Silicone Rubber: The Innovator Behind Renewable Consumer Goods

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution and Objectives

Silicone rubber, a versatile synthetic elastomer, has undergone significant evolution since its inception in the 1940s. Initially developed for industrial applications, it has gradually found its way into various consumer goods sectors due to its unique properties. The journey of silicone rubber from a niche industrial material to a key component in renewable consumer products reflects the changing priorities of manufacturers and consumers alike.

The evolution of silicone rubber has been driven by advancements in polymer science and a growing demand for sustainable materials. Early formulations focused on improving heat resistance and electrical insulation properties. As environmental concerns gained prominence, researchers began exploring ways to enhance the biodegradability and recyclability of silicone rubber without compromising its performance characteristics.

In recent years, the objectives for silicone rubber development have shifted towards sustainability and renewability. Manufacturers are now aiming to create silicone rubber compounds that incorporate bio-based ingredients, reducing reliance on petroleum-derived components. This aligns with the global push for more environmentally friendly consumer goods and circular economy principles.

Another key objective in the evolution of silicone rubber is to improve its end-of-life management. Efforts are being made to develop silicone rubber formulations that can be more easily separated from other materials in consumer products, facilitating recycling processes. Additionally, research is ongoing to create silicone rubber variants that can biodegrade under specific conditions without releasing harmful substances into the environment.

The durability and longevity of silicone rubber products are also being reevaluated in the context of sustainability. While these properties have traditionally been seen as advantages, there is now a focus on balancing longevity with the need for materials that can be more readily reintegrated into production cycles or safely returned to the environment.

Innovation in silicone rubber technology is increasingly aimed at expanding its applications in renewable consumer goods. This includes developing silicone rubber formulations with enhanced properties such as improved UV resistance for outdoor products, antimicrobial properties for healthcare items, and food-grade safety for kitchenware. These advancements are opening up new possibilities for replacing less sustainable materials in various consumer product categories.

As the field progresses, the objectives for silicone rubber research are becoming more ambitious. Scientists and engineers are exploring ways to create "smart" silicone rubber materials that can respond to environmental stimuli, self-heal, or change properties on demand. These innovations could lead to a new generation of adaptive and highly efficient consumer products, further cementing silicone rubber's role as an innovator in the renewable consumer goods sector.

The evolution of silicone rubber has been driven by advancements in polymer science and a growing demand for sustainable materials. Early formulations focused on improving heat resistance and electrical insulation properties. As environmental concerns gained prominence, researchers began exploring ways to enhance the biodegradability and recyclability of silicone rubber without compromising its performance characteristics.

In recent years, the objectives for silicone rubber development have shifted towards sustainability and renewability. Manufacturers are now aiming to create silicone rubber compounds that incorporate bio-based ingredients, reducing reliance on petroleum-derived components. This aligns with the global push for more environmentally friendly consumer goods and circular economy principles.

Another key objective in the evolution of silicone rubber is to improve its end-of-life management. Efforts are being made to develop silicone rubber formulations that can be more easily separated from other materials in consumer products, facilitating recycling processes. Additionally, research is ongoing to create silicone rubber variants that can biodegrade under specific conditions without releasing harmful substances into the environment.

The durability and longevity of silicone rubber products are also being reevaluated in the context of sustainability. While these properties have traditionally been seen as advantages, there is now a focus on balancing longevity with the need for materials that can be more readily reintegrated into production cycles or safely returned to the environment.

Innovation in silicone rubber technology is increasingly aimed at expanding its applications in renewable consumer goods. This includes developing silicone rubber formulations with enhanced properties such as improved UV resistance for outdoor products, antimicrobial properties for healthcare items, and food-grade safety for kitchenware. These advancements are opening up new possibilities for replacing less sustainable materials in various consumer product categories.

As the field progresses, the objectives for silicone rubber research are becoming more ambitious. Scientists and engineers are exploring ways to create "smart" silicone rubber materials that can respond to environmental stimuli, self-heal, or change properties on demand. These innovations could lead to a new generation of adaptive and highly efficient consumer products, further cementing silicone rubber's role as an innovator in the renewable consumer goods sector.

Renewable Consumer Goods Market Analysis

The renewable consumer goods market has experienced significant growth in recent years, driven by increasing environmental awareness and a shift towards sustainable consumption. This market encompasses a wide range of products, including eco-friendly packaging, biodegradable materials, and reusable alternatives to single-use items. The global market for renewable consumer goods is expected to continue its upward trajectory, with projections indicating substantial expansion over the next decade.

Consumer demand for sustainable products has been a key driver of market growth. A growing segment of environmentally conscious consumers is actively seeking out products that align with their values, leading to increased sales of renewable and eco-friendly alternatives. This trend is particularly pronounced among younger generations, who are more likely to prioritize sustainability in their purchasing decisions.

The market for renewable consumer goods is characterized by diverse product categories. Packaging solutions, such as compostable food containers and recyclable shopping bags, represent a significant portion of the market. Personal care products, including bamboo toothbrushes and refillable cosmetics, have also gained traction. Additionally, household goods like reusable water bottles, beeswax food wraps, and biodegradable cleaning products have seen increased adoption.

Silicone rubber, as an innovative material in this space, offers unique properties that align well with the demands of the renewable consumer goods market. Its durability, flexibility, and resistance to extreme temperatures make it an attractive option for a variety of applications. Silicone rubber products can often replace single-use plastics, offering a more sustainable alternative with a longer lifespan.

The market for silicone rubber in renewable consumer goods is still emerging but shows promising growth potential. Its applications range from reusable food storage containers and baking mats to durable, long-lasting kitchenware and personal care items. The material's non-toxic nature and ability to withstand repeated use and cleaning cycles make it particularly appealing for food-related and personal care applications.

However, challenges remain in the broader renewable consumer goods market. Price sensitivity among consumers can be a barrier to adoption, as sustainable alternatives often come with a higher upfront cost. Additionally, there is a need for improved infrastructure to support the recycling and proper disposal of these materials at the end of their lifecycle.

Despite these challenges, the market outlook remains positive. Technological advancements in material science and manufacturing processes are expected to drive down costs and improve the performance of renewable consumer goods. Government regulations and corporate sustainability initiatives are also likely to fuel further growth in this sector, creating opportunities for innovative materials like silicone rubber to gain market share.

Consumer demand for sustainable products has been a key driver of market growth. A growing segment of environmentally conscious consumers is actively seeking out products that align with their values, leading to increased sales of renewable and eco-friendly alternatives. This trend is particularly pronounced among younger generations, who are more likely to prioritize sustainability in their purchasing decisions.

The market for renewable consumer goods is characterized by diverse product categories. Packaging solutions, such as compostable food containers and recyclable shopping bags, represent a significant portion of the market. Personal care products, including bamboo toothbrushes and refillable cosmetics, have also gained traction. Additionally, household goods like reusable water bottles, beeswax food wraps, and biodegradable cleaning products have seen increased adoption.

Silicone rubber, as an innovative material in this space, offers unique properties that align well with the demands of the renewable consumer goods market. Its durability, flexibility, and resistance to extreme temperatures make it an attractive option for a variety of applications. Silicone rubber products can often replace single-use plastics, offering a more sustainable alternative with a longer lifespan.

The market for silicone rubber in renewable consumer goods is still emerging but shows promising growth potential. Its applications range from reusable food storage containers and baking mats to durable, long-lasting kitchenware and personal care items. The material's non-toxic nature and ability to withstand repeated use and cleaning cycles make it particularly appealing for food-related and personal care applications.

However, challenges remain in the broader renewable consumer goods market. Price sensitivity among consumers can be a barrier to adoption, as sustainable alternatives often come with a higher upfront cost. Additionally, there is a need for improved infrastructure to support the recycling and proper disposal of these materials at the end of their lifecycle.

Despite these challenges, the market outlook remains positive. Technological advancements in material science and manufacturing processes are expected to drive down costs and improve the performance of renewable consumer goods. Government regulations and corporate sustainability initiatives are also likely to fuel further growth in this sector, creating opportunities for innovative materials like silicone rubber to gain market share.

Silicone Rubber Technology Status and Challenges

Silicone rubber technology has made significant strides in recent years, positioning itself as a key player in the development of renewable consumer goods. However, the current status of this technology presents both opportunities and challenges that warrant careful consideration.

The global market for silicone rubber is experiencing robust growth, driven by increasing demand across various industries, including consumer goods, automotive, and healthcare. This growth is attributed to silicone rubber's unique properties, such as heat resistance, durability, and flexibility. However, the technology faces challenges in terms of sustainability and cost-effectiveness.

One of the primary challenges in silicone rubber technology is the environmental impact of its production process. Traditional methods of silicone rubber manufacturing often involve energy-intensive processes and the use of potentially harmful chemicals. This has led to a growing need for more sustainable production techniques that can reduce the carbon footprint and minimize environmental risks.

Another significant challenge lies in the recyclability of silicone rubber products. While silicone rubber is known for its durability, this very characteristic makes it difficult to recycle effectively. Current recycling methods for silicone rubber are limited and often energy-intensive, presenting a barrier to its widespread adoption in renewable consumer goods.

The development of bio-based silicone rubber alternatives is an emerging area of research that shows promise. These alternatives aim to replace petroleum-based ingredients with renewable, plant-based sources. However, challenges remain in achieving comparable performance and cost-effectiveness to traditional silicone rubber.

Advancements in nanotechnology have opened up new possibilities for enhancing the properties of silicone rubber. Researchers are exploring the incorporation of nanoparticles to improve strength, thermal conductivity, and even self-healing capabilities. While these developments are promising, scaling up production and ensuring consistent quality remain significant hurdles.

The regulatory landscape surrounding silicone rubber in consumer goods is evolving, with increasing focus on safety and environmental impact. Manufacturers face the challenge of adapting to stricter regulations while maintaining product performance and economic viability.

In terms of geographical distribution, silicone rubber technology development is concentrated in regions with strong chemical and materials science industries, such as North America, Europe, and East Asia. This concentration presents challenges in terms of global access and adoption, particularly in developing markets.

As the demand for sustainable materials grows, the pressure on silicone rubber technology to innovate and adapt is intensifying. The industry must balance the need for improved environmental performance with maintaining the unique properties that make silicone rubber valuable in consumer goods applications.

The global market for silicone rubber is experiencing robust growth, driven by increasing demand across various industries, including consumer goods, automotive, and healthcare. This growth is attributed to silicone rubber's unique properties, such as heat resistance, durability, and flexibility. However, the technology faces challenges in terms of sustainability and cost-effectiveness.

One of the primary challenges in silicone rubber technology is the environmental impact of its production process. Traditional methods of silicone rubber manufacturing often involve energy-intensive processes and the use of potentially harmful chemicals. This has led to a growing need for more sustainable production techniques that can reduce the carbon footprint and minimize environmental risks.

Another significant challenge lies in the recyclability of silicone rubber products. While silicone rubber is known for its durability, this very characteristic makes it difficult to recycle effectively. Current recycling methods for silicone rubber are limited and often energy-intensive, presenting a barrier to its widespread adoption in renewable consumer goods.

The development of bio-based silicone rubber alternatives is an emerging area of research that shows promise. These alternatives aim to replace petroleum-based ingredients with renewable, plant-based sources. However, challenges remain in achieving comparable performance and cost-effectiveness to traditional silicone rubber.

Advancements in nanotechnology have opened up new possibilities for enhancing the properties of silicone rubber. Researchers are exploring the incorporation of nanoparticles to improve strength, thermal conductivity, and even self-healing capabilities. While these developments are promising, scaling up production and ensuring consistent quality remain significant hurdles.

The regulatory landscape surrounding silicone rubber in consumer goods is evolving, with increasing focus on safety and environmental impact. Manufacturers face the challenge of adapting to stricter regulations while maintaining product performance and economic viability.

In terms of geographical distribution, silicone rubber technology development is concentrated in regions with strong chemical and materials science industries, such as North America, Europe, and East Asia. This concentration presents challenges in terms of global access and adoption, particularly in developing markets.

As the demand for sustainable materials grows, the pressure on silicone rubber technology to innovate and adapt is intensifying. The industry must balance the need for improved environmental performance with maintaining the unique properties that make silicone rubber valuable in consumer goods applications.

Current Silicone Rubber Applications in Consumer Goods

01 Composition and formulation of silicone rubber

Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing behavior.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness or elasticity to suit particular applications.

- Silicone rubber in medical and healthcare applications: Silicone rubber is widely used in medical and healthcare products due to its biocompatibility, flexibility, and durability. Applications include medical implants, prosthetics, drug delivery systems, and various medical devices. Special formulations may be developed to meet specific medical requirements such as antimicrobial properties or controlled drug release.

- Silicone rubber in electronic and electrical applications: Silicone rubber finds extensive use in electronic and electrical applications due to its excellent insulating properties and resistance to extreme temperatures. It is used in the production of cables, connectors, keypads, and various electronic components. Specialized formulations may include conductive additives for specific electronic applications.

- Environmental and industrial applications of silicone rubber: Silicone rubber is utilized in various environmental and industrial applications due to its resistance to weathering, chemicals, and extreme temperatures. It is used in seals, gaskets, coatings, and other components in industries such as automotive, aerospace, and construction. Specialized formulations may be developed for specific environmental conditions or industrial processes.

02 Manufacturing processes for silicone rubber products

Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape, size, and properties of the final product. Curing methods such as heat curing or room temperature vulcanization (RTV) are used to set the rubber.Expand Specific Solutions03 Modifications and improvements to silicone rubber

Ongoing research focuses on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of nanofillers, and surface treatments. These modifications aim to improve mechanical strength, thermal stability, and chemical resistance of silicone rubber materials.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds widespread use across multiple industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for diverse applications.Expand Specific Solutions05 Environmental and safety considerations in silicone rubber production

The production and use of silicone rubber involve considerations for environmental impact and safety. This includes the development of eco-friendly formulations, reduction of volatile organic compounds (VOCs), and ensuring compliance with regulatory standards. Efforts are made to improve the recyclability and biodegradability of silicone rubber products.Expand Specific Solutions

Key Players in Silicone Rubber Industry

The research on silicone rubber as an innovator in renewable consumer goods is in a growth phase, with increasing market size and technological advancements. The global silicone rubber market is expanding due to its versatile applications and eco-friendly properties. Key players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie are driving innovation in this field. These companies, along with Momentive Performance Materials and Evonik Operations, are investing heavily in R&D to improve the performance and sustainability of silicone rubber products. The technology is maturing rapidly, with advancements in formulations and manufacturing processes enhancing its potential for renewable consumer goods applications.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed innovative silicone rubber compounds specifically designed for renewable consumer goods. Their research focuses on enhancing the durability and flexibility of silicone rubber to extend the lifespan of products, reducing waste and promoting sustainability. The company has introduced a new line of bio-based silicone rubbers, incorporating renewable raw materials to decrease reliance on fossil fuels[1]. They have also developed advanced crosslinking technologies that improve the mechanical properties and heat resistance of silicone rubber, making it suitable for a wider range of consumer applications[2]. Additionally, Shin-Etsu has invested in research on self-healing silicone rubber materials, which can repair minor damage autonomously, further extending product life cycles[3].

Strengths: Industry leader in silicone technology, strong R&D capabilities, and a wide range of applications. Weaknesses: Higher production costs compared to traditional materials, and potential limitations in scalability for some specialized formulations.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has made significant strides in developing sustainable silicone rubber solutions for renewable consumer goods. Their research focuses on creating silicone rubber formulations with reduced environmental impact throughout the product lifecycle. Dow has introduced a series of low-volatile organic compound (VOC) silicone rubbers, which contribute to improved air quality in consumer applications[4]. The company has also developed silicone rubber composites that incorporate recycled materials, promoting circular economy principles[5]. Furthermore, Dow's research includes the development of silicone rubber with enhanced biodegradability, addressing end-of-life concerns for consumer products[6]. Their innovative approach extends to energy-efficient curing processes for silicone rubber, reducing the overall carbon footprint of manufacturing.

Strengths: Extensive global reach, diverse product portfolio, and strong focus on sustainability. Weaknesses: Potential challenges in balancing performance with eco-friendly formulations, and dependency on raw material availability.

Breakthrough Silicone Rubber Technologies

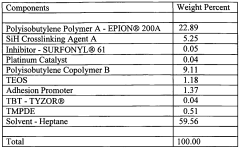

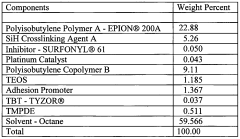

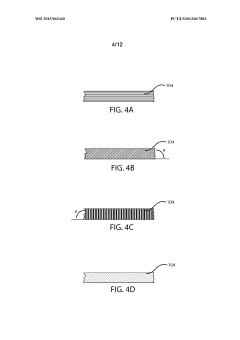

Improved PIB barrier coating composition for permeation reduction of silicone rubber parts

PatentWO2005035637A1

Innovation

- A cured polyisobutylene coating composition is applied to untreated silicone rubber substrates, comprising a polyisobutylene polymer, crosslinking agent, catalyst, and an adhesion promoter containing polysiloxane and epoxy silane, eliminating the need for surface treatment.

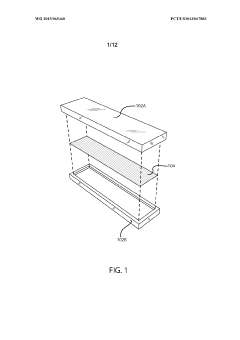

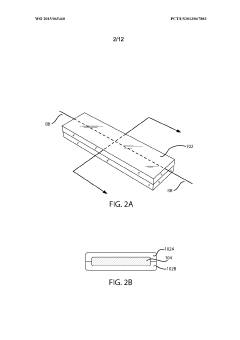

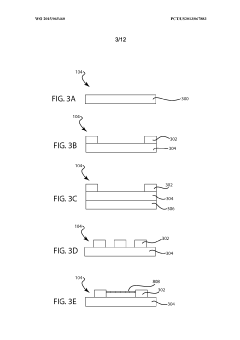

Flexibility-controlled composite material and method of manufacture

PatentWO2015065460A1

Innovation

- A composite material is created by combining a flexible silicone rubber with a second material that resists elongation, such as fiber strands or woven fabric, which is encapsulated within the silicone rubber, allowing for controlled modification of flexibility characteristics through the orientation and configuration of the second material.

Environmental Impact Assessment

The environmental impact of silicone rubber in renewable consumer goods is a critical aspect to consider in the context of sustainable product development. Silicone rubber, derived from silica, offers several environmental advantages over traditional petroleum-based rubbers. Its production process generally requires less energy and generates fewer greenhouse gas emissions compared to conventional rubber manufacturing.

One of the key environmental benefits of silicone rubber is its durability and longevity. Products made with silicone rubber tend to have a longer lifespan, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with production and disposal. This characteristic aligns well with the principles of circular economy and waste reduction.

Silicone rubber also demonstrates excellent resistance to extreme temperatures, UV radiation, and chemical exposure. This resilience contributes to the material's ability to maintain its properties over time, further extending product life cycles and reducing the need for premature replacements. Additionally, silicone rubber's thermal stability allows for efficient energy use in applications where temperature regulation is crucial.

In terms of end-of-life management, silicone rubber presents both opportunities and challenges. While it is not biodegradable, silicone rubber can be recycled through specialized processes. These recycling methods can recover valuable materials, potentially reducing the demand for virgin silicone production. However, the infrastructure for silicone rubber recycling is not yet widely established, which currently limits its recyclability in practice.

The water-repellent nature of silicone rubber contributes to its environmental profile in certain applications. For instance, in waterproofing or sealing products, silicone rubber can enhance energy efficiency and reduce water consumption, indirectly lowering the environmental impact of the products it is used in.

It is important to note that while silicone rubber offers several environmental advantages, its production still relies on the extraction of raw materials and energy-intensive processes. The mining of silica and the chemical processes involved in silicone production have their own environmental implications, including habitat disruption and potential chemical emissions.

When considering the use of silicone rubber in renewable consumer goods, a comprehensive life cycle assessment is essential. This assessment should account for raw material extraction, manufacturing processes, product use phase, and end-of-life scenarios. Such an analysis would provide a more holistic view of the environmental impact, allowing for informed decisions in product design and material selection.

One of the key environmental benefits of silicone rubber is its durability and longevity. Products made with silicone rubber tend to have a longer lifespan, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with production and disposal. This characteristic aligns well with the principles of circular economy and waste reduction.

Silicone rubber also demonstrates excellent resistance to extreme temperatures, UV radiation, and chemical exposure. This resilience contributes to the material's ability to maintain its properties over time, further extending product life cycles and reducing the need for premature replacements. Additionally, silicone rubber's thermal stability allows for efficient energy use in applications where temperature regulation is crucial.

In terms of end-of-life management, silicone rubber presents both opportunities and challenges. While it is not biodegradable, silicone rubber can be recycled through specialized processes. These recycling methods can recover valuable materials, potentially reducing the demand for virgin silicone production. However, the infrastructure for silicone rubber recycling is not yet widely established, which currently limits its recyclability in practice.

The water-repellent nature of silicone rubber contributes to its environmental profile in certain applications. For instance, in waterproofing or sealing products, silicone rubber can enhance energy efficiency and reduce water consumption, indirectly lowering the environmental impact of the products it is used in.

It is important to note that while silicone rubber offers several environmental advantages, its production still relies on the extraction of raw materials and energy-intensive processes. The mining of silica and the chemical processes involved in silicone production have their own environmental implications, including habitat disruption and potential chemical emissions.

When considering the use of silicone rubber in renewable consumer goods, a comprehensive life cycle assessment is essential. This assessment should account for raw material extraction, manufacturing processes, product use phase, and end-of-life scenarios. Such an analysis would provide a more holistic view of the environmental impact, allowing for informed decisions in product design and material selection.

Regulatory Framework for Silicone-Based Consumer Products

The regulatory framework for silicone-based consumer products is a complex and evolving landscape that plays a crucial role in ensuring the safety and quality of these innovative materials. In the United States, the Food and Drug Administration (FDA) oversees the regulation of silicone products used in food contact applications, medical devices, and cosmetics. The FDA has established specific guidelines for the use of silicone rubber in various consumer goods, including requirements for toxicity testing, biocompatibility assessments, and manufacturing processes.

In the European Union, the regulatory framework is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers and importers of silicone-based products to register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU has implemented specific regulations for food contact materials, including Commission Regulation (EU) No 10/2011, which sets out specific migration limits for silicone additives used in food packaging.

Japan has its own regulatory system for silicone-based consumer products, administered by the Ministry of Health, Labour and Welfare. The Japanese regulatory framework includes the Food Sanitation Act, which governs the use of silicone materials in food contact applications, and the Pharmaceutical Affairs Law, which regulates silicone-based medical devices and cosmetics.

Environmental regulations also play a significant role in shaping the use of silicone rubber in renewable consumer goods. Many countries have implemented regulations to promote the use of sustainable materials and reduce environmental impact. For instance, the EU's Circular Economy Action Plan encourages the development of durable, repairable, and recyclable products, which aligns well with the properties of silicone rubber.

As the use of silicone rubber in renewable consumer goods continues to expand, regulatory bodies are adapting their frameworks to address new applications and potential risks. This includes the development of standards for biodegradable silicone materials and guidelines for the recycling and disposal of silicone-based products. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and drive innovation in the field of silicone-based renewable consumer goods.

In the European Union, the regulatory framework is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH requires manufacturers and importers of silicone-based products to register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU has implemented specific regulations for food contact materials, including Commission Regulation (EU) No 10/2011, which sets out specific migration limits for silicone additives used in food packaging.

Japan has its own regulatory system for silicone-based consumer products, administered by the Ministry of Health, Labour and Welfare. The Japanese regulatory framework includes the Food Sanitation Act, which governs the use of silicone materials in food contact applications, and the Pharmaceutical Affairs Law, which regulates silicone-based medical devices and cosmetics.

Environmental regulations also play a significant role in shaping the use of silicone rubber in renewable consumer goods. Many countries have implemented regulations to promote the use of sustainable materials and reduce environmental impact. For instance, the EU's Circular Economy Action Plan encourages the development of durable, repairable, and recyclable products, which aligns well with the properties of silicone rubber.

As the use of silicone rubber in renewable consumer goods continues to expand, regulatory bodies are adapting their frameworks to address new applications and potential risks. This includes the development of standards for biodegradable silicone materials and guidelines for the recycling and disposal of silicone-based products. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and drive innovation in the field of silicone-based renewable consumer goods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!