Leading Silicone Rubber Technologies in Next-Level Components

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Tech Evolution and Objectives

Silicone rubber technology has undergone significant evolution since its inception in the 1940s. Initially developed as a high-performance elastomer, silicone rubber has continuously expanded its applications across various industries due to its unique properties. The technology has progressed from basic formulations to advanced composites, addressing the growing demands for specialized materials in next-level components.

The primary objective of current silicone rubber research is to enhance its performance characteristics while maintaining its inherent advantages. This includes improving mechanical strength, thermal stability, and electrical properties without compromising flexibility and durability. Researchers are focusing on developing silicone rubber compounds that can withstand extreme conditions, such as high temperatures, corrosive environments, and prolonged exposure to UV radiation.

One of the key trends in silicone rubber technology is the development of self-healing materials. This innovative approach aims to create rubber compounds capable of autonomously repairing damage, significantly extending the lifespan of components and reducing maintenance costs. Another important objective is the integration of smart functionalities, such as sensing and actuation capabilities, directly into silicone rubber matrices.

Nanotechnology has emerged as a crucial factor in advancing silicone rubber properties. The incorporation of nanoparticles and nanostructures into silicone rubber formulations has led to substantial improvements in mechanical, thermal, and electrical properties. This has opened up new possibilities for applications in aerospace, automotive, and electronics industries, where high-performance materials are essential.

Sustainability is becoming an increasingly important focus in silicone rubber research. Efforts are being made to develop bio-based silicone rubbers and improve the recyclability of silicone products. This aligns with global initiatives to reduce environmental impact and promote circular economy principles in materials science.

The miniaturization trend in electronics and medical devices has driven research towards ultra-thin silicone rubber films and coatings. These materials must maintain their protective and insulating properties at microscale thicknesses, presenting unique challenges in material design and manufacturing processes.

Looking ahead, the objectives for silicone rubber technology include achieving higher temperature resistance, improved chemical compatibility, and enhanced electrical properties. There is also a push towards developing silicone rubber composites that combine the benefits of silicone with other high-performance materials, creating hybrid solutions for next-generation applications.

The primary objective of current silicone rubber research is to enhance its performance characteristics while maintaining its inherent advantages. This includes improving mechanical strength, thermal stability, and electrical properties without compromising flexibility and durability. Researchers are focusing on developing silicone rubber compounds that can withstand extreme conditions, such as high temperatures, corrosive environments, and prolonged exposure to UV radiation.

One of the key trends in silicone rubber technology is the development of self-healing materials. This innovative approach aims to create rubber compounds capable of autonomously repairing damage, significantly extending the lifespan of components and reducing maintenance costs. Another important objective is the integration of smart functionalities, such as sensing and actuation capabilities, directly into silicone rubber matrices.

Nanotechnology has emerged as a crucial factor in advancing silicone rubber properties. The incorporation of nanoparticles and nanostructures into silicone rubber formulations has led to substantial improvements in mechanical, thermal, and electrical properties. This has opened up new possibilities for applications in aerospace, automotive, and electronics industries, where high-performance materials are essential.

Sustainability is becoming an increasingly important focus in silicone rubber research. Efforts are being made to develop bio-based silicone rubbers and improve the recyclability of silicone products. This aligns with global initiatives to reduce environmental impact and promote circular economy principles in materials science.

The miniaturization trend in electronics and medical devices has driven research towards ultra-thin silicone rubber films and coatings. These materials must maintain their protective and insulating properties at microscale thicknesses, presenting unique challenges in material design and manufacturing processes.

Looking ahead, the objectives for silicone rubber technology include achieving higher temperature resistance, improved chemical compatibility, and enhanced electrical properties. There is also a push towards developing silicone rubber composites that combine the benefits of silicone with other high-performance materials, creating hybrid solutions for next-generation applications.

Market Demand for Advanced Silicone Components

The demand for advanced silicone components has been steadily increasing across various industries, driven by the unique properties and versatility of silicone rubber. This market growth is particularly evident in sectors such as automotive, electronics, healthcare, and aerospace, where high-performance materials are crucial for innovation and product development.

In the automotive industry, there is a growing need for silicone components that can withstand extreme temperatures, resist chemical degradation, and provide excellent electrical insulation. As vehicles become more electrified and autonomous, the demand for advanced silicone parts in sensors, connectors, and sealing systems is expected to surge. The push for lightweight materials to improve fuel efficiency also favors silicone rubber due to its low density and durability.

The electronics sector is another major driver of demand for advanced silicone components. With the miniaturization of devices and the rise of wearable technology, manufacturers are seeking silicone materials that offer superior flexibility, thermal management, and protection against environmental factors. The development of 5G networks and Internet of Things (IoT) devices further amplifies this demand, as silicone components play a crucial role in ensuring reliable performance in challenging conditions.

In healthcare, the biocompatibility and sterilization resistance of silicone rubber make it an ideal material for medical devices and implants. The aging population and increasing prevalence of chronic diseases are fueling the demand for advanced silicone components in applications such as prosthetics, drug delivery systems, and surgical instruments. The COVID-19 pandemic has also highlighted the importance of silicone in personal protective equipment and medical devices, further boosting market demand.

The aerospace industry requires materials that can perform under extreme conditions, making advanced silicone components essential for applications in aircraft engines, seals, and insulation. As the industry focuses on developing more fuel-efficient and environmentally friendly aircraft, the demand for lightweight and high-performance silicone materials is expected to grow significantly.

Moreover, the global trend towards sustainability and environmental consciousness is influencing the market for advanced silicone components. Manufacturers are increasingly seeking silicone materials that are recyclable, bio-based, or have a reduced environmental footprint. This shift is creating new opportunities for innovation in silicone rubber technologies, driving research and development efforts to meet these evolving market demands.

As industries continue to push the boundaries of performance and reliability, the market for advanced silicone components is poised for substantial growth. The ability of silicone rubber to be customized for specific applications, combined with its excellent mechanical and chemical properties, positions it as a critical material for next-generation products across multiple sectors.

In the automotive industry, there is a growing need for silicone components that can withstand extreme temperatures, resist chemical degradation, and provide excellent electrical insulation. As vehicles become more electrified and autonomous, the demand for advanced silicone parts in sensors, connectors, and sealing systems is expected to surge. The push for lightweight materials to improve fuel efficiency also favors silicone rubber due to its low density and durability.

The electronics sector is another major driver of demand for advanced silicone components. With the miniaturization of devices and the rise of wearable technology, manufacturers are seeking silicone materials that offer superior flexibility, thermal management, and protection against environmental factors. The development of 5G networks and Internet of Things (IoT) devices further amplifies this demand, as silicone components play a crucial role in ensuring reliable performance in challenging conditions.

In healthcare, the biocompatibility and sterilization resistance of silicone rubber make it an ideal material for medical devices and implants. The aging population and increasing prevalence of chronic diseases are fueling the demand for advanced silicone components in applications such as prosthetics, drug delivery systems, and surgical instruments. The COVID-19 pandemic has also highlighted the importance of silicone in personal protective equipment and medical devices, further boosting market demand.

The aerospace industry requires materials that can perform under extreme conditions, making advanced silicone components essential for applications in aircraft engines, seals, and insulation. As the industry focuses on developing more fuel-efficient and environmentally friendly aircraft, the demand for lightweight and high-performance silicone materials is expected to grow significantly.

Moreover, the global trend towards sustainability and environmental consciousness is influencing the market for advanced silicone components. Manufacturers are increasingly seeking silicone materials that are recyclable, bio-based, or have a reduced environmental footprint. This shift is creating new opportunities for innovation in silicone rubber technologies, driving research and development efforts to meet these evolving market demands.

As industries continue to push the boundaries of performance and reliability, the market for advanced silicone components is poised for substantial growth. The ability of silicone rubber to be customized for specific applications, combined with its excellent mechanical and chemical properties, positions it as a critical material for next-generation products across multiple sectors.

Current Challenges in Silicone Rubber Development

Silicone rubber technology, despite its widespread use and continuous advancements, still faces several significant challenges in its development for next-level components. One of the primary issues is the trade-off between mechanical strength and flexibility. While silicone rubber is renowned for its elasticity, improving its tensile strength and tear resistance without compromising flexibility remains a complex task. This balance is crucial for applications in aerospace, automotive, and medical industries where durability and performance under extreme conditions are paramount.

Another challenge lies in enhancing the thermal stability of silicone rubber. Although it already possesses excellent heat resistance compared to many other elastomers, pushing the boundaries of its thermal capabilities is essential for emerging high-temperature applications. Researchers are grappling with ways to maintain the rubber's properties at even higher temperatures without degradation or loss of functionality.

The electrical properties of silicone rubber present another area of ongoing development. While it is an excellent electrical insulator, there is a growing demand for silicone rubber with tailored electrical conductivity for specific applications, such as electromagnetic interference (EMI) shielding in electronic devices. Achieving precise control over electrical properties while maintaining other desirable characteristics of silicone rubber is a significant challenge.

Adhesion is another critical area of focus. Silicone rubber's inherent low surface energy makes bonding to other materials difficult. This poses challenges in multi-material assemblies and composite structures, where strong and durable interfaces are crucial. Developing surface modification techniques or new formulations to improve adhesion without altering the bulk properties of the silicone rubber is an ongoing research endeavor.

Environmental concerns and sustainability also present challenges in silicone rubber development. There is a growing need for bio-based alternatives and environmentally friendly production processes. Researchers are exploring ways to reduce the carbon footprint of silicone rubber manufacturing and improve its biodegradability without sacrificing performance.

Lastly, the customization and rapid prototyping of silicone rubber components face limitations. The current manufacturing processes, while well-established, often lack the flexibility needed for quick iterations in product development. Adapting silicone rubber formulations and processing techniques to emerging technologies like 3D printing presents both opportunities and challenges in terms of maintaining material properties and achieving desired geometries.

Another challenge lies in enhancing the thermal stability of silicone rubber. Although it already possesses excellent heat resistance compared to many other elastomers, pushing the boundaries of its thermal capabilities is essential for emerging high-temperature applications. Researchers are grappling with ways to maintain the rubber's properties at even higher temperatures without degradation or loss of functionality.

The electrical properties of silicone rubber present another area of ongoing development. While it is an excellent electrical insulator, there is a growing demand for silicone rubber with tailored electrical conductivity for specific applications, such as electromagnetic interference (EMI) shielding in electronic devices. Achieving precise control over electrical properties while maintaining other desirable characteristics of silicone rubber is a significant challenge.

Adhesion is another critical area of focus. Silicone rubber's inherent low surface energy makes bonding to other materials difficult. This poses challenges in multi-material assemblies and composite structures, where strong and durable interfaces are crucial. Developing surface modification techniques or new formulations to improve adhesion without altering the bulk properties of the silicone rubber is an ongoing research endeavor.

Environmental concerns and sustainability also present challenges in silicone rubber development. There is a growing need for bio-based alternatives and environmentally friendly production processes. Researchers are exploring ways to reduce the carbon footprint of silicone rubber manufacturing and improve its biodegradability without sacrificing performance.

Lastly, the customization and rapid prototyping of silicone rubber components face limitations. The current manufacturing processes, while well-established, often lack the flexibility needed for quick iterations in product development. Adapting silicone rubber formulations and processing techniques to emerging technologies like 3D printing presents both opportunities and challenges in terms of maintaining material properties and achieving desired geometries.

Cutting-edge Silicone Rubber Solutions

01 Composition and preparation of silicone rubber

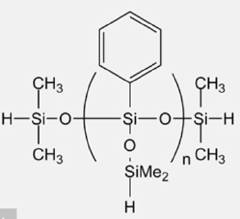

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, elasticity, and heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the manufacturing process. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating nanoparticles.

- Applications of silicone rubber: Silicone rubber finds wide applications across various industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, cookware, and construction materials. Its biocompatibility makes it suitable for implants and prosthetics, while its heat resistance is valuable in industrial seals and gaskets.

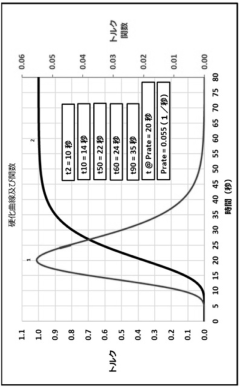

- Curing methods for silicone rubber: Various curing methods are employed in the production of silicone rubber, including room temperature vulcanization (RTV), heat-activated curing, and UV-curing. Each method affects the final properties of the rubber differently and is chosen based on the specific application requirements and manufacturing constraints.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing with fibers, blending with other elastomers, or incorporating functional fillers. These composites can offer improved mechanical strength, electrical conductivity, or specific functional properties tailored for particular applications.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be formulated for use in medical devices, implants, prosthetics, and drug delivery systems. Special attention is given to ensuring the material meets stringent medical-grade standards.Expand Specific Solutions04 Silicone rubber in electronic and electrical applications

Silicone rubber finds extensive use in electronic and electrical applications due to its excellent insulating properties and resistance to extreme temperatures. It can be formulated for use in cable insulation, gaskets, seals, and other components in electronic devices and electrical systems.Expand Specific Solutions05 Advanced processing techniques for silicone rubber

Various advanced processing techniques are employed in the manufacture of silicone rubber products. These can include injection molding, extrusion, compression molding, and 3D printing. Each technique offers specific advantages in terms of product design, production efficiency, and material properties, allowing for the creation of complex shapes and structures.Expand Specific Solutions

Key Players in Silicone Rubber Industry

The research on leading silicone rubber technologies for next-level components is in a mature yet evolving stage, with a growing market driven by increasing demand across various industries. The global silicone rubber market is substantial, expected to reach $9.34 billion by 2026. Technologically, the field is well-established but continues to innovate, with companies like Shin-Etsu Chemical, Dow Silicones, and Momentive Performance Materials leading the way. These industry giants, along with emerging players such as Elkem Silicones and Wacker Chemie, are pushing the boundaries of silicone rubber applications, focusing on enhancing properties like heat resistance, durability, and flexibility for advanced components in electronics, automotive, and medical sectors.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed advanced silicone rubber technologies for next-level components, focusing on high-performance silicone elastomers. Their research includes the development of liquid silicone rubber (LSR) with improved thermal stability and electrical properties[1]. They have also introduced a new line of optically clear silicone rubbers with enhanced light transmission and weather resistance for automotive and electronic applications[2]. Shin-Etsu's silicone rubber compounds feature self-adhesive properties, eliminating the need for primers in many applications, thus streamlining manufacturing processes[3]. The company has also made significant strides in developing silicone rubber with improved compression set and tear strength for demanding industrial applications[4].

Strengths: Wide range of specialized silicone rubber formulations, strong R&D capabilities, global market presence. Weaknesses: High production costs, potential environmental concerns related to silicone production processes.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has been at the forefront of silicone rubber technology research for next-level components. They have developed SILASTIC™ silicone elastomers with enhanced thermal conductivity, crucial for advanced electronic and automotive applications[1]. Their research also includes the creation of self-healing silicone rubbers that can repair minor damage autonomously, increasing the longevity of components[2]. Dow has introduced fluorosilicone rubbers with exceptional resistance to fuels and oils, targeting aerospace and automotive industries[3]. Additionally, they have made advancements in silicone foam technologies, offering lightweight solutions with improved insulation properties for various industrial applications[4].

Strengths: Innovative product portfolio, strong industry partnerships, global manufacturing capabilities. Weaknesses: Dependency on raw material prices, potential regulatory challenges in certain markets.

Breakthrough Innovations in Silicone Materials

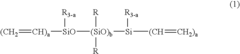

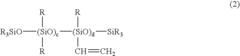

Addition reaction-curable liquid silicone rubber compositions and process of preparing same

PatentActiveUS20050277725A1

Innovation

- An addition reaction-curable liquid silicone rubber composition comprising specific organopolysiloxanes, finely divided silica, hexamethyldisilazane, water, and an organohydrogenpolysiloxane, along with a hydrosilation catalyst, is developed, allowing for a cured product with a hardness of at least 75 and an elongation at break of at least 200%, enabling broader application beyond insulation potting.

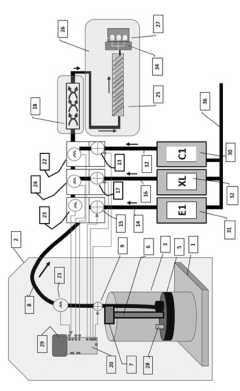

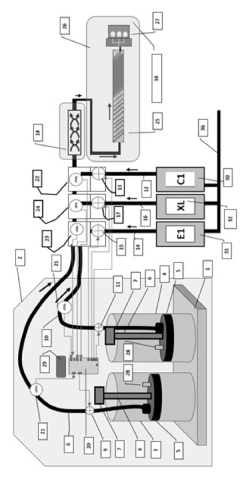

Process and equipment assembly useful for manufacturing silicone rubber articles by injection molding from liquid silicone rubber compositions

PatentActiveJP2022542424A

Innovation

- A method involving separate supply lines for inhibitor masterbatch, catalyst masterbatch, and crosslinker, with controlled molar ratios and lower curing temperatures (less than 160°C) to achieve rapid curing and flexible manufacturing of silicone rubber products, allowing overmolding on heat-sensitive substrates.

Environmental Impact of Silicone Technologies

Silicone rubber technologies have gained significant attention in recent years due to their versatile properties and wide-ranging applications. However, as with any industrial material, it is crucial to consider the environmental impact of these technologies throughout their lifecycle. The production, use, and disposal of silicone rubber products have both positive and negative implications for the environment.

The manufacturing process of silicone rubber involves the use of various chemicals and energy-intensive processes. While the raw materials used in silicone production are abundant and relatively low-impact, the energy consumption during manufacturing can contribute to greenhouse gas emissions. However, advancements in production techniques have led to more efficient processes, reducing the overall environmental footprint of silicone rubber manufacturing.

One of the key environmental benefits of silicone rubber is its durability and longevity. Products made from silicone rubber often have extended lifespans compared to alternative materials, reducing the need for frequent replacements and minimizing waste generation. This durability also contributes to resource conservation, as fewer raw materials are required over time to meet consumer demands.

Silicone rubber's resistance to extreme temperatures and weathering makes it an excellent choice for outdoor applications, potentially reducing the need for environmentally harmful protective coatings or frequent maintenance. Additionally, its low thermal conductivity properties can contribute to energy efficiency in various applications, such as building insulation or automotive components.

The disposal of silicone rubber products presents both challenges and opportunities. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Advanced recycling technologies have been developed to break down silicone rubber into its constituent components, allowing for the recovery and reuse of valuable materials. However, the availability and implementation of these recycling processes are not yet widespread, presenting an area for future improvement.

In terms of toxicity, silicone rubber is generally considered inert and non-toxic, posing minimal risk to human health and ecosystems. This characteristic makes it a preferred material in many applications where environmental safety is a concern, such as in medical devices or food packaging.

The water-repellent nature of silicone rubber can have both positive and negative environmental implications. While it can help prevent water damage and extend the life of certain products, it may also contribute to the accumulation of microplastics in aquatic environments if not properly managed.

As research in silicone rubber technologies continues to advance, there is a growing focus on developing more sustainable formulations and production methods. Bio-based silicones, derived from renewable resources, are emerging as a promising alternative to traditional petroleum-based silicones, potentially reducing the carbon footprint of these materials.

The manufacturing process of silicone rubber involves the use of various chemicals and energy-intensive processes. While the raw materials used in silicone production are abundant and relatively low-impact, the energy consumption during manufacturing can contribute to greenhouse gas emissions. However, advancements in production techniques have led to more efficient processes, reducing the overall environmental footprint of silicone rubber manufacturing.

One of the key environmental benefits of silicone rubber is its durability and longevity. Products made from silicone rubber often have extended lifespans compared to alternative materials, reducing the need for frequent replacements and minimizing waste generation. This durability also contributes to resource conservation, as fewer raw materials are required over time to meet consumer demands.

Silicone rubber's resistance to extreme temperatures and weathering makes it an excellent choice for outdoor applications, potentially reducing the need for environmentally harmful protective coatings or frequent maintenance. Additionally, its low thermal conductivity properties can contribute to energy efficiency in various applications, such as building insulation or automotive components.

The disposal of silicone rubber products presents both challenges and opportunities. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Advanced recycling technologies have been developed to break down silicone rubber into its constituent components, allowing for the recovery and reuse of valuable materials. However, the availability and implementation of these recycling processes are not yet widespread, presenting an area for future improvement.

In terms of toxicity, silicone rubber is generally considered inert and non-toxic, posing minimal risk to human health and ecosystems. This characteristic makes it a preferred material in many applications where environmental safety is a concern, such as in medical devices or food packaging.

The water-repellent nature of silicone rubber can have both positive and negative environmental implications. While it can help prevent water damage and extend the life of certain products, it may also contribute to the accumulation of microplastics in aquatic environments if not properly managed.

As research in silicone rubber technologies continues to advance, there is a growing focus on developing more sustainable formulations and production methods. Bio-based silicones, derived from renewable resources, are emerging as a promising alternative to traditional petroleum-based silicones, potentially reducing the carbon footprint of these materials.

Silicone Rubber Standards and Regulations

Silicone rubber standards and regulations play a crucial role in ensuring the quality, safety, and performance of silicone rubber components across various industries. These standards are developed and maintained by international organizations, national bodies, and industry associations to establish consistent guidelines for manufacturers, suppliers, and end-users.

The International Organization for Standardization (ISO) has developed several standards specific to silicone rubber, including ISO 2781 for determining density and ISO 3417 for measuring rheological properties. These standards provide a common framework for testing and evaluating silicone rubber materials, enabling consistent quality control and comparison across different manufacturers and applications.

In the United States, the American Society for Testing and Materials (ASTM) has established numerous standards for silicone rubber, such as ASTM D2240 for durometer hardness testing and ASTM D412 for tensile strength and elongation properties. These standards are widely adopted in the industry and serve as benchmarks for product specifications and performance requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of certain chemicals in silicone rubber formulations. Manufacturers must comply with REACH requirements to ensure the safety of their products and protect human health and the environment.

In the automotive industry, the International Automotive Task Force (IATF) 16949 standard sets quality management system requirements for automotive production and relevant service part organizations. This standard includes specific provisions for silicone rubber components used in automotive applications, ensuring they meet stringent performance and reliability criteria.

The medical device industry is subject to rigorous regulations, including ISO 10993 for biocompatibility testing of materials used in medical devices. Silicone rubber components intended for medical applications must undergo extensive testing to demonstrate their safety and suitability for use in the human body.

As the demand for high-performance silicone rubber components grows, regulatory bodies continue to update and refine their standards to address emerging technologies and applications. For instance, the development of electrically conductive silicone rubber has led to the creation of new standards for measuring electrical properties and ensuring electromagnetic compatibility.

Compliance with these standards and regulations is essential for manufacturers to maintain product quality, ensure market access, and meet customer expectations. As silicone rubber technologies advance, it is crucial for companies to stay informed about evolving standards and adapt their production processes accordingly to remain competitive in the global market.

The International Organization for Standardization (ISO) has developed several standards specific to silicone rubber, including ISO 2781 for determining density and ISO 3417 for measuring rheological properties. These standards provide a common framework for testing and evaluating silicone rubber materials, enabling consistent quality control and comparison across different manufacturers and applications.

In the United States, the American Society for Testing and Materials (ASTM) has established numerous standards for silicone rubber, such as ASTM D2240 for durometer hardness testing and ASTM D412 for tensile strength and elongation properties. These standards are widely adopted in the industry and serve as benchmarks for product specifications and performance requirements.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of certain chemicals in silicone rubber formulations. Manufacturers must comply with REACH requirements to ensure the safety of their products and protect human health and the environment.

In the automotive industry, the International Automotive Task Force (IATF) 16949 standard sets quality management system requirements for automotive production and relevant service part organizations. This standard includes specific provisions for silicone rubber components used in automotive applications, ensuring they meet stringent performance and reliability criteria.

The medical device industry is subject to rigorous regulations, including ISO 10993 for biocompatibility testing of materials used in medical devices. Silicone rubber components intended for medical applications must undergo extensive testing to demonstrate their safety and suitability for use in the human body.

As the demand for high-performance silicone rubber components grows, regulatory bodies continue to update and refine their standards to address emerging technologies and applications. For instance, the development of electrically conductive silicone rubber has led to the creation of new standards for measuring electrical properties and ensuring electromagnetic compatibility.

Compliance with these standards and regulations is essential for manufacturers to maintain product quality, ensure market access, and meet customer expectations. As silicone rubber technologies advance, it is crucial for companies to stay informed about evolving standards and adapt their production processes accordingly to remain competitive in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!