A kind of Fe3O4/C composite material for negative electrode material of lithium ion battery and its preparation method and application

A lithium-ion battery and composite material technology, applied in the field of Fe3O4/C composite material and its preparation, can solve the problems of electrode damage, limit practical application, poor battery rate performance and cycle stability, and achieve good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of biomaterial / iron ion composite gel:

[0058] Disperse 2g of agar evenly in 98mL of deionized water under stirring conditions, stir and dissolve at room temperature to form an agar solution (2wt%), then inject the agar solution into a concentration of 1mol / L nitric acid under the condition of 0.45MPa In the iron solution, a filamentous agar / iron ion composite gel was obtained.

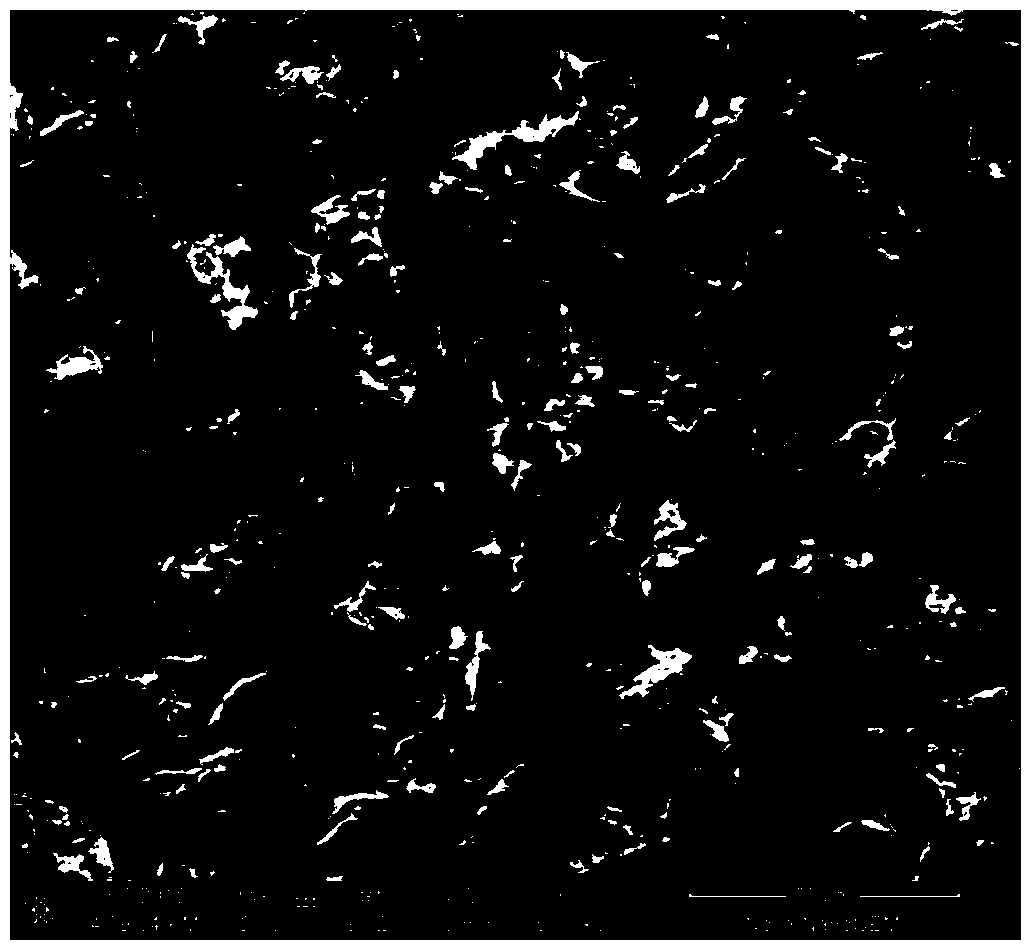

[0059] (2) Preparation of biological material / iron ion composite filament:

[0060] Place the agar / iron ion composite gel in a ferric nitrate solution with a concentration of 1mol / L for 10h, then take it out and freeze-dry it at -40°C for 4 days to obtain a yellow-brown agar / iron ion composite filament. Its shape is as figure 1 shown.

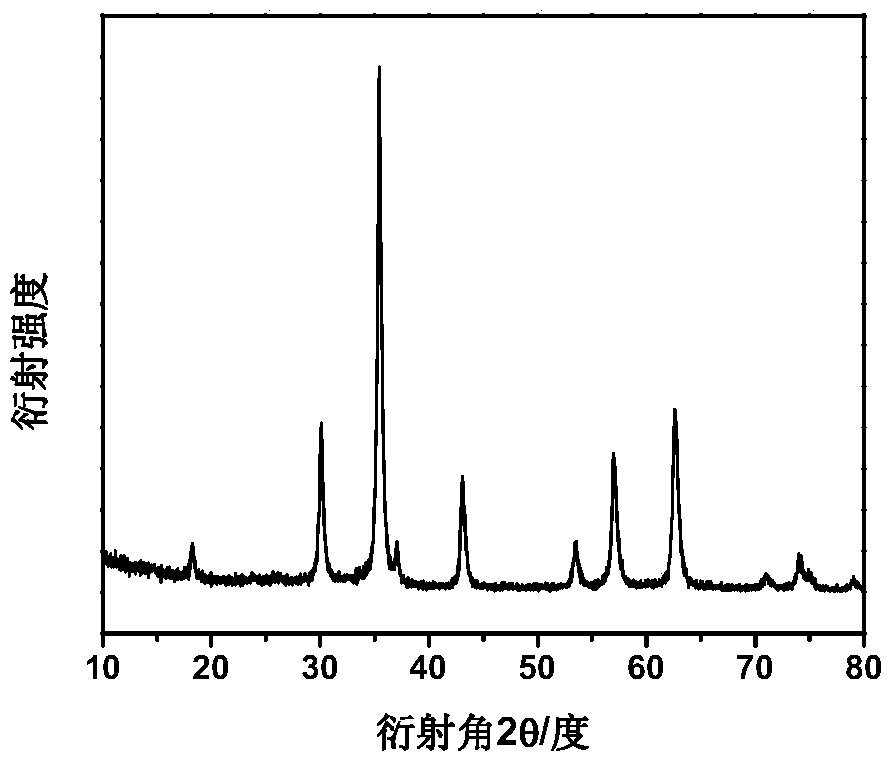

[0061] (3) Preparation of Fe 3 o 4 / C composite material:

[0062] The agar / iron ion composite filaments were calcined at 400°C for 1 h in an argon atmosphere. After calcining, they were taken out and acidified in a hydrochloric acid solut...

Embodiment 2

[0066] (1) Preparation of biomaterial / iron ion composite gel:

[0067] Under stirring condition, 2g agar is uniformly dispersed in 198mL deionized water, stirred and dissolved at room temperature to form an agar solution (1wt%), and then the agar solution is injected into a concentration of 1mol / L nitric acid under the condition of a pressure of 0.45MPa In the iron solution, a filamentous agar / iron ion composite gel was obtained.

[0068] (2) Preparation of biological material / iron ion composite filament:

[0069] The agar / iron ion composite gel was placed in a ferric nitrate solution with a concentration of 1 mol / L for 10 hours, and then taken out and freeze-dried at -40°C for 3 days to obtain a yellow-brown agar / iron ion composite filament.

[0070] (3) Preparation of Fe 3 o 4 / C composite material:

[0071] The agar / iron ion composite filaments were calcined at 400°C for 1 h in an argon atmosphere. After calcining, they were taken out and acidified in a hydrochloric aci...

Embodiment 3

[0074] (1) Preparation of biomaterial / iron ion composite gel:

[0075] Under stirring condition, 2g agar is uniformly dispersed in 98mL deionized water, stirred and dissolved at room temperature to form an agar solution (2wt%), and then the agar solution is injected into the concentration of 0.2mol / L under the condition of 0.45MPa. In the ferric nitrate solution, a filamentous agar / iron ion composite gel was obtained.

[0076] (2) Preparation of biological material / iron ion composite filament:

[0077] Place the agar / iron ion composite gel in a ferric nitrate solution with a concentration of 0.2mol / L for 10 hours, then take it out and freeze-dry it at -40°C for 5 days to obtain a yellow-brown agar / iron ion composite filament .

[0078] (3) Preparation of Fe 3 o 4 / C composite material:

[0079] The agar / iron ion composite filaments were calcined at 400°C for 1 h in an argon atmosphere. After calcining, they were taken out and acidified in a hydrochloric acid solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com