Understanding K24 Engine Dynamics in Competitive Motorsport

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, originally developed by Honda, has undergone significant evolution since its inception in the early 2000s. This four-cylinder powerplant has become a staple in competitive motorsport, particularly in touring car and endurance racing categories. Its journey from a stock engine to a high-performance racing unit exemplifies the continuous innovation in automotive engineering.

Initially designed for road-going vehicles, the K24 engine quickly caught the attention of racing teams due to its robust design and tuning potential. The early versions, such as those found in the Honda Accord and CR-V, provided a solid foundation for further development. As motorsport engineers began to explore its capabilities, the K24 underwent a series of modifications to enhance its performance characteristics.

One of the key evolutionary steps was the improvement of the engine's breathing capabilities. This involved redesigning the cylinder head to accommodate larger valves and more aggressive camshaft profiles. The intake and exhaust ports were also reshaped to optimize flow, allowing for increased air and fuel mixture into the combustion chambers and more efficient exhaust gas evacuation.

The bottom end of the engine saw substantial reinforcement to withstand the higher stresses of racing conditions. Forged pistons, stronger connecting rods, and a balanced crankshaft became standard modifications. These upgrades allowed for higher revs and increased power output while maintaining reliability under extreme conditions.

Fuel delivery systems evolved from port injection to direct injection in later iterations, providing more precise fuel metering and improved combustion efficiency. This change not only increased power output but also enhanced fuel economy, a critical factor in endurance racing scenarios.

Turbocharging became a significant part of the K24's evolution in motorsport applications. The addition of forced induction systems dramatically increased the engine's power potential, with some racing variants producing over 500 horsepower. This required further modifications to the engine's internals and cooling systems to handle the increased thermal and mechanical loads.

Electronic engine management systems played a crucial role in the K24's development. Advanced ECUs allowed for more precise control over fuel injection, ignition timing, and boost pressure in turbocharged applications. This level of control enabled teams to fine-tune engine performance for specific racing conditions and regulations.

The K24's evolution also saw advancements in materials technology. Lightweight alloys and composite materials were increasingly used for engine components, reducing overall weight while maintaining or improving strength. This weight reduction contributed to better power-to-weight ratios and improved vehicle dynamics on the track.

Throughout its evolution, the K24 engine has demonstrated remarkable adaptability to various racing formats and regulations. Its continued presence in competitive motorsport is a testament to its robust design and the ongoing efforts of engineers to extract maximum performance from this versatile powerplant.

Initially designed for road-going vehicles, the K24 engine quickly caught the attention of racing teams due to its robust design and tuning potential. The early versions, such as those found in the Honda Accord and CR-V, provided a solid foundation for further development. As motorsport engineers began to explore its capabilities, the K24 underwent a series of modifications to enhance its performance characteristics.

One of the key evolutionary steps was the improvement of the engine's breathing capabilities. This involved redesigning the cylinder head to accommodate larger valves and more aggressive camshaft profiles. The intake and exhaust ports were also reshaped to optimize flow, allowing for increased air and fuel mixture into the combustion chambers and more efficient exhaust gas evacuation.

The bottom end of the engine saw substantial reinforcement to withstand the higher stresses of racing conditions. Forged pistons, stronger connecting rods, and a balanced crankshaft became standard modifications. These upgrades allowed for higher revs and increased power output while maintaining reliability under extreme conditions.

Fuel delivery systems evolved from port injection to direct injection in later iterations, providing more precise fuel metering and improved combustion efficiency. This change not only increased power output but also enhanced fuel economy, a critical factor in endurance racing scenarios.

Turbocharging became a significant part of the K24's evolution in motorsport applications. The addition of forced induction systems dramatically increased the engine's power potential, with some racing variants producing over 500 horsepower. This required further modifications to the engine's internals and cooling systems to handle the increased thermal and mechanical loads.

Electronic engine management systems played a crucial role in the K24's development. Advanced ECUs allowed for more precise control over fuel injection, ignition timing, and boost pressure in turbocharged applications. This level of control enabled teams to fine-tune engine performance for specific racing conditions and regulations.

The K24's evolution also saw advancements in materials technology. Lightweight alloys and composite materials were increasingly used for engine components, reducing overall weight while maintaining or improving strength. This weight reduction contributed to better power-to-weight ratios and improved vehicle dynamics on the track.

Throughout its evolution, the K24 engine has demonstrated remarkable adaptability to various racing formats and regulations. Its continued presence in competitive motorsport is a testament to its robust design and the ongoing efforts of engineers to extract maximum performance from this versatile powerplant.

Motorsport Market Demand

The motorsport industry has experienced significant growth in recent years, driven by increasing global interest in competitive racing events and technological advancements in vehicle performance. The market demand for high-performance engines, particularly the K24 engine, has surged due to its versatility and potential for modification in competitive motorsport applications.

The global motorsport market size was valued at approximately $5 billion in 2020, with projections indicating a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth is largely attributed to the rising popularity of motorsport events, increased sponsorship investments, and technological innovations in racing vehicles.

Within this expanding market, the demand for K24 engines has shown remarkable growth. Originally designed for Honda's passenger vehicles, the K24 engine has gained significant traction in the motorsport sector due to its robust design, reliability, and potential for performance enhancements. The aftermarket for K24 engine parts and modifications has experienced double-digit growth rates in recent years, reflecting the increasing adoption of this engine in various racing categories.

The demand for K24 engines in motorsport is driven by several factors. Firstly, the engine's versatility allows it to be adapted for different racing disciplines, from circuit racing to drag racing and even off-road competitions. This adaptability has expanded its market reach across various motorsport segments.

Secondly, the K24 engine's relatively compact size and lightweight design make it an attractive option for teams looking to optimize vehicle weight distribution and overall performance. This has led to increased demand from both professional racing teams and amateur enthusiasts seeking competitive advantages.

Furthermore, the availability of aftermarket parts and tuning expertise for the K24 engine has created a thriving ecosystem of suppliers, tuners, and performance shops. This ecosystem has not only fueled demand but also contributed to ongoing innovation and performance improvements in K24-based racing engines.

The market demand for K24 engines in motorsport is also influenced by regulatory changes in various racing series. As governing bodies implement stricter emissions and fuel efficiency standards, the K24 engine's potential for balancing performance with environmental considerations has become increasingly attractive to teams and manufacturers.

Looking ahead, the demand for K24 engines in competitive motorsport is expected to continue its upward trajectory. Emerging trends such as electric and hybrid powertrains may impact the traditional combustion engine market, but the K24's established presence and ongoing development are likely to sustain its demand in the near to medium term.

The global motorsport market size was valued at approximately $5 billion in 2020, with projections indicating a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth is largely attributed to the rising popularity of motorsport events, increased sponsorship investments, and technological innovations in racing vehicles.

Within this expanding market, the demand for K24 engines has shown remarkable growth. Originally designed for Honda's passenger vehicles, the K24 engine has gained significant traction in the motorsport sector due to its robust design, reliability, and potential for performance enhancements. The aftermarket for K24 engine parts and modifications has experienced double-digit growth rates in recent years, reflecting the increasing adoption of this engine in various racing categories.

The demand for K24 engines in motorsport is driven by several factors. Firstly, the engine's versatility allows it to be adapted for different racing disciplines, from circuit racing to drag racing and even off-road competitions. This adaptability has expanded its market reach across various motorsport segments.

Secondly, the K24 engine's relatively compact size and lightweight design make it an attractive option for teams looking to optimize vehicle weight distribution and overall performance. This has led to increased demand from both professional racing teams and amateur enthusiasts seeking competitive advantages.

Furthermore, the availability of aftermarket parts and tuning expertise for the K24 engine has created a thriving ecosystem of suppliers, tuners, and performance shops. This ecosystem has not only fueled demand but also contributed to ongoing innovation and performance improvements in K24-based racing engines.

The market demand for K24 engines in motorsport is also influenced by regulatory changes in various racing series. As governing bodies implement stricter emissions and fuel efficiency standards, the K24 engine's potential for balancing performance with environmental considerations has become increasingly attractive to teams and manufacturers.

Looking ahead, the demand for K24 engines in competitive motorsport is expected to continue its upward trajectory. Emerging trends such as electric and hybrid powertrains may impact the traditional combustion engine market, but the K24's established presence and ongoing development are likely to sustain its demand in the near to medium term.

K24 Performance Limits

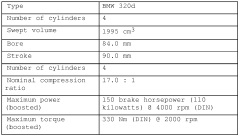

The K24 engine, renowned for its robust design and versatility, has become a popular choice in competitive motorsport. However, like all engines, it has inherent performance limitations that must be understood and addressed to maximize its potential on the track.

One of the primary constraints of the K24 engine is its stock redline, typically around 7,000 to 7,500 RPM. While this is respectable for a production engine, it falls short of the high-revving capabilities desired in many racing applications. Pushing beyond this limit without proper modifications can lead to valve float, reduced power output, and potential engine damage.

The stock internals of the K24 engine, while durable for street use, become a limiting factor when pursuing high-performance goals. The connecting rods, pistons, and crankshaft are not designed to withstand the extreme forces generated by significant power increases or sustained high-RPM operation. This necessitates upgrading these components when aiming for substantial power gains or extended high-speed racing.

Thermal management presents another challenge, particularly in endurance racing scenarios. The K24's cooling system, adequate for street use, may struggle to dissipate heat effectively under prolonged high-load conditions. This can lead to reduced power output and increased risk of engine failure if not addressed through enhanced cooling solutions.

The stock fuel system of the K24 engine becomes a bottleneck when pursuing significant power increases. The fuel injectors and pump are sized for stock power levels and cannot supply sufficient fuel for heavily modified engines. This limitation necessitates upgrades to the entire fuel delivery system to support higher power outputs.

Oil control and lubrication also become critical factors at the upper limits of the K24's performance envelope. The stock oil pan and pump may not provide adequate oil pressure or scavenging under high G-forces experienced in racing conditions, potentially leading to oil starvation and engine damage.

Lastly, the K24's stock engine management system imposes limitations on tuning flexibility. While capable for stock applications, it may not offer the fine control and adjustability required for optimizing performance in highly modified racing engines. This often necessitates the use of aftermarket engine management systems to fully exploit the engine's potential.

Understanding these performance limits is crucial for teams and engineers working with K24 engines in competitive motorsport. By addressing these constraints through careful modification and tuning, it's possible to significantly extend the K24's performance envelope while maintaining reliability in the demanding world of racing.

One of the primary constraints of the K24 engine is its stock redline, typically around 7,000 to 7,500 RPM. While this is respectable for a production engine, it falls short of the high-revving capabilities desired in many racing applications. Pushing beyond this limit without proper modifications can lead to valve float, reduced power output, and potential engine damage.

The stock internals of the K24 engine, while durable for street use, become a limiting factor when pursuing high-performance goals. The connecting rods, pistons, and crankshaft are not designed to withstand the extreme forces generated by significant power increases or sustained high-RPM operation. This necessitates upgrading these components when aiming for substantial power gains or extended high-speed racing.

Thermal management presents another challenge, particularly in endurance racing scenarios. The K24's cooling system, adequate for street use, may struggle to dissipate heat effectively under prolonged high-load conditions. This can lead to reduced power output and increased risk of engine failure if not addressed through enhanced cooling solutions.

The stock fuel system of the K24 engine becomes a bottleneck when pursuing significant power increases. The fuel injectors and pump are sized for stock power levels and cannot supply sufficient fuel for heavily modified engines. This limitation necessitates upgrades to the entire fuel delivery system to support higher power outputs.

Oil control and lubrication also become critical factors at the upper limits of the K24's performance envelope. The stock oil pan and pump may not provide adequate oil pressure or scavenging under high G-forces experienced in racing conditions, potentially leading to oil starvation and engine damage.

Lastly, the K24's stock engine management system imposes limitations on tuning flexibility. While capable for stock applications, it may not offer the fine control and adjustability required for optimizing performance in highly modified racing engines. This often necessitates the use of aftermarket engine management systems to fully exploit the engine's potential.

Understanding these performance limits is crucial for teams and engineers working with K24 engines in competitive motorsport. By addressing these constraints through careful modification and tuning, it's possible to significantly extend the K24's performance envelope while maintaining reliability in the demanding world of racing.

Current K24 Tuning

01 Engine performance optimization

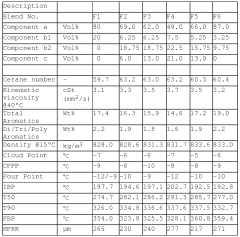

Various methods and systems are employed to optimize the performance of K24 engines. This includes improving combustion efficiency, enhancing fuel injection systems, and implementing advanced control strategies to balance power output with fuel economy. These optimizations aim to increase engine power, reduce emissions, and improve overall engine dynamics.- Engine dynamics analysis and control: Advanced techniques for analyzing and controlling engine dynamics in K24 engines, including methods for optimizing performance, reducing vibrations, and improving overall efficiency. This involves sophisticated monitoring systems, adaptive control algorithms, and real-time adjustments to engine parameters based on operating conditions.

- Combustion optimization in K24 engines: Innovative approaches to optimize the combustion process in K24 engines, focusing on fuel injection timing, air-fuel mixture control, and exhaust gas recirculation. These methods aim to enhance power output, reduce emissions, and improve fuel efficiency through precise management of the combustion cycle.

- Thermal management and cooling systems: Advanced thermal management strategies for K24 engines, including innovative cooling systems and heat dissipation techniques. These solutions aim to maintain optimal operating temperatures, prevent overheating, and improve overall engine performance and longevity.

- Valve timing and lift control: Sophisticated valve timing and lift control mechanisms for K24 engines, including variable valve timing (VVT) and variable valve lift (VVL) systems. These technologies allow for dynamic adjustment of valve operation to optimize engine performance across different operating conditions and load ranges.

- Engine monitoring and diagnostics: Advanced monitoring and diagnostic systems for K24 engines, incorporating sensors, data analysis algorithms, and predictive maintenance techniques. These systems provide real-time information on engine performance, detect potential issues before they become critical, and facilitate proactive maintenance to ensure optimal engine operation.

02 Vibration and noise reduction

Techniques are developed to minimize vibration and noise in K24 engines. This involves designing improved engine mounts, implementing active noise cancellation systems, and optimizing the engine's internal components to reduce mechanical noise. These measures enhance the engine's smoothness and overall driving experience.Expand Specific Solutions03 Thermal management and cooling systems

Advanced thermal management and cooling systems are crucial for maintaining optimal K24 engine performance. This includes developing efficient coolant circulation systems, implementing advanced heat exchangers, and utilizing thermal sensors for precise temperature control. These innovations help prevent overheating and ensure consistent engine performance under various operating conditions.Expand Specific Solutions04 Engine control and diagnostics

Sophisticated engine control units (ECUs) and diagnostic systems are developed for K24 engines. These systems monitor various engine parameters in real-time, adjust operating conditions for optimal performance, and provide detailed diagnostics for maintenance and troubleshooting. Advanced algorithms and sensors are used to ensure precise control and early detection of potential issues.Expand Specific Solutions05 Emissions reduction and fuel efficiency

Technologies are implemented to reduce emissions and improve fuel efficiency in K24 engines. This includes developing advanced catalytic converters, optimizing fuel injection timing, and implementing start-stop systems. These innovations help meet stringent emissions standards while maintaining or improving engine performance and fuel economy.Expand Specific Solutions

Key Motorsport Players

The competitive landscape for understanding K24 engine dynamics in motorsport is characterized by a mature market with significant technological advancements. Major players like GM Global Technology Operations, Honda Motor Co., and Toyota Motor Corp. are at the forefront of engine development. The market size is substantial, driven by the high-performance demands of competitive racing. Technological maturity is evident, with companies like BorgWarner and Robert Bosch GmbH contributing advanced solutions. Academic institutions such as Jilin University and Beijing Institute of Technology are also actively involved in research, indicating a strong focus on innovation and continuous improvement in this field.

GM Global Technology Operations LLC

Technical Solution: GM's approach to understanding K24 engine dynamics in competitive motorsport involves advanced simulation and testing techniques. They utilize high-fidelity computational fluid dynamics (CFD) models to analyze combustion processes and optimize fuel efficiency[1]. GM has developed a proprietary engine management system that continuously adjusts parameters such as fuel injection timing and valve timing based on real-time data from multiple sensors[3]. This system allows for precise control of engine performance under varying race conditions. Additionally, GM employs advanced materials such as ceramic coatings on critical engine components to reduce friction and improve heat management, contributing to enhanced durability and power output in high-stress racing environments[5].

Strengths: Comprehensive simulation capabilities, real-time adaptive engine management, and advanced materials technology. Weaknesses: Potentially higher development costs and complexity in implementation compared to simpler systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's approach to K24 engine dynamics in motorsport focuses on innovative turbocharging and intercooling systems. They have developed a twin-scroll turbocharger design that significantly reduces turbo lag and improves low-end torque[2]. Hyundai's engineers have also implemented an advanced intercooling system that utilizes a water-to-air heat exchanger, allowing for more efficient cooling of the intake charge[4]. This system maintains consistent power output even under prolonged high-load conditions typical in motorsport. Furthermore, Hyundai has integrated a sophisticated knock detection and mitigation system that allows the engine to operate safely at higher compression ratios, enhancing both power and efficiency[6].

Strengths: Efficient turbocharging, advanced cooling systems, and high-compression operation. Weaknesses: Potential reliability concerns with complex turbocharging systems in extreme racing conditions.

K24 Innovations

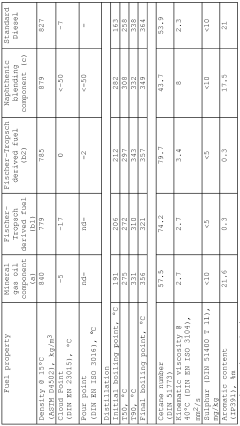

Diesel fuel compositions

PatentWO2007104709A1

Innovation

- A fuel composition with a cetane number of at least 62, kinematic viscosity greater than 3.0 cSt at 40°C, and a density above 830 kg/m³, incorporating a hydrocarbon blend of paraffinic, mineral-derived gas oil, and naphthenic components, along with additives like lubricity enhancers, to improve Wear Scar value and meet racing and consumer fuel standards.

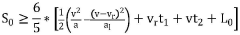

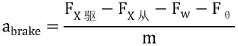

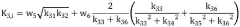

Intelligent driving and braking combination system based on commercial vehicle formation

PatentPendingCN117593898A

Innovation

- An intelligent driving and braking combination system based on commercial vehicle formation is designed, which adjusts the vehicle's driving force and braking deceleration through the vehicle information collection module, driving and braking index analysis module, driving and braking adjustment module and adjustment efficiency determination module. , ensuring safety when braking and energy saving when starting.

Regulatory Compliance

Regulatory compliance plays a crucial role in competitive motorsport, particularly when it comes to engine dynamics and performance. In the context of K24 engine dynamics, adherence to regulations is essential for ensuring fair competition and maintaining safety standards across various racing categories.

The regulatory landscape for K24 engines in motorsport is complex and varies depending on the specific racing series or event. Governing bodies such as the FIA (Fédération Internationale de l'Automobile) and national motorsport authorities establish and enforce these regulations. These rules typically cover aspects such as engine displacement, power output, fuel composition, and emissions standards.

One of the primary regulatory considerations for K24 engines is displacement limits. Many racing series impose strict restrictions on engine capacity to maintain competitive balance and control costs. Teams must carefully optimize their K24 engine designs to extract maximum performance within these displacement constraints, often leading to innovative engineering solutions.

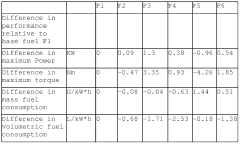

Power output regulations are another critical aspect of compliance. Governing bodies may mandate specific power-to-weight ratios or impose absolute power limits to ensure parity among competitors. This necessitates precise engine tuning and management strategies to achieve optimal performance while staying within regulatory boundaries.

Fuel regulations also significantly impact K24 engine dynamics in competitive motorsport. Rules may dictate the type of fuel allowed, its composition, and even the maximum fuel flow rate. These restrictions influence engine design, combustion efficiency, and overall performance characteristics. Teams must develop fuel strategies that balance power output with consumption to comply with regulations while maximizing race performance.

Emissions standards are becoming increasingly important in motorsport regulations, reflecting broader environmental concerns. Even in high-performance applications, K24 engines must meet specified emissions targets, which can impact engine design, tuning, and overall efficiency. This regulatory pressure drives innovation in areas such as exhaust gas treatment and combustion optimization.

Technical inspections and scrutineering processes are integral to ensuring regulatory compliance. Race officials conduct thorough examinations of engines, often using sophisticated measurement and analysis techniques to verify adherence to rules. This includes checks on engine seals, component weights, and performance parameters.

The dynamic nature of motorsport regulations requires teams to be adaptable and forward-thinking in their approach to K24 engine development. Rule changes can significantly impact engine design and performance strategies, necessitating ongoing research and development efforts to maintain competitiveness while ensuring compliance.

The regulatory landscape for K24 engines in motorsport is complex and varies depending on the specific racing series or event. Governing bodies such as the FIA (Fédération Internationale de l'Automobile) and national motorsport authorities establish and enforce these regulations. These rules typically cover aspects such as engine displacement, power output, fuel composition, and emissions standards.

One of the primary regulatory considerations for K24 engines is displacement limits. Many racing series impose strict restrictions on engine capacity to maintain competitive balance and control costs. Teams must carefully optimize their K24 engine designs to extract maximum performance within these displacement constraints, often leading to innovative engineering solutions.

Power output regulations are another critical aspect of compliance. Governing bodies may mandate specific power-to-weight ratios or impose absolute power limits to ensure parity among competitors. This necessitates precise engine tuning and management strategies to achieve optimal performance while staying within regulatory boundaries.

Fuel regulations also significantly impact K24 engine dynamics in competitive motorsport. Rules may dictate the type of fuel allowed, its composition, and even the maximum fuel flow rate. These restrictions influence engine design, combustion efficiency, and overall performance characteristics. Teams must develop fuel strategies that balance power output with consumption to comply with regulations while maximizing race performance.

Emissions standards are becoming increasingly important in motorsport regulations, reflecting broader environmental concerns. Even in high-performance applications, K24 engines must meet specified emissions targets, which can impact engine design, tuning, and overall efficiency. This regulatory pressure drives innovation in areas such as exhaust gas treatment and combustion optimization.

Technical inspections and scrutineering processes are integral to ensuring regulatory compliance. Race officials conduct thorough examinations of engines, often using sophisticated measurement and analysis techniques to verify adherence to rules. This includes checks on engine seals, component weights, and performance parameters.

The dynamic nature of motorsport regulations requires teams to be adaptable and forward-thinking in their approach to K24 engine development. Rule changes can significantly impact engine design and performance strategies, necessitating ongoing research and development efforts to maintain competitiveness while ensuring compliance.

Sustainability in Racing

Sustainability in racing has become a critical focus in competitive motorsport, particularly in the context of K24 engine dynamics. As the automotive industry shifts towards more environmentally friendly practices, racing organizations are increasingly prioritizing sustainable technologies and practices. This trend is driven by both regulatory pressures and a growing awareness of the environmental impact of motorsports.

In the realm of K24 engine dynamics, sustainability efforts are primarily focused on improving fuel efficiency and reducing emissions without compromising performance. Advanced engine management systems are being developed to optimize fuel consumption and minimize waste. These systems utilize sophisticated algorithms to fine-tune engine parameters in real-time, ensuring peak efficiency across various racing conditions.

Material science plays a crucial role in enhancing sustainability in K24 engines. Lightweight, durable materials are being incorporated into engine components, reducing overall weight and improving fuel economy. Additionally, the use of recycled and recyclable materials in engine construction is gaining traction, aligning with circular economy principles.

Alternative fuels are another key area of focus in sustainable racing. Biofuels and synthetic fuels are being tested and implemented in K24 engines, offering reduced carbon footprints compared to traditional fossil fuels. These alternative fuels often require modifications to engine design and tuning to maintain optimal performance while meeting sustainability goals.

Heat recovery systems are being integrated into K24 engine designs to capture and utilize waste heat, improving overall energy efficiency. Technologies such as thermoelectric generators and exhaust heat recovery systems are being explored to convert thermal energy into usable electrical power, further enhancing the sustainability profile of racing vehicles.

Longevity and repairability of K24 engines are also receiving increased attention in the context of sustainability. Designers are focusing on creating engines with modular components that can be easily replaced or upgraded, extending the lifespan of the engine and reducing waste. This approach not only supports sustainability goals but also offers potential cost benefits to racing teams.

As the motorsport industry continues to evolve, the integration of sustainable practices in K24 engine dynamics will likely accelerate. This shift presents both challenges and opportunities for engine designers, race teams, and governing bodies. Balancing the demands of high-performance racing with environmental responsibility will be crucial in shaping the future of competitive motorsport.

In the realm of K24 engine dynamics, sustainability efforts are primarily focused on improving fuel efficiency and reducing emissions without compromising performance. Advanced engine management systems are being developed to optimize fuel consumption and minimize waste. These systems utilize sophisticated algorithms to fine-tune engine parameters in real-time, ensuring peak efficiency across various racing conditions.

Material science plays a crucial role in enhancing sustainability in K24 engines. Lightweight, durable materials are being incorporated into engine components, reducing overall weight and improving fuel economy. Additionally, the use of recycled and recyclable materials in engine construction is gaining traction, aligning with circular economy principles.

Alternative fuels are another key area of focus in sustainable racing. Biofuels and synthetic fuels are being tested and implemented in K24 engines, offering reduced carbon footprints compared to traditional fossil fuels. These alternative fuels often require modifications to engine design and tuning to maintain optimal performance while meeting sustainability goals.

Heat recovery systems are being integrated into K24 engine designs to capture and utilize waste heat, improving overall energy efficiency. Technologies such as thermoelectric generators and exhaust heat recovery systems are being explored to convert thermal energy into usable electrical power, further enhancing the sustainability profile of racing vehicles.

Longevity and repairability of K24 engines are also receiving increased attention in the context of sustainability. Designers are focusing on creating engines with modular components that can be easily replaced or upgraded, extending the lifespan of the engine and reducing waste. This approach not only supports sustainability goals but also offers potential cost benefits to racing teams.

As the motorsport industry continues to evolve, the integration of sustainable practices in K24 engine dynamics will likely accelerate. This shift presents both challenges and opportunities for engine designers, race teams, and governing bodies. Balancing the demands of high-performance racing with environmental responsibility will be crucial in shaping the future of competitive motorsport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!