Silicone Rubber: Leading Innovations in Personal Care Products

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution

Silicone rubber has undergone a remarkable evolution in the personal care industry, transforming from a niche material to a ubiquitous component in countless products. The journey began in the 1940s when silicone polymers were first synthesized, but it wasn't until the 1970s that their potential in personal care applications was fully recognized.

Initially, silicone rubber found limited use in medical-grade products due to its biocompatibility and inert nature. The 1980s marked a significant turning point as cosmetic formulators began to explore silicone rubber's unique properties, particularly its ability to create smooth, non-greasy textures. This led to the development of silicone-based foundations and primers, which revolutionized the makeup industry.

The 1990s saw a surge in silicone rubber innovations for skincare products. Manufacturers developed advanced crosslinking techniques, allowing for the creation of silicone elastomers with varying degrees of softness and elasticity. These advancements enabled the production of lightweight, breathable formulations that could deliver active ingredients more effectively while providing a luxurious skin feel.

In the early 2000s, the focus shifted towards sustainability and eco-friendliness. Researchers began developing biodegradable silicone rubber variants and exploring ways to reduce the environmental impact of silicone production. This period also saw the emergence of hybrid materials, combining silicone rubber with natural ingredients to cater to the growing demand for "green" cosmetics.

The past decade has witnessed a rapid acceleration in silicone rubber technology for personal care. Nanotechnology has played a crucial role, with the development of silicone nanoparticles and nanocomposites offering enhanced performance in areas such as UV protection and controlled release of active ingredients. Smart silicone rubbers, capable of responding to environmental stimuli like temperature or pH changes, have opened up new possibilities for adaptive skincare solutions.

Recent innovations have focused on customization and multifunctionality. Advanced manufacturing techniques, including 3D printing of silicone rubber, have enabled the creation of personalized care products tailored to individual needs. Additionally, the integration of silicone rubber with electronic components has led to the development of wearable beauty devices and smart packaging solutions.

Looking ahead, the evolution of silicone rubber in personal care products shows no signs of slowing down. Emerging trends include the development of self-healing silicone rubbers for long-lasting products, biofunctional silicones that interact with the skin's microbiome, and sustainable silicone alternatives derived from renewable resources. As consumer demands for performance, safety, and sustainability continue to grow, silicone rubber will undoubtedly remain at the forefront of innovation in the personal care industry.

Initially, silicone rubber found limited use in medical-grade products due to its biocompatibility and inert nature. The 1980s marked a significant turning point as cosmetic formulators began to explore silicone rubber's unique properties, particularly its ability to create smooth, non-greasy textures. This led to the development of silicone-based foundations and primers, which revolutionized the makeup industry.

The 1990s saw a surge in silicone rubber innovations for skincare products. Manufacturers developed advanced crosslinking techniques, allowing for the creation of silicone elastomers with varying degrees of softness and elasticity. These advancements enabled the production of lightweight, breathable formulations that could deliver active ingredients more effectively while providing a luxurious skin feel.

In the early 2000s, the focus shifted towards sustainability and eco-friendliness. Researchers began developing biodegradable silicone rubber variants and exploring ways to reduce the environmental impact of silicone production. This period also saw the emergence of hybrid materials, combining silicone rubber with natural ingredients to cater to the growing demand for "green" cosmetics.

The past decade has witnessed a rapid acceleration in silicone rubber technology for personal care. Nanotechnology has played a crucial role, with the development of silicone nanoparticles and nanocomposites offering enhanced performance in areas such as UV protection and controlled release of active ingredients. Smart silicone rubbers, capable of responding to environmental stimuli like temperature or pH changes, have opened up new possibilities for adaptive skincare solutions.

Recent innovations have focused on customization and multifunctionality. Advanced manufacturing techniques, including 3D printing of silicone rubber, have enabled the creation of personalized care products tailored to individual needs. Additionally, the integration of silicone rubber with electronic components has led to the development of wearable beauty devices and smart packaging solutions.

Looking ahead, the evolution of silicone rubber in personal care products shows no signs of slowing down. Emerging trends include the development of self-healing silicone rubbers for long-lasting products, biofunctional silicones that interact with the skin's microbiome, and sustainable silicone alternatives derived from renewable resources. As consumer demands for performance, safety, and sustainability continue to grow, silicone rubber will undoubtedly remain at the forefront of innovation in the personal care industry.

Personal Care Market Trends

The personal care market has been experiencing significant growth and transformation in recent years, driven by changing consumer preferences, technological advancements, and increasing awareness of health and wellness. This trend has created a fertile ground for innovations in silicone rubber applications within the personal care industry.

One of the key market trends is the growing demand for multifunctional and high-performance products. Consumers are seeking personal care items that offer multiple benefits in a single formulation, such as skincare products that provide hydration, sun protection, and anti-aging properties simultaneously. This trend has led to the development of advanced silicone rubber formulations that can deliver multiple active ingredients effectively and improve the overall performance of personal care products.

Another notable trend is the increasing focus on natural and sustainable ingredients. While silicone rubber is synthetic, manufacturers are developing eco-friendly alternatives and modifying existing formulations to align with sustainability goals. This includes the creation of biodegradable silicone rubber variants and the use of renewable resources in production processes.

The rise of personalized beauty and skincare solutions is also shaping the personal care market. Consumers are looking for products tailored to their specific needs and preferences. This trend has spurred innovations in silicone rubber technologies that allow for customizable textures, sensory experiences, and delivery systems in personal care products.

Digital technology and smart devices are increasingly influencing the personal care market. This has led to the development of silicone rubber components for wearable beauty devices and smart packaging solutions. These innovations enable real-time monitoring of skin conditions and personalized product recommendations, enhancing the overall user experience.

The global pandemic has accelerated the demand for hygiene and sanitization products, creating new opportunities for silicone rubber applications in personal care. Antimicrobial and self-cleaning silicone rubber formulations have gained traction in various personal care items, from cosmetic applicators to packaging materials.

Lastly, the aging population in many countries has driven the demand for anti-aging and age-defying personal care products. This demographic shift has prompted research into advanced silicone rubber formulations that can effectively deliver active ingredients to target signs of aging, such as wrinkles and loss of skin elasticity.

These market trends collectively indicate a dynamic and evolving landscape for silicone rubber innovations in the personal care industry, with ample opportunities for technological advancements and product development.

One of the key market trends is the growing demand for multifunctional and high-performance products. Consumers are seeking personal care items that offer multiple benefits in a single formulation, such as skincare products that provide hydration, sun protection, and anti-aging properties simultaneously. This trend has led to the development of advanced silicone rubber formulations that can deliver multiple active ingredients effectively and improve the overall performance of personal care products.

Another notable trend is the increasing focus on natural and sustainable ingredients. While silicone rubber is synthetic, manufacturers are developing eco-friendly alternatives and modifying existing formulations to align with sustainability goals. This includes the creation of biodegradable silicone rubber variants and the use of renewable resources in production processes.

The rise of personalized beauty and skincare solutions is also shaping the personal care market. Consumers are looking for products tailored to their specific needs and preferences. This trend has spurred innovations in silicone rubber technologies that allow for customizable textures, sensory experiences, and delivery systems in personal care products.

Digital technology and smart devices are increasingly influencing the personal care market. This has led to the development of silicone rubber components for wearable beauty devices and smart packaging solutions. These innovations enable real-time monitoring of skin conditions and personalized product recommendations, enhancing the overall user experience.

The global pandemic has accelerated the demand for hygiene and sanitization products, creating new opportunities for silicone rubber applications in personal care. Antimicrobial and self-cleaning silicone rubber formulations have gained traction in various personal care items, from cosmetic applicators to packaging materials.

Lastly, the aging population in many countries has driven the demand for anti-aging and age-defying personal care products. This demographic shift has prompted research into advanced silicone rubber formulations that can effectively deliver active ingredients to target signs of aging, such as wrinkles and loss of skin elasticity.

These market trends collectively indicate a dynamic and evolving landscape for silicone rubber innovations in the personal care industry, with ample opportunities for technological advancements and product development.

Technical Challenges

Silicone rubber, a versatile material widely used in personal care products, faces several technical challenges that hinder its full potential in this rapidly evolving industry. One of the primary obstacles is achieving optimal balance between softness and durability. While silicone rubber is prized for its skin-like texture, enhancing its resilience without compromising its gentle feel remains a significant hurdle for manufacturers.

Another critical challenge lies in improving the material's compatibility with a diverse range of active ingredients commonly found in personal care formulations. Silicone rubber's inherent hydrophobicity can sometimes interfere with the efficacy of water-based active components, limiting its application in certain product categories. Developing advanced surface modification techniques or novel silicone rubber compositions that enhance ingredient interaction is crucial for expanding its use across various personal care applications.

The environmental impact of silicone rubber production and disposal presents another substantial challenge. As consumers become increasingly eco-conscious, there is growing pressure on manufacturers to develop more sustainable silicone rubber alternatives or improve the biodegradability of existing formulations. This necessitates innovative approaches to material science and production processes that maintain the desirable properties of silicone rubber while reducing its environmental footprint.

Scalability and cost-effectiveness in manufacturing high-quality silicone rubber for personal care products also pose significant challenges. The intricate molding and curing processes required for producing complex shapes and textures can be time-consuming and expensive, particularly for smaller-scale production runs. Developing more efficient manufacturing techniques that maintain product quality while reducing production costs is essential for wider adoption in the personal care industry.

Additionally, ensuring consistent performance across various environmental conditions remains a technical hurdle. Silicone rubber's properties can be affected by factors such as temperature, humidity, and exposure to UV radiation. Enhancing the material's stability and maintaining its desirable characteristics across diverse usage scenarios is crucial for meeting the demanding requirements of personal care applications.

Lastly, the regulatory landscape surrounding silicone rubber in personal care products presents ongoing challenges. As safety standards and regulations evolve, manufacturers must continuously adapt their formulations and production processes to comply with new requirements. This necessitates ongoing research and development efforts to ensure that silicone rubber products meet or exceed regulatory standards while maintaining their performance and consumer appeal.

Another critical challenge lies in improving the material's compatibility with a diverse range of active ingredients commonly found in personal care formulations. Silicone rubber's inherent hydrophobicity can sometimes interfere with the efficacy of water-based active components, limiting its application in certain product categories. Developing advanced surface modification techniques or novel silicone rubber compositions that enhance ingredient interaction is crucial for expanding its use across various personal care applications.

The environmental impact of silicone rubber production and disposal presents another substantial challenge. As consumers become increasingly eco-conscious, there is growing pressure on manufacturers to develop more sustainable silicone rubber alternatives or improve the biodegradability of existing formulations. This necessitates innovative approaches to material science and production processes that maintain the desirable properties of silicone rubber while reducing its environmental footprint.

Scalability and cost-effectiveness in manufacturing high-quality silicone rubber for personal care products also pose significant challenges. The intricate molding and curing processes required for producing complex shapes and textures can be time-consuming and expensive, particularly for smaller-scale production runs. Developing more efficient manufacturing techniques that maintain product quality while reducing production costs is essential for wider adoption in the personal care industry.

Additionally, ensuring consistent performance across various environmental conditions remains a technical hurdle. Silicone rubber's properties can be affected by factors such as temperature, humidity, and exposure to UV radiation. Enhancing the material's stability and maintaining its desirable characteristics across diverse usage scenarios is crucial for meeting the demanding requirements of personal care applications.

Lastly, the regulatory landscape surrounding silicone rubber in personal care products presents ongoing challenges. As safety standards and regulations evolve, manufacturers must continuously adapt their formulations and production processes to comply with new requirements. This necessitates ongoing research and development efforts to ensure that silicone rubber products meet or exceed regulatory standards while maintaining their performance and consumer appeal.

Current Silicone Solutions

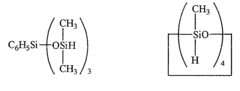

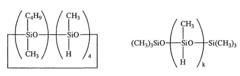

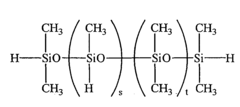

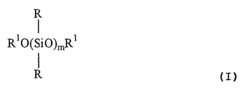

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, elasticity, and heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the manufacturing process. This can include improving thermal stability, increasing mechanical strength, enhancing electrical properties, or adjusting the rubber's hardness or flexibility to suit specific applications.

- Applications of silicone rubber: Silicone rubber finds wide-ranging applications across various industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, cookware, and many other products where heat resistance, flexibility, and durability are required. Its biocompatibility makes it particularly suitable for medical and food-related applications.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This can involve incorporating nanoparticles, fibers, or other polymers to improve specific characteristics such as strength, conductivity, or flame resistance. These composites expand the potential applications of silicone rubber materials.

- Curing and processing techniques for silicone rubber: Various curing and processing techniques are employed in the production of silicone rubber products. These can include heat curing, room temperature vulcanization (RTV), and UV curing. Advanced processing methods such as injection molding, extrusion, and 3D printing are also used to shape silicone rubber into complex forms for specific applications.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the manufacturing process. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating nanoparticles.Expand Specific Solutions03 Applications of silicone rubber

Silicone rubber finds wide applications across various industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, cookware, and many other products. Its biocompatibility makes it suitable for implants and prosthetics, while its heat resistance is valuable in industrial applications.Expand Specific Solutions04 Curing methods for silicone rubber

Various curing methods are employed in the production of silicone rubber, including heat curing, room temperature vulcanization (RTV), and UV curing. Each method has its advantages and is chosen based on the specific application and desired properties of the final product. Curing agents and catalysts play a crucial role in these processes.Expand Specific Solutions05 Silicone rubber composites and blends

Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing with fibers, blending with other elastomers, or incorporating functional fillers. These composites often exhibit improved mechanical strength, thermal conductivity, or specific functional properties tailored for particular applications.Expand Specific Solutions

Key Industry Players

The silicone rubber market for personal care products is in a mature growth stage, characterized by steady expansion and innovation. The global market size is substantial, estimated to be in the billions of dollars, driven by increasing demand for advanced personal care formulations. Technologically, silicone rubber applications are well-established but continue to evolve. Leading players like Momentive Performance Materials, Shin-Etsu Chemical, and Dow Silicones are at the forefront of innovation, developing specialized silicone formulations for enhanced product performance. These companies, along with Wacker Chemie, are investing in R&D to improve material properties and expand applications, indicating a competitive landscape focused on differentiation through technological advancements and product customization.

Momentive Performance Materials, Inc.

Technical Solution: Momentive has developed advanced silicone elastomers specifically for personal care applications. Their innovative SilForm™ technology combines the benefits of silicone elastomers with additional functionalities. This includes the creation of self-emulsifying elastomers that can form stable emulsions without additional emulsifiers, enhancing the texture and feel of skincare products[1]. They have also introduced specialty silicone elastomer blends that offer unique sensory properties and improved compatibility with various cosmetic ingredients[2]. Momentive's research focuses on creating customizable silicone solutions that can be tailored to specific formulation needs, such as enhanced spreadability, improved skin feel, and long-lasting effects in makeup and skincare products[3].

Strengths: Highly customizable solutions, advanced emulsion technology, and improved sensory properties. Weaknesses: May require specialized formulation expertise to fully utilize the advanced properties.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu has pioneered the development of silicone rubber compounds for personal care applications. Their KSG series of silicone elastomers offers a range of innovative products, including those with unique film-forming properties that enhance the longevity and water resistance of cosmetic formulations[4]. They have also developed silicone rubber powders that provide a smooth, matte finish in makeup products while offering excellent sebum absorption[5]. Shin-Etsu's research extends to the creation of novel silicone-based delivery systems for active ingredients in skincare, improving efficacy and stability of formulations[6]. Their focus on sustainability has led to the development of bio-based silicone alternatives, addressing the growing demand for eco-friendly personal care products[7].

Strengths: Wide range of specialized silicone products, innovative delivery systems, and focus on sustainability. Weaknesses: Higher cost compared to traditional ingredients, potential regulatory challenges with novel materials.

Breakthrough Technologies

Silicone rubber compositions, their preparation and use

PatentInactiveEP1557446A1

Innovation

- A silicone rubber composition comprising an organopolysiloxane with a degree of polymerization of 100 or higher and at least two silicon-bonded alkenyl groups, combined with wet silica having a specific surface area of 50 m^2/g or larger and a water content of 4% or lower, and an effective curing agent, which inhibits foaming during hot air vulcanization and enhances electrical properties.

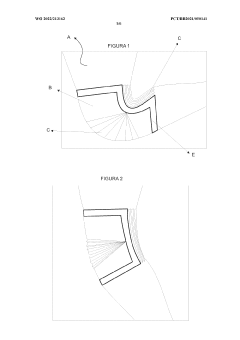

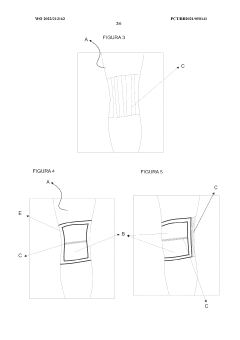

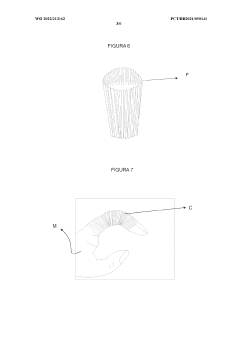

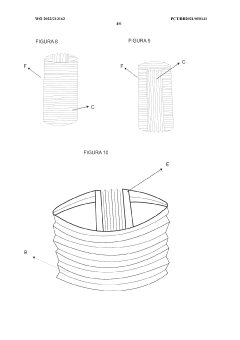

Configuration for product made of liquid silicone rubber (LSR) for providing comfort, protection, rehabilitation and bodily care

PatentWO2022213162A1

Innovation

- The use of Liquid Silicone Rubber (LSR) with pleated designs and gel inserts in products like gloves, socks, sleeves, and pads, which can be heated or cooled, providing a flexible, adherent, and protective layer that prevents friction and allows full mobility, while incorporating therapeutic benefits.

Regulatory Compliance

Regulatory compliance is a critical aspect of silicone rubber innovations in personal care products. The industry must adhere to stringent regulations set by various governing bodies to ensure product safety and efficacy. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the use of silicone rubber in personal care items. The FDA classifies these materials based on their intended use and potential risks, with different regulatory pathways for cosmetics, medical devices, and over-the-counter drugs.

The European Union's regulatory framework, governed by the European Chemicals Agency (ECHA), imposes strict requirements through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive approach mandates thorough safety assessments and documentation for silicone rubber components used in personal care products. Manufacturers must provide detailed information on the chemical composition, potential hazards, and safe use guidelines for their silicone-based ingredients.

In Asia, countries like Japan and South Korea have established their own regulatory bodies and standards for personal care products. The Japanese Cosmetic Ingredients Codex (JCIC) and the Korean Cosmetic Act set forth specific guidelines for the use of silicone rubber in cosmetics and personal care items. These regulations often focus on purity standards, permissible concentrations, and labeling requirements.

Global harmonization efforts, such as the International Cooperation on Cosmetics Regulation (ICCR), aim to streamline regulatory processes across different regions. This initiative facilitates the exchange of scientific information and promotes consistent safety standards for silicone rubber applications in personal care products worldwide.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct toxicological assessments, stability studies, and efficacy trials to demonstrate the safety and performance of their silicone rubber formulations. Additionally, companies must maintain detailed records of their manufacturing processes, quality control measures, and post-market surveillance to ensure ongoing compliance.

As environmental concerns gain prominence, regulatory bodies are increasingly focusing on the sustainability aspects of silicone rubber in personal care products. This includes assessing the environmental impact of production processes, biodegradability of materials, and potential for microplastic pollution. Manufacturers are now required to consider these factors in their product development and regulatory compliance strategies.

The European Union's regulatory framework, governed by the European Chemicals Agency (ECHA), imposes strict requirements through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive approach mandates thorough safety assessments and documentation for silicone rubber components used in personal care products. Manufacturers must provide detailed information on the chemical composition, potential hazards, and safe use guidelines for their silicone-based ingredients.

In Asia, countries like Japan and South Korea have established their own regulatory bodies and standards for personal care products. The Japanese Cosmetic Ingredients Codex (JCIC) and the Korean Cosmetic Act set forth specific guidelines for the use of silicone rubber in cosmetics and personal care items. These regulations often focus on purity standards, permissible concentrations, and labeling requirements.

Global harmonization efforts, such as the International Cooperation on Cosmetics Regulation (ICCR), aim to streamline regulatory processes across different regions. This initiative facilitates the exchange of scientific information and promotes consistent safety standards for silicone rubber applications in personal care products worldwide.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct toxicological assessments, stability studies, and efficacy trials to demonstrate the safety and performance of their silicone rubber formulations. Additionally, companies must maintain detailed records of their manufacturing processes, quality control measures, and post-market surveillance to ensure ongoing compliance.

As environmental concerns gain prominence, regulatory bodies are increasingly focusing on the sustainability aspects of silicone rubber in personal care products. This includes assessing the environmental impact of production processes, biodegradability of materials, and potential for microplastic pollution. Manufacturers are now required to consider these factors in their product development and regulatory compliance strategies.

Environmental Impact

The environmental impact of silicone rubber in personal care products is a critical consideration in the industry's pursuit of sustainability. Silicone rubber, while offering numerous benefits in terms of product performance and user experience, presents both challenges and opportunities from an environmental perspective.

One of the primary environmental concerns associated with silicone rubber is its persistence in the environment. Unlike many organic materials, silicone rubber does not biodegrade easily, potentially leading to long-term accumulation in ecosystems. This persistence has raised questions about its impact on marine life and terrestrial environments, particularly when personal care products containing silicone rubber are washed off and enter water systems.

However, the durability of silicone rubber also contributes to its potential for reducing overall environmental impact. Personal care products formulated with silicone rubber often have longer shelf lives and require less frequent replacement, potentially reducing the overall consumption of resources and generation of waste. This longevity can lead to a decrease in packaging waste and transportation-related emissions associated with product distribution.

The production process of silicone rubber for personal care applications has also been scrutinized for its environmental footprint. While the manufacturing of silicone rubber requires significant energy input, advancements in production technologies have led to more efficient processes. Some manufacturers have implemented closed-loop systems and energy recovery methods to minimize waste and reduce energy consumption.

Water usage is another environmental factor to consider. Silicone rubber-based personal care products often require less water during use compared to traditional alternatives. This can contribute to water conservation efforts, particularly in regions where water scarcity is a pressing issue. Additionally, the water-repellent properties of silicone rubber can lead to reduced water consumption in certain applications, such as waterproof cosmetics or skincare products.

The end-of-life management of silicone rubber in personal care products remains a challenge. While some recycling technologies for silicone rubber exist, they are not widely implemented in the personal care industry. Innovations in recycling and upcycling of silicone rubber are emerging, with some companies exploring methods to break down and repurpose used silicone materials.

As the personal care industry continues to evolve, there is a growing focus on developing more environmentally friendly alternatives to traditional silicone rubber. Bio-based silicones and hybrid materials that combine the benefits of silicone rubber with improved biodegradability are areas of active research and development. These innovations aim to address the environmental persistence concerns while maintaining the desirable properties that have made silicone rubber a staple in personal care formulations.

One of the primary environmental concerns associated with silicone rubber is its persistence in the environment. Unlike many organic materials, silicone rubber does not biodegrade easily, potentially leading to long-term accumulation in ecosystems. This persistence has raised questions about its impact on marine life and terrestrial environments, particularly when personal care products containing silicone rubber are washed off and enter water systems.

However, the durability of silicone rubber also contributes to its potential for reducing overall environmental impact. Personal care products formulated with silicone rubber often have longer shelf lives and require less frequent replacement, potentially reducing the overall consumption of resources and generation of waste. This longevity can lead to a decrease in packaging waste and transportation-related emissions associated with product distribution.

The production process of silicone rubber for personal care applications has also been scrutinized for its environmental footprint. While the manufacturing of silicone rubber requires significant energy input, advancements in production technologies have led to more efficient processes. Some manufacturers have implemented closed-loop systems and energy recovery methods to minimize waste and reduce energy consumption.

Water usage is another environmental factor to consider. Silicone rubber-based personal care products often require less water during use compared to traditional alternatives. This can contribute to water conservation efforts, particularly in regions where water scarcity is a pressing issue. Additionally, the water-repellent properties of silicone rubber can lead to reduced water consumption in certain applications, such as waterproof cosmetics or skincare products.

The end-of-life management of silicone rubber in personal care products remains a challenge. While some recycling technologies for silicone rubber exist, they are not widely implemented in the personal care industry. Innovations in recycling and upcycling of silicone rubber are emerging, with some companies exploring methods to break down and repurpose used silicone materials.

As the personal care industry continues to evolve, there is a growing focus on developing more environmentally friendly alternatives to traditional silicone rubber. Bio-based silicones and hybrid materials that combine the benefits of silicone rubber with improved biodegradability are areas of active research and development. These innovations aim to address the environmental persistence concerns while maintaining the desirable properties that have made silicone rubber a staple in personal care formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!