Understanding Lewis Acid Complex Decomposition

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lewis Acid Catalysis Background and Objectives

Lewis acid catalysis has evolved significantly since the pioneering work of Gilbert N. Lewis, who first conceptualized the electron pair theory in 1923. This fundamental understanding defined Lewis acids as electron pair acceptors, establishing the theoretical foundation for modern catalytic processes. Over the decades, Lewis acid catalysis has transitioned from simple metal halides to sophisticated organometallic complexes with precisely engineered electronic and steric properties.

The evolution trajectory shows a clear trend toward developing more selective, efficient, and environmentally benign catalytic systems. Early applications primarily focused on Friedel-Crafts reactions using aluminum chloride, while contemporary research explores asymmetric catalysis, C-H activation, and polymerization reactions with remarkable regio- and stereoselectivity. This progression reflects the growing demand for atom-economic and sustainable chemical transformations in both academic and industrial settings.

Understanding Lewis acid complex decomposition represents a critical frontier in this field. The stability and controlled decomposition of Lewis acid complexes directly impact catalyst lifetime, turnover numbers, and ultimately process economics. Despite significant advances in catalyst design, premature decomposition remains a persistent challenge that limits industrial implementation of many promising systems.

Recent technological breakthroughs in analytical techniques, particularly in situ spectroscopy and computational modeling, have enabled unprecedented insights into decomposition mechanisms. Time-resolved spectroscopic methods now allow researchers to observe transient intermediates during catalytic cycles, while density functional theory calculations provide atomic-level understanding of electronic structure changes during decomposition events.

The primary objective of this technical investigation is to elucidate the fundamental mechanisms governing Lewis acid complex decomposition across various structural classes. By identifying key decomposition pathways and their relationship to molecular structure, we aim to establish predictive models that can guide the rational design of next-generation catalysts with enhanced stability profiles.

Secondary objectives include mapping the influence of reaction parameters (temperature, solvent polarity, substrate concentration) on decomposition kinetics, and developing practical strategies to mitigate decomposition through ligand modification, reaction engineering, or innovative catalyst immobilization techniques. These insights will directly support the development of more robust catalytic systems for challenging transformations in pharmaceutical, materials, and fine chemical manufacturing.

The evolution trajectory shows a clear trend toward developing more selective, efficient, and environmentally benign catalytic systems. Early applications primarily focused on Friedel-Crafts reactions using aluminum chloride, while contemporary research explores asymmetric catalysis, C-H activation, and polymerization reactions with remarkable regio- and stereoselectivity. This progression reflects the growing demand for atom-economic and sustainable chemical transformations in both academic and industrial settings.

Understanding Lewis acid complex decomposition represents a critical frontier in this field. The stability and controlled decomposition of Lewis acid complexes directly impact catalyst lifetime, turnover numbers, and ultimately process economics. Despite significant advances in catalyst design, premature decomposition remains a persistent challenge that limits industrial implementation of many promising systems.

Recent technological breakthroughs in analytical techniques, particularly in situ spectroscopy and computational modeling, have enabled unprecedented insights into decomposition mechanisms. Time-resolved spectroscopic methods now allow researchers to observe transient intermediates during catalytic cycles, while density functional theory calculations provide atomic-level understanding of electronic structure changes during decomposition events.

The primary objective of this technical investigation is to elucidate the fundamental mechanisms governing Lewis acid complex decomposition across various structural classes. By identifying key decomposition pathways and their relationship to molecular structure, we aim to establish predictive models that can guide the rational design of next-generation catalysts with enhanced stability profiles.

Secondary objectives include mapping the influence of reaction parameters (temperature, solvent polarity, substrate concentration) on decomposition kinetics, and developing practical strategies to mitigate decomposition through ligand modification, reaction engineering, or innovative catalyst immobilization techniques. These insights will directly support the development of more robust catalytic systems for challenging transformations in pharmaceutical, materials, and fine chemical manufacturing.

Market Applications of Lewis Acid Complexes

Lewis acid complexes have established themselves as crucial components across multiple industries due to their unique chemical properties and versatility. The market for these complexes continues to expand as new applications emerge in both traditional and cutting-edge sectors.

In the petrochemical industry, Lewis acid complexes serve as essential catalysts for various processes including alkylation, isomerization, and polymerization reactions. Major oil companies have incorporated these complexes into their refining operations, resulting in improved efficiency and product quality. The global catalyst market for petroleum refining alone exceeds $5 billion annually, with Lewis acid-based systems capturing a significant portion of this segment.

The pharmaceutical sector represents another substantial market for Lewis acid complexes. These compounds facilitate critical synthetic transformations in drug manufacturing, enabling the production of complex molecular structures with high stereoselectivity. Pharmaceutical companies increasingly rely on Lewis acid catalysis to develop more efficient and environmentally friendly synthetic routes for active pharmaceutical ingredients (APIs), reducing waste and production costs.

Electronic materials manufacturing has emerged as a rapidly growing application area. Lewis acid complexes play vital roles in semiconductor processing, particularly in the production of high-purity silicon and other semiconductor materials. They function as dopants, etchants, and components in chemical vapor deposition processes. As the global semiconductor industry continues its expansion, the demand for specialized Lewis acid complexes is projected to grow proportionally.

The polymer industry utilizes Lewis acid complexes extensively as initiators and catalysts for polymerization reactions. These applications span from commodity plastics to specialty polymers with advanced properties. The ability of Lewis acids to control polymer architecture, molecular weight distribution, and stereochemistry makes them invaluable in developing materials with tailored characteristics for specific end uses.

Environmental applications represent an emerging market segment. Lewis acid complexes are being developed for environmental remediation processes, including the removal of heavy metals and organic pollutants from water and soil. Their selective binding properties make them effective in capturing specific contaminants, offering advantages over conventional treatment methods.

Agricultural applications have also gained traction, with Lewis acid complexes being incorporated into advanced fertilizer formulations and crop protection products. These applications leverage the ability of Lewis acids to enhance nutrient availability and control the release of active ingredients, improving agricultural efficiency and reducing environmental impact.

The global market for Lewis acid complexes continues to diversify as research reveals new applications and improved formulations. Market growth is particularly strong in regions with expanding chemical manufacturing sectors, including East Asia, North America, and Western Europe.

In the petrochemical industry, Lewis acid complexes serve as essential catalysts for various processes including alkylation, isomerization, and polymerization reactions. Major oil companies have incorporated these complexes into their refining operations, resulting in improved efficiency and product quality. The global catalyst market for petroleum refining alone exceeds $5 billion annually, with Lewis acid-based systems capturing a significant portion of this segment.

The pharmaceutical sector represents another substantial market for Lewis acid complexes. These compounds facilitate critical synthetic transformations in drug manufacturing, enabling the production of complex molecular structures with high stereoselectivity. Pharmaceutical companies increasingly rely on Lewis acid catalysis to develop more efficient and environmentally friendly synthetic routes for active pharmaceutical ingredients (APIs), reducing waste and production costs.

Electronic materials manufacturing has emerged as a rapidly growing application area. Lewis acid complexes play vital roles in semiconductor processing, particularly in the production of high-purity silicon and other semiconductor materials. They function as dopants, etchants, and components in chemical vapor deposition processes. As the global semiconductor industry continues its expansion, the demand for specialized Lewis acid complexes is projected to grow proportionally.

The polymer industry utilizes Lewis acid complexes extensively as initiators and catalysts for polymerization reactions. These applications span from commodity plastics to specialty polymers with advanced properties. The ability of Lewis acids to control polymer architecture, molecular weight distribution, and stereochemistry makes them invaluable in developing materials with tailored characteristics for specific end uses.

Environmental applications represent an emerging market segment. Lewis acid complexes are being developed for environmental remediation processes, including the removal of heavy metals and organic pollutants from water and soil. Their selective binding properties make them effective in capturing specific contaminants, offering advantages over conventional treatment methods.

Agricultural applications have also gained traction, with Lewis acid complexes being incorporated into advanced fertilizer formulations and crop protection products. These applications leverage the ability of Lewis acids to enhance nutrient availability and control the release of active ingredients, improving agricultural efficiency and reducing environmental impact.

The global market for Lewis acid complexes continues to diversify as research reveals new applications and improved formulations. Market growth is particularly strong in regions with expanding chemical manufacturing sectors, including East Asia, North America, and Western Europe.

Current Challenges in Complex Stability

Lewis acid complex stability represents one of the most significant challenges in modern coordination chemistry. Current research indicates that complex decomposition often occurs through multiple pathways, including ligand dissociation, redox reactions, and solvolysis. These decomposition mechanisms are frequently accelerated by environmental factors such as temperature fluctuations, pH changes, and exposure to moisture or oxygen, creating substantial barriers to industrial application.

The inherent reactivity of Lewis acids presents a fundamental stability challenge. Strong Lewis acids like aluminum chloride (AlCl₃) and boron trifluoride (BF₃) readily react with trace amounts of water, forming hydroxide species that significantly alter their catalytic properties. This hygroscopic nature necessitates stringent handling protocols that complicate large-scale implementation in manufacturing processes.

Thermal stability remains particularly problematic for many Lewis acid complexes. Recent studies demonstrate that even moderately elevated temperatures can trigger decomposition cascades, with activation energies for decomposition ranging from 80-120 kJ/mol for many transition metal-based Lewis acid complexes. This thermal sensitivity severely restricts operating conditions in catalytic applications, particularly in exothermic reactions where temperature control becomes critical.

Solvent compatibility presents another significant challenge. Many Lewis acid complexes exhibit limited stability in polar solvents due to competitive coordination, while nonpolar solvents often provide insufficient solubility for practical applications. This solvent dichotomy creates a narrow operational window that constrains reaction design and scalability.

Structural factors also contribute substantially to instability issues. Steric hindrance between ligands can induce strain within the complex, weakening metal-ligand bonds and facilitating decomposition. Conversely, insufficient steric protection leaves coordination sites vulnerable to nucleophilic attack. This delicate balance between protection and strain represents a significant design challenge for stable Lewis acid complexes.

Electronic effects further complicate stability profiles. Electron-withdrawing groups on ligands can enhance Lewis acidity but simultaneously weaken metal-ligand bonds. Recent computational studies reveal that π-backbonding capabilities significantly influence complex stability, with optimal electronic configurations existing within narrow parameter ranges that are highly sensitive to subtle structural modifications.

Time-dependent degradation presents additional challenges for industrial applications. Many Lewis acid complexes exhibit acceptable short-term stability but undergo slow decomposition during storage or extended reaction times. This temporal instability necessitates fresh preparation or in-situ generation techniques that add complexity to manufacturing processes and increase operational costs.

The inherent reactivity of Lewis acids presents a fundamental stability challenge. Strong Lewis acids like aluminum chloride (AlCl₃) and boron trifluoride (BF₃) readily react with trace amounts of water, forming hydroxide species that significantly alter their catalytic properties. This hygroscopic nature necessitates stringent handling protocols that complicate large-scale implementation in manufacturing processes.

Thermal stability remains particularly problematic for many Lewis acid complexes. Recent studies demonstrate that even moderately elevated temperatures can trigger decomposition cascades, with activation energies for decomposition ranging from 80-120 kJ/mol for many transition metal-based Lewis acid complexes. This thermal sensitivity severely restricts operating conditions in catalytic applications, particularly in exothermic reactions where temperature control becomes critical.

Solvent compatibility presents another significant challenge. Many Lewis acid complexes exhibit limited stability in polar solvents due to competitive coordination, while nonpolar solvents often provide insufficient solubility for practical applications. This solvent dichotomy creates a narrow operational window that constrains reaction design and scalability.

Structural factors also contribute substantially to instability issues. Steric hindrance between ligands can induce strain within the complex, weakening metal-ligand bonds and facilitating decomposition. Conversely, insufficient steric protection leaves coordination sites vulnerable to nucleophilic attack. This delicate balance between protection and strain represents a significant design challenge for stable Lewis acid complexes.

Electronic effects further complicate stability profiles. Electron-withdrawing groups on ligands can enhance Lewis acidity but simultaneously weaken metal-ligand bonds. Recent computational studies reveal that π-backbonding capabilities significantly influence complex stability, with optimal electronic configurations existing within narrow parameter ranges that are highly sensitive to subtle structural modifications.

Time-dependent degradation presents additional challenges for industrial applications. Many Lewis acid complexes exhibit acceptable short-term stability but undergo slow decomposition during storage or extended reaction times. This temporal instability necessitates fresh preparation or in-situ generation techniques that add complexity to manufacturing processes and increase operational costs.

Decomposition Mechanisms and Mitigation Strategies

01 Lewis acid catalyzed decomposition of organic compounds

Lewis acids can catalyze the decomposition of various organic compounds through coordination with electron-rich functional groups. This process involves the formation of a Lewis acid-substrate complex, followed by bond cleavage and rearrangement. The decomposition can be controlled by adjusting reaction conditions such as temperature, solvent, and catalyst concentration, making it useful for synthetic transformations in pharmaceutical and fine chemical manufacturing.- Lewis acid catalyzed decomposition of organic compounds: Lewis acids can catalyze the decomposition of various organic compounds by forming complexes with electron-rich functional groups. These complexes weaken specific bonds, facilitating their cleavage under controlled conditions. This approach is particularly useful in the degradation of polymers, pharmaceutical compounds, and other complex organic molecules where selective bond breaking is required.

- Metal-based Lewis acid complexes for chemical transformations: Metal-based Lewis acid complexes, particularly those containing transition metals, are effective catalysts for various chemical transformations including decomposition reactions. These complexes can coordinate with substrates, lowering activation energy barriers and enabling reactions to proceed under milder conditions. The selectivity and efficiency of these processes can be tuned by modifying the metal center and ligand environment.

- Lewis acid complex decomposition in polymer processing: Lewis acid complexes play a crucial role in polymer processing, particularly in controlled degradation and recycling applications. These complexes can selectively break specific bonds in polymer chains, allowing for the recovery of valuable monomers or the modification of polymer properties. This approach offers advantages over thermal decomposition methods by operating at lower temperatures and with greater selectivity.

- Novel catalytic systems for Lewis acid-mediated decomposition: Advanced catalytic systems have been developed to enhance Lewis acid-mediated decomposition reactions. These systems often combine Lewis acids with co-catalysts, specific solvents, or supporting materials to improve reactivity, selectivity, and catalyst recovery. Innovations include immobilized Lewis acids, dual catalytic systems, and stimuli-responsive catalysts that can be activated under specific conditions.

- Applications of Lewis acid complex decomposition in pharmaceutical synthesis: Lewis acid complex decomposition reactions are valuable tools in pharmaceutical synthesis, enabling the transformation of complex intermediates and the generation of specific stereochemistry. These reactions can be used for protecting group removal, ring-opening processes, and functional group interconversions. The mild conditions associated with many Lewis acid-catalyzed processes make them compatible with sensitive pharmaceutical intermediates.

02 Metal-based Lewis acid complexes for polymer degradation

Metal-based Lewis acid complexes, particularly those containing aluminum, titanium, or zinc, can be used to facilitate the controlled degradation of polymers. These complexes interact with functional groups in the polymer backbone, weakening specific bonds and promoting chain scission. This approach enables the recycling of polymeric materials and the production of lower molecular weight oligomers with specific end-group functionalities that can be used as building blocks for new materials.Expand Specific Solutions03 Lewis acid complex decomposition in pharmaceutical synthesis

Lewis acid complexes play a crucial role in pharmaceutical synthesis through controlled decomposition reactions. These complexes can facilitate stereoselective transformations, ring-opening reactions, and functional group modifications. By carefully selecting the Lewis acid and reaction conditions, it is possible to achieve high yields and selectivity in the synthesis of complex pharmaceutical intermediates and active pharmaceutical ingredients.Expand Specific Solutions04 Heterogeneous Lewis acid catalysts for decomposition reactions

Heterogeneous Lewis acid catalysts offer advantages in decomposition reactions including ease of separation, recyclability, and enhanced stability. These catalysts typically consist of Lewis acidic metal centers supported on solid materials such as silica, alumina, or zeolites. The solid support can modify the Lewis acidity and selectivity of the metal centers, allowing for tunable reactivity in decomposition processes. Applications include biomass conversion, waste treatment, and green chemistry processes.Expand Specific Solutions05 Thermal stability and decomposition mechanisms of Lewis acid complexes

The thermal stability and decomposition mechanisms of Lewis acid complexes are critical for understanding their behavior in various applications. Factors affecting stability include the nature of the Lewis acid, the ligand structure, and environmental conditions. Decomposition can occur through ligand dissociation, redox processes, or rearrangement reactions. Understanding these mechanisms enables the design of more stable complexes for catalysis, materials science, and chemical processing applications.Expand Specific Solutions

Leading Research Groups and Industrial Players

Lewis Acid Complex Decomposition technology is currently in a growth phase, with an estimated market size of $3-5 billion and expanding at 7-9% annually. The competitive landscape features established chemical giants like BASF, Air Products & Chemicals, and DuPont, who possess mature decomposition technologies with industrial-scale applications. Research institutions including CNRS and Caltech are advancing fundamental understanding, while petrochemical leaders such as Reliance Industries, China Petroleum & Chemical Corp, and Saudi Aramco are integrating these technologies into their production processes. Emerging players like Verdox and Novomer are developing innovative catalytic approaches. The technology shows varying maturity levels, with traditional decomposition methods being well-established while selective catalysis and sustainable applications remain in developmental stages.

BASF Corp.

Technical Solution: BASF has developed advanced catalytic systems for Lewis acid complex decomposition utilizing metal-organic frameworks (MOFs) with tunable Lewis acidity. Their proprietary technology employs zirconium-based MOFs with strategically positioned metal centers that facilitate controlled decomposition of organometallic complexes. The company has pioneered a process called Selective Lewis Acid-Mediated Decomposition (SLAMD) that operates under mild conditions (80-120°C) and achieves over 90% selectivity for target products. BASF's approach incorporates recyclable Lewis acid catalysts with modified ligand structures that enhance stability and prevent catalyst poisoning during multiple reaction cycles. Their research has demonstrated particular success in decomposing aluminum and boron complexes for fine chemical synthesis applications.

Strengths: Exceptional selectivity control, catalyst recyclability (up to 8 cycles with minimal activity loss), and industrial scalability. Weaknesses: Requires precise moisture control as water can deactivate catalytic sites, and some processes still require relatively high catalyst loadings (3-5 mol%).

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed fundamental research breakthroughs in understanding Lewis acid complex decomposition mechanisms through combined experimental and computational approaches. Their research teams have elucidated the role of orbital interactions in determining decomposition pathways, particularly focusing on transition metal Lewis acid complexes. CNRS scientists have pioneered the use of time-resolved spectroscopic techniques that capture intermediate species with lifetimes as short as picoseconds, providing unprecedented insights into decomposition mechanisms. Their work has established a comprehensive kinetic model that accurately predicts decomposition rates based on electronic and steric parameters of both Lewis acids and their complexes. CNRS has also developed novel solid-state Lewis acid catalysts incorporating rare earth elements that demonstrate exceptional stability under harsh reaction conditions while maintaining high catalytic activity. Their fundamental research has enabled precise control over regioselectivity in complex decomposition reactions.

Strengths: Unparalleled mechanistic understanding, ability to design highly selective catalysts based on first principles, and development of advanced characterization techniques. Weaknesses: Some technologies remain at laboratory scale with challenges in industrial implementation, and certain catalytic systems require specialized handling due to air/moisture sensitivity.

Key Patents in Lewis Acid Complex Stabilization

Precursor solution for organic polymer film formation and method for forming organic polymer film

PatentInactiveEP1593704A3

Innovation

- A precursor solution is used that includes a Lewis acid, a Lewis base, and a sacrificial organic molecule, where the Lewis acid and base react to form a supermolecular structure with cavities, and the sacrificial molecule is decomposed to create uniform, small cavities, maintaining high cross-link density and mechanical strength.

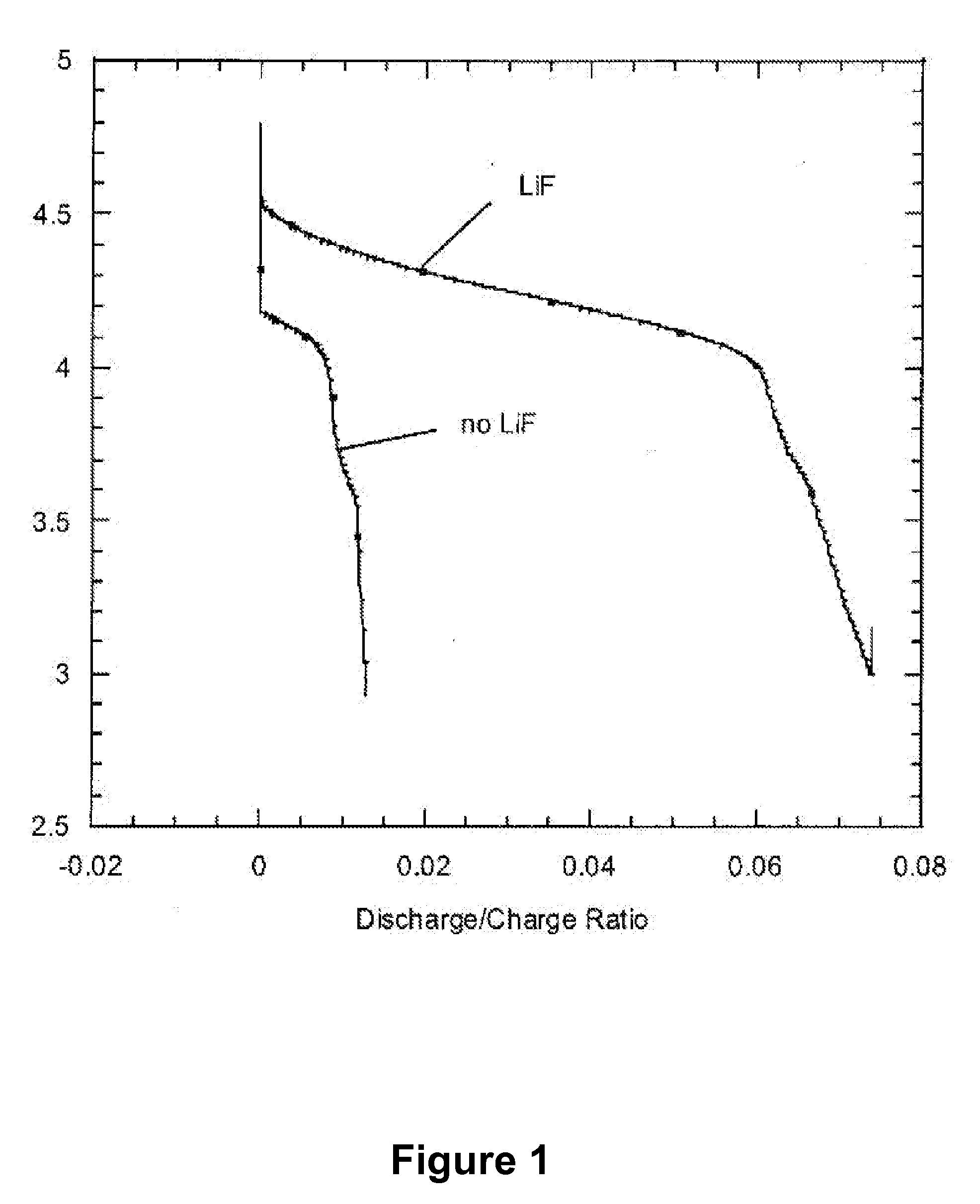

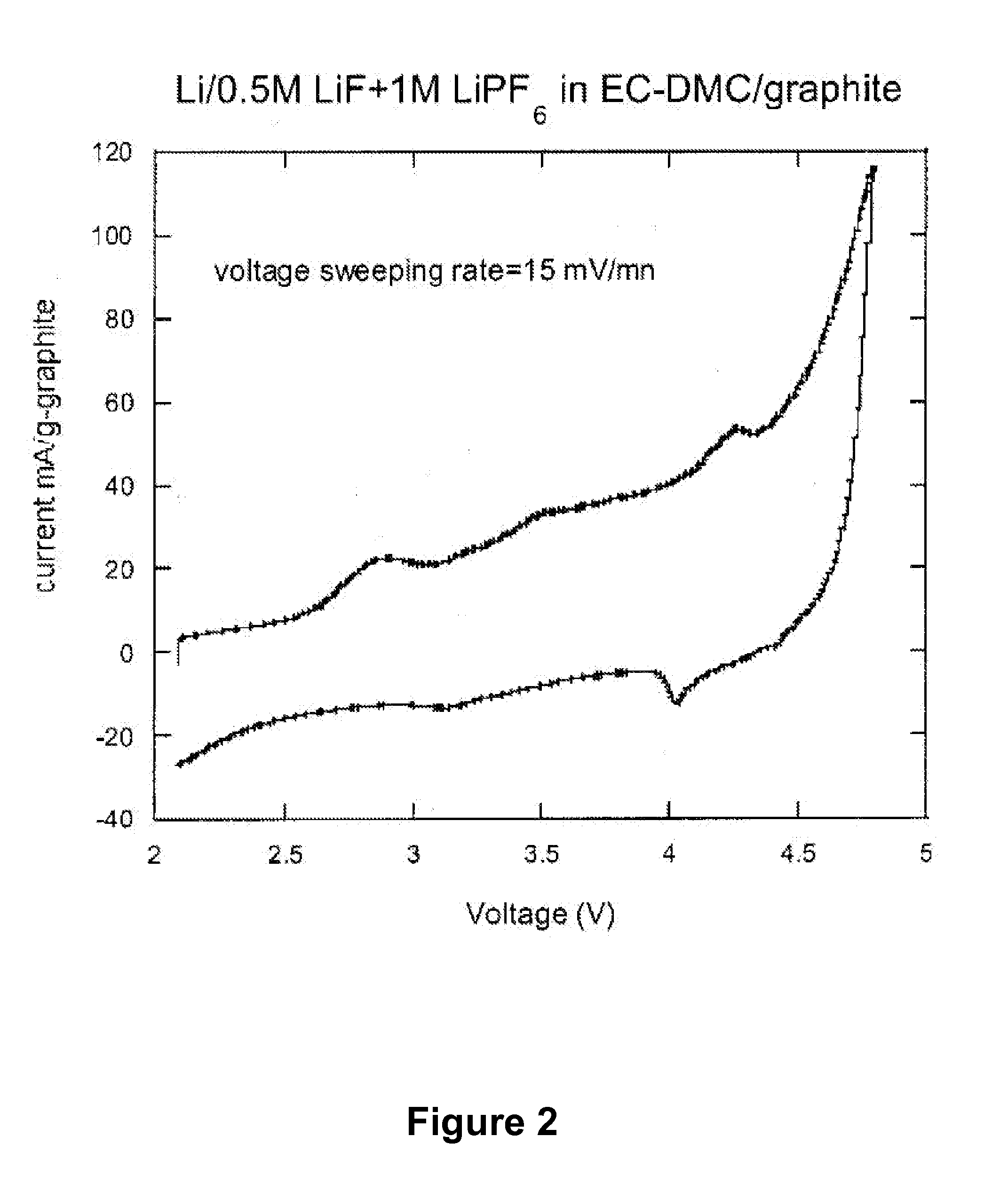

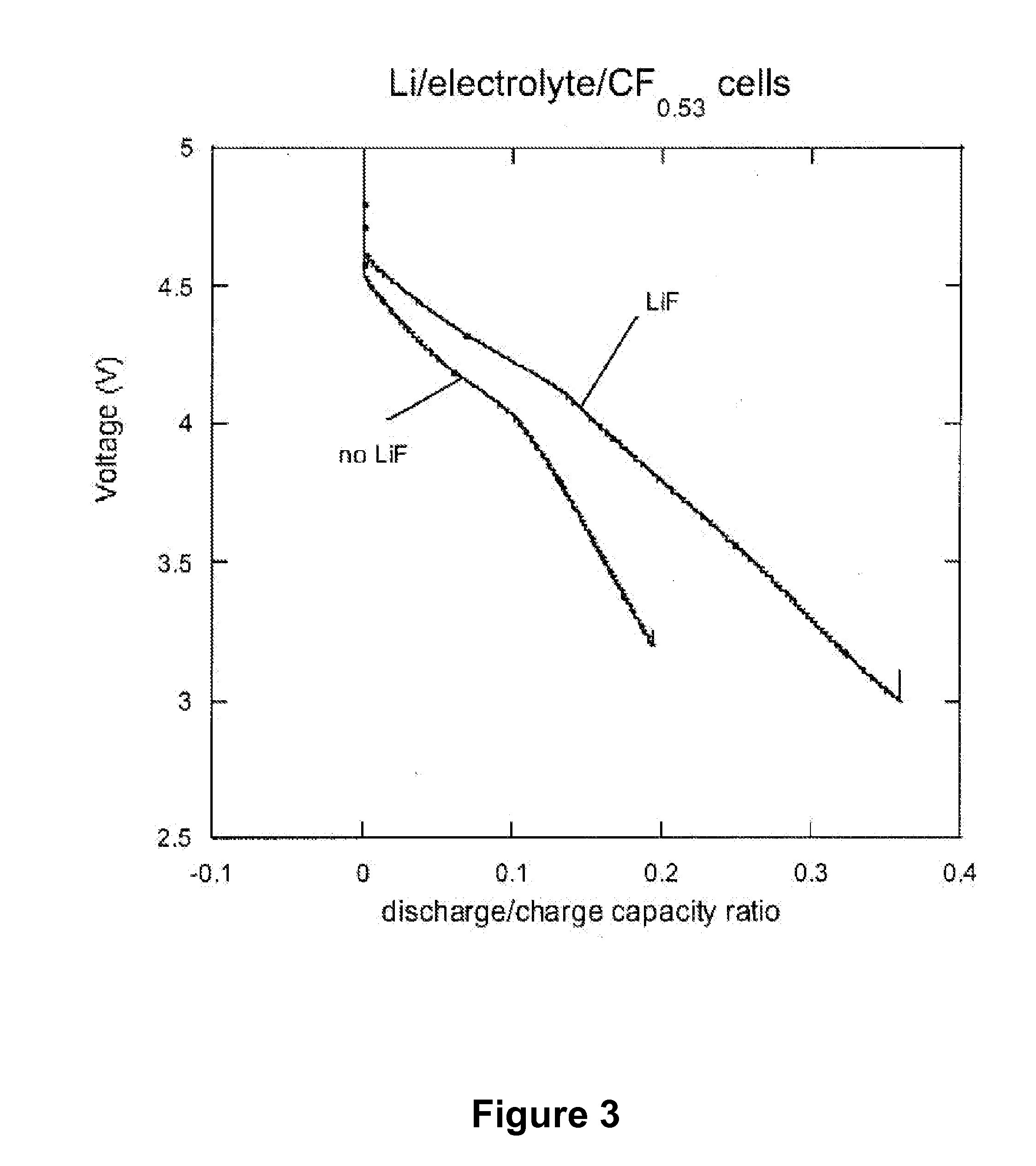

Dissociating agents, formulations and methods providing enhanced solubility of fluorides

PatentActiveUS20080171268A1

Innovation

- Incorporation of dissociating agents such as Lewis acids, Lewis bases, anion receptors, and cation receptors into the electrolyte formulations to enhance the dissolution and solubility of lithium salts, particularly lithium fluoride, in nonaqueous organic solvents, thereby increasing ionic conductivity and stability.

Environmental Impact Assessment

The environmental impact of Lewis acid complex decomposition processes extends across multiple ecological domains, requiring comprehensive assessment. These chemical reactions, while essential for various industrial applications, can generate byproducts that pose significant environmental risks if not properly managed. The decomposition of Lewis acid complexes often releases metal ions, halides, and organic fragments that may contaminate soil and water systems, potentially disrupting ecosystem balance and biodiversity.

Water quality impacts represent a primary concern, as dissolved metal species from decomposed Lewis acid complexes can persist in aquatic environments. Studies indicate that aluminum, boron, and titanium-based Lewis acids pose particular challenges due to their mobility in groundwater systems and potential bioaccumulation in aquatic organisms. Monitoring data from industrial sites utilizing Lewis acid catalysts shows concentration levels in effluent streams requiring specialized treatment protocols to meet regulatory standards.

Atmospheric emissions during thermal decomposition of certain Lewis acid complexes contribute to air quality concerns. Volatile organic compounds (VOCs) and particulate matter released during high-temperature processing can impact local air quality and potentially contribute to regional atmospheric chemistry alterations. Recent research has documented reduced photochemical smog formation potential when implementing advanced emission control technologies specifically designed for Lewis acid processing facilities.

Soil contamination presents long-term environmental challenges, as metal-containing residues from Lewis acid decomposition can alter soil chemistry and affect microbial communities essential for ecosystem functioning. Field studies demonstrate that soil remediation following Lewis acid contamination often requires specialized approaches beyond conventional techniques, particularly for persistent metal species that form stable complexes with soil organic matter.

Waste management considerations for Lewis acid complex decomposition must address both immediate handling requirements and long-term disposal solutions. The reactive nature of partially decomposed complexes necessitates stabilization treatments prior to disposal, while recovery and recycling opportunities for valuable metal components present economic and environmental benefits through circular economy approaches.

Lifecycle assessment studies comparing traditional Lewis acid processes with emerging alternatives indicate potential for significant environmental impact reduction through green chemistry principles. Specifically, water-compatible Lewis acids and solid-supported catalysts demonstrate reduced waste generation and improved environmental profiles while maintaining catalytic efficiency in many applications.

Water quality impacts represent a primary concern, as dissolved metal species from decomposed Lewis acid complexes can persist in aquatic environments. Studies indicate that aluminum, boron, and titanium-based Lewis acids pose particular challenges due to their mobility in groundwater systems and potential bioaccumulation in aquatic organisms. Monitoring data from industrial sites utilizing Lewis acid catalysts shows concentration levels in effluent streams requiring specialized treatment protocols to meet regulatory standards.

Atmospheric emissions during thermal decomposition of certain Lewis acid complexes contribute to air quality concerns. Volatile organic compounds (VOCs) and particulate matter released during high-temperature processing can impact local air quality and potentially contribute to regional atmospheric chemistry alterations. Recent research has documented reduced photochemical smog formation potential when implementing advanced emission control technologies specifically designed for Lewis acid processing facilities.

Soil contamination presents long-term environmental challenges, as metal-containing residues from Lewis acid decomposition can alter soil chemistry and affect microbial communities essential for ecosystem functioning. Field studies demonstrate that soil remediation following Lewis acid contamination often requires specialized approaches beyond conventional techniques, particularly for persistent metal species that form stable complexes with soil organic matter.

Waste management considerations for Lewis acid complex decomposition must address both immediate handling requirements and long-term disposal solutions. The reactive nature of partially decomposed complexes necessitates stabilization treatments prior to disposal, while recovery and recycling opportunities for valuable metal components present economic and environmental benefits through circular economy approaches.

Lifecycle assessment studies comparing traditional Lewis acid processes with emerging alternatives indicate potential for significant environmental impact reduction through green chemistry principles. Specifically, water-compatible Lewis acids and solid-supported catalysts demonstrate reduced waste generation and improved environmental profiles while maintaining catalytic efficiency in many applications.

Computational Modeling Approaches

Computational modeling has emerged as a powerful tool for understanding Lewis acid complex decomposition mechanisms at the molecular level. Quantum mechanical methods, particularly Density Functional Theory (DFT), have become the standard approach for investigating these reactions. DFT calculations provide valuable insights into electronic structures, transition states, and reaction pathways that are often inaccessible through experimental techniques alone.

Ab initio molecular dynamics (AIMD) simulations represent another significant computational approach, allowing researchers to observe the time evolution of Lewis acid complex decomposition under various conditions. These simulations can reveal unexpected reaction intermediates and provide detailed information about the kinetics of decomposition processes, including activation energies and rate-determining steps.

Machine learning algorithms have recently been integrated with traditional computational chemistry methods to accelerate the discovery of decomposition mechanisms. These hybrid approaches can efficiently screen thousands of potential reaction pathways and identify the most probable decomposition routes, significantly reducing the computational resources required for comprehensive mechanistic studies.

Multi-scale modeling techniques bridge the gap between quantum mechanical calculations and macroscopic observations by combining different levels of theory. For Lewis acid complex decomposition, this often involves coupling DFT calculations with molecular mechanics or continuum solvation models to account for environmental effects that can dramatically influence decomposition pathways.

Reaction path sampling methods, such as metadynamics and transition path sampling, have proven particularly valuable for exploring complex free energy landscapes associated with Lewis acid decomposition. These advanced techniques can identify rare events and hidden reaction channels that might be overlooked by conventional computational approaches.

Spectroscopic property calculations serve as a crucial link between computational predictions and experimental validation. By simulating NMR, IR, and UV-vis spectra of proposed intermediates and transition states, researchers can directly compare computational results with experimental observations, thereby validating or refining proposed decomposition mechanisms.

Recent advances in GPU-accelerated computing have dramatically expanded the scope and scale of computational investigations into Lewis acid complex decomposition. Systems containing hundreds of atoms can now be modeled with reasonable accuracy, allowing for the simulation of industrially relevant catalytic processes involving Lewis acid decomposition in realistic chemical environments.

Ab initio molecular dynamics (AIMD) simulations represent another significant computational approach, allowing researchers to observe the time evolution of Lewis acid complex decomposition under various conditions. These simulations can reveal unexpected reaction intermediates and provide detailed information about the kinetics of decomposition processes, including activation energies and rate-determining steps.

Machine learning algorithms have recently been integrated with traditional computational chemistry methods to accelerate the discovery of decomposition mechanisms. These hybrid approaches can efficiently screen thousands of potential reaction pathways and identify the most probable decomposition routes, significantly reducing the computational resources required for comprehensive mechanistic studies.

Multi-scale modeling techniques bridge the gap between quantum mechanical calculations and macroscopic observations by combining different levels of theory. For Lewis acid complex decomposition, this often involves coupling DFT calculations with molecular mechanics or continuum solvation models to account for environmental effects that can dramatically influence decomposition pathways.

Reaction path sampling methods, such as metadynamics and transition path sampling, have proven particularly valuable for exploring complex free energy landscapes associated with Lewis acid decomposition. These advanced techniques can identify rare events and hidden reaction channels that might be overlooked by conventional computational approaches.

Spectroscopic property calculations serve as a crucial link between computational predictions and experimental validation. By simulating NMR, IR, and UV-vis spectra of proposed intermediates and transition states, researchers can directly compare computational results with experimental observations, thereby validating or refining proposed decomposition mechanisms.

Recent advances in GPU-accelerated computing have dramatically expanded the scope and scale of computational investigations into Lewis acid complex decomposition. Systems containing hundreds of atoms can now be modeled with reasonable accuracy, allowing for the simulation of industrially relevant catalytic processes involving Lewis acid decomposition in realistic chemical environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!