Silicone Rubber in Next-Gen Ergonomic Innovations

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution and Innovation Goals

Silicone rubber has undergone significant evolution since its inception in the 1940s. Initially developed as a high-performance elastomer, it has continuously adapted to meet the changing demands of various industries. The journey of silicone rubber began with its unique combination of properties, including excellent thermal stability, electrical insulation, and resistance to environmental factors.

Over the decades, silicone rubber has seen remarkable advancements in its formulation and processing techniques. The introduction of liquid silicone rubber (LSR) in the 1970s marked a pivotal moment, enabling more complex and precise molding capabilities. This innovation opened up new possibilities for product design and manufacturing efficiency, particularly in medical and consumer goods sectors.

Recent years have witnessed a surge in the development of specialized silicone rubber compounds. These include self-healing silicones, which can repair minor damage autonomously, and electrically conductive silicones that maintain the material's flexibility while offering new functional properties. Such advancements have significantly expanded the application scope of silicone rubber in emerging technologies.

In the context of next-generation ergonomic innovations, silicone rubber stands at the forefront of material science. The primary goal is to enhance human-product interactions by leveraging silicone rubber's unique characteristics. This includes developing silicone formulations with improved tactile feedback, customizable hardness gradients, and enhanced durability under repetitive stress.

Another key objective is to integrate smart functionalities into silicone rubber components. This involves incorporating sensors and responsive elements directly into the material, enabling products to adapt to user needs in real-time. Such innovations aim to create more intuitive and personalized ergonomic solutions across various applications, from wearable technology to adaptive furniture.

Sustainability is also a crucial focus in the evolution of silicone rubber. Research efforts are directed towards developing bio-based silicone alternatives and improving the recyclability of silicone products. These initiatives align with the growing demand for environmentally responsible materials in ergonomic design.

The ultimate goal of silicone rubber innovation in ergonomics is to create a new generation of products that seamlessly blend comfort, functionality, and adaptability. This involves pushing the boundaries of material science to develop silicone rubbers that can mimic biological tissues, respond to environmental stimuli, and provide unprecedented levels of customization to end-users.

Over the decades, silicone rubber has seen remarkable advancements in its formulation and processing techniques. The introduction of liquid silicone rubber (LSR) in the 1970s marked a pivotal moment, enabling more complex and precise molding capabilities. This innovation opened up new possibilities for product design and manufacturing efficiency, particularly in medical and consumer goods sectors.

Recent years have witnessed a surge in the development of specialized silicone rubber compounds. These include self-healing silicones, which can repair minor damage autonomously, and electrically conductive silicones that maintain the material's flexibility while offering new functional properties. Such advancements have significantly expanded the application scope of silicone rubber in emerging technologies.

In the context of next-generation ergonomic innovations, silicone rubber stands at the forefront of material science. The primary goal is to enhance human-product interactions by leveraging silicone rubber's unique characteristics. This includes developing silicone formulations with improved tactile feedback, customizable hardness gradients, and enhanced durability under repetitive stress.

Another key objective is to integrate smart functionalities into silicone rubber components. This involves incorporating sensors and responsive elements directly into the material, enabling products to adapt to user needs in real-time. Such innovations aim to create more intuitive and personalized ergonomic solutions across various applications, from wearable technology to adaptive furniture.

Sustainability is also a crucial focus in the evolution of silicone rubber. Research efforts are directed towards developing bio-based silicone alternatives and improving the recyclability of silicone products. These initiatives align with the growing demand for environmentally responsible materials in ergonomic design.

The ultimate goal of silicone rubber innovation in ergonomics is to create a new generation of products that seamlessly blend comfort, functionality, and adaptability. This involves pushing the boundaries of material science to develop silicone rubbers that can mimic biological tissues, respond to environmental stimuli, and provide unprecedented levels of customization to end-users.

Ergonomic Market Demand Analysis

The ergonomic market has experienced significant growth in recent years, driven by increasing awareness of workplace health and safety, rising healthcare costs, and a growing emphasis on employee well-being. The global ergonomic products market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

Silicone rubber, known for its versatility and unique properties, is poised to play a crucial role in next-generation ergonomic innovations. The material's flexibility, durability, and ability to conform to various shapes make it ideal for ergonomic applications. As businesses and consumers alike seek more comfortable and health-conscious products, the demand for silicone rubber-based ergonomic solutions is expected to surge.

In the office furniture sector, there is a growing need for ergonomic chairs, desks, and accessories that incorporate silicone rubber components. These products aim to reduce musculoskeletal disorders and improve overall comfort during long working hours. The rise of remote work has further accelerated this trend, as individuals invest in creating ergonomic home office setups.

The healthcare industry represents another significant market for silicone rubber ergonomic innovations. Hospitals, clinics, and long-term care facilities are increasingly adopting ergonomic equipment to enhance patient comfort and reduce the risk of injuries among healthcare workers. Silicone rubber's hypoallergenic and easy-to-clean properties make it particularly suitable for medical applications.

Consumer electronics is yet another sector driving demand for ergonomic silicone rubber solutions. As people spend more time interacting with devices, there is a growing need for ergonomic accessories such as keyboard wrist rests, mouse pads, and smartphone cases. Silicone rubber's tactile properties and ability to absorb shock make it an excellent material for these applications.

The automotive industry is also embracing ergonomic design, with a focus on improving driver and passenger comfort. Silicone rubber components are being integrated into steering wheels, gear shifts, and seat cushions to enhance the overall driving experience and reduce fatigue during long journeys.

Market research indicates that consumers are willing to pay a premium for ergonomic products that offer tangible benefits in terms of comfort and health. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize wellness and are more likely to invest in ergonomic solutions for both work and leisure activities.

As environmental concerns gain prominence, there is also a growing demand for sustainable ergonomic products. Silicone rubber's durability and potential for recycling align well with this trend, positioning it as a material of choice for eco-conscious consumers and businesses alike.

Silicone rubber, known for its versatility and unique properties, is poised to play a crucial role in next-generation ergonomic innovations. The material's flexibility, durability, and ability to conform to various shapes make it ideal for ergonomic applications. As businesses and consumers alike seek more comfortable and health-conscious products, the demand for silicone rubber-based ergonomic solutions is expected to surge.

In the office furniture sector, there is a growing need for ergonomic chairs, desks, and accessories that incorporate silicone rubber components. These products aim to reduce musculoskeletal disorders and improve overall comfort during long working hours. The rise of remote work has further accelerated this trend, as individuals invest in creating ergonomic home office setups.

The healthcare industry represents another significant market for silicone rubber ergonomic innovations. Hospitals, clinics, and long-term care facilities are increasingly adopting ergonomic equipment to enhance patient comfort and reduce the risk of injuries among healthcare workers. Silicone rubber's hypoallergenic and easy-to-clean properties make it particularly suitable for medical applications.

Consumer electronics is yet another sector driving demand for ergonomic silicone rubber solutions. As people spend more time interacting with devices, there is a growing need for ergonomic accessories such as keyboard wrist rests, mouse pads, and smartphone cases. Silicone rubber's tactile properties and ability to absorb shock make it an excellent material for these applications.

The automotive industry is also embracing ergonomic design, with a focus on improving driver and passenger comfort. Silicone rubber components are being integrated into steering wheels, gear shifts, and seat cushions to enhance the overall driving experience and reduce fatigue during long journeys.

Market research indicates that consumers are willing to pay a premium for ergonomic products that offer tangible benefits in terms of comfort and health. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize wellness and are more likely to invest in ergonomic solutions for both work and leisure activities.

As environmental concerns gain prominence, there is also a growing demand for sustainable ergonomic products. Silicone rubber's durability and potential for recycling align well with this trend, positioning it as a material of choice for eco-conscious consumers and businesses alike.

Silicone Rubber Tech Challenges

Silicone rubber, a versatile elastomer, faces several technical challenges in its application to next-generation ergonomic innovations. One of the primary obstacles is achieving an optimal balance between softness and durability. While silicone rubber is prized for its flexibility and comfort, enhancing its resistance to wear and tear without compromising its ergonomic properties remains a significant hurdle.

Another challenge lies in improving the material's thermal management capabilities. As ergonomic devices often involve prolonged contact with the human body, efficient heat dissipation is crucial. Current silicone rubber formulations struggle to effectively conduct and distribute heat, potentially leading to discomfort or even safety concerns in extended-use scenarios.

The adhesion properties of silicone rubber present a dual challenge. On one hand, improving its bonding capabilities with other materials is essential for creating complex, multi-component ergonomic products. On the other hand, controlling unwanted adhesion, such as reducing tackiness or preventing dust accumulation, is equally important for maintaining product quality and user comfort over time.

Customization and precision manufacturing of silicone rubber components pose additional technical difficulties. As ergonomic innovations demand increasingly intricate designs and personalized solutions, developing manufacturing processes that can consistently produce complex shapes with high dimensional accuracy and surface finish quality becomes more challenging.

Environmental concerns also present a significant hurdle. While silicone rubber is generally considered more environmentally friendly than many synthetic rubbers, improving its biodegradability and recyclability without sacrificing performance characteristics remains a key area of research. This challenge is particularly pertinent as sustainability becomes a more critical factor in product development and consumer choice.

Lastly, enhancing the smart capabilities of silicone rubber is an emerging challenge. Integrating sensors, actuators, or other electronic components into silicone rubber matrices while maintaining the material's core properties requires innovative approaches in material science and manufacturing techniques. This integration is crucial for developing next-generation ergonomic products that can adapt to user needs or provide real-time feedback.

Addressing these technical challenges will be key to unlocking the full potential of silicone rubber in ergonomic innovations, paving the way for more comfortable, durable, and advanced products across various industries.

Another challenge lies in improving the material's thermal management capabilities. As ergonomic devices often involve prolonged contact with the human body, efficient heat dissipation is crucial. Current silicone rubber formulations struggle to effectively conduct and distribute heat, potentially leading to discomfort or even safety concerns in extended-use scenarios.

The adhesion properties of silicone rubber present a dual challenge. On one hand, improving its bonding capabilities with other materials is essential for creating complex, multi-component ergonomic products. On the other hand, controlling unwanted adhesion, such as reducing tackiness or preventing dust accumulation, is equally important for maintaining product quality and user comfort over time.

Customization and precision manufacturing of silicone rubber components pose additional technical difficulties. As ergonomic innovations demand increasingly intricate designs and personalized solutions, developing manufacturing processes that can consistently produce complex shapes with high dimensional accuracy and surface finish quality becomes more challenging.

Environmental concerns also present a significant hurdle. While silicone rubber is generally considered more environmentally friendly than many synthetic rubbers, improving its biodegradability and recyclability without sacrificing performance characteristics remains a key area of research. This challenge is particularly pertinent as sustainability becomes a more critical factor in product development and consumer choice.

Lastly, enhancing the smart capabilities of silicone rubber is an emerging challenge. Integrating sensors, actuators, or other electronic components into silicone rubber matrices while maintaining the material's core properties requires innovative approaches in material science and manufacturing techniques. This integration is crucial for developing next-generation ergonomic products that can adapt to user needs or provide real-time feedback.

Addressing these technical challenges will be key to unlocking the full potential of silicone rubber in ergonomic innovations, paving the way for more comfortable, durable, and advanced products across various industries.

Current Ergonomic Silicone Solutions

01 Ergonomic design of silicone rubber products

Silicone rubber is used in the design of ergonomic products due to its flexibility, durability, and comfort. These products are shaped to fit the human body comfortably, reducing strain and improving user experience. Applications include ergonomic keyboards, mouse pads, and other computer accessories.- Ergonomic design of silicone rubber products: Silicone rubber is used in the design of ergonomic products due to its flexibility, durability, and comfort. These products are shaped to fit the human body comfortably, reducing strain and improving user experience. Applications include ergonomic keyboards, mouse pads, and other computer accessories.

- Silicone rubber formulations for improved ergonomics: Specific silicone rubber formulations are developed to enhance ergonomic properties. These may include additives to improve softness, tackiness, or durability. The formulations aim to create materials that provide optimal comfort and support for various ergonomic applications.

- Manufacturing processes for ergonomic silicone rubber components: Specialized manufacturing techniques are employed to produce ergonomic silicone rubber components. These may include injection molding, compression molding, or 3D printing processes tailored to create complex ergonomic shapes while maintaining the desired material properties.

- Integration of silicone rubber in ergonomic medical devices: Silicone rubber is utilized in the development of ergonomic medical devices such as prosthetics, orthopedic supports, and rehabilitation equipment. The material's biocompatibility and customizable properties make it ideal for creating comfortable, user-friendly medical solutions.

- Silicone rubber coatings for ergonomic enhancement: Silicone rubber coatings are applied to various surfaces to improve ergonomics. These coatings can enhance grip, reduce vibration, or provide cushioning. Applications include tool handles, sports equipment, and automotive interiors, where the coating improves user comfort and control.

02 Silicone rubber formulations for improved ergonomics

Specific silicone rubber formulations are developed to enhance ergonomic properties. These may include additives to adjust hardness, elasticity, and tactile feel. The goal is to create materials that provide optimal comfort and support for various ergonomic applications.Expand Specific Solutions03 Manufacturing processes for ergonomic silicone rubber components

Advanced manufacturing techniques are employed to produce ergonomic silicone rubber components. These may include injection molding, compression molding, or 3D printing processes tailored to create complex ergonomic shapes with precise material properties.Expand Specific Solutions04 Integration of silicone rubber in multi-material ergonomic designs

Silicone rubber is often combined with other materials in ergonomic product designs. This integration allows for optimized performance, such as combining soft silicone grips with rigid structural components to create ergonomic tools or medical devices.Expand Specific Solutions05 Testing and evaluation of silicone rubber ergonomics

Methods and systems for testing the ergonomic properties of silicone rubber products are developed. These may include simulations, user trials, and specialized equipment to measure factors such as pressure distribution, comfort over time, and durability under repeated use.Expand Specific Solutions

Key Silicone Industry Players

The research on silicone rubber in next-generation ergonomic innovations is in a growth phase, with increasing market size and technological advancements. The global silicone market is expected to expand significantly, driven by demand in various industries. Key players like Shin-Etsu Chemical, Dow Silicones, and Momentive Performance Materials are leading the technological development, with a focus on enhancing material properties for ergonomic applications. Companies such as Wacker Chemie and Sumitomo Bakelite are also contributing to the field's progress. The technology is maturing, with ongoing research at institutions like Tianjin University and the University of Akron pushing the boundaries of silicone rubber's capabilities in ergonomic design.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically for ergonomic applications. Their proprietary formulations incorporate nano-scale silica fillers to enhance mechanical properties while maintaining flexibility[1]. The company has also introduced self-healing silicone rubbers that can recover from minor cuts or abrasions, improving durability in high-wear ergonomic products[3]. Additionally, Shin-Etsu has pioneered temperature-responsive silicone rubbers that adjust their softness based on body heat, providing adaptive comfort in ergonomic supports and cushions[5].

Strengths: Industry-leading material science expertise, wide range of specialized formulations. Weaknesses: Higher cost compared to standard silicone rubbers, may require specialized processing.

Dow Silicones Corp.

Technical Solution: Dow Silicones has focused on developing silicone rubber technologies for next-generation wearable ergonomic devices. Their research includes stretchable silicone-based electronic materials that can be integrated into fabrics for smart clothing and supports[2]. The company has also created breathable silicone rubber membranes that allow moisture vapor transmission while maintaining waterproofing, enhancing comfort in close-fitting ergonomic products[4]. Dow's latest innovation is a series of biocompatible silicone rubbers with customizable durometers, allowing fine-tuned ergonomic performance for medical devices and prosthetics[6].

Strengths: Strong focus on wearable technologies, extensive R&D capabilities. Weaknesses: Some formulations may have limited high-temperature performance, potential regulatory hurdles for medical applications.

Breakthrough Silicone Formulations

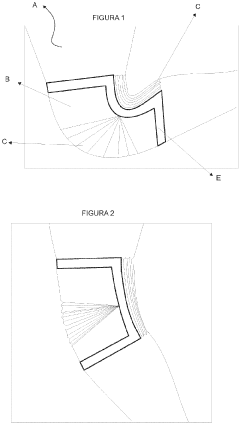

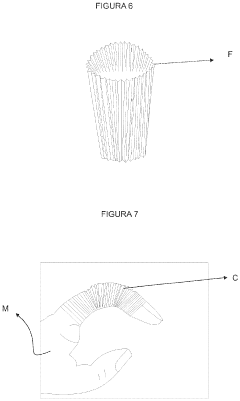

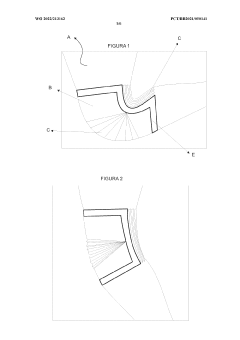

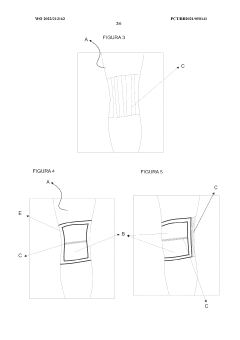

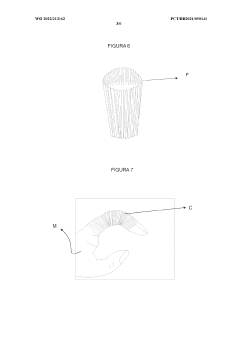

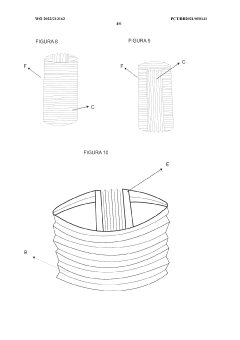

Configuration for product made of liquid silicone rubber (LSR) for providing comfort, protection, rehabilitation and bodily care

PatentPendingEP4321046A1

Innovation

- The use of Liquid Silicone Rubber (LSR) with innovative pleating and ruffling designs allows for full adhesion to the skin, flexibility, and mobility, combined with the ability to be heated or cooled, providing therapeutic benefits and preventing friction-related injuries, while being hypoallergenic and antifungal.

Configuration for product made of liquid silicone rubber (LSR) for providing comfort, protection, rehabilitation and bodily care

PatentWO2022213162A1

Innovation

- The use of Liquid Silicone Rubber (LSR) with pleated designs and gel inserts in products like gloves, socks, sleeves, and pads, which can be heated or cooled, providing a flexible, adherent, and protective layer that prevents friction and allows full mobility, while incorporating therapeutic benefits.

Sustainability in Silicone Production

Sustainability in silicone production has become a critical focus in the development of next-generation ergonomic innovations using silicone rubber. As environmental concerns continue to grow, manufacturers are increasingly seeking ways to reduce the ecological footprint of silicone production while maintaining the material's exceptional properties for ergonomic applications.

One of the primary sustainability challenges in silicone production is the energy-intensive nature of the manufacturing process. Traditional methods require high temperatures and pressures, resulting in significant energy consumption and associated carbon emissions. To address this, researchers are exploring novel catalysts and reaction pathways that can lower the energy requirements of silicone synthesis. These advancements not only reduce the environmental impact but also potentially decrease production costs.

Water consumption is another area of concern in silicone production. The industry is investing in closed-loop water systems and advanced filtration technologies to minimize water usage and improve recycling rates. By implementing these systems, manufacturers can significantly reduce their freshwater intake and wastewater discharge, contributing to more sustainable operations.

The sourcing of raw materials for silicone production also plays a crucial role in sustainability efforts. Traditionally, silicone is derived from quartz, which is abundant but requires energy-intensive processing. Innovative approaches are being developed to utilize alternative silicon sources, including recycled materials and bio-based precursors. These alternatives have the potential to reduce the reliance on virgin resources and decrease the overall environmental impact of silicone production.

End-of-life considerations are becoming increasingly important in the sustainability of silicone products. While silicone rubber is known for its durability, this characteristic can also lead to challenges in disposal and recycling. Research is underway to develop more easily recyclable silicone formulations and to establish efficient recycling processes for silicone-based products. These efforts aim to create a circular economy for silicone materials, reducing waste and conserving resources.

In the context of ergonomic innovations, sustainable silicone production is particularly relevant. As consumers become more environmentally conscious, there is a growing demand for eco-friendly ergonomic products. Manufacturers are responding by incorporating sustainability metrics into their product development processes, considering factors such as carbon footprint, recyclability, and the use of renewable resources throughout the lifecycle of silicone-based ergonomic solutions.

The pursuit of sustainability in silicone production is driving collaboration between material scientists, chemical engineers, and environmental experts. This interdisciplinary approach is yielding promising results in the development of greener production methods and more sustainable silicone formulations. As these innovations continue to evolve, they are expected to play a crucial role in shaping the future of ergonomic product design and manufacturing.

One of the primary sustainability challenges in silicone production is the energy-intensive nature of the manufacturing process. Traditional methods require high temperatures and pressures, resulting in significant energy consumption and associated carbon emissions. To address this, researchers are exploring novel catalysts and reaction pathways that can lower the energy requirements of silicone synthesis. These advancements not only reduce the environmental impact but also potentially decrease production costs.

Water consumption is another area of concern in silicone production. The industry is investing in closed-loop water systems and advanced filtration technologies to minimize water usage and improve recycling rates. By implementing these systems, manufacturers can significantly reduce their freshwater intake and wastewater discharge, contributing to more sustainable operations.

The sourcing of raw materials for silicone production also plays a crucial role in sustainability efforts. Traditionally, silicone is derived from quartz, which is abundant but requires energy-intensive processing. Innovative approaches are being developed to utilize alternative silicon sources, including recycled materials and bio-based precursors. These alternatives have the potential to reduce the reliance on virgin resources and decrease the overall environmental impact of silicone production.

End-of-life considerations are becoming increasingly important in the sustainability of silicone products. While silicone rubber is known for its durability, this characteristic can also lead to challenges in disposal and recycling. Research is underway to develop more easily recyclable silicone formulations and to establish efficient recycling processes for silicone-based products. These efforts aim to create a circular economy for silicone materials, reducing waste and conserving resources.

In the context of ergonomic innovations, sustainable silicone production is particularly relevant. As consumers become more environmentally conscious, there is a growing demand for eco-friendly ergonomic products. Manufacturers are responding by incorporating sustainability metrics into their product development processes, considering factors such as carbon footprint, recyclability, and the use of renewable resources throughout the lifecycle of silicone-based ergonomic solutions.

The pursuit of sustainability in silicone production is driving collaboration between material scientists, chemical engineers, and environmental experts. This interdisciplinary approach is yielding promising results in the development of greener production methods and more sustainable silicone formulations. As these innovations continue to evolve, they are expected to play a crucial role in shaping the future of ergonomic product design and manufacturing.

Silicone Safety and Regulations

The safety and regulatory landscape surrounding silicone rubber in ergonomic innovations is complex and evolving. As silicone materials gain prominence in next-generation ergonomic products, manufacturers and researchers must navigate a web of regulations to ensure consumer safety and compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating silicone-based products, particularly those intended for medical or food-contact applications. The FDA's guidance on silicone rubber focuses on its biocompatibility and potential for leaching harmful substances. Manufacturers must demonstrate that their silicone formulations meet stringent safety standards, especially for products that come into prolonged contact with the human body.

The European Union's regulatory framework is equally stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governing the use of silicone materials. REACH requires manufacturers to register chemical substances and provide detailed safety information. Additionally, the EU's General Product Safety Directive (GPSD) sets overarching safety requirements for consumer products, including those incorporating silicone rubber.

Environmental concerns have led to increased scrutiny of silicone production and disposal. While silicone rubber is generally considered inert and non-toxic, questions about its biodegradability and potential environmental impact have prompted research into more sustainable formulations. Some jurisdictions have implemented regulations on silicone waste management and recycling, pushing manufacturers to develop eco-friendly alternatives or improved recycling processes.

Occupational safety is another critical aspect of silicone rubber regulations. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US provide guidelines for handling silicone materials in manufacturing settings. These regulations address exposure limits, personal protective equipment requirements, and proper ventilation systems to protect workers from potential health hazards associated with silicone processing.

As ergonomic innovations push the boundaries of silicone rubber applications, new regulatory challenges emerge. For instance, the use of silicone in wearable technology has raised questions about data privacy and electromagnetic emissions, leading to the development of specific guidelines in some regions. The integration of silicone with other materials in composite structures has also necessitated the creation of new testing protocols to ensure the safety and durability of these hybrid products.

Standardization bodies such as the International Organization for Standardization (ISO) and ASTM International play a crucial role in establishing global standards for silicone rubber quality and performance. These standards help ensure consistency and safety across international markets, facilitating trade and innovation in the ergonomics sector.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating silicone-based products, particularly those intended for medical or food-contact applications. The FDA's guidance on silicone rubber focuses on its biocompatibility and potential for leaching harmful substances. Manufacturers must demonstrate that their silicone formulations meet stringent safety standards, especially for products that come into prolonged contact with the human body.

The European Union's regulatory framework is equally stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governing the use of silicone materials. REACH requires manufacturers to register chemical substances and provide detailed safety information. Additionally, the EU's General Product Safety Directive (GPSD) sets overarching safety requirements for consumer products, including those incorporating silicone rubber.

Environmental concerns have led to increased scrutiny of silicone production and disposal. While silicone rubber is generally considered inert and non-toxic, questions about its biodegradability and potential environmental impact have prompted research into more sustainable formulations. Some jurisdictions have implemented regulations on silicone waste management and recycling, pushing manufacturers to develop eco-friendly alternatives or improved recycling processes.

Occupational safety is another critical aspect of silicone rubber regulations. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US provide guidelines for handling silicone materials in manufacturing settings. These regulations address exposure limits, personal protective equipment requirements, and proper ventilation systems to protect workers from potential health hazards associated with silicone processing.

As ergonomic innovations push the boundaries of silicone rubber applications, new regulatory challenges emerge. For instance, the use of silicone in wearable technology has raised questions about data privacy and electromagnetic emissions, leading to the development of specific guidelines in some regions. The integration of silicone with other materials in composite structures has also necessitated the creation of new testing protocols to ensure the safety and durability of these hybrid products.

Standardization bodies such as the International Organization for Standardization (ISO) and ASTM International play a crucial role in establishing global standards for silicone rubber quality and performance. These standards help ensure consistency and safety across international markets, facilitating trade and innovation in the ergonomics sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!