Silicone Rubber: Shaping the Future of Smart Textiles

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Smart Textiles: Evolution and Objectives

Silicone rubber has emerged as a transformative material in the realm of smart textiles, marking a significant evolution in the integration of technology and fabric. The journey of silicone rubber in this field began with its unique properties of flexibility, durability, and electrical insulation. These characteristics made it an ideal candidate for creating conductive pathways and sensors within textiles, paving the way for the development of wearable technology.

The evolution of silicone rubber in smart textiles has been driven by the increasing demand for functional and interactive clothing. Initially, its application was limited to simple waterproofing and insulation. However, as technology advanced, researchers and engineers recognized its potential for more sophisticated applications. The material's ability to be molded into various shapes and its compatibility with electronic components opened up new possibilities for embedding sensors, actuators, and other smart elements directly into fabric structures.

A key milestone in this evolution was the development of stretchable electronics using silicone rubber as a substrate. This breakthrough allowed for the creation of electronic circuits that could withstand the bending, stretching, and twisting associated with normal textile use. As a result, smart textiles incorporating silicone rubber began to offer enhanced functionality, including real-time health monitoring, temperature regulation, and even energy harvesting capabilities.

The objectives of silicone rubber in smart textiles have expanded significantly over time. Current research aims to further improve the integration of electronic components with textiles, focusing on enhancing durability, washability, and user comfort. There is a growing emphasis on developing silicone-based materials that can seamlessly blend with traditional fabrics while maintaining their smart functionalities.

Another important objective is to increase the scalability and cost-effectiveness of silicone rubber-based smart textiles. As the demand for wearable technology grows, there is a push to develop manufacturing processes that can produce these advanced textiles at a commercial scale. This includes improving the methods for applying silicone rubber to fabrics and optimizing the integration of electronic components.

Looking ahead, the future objectives for silicone rubber in smart textiles include the development of self-healing properties to extend the lifespan of wearable devices, as well as exploring biodegradable silicone formulations to address environmental concerns. Additionally, there is a focus on enhancing the energy efficiency of silicone-based smart textiles, potentially leading to self-powered garments that can generate and store their own energy.

The evolution of silicone rubber in smart textiles has been driven by the increasing demand for functional and interactive clothing. Initially, its application was limited to simple waterproofing and insulation. However, as technology advanced, researchers and engineers recognized its potential for more sophisticated applications. The material's ability to be molded into various shapes and its compatibility with electronic components opened up new possibilities for embedding sensors, actuators, and other smart elements directly into fabric structures.

A key milestone in this evolution was the development of stretchable electronics using silicone rubber as a substrate. This breakthrough allowed for the creation of electronic circuits that could withstand the bending, stretching, and twisting associated with normal textile use. As a result, smart textiles incorporating silicone rubber began to offer enhanced functionality, including real-time health monitoring, temperature regulation, and even energy harvesting capabilities.

The objectives of silicone rubber in smart textiles have expanded significantly over time. Current research aims to further improve the integration of electronic components with textiles, focusing on enhancing durability, washability, and user comfort. There is a growing emphasis on developing silicone-based materials that can seamlessly blend with traditional fabrics while maintaining their smart functionalities.

Another important objective is to increase the scalability and cost-effectiveness of silicone rubber-based smart textiles. As the demand for wearable technology grows, there is a push to develop manufacturing processes that can produce these advanced textiles at a commercial scale. This includes improving the methods for applying silicone rubber to fabrics and optimizing the integration of electronic components.

Looking ahead, the future objectives for silicone rubber in smart textiles include the development of self-healing properties to extend the lifespan of wearable devices, as well as exploring biodegradable silicone formulations to address environmental concerns. Additionally, there is a focus on enhancing the energy efficiency of silicone-based smart textiles, potentially leading to self-powered garments that can generate and store their own energy.

Market Analysis for Smart Textile Applications

The smart textiles market is experiencing rapid growth, driven by advancements in material science and increasing demand for wearable technology. Silicone rubber, with its unique properties, is playing a pivotal role in shaping this market. The global smart textiles market is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors.

The integration of silicone rubber in smart textiles is opening up new applications across various industries. In the healthcare sector, there is a growing demand for medical-grade smart textiles that can monitor vital signs, administer medication, and provide real-time health data. Silicone rubber's biocompatibility and flexibility make it an ideal material for these applications, driving market growth in this segment.

In the sports and fitness industry, smart textiles enhanced with silicone rubber are gaining traction. These materials offer improved performance, comfort, and durability for athletes and fitness enthusiasts. The market for smart sportswear is expanding, with major sportswear brands investing heavily in research and development of silicone-based smart textiles.

The automotive industry is another key market for smart textiles incorporating silicone rubber. These materials are being used in car interiors for enhanced comfort, safety, and user experience. The trend towards autonomous and electric vehicles is further boosting the demand for smart textiles in this sector.

Consumer electronics is yet another area where silicone-based smart textiles are making significant inroads. From smart clothing with integrated sensors to flexible displays and touch-sensitive interfaces, the applications are diverse and growing. This segment is expected to be a major driver of market growth in the coming years.

The military and defense sector is also adopting smart textiles with silicone rubber components. These materials are being used in protective gear, communication systems, and camouflage technologies. The need for advanced, lightweight, and durable materials in military applications is fueling market growth in this segment.

Geographically, North America and Europe are currently leading the smart textiles market, with Asia-Pacific showing the fastest growth rate. The presence of major technology companies, research institutions, and a strong manufacturing base in these regions is contributing to their market dominance. However, emerging economies in Asia are rapidly catching up, driven by increasing investments in research and development and growing consumer demand for smart wearables.

The integration of silicone rubber in smart textiles is opening up new applications across various industries. In the healthcare sector, there is a growing demand for medical-grade smart textiles that can monitor vital signs, administer medication, and provide real-time health data. Silicone rubber's biocompatibility and flexibility make it an ideal material for these applications, driving market growth in this segment.

In the sports and fitness industry, smart textiles enhanced with silicone rubber are gaining traction. These materials offer improved performance, comfort, and durability for athletes and fitness enthusiasts. The market for smart sportswear is expanding, with major sportswear brands investing heavily in research and development of silicone-based smart textiles.

The automotive industry is another key market for smart textiles incorporating silicone rubber. These materials are being used in car interiors for enhanced comfort, safety, and user experience. The trend towards autonomous and electric vehicles is further boosting the demand for smart textiles in this sector.

Consumer electronics is yet another area where silicone-based smart textiles are making significant inroads. From smart clothing with integrated sensors to flexible displays and touch-sensitive interfaces, the applications are diverse and growing. This segment is expected to be a major driver of market growth in the coming years.

The military and defense sector is also adopting smart textiles with silicone rubber components. These materials are being used in protective gear, communication systems, and camouflage technologies. The need for advanced, lightweight, and durable materials in military applications is fueling market growth in this segment.

Geographically, North America and Europe are currently leading the smart textiles market, with Asia-Pacific showing the fastest growth rate. The presence of major technology companies, research institutions, and a strong manufacturing base in these regions is contributing to their market dominance. However, emerging economies in Asia are rapidly catching up, driven by increasing investments in research and development and growing consumer demand for smart wearables.

Current Challenges in Silicone-Based Smart Textiles

Despite the promising potential of silicone-based smart textiles, several significant challenges currently hinder their widespread adoption and development. One of the primary obstacles is the integration of electronic components with silicone rubber materials. While silicone rubber offers excellent flexibility and durability, it poses difficulties in creating stable and reliable connections with rigid electronic elements such as sensors, microcontrollers, and power sources.

The durability of these connections under repeated stretching and bending remains a critical concern. As smart textiles are expected to withstand regular wear and tear, ensuring that the electronic components remain securely attached and functional throughout the garment's lifecycle is crucial. This challenge is further compounded by the need for washability, as many smart textile applications require the ability to clean the garments without damaging the embedded electronics.

Another significant hurdle is the development of stretchable and durable conductive pathways within the silicone matrix. Traditional conductive materials often lack the elasticity required to maintain conductivity when stretched, leading to performance degradation or failure of the smart textile system. Researchers are exploring various approaches, including conductive nanoparticle-filled silicone composites and liquid metal alloys, but each solution presents its own set of challenges in terms of manufacturability, cost, and long-term reliability.

Power management and energy harvesting represent additional areas of concern. Many smart textile applications require continuous power supply, yet conventional batteries are bulky and rigid, conflicting with the desired flexibility of silicone-based textiles. Developing thin, flexible, and high-capacity energy storage solutions that can be seamlessly integrated into silicone rubber matrices remains an ongoing challenge.

Scalability and mass production present further obstacles. Current manufacturing processes for silicone-based smart textiles are often labor-intensive and not easily adaptable to large-scale production. Developing automated manufacturing techniques that can efficiently produce these advanced textiles while maintaining consistent quality and performance is essential for their commercial viability.

Lastly, the environmental impact and recyclability of silicone-based smart textiles pose significant challenges. As the world moves towards more sustainable practices, finding ways to recycle or safely dispose of these complex materials at the end of their lifecycle is crucial. This includes developing methods to separate and recover valuable electronic components from the silicone matrix without causing environmental harm.

The durability of these connections under repeated stretching and bending remains a critical concern. As smart textiles are expected to withstand regular wear and tear, ensuring that the electronic components remain securely attached and functional throughout the garment's lifecycle is crucial. This challenge is further compounded by the need for washability, as many smart textile applications require the ability to clean the garments without damaging the embedded electronics.

Another significant hurdle is the development of stretchable and durable conductive pathways within the silicone matrix. Traditional conductive materials often lack the elasticity required to maintain conductivity when stretched, leading to performance degradation or failure of the smart textile system. Researchers are exploring various approaches, including conductive nanoparticle-filled silicone composites and liquid metal alloys, but each solution presents its own set of challenges in terms of manufacturability, cost, and long-term reliability.

Power management and energy harvesting represent additional areas of concern. Many smart textile applications require continuous power supply, yet conventional batteries are bulky and rigid, conflicting with the desired flexibility of silicone-based textiles. Developing thin, flexible, and high-capacity energy storage solutions that can be seamlessly integrated into silicone rubber matrices remains an ongoing challenge.

Scalability and mass production present further obstacles. Current manufacturing processes for silicone-based smart textiles are often labor-intensive and not easily adaptable to large-scale production. Developing automated manufacturing techniques that can efficiently produce these advanced textiles while maintaining consistent quality and performance is essential for their commercial viability.

Lastly, the environmental impact and recyclability of silicone-based smart textiles pose significant challenges. As the world moves towards more sustainable practices, finding ways to recycle or safely dispose of these complex materials at the end of their lifecycle is crucial. This includes developing methods to separate and recover valuable electronic components from the silicone matrix without causing environmental harm.

Existing Silicone Integration Methods for Smart Fabrics

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness. Such modifications allow for the customization of silicone rubber for various applications.

- Silicone rubber in medical and healthcare applications: Silicone rubber is widely used in medical and healthcare products due to its biocompatibility, flexibility, and durability. Applications include medical implants, prosthetics, drug delivery systems, and various medical devices. The material can be formulated to meet specific requirements such as antimicrobial properties or controlled drug release.

- Silicone rubber composites and blends: Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This includes mixing with other polymers, incorporating nanoparticles, or adding reinforcing fibers. These composites often exhibit improved mechanical properties, thermal stability, or specific functionalities that pure silicone rubber lacks.

- Manufacturing processes for silicone rubber products: Various manufacturing processes are used to produce silicone rubber products, including injection molding, extrusion, compression molding, and 3D printing. Each process has its advantages and is suited for different types of products or applications. Innovations in manufacturing techniques focus on improving efficiency, reducing waste, and enabling the production of complex shapes.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving mechanical strength, increasing thermal stability, enhancing electrical properties, or adjusting the rubber's hardness or elasticity to suit specific applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It can be formulated for use in medical devices, implants, prosthetics, and drug delivery systems. Special grades of silicone rubber can be developed to meet specific medical requirements such as sterilization resistance or long-term implantation.Expand Specific Solutions04 Silicone rubber composites and blends

Silicone rubber can be combined with other materials to create composites or blends with enhanced properties. This can include mixing with other polymers, incorporating nanoparticles, or adding reinforcing fibers. These composites often exhibit improved mechanical properties, thermal stability, or specific functional characteristics not achievable with silicone rubber alone.Expand Specific Solutions05 Manufacturing processes for silicone rubber products

Various manufacturing processes are employed to produce silicone rubber products, including injection molding, extrusion, compression molding, and liquid silicone rubber molding. Each process has specific advantages and is suited to different product types and production volumes. Advanced manufacturing techniques may involve automation, precision control, or specialized curing methods to achieve desired product characteristics.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The smart textiles market, driven by innovations in silicone rubber technology, is in a growth phase with increasing market size and evolving technological maturity. The competitive landscape is diverse, featuring established chemical companies like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie, alongside emerging players and research institutions. Major tech firms such as Apple are also entering the space, indicating its potential. The market is characterized by collaborations between industry and academia, with universities like Zhejiang Sci-Tech and NUS contributing to R&D. As the technology matures, we're seeing a shift from basic material development to more sophisticated applications, with companies like Myant focusing on integrating smart textiles into wearable technology.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds specifically designed for smart textiles. Their technology focuses on creating highly flexible and durable silicone materials that can be seamlessly integrated into fabric structures. The company's silicone rubber formulations offer excellent electrical conductivity while maintaining softness and stretchability, making them ideal for wearable electronics and e-textiles[1]. Shin-Etsu's silicone rubber compounds also feature enhanced thermal stability and resistance to environmental factors, ensuring long-lasting performance in various applications[3]. The company has implemented a proprietary cross-linking process that allows for precise control of the silicone rubber's mechanical properties, enabling customization for specific smart textile requirements[5].

Strengths: Superior flexibility and durability, excellent electrical conductivity, customizable mechanical properties. Weaknesses: Potentially higher cost compared to traditional textile materials, may require specialized manufacturing processes.

Apple, Inc.

Technical Solution: Apple has been investing heavily in smart textile technology, particularly focusing on integrating silicone rubber into wearable devices. Their approach involves developing ultra-thin, stretchable silicone-based sensors that can be seamlessly incorporated into fabric[2]. Apple's technology utilizes a network of micro-channels filled with liquid metal encased in silicone rubber, allowing for precise touch and pressure sensing while maintaining flexibility[4]. The company has also patented a method for creating three-dimensional silicone structures within textiles, enabling the integration of complex electronic components without compromising comfort[6]. Apple's smart textile solutions aim to enhance user experience in their wearable devices by providing more accurate health monitoring and intuitive user interfaces[8].

Strengths: Cutting-edge sensor technology, seamless integration with existing product ecosystem. Weaknesses: Potentially limited to proprietary applications, high development costs.

Innovative Silicone Formulations for Enhanced Functionality

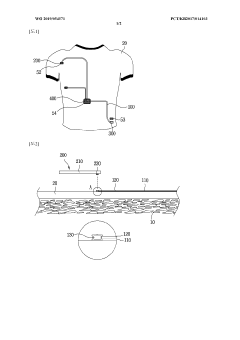

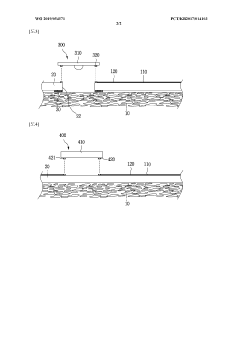

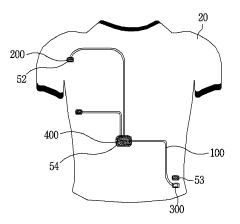

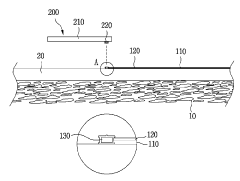

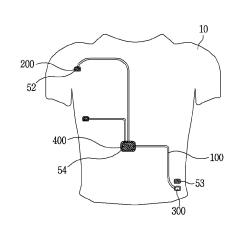

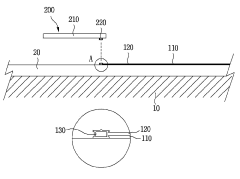

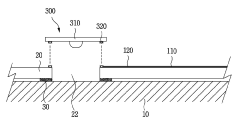

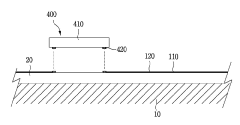

Smart garment integrated with wire coated with conductive silicone rubber

PatentWO2019054571A1

Innovation

- The integration of wires coated with elastic conductive silicone rubber allows for easy attachment and detachment of sensors and devices, with electrically conductive Velcro or metal snap buttons, and a breathable cover for durability and flexibility, enabling real-time biometric data collection during activities.

Smart cloth having integrally formed-wire coated with electric conductive silicon rubber

PatentActiveKR1020190029541A

Innovation

- A smart clothing design featuring conductive patterns coated with electrically conductive silicone rubber, using snap buttons for easy attachment and detachment of sensors, micro-measuring devices, and controllers, with an insulating layer for protection and durability.

Environmental Impact and Sustainability Considerations

The integration of silicone rubber in smart textiles presents both opportunities and challenges from an environmental and sustainability perspective. As the demand for smart textiles grows, it is crucial to consider the ecological footprint of silicone rubber production and its long-term impact on the environment.

Silicone rubber offers several environmental advantages compared to traditional textile materials. Its durability and resistance to degradation mean that products incorporating silicone rubber typically have a longer lifespan, potentially reducing the need for frequent replacements and minimizing waste. Additionally, silicone rubber is inert and non-toxic, posing minimal risk of harmful chemical leaching into the environment during use or disposal.

However, the production of silicone rubber does raise some environmental concerns. The primary raw material for silicone rubber is silica, which is abundant but requires energy-intensive mining and processing. The synthesis of silicone polymers also involves the use of organic solvents and catalysts, some of which may have environmental implications if not properly managed. Manufacturers are increasingly adopting cleaner production methods and closed-loop systems to mitigate these impacts.

End-of-life considerations for silicone rubber in smart textiles are an area of ongoing research and development. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Mechanical recycling can be used to grind and repurpose silicone rubber into new products, while chemical recycling methods are being developed to break down silicone polymers into their constituent parts for reuse.

The integration of electronic components in smart textiles adds another layer of complexity to sustainability considerations. The e-waste generated from discarded smart textiles could become a significant environmental issue if not properly addressed. Designers and manufacturers are exploring modular designs that allow for easy separation of electronic components from the textile base, facilitating recycling and reducing overall environmental impact.

As the smart textile industry evolves, there is a growing focus on developing more sustainable alternatives to traditional silicone rubber. Bio-based silicones derived from plant sources are emerging as a promising option, offering similar performance characteristics with a potentially lower environmental footprint. Research is also underway to create biodegradable silicone-like materials that could revolutionize the sustainability profile of smart textiles.

In conclusion, while silicone rubber offers many benefits for smart textiles, its environmental impact and sustainability considerations are complex and multifaceted. The industry must continue to innovate in materials science, manufacturing processes, and recycling technologies to ensure that the future of smart textiles aligns with global sustainability goals.

Silicone rubber offers several environmental advantages compared to traditional textile materials. Its durability and resistance to degradation mean that products incorporating silicone rubber typically have a longer lifespan, potentially reducing the need for frequent replacements and minimizing waste. Additionally, silicone rubber is inert and non-toxic, posing minimal risk of harmful chemical leaching into the environment during use or disposal.

However, the production of silicone rubber does raise some environmental concerns. The primary raw material for silicone rubber is silica, which is abundant but requires energy-intensive mining and processing. The synthesis of silicone polymers also involves the use of organic solvents and catalysts, some of which may have environmental implications if not properly managed. Manufacturers are increasingly adopting cleaner production methods and closed-loop systems to mitigate these impacts.

End-of-life considerations for silicone rubber in smart textiles are an area of ongoing research and development. While silicone rubber is not biodegradable, it can be recycled through specialized processes. Mechanical recycling can be used to grind and repurpose silicone rubber into new products, while chemical recycling methods are being developed to break down silicone polymers into their constituent parts for reuse.

The integration of electronic components in smart textiles adds another layer of complexity to sustainability considerations. The e-waste generated from discarded smart textiles could become a significant environmental issue if not properly addressed. Designers and manufacturers are exploring modular designs that allow for easy separation of electronic components from the textile base, facilitating recycling and reducing overall environmental impact.

As the smart textile industry evolves, there is a growing focus on developing more sustainable alternatives to traditional silicone rubber. Bio-based silicones derived from plant sources are emerging as a promising option, offering similar performance characteristics with a potentially lower environmental footprint. Research is also underway to create biodegradable silicone-like materials that could revolutionize the sustainability profile of smart textiles.

In conclusion, while silicone rubber offers many benefits for smart textiles, its environmental impact and sustainability considerations are complex and multifaceted. The industry must continue to innovate in materials science, manufacturing processes, and recycling technologies to ensure that the future of smart textiles aligns with global sustainability goals.

Standardization and Quality Control in Smart Textile Production

The integration of silicone rubber in smart textiles has revolutionized the industry, necessitating robust standardization and quality control measures. As the production of smart textiles incorporating silicone rubber components becomes more widespread, establishing uniform standards and rigorous quality control processes is crucial for ensuring product consistency, reliability, and safety.

Standardization efforts in smart textile production focus on several key areas. Material specifications for silicone rubber used in smart textiles must be clearly defined, including parameters such as elasticity, durability, and electrical conductivity. These specifications ensure that the silicone rubber components meet the required performance criteria for various applications, from wearable electronics to medical devices.

Manufacturing processes for integrating silicone rubber into textiles also require standardization. This includes guidelines for bonding techniques, curing methods, and encapsulation procedures. Standardized processes help maintain consistency across different production batches and facilities, reducing variability in the final product.

Quality control in smart textile production involving silicone rubber components encompasses multiple stages. Incoming material inspection is critical to verify that the silicone rubber meets the specified requirements before integration into the textile. This may involve testing for mechanical properties, chemical composition, and electrical characteristics.

During the manufacturing process, in-line quality control measures are implemented to monitor the integration of silicone rubber components. This can include visual inspections, automated sensor-based checks, and real-time monitoring of process parameters such as temperature and pressure during curing or bonding stages.

Post-production testing is another crucial aspect of quality control. Finished smart textiles undergo a battery of tests to ensure functionality, durability, and safety. These tests may include wash cycle resistance, stretch and recovery performance, and electrical conductivity retention after repeated use.

The development of industry-wide standards for smart textiles incorporating silicone rubber is an ongoing process. Organizations such as ASTM International and ISO are working on creating comprehensive standards that address the unique challenges of these innovative materials. These standards will cover aspects such as test methods, performance requirements, and safety guidelines specific to smart textiles with silicone rubber components.

Implementing robust quality management systems is essential for manufacturers in this field. This includes documenting procedures, maintaining traceability of materials and processes, and conducting regular audits to ensure compliance with established standards and quality control protocols.

As the smart textile industry continues to evolve, standardization and quality control measures must adapt to new technologies and applications. This may involve developing new test methods, updating existing standards, and incorporating emerging best practices to address the unique challenges posed by advanced silicone rubber-based smart textiles.

Standardization efforts in smart textile production focus on several key areas. Material specifications for silicone rubber used in smart textiles must be clearly defined, including parameters such as elasticity, durability, and electrical conductivity. These specifications ensure that the silicone rubber components meet the required performance criteria for various applications, from wearable electronics to medical devices.

Manufacturing processes for integrating silicone rubber into textiles also require standardization. This includes guidelines for bonding techniques, curing methods, and encapsulation procedures. Standardized processes help maintain consistency across different production batches and facilities, reducing variability in the final product.

Quality control in smart textile production involving silicone rubber components encompasses multiple stages. Incoming material inspection is critical to verify that the silicone rubber meets the specified requirements before integration into the textile. This may involve testing for mechanical properties, chemical composition, and electrical characteristics.

During the manufacturing process, in-line quality control measures are implemented to monitor the integration of silicone rubber components. This can include visual inspections, automated sensor-based checks, and real-time monitoring of process parameters such as temperature and pressure during curing or bonding stages.

Post-production testing is another crucial aspect of quality control. Finished smart textiles undergo a battery of tests to ensure functionality, durability, and safety. These tests may include wash cycle resistance, stretch and recovery performance, and electrical conductivity retention after repeated use.

The development of industry-wide standards for smart textiles incorporating silicone rubber is an ongoing process. Organizations such as ASTM International and ISO are working on creating comprehensive standards that address the unique challenges of these innovative materials. These standards will cover aspects such as test methods, performance requirements, and safety guidelines specific to smart textiles with silicone rubber components.

Implementing robust quality management systems is essential for manufacturers in this field. This includes documenting procedures, maintaining traceability of materials and processes, and conducting regular audits to ensure compliance with established standards and quality control protocols.

As the smart textile industry continues to evolve, standardization and quality control measures must adapt to new technologies and applications. This may involve developing new test methods, updating existing standards, and incorporating emerging best practices to address the unique challenges posed by advanced silicone rubber-based smart textiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!