Silicone Rubber in Efficient Thermal Management Solutions

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Thermal Management Background

Silicone rubber has emerged as a key material in the field of thermal management, offering unique properties that make it particularly suitable for efficient heat dissipation solutions. The background of silicone rubber in thermal management applications can be traced back to the mid-20th century when its potential for heat transfer was first recognized.

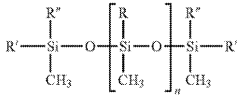

Initially developed for industrial applications, silicone rubber's thermal conductivity properties were discovered to be superior to many conventional materials. This realization led to increased research and development efforts to enhance its thermal management capabilities. Over the years, scientists and engineers have worked to modify the chemical structure and composition of silicone rubber to improve its thermal conductivity while maintaining its other desirable properties such as flexibility, electrical insulation, and resistance to extreme temperatures.

The growing demand for more efficient thermal management solutions in various industries has been a significant driver for the advancement of silicone rubber technology. As electronic devices became more compact and powerful, the need for effective heat dissipation became critical. Silicone rubber's ability to conform to irregular surfaces and its stability over a wide temperature range made it an ideal candidate for thermal interface materials (TIMs) in electronics cooling applications.

In the automotive sector, the shift towards electric and hybrid vehicles has further accelerated the development of silicone rubber-based thermal management solutions. These vehicles require advanced cooling systems for batteries, power electronics, and electric motors, where silicone rubber plays a crucial role in ensuring optimal performance and longevity of components.

The aerospace industry has also contributed to the evolution of silicone rubber in thermal management. The extreme temperature fluctuations and harsh environmental conditions encountered in space applications necessitated materials with exceptional thermal stability and reliability. Silicone rubber's ability to maintain its properties in such demanding environments has led to its widespread use in spacecraft thermal control systems.

Recent advancements in nanotechnology have opened new avenues for enhancing the thermal conductivity of silicone rubber. The incorporation of nanoparticles, such as carbon nanotubes, graphene, and metal oxides, into silicone rubber matrices has resulted in significant improvements in heat transfer capabilities. These nanocomposites have shown promise in addressing the thermal management challenges in cutting-edge technologies like 5G communications, artificial intelligence hardware, and high-performance computing systems.

As environmental concerns gain prominence, the focus on developing sustainable and eco-friendly thermal management solutions has also influenced silicone rubber research. Efforts are being made to create bio-based silicone rubbers and improve the recyclability of silicone rubber products, aligning with global sustainability goals while maintaining their thermal management efficacy.

Initially developed for industrial applications, silicone rubber's thermal conductivity properties were discovered to be superior to many conventional materials. This realization led to increased research and development efforts to enhance its thermal management capabilities. Over the years, scientists and engineers have worked to modify the chemical structure and composition of silicone rubber to improve its thermal conductivity while maintaining its other desirable properties such as flexibility, electrical insulation, and resistance to extreme temperatures.

The growing demand for more efficient thermal management solutions in various industries has been a significant driver for the advancement of silicone rubber technology. As electronic devices became more compact and powerful, the need for effective heat dissipation became critical. Silicone rubber's ability to conform to irregular surfaces and its stability over a wide temperature range made it an ideal candidate for thermal interface materials (TIMs) in electronics cooling applications.

In the automotive sector, the shift towards electric and hybrid vehicles has further accelerated the development of silicone rubber-based thermal management solutions. These vehicles require advanced cooling systems for batteries, power electronics, and electric motors, where silicone rubber plays a crucial role in ensuring optimal performance and longevity of components.

The aerospace industry has also contributed to the evolution of silicone rubber in thermal management. The extreme temperature fluctuations and harsh environmental conditions encountered in space applications necessitated materials with exceptional thermal stability and reliability. Silicone rubber's ability to maintain its properties in such demanding environments has led to its widespread use in spacecraft thermal control systems.

Recent advancements in nanotechnology have opened new avenues for enhancing the thermal conductivity of silicone rubber. The incorporation of nanoparticles, such as carbon nanotubes, graphene, and metal oxides, into silicone rubber matrices has resulted in significant improvements in heat transfer capabilities. These nanocomposites have shown promise in addressing the thermal management challenges in cutting-edge technologies like 5G communications, artificial intelligence hardware, and high-performance computing systems.

As environmental concerns gain prominence, the focus on developing sustainable and eco-friendly thermal management solutions has also influenced silicone rubber research. Efforts are being made to create bio-based silicone rubbers and improve the recyclability of silicone rubber products, aligning with global sustainability goals while maintaining their thermal management efficacy.

Market Demand Analysis

The market demand for efficient thermal management solutions utilizing silicone rubber has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for effective heat dissipation in various industries, including electronics, automotive, aerospace, and renewable energy sectors.

In the electronics industry, the miniaturization of devices and the rise of high-performance computing have led to a greater demand for thermal management materials that can efficiently dissipate heat in compact spaces. Silicone rubber, with its excellent thermal conductivity and flexibility, has emerged as a preferred material for thermal interface applications in smartphones, laptops, and other consumer electronics.

The automotive sector has also been a major contributor to the growing demand for silicone rubber-based thermal management solutions. With the rapid adoption of electric vehicles (EVs) and the increasing complexity of automotive electronics, there is a pressing need for materials that can effectively manage heat in battery systems, power electronics, and other critical components. Silicone rubber's ability to maintain its properties over a wide temperature range makes it particularly suitable for these applications.

In the aerospace industry, the demand for lightweight and high-performance thermal management materials has been driving the adoption of silicone rubber solutions. The material's low density, coupled with its thermal properties, makes it an attractive option for managing heat in aircraft and spacecraft systems, where weight reduction is crucial.

The renewable energy sector, particularly solar and wind power industries, has also shown increasing interest in silicone rubber-based thermal management solutions. As solar panels and wind turbines become more efficient and powerful, the need for effective heat dissipation to maintain optimal performance and longevity has grown significantly.

Market analysts project that the global thermal management market, including silicone rubber-based solutions, will continue to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is expected to be fueled by ongoing technological advancements, the proliferation of IoT devices, and the increasing adoption of electric vehicles and renewable energy systems.

Furthermore, the COVID-19 pandemic has accelerated the digitalization trend across various industries, leading to an increased demand for data centers and cloud computing infrastructure. This has, in turn, boosted the need for efficient thermal management solutions, including those based on silicone rubber, to ensure the reliable operation of these critical facilities.

As environmental concerns and energy efficiency regulations become more stringent, there is a growing emphasis on developing sustainable and eco-friendly thermal management solutions. This trend is expected to further drive innovation in silicone rubber formulations and applications, opening up new market opportunities in the coming years.

In the electronics industry, the miniaturization of devices and the rise of high-performance computing have led to a greater demand for thermal management materials that can efficiently dissipate heat in compact spaces. Silicone rubber, with its excellent thermal conductivity and flexibility, has emerged as a preferred material for thermal interface applications in smartphones, laptops, and other consumer electronics.

The automotive sector has also been a major contributor to the growing demand for silicone rubber-based thermal management solutions. With the rapid adoption of electric vehicles (EVs) and the increasing complexity of automotive electronics, there is a pressing need for materials that can effectively manage heat in battery systems, power electronics, and other critical components. Silicone rubber's ability to maintain its properties over a wide temperature range makes it particularly suitable for these applications.

In the aerospace industry, the demand for lightweight and high-performance thermal management materials has been driving the adoption of silicone rubber solutions. The material's low density, coupled with its thermal properties, makes it an attractive option for managing heat in aircraft and spacecraft systems, where weight reduction is crucial.

The renewable energy sector, particularly solar and wind power industries, has also shown increasing interest in silicone rubber-based thermal management solutions. As solar panels and wind turbines become more efficient and powerful, the need for effective heat dissipation to maintain optimal performance and longevity has grown significantly.

Market analysts project that the global thermal management market, including silicone rubber-based solutions, will continue to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is expected to be fueled by ongoing technological advancements, the proliferation of IoT devices, and the increasing adoption of electric vehicles and renewable energy systems.

Furthermore, the COVID-19 pandemic has accelerated the digitalization trend across various industries, leading to an increased demand for data centers and cloud computing infrastructure. This has, in turn, boosted the need for efficient thermal management solutions, including those based on silicone rubber, to ensure the reliable operation of these critical facilities.

As environmental concerns and energy efficiency regulations become more stringent, there is a growing emphasis on developing sustainable and eco-friendly thermal management solutions. This trend is expected to further drive innovation in silicone rubber formulations and applications, opening up new market opportunities in the coming years.

Current Challenges in Thermal Management

Thermal management has become a critical challenge in various industries, particularly in electronics, automotive, and aerospace sectors. As devices become more compact and powerful, the need for efficient heat dissipation has intensified. Silicone rubber, with its unique properties, has emerged as a promising material for addressing these thermal management challenges.

One of the primary challenges in thermal management is the increasing power density of electronic components. As transistor counts continue to rise and chip sizes shrink, the heat generated per unit area has escalated dramatically. This trend has pushed traditional cooling methods to their limits, necessitating innovative solutions that can effectively dissipate heat in confined spaces.

Another significant challenge is the thermal interface resistance between different components. In complex systems, heat must be transferred across multiple interfaces, each of which can act as a barrier to efficient heat flow. Reducing this interface resistance is crucial for improving overall thermal management performance.

The demand for flexible and conformable thermal management solutions presents another hurdle. Many modern devices have irregular shapes or require bendable components, making rigid heat sinks or thermal pads inadequate. This challenge is particularly pronounced in wearable technology and flexible electronics.

Durability and long-term reliability of thermal management solutions are also major concerns. Materials used in thermal management applications must withstand repeated thermal cycling, mechanical stress, and environmental factors without degrading performance over time.

Weight considerations pose an additional challenge, especially in aerospace and portable electronics applications. Thermal management solutions must be lightweight to avoid adding significant mass to the overall system, which can impact energy efficiency and portability.

Cost-effectiveness remains a persistent challenge in thermal management. While high-performance solutions exist, they are often prohibitively expensive for mass-market applications. Balancing thermal performance with economic viability is crucial for widespread adoption.

Environmental concerns and regulatory pressures add another layer of complexity to thermal management challenges. There is a growing need for eco-friendly materials and solutions that minimize the use of harmful substances and are easily recyclable at the end of their lifecycle.

In the context of silicone rubber research for thermal management, addressing these challenges requires a multifaceted approach. Researchers must focus on enhancing the thermal conductivity of silicone rubber while maintaining its desirable properties such as flexibility, electrical insulation, and chemical stability. Developing novel composites, optimizing filler materials, and exploring surface modification techniques are key areas of investigation to overcome these thermal management hurdles.

One of the primary challenges in thermal management is the increasing power density of electronic components. As transistor counts continue to rise and chip sizes shrink, the heat generated per unit area has escalated dramatically. This trend has pushed traditional cooling methods to their limits, necessitating innovative solutions that can effectively dissipate heat in confined spaces.

Another significant challenge is the thermal interface resistance between different components. In complex systems, heat must be transferred across multiple interfaces, each of which can act as a barrier to efficient heat flow. Reducing this interface resistance is crucial for improving overall thermal management performance.

The demand for flexible and conformable thermal management solutions presents another hurdle. Many modern devices have irregular shapes or require bendable components, making rigid heat sinks or thermal pads inadequate. This challenge is particularly pronounced in wearable technology and flexible electronics.

Durability and long-term reliability of thermal management solutions are also major concerns. Materials used in thermal management applications must withstand repeated thermal cycling, mechanical stress, and environmental factors without degrading performance over time.

Weight considerations pose an additional challenge, especially in aerospace and portable electronics applications. Thermal management solutions must be lightweight to avoid adding significant mass to the overall system, which can impact energy efficiency and portability.

Cost-effectiveness remains a persistent challenge in thermal management. While high-performance solutions exist, they are often prohibitively expensive for mass-market applications. Balancing thermal performance with economic viability is crucial for widespread adoption.

Environmental concerns and regulatory pressures add another layer of complexity to thermal management challenges. There is a growing need for eco-friendly materials and solutions that minimize the use of harmful substances and are easily recyclable at the end of their lifecycle.

In the context of silicone rubber research for thermal management, addressing these challenges requires a multifaceted approach. Researchers must focus on enhancing the thermal conductivity of silicone rubber while maintaining its desirable properties such as flexibility, electrical insulation, and chemical stability. Developing novel composites, optimizing filler materials, and exploring surface modification techniques are key areas of investigation to overcome these thermal management hurdles.

Existing Thermal Solutions

01 Thermal management in electronic devices

Silicone rubber is used for thermal management in electronic devices, particularly in image forming apparatuses. It helps in dissipating heat generated by components, improving overall device performance and longevity. The material's properties allow for efficient heat transfer while maintaining flexibility and electrical insulation.- Thermal management in electronic devices: Silicone rubber is used for thermal management in electronic devices, particularly in image forming apparatuses. It helps in heat dissipation and temperature control, ensuring optimal performance and longevity of the components. The material's properties allow for efficient heat transfer and thermal insulation where needed.

- Composition of thermally conductive silicone rubber: Thermally conductive silicone rubber compositions are developed by incorporating specific fillers and additives. These compositions often include metal oxides, ceramic particles, or other thermally conductive materials to enhance heat dissipation properties while maintaining the flexibility and durability of silicone rubber.

- Manufacturing processes for thermal management silicone rubber: Various manufacturing processes are employed to produce silicone rubber with enhanced thermal management properties. These may include specific mixing techniques, curing methods, and surface treatments to optimize the material's thermal conductivity and heat dissipation capabilities.

- Application in automotive and industrial sectors: Silicone rubber with thermal management properties finds applications in automotive and industrial sectors. It is used in engine components, electrical systems, and industrial machinery where heat dissipation and temperature regulation are critical for performance and safety.

- Integration with other materials for enhanced thermal performance: Silicone rubber is often combined or integrated with other materials to create hybrid solutions for improved thermal management. This may include layered structures, composites, or coatings that leverage the properties of silicone rubber along with other thermally conductive or insulating materials.

02 Thermally conductive silicone rubber compositions

Specialized silicone rubber compositions are developed with enhanced thermal conductivity. These compositions often include fillers such as metal oxides or other thermally conductive particles. The formulations aim to balance thermal conductivity with other desirable properties like flexibility, electrical insulation, and ease of processing.Expand Specific Solutions03 Heat dissipation in LED lighting

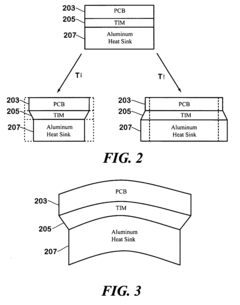

Silicone rubber is utilized in LED lighting systems for effective heat management. The material's properties allow for efficient heat dissipation from LED components, crucial for maintaining light output and extending the lifespan of LED devices. Specialized formulations may be used to enhance thermal conductivity while retaining optical properties.Expand Specific Solutions04 Thermal interface materials

Silicone rubber-based thermal interface materials are developed for use between heat-generating components and heat sinks. These materials aim to minimize thermal resistance at the interface, improving overall heat transfer efficiency. Formulations may include specific fillers or additives to enhance thermal conductivity while maintaining conformability and ease of application.Expand Specific Solutions05 Manufacturing processes for thermally conductive silicone rubber

Various manufacturing processes are developed to produce thermally conductive silicone rubber materials. These may include specific mixing techniques, curing methods, or post-processing treatments to optimize thermal properties. The processes aim to ensure uniform distribution of conductive fillers and achieve desired material characteristics for thermal management applications.Expand Specific Solutions

Key Industry Players

The research on silicone rubber in efficient thermal management solutions is in a growth phase, with increasing market demand driven by the expanding electronics and automotive industries. The global market size for thermal management materials is projected to reach significant figures in the coming years. Technologically, silicone rubber solutions are advancing rapidly, with key players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie leading innovation. These companies, along with Momentive Performance Materials and others, are developing high-performance silicone rubber compounds with enhanced thermal conductivity and stability. The competitive landscape is characterized by ongoing R&D efforts to improve product efficiency and expand applications in emerging sectors such as electric vehicles and 5G technology.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically designed for thermal management solutions. Their proprietary formulations incorporate high thermal conductivity fillers, achieving thermal conductivity values up to 13 W/m·K [1]. These materials maintain excellent electrical insulation properties while providing efficient heat dissipation. Shin-Etsu's silicone rubber solutions are engineered to be highly flexible and resistant to thermal cycling, making them ideal for applications in power electronics, automotive, and LED lighting industries [2]. The company has also introduced self-adhesive thermal interface materials that eliminate the need for additional bonding agents, streamlining the manufacturing process [3].

Strengths: Industry-leading thermal conductivity, excellent electrical insulation, high flexibility, and resistance to thermal cycling. Weaknesses: Potentially higher cost compared to conventional materials, may require specialized processing equipment.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered the development of silicone elastomers with enhanced thermal management properties. Their SILASTIC™ brand of thermally conductive silicone rubbers offers a range of solutions with thermal conductivity values ranging from 1.0 to 3.0 W/m·K [4]. These materials are designed to maintain their properties over a wide temperature range (-45°C to 200°C) and provide excellent stress relief during thermal cycling. Dow's silicone rubbers also feature low viscosity for ease of processing and can be formulated for either compression molding or liquid injection molding [5]. The company has recently introduced optically clear, thermally conductive silicones for LED applications, addressing both heat management and light transmission requirements [6].

Strengths: Wide operating temperature range, versatile processing options, and specialized formulations for specific applications. Weaknesses: Lower maximum thermal conductivity compared to some competitors, may require longer curing times.

Core Silicone Innovations

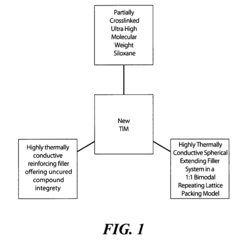

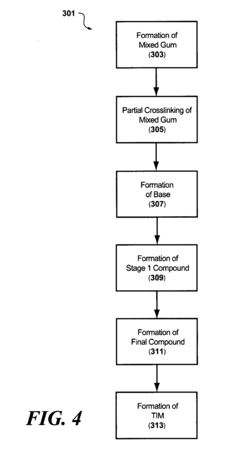

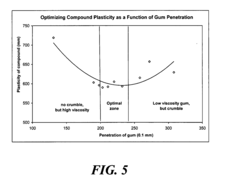

Silicone based compositions for thermal interface materials

PatentInactiveUS20080166552A1

Innovation

- A silicone-based composition with a partially crosslinked polyorganosiloxane continuous phase, incorporating fumed titanium dioxide coated with a silane functional coating, and a combination of spherical extending fillers like boron nitride and aluminum oxide, optimized for calendaring, extruding, and molding processes, which enhances thermal conductivity and mechanical properties.

Silicone rubber foam with thermal insulation properties

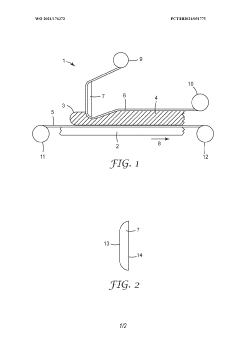

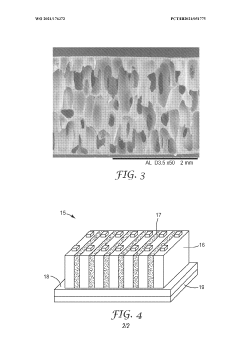

PatentWO2021176372A1

Innovation

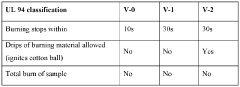

- A silicone rubber foam layer is manufactured using a process involving a curable and foamable precursor, applied with a coating tool to form a layer that exhibits excellent thermal insulation, heat resistance, and compressibility, suitable for use as a thermal barrier in battery assemblies.

Environmental Impact

The environmental impact of silicone rubber in thermal management solutions is a critical consideration in the context of sustainable technology development. Silicone rubber, while offering excellent thermal properties, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of silicone rubber in thermal management is its durability and longevity. The material's resistance to degradation under high temperatures and harsh conditions means that products using silicone rubber for thermal management typically have longer lifespans. This longevity reduces the frequency of replacement and, consequently, the overall environmental impact associated with manufacturing and disposal.

However, the production of silicone rubber does raise some environmental concerns. The process involves the use of silica and hydrocarbons, which are energy-intensive to extract and process. The manufacturing of silicone rubber also generates volatile organic compounds (VOCs) and other emissions that can contribute to air pollution if not properly controlled.

On the positive side, silicone rubber is generally considered inert and non-toxic once cured, which minimizes its impact on ecosystems during use. Additionally, its ability to improve the energy efficiency of devices and systems through effective thermal management indirectly contributes to reduced energy consumption and lower carbon emissions over the lifecycle of products.

End-of-life considerations for silicone rubber are complex. While the material is not biodegradable, it can be recycled through specialized processes. However, the infrastructure for silicone recycling is not yet widely available, which often leads to disposal in landfills. Research into more efficient recycling methods and the development of biodegradable silicone alternatives are ongoing areas of focus to address this challenge.

The use of silicone rubber in thermal management solutions also intersects with broader environmental initiatives. For instance, its application in electric vehicle battery thermal management systems supports the transition to cleaner transportation. Similarly, its use in solar panel manufacturing enhances the efficiency and lifespan of renewable energy technologies.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing silicone rubber formulations with reduced environmental impact. This includes efforts to minimize the use of harmful additives, improve production efficiency to reduce energy consumption, and explore bio-based alternatives for certain components of silicone rubber.

One of the primary environmental benefits of silicone rubber in thermal management is its durability and longevity. The material's resistance to degradation under high temperatures and harsh conditions means that products using silicone rubber for thermal management typically have longer lifespans. This longevity reduces the frequency of replacement and, consequently, the overall environmental impact associated with manufacturing and disposal.

However, the production of silicone rubber does raise some environmental concerns. The process involves the use of silica and hydrocarbons, which are energy-intensive to extract and process. The manufacturing of silicone rubber also generates volatile organic compounds (VOCs) and other emissions that can contribute to air pollution if not properly controlled.

On the positive side, silicone rubber is generally considered inert and non-toxic once cured, which minimizes its impact on ecosystems during use. Additionally, its ability to improve the energy efficiency of devices and systems through effective thermal management indirectly contributes to reduced energy consumption and lower carbon emissions over the lifecycle of products.

End-of-life considerations for silicone rubber are complex. While the material is not biodegradable, it can be recycled through specialized processes. However, the infrastructure for silicone recycling is not yet widely available, which often leads to disposal in landfills. Research into more efficient recycling methods and the development of biodegradable silicone alternatives are ongoing areas of focus to address this challenge.

The use of silicone rubber in thermal management solutions also intersects with broader environmental initiatives. For instance, its application in electric vehicle battery thermal management systems supports the transition to cleaner transportation. Similarly, its use in solar panel manufacturing enhances the efficiency and lifespan of renewable energy technologies.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing silicone rubber formulations with reduced environmental impact. This includes efforts to minimize the use of harmful additives, improve production efficiency to reduce energy consumption, and explore bio-based alternatives for certain components of silicone rubber.

Cost-Benefit Analysis

The cost-benefit analysis of silicone rubber in efficient thermal management solutions reveals a complex interplay of economic factors. Initially, the implementation of silicone rubber-based thermal management systems may incur higher upfront costs compared to traditional materials. This is primarily due to the specialized manufacturing processes and the intrinsic value of silicone rubber as a high-performance material.

However, the long-term benefits often outweigh these initial expenses. Silicone rubber's exceptional thermal conductivity and durability contribute to improved energy efficiency in various applications, leading to significant reductions in operational costs over time. For instance, in electronic devices, the enhanced heat dissipation properties of silicone rubber can extend the lifespan of components, reducing replacement and maintenance costs.

In industrial settings, the use of silicone rubber in thermal management can lead to increased productivity by maintaining optimal operating temperatures for machinery and equipment. This results in fewer production interruptions and lower downtime-related losses. Additionally, the material's resistance to extreme temperatures and environmental factors reduces the frequency of repairs and replacements, further lowering long-term maintenance costs.

The versatility of silicone rubber also offers cost advantages in terms of design flexibility. Its ability to be molded into complex shapes allows for the creation of more efficient and compact thermal management solutions, potentially reducing material usage and associated costs in product manufacturing.

From an environmental perspective, the improved energy efficiency and longer product lifespans facilitated by silicone rubber contribute to reduced carbon footprints and lower energy consumption. This not only aligns with increasingly stringent environmental regulations but can also result in cost savings through reduced energy bills and potential carbon tax avoidance.

However, it's important to consider potential drawbacks. The higher initial cost of silicone rubber may pose challenges for companies with limited capital, particularly in price-sensitive markets. Additionally, the specialized nature of silicone rubber production may lead to supply chain dependencies and potential price volatility.

In conclusion, while the upfront costs of implementing silicone rubber in thermal management solutions can be higher, the long-term benefits in terms of energy efficiency, durability, and reduced maintenance often result in a favorable cost-benefit ratio. The decision to adopt this technology should be based on a comprehensive analysis of specific application requirements, long-term operational costs, and strategic business objectives.

However, the long-term benefits often outweigh these initial expenses. Silicone rubber's exceptional thermal conductivity and durability contribute to improved energy efficiency in various applications, leading to significant reductions in operational costs over time. For instance, in electronic devices, the enhanced heat dissipation properties of silicone rubber can extend the lifespan of components, reducing replacement and maintenance costs.

In industrial settings, the use of silicone rubber in thermal management can lead to increased productivity by maintaining optimal operating temperatures for machinery and equipment. This results in fewer production interruptions and lower downtime-related losses. Additionally, the material's resistance to extreme temperatures and environmental factors reduces the frequency of repairs and replacements, further lowering long-term maintenance costs.

The versatility of silicone rubber also offers cost advantages in terms of design flexibility. Its ability to be molded into complex shapes allows for the creation of more efficient and compact thermal management solutions, potentially reducing material usage and associated costs in product manufacturing.

From an environmental perspective, the improved energy efficiency and longer product lifespans facilitated by silicone rubber contribute to reduced carbon footprints and lower energy consumption. This not only aligns with increasingly stringent environmental regulations but can also result in cost savings through reduced energy bills and potential carbon tax avoidance.

However, it's important to consider potential drawbacks. The higher initial cost of silicone rubber may pose challenges for companies with limited capital, particularly in price-sensitive markets. Additionally, the specialized nature of silicone rubber production may lead to supply chain dependencies and potential price volatility.

In conclusion, while the upfront costs of implementing silicone rubber in thermal management solutions can be higher, the long-term benefits in terms of energy efficiency, durability, and reduced maintenance often result in a favorable cost-benefit ratio. The decision to adopt this technology should be based on a comprehensive analysis of specific application requirements, long-term operational costs, and strategic business objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!