Silicone Rubber: Building Smarter Smart Home Devices

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Smart Home: Background and Objectives

Silicone rubber has emerged as a pivotal material in the evolution of smart home devices, offering a unique combination of properties that align perfectly with the demands of modern, intelligent household appliances. This versatile elastomer has a rich history dating back to its discovery in the 1930s, with its applications expanding rapidly across various industries due to its exceptional characteristics.

In the context of smart home technology, silicone rubber's journey began as a simple insulating and protective material. However, as the Internet of Things (IoT) and home automation gained traction, the potential of silicone rubber in creating more sophisticated and responsive devices became increasingly apparent. Its ability to withstand extreme temperatures, resist moisture, and maintain flexibility has made it an ideal candidate for the outer casings and internal components of smart home devices.

The technological evolution in this field has been driven by the growing consumer demand for seamless, intuitive, and interconnected home environments. As smart homes transition from novelty to necessity, the expectations for device performance, durability, and functionality have skyrocketed. This shift has placed silicone rubber at the forefront of material science innovation for smart home applications.

The primary objective of researching silicone rubber for smarter smart home devices is to enhance the overall user experience while improving device functionality and longevity. This involves exploring ways to integrate advanced sensing capabilities directly into the silicone rubber matrix, potentially eliminating the need for separate sensor components. Such integration could lead to more compact, efficient, and responsive smart home devices.

Another crucial goal is to develop silicone rubber formulations that can adapt to environmental changes, potentially allowing devices to self-regulate their properties based on external conditions. This could result in smart home devices that are more energy-efficient and have extended lifespans, addressing key consumer concerns about sustainability and device longevity.

Furthermore, research aims to leverage silicone rubber's unique properties to create more intuitive user interfaces. By enhancing the material's tactile feedback mechanisms and incorporating visual cues through color-changing capabilities, future smart home devices could offer more natural and instinctive interactions, bridging the gap between technology and human intuition.

As we look towards the future, the research on silicone rubber for smart home devices is poised to revolutionize the way we interact with our living spaces. By pushing the boundaries of material science and smart technology integration, this field of study holds the promise of creating homes that are not just automated, but truly intelligent and responsive to our needs.

In the context of smart home technology, silicone rubber's journey began as a simple insulating and protective material. However, as the Internet of Things (IoT) and home automation gained traction, the potential of silicone rubber in creating more sophisticated and responsive devices became increasingly apparent. Its ability to withstand extreme temperatures, resist moisture, and maintain flexibility has made it an ideal candidate for the outer casings and internal components of smart home devices.

The technological evolution in this field has been driven by the growing consumer demand for seamless, intuitive, and interconnected home environments. As smart homes transition from novelty to necessity, the expectations for device performance, durability, and functionality have skyrocketed. This shift has placed silicone rubber at the forefront of material science innovation for smart home applications.

The primary objective of researching silicone rubber for smarter smart home devices is to enhance the overall user experience while improving device functionality and longevity. This involves exploring ways to integrate advanced sensing capabilities directly into the silicone rubber matrix, potentially eliminating the need for separate sensor components. Such integration could lead to more compact, efficient, and responsive smart home devices.

Another crucial goal is to develop silicone rubber formulations that can adapt to environmental changes, potentially allowing devices to self-regulate their properties based on external conditions. This could result in smart home devices that are more energy-efficient and have extended lifespans, addressing key consumer concerns about sustainability and device longevity.

Furthermore, research aims to leverage silicone rubber's unique properties to create more intuitive user interfaces. By enhancing the material's tactile feedback mechanisms and incorporating visual cues through color-changing capabilities, future smart home devices could offer more natural and instinctive interactions, bridging the gap between technology and human intuition.

As we look towards the future, the research on silicone rubber for smart home devices is poised to revolutionize the way we interact with our living spaces. By pushing the boundaries of material science and smart technology integration, this field of study holds the promise of creating homes that are not just automated, but truly intelligent and responsive to our needs.

Market Analysis for Smart Home Silicone Applications

The smart home market has experienced significant growth in recent years, with silicone rubber playing a crucial role in the development of innovative devices. The global smart home market is projected to reach $135.3 billion by 2025, growing at a CAGR of 11.6% from 2020 to 2025. Silicone rubber applications in smart home devices are expected to contribute substantially to this growth, driven by the material's unique properties and versatility.

Silicone rubber's excellent thermal stability, electrical insulation, and flexibility make it an ideal material for various smart home applications. These include touch-sensitive controls, waterproof enclosures for outdoor devices, and durable seals for appliances. The demand for silicone-based products in smart homes is particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia-Pacific.

The smart home silicone market is segmented into several key application areas. Smart speakers and voice assistants represent a significant portion of the market, with silicone rubber used in components like buttons, seals, and protective covers. Home security systems, including cameras and sensors, also utilize silicone for weather-resistant housings and flexible connectors. Smart lighting solutions incorporate silicone in LED encapsulation and diffusers, enhancing durability and light distribution.

Consumer preferences are driving the adoption of silicone-based smart home products. The material's soft touch and hypoallergenic properties appeal to users seeking comfortable and safe interactions with their devices. Additionally, the growing awareness of environmental sustainability has led to increased demand for silicone rubber, as it is more durable and recyclable compared to many traditional plastics.

Market trends indicate a shift towards more integrated and interconnected smart home ecosystems. This trend is creating opportunities for silicone manufacturers to develop specialized formulations that can withstand the rigors of constant use and exposure to various environmental conditions. The rise of IoT (Internet of Things) devices is also expanding the potential applications for silicone rubber in smart home products, particularly in areas requiring flexible and durable materials for sensors and actuators.

Challenges in the smart home silicone market include the need for continuous innovation to meet evolving consumer expectations and regulatory requirements. Manufacturers must balance performance, cost-effectiveness, and sustainability in their product development efforts. Despite these challenges, the outlook for silicone rubber in smart home applications remains highly positive, with ample room for growth and innovation in the coming years.

Silicone rubber's excellent thermal stability, electrical insulation, and flexibility make it an ideal material for various smart home applications. These include touch-sensitive controls, waterproof enclosures for outdoor devices, and durable seals for appliances. The demand for silicone-based products in smart homes is particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia-Pacific.

The smart home silicone market is segmented into several key application areas. Smart speakers and voice assistants represent a significant portion of the market, with silicone rubber used in components like buttons, seals, and protective covers. Home security systems, including cameras and sensors, also utilize silicone for weather-resistant housings and flexible connectors. Smart lighting solutions incorporate silicone in LED encapsulation and diffusers, enhancing durability and light distribution.

Consumer preferences are driving the adoption of silicone-based smart home products. The material's soft touch and hypoallergenic properties appeal to users seeking comfortable and safe interactions with their devices. Additionally, the growing awareness of environmental sustainability has led to increased demand for silicone rubber, as it is more durable and recyclable compared to many traditional plastics.

Market trends indicate a shift towards more integrated and interconnected smart home ecosystems. This trend is creating opportunities for silicone manufacturers to develop specialized formulations that can withstand the rigors of constant use and exposure to various environmental conditions. The rise of IoT (Internet of Things) devices is also expanding the potential applications for silicone rubber in smart home products, particularly in areas requiring flexible and durable materials for sensors and actuators.

Challenges in the smart home silicone market include the need for continuous innovation to meet evolving consumer expectations and regulatory requirements. Manufacturers must balance performance, cost-effectiveness, and sustainability in their product development efforts. Despite these challenges, the outlook for silicone rubber in smart home applications remains highly positive, with ample room for growth and innovation in the coming years.

Current Challenges in Silicone Rubber for Smart Devices

The integration of silicone rubber in smart home devices has revolutionized the industry, yet it faces several challenges that hinder its full potential. One of the primary issues is the material's thermal conductivity. While silicone rubber offers excellent electrical insulation, its poor thermal conductivity can lead to heat buildup in devices, potentially affecting performance and longevity. This is particularly problematic in smart devices that generate significant heat during operation, such as smart thermostats or high-powered smart lighting systems.

Another challenge lies in the material's mechanical properties. Although silicone rubber is known for its flexibility and durability, achieving the right balance between softness and strength for specific applications can be difficult. Smart home devices often require materials that can withstand repeated use and environmental stresses while maintaining their form and function. The current formulations of silicone rubber may not always meet these diverse requirements across the range of smart home products.

Adhesion is another area of concern. Silicone rubber's inherent low surface energy can make it challenging to bond with other materials commonly used in smart home devices, such as plastics or metals. This can lead to issues in manufacturing processes and product durability, potentially compromising the integrity of sealed components or the overall structure of devices.

The environmental stability of silicone rubber also presents challenges. While generally resistant to weathering, extreme temperatures, and UV radiation, some formulations may degrade over time when exposed to certain chemicals or environmental conditions. This is particularly relevant for smart home devices used in outdoor settings or in areas with high humidity or pollutants.

Furthermore, the customization of silicone rubber properties for specific smart home applications remains a complex task. Different devices may require varying degrees of flexibility, strength, or electrical properties. Current manufacturing processes may struggle to efficiently produce silicone rubber components with precisely tailored characteristics for each unique application.

Lastly, the cost of high-quality silicone rubber suitable for smart home devices can be prohibitive for mass-market products. Balancing performance requirements with cost-effectiveness is an ongoing challenge for manufacturers, especially as the smart home market becomes increasingly competitive and price-sensitive.

Addressing these challenges requires ongoing research and development efforts to improve silicone rubber formulations, processing techniques, and integration methods. Innovations in these areas will be crucial for unlocking the full potential of silicone rubber in the next generation of smart home devices.

Another challenge lies in the material's mechanical properties. Although silicone rubber is known for its flexibility and durability, achieving the right balance between softness and strength for specific applications can be difficult. Smart home devices often require materials that can withstand repeated use and environmental stresses while maintaining their form and function. The current formulations of silicone rubber may not always meet these diverse requirements across the range of smart home products.

Adhesion is another area of concern. Silicone rubber's inherent low surface energy can make it challenging to bond with other materials commonly used in smart home devices, such as plastics or metals. This can lead to issues in manufacturing processes and product durability, potentially compromising the integrity of sealed components or the overall structure of devices.

The environmental stability of silicone rubber also presents challenges. While generally resistant to weathering, extreme temperatures, and UV radiation, some formulations may degrade over time when exposed to certain chemicals or environmental conditions. This is particularly relevant for smart home devices used in outdoor settings or in areas with high humidity or pollutants.

Furthermore, the customization of silicone rubber properties for specific smart home applications remains a complex task. Different devices may require varying degrees of flexibility, strength, or electrical properties. Current manufacturing processes may struggle to efficiently produce silicone rubber components with precisely tailored characteristics for each unique application.

Lastly, the cost of high-quality silicone rubber suitable for smart home devices can be prohibitive for mass-market products. Balancing performance requirements with cost-effectiveness is an ongoing challenge for manufacturers, especially as the smart home market becomes increasingly competitive and price-sensitive.

Addressing these challenges requires ongoing research and development efforts to improve silicone rubber formulations, processing techniques, and integration methods. Innovations in these areas will be crucial for unlocking the full potential of silicone rubber in the next generation of smart home devices.

Existing Silicone Solutions for Smart Home Devices

01 Composition and formulation of silicone rubber

Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing behavior.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving mechanical strength, enhancing thermal stability, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating reinforcing fillers.

- Applications of silicone rubber: Silicone rubber finds wide-ranging applications due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, and consumer products. Its biocompatibility, heat resistance, and flexibility make it suitable for diverse industrial and commercial uses.

- Curing methods for silicone rubber: Various curing methods are employed in the production of silicone rubber, including heat curing, room temperature vulcanization (RTV), and UV curing. Each method affects the final properties of the rubber and is chosen based on the specific application requirements and manufacturing constraints.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes mixing with organic polymers, incorporating nanoparticles, or creating hybrid materials. These combinations can result in materials with improved mechanical, thermal, or electrical characteristics.

02 Manufacturing processes for silicone rubber products

Manufacturing methods for silicone rubber products include molding, extrusion, and calendering. The process may involve heat curing or room temperature vulcanization (RTV). Specialized techniques can be employed for creating complex shapes or incorporating reinforcements.Expand Specific Solutions03 Modifications and enhancements of silicone rubber properties

Silicone rubber properties can be modified through the addition of specific compounds or by altering the polymer structure. This can result in improved mechanical strength, chemical resistance, or electrical properties. Surface treatments may also be applied to enhance adhesion or other surface characteristics.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds applications in diverse industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for specialized applications.Expand Specific Solutions05 Advancements in silicone rubber technology

Recent advancements in silicone rubber technology include the development of self-healing silicone rubbers, nanocomposite silicone rubbers with enhanced properties, and silicone rubbers with improved environmental sustainability. Research is ongoing to expand the material's capabilities and explore new applications.Expand Specific Solutions

Key Players in Silicone and Smart Home Industries

The research on silicone rubber for smarter smart home devices is in a growth phase, with increasing market demand and technological advancements. The global smart home market is projected to reach $135.3 billion by 2025, driving innovation in materials like silicone rubber. Key players such as Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie are leading the development of advanced silicone formulations. These companies are focusing on enhancing properties like flexibility, durability, and thermal stability to meet the evolving requirements of smart home devices. The technology is maturing rapidly, with companies like Apple and Dow Silicones Corp. integrating silicone-based components into their products, indicating a growing adoption across the industry.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically for smart home devices. Their technology focuses on improving the durability and flexibility of silicone materials used in touch-sensitive interfaces and flexible displays. They have introduced a new line of silicone elastomers with enhanced electrical properties, allowing for better integration of sensors and circuitry within smart home devices[1]. The company has also developed silicone materials with improved thermal management capabilities, addressing the heat dissipation challenges in compact smart home electronics[3]. Additionally, Shin-Etsu has created silicone formulations that offer superior resistance to environmental factors such as UV radiation and moisture, extending the lifespan of outdoor smart home devices[5].

Strengths: Industry-leading expertise in silicone technology, wide range of specialized formulations for different smart home applications. Weaknesses: Higher cost compared to some alternatives, potential supply chain dependencies for specialized materials.

Apple, Inc.

Technical Solution: Apple has been investing heavily in silicone rubber research for its smart home devices, particularly for the HomePod and other upcoming products. Their focus has been on developing silicone materials that offer superior acoustic properties while maintaining durability and aesthetics. Apple has patented a unique silicone rubber formulation that allows for precise control of sound transmission and absorption, enhancing the audio quality of their smart speakers[8]. They have also developed a manufacturing process for creating seamless, high-precision silicone rubber components that integrate multiple functions, such as touch-sensitive controls and LED light diffusion[10]. Additionally, Apple's research has yielded silicone materials with improved resistance to oils and other household contaminants, ensuring long-term performance in various home environments[12].

Strengths: Strong integration of hardware and software, focus on user experience, significant R&D resources. Weaknesses: Proprietary technologies may limit broader industry adoption, potential higher costs for consumers.

Innovative Silicone Rubber Technologies for IoT Integration

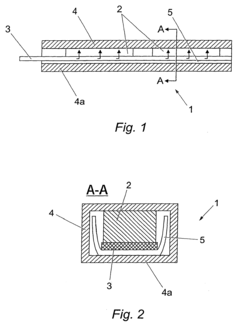

Heating device

PatentInactiveEP1666286A1

Innovation

- A heating device employing a flexible and heat-conductive silicone rubber insulating sheet between the contact sheet and the housing to ensure electrical insulation while enhancing thermal energy transfer and durability.

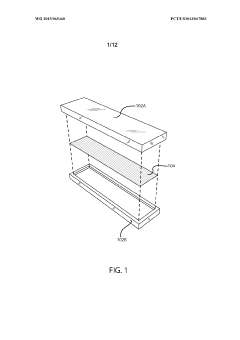

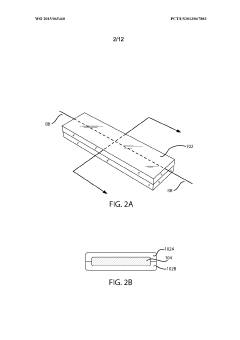

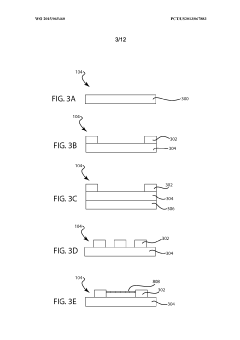

Flexibility-controlled composite material and method of manufacture

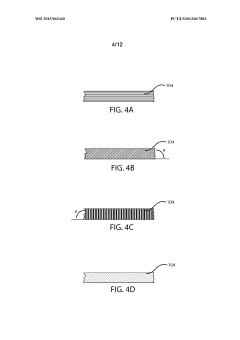

PatentWO2015065460A1

Innovation

- A composite material is created by combining a flexible silicone rubber with a second material that resists elongation, such as fiber strands or woven fabric, which is encapsulated within the silicone rubber, allowing for controlled modification of flexibility characteristics through the orientation and configuration of the second material.

Environmental Impact of Silicone in Smart Home Products

The environmental impact of silicone in smart home products is a crucial consideration as these devices become increasingly prevalent in modern households. Silicone rubber, a key component in many smart home devices, offers numerous advantages but also raises environmental concerns throughout its lifecycle.

During the production phase, silicone manufacturing processes consume significant energy and resources. The primary raw materials, silicon and methyl chloride, are derived from non-renewable sources, contributing to resource depletion. However, compared to many other plastics, silicone production generally has a lower carbon footprint and requires less water usage.

In the use phase, silicone's durability and longevity contribute positively to sustainability. Smart home devices made with silicone components tend to have extended lifespans, reducing the frequency of replacements and associated waste. Additionally, silicone's excellent insulation properties can enhance the energy efficiency of certain smart home devices, potentially lowering overall energy consumption in households.

End-of-life management presents both challenges and opportunities. Silicone is not biodegradable, which means it persists in the environment for extended periods if not properly disposed of. However, it is recyclable, and advancements in recycling technologies are making it increasingly feasible to recover and repurpose silicone from discarded smart home devices.

The potential for silicone to leach chemicals into the environment is a concern, particularly for outdoor smart home devices exposed to weathering. While silicone is generally considered inert, some studies suggest that certain additives or breakdown products may have ecological impacts, necessitating further research and monitoring.

From a broader perspective, the integration of silicone in smart home devices contributes to the overall environmental impact of the Internet of Things (IoT) ecosystem. While these devices can promote energy efficiency and resource optimization in homes, the cumulative effect of manufacturing, powering, and eventually disposing of millions of smart devices presents significant environmental challenges.

As the smart home industry evolves, there is a growing emphasis on developing more sustainable alternatives to traditional silicone. Bio-based silicones, derived from renewable resources, are emerging as a promising option to reduce the environmental footprint of smart home products. Additionally, design for disassembly and recyclability is becoming increasingly important to facilitate easier end-of-life processing and material recovery.

During the production phase, silicone manufacturing processes consume significant energy and resources. The primary raw materials, silicon and methyl chloride, are derived from non-renewable sources, contributing to resource depletion. However, compared to many other plastics, silicone production generally has a lower carbon footprint and requires less water usage.

In the use phase, silicone's durability and longevity contribute positively to sustainability. Smart home devices made with silicone components tend to have extended lifespans, reducing the frequency of replacements and associated waste. Additionally, silicone's excellent insulation properties can enhance the energy efficiency of certain smart home devices, potentially lowering overall energy consumption in households.

End-of-life management presents both challenges and opportunities. Silicone is not biodegradable, which means it persists in the environment for extended periods if not properly disposed of. However, it is recyclable, and advancements in recycling technologies are making it increasingly feasible to recover and repurpose silicone from discarded smart home devices.

The potential for silicone to leach chemicals into the environment is a concern, particularly for outdoor smart home devices exposed to weathering. While silicone is generally considered inert, some studies suggest that certain additives or breakdown products may have ecological impacts, necessitating further research and monitoring.

From a broader perspective, the integration of silicone in smart home devices contributes to the overall environmental impact of the Internet of Things (IoT) ecosystem. While these devices can promote energy efficiency and resource optimization in homes, the cumulative effect of manufacturing, powering, and eventually disposing of millions of smart devices presents significant environmental challenges.

As the smart home industry evolves, there is a growing emphasis on developing more sustainable alternatives to traditional silicone. Bio-based silicones, derived from renewable resources, are emerging as a promising option to reduce the environmental footprint of smart home products. Additionally, design for disassembly and recyclability is becoming increasingly important to facilitate easier end-of-life processing and material recovery.

Regulatory Landscape for Smart Home Materials

The regulatory landscape for smart home materials, particularly silicone rubber used in smart devices, is complex and evolving. In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of consumer products, including smart home devices. The CPSC has established guidelines for the use of materials in consumer electronics, with a focus on fire safety and toxicity.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electrical and electronic equipment. This directive impacts the composition of silicone rubber used in smart home devices, requiring manufacturers to ensure compliance with strict material standards.

In addition to RoHS, the EU's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation affects the use of chemicals in consumer products, including those used in silicone rubber formulations. Manufacturers must register substances used in their products and provide safety information to ensure compliance with REACH requirements.

The International Electrotechnical Commission (IEC) has developed standards for smart home devices, including IEC 62368-1, which covers safety requirements for audio/video, information, and communication technology equipment. This standard includes specifications for materials used in device construction, impacting the selection and application of silicone rubber in smart home products.

In Asia, countries like China and Japan have their own regulatory frameworks for smart home materials. China's Restriction of Hazardous Substances (China RoHS) regulation is similar to the EU's RoHS directive but has some unique requirements. Japan's J-Moss (Japanese RoHS) also regulates hazardous substances in electronic products.

Globally, the International Organization for Standardization (ISO) has developed standards relevant to smart home materials, such as ISO 14001 for environmental management systems. These standards influence the selection and use of materials like silicone rubber in smart home devices, encouraging manufacturers to consider environmental impacts throughout the product lifecycle.

As smart home technology advances, regulatory bodies are increasingly focusing on data privacy and cybersecurity. While these regulations primarily address software and connectivity aspects, they indirectly impact material choices by influencing device design and functionality requirements.

The regulatory landscape for smart home materials is dynamic, with ongoing updates to existing regulations and the introduction of new standards. Manufacturers must stay informed about these changes and adapt their material selection and product design processes accordingly to ensure compliance across different markets and jurisdictions.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electrical and electronic equipment. This directive impacts the composition of silicone rubber used in smart home devices, requiring manufacturers to ensure compliance with strict material standards.

In addition to RoHS, the EU's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation affects the use of chemicals in consumer products, including those used in silicone rubber formulations. Manufacturers must register substances used in their products and provide safety information to ensure compliance with REACH requirements.

The International Electrotechnical Commission (IEC) has developed standards for smart home devices, including IEC 62368-1, which covers safety requirements for audio/video, information, and communication technology equipment. This standard includes specifications for materials used in device construction, impacting the selection and application of silicone rubber in smart home products.

In Asia, countries like China and Japan have their own regulatory frameworks for smart home materials. China's Restriction of Hazardous Substances (China RoHS) regulation is similar to the EU's RoHS directive but has some unique requirements. Japan's J-Moss (Japanese RoHS) also regulates hazardous substances in electronic products.

Globally, the International Organization for Standardization (ISO) has developed standards relevant to smart home materials, such as ISO 14001 for environmental management systems. These standards influence the selection and use of materials like silicone rubber in smart home devices, encouraging manufacturers to consider environmental impacts throughout the product lifecycle.

As smart home technology advances, regulatory bodies are increasingly focusing on data privacy and cybersecurity. While these regulations primarily address software and connectivity aspects, they indirectly impact material choices by influencing device design and functionality requirements.

The regulatory landscape for smart home materials is dynamic, with ongoing updates to existing regulations and the introduction of new standards. Manufacturers must stay informed about these changes and adapt their material selection and product design processes accordingly to ensure compliance across different markets and jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!