Silicone Rubber Innovations in Optical Device Manufacturing

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Optics: Background and Objectives

Silicone rubber has emerged as a revolutionary material in the field of optical device manufacturing, offering unique properties that have transformed the industry. The journey of silicone rubber in optics began in the mid-20th century when researchers discovered its exceptional optical clarity, thermal stability, and moldability. These characteristics made it an ideal candidate for various optical applications, from lenses to light guides.

The evolution of silicone rubber in optics has been driven by the increasing demand for high-performance, lightweight, and cost-effective optical components. As technology advanced, the need for materials that could withstand extreme conditions while maintaining optical integrity became paramount. Silicone rubber, with its ability to remain flexible across a wide temperature range and resist degradation from UV exposure, quickly became a material of choice for many optical device manufacturers.

In recent years, the focus has shifted towards developing silicone rubber formulations with enhanced optical properties. Researchers have been working on improving refractive indices, reducing optical losses, and increasing the material's resistance to environmental factors. These advancements have opened up new possibilities in fields such as augmented reality, automotive lighting, and medical imaging.

The objectives of current research and development in silicone rubber for optical applications are multifaceted. One primary goal is to further improve the optical clarity and transmission efficiency of silicone-based components. This involves refining the molecular structure of silicone rubber to minimize light scattering and absorption. Another objective is to develop silicone rubber formulations with tailored refractive indices, allowing for the creation of gradient-index optics and more complex optical designs.

Additionally, researchers are exploring ways to enhance the durability and longevity of silicone rubber optical components. This includes developing formulations that are more resistant to yellowing, mechanical stress, and chemical exposure. The aim is to create optical devices that can maintain their performance over extended periods, even in harsh environments.

Another critical objective is to improve the manufacturability of silicone rubber optical components. This involves developing new molding and curing techniques that allow for the production of more intricate and precise optical geometries. Researchers are also working on methods to integrate silicone rubber optics with other materials and electronic components, paving the way for advanced integrated optical systems.

As the field progresses, there is a growing emphasis on sustainability and environmental considerations. Researchers are exploring bio-based silicone rubber formulations and investigating recycling methods for silicone optical components. These efforts align with the broader industry trend towards more sustainable manufacturing practices and circular economy principles.

The evolution of silicone rubber in optics has been driven by the increasing demand for high-performance, lightweight, and cost-effective optical components. As technology advanced, the need for materials that could withstand extreme conditions while maintaining optical integrity became paramount. Silicone rubber, with its ability to remain flexible across a wide temperature range and resist degradation from UV exposure, quickly became a material of choice for many optical device manufacturers.

In recent years, the focus has shifted towards developing silicone rubber formulations with enhanced optical properties. Researchers have been working on improving refractive indices, reducing optical losses, and increasing the material's resistance to environmental factors. These advancements have opened up new possibilities in fields such as augmented reality, automotive lighting, and medical imaging.

The objectives of current research and development in silicone rubber for optical applications are multifaceted. One primary goal is to further improve the optical clarity and transmission efficiency of silicone-based components. This involves refining the molecular structure of silicone rubber to minimize light scattering and absorption. Another objective is to develop silicone rubber formulations with tailored refractive indices, allowing for the creation of gradient-index optics and more complex optical designs.

Additionally, researchers are exploring ways to enhance the durability and longevity of silicone rubber optical components. This includes developing formulations that are more resistant to yellowing, mechanical stress, and chemical exposure. The aim is to create optical devices that can maintain their performance over extended periods, even in harsh environments.

Another critical objective is to improve the manufacturability of silicone rubber optical components. This involves developing new molding and curing techniques that allow for the production of more intricate and precise optical geometries. Researchers are also working on methods to integrate silicone rubber optics with other materials and electronic components, paving the way for advanced integrated optical systems.

As the field progresses, there is a growing emphasis on sustainability and environmental considerations. Researchers are exploring bio-based silicone rubber formulations and investigating recycling methods for silicone optical components. These efforts align with the broader industry trend towards more sustainable manufacturing practices and circular economy principles.

Market Analysis for Silicone-Based Optical Devices

The market for silicone-based optical devices has experienced significant growth in recent years, driven by advancements in optical technology and increasing demand for high-performance optical components. Silicone rubber, with its unique properties such as optical clarity, flexibility, and thermal stability, has emerged as a key material in the manufacturing of various optical devices.

The global market for silicone-based optical devices is primarily segmented into consumer electronics, automotive, healthcare, and telecommunications sectors. In the consumer electronics segment, silicone-based optical components are widely used in smartphones, tablets, and wearable devices for applications such as camera lenses, light guides, and display components. The automotive industry has also seen a surge in demand for silicone-based optical devices, particularly in advanced driver assistance systems (ADAS) and lighting applications.

The healthcare sector represents another significant market for silicone-based optical devices, with applications in medical imaging, endoscopy, and wearable medical devices. The biocompatibility and durability of silicone rubber make it an ideal material for these applications. In the telecommunications industry, silicone-based optical components are utilized in fiber optic networks and data centers, contributing to improved signal transmission and network performance.

Market trends indicate a growing preference for miniaturization and integration of optical components, driving the development of more compact and efficient silicone-based devices. Additionally, the increasing adoption of augmented reality (AR) and virtual reality (VR) technologies is creating new opportunities for silicone-based optical components in display systems and imaging devices.

The Asia-Pacific region dominates the market for silicone-based optical devices, with China and Japan being the major contributors. This is primarily due to the presence of a large number of consumer electronics manufacturers and a robust automotive industry in these countries. North America and Europe follow closely, with significant market share driven by advancements in healthcare technology and telecommunications infrastructure.

Key market drivers include the growing demand for high-quality imaging systems, increasing investments in 5G infrastructure, and the rising adoption of Internet of Things (IoT) devices. However, challenges such as the high cost of silicone materials and competition from alternative materials like thermoplastic polymers may impact market growth to some extent.

Looking ahead, the market for silicone-based optical devices is expected to continue its growth trajectory, fueled by ongoing technological advancements and expanding applications across various industries. The development of novel silicone formulations with enhanced optical properties and the integration of smart functionalities into optical devices are likely to open up new avenues for market expansion in the coming years.

The global market for silicone-based optical devices is primarily segmented into consumer electronics, automotive, healthcare, and telecommunications sectors. In the consumer electronics segment, silicone-based optical components are widely used in smartphones, tablets, and wearable devices for applications such as camera lenses, light guides, and display components. The automotive industry has also seen a surge in demand for silicone-based optical devices, particularly in advanced driver assistance systems (ADAS) and lighting applications.

The healthcare sector represents another significant market for silicone-based optical devices, with applications in medical imaging, endoscopy, and wearable medical devices. The biocompatibility and durability of silicone rubber make it an ideal material for these applications. In the telecommunications industry, silicone-based optical components are utilized in fiber optic networks and data centers, contributing to improved signal transmission and network performance.

Market trends indicate a growing preference for miniaturization and integration of optical components, driving the development of more compact and efficient silicone-based devices. Additionally, the increasing adoption of augmented reality (AR) and virtual reality (VR) technologies is creating new opportunities for silicone-based optical components in display systems and imaging devices.

The Asia-Pacific region dominates the market for silicone-based optical devices, with China and Japan being the major contributors. This is primarily due to the presence of a large number of consumer electronics manufacturers and a robust automotive industry in these countries. North America and Europe follow closely, with significant market share driven by advancements in healthcare technology and telecommunications infrastructure.

Key market drivers include the growing demand for high-quality imaging systems, increasing investments in 5G infrastructure, and the rising adoption of Internet of Things (IoT) devices. However, challenges such as the high cost of silicone materials and competition from alternative materials like thermoplastic polymers may impact market growth to some extent.

Looking ahead, the market for silicone-based optical devices is expected to continue its growth trajectory, fueled by ongoing technological advancements and expanding applications across various industries. The development of novel silicone formulations with enhanced optical properties and the integration of smart functionalities into optical devices are likely to open up new avenues for market expansion in the coming years.

Current Challenges in Silicone Rubber Optics

Despite significant advancements in silicone rubber technology for optical device manufacturing, several challenges persist in the field of silicone rubber optics. These challenges primarily stem from the material's inherent properties and the increasing demands of modern optical applications.

One of the foremost challenges is achieving and maintaining optical clarity over extended periods. While silicone rubber offers excellent initial transparency, prolonged exposure to environmental factors such as UV radiation and temperature fluctuations can lead to yellowing and degradation of optical properties. This issue is particularly critical in outdoor applications or devices with long service lives.

Another significant challenge lies in controlling the refractive index of silicone rubber with high precision. As optical devices become more sophisticated, there is a growing need for materials with specific, stable refractive indices. However, achieving fine-tuned control over the refractive index while maintaining other desirable properties of silicone rubber remains a complex task.

The dimensional stability of silicone rubber optics under varying environmental conditions also presents a challenge. Thermal expansion and contraction can affect the shape and focal properties of optical components, potentially leading to performance issues in precision applications. Mitigating these effects without compromising the material's flexibility and other advantageous characteristics is an ongoing area of research.

Surface quality and moldability present another set of challenges. While silicone rubber is generally easy to mold, achieving the ultra-smooth surfaces required for high-performance optics can be difficult. Micro-defects and surface irregularities can significantly impact optical performance, necessitating advanced molding and post-processing techniques.

Adhesion to other materials, particularly in multi-component optical systems, remains a challenge. The inherent low surface energy of silicone rubber can make it difficult to achieve strong, durable bonds with other optical materials or structural components. This limitation can complicate the design and manufacturing of complex optical devices.

Lastly, there are challenges related to the integration of functional additives into silicone rubber for enhanced optical properties. While additives can impart desirable characteristics such as UV resistance or specific optical effects, they can also negatively impact other properties of the material, such as transparency or mechanical stability. Balancing these trade-offs to create optimized materials for specific applications is an ongoing challenge in the field.

Addressing these challenges requires interdisciplinary approaches, combining expertise in materials science, optical engineering, and manufacturing processes. As the demand for advanced optical devices continues to grow, overcoming these hurdles in silicone rubber optics will be crucial for unlocking new possibilities in optical device manufacturing.

One of the foremost challenges is achieving and maintaining optical clarity over extended periods. While silicone rubber offers excellent initial transparency, prolonged exposure to environmental factors such as UV radiation and temperature fluctuations can lead to yellowing and degradation of optical properties. This issue is particularly critical in outdoor applications or devices with long service lives.

Another significant challenge lies in controlling the refractive index of silicone rubber with high precision. As optical devices become more sophisticated, there is a growing need for materials with specific, stable refractive indices. However, achieving fine-tuned control over the refractive index while maintaining other desirable properties of silicone rubber remains a complex task.

The dimensional stability of silicone rubber optics under varying environmental conditions also presents a challenge. Thermal expansion and contraction can affect the shape and focal properties of optical components, potentially leading to performance issues in precision applications. Mitigating these effects without compromising the material's flexibility and other advantageous characteristics is an ongoing area of research.

Surface quality and moldability present another set of challenges. While silicone rubber is generally easy to mold, achieving the ultra-smooth surfaces required for high-performance optics can be difficult. Micro-defects and surface irregularities can significantly impact optical performance, necessitating advanced molding and post-processing techniques.

Adhesion to other materials, particularly in multi-component optical systems, remains a challenge. The inherent low surface energy of silicone rubber can make it difficult to achieve strong, durable bonds with other optical materials or structural components. This limitation can complicate the design and manufacturing of complex optical devices.

Lastly, there are challenges related to the integration of functional additives into silicone rubber for enhanced optical properties. While additives can impart desirable characteristics such as UV resistance or specific optical effects, they can also negatively impact other properties of the material, such as transparency or mechanical stability. Balancing these trade-offs to create optimized materials for specific applications is an ongoing challenge in the field.

Addressing these challenges requires interdisciplinary approaches, combining expertise in materials science, optical engineering, and manufacturing processes. As the demand for advanced optical devices continues to grow, overcoming these hurdles in silicone rubber optics will be crucial for unlocking new possibilities in optical device manufacturing.

Existing Silicone Rubber Optical Solutions

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness. Such modifications allow for the customization of silicone rubber for various applications.

- Silicone rubber in medical and healthcare applications: Silicone rubber is widely used in medical and healthcare products due to its biocompatibility, flexibility, and durability. Applications include medical implants, prosthetics, drug delivery systems, and various medical devices. The material can be formulated to meet specific requirements for these sensitive applications.

- Manufacturing processes for silicone rubber products: Various manufacturing processes are employed to produce silicone rubber products, including injection molding, extrusion, compression molding, and liquid silicone rubber molding. Each process has its advantages and is suited for different types of products or production scales. Innovations in these processes focus on improving efficiency, reducing waste, and enhancing product quality.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing silicone rubber with various fillers, blending it with other elastomers, or incorporating it into hybrid materials. These composites and blends can offer improved mechanical properties, thermal resistance, or specific functionalities not achievable with pure silicone rubber.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving mechanical strength, enhancing thermal stability, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating nanoparticles.Expand Specific Solutions03 Applications of silicone rubber

Silicone rubber finds wide-ranging applications due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, cookware, and various industrial applications. Its biocompatibility makes it suitable for implants and other medical uses, while its heat resistance and electrical properties make it valuable in electronics and automotive industries.Expand Specific Solutions04 Manufacturing processes for silicone rubber products

Various manufacturing processes are employed to produce silicone rubber products, including injection molding, extrusion, and compression molding. These processes can be optimized for different product types and scales of production. Advanced techniques may involve precision molding for complex shapes or the use of specialized equipment for consistent quality.Expand Specific Solutions05 Innovations in silicone rubber technology

Ongoing research in silicone rubber technology focuses on developing new formulations with enhanced properties. This includes creating self-healing silicone rubbers, improving adhesion to other materials, and developing silicone composites with unique characteristics. Innovations also extend to more environmentally friendly production methods and the incorporation of smart or responsive features.Expand Specific Solutions

Key Players in Silicone Optical Device Industry

The silicone rubber innovations in optical device manufacturing sector is in a growth phase, driven by increasing demand for advanced optical components across industries. The market size is expanding, with projections indicating significant growth potential. Technologically, the field is advancing rapidly, with key players like Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie leading innovation. These companies are developing high-performance silicone materials tailored for optical applications, focusing on improving optical clarity, durability, and precision molding capabilities. Universities such as Shandong University and Xi'an Jiaotong University are contributing to research advancements, while companies like Apple and Intel are driving demand for cutting-edge optical solutions in consumer electronics and computing.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically tailored for optical device manufacturing. Their innovative approach includes the creation of highly transparent silicone elastomers with excellent light transmission properties[1]. These materials feature low birefringence and minimal yellowing under prolonged UV exposure, making them ideal for lens encapsulation and optical waveguides[2]. The company has also introduced self-healing silicone rubbers that can recover from surface damage, enhancing the durability of optical components[3]. Additionally, Shin-Etsu has developed silicone-based adhesives with precise refractive index matching capabilities, crucial for reducing interface reflections in multi-layer optical devices[4].

Strengths: Superior optical clarity, UV resistance, and self-healing properties. Weaknesses: Potentially higher cost compared to traditional materials, and may require specialized processing techniques.

Momentive Performance Materials Japan LLC

Technical Solution: Momentive has pioneered the development of optically clear silicone rubbers with enhanced thermal stability for high-power LED applications. Their innovative materials exhibit minimal color shift at elevated temperatures, maintaining optical performance over extended periods[5]. The company has also introduced silicone-based optical coupling materials with tunable refractive indices, allowing for precise light management in complex optical systems[6]. Momentive's silicone rubbers feature improved adhesion to various substrates, reducing the need for additional primers in optical device assembly[7]. Furthermore, they have developed silicone formulations with ultra-low volatile organic compound (VOC) emissions, addressing environmental concerns in manufacturing processes[8].

Strengths: Excellent thermal stability, customizable optical properties, and improved adhesion. Weaknesses: May have limitations in extreme temperature applications and potentially higher material costs.

Core Innovations in Silicone Optical Materials

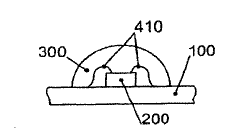

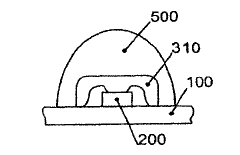

Optoelectronic device and manufacturing method thereof

PatentInactiveJP2009500834A

Innovation

- The use of optically transparent silicon dioxide adhesive layers to enhance adhesion between components, providing durable connections that withstand temperature and humidity changes, using silicon-based materials without additional structural support.

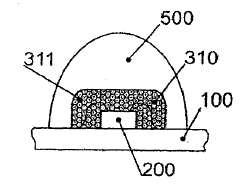

Isocyanuric ring-containing polysiloxane having vinyl groups at the terminals

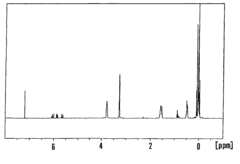

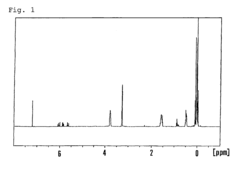

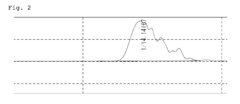

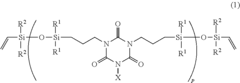

PatentActiveUS8124715B2

Innovation

- An organopolysiloxane with an isocyanuric ring and vinyl siloxy groups at both terminals, represented by a specific molecular formula, is developed, allowing for a cured product with improved mechanical, electrical, and optical properties through a hydrosilylation reaction process involving diallyl isocyanurate, alkoxysilane, and a terminal vinyl-modified organosiloxane, using platinum as a catalyst.

Environmental Impact of Silicone Optical Devices

The environmental impact of silicone optical devices is a critical consideration in the context of sustainable manufacturing and product lifecycle management. Silicone rubber, a key material in optical device manufacturing, offers several environmental advantages over traditional materials. Its durability and resistance to degradation contribute to longer product lifespans, reducing the frequency of replacement and, consequently, waste generation.

The production process of silicone optical devices generally requires less energy compared to glass or plastic alternatives. This lower energy demand translates to reduced carbon emissions during manufacturing. Additionally, silicone's ability to cure at room temperature in many applications further minimizes energy consumption, aligning with global efforts to reduce industrial carbon footprints.

Silicone's inert nature presents both benefits and challenges from an environmental perspective. While it does not leach harmful chemicals into the environment during use, its resistance to biodegradation poses end-of-life disposal concerns. However, advancements in recycling technologies are addressing this issue, with methods being developed to break down silicone products for reuse in new applications.

The optical clarity and light transmission properties of silicone contribute to the energy efficiency of devices such as LED lamps and solar panels. By enhancing light output and capture, silicone optical components indirectly support the transition to more sustainable lighting and energy generation technologies.

Water conservation is another area where silicone optical devices make a positive environmental impact. The hydrophobic nature of silicone reduces water consumption in cleaning processes for optical equipment, particularly in industrial and medical settings where frequent sanitization is required.

In terms of raw material sourcing, silicone production relies primarily on silicon, one of the Earth's most abundant elements. This abundance reduces the environmental strain associated with rare or difficult-to-extract materials often used in other optical applications. However, the petrochemical components used in silicone synthesis do present some environmental concerns, driving research into bio-based alternatives.

As environmental regulations become more stringent, the low volatile organic compound (VOC) emissions of silicone during manufacturing and use position it favorably compared to other polymers. This characteristic not only reduces air pollution but also improves indoor air quality in applications such as LED lighting fixtures.

Looking forward, the environmental profile of silicone optical devices is likely to improve further. Ongoing research into bio-based silicones, more efficient recycling methods, and the integration of silicone optical components into circular economy models promise to enhance the sustainability of these essential materials in the optics industry.

The production process of silicone optical devices generally requires less energy compared to glass or plastic alternatives. This lower energy demand translates to reduced carbon emissions during manufacturing. Additionally, silicone's ability to cure at room temperature in many applications further minimizes energy consumption, aligning with global efforts to reduce industrial carbon footprints.

Silicone's inert nature presents both benefits and challenges from an environmental perspective. While it does not leach harmful chemicals into the environment during use, its resistance to biodegradation poses end-of-life disposal concerns. However, advancements in recycling technologies are addressing this issue, with methods being developed to break down silicone products for reuse in new applications.

The optical clarity and light transmission properties of silicone contribute to the energy efficiency of devices such as LED lamps and solar panels. By enhancing light output and capture, silicone optical components indirectly support the transition to more sustainable lighting and energy generation technologies.

Water conservation is another area where silicone optical devices make a positive environmental impact. The hydrophobic nature of silicone reduces water consumption in cleaning processes for optical equipment, particularly in industrial and medical settings where frequent sanitization is required.

In terms of raw material sourcing, silicone production relies primarily on silicon, one of the Earth's most abundant elements. This abundance reduces the environmental strain associated with rare or difficult-to-extract materials often used in other optical applications. However, the petrochemical components used in silicone synthesis do present some environmental concerns, driving research into bio-based alternatives.

As environmental regulations become more stringent, the low volatile organic compound (VOC) emissions of silicone during manufacturing and use position it favorably compared to other polymers. This characteristic not only reduces air pollution but also improves indoor air quality in applications such as LED lighting fixtures.

Looking forward, the environmental profile of silicone optical devices is likely to improve further. Ongoing research into bio-based silicones, more efficient recycling methods, and the integration of silicone optical components into circular economy models promise to enhance the sustainability of these essential materials in the optics industry.

Intellectual Property Landscape in Silicone Optics

The intellectual property landscape in silicone optics has witnessed significant growth and diversification in recent years, reflecting the increasing importance of silicone rubber innovations in optical device manufacturing. A comprehensive analysis of patent filings and granted patents reveals several key trends and focal areas within this domain.

One prominent trend is the surge in patents related to silicone-based optical components, particularly for applications in LED lighting, automotive lighting, and consumer electronics. Major players in the optics industry, such as Dow Corning, Momentive Performance Materials, and Shin-Etsu Chemical, have been actively filing patents for novel silicone formulations with enhanced optical properties, including improved light transmission, refractive index control, and thermal stability.

Another significant area of patent activity revolves around manufacturing processes for silicone optical components. Innovations in molding techniques, such as liquid injection molding and compression molding, have been the subject of numerous patent filings. These patents often focus on improving precision, reducing cycle times, and enhancing surface quality of molded silicone optics.

The integration of silicone optics with other materials and technologies has also been a fertile ground for intellectual property development. Patents covering hybrid optical systems combining silicone with glass or other polymers have emerged, aiming to leverage the unique properties of each material for optimal performance in specific applications.

In the realm of surface treatments and coatings, there has been a noticeable increase in patent filings related to enhancing the durability and functionality of silicone optical surfaces. These innovations address challenges such as scratch resistance, anti-reflective properties, and resistance to environmental factors like UV radiation and moisture.

Geographically, the patent landscape shows a concentration of activity in regions with strong optics and materials science industries. The United States, Japan, and Germany lead in terms of patent filings, with China showing rapid growth in recent years. This distribution reflects the global nature of the silicone optics industry and the intense competition among key players.

Emerging areas of patent activity include the application of silicone optics in advanced technologies such as augmented reality (AR) and virtual reality (VR) devices, as well as in next-generation automotive lighting systems. These patents often focus on achieving precise optical characteristics while maintaining the flexibility and durability inherent to silicone materials.

The intellectual property landscape also reveals a trend towards sustainability and environmental considerations. Patents addressing the recyclability of silicone optical components and the development of bio-based silicone alternatives are beginning to appear, albeit in smaller numbers compared to performance-focused innovations.

One prominent trend is the surge in patents related to silicone-based optical components, particularly for applications in LED lighting, automotive lighting, and consumer electronics. Major players in the optics industry, such as Dow Corning, Momentive Performance Materials, and Shin-Etsu Chemical, have been actively filing patents for novel silicone formulations with enhanced optical properties, including improved light transmission, refractive index control, and thermal stability.

Another significant area of patent activity revolves around manufacturing processes for silicone optical components. Innovations in molding techniques, such as liquid injection molding and compression molding, have been the subject of numerous patent filings. These patents often focus on improving precision, reducing cycle times, and enhancing surface quality of molded silicone optics.

The integration of silicone optics with other materials and technologies has also been a fertile ground for intellectual property development. Patents covering hybrid optical systems combining silicone with glass or other polymers have emerged, aiming to leverage the unique properties of each material for optimal performance in specific applications.

In the realm of surface treatments and coatings, there has been a noticeable increase in patent filings related to enhancing the durability and functionality of silicone optical surfaces. These innovations address challenges such as scratch resistance, anti-reflective properties, and resistance to environmental factors like UV radiation and moisture.

Geographically, the patent landscape shows a concentration of activity in regions with strong optics and materials science industries. The United States, Japan, and Germany lead in terms of patent filings, with China showing rapid growth in recent years. This distribution reflects the global nature of the silicone optics industry and the intense competition among key players.

Emerging areas of patent activity include the application of silicone optics in advanced technologies such as augmented reality (AR) and virtual reality (VR) devices, as well as in next-generation automotive lighting systems. These patents often focus on achieving precise optical characteristics while maintaining the flexibility and durability inherent to silicone materials.

The intellectual property landscape also reveals a trend towards sustainability and environmental considerations. Patents addressing the recyclability of silicone optical components and the development of bio-based silicone alternatives are beginning to appear, albeit in smaller numbers compared to performance-focused innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!