The Use of Laminar Flow in Modern Medical Facilities

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Evolution and Objectives

Laminar flow technology has evolved significantly since its inception in the early 20th century. Initially developed for industrial applications, it has found a crucial role in modern medical facilities. The primary objective of laminar flow in healthcare settings is to create a controlled environment that minimizes the risk of airborne contamination, thereby enhancing patient safety and improving medical outcomes.

The evolution of laminar flow in medical facilities can be traced back to the 1960s when it was first introduced in operating rooms. Since then, the technology has undergone continuous refinement, driven by advancements in fluid dynamics, materials science, and infection control practices. The development of high-efficiency particulate air (HEPA) filters in the 1940s played a pivotal role in enhancing the effectiveness of laminar flow systems, allowing for the removal of particles as small as 0.3 microns with 99.97% efficiency.

In recent years, the objectives of laminar flow technology in medical facilities have expanded beyond surgical suites to include cleanrooms for pharmaceutical manufacturing, isolation rooms for infectious disease control, and specialized treatment areas for immunocompromised patients. The primary goals now encompass not only the reduction of surgical site infections but also the prevention of cross-contamination in various healthcare settings.

The current technological landscape aims to achieve more precise control over airflow patterns, temperature, and humidity levels. Advanced computational fluid dynamics (CFD) modeling has enabled designers to optimize laminar flow systems for specific room configurations and medical procedures. This has led to the development of hybrid systems that combine laminar and turbulent flow characteristics to maximize efficiency and effectiveness in different areas of medical facilities.

Looking forward, the objectives of laminar flow technology in healthcare are evolving to address emerging challenges. These include the need for energy-efficient systems that maintain stringent cleanliness standards while reducing operational costs. Additionally, there is a growing focus on creating flexible and adaptable laminar flow environments that can quickly respond to changing medical needs, such as during pandemic situations or for multi-purpose medical spaces.

The integration of smart technologies and IoT sensors into laminar flow systems represents another key objective. These advancements aim to provide real-time monitoring and adjustment of airflow parameters, ensuring optimal performance and early detection of potential system failures. Furthermore, research is ongoing to develop novel materials and designs that can enhance the efficacy of laminar flow while minimizing maintenance requirements and improving overall system longevity.

The evolution of laminar flow in medical facilities can be traced back to the 1960s when it was first introduced in operating rooms. Since then, the technology has undergone continuous refinement, driven by advancements in fluid dynamics, materials science, and infection control practices. The development of high-efficiency particulate air (HEPA) filters in the 1940s played a pivotal role in enhancing the effectiveness of laminar flow systems, allowing for the removal of particles as small as 0.3 microns with 99.97% efficiency.

In recent years, the objectives of laminar flow technology in medical facilities have expanded beyond surgical suites to include cleanrooms for pharmaceutical manufacturing, isolation rooms for infectious disease control, and specialized treatment areas for immunocompromised patients. The primary goals now encompass not only the reduction of surgical site infections but also the prevention of cross-contamination in various healthcare settings.

The current technological landscape aims to achieve more precise control over airflow patterns, temperature, and humidity levels. Advanced computational fluid dynamics (CFD) modeling has enabled designers to optimize laminar flow systems for specific room configurations and medical procedures. This has led to the development of hybrid systems that combine laminar and turbulent flow characteristics to maximize efficiency and effectiveness in different areas of medical facilities.

Looking forward, the objectives of laminar flow technology in healthcare are evolving to address emerging challenges. These include the need for energy-efficient systems that maintain stringent cleanliness standards while reducing operational costs. Additionally, there is a growing focus on creating flexible and adaptable laminar flow environments that can quickly respond to changing medical needs, such as during pandemic situations or for multi-purpose medical spaces.

The integration of smart technologies and IoT sensors into laminar flow systems represents another key objective. These advancements aim to provide real-time monitoring and adjustment of airflow parameters, ensuring optimal performance and early detection of potential system failures. Furthermore, research is ongoing to develop novel materials and designs that can enhance the efficacy of laminar flow while minimizing maintenance requirements and improving overall system longevity.

Healthcare Demand Analysis

The demand for laminar flow technology in modern medical facilities has been steadily increasing due to its crucial role in maintaining sterile environments and preventing healthcare-associated infections (HAIs). Hospitals, surgical centers, and pharmaceutical manufacturing facilities are the primary drivers of this growing market. The global healthcare-associated infection control market, which includes laminar flow systems, was valued at $29.53 billion in 2020 and is projected to reach $38.61 billion by 2027, with a compound annual growth rate (CAGR) of 3.9%.

Laminar flow systems are particularly essential in operating rooms, intensive care units, and isolation wards, where maintaining a sterile environment is critical for patient safety. The COVID-19 pandemic has further accelerated the adoption of advanced air purification and ventilation systems, including laminar flow technology, to reduce the risk of airborne transmission of pathogens.

In the pharmaceutical industry, the demand for laminar flow systems is driven by the need for contamination-free environments in drug manufacturing and research laboratories. The global pharmaceutical manufacturing market, which heavily relies on clean room technologies, is expected to grow at a CAGR of 11.34% from 2021 to 2028, indirectly boosting the demand for laminar flow systems.

Emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in healthcare infrastructure development, contributing significantly to the increasing demand for laminar flow technology. These regions are witnessing a surge in the construction of new hospitals and upgrading of existing facilities to meet international standards, driving the adoption of advanced clean room technologies.

The aging population in developed countries is another factor influencing the demand for laminar flow systems in healthcare facilities. As the elderly are more susceptible to infections, there is a growing emphasis on creating safer healthcare environments, particularly in long-term care facilities and specialized geriatric units.

Regulatory bodies worldwide are implementing stricter guidelines for infection control in healthcare settings, further propelling the adoption of laminar flow technology. For instance, the Joint Commission on Accreditation of Healthcare Organizations (JCAHO) in the United States has established stringent standards for air quality in healthcare facilities, encouraging hospitals to invest in advanced air purification systems.

The trend towards minimally invasive surgeries and the increasing number of outpatient procedures have also contributed to the demand for portable and modular laminar flow systems. These systems offer flexibility and cost-effectiveness for smaller healthcare facilities and specialized clinics, expanding the market for laminar flow technology beyond traditional hospital settings.

Laminar flow systems are particularly essential in operating rooms, intensive care units, and isolation wards, where maintaining a sterile environment is critical for patient safety. The COVID-19 pandemic has further accelerated the adoption of advanced air purification and ventilation systems, including laminar flow technology, to reduce the risk of airborne transmission of pathogens.

In the pharmaceutical industry, the demand for laminar flow systems is driven by the need for contamination-free environments in drug manufacturing and research laboratories. The global pharmaceutical manufacturing market, which heavily relies on clean room technologies, is expected to grow at a CAGR of 11.34% from 2021 to 2028, indirectly boosting the demand for laminar flow systems.

Emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in healthcare infrastructure development, contributing significantly to the increasing demand for laminar flow technology. These regions are witnessing a surge in the construction of new hospitals and upgrading of existing facilities to meet international standards, driving the adoption of advanced clean room technologies.

The aging population in developed countries is another factor influencing the demand for laminar flow systems in healthcare facilities. As the elderly are more susceptible to infections, there is a growing emphasis on creating safer healthcare environments, particularly in long-term care facilities and specialized geriatric units.

Regulatory bodies worldwide are implementing stricter guidelines for infection control in healthcare settings, further propelling the adoption of laminar flow technology. For instance, the Joint Commission on Accreditation of Healthcare Organizations (JCAHO) in the United States has established stringent standards for air quality in healthcare facilities, encouraging hospitals to invest in advanced air purification systems.

The trend towards minimally invasive surgeries and the increasing number of outpatient procedures have also contributed to the demand for portable and modular laminar flow systems. These systems offer flexibility and cost-effectiveness for smaller healthcare facilities and specialized clinics, expanding the market for laminar flow technology beyond traditional hospital settings.

Laminar Flow Tech Status

Laminar flow technology has become an integral part of modern medical facilities, playing a crucial role in maintaining sterile environments and preventing the spread of infections. The current state of laminar flow technology in healthcare settings is characterized by advanced systems that create unidirectional airflow patterns, effectively minimizing the movement of airborne contaminants.

In operating rooms, laminar flow systems are widely implemented to create ultra-clean environments. These systems typically consist of high-efficiency particulate air (HEPA) filters installed in the ceiling, which push filtered air downwards in a uniform pattern. This vertical laminar flow helps to sweep away airborne particles and microorganisms from the surgical site, significantly reducing the risk of surgical site infections.

The adoption of laminar flow technology extends beyond operating rooms to other critical areas within medical facilities. Clean rooms used for pharmaceutical manufacturing, laboratory research, and sterile compounding pharmacies also utilize laminar flow systems to maintain controlled environments. In these settings, horizontal laminar flow is often employed to protect sensitive processes and materials from contamination.

Recent advancements in laminar flow technology have focused on improving energy efficiency and system performance. Variable air volume (VAV) systems have been introduced to optimize airflow rates based on occupancy and activity levels, reducing energy consumption without compromising air quality. Additionally, computational fluid dynamics (CFD) modeling is increasingly used to design and validate laminar flow systems, ensuring optimal airflow patterns and identifying potential areas of turbulence or dead zones.

The integration of smart sensors and monitoring systems has enhanced the reliability and effectiveness of laminar flow technology in medical facilities. Real-time particle counting and pressure differential monitoring allow for continuous assessment of air quality and system performance. These systems can trigger alerts when parameters deviate from set standards, enabling prompt corrective actions to maintain the integrity of sterile environments.

Despite the widespread implementation of laminar flow technology, challenges remain in achieving consistent performance across diverse medical settings. Factors such as door openings, personnel movement, and equipment placement can disrupt laminar flow patterns, potentially compromising air quality. Ongoing research is focused on developing more resilient laminar flow systems that can adapt to these dynamic environments while maintaining their protective function.

As healthcare-associated infections continue to be a significant concern, the importance of laminar flow technology in medical facilities is expected to grow. Future developments are likely to focus on further enhancing energy efficiency, improving adaptability to different room configurations, and integrating with other infection control measures to create comprehensive sterile environments.

In operating rooms, laminar flow systems are widely implemented to create ultra-clean environments. These systems typically consist of high-efficiency particulate air (HEPA) filters installed in the ceiling, which push filtered air downwards in a uniform pattern. This vertical laminar flow helps to sweep away airborne particles and microorganisms from the surgical site, significantly reducing the risk of surgical site infections.

The adoption of laminar flow technology extends beyond operating rooms to other critical areas within medical facilities. Clean rooms used for pharmaceutical manufacturing, laboratory research, and sterile compounding pharmacies also utilize laminar flow systems to maintain controlled environments. In these settings, horizontal laminar flow is often employed to protect sensitive processes and materials from contamination.

Recent advancements in laminar flow technology have focused on improving energy efficiency and system performance. Variable air volume (VAV) systems have been introduced to optimize airflow rates based on occupancy and activity levels, reducing energy consumption without compromising air quality. Additionally, computational fluid dynamics (CFD) modeling is increasingly used to design and validate laminar flow systems, ensuring optimal airflow patterns and identifying potential areas of turbulence or dead zones.

The integration of smart sensors and monitoring systems has enhanced the reliability and effectiveness of laminar flow technology in medical facilities. Real-time particle counting and pressure differential monitoring allow for continuous assessment of air quality and system performance. These systems can trigger alerts when parameters deviate from set standards, enabling prompt corrective actions to maintain the integrity of sterile environments.

Despite the widespread implementation of laminar flow technology, challenges remain in achieving consistent performance across diverse medical settings. Factors such as door openings, personnel movement, and equipment placement can disrupt laminar flow patterns, potentially compromising air quality. Ongoing research is focused on developing more resilient laminar flow systems that can adapt to these dynamic environments while maintaining their protective function.

As healthcare-associated infections continue to be a significant concern, the importance of laminar flow technology in medical facilities is expected to grow. Future developments are likely to focus on further enhancing energy efficiency, improving adaptability to different room configurations, and integrating with other infection control measures to create comprehensive sterile environments.

Current Laminar Solutions

01 Laminar flow control in aircraft

Techniques for controlling laminar airflow over aircraft surfaces to reduce drag and improve fuel efficiency. This includes methods for maintaining laminar flow on wings, fuselage, and other aerodynamic surfaces through careful design and surface treatments.- Laminar flow control in aircraft: Techniques for controlling laminar airflow over aircraft surfaces to reduce drag and improve fuel efficiency. This includes design of wing surfaces, fuselage, and other aerodynamic components to maintain smooth airflow and delay transition to turbulent flow.

- Laminar flow in HVAC systems: Methods and devices for creating and maintaining laminar airflow in heating, ventilation, and air conditioning systems. This includes designs for air ducts, diffusers, and other components to ensure smooth, uniform air distribution and improved energy efficiency.

- Laminar flow in clean room environments: Systems and techniques for maintaining laminar airflow in clean room and controlled environments. This includes specialized air handling units, filtration systems, and room designs to minimize particulate contamination and ensure consistent air quality.

- Laminar flow in fluid measurement and control: Devices and methods utilizing laminar airflow for precise fluid measurement and control applications. This includes flow meters, sensors, and control valves that rely on laminar flow principles for accurate operation and reduced turbulence.

- Laminar flow in electronic cooling systems: Techniques for using laminar airflow to cool electronic components and systems. This includes designs for computer chassis, server racks, and other electronic enclosures that optimize airflow patterns to improve heat dissipation and thermal management.

02 Laminar flow in HVAC systems

Applications of laminar airflow in heating, ventilation, and air conditioning systems to improve air distribution, energy efficiency, and indoor air quality. This involves designing ducts, vents, and air handlers to promote smooth, non-turbulent airflow.Expand Specific Solutions03 Laminar flow in clean room environments

Utilization of laminar airflow in clean rooms and controlled environments to maintain particle-free conditions. This includes design of air filtration systems, flow patterns, and room layouts to ensure consistent, unidirectional airflow that minimizes contamination.Expand Specific Solutions04 Laminar flow in fluid handling equipment

Implementation of laminar flow principles in pumps, valves, and other fluid handling equipment to improve efficiency and reduce turbulence. This involves optimizing internal geometries and flow paths to maintain smooth, predictable fluid movement.Expand Specific Solutions05 Measurement and analysis of laminar airflow

Methods and devices for measuring, visualizing, and analyzing laminar airflow characteristics. This includes sensors, imaging techniques, and computational tools used to study and optimize laminar flow in various applications.Expand Specific Solutions

Medical Facility Innovators

The use of laminar flow in modern medical facilities is at a mature stage of development, with a growing market driven by increasing demand for sterile environments in healthcare settings. The global market size for laminar flow technologies in medical applications is estimated to be substantial, with steady growth projected. Companies like Koninklijke Philips NV, ResMed Pty Ltd., and St. Jude Medical are leading players, leveraging their expertise in medical device manufacturing to develop advanced laminar flow systems. Emerging players such as Nanoshell Co. LLC and Vascular Flow Technologies Ltd. are introducing innovative applications, particularly in drug delivery and vascular interventions. Research institutions like the University of Washington and Colorado School of Mines are contributing to technological advancements, ensuring continued evolution in this field.

Koninklijke Philips NV

Technical Solution: Philips has innovated in the field of laminar flow technology for medical facilities with their advanced air purification and flow management systems. Their solutions combine UV-C light disinfection with HEPA filtration to create ultra-clean environments. Philips' laminar flow systems are designed to create a protective air curtain around critical areas such as operating tables and patient beds. The company has developed intelligent control systems that adjust airflow patterns based on real-time air quality measurements and room occupancy[2]. Philips has also introduced portable laminar flow units for temporary clean zones in emergency situations or resource-limited settings. Their technology incorporates energy-efficient designs, reducing operational costs while maintaining high standards of air cleanliness[4].

Strengths: Versatile applications, energy-efficient designs, integration of multiple purification technologies. Weaknesses: Complexity of systems may require specialized training for staff.

ResMed Pty Ltd.

Technical Solution: ResMed has applied laminar flow principles to their respiratory care devices, particularly in the design of continuous positive airway pressure (CPAP) and bilevel positive airway pressure (BiPAP) machines. Their technology focuses on creating smooth, laminar airflow within the breathing circuits to reduce turbulence and improve patient comfort. ResMed's devices incorporate advanced flow sensors and algorithms to maintain consistent pressure and flow rates throughout the respiratory cycle. The company has also developed mask designs that utilize laminar flow principles to minimize air leaks and optimize therapy delivery. ResMed's research has shown that their laminar flow-based systems can significantly reduce respiratory events and improve sleep quality for patients with sleep apnea[7][8].

Strengths: Specialized application in respiratory care, patient-centric design approach. Weaknesses: Limited to specific medical applications, may not be directly applicable to broader facility-wide laminar flow systems.

Key Laminar Innovations

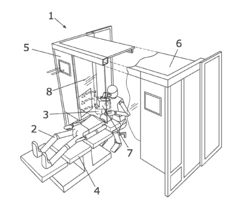

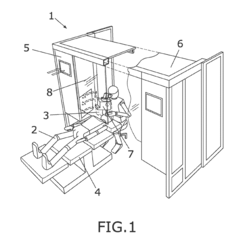

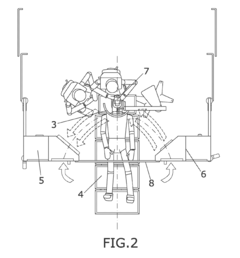

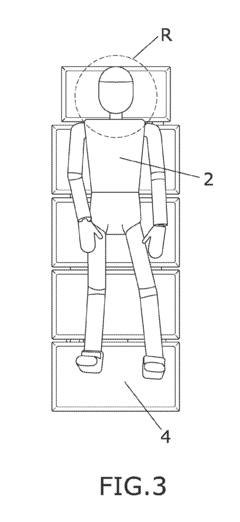

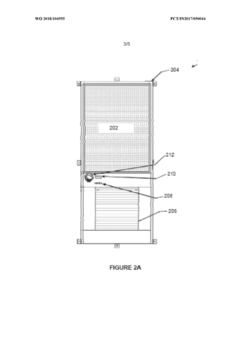

Laminar-flow operating theatre

PatentActiveUS20180250182A1

Innovation

- The operating theater incorporates an oblique laminar flow emitting unit and air absorption unit, with both units positioned at angles between 40° to 60°, creating a horizontal arc flow that avoids instruments and ensures particles do not migrate to the surgical region, while an optional casing with a porous surface further enhances particle containment.

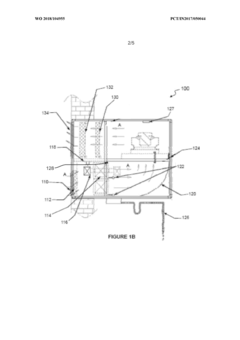

System for conditioning and sterilizing air

PatentWO2018104955A1

Innovation

- A ductless air conditioning and sterilization system that uses upward airflow, UV ozone-producing lamps, HEPA and microvee filters, and acoustic panels to provide 25 air changes per hour, reducing particulate matter count and maintaining optimal temperature and humidity, while minimizing biological loads and noise.

Regulatory Compliance

The implementation of laminar flow systems in modern medical facilities is subject to stringent regulatory requirements to ensure patient safety and maintain high standards of hygiene. In the United States, the Food and Drug Administration (FDA) and the Centers for Disease Control and Prevention (CDC) provide guidelines for the use of laminar flow in healthcare settings. These regulations typically focus on air quality, particle count, and microbial contamination levels in critical areas such as operating rooms and clean rooms.

The International Organization for Standardization (ISO) has established standards for cleanroom classifications, which are widely adopted in medical facilities utilizing laminar flow systems. ISO 14644 provides guidelines for cleanroom design, construction, and operation, including specifications for air filtration, pressure differentials, and monitoring protocols. Compliance with these standards is often mandatory for medical facilities to obtain and maintain accreditation.

In the European Union, the European Medicines Agency (EMA) and national health authorities enforce regulations related to laminar flow in medical environments. These regulations are aligned with Good Manufacturing Practice (GMP) guidelines, which specify requirements for air quality, particulate matter control, and microbial contamination prevention in pharmaceutical and medical device production areas.

Regulatory bodies also mandate regular testing and validation of laminar flow systems to ensure ongoing compliance. This includes periodic particle counting, airflow velocity measurements, and microbial sampling. Documentation of these tests and any corrective actions taken is crucial for regulatory audits and inspections.

Facility managers and healthcare administrators must stay informed about evolving regulations and guidelines related to laminar flow systems. This includes understanding the specific requirements for different types of medical procedures and environments, such as oncology units, transplant wards, and sterile compounding areas in pharmacies.

Compliance with regulatory standards often necessitates significant investment in infrastructure and training. Medical facilities must ensure that staff are properly trained in the operation and maintenance of laminar flow systems, as well as in the protocols for working in controlled environments. This includes proper gowning procedures, aseptic techniques, and understanding the principles of laminar airflow.

Failure to comply with regulatory standards can result in severe consequences, including fines, loss of accreditation, and potential closure of facilities. Therefore, healthcare institutions often employ specialized compliance officers or consultants to oversee the implementation and maintenance of laminar flow systems in accordance with regulatory requirements.

As medical technologies advance and our understanding of infection control improves, regulatory standards for laminar flow systems continue to evolve. Healthcare facilities must remain vigilant and adaptable to ensure ongoing compliance and maintain the highest standards of patient care and safety.

The International Organization for Standardization (ISO) has established standards for cleanroom classifications, which are widely adopted in medical facilities utilizing laminar flow systems. ISO 14644 provides guidelines for cleanroom design, construction, and operation, including specifications for air filtration, pressure differentials, and monitoring protocols. Compliance with these standards is often mandatory for medical facilities to obtain and maintain accreditation.

In the European Union, the European Medicines Agency (EMA) and national health authorities enforce regulations related to laminar flow in medical environments. These regulations are aligned with Good Manufacturing Practice (GMP) guidelines, which specify requirements for air quality, particulate matter control, and microbial contamination prevention in pharmaceutical and medical device production areas.

Regulatory bodies also mandate regular testing and validation of laminar flow systems to ensure ongoing compliance. This includes periodic particle counting, airflow velocity measurements, and microbial sampling. Documentation of these tests and any corrective actions taken is crucial for regulatory audits and inspections.

Facility managers and healthcare administrators must stay informed about evolving regulations and guidelines related to laminar flow systems. This includes understanding the specific requirements for different types of medical procedures and environments, such as oncology units, transplant wards, and sterile compounding areas in pharmacies.

Compliance with regulatory standards often necessitates significant investment in infrastructure and training. Medical facilities must ensure that staff are properly trained in the operation and maintenance of laminar flow systems, as well as in the protocols for working in controlled environments. This includes proper gowning procedures, aseptic techniques, and understanding the principles of laminar airflow.

Failure to comply with regulatory standards can result in severe consequences, including fines, loss of accreditation, and potential closure of facilities. Therefore, healthcare institutions often employ specialized compliance officers or consultants to oversee the implementation and maintenance of laminar flow systems in accordance with regulatory requirements.

As medical technologies advance and our understanding of infection control improves, regulatory standards for laminar flow systems continue to evolve. Healthcare facilities must remain vigilant and adaptable to ensure ongoing compliance and maintain the highest standards of patient care and safety.

Energy Efficiency Impact

The implementation of laminar flow systems in modern medical facilities has a significant impact on energy efficiency. These systems, designed to create a controlled airflow environment, contribute to both improved patient care and reduced energy consumption. By maintaining a unidirectional airflow pattern, laminar flow systems minimize air turbulence and reduce the spread of airborne contaminants, which is crucial in healthcare settings.

One of the primary energy efficiency benefits of laminar flow systems is their ability to optimize air circulation and filtration. Unlike traditional HVAC systems that rely on large volumes of air exchange, laminar flow systems can achieve the same level of air quality with lower air change rates. This reduction in air volume translates directly to energy savings, as less air needs to be conditioned, moved, and filtered.

The precise control of air distribution in laminar flow systems also allows for more targeted cooling or heating of specific areas within medical facilities. This zonal approach to temperature management reduces the energy required to maintain comfortable conditions throughout the entire facility. By focusing on critical areas such as operating rooms or isolation units, healthcare providers can allocate energy resources more efficiently.

Furthermore, the integration of advanced sensors and control systems in modern laminar flow installations enhances their energy efficiency. These smart systems can adjust airflow rates and filtration levels based on real-time occupancy and contamination data, ensuring that energy is not wasted on unnecessary air processing during periods of low activity or in unoccupied spaces.

The use of high-efficiency particulate air (HEPA) filters in laminar flow systems, while initially more energy-intensive, can lead to long-term energy savings. These filters, although requiring more power to push air through their dense media, provide superior air quality that reduces the need for frequent air changes. This balance between filtration efficiency and energy consumption is crucial for optimizing overall system performance.

Additionally, the implementation of laminar flow systems often coincides with improvements in building envelope design and insulation. The controlled environment created by these systems is most effective when external influences are minimized, leading to better-sealed and insulated medical facilities. This synergy between laminar flow technology and building design contributes to overall energy efficiency by reducing heat transfer and air leakage.

In conclusion, the adoption of laminar flow systems in modern medical facilities offers a dual benefit of enhanced infection control and improved energy efficiency. As healthcare providers increasingly prioritize sustainability alongside patient care, the role of laminar flow technology in achieving these goals becomes increasingly significant.

One of the primary energy efficiency benefits of laminar flow systems is their ability to optimize air circulation and filtration. Unlike traditional HVAC systems that rely on large volumes of air exchange, laminar flow systems can achieve the same level of air quality with lower air change rates. This reduction in air volume translates directly to energy savings, as less air needs to be conditioned, moved, and filtered.

The precise control of air distribution in laminar flow systems also allows for more targeted cooling or heating of specific areas within medical facilities. This zonal approach to temperature management reduces the energy required to maintain comfortable conditions throughout the entire facility. By focusing on critical areas such as operating rooms or isolation units, healthcare providers can allocate energy resources more efficiently.

Furthermore, the integration of advanced sensors and control systems in modern laminar flow installations enhances their energy efficiency. These smart systems can adjust airflow rates and filtration levels based on real-time occupancy and contamination data, ensuring that energy is not wasted on unnecessary air processing during periods of low activity or in unoccupied spaces.

The use of high-efficiency particulate air (HEPA) filters in laminar flow systems, while initially more energy-intensive, can lead to long-term energy savings. These filters, although requiring more power to push air through their dense media, provide superior air quality that reduces the need for frequent air changes. This balance between filtration efficiency and energy consumption is crucial for optimizing overall system performance.

Additionally, the implementation of laminar flow systems often coincides with improvements in building envelope design and insulation. The controlled environment created by these systems is most effective when external influences are minimized, leading to better-sealed and insulated medical facilities. This synergy between laminar flow technology and building design contributes to overall energy efficiency by reducing heat transfer and air leakage.

In conclusion, the adoption of laminar flow systems in modern medical facilities offers a dual benefit of enhanced infection control and improved energy efficiency. As healthcare providers increasingly prioritize sustainability alongside patient care, the role of laminar flow technology in achieving these goals becomes increasingly significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!