical devices, diagnostic equipment, and hospital power systems require stable and efficient power conversion. As healthcare facilities upgrade their infrastructure and adopt more advanced medical technologies, the demand for high-quality rectifiers is expected to rise.

Regulatory standards play a crucial role in shaping the market demand for half wave rectifiers. Stringent energy efficiency regulations and power quality requirements across different regions are driving manufacturers to develop more advanced and compliant rectifier solutions. This regulatory landscape is not only influencing product development but also creating new market opportunities for innovative and high-performance rectifier technologies.

In the renewable energy sector, half wave rectifiers play a crucial role in converting alternating current (AC) from solar panels and wind turbines into direct current (DC) for storage and distribution. As countries worldwide push for cleaner energy solutions, the demand for efficient power conversion technologies, including half wave rectifiers, is expected to surge.

The automotive industry, particularly the electric vehicle (EV) segment, represents another significant market for half wave rectifiers. These components are essential in EV charging stations and onboard power management systems. With the global shift towards electrification of transportation, the demand for reliable and efficient rectifiers is set to increase substantially.

Consumer electronics continue to be a major driver for half wave rectifier demand. Smartphones, laptops, and other portable devices require compact and efficient power conversion solutions. As these devices become more sophisticated and energy-demanding, manufacturers are seeking advanced rectifier technologies to improve power efficiency and reduce heat generation.

Industrial applications also contribute significantly to the market demand for half wave rectifiers. In sectors such as manufacturing, telecommunications, and data centers, there is a growing need for reliable power conversion and management solutions. Half wave rectifiers are utilized in various industrial equipment and power supplies, supporting the overall growth of the market.

The healthcare sector presents an emerging opportunity for half wave rectifiers. Medical devices, diagnostic equipment, and hospital power systems require stable and efficient power conversion. As healthcare facilities upgrade their infrastructure and adopt more advanced medical technologies, the demand for high-quality rectifiers is expected to rise.

Regulatory standards play a crucial role in shaping the market demand for half wave rectifiers. Stringent energy efficiency regulations and power quality requirements across different regions are driving manufacturers to develop more advanced and compliant rectifier solutions. This regulatory landscape is not only influencing product development but also creating new market opportunities for innovative and high-performance rectifier technologies.

Technical Challenges

Half wave rectifiers, while seemingly simple in design, face several technical challenges that impact their performance and regulatory compliance. One of the primary issues is the inherent inefficiency of these devices. By nature, half wave rectifiers only utilize one half of the AC cycle, resulting in significant power loss and reduced overall efficiency. This inefficiency not only affects the device's performance but also raises concerns about energy conservation and sustainability, which are increasingly important in modern regulatory frameworks.

Another critical challenge is the generation of harmonics. Half wave rectifiers produce a non-sinusoidal output waveform, which introduces harmonic distortion into the electrical system. These harmonics can cause interference with other electronic equipment, potentially leading to malfunctions or reduced performance of nearby devices. Regulatory bodies are becoming increasingly stringent about harmonic emissions, requiring manufacturers to implement sophisticated filtering techniques to mitigate this issue.

The pulsating DC output of half wave rectifiers presents another technical hurdle. The large ripple in the output voltage can be problematic for many applications that require a stable DC supply. This ripple can lead to noise in audio systems, flickering in lighting applications, and inconsistent performance in various electronic devices. Addressing this issue often requires additional smoothing circuits, which add complexity and cost to the overall system design.

Electromagnetic interference (EMI) is another significant concern for half wave rectifiers. The abrupt current flow during the conduction phase can generate electromagnetic emissions that may interfere with other electronic systems. Meeting EMI regulations often necessitates careful circuit design and shielding, adding to the complexity and cost of products incorporating these rectifiers.

Voltage stress on components is an additional challenge. During the non-conducting half of the AC cycle, the peak inverse voltage across the rectifying diode can be substantial. This stress can lead to premature component failure if not properly managed, necessitating the use of higher-rated components or protective circuits, which again impacts cost and design complexity.

Lastly, the issue of power factor is a growing concern in regulatory standards. Half wave rectifiers typically have a poor power factor due to their non-linear current draw. This can lead to inefficient power transmission and distribution, potentially violating power quality standards set by regulatory bodies. Improving the power factor often requires additional circuitry, further complicating the design and increasing costs.

These technical challenges collectively pose significant hurdles for designers and manufacturers in meeting evolving regulatory standards while maintaining product performance and cost-effectiveness. As regulations continue to tighten, innovative solutions and alternative technologies may need to be explored to address these limitations inherent to half wave rectifiers.

Another critical challenge is the generation of harmonics. Half wave rectifiers produce a non-sinusoidal output waveform, which introduces harmonic distortion into the electrical system. These harmonics can cause interference with other electronic equipment, potentially leading to malfunctions or reduced performance of nearby devices. Regulatory bodies are becoming increasingly stringent about harmonic emissions, requiring manufacturers to implement sophisticated filtering techniques to mitigate this issue.

The pulsating DC output of half wave rectifiers presents another technical hurdle. The large ripple in the output voltage can be problematic for many applications that require a stable DC supply. This ripple can lead to noise in audio systems, flickering in lighting applications, and inconsistent performance in various electronic devices. Addressing this issue often requires additional smoothing circuits, which add complexity and cost to the overall system design.

Electromagnetic interference (EMI) is another significant concern for half wave rectifiers. The abrupt current flow during the conduction phase can generate electromagnetic emissions that may interfere with other electronic systems. Meeting EMI regulations often necessitates careful circuit design and shielding, adding to the complexity and cost of products incorporating these rectifiers.

Voltage stress on components is an additional challenge. During the non-conducting half of the AC cycle, the peak inverse voltage across the rectifying diode can be substantial. This stress can lead to premature component failure if not properly managed, necessitating the use of higher-rated components or protective circuits, which again impacts cost and design complexity.

Lastly, the issue of power factor is a growing concern in regulatory standards. Half wave rectifiers typically have a poor power factor due to their non-linear current draw. This can lead to inefficient power transmission and distribution, potentially violating power quality standards set by regulatory bodies. Improving the power factor often requires additional circuitry, further complicating the design and increasing costs.

These technical challenges collectively pose significant hurdles for designers and manufacturers in meeting evolving regulatory standards while maintaining product performance and cost-effectiveness. As regulations continue to tighten, innovative solutions and alternative technologies may need to be explored to address these limitations inherent to half wave rectifiers.

Current Regulatory Solutions

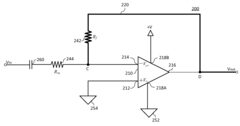

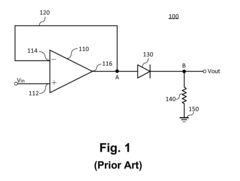

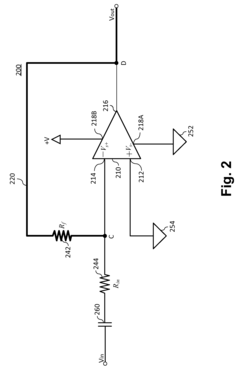

01 Circuit design for half-wave rectifiers

Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC). The circuit typically includes a diode that allows current to flow in only one direction during each AC cycle. This design is fundamental to power supply systems and can be optimized for various applications.- Circuit design for half-wave rectifiers: Half-wave rectifiers are designed to convert alternating current (AC) to pulsating direct current (DC) by allowing current flow in only one direction. The circuit typically consists of a diode and a load resistor. During the positive half-cycle of the AC input, the diode conducts, allowing current to flow through the load. During the negative half-cycle, the diode blocks current flow, resulting in a pulsating DC output.

- Efficiency improvements in half-wave rectifiers: Various techniques are employed to improve the efficiency of half-wave rectifiers. These may include the use of high-speed switching diodes, optimized circuit layouts to reduce parasitic capacitance, and the implementation of snubber circuits to suppress voltage spikes. Some designs incorporate synchronous rectification, where MOSFETs replace diodes to reduce forward voltage drop and improve overall efficiency.

- Applications of half-wave rectifiers in power supplies: Half-wave rectifiers find applications in various power supply designs, particularly in low-power or cost-sensitive applications. They are used in simple AC adapters, battery chargers, and some electronic devices where power consumption is not critical. In some cases, they are combined with voltage regulators or filtering circuits to produce smoother DC output for sensitive electronic components.

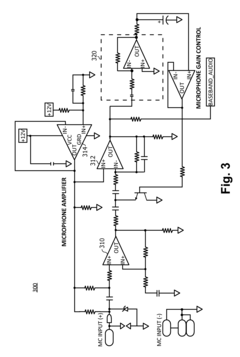

- Integration of half-wave rectifiers in electronic systems: Half-wave rectifiers are integrated into various electronic systems, including power management circuits, signal processing units, and sensor interfaces. They can be found in automotive electronics, consumer devices, and industrial control systems. Some designs incorporate multiple half-wave rectifiers in parallel or series configurations to handle higher currents or voltages, or to create multi-phase rectification systems.

- Protection and control features in half-wave rectifier circuits: Modern half-wave rectifier designs often include protection and control features to enhance reliability and performance. These may include overvoltage protection circuits, current limiting mechanisms, and thermal shutdown capabilities. Some advanced designs incorporate microcontroller-based monitoring and control systems to optimize rectifier operation based on load conditions and input voltage variations.

02 Efficiency improvements in half-wave rectifiers

Advancements in half-wave rectifier designs focus on improving efficiency and reducing power losses. This includes the use of high-performance diodes, optimized circuit layouts, and advanced control strategies to minimize voltage drops and heat generation during the rectification process.Expand Specific Solutions03 Integration of half-wave rectifiers in power supply systems

Half-wave rectifiers are integrated into various power supply systems, including those used in electronic devices, industrial equipment, and renewable energy applications. The integration involves careful consideration of load requirements, filtering techniques, and voltage regulation to ensure stable and reliable DC output.Expand Specific Solutions04 Protection and safety features in half-wave rectifier circuits

Modern half-wave rectifier designs incorporate protection and safety features to prevent damage from overcurrent, overvoltage, and reverse polarity. These features may include fuses, surge suppressors, and specialized circuit configurations to enhance the reliability and longevity of the rectifier system.Expand Specific Solutions05 Application-specific half-wave rectifier designs

Half-wave rectifiers are tailored for specific applications, such as battery charging, LED drivers, and sensor systems. These designs consider factors like input voltage range, output current requirements, and environmental conditions to optimize performance for the intended use case.Expand Specific Solutions

Key Industry Players

The regulatory standards for half wave rectifiers are in a mature stage of development, with established guidelines across various industries. The market size for this technology is substantial, driven by its widespread use in power supplies and signal processing applications. Technologically, half wave rectifiers are well-established, with companies like Infineon Technologies AG, Sanken Electric Co., Ltd., and TDK Corp. offering advanced solutions. These firms, along with others such as Semiconductor Energy Laboratory Co., Ltd. and Hitachi Power Semiconductor Device Ltd., continue to innovate in areas like efficiency improvement and miniaturization, indicating ongoing refinement within a mature technological landscape.

Infineon Technologies AG

Technical Solution: Infineon Technologies AG has developed advanced half-wave rectifier solutions that comply with stringent regulatory standards. Their silicon carbide (SiC) based rectifiers offer superior performance in high-voltage applications, with breakdown voltages up to 1200V [1]. These rectifiers feature low forward voltage drop and fast recovery times, enabling high efficiency in power conversion systems. Infineon's rectifiers incorporate advanced thermal management techniques and EMI suppression features to meet electromagnetic compatibility (EMC) standards [2]. The company also provides comprehensive documentation and design support to ensure compliance with safety regulations such as IEC 60950 for IT equipment and IEC 61000 for EMC [3].

Strengths: High-performance SiC technology, wide voltage range, excellent thermal management. Weaknesses: Higher cost compared to traditional silicon rectifiers, may require specialized design considerations.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei Technologies has developed innovative half-wave rectifier solutions for their power supply units in telecommunications equipment. Their rectifiers incorporate advanced control algorithms to minimize harmonic distortion, meeting IEC 61000-3-2 standards for harmonic current emissions [4]. Huawei's rectifiers feature high power density and efficiency, typically exceeding 96% [5]. To comply with safety standards, they implement multiple protection mechanisms, including over-voltage, over-current, and over-temperature protection. Huawei also focuses on reducing electromagnetic interference, adhering to CISPR 22 and EN 55022 standards for radiated and conducted emissions [6].

Strengths: High efficiency, advanced harmonic control, comprehensive protection features. Weaknesses: Primarily focused on telecom applications, may have limited adaptability to other sectors.

Core Regulatory Innovations

Ac to DC conversion circuit

PatentActiveUS20090080224A1

Innovation

- A diode-less half-wave rectifier circuit utilizing an operational amplifier with a capacitor and resistors in a negative feedback loop, allowing low-level signals to be converted to DC without clipping, thereby extending the dynamic range of rectification.

A method and system for driving a voice coil of a loudspeaker

PatentActiveGB2591767A

Innovation

- A voice coil driving system with segmented voice coil sections, where a centre voice coil section and auxiliary voice coil sections are driven by centre and auxiliary driving signals, respectively, with rectifying units attenuating or blocking currents in specific directions to minimize power consumption and heating by only powering sections within the air gap.

Global Regulatory Landscape

The global regulatory landscape for half wave rectifiers is characterized by a complex network of standards and guidelines that vary across regions and industries. In the United States, the Federal Communications Commission (FCC) plays a crucial role in regulating electromagnetic compatibility (EMC) and radio frequency interference (RFI) for electronic devices, including those incorporating half wave rectifiers. The FCC's Part 15 rules are particularly relevant, setting limits on conducted and radiated emissions.

In the European Union, the Electromagnetic Compatibility Directive (EMC Directive) 2014/30/EU establishes essential requirements for electronic equipment. This directive is supported by harmonized standards such as EN 61000-3-2, which specifically addresses harmonic current emissions for equipment with input current ≤16A per phase. Half wave rectifiers, known for their harmonic-rich output, are subject to these regulations.

Asia-Pacific countries have their own regulatory frameworks. Japan's Voluntary Control Council for Interference (VCCI) sets EMC standards similar to those in the EU and US. China's China Compulsory Certification (CCC) system includes EMC requirements for many electronic products, potentially affecting devices using half wave rectifiers.

International standards also play a significant role. The International Electrotechnical Commission (IEC) develops globally relevant standards, with IEC 61000 series being particularly important for EMC. These standards are often adopted or referenced by national regulatory bodies, creating a degree of global harmonization.

Industry-specific regulations add another layer of complexity. For instance, in the automotive sector, standards like ISO 7637 address electrical transients and EMC, which can impact the design and implementation of half wave rectifiers in vehicle electronics.

Energy efficiency regulations, such as those set by the US Department of Energy and the EU's Ecodesign Directive, indirectly affect half wave rectifier applications. These regulations often mandate minimum efficiency levels for power supplies and electronic devices, encouraging the use of more efficient rectification methods.

Safety standards, including those from Underwriters Laboratories (UL) in the US and the International Electrotechnical Commission (IEC 60950 for IT equipment), also influence the design and implementation of circuits containing half wave rectifiers. These standards focus on preventing electrical hazards and ensuring product safety.

As technology evolves, regulatory bodies are continuously updating their standards to address new challenges and applications. This dynamic regulatory environment requires manufacturers and designers to stay informed and adaptable, ensuring their half wave rectifier implementations comply with the latest global standards and regional variations.

In the European Union, the Electromagnetic Compatibility Directive (EMC Directive) 2014/30/EU establishes essential requirements for electronic equipment. This directive is supported by harmonized standards such as EN 61000-3-2, which specifically addresses harmonic current emissions for equipment with input current ≤16A per phase. Half wave rectifiers, known for their harmonic-rich output, are subject to these regulations.

Asia-Pacific countries have their own regulatory frameworks. Japan's Voluntary Control Council for Interference (VCCI) sets EMC standards similar to those in the EU and US. China's China Compulsory Certification (CCC) system includes EMC requirements for many electronic products, potentially affecting devices using half wave rectifiers.

International standards also play a significant role. The International Electrotechnical Commission (IEC) develops globally relevant standards, with IEC 61000 series being particularly important for EMC. These standards are often adopted or referenced by national regulatory bodies, creating a degree of global harmonization.

Industry-specific regulations add another layer of complexity. For instance, in the automotive sector, standards like ISO 7637 address electrical transients and EMC, which can impact the design and implementation of half wave rectifiers in vehicle electronics.

Energy efficiency regulations, such as those set by the US Department of Energy and the EU's Ecodesign Directive, indirectly affect half wave rectifier applications. These regulations often mandate minimum efficiency levels for power supplies and electronic devices, encouraging the use of more efficient rectification methods.

Safety standards, including those from Underwriters Laboratories (UL) in the US and the International Electrotechnical Commission (IEC 60950 for IT equipment), also influence the design and implementation of circuits containing half wave rectifiers. These standards focus on preventing electrical hazards and ensuring product safety.

As technology evolves, regulatory bodies are continuously updating their standards to address new challenges and applications. This dynamic regulatory environment requires manufacturers and designers to stay informed and adaptable, ensuring their half wave rectifier implementations comply with the latest global standards and regional variations.

Environmental Impact Assessment

The environmental impact assessment of half wave rectifiers is a crucial aspect of their regulatory standards, considering the growing emphasis on sustainable technology. These devices, while essential in various electronic applications, can have significant environmental implications throughout their lifecycle.

One primary environmental concern is the energy efficiency of half wave rectifiers. Due to their design, they only utilize half of the AC input waveform, resulting in lower power conversion efficiency compared to full wave rectifiers. This inefficiency leads to increased energy consumption and, consequently, higher carbon emissions from power generation sources. Regulatory bodies are increasingly focusing on improving the energy efficiency of electronic devices, including power conversion systems, to mitigate climate change impacts.

The manufacturing process of half wave rectifiers also poses environmental challenges. The production of semiconductor materials, such as silicon diodes used in these rectifiers, involves energy-intensive processes and potentially harmful chemicals. Regulatory standards are evolving to address these issues by promoting cleaner manufacturing techniques and encouraging the use of more environmentally friendly materials.

Electronic waste (e-waste) management is another critical environmental consideration. As half wave rectifiers are components in many electronic devices, their disposal at the end of their lifecycle contributes to the growing e-waste problem. Regulatory standards are increasingly focusing on extended producer responsibility, requiring manufacturers to implement take-back programs and ensure proper recycling of electronic components, including rectifiers.

Electromagnetic interference (EMI) generated by half wave rectifiers is an environmental concern that affects both human health and ecosystems. Regulatory bodies have established strict EMI emission limits to minimize the potential negative impacts on wildlife and sensitive electronic equipment. Manufacturers must adhere to these standards to ensure their products do not contribute to electromagnetic pollution.

The use of hazardous substances in electronic components, including half wave rectifiers, is another area of environmental focus. Regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive limit the use of certain toxic materials like lead, mercury, and cadmium. Compliance with these standards not only reduces the environmental impact during the product's use but also facilitates safer recycling and disposal processes.

As the demand for electronic devices continues to grow, regulatory standards for half wave rectifiers are likely to become more stringent in terms of environmental protection. Future regulations may focus on promoting circular economy principles, encouraging the use of recycled materials in manufacturing, and improving the overall lifecycle sustainability of electronic components. This evolving regulatory landscape will drive innovation in rectifier design and manufacturing processes, ultimately leading to more environmentally friendly power conversion solutions.

One primary environmental concern is the energy efficiency of half wave rectifiers. Due to their design, they only utilize half of the AC input waveform, resulting in lower power conversion efficiency compared to full wave rectifiers. This inefficiency leads to increased energy consumption and, consequently, higher carbon emissions from power generation sources. Regulatory bodies are increasingly focusing on improving the energy efficiency of electronic devices, including power conversion systems, to mitigate climate change impacts.

The manufacturing process of half wave rectifiers also poses environmental challenges. The production of semiconductor materials, such as silicon diodes used in these rectifiers, involves energy-intensive processes and potentially harmful chemicals. Regulatory standards are evolving to address these issues by promoting cleaner manufacturing techniques and encouraging the use of more environmentally friendly materials.

Electronic waste (e-waste) management is another critical environmental consideration. As half wave rectifiers are components in many electronic devices, their disposal at the end of their lifecycle contributes to the growing e-waste problem. Regulatory standards are increasingly focusing on extended producer responsibility, requiring manufacturers to implement take-back programs and ensure proper recycling of electronic components, including rectifiers.

Electromagnetic interference (EMI) generated by half wave rectifiers is an environmental concern that affects both human health and ecosystems. Regulatory bodies have established strict EMI emission limits to minimize the potential negative impacts on wildlife and sensitive electronic equipment. Manufacturers must adhere to these standards to ensure their products do not contribute to electromagnetic pollution.

The use of hazardous substances in electronic components, including half wave rectifiers, is another area of environmental focus. Regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive limit the use of certain toxic materials like lead, mercury, and cadmium. Compliance with these standards not only reduces the environmental impact during the product's use but also facilitates safer recycling and disposal processes.

As the demand for electronic devices continues to grow, regulatory standards for half wave rectifiers are likely to become more stringent in terms of environmental protection. Future regulations may focus on promoting circular economy principles, encouraging the use of recycled materials in manufacturing, and improving the overall lifecycle sustainability of electronic components. This evolving regulatory landscape will drive innovation in rectifier design and manufacturing processes, ultimately leading to more environmentally friendly power conversion solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!