Patents

Literature

33324 results about "Ferric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, iron(III) refers to the element iron in its +3 oxidation state. In ionic compounds (salts), such an atom may occur as a separate cation (positive ion) denoted by Fe³⁺. The adjective ferric or the prefix ferri- is often used to specify such compounds — as in "ferric chloride" for iron(III) chloride, FeCl3. The adjective "ferrous" is used instead for iron(II) salts, containing the cation or Fe²⁺. The word ferric is derived from the Latin word ferrum for iron.

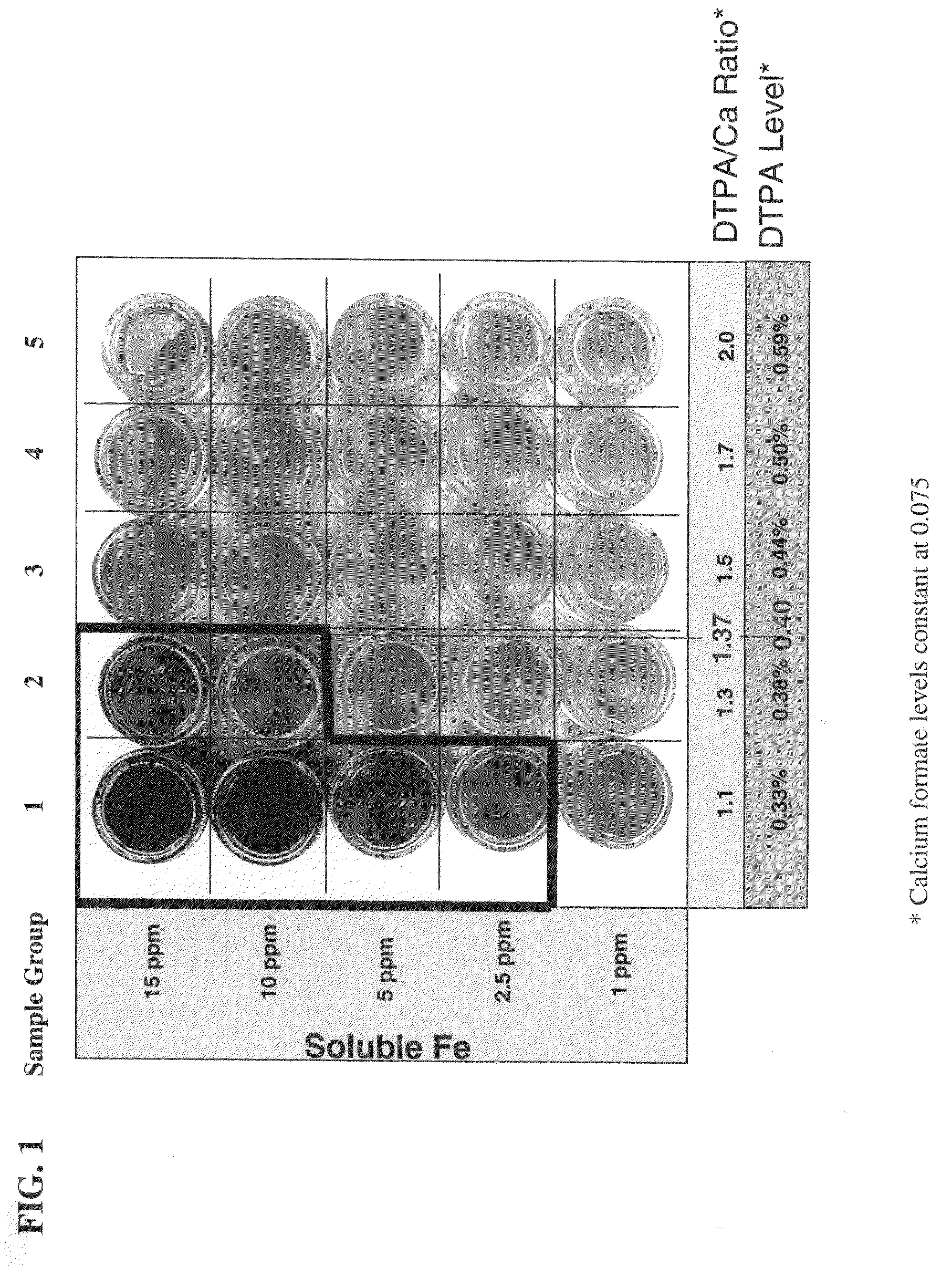

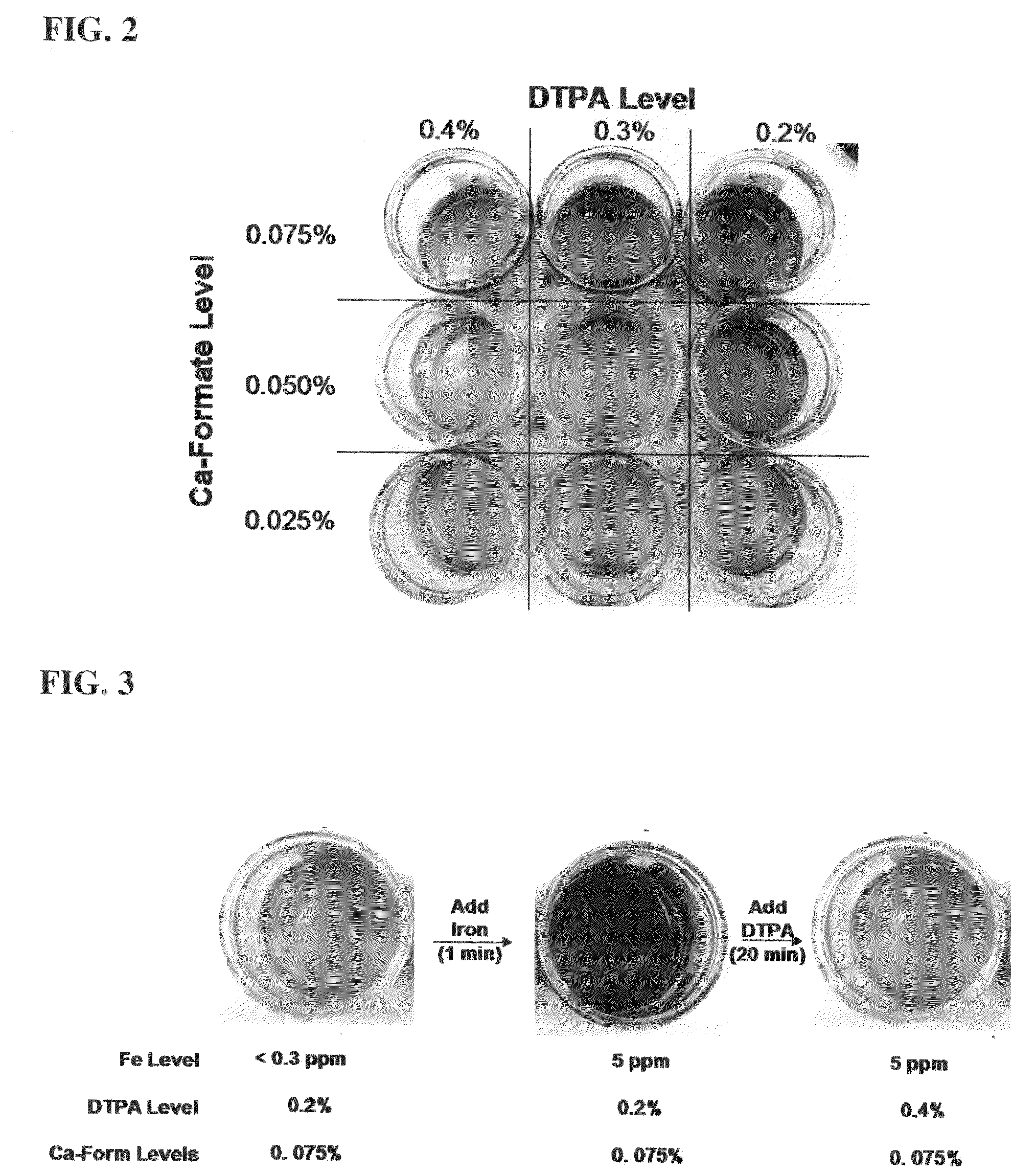

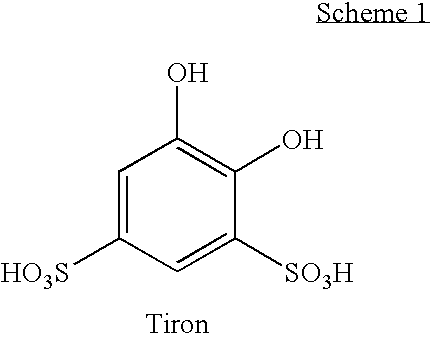

Detergents having acceptable color

InactiveUS20090176684A1Reduce intensityOrganic detergent compounding agentsSurface-active detergent compositionsBenzeneTitanium

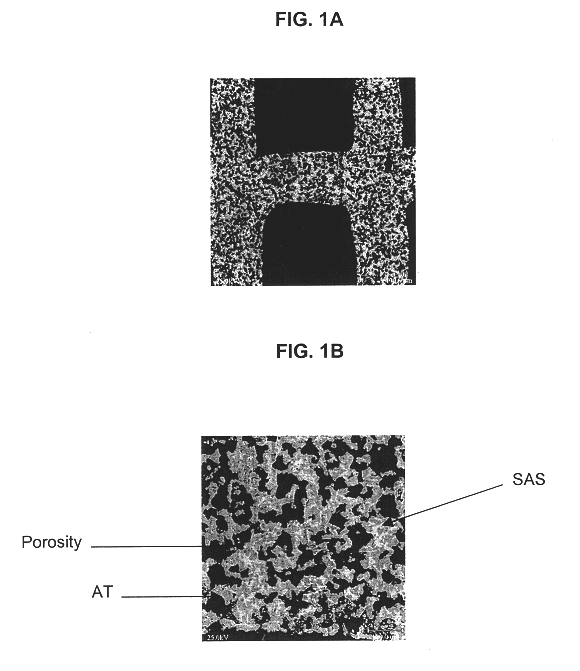

Detergent compositions containing catechols, such as tiron (1,2-dihydroxybenzene-3,5-disulfonic acid), which do not have or do not develop the reddish color associated with the catechol / ferric iron chelate are disclosed. Methods for reducing the intensity of red color in a tiron containing detergent composition are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

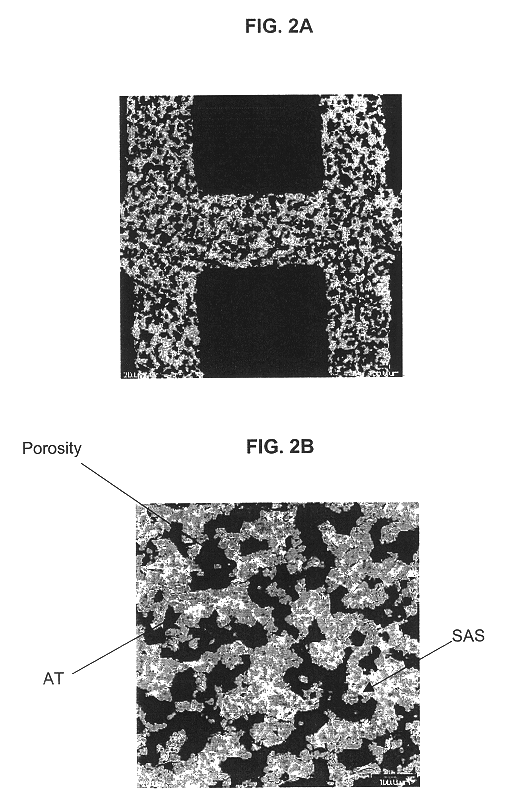

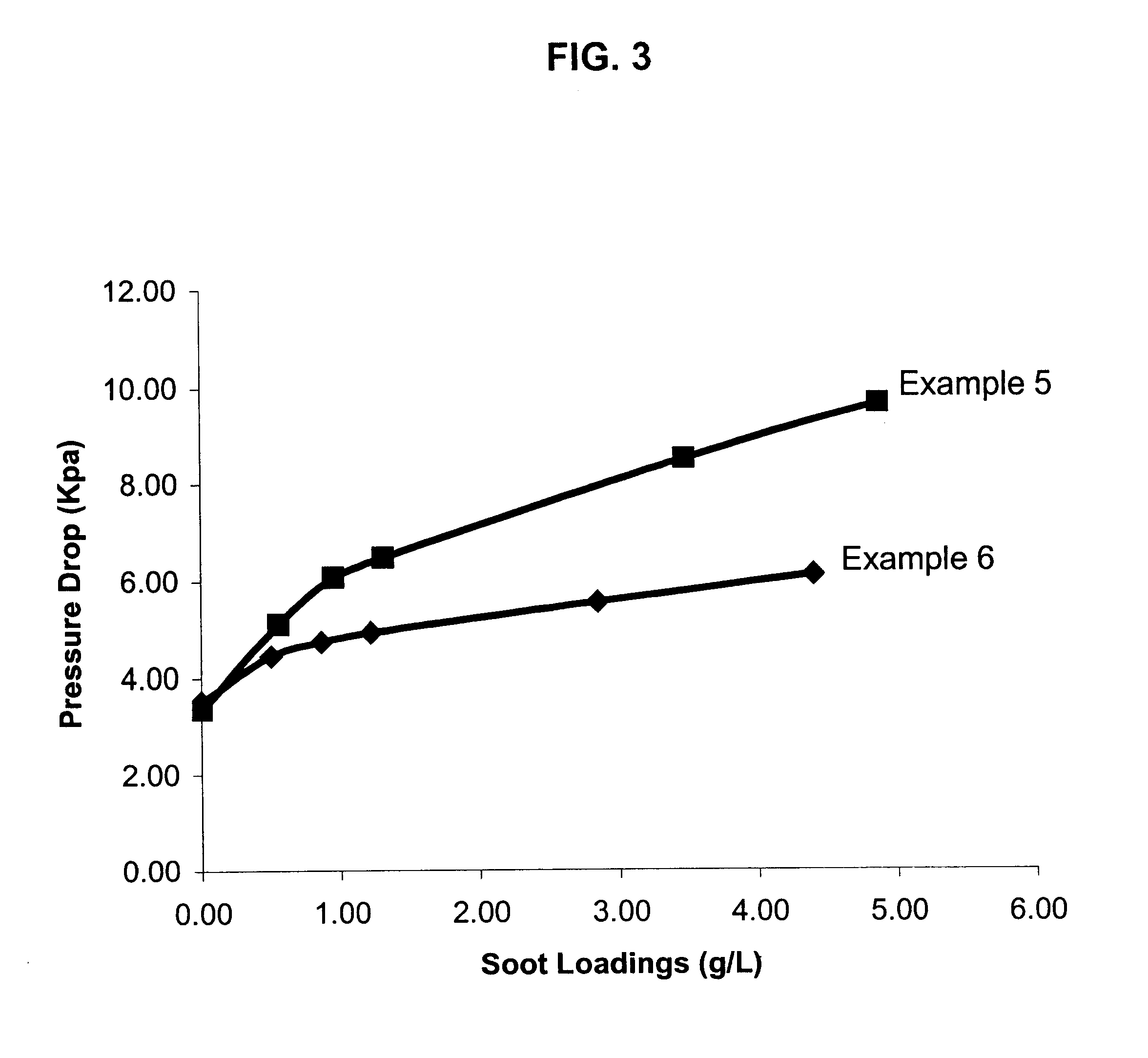

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

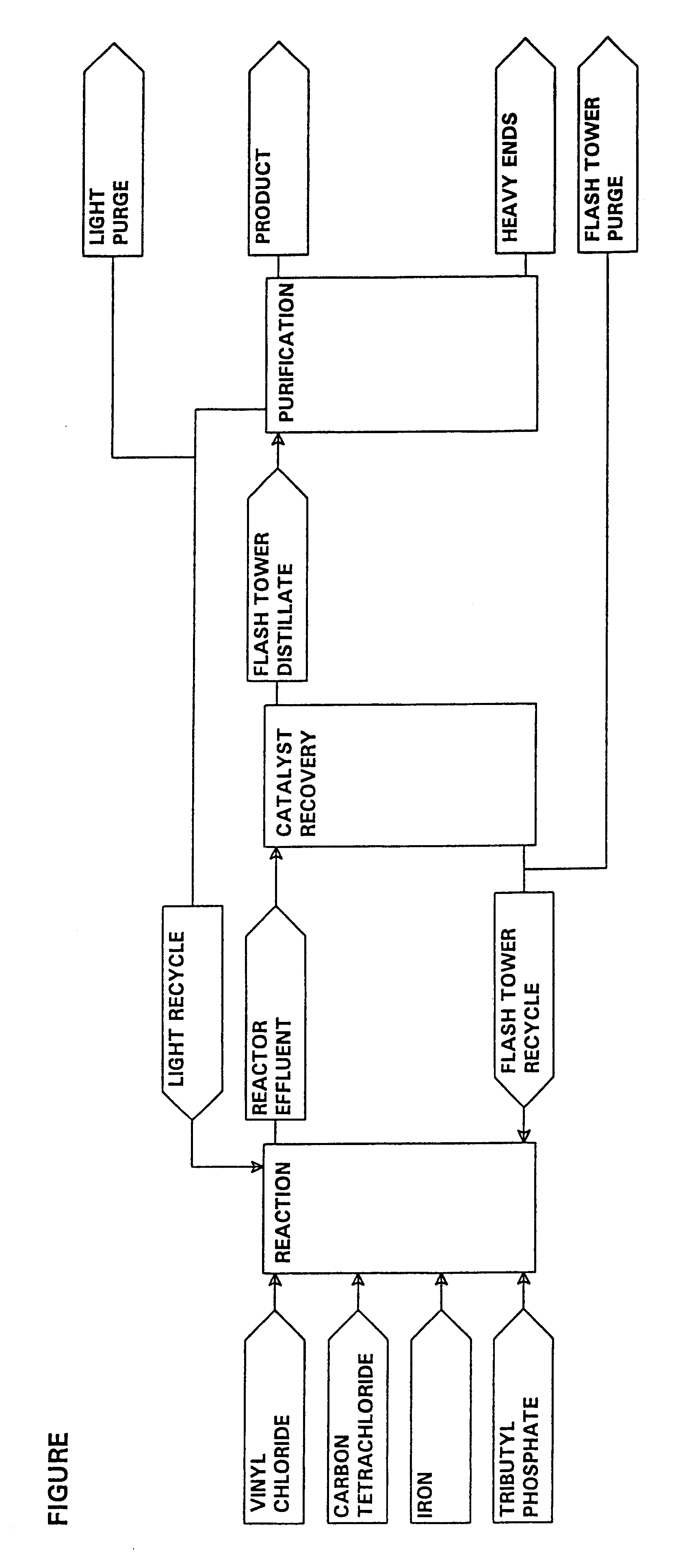

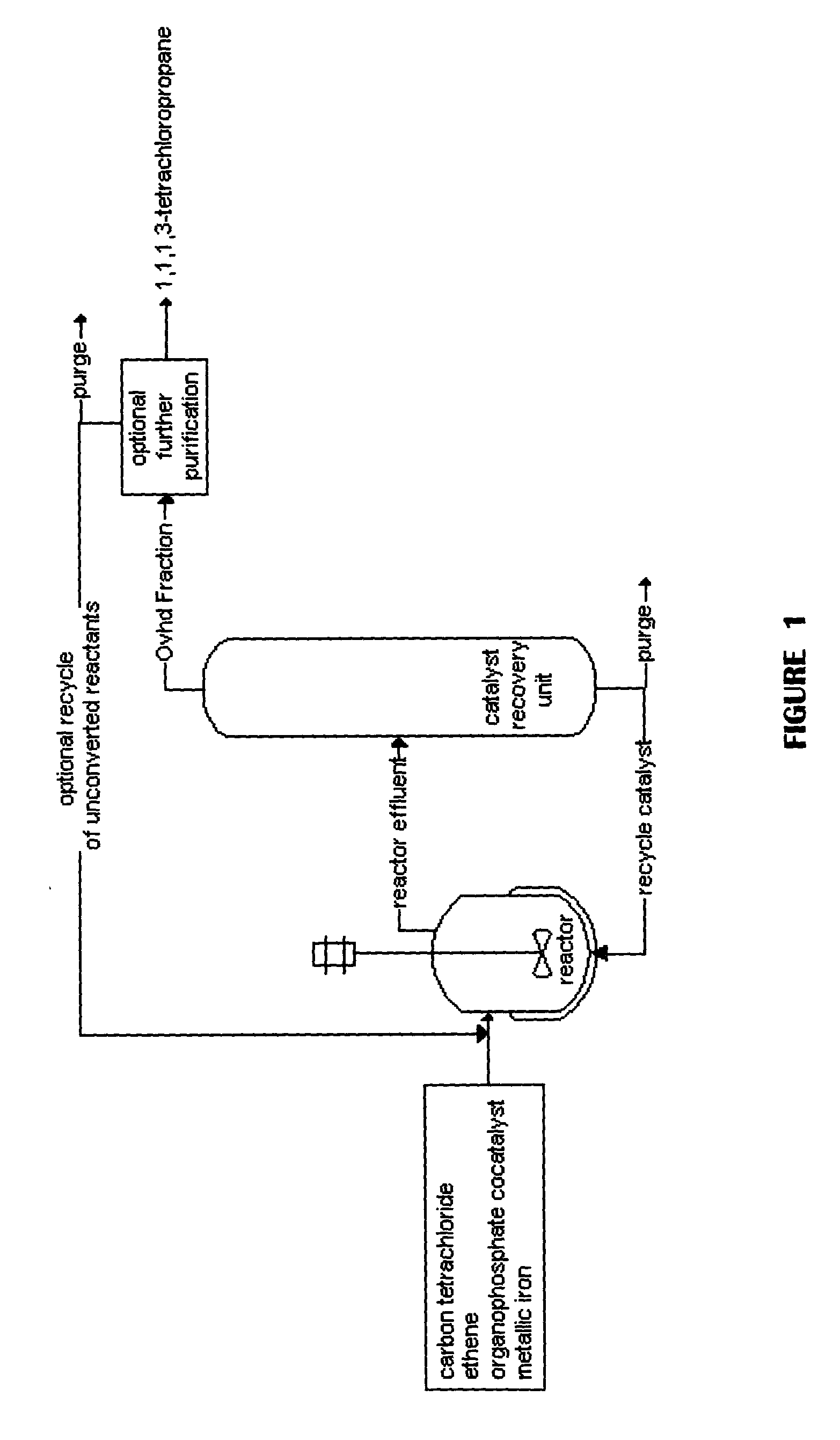

Process for the manufacture of 1, 1, 1, 3, 3-pentachloropropane

InactiveUS6313360B1Improve degradation rateShorten the timeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationChlorideOrganic phosphates

A process is provided for the production of 1,1,1,3,3-pentachloropropane. The process comprises: (a) producing a product mixture in a reactor by reacting carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture comprising organophosphate solvent, iron metal and ferric chloride under conditions sufficient to produce 1,1,1,3,3-pentachloropropane; (b) subjecting the 1,1,1,3,3-pentachloropropane containing product mixture from step (a) to evaporation such that a fraction enriched in 1,1,1,3,3-pentachloropropane is separated from the product mixture and a bottoms fraction results which comprises the iron metal / ferric chloride catalyst components and heavy end by-products; and (c) recycling at least a portion of the bottoms fraction from step (b) to the reactor.

Owner:OCCIDENTAL CHEM CORP

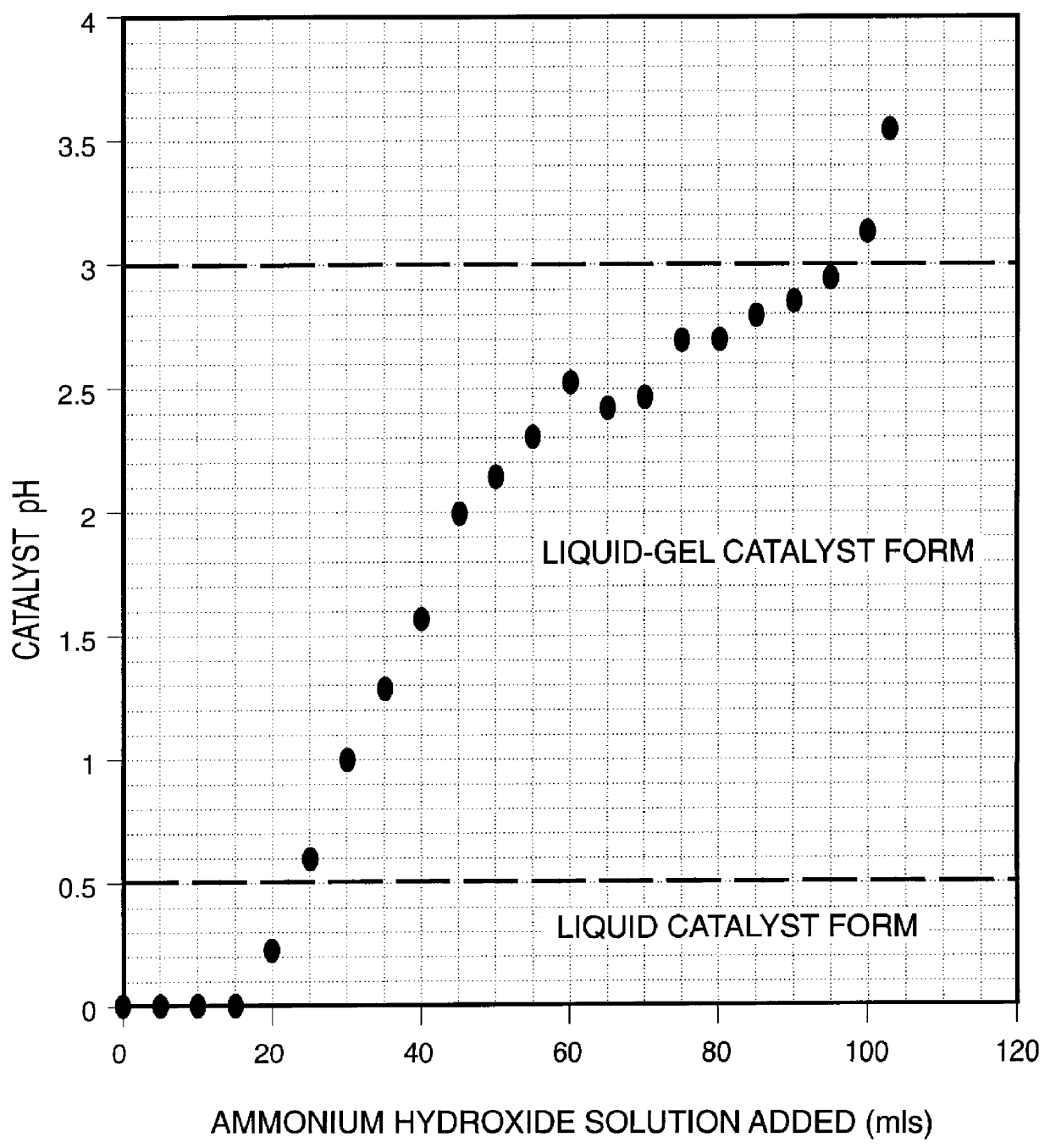

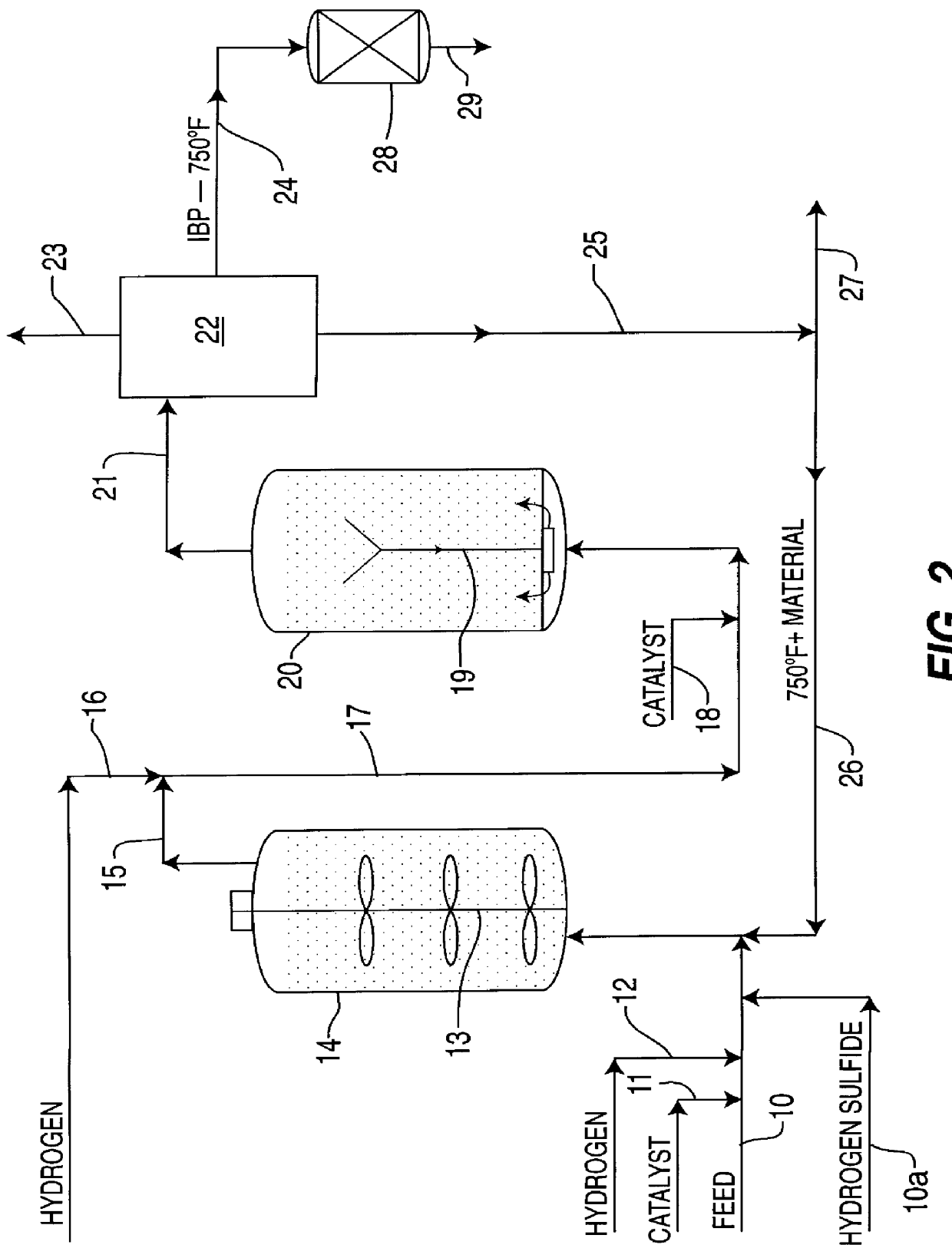

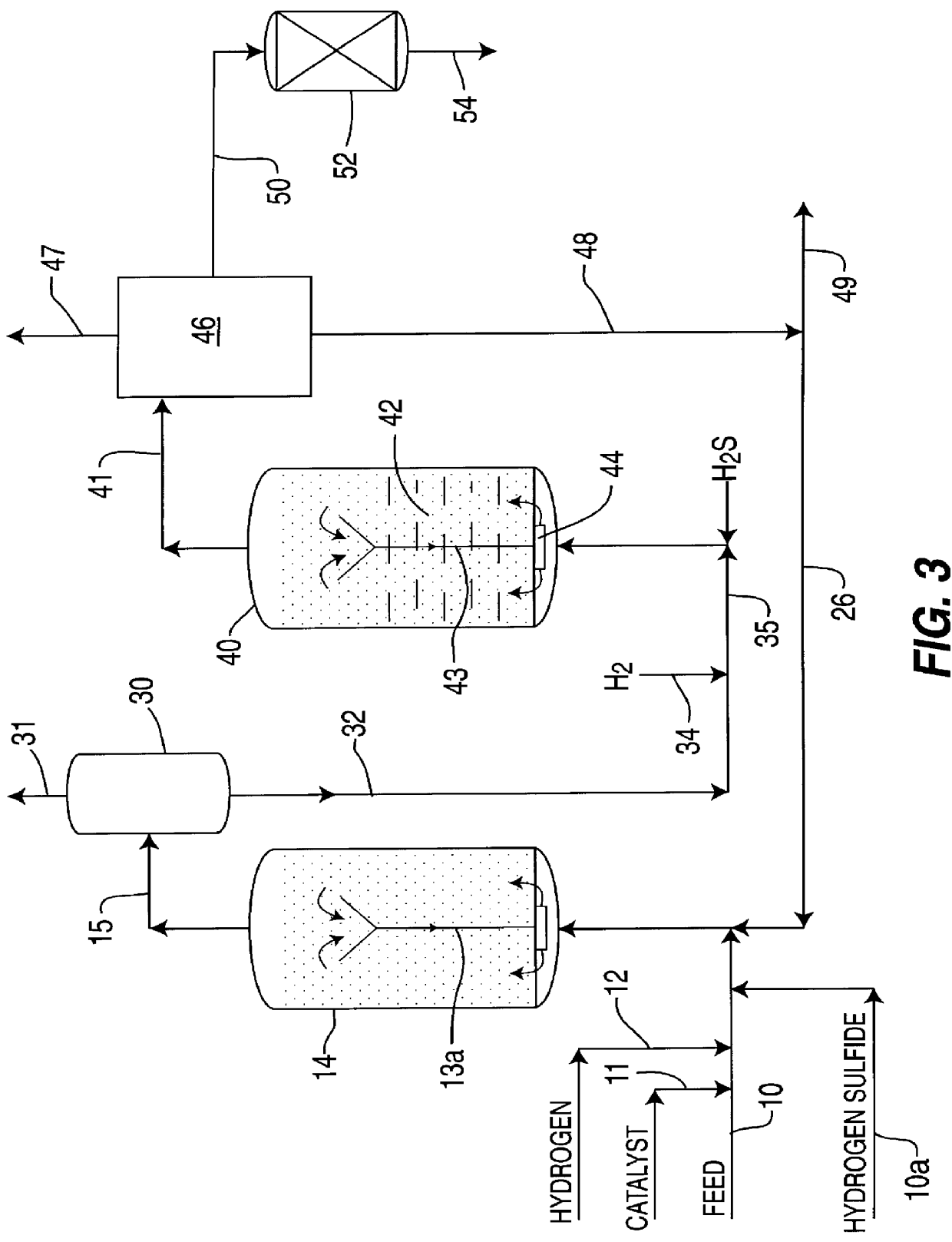

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

Pretreatment compositions and methods for coating a metal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

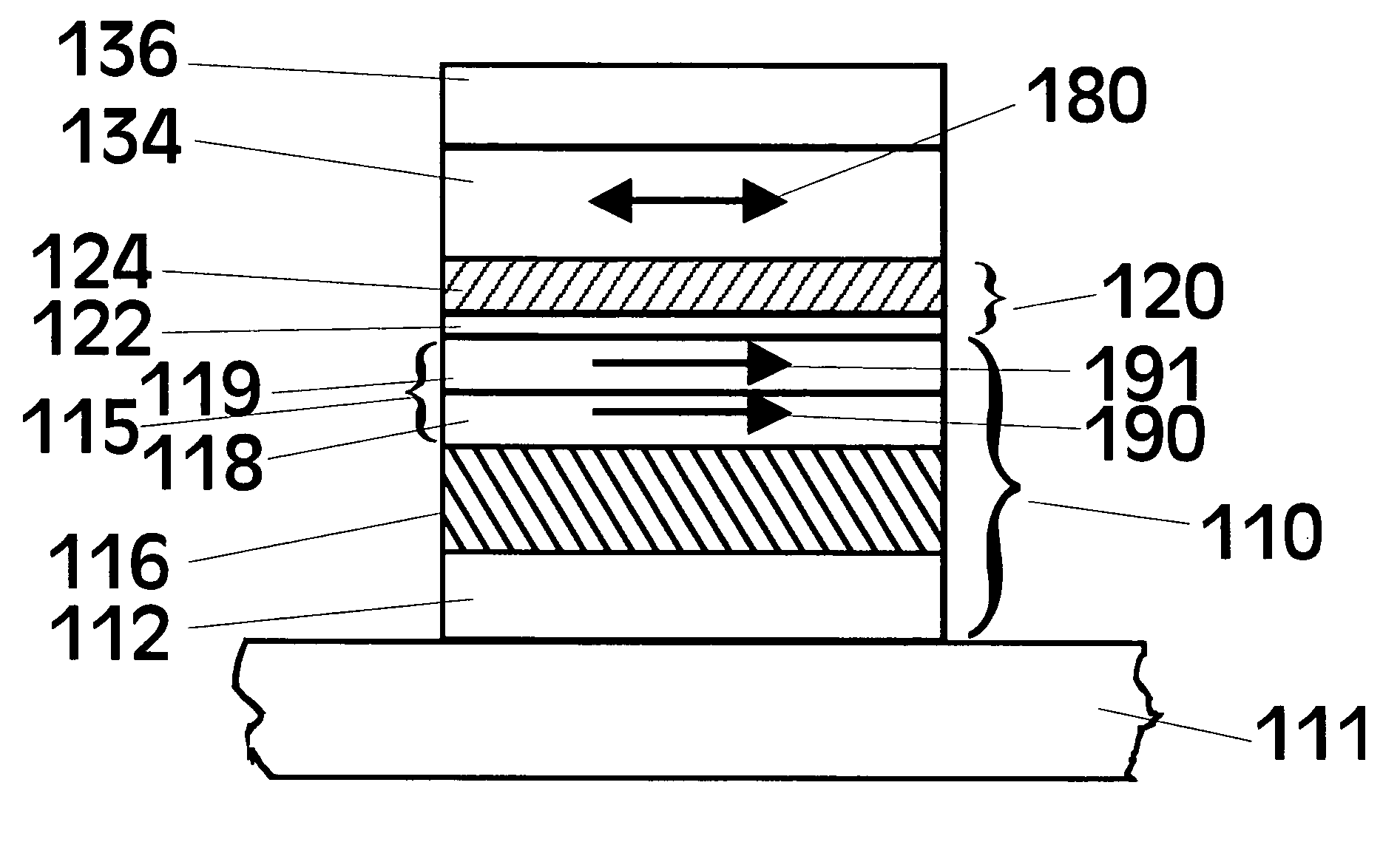

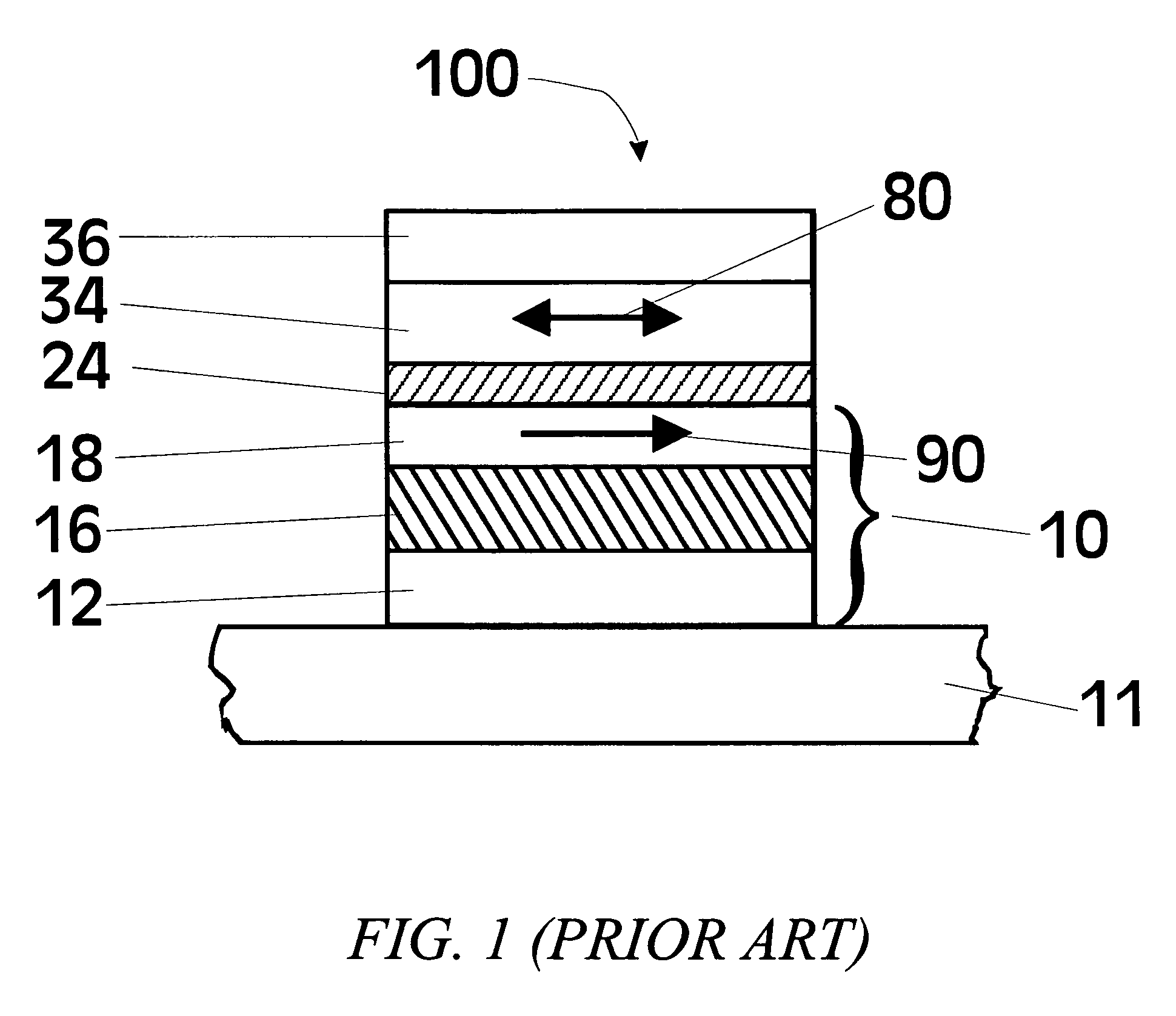

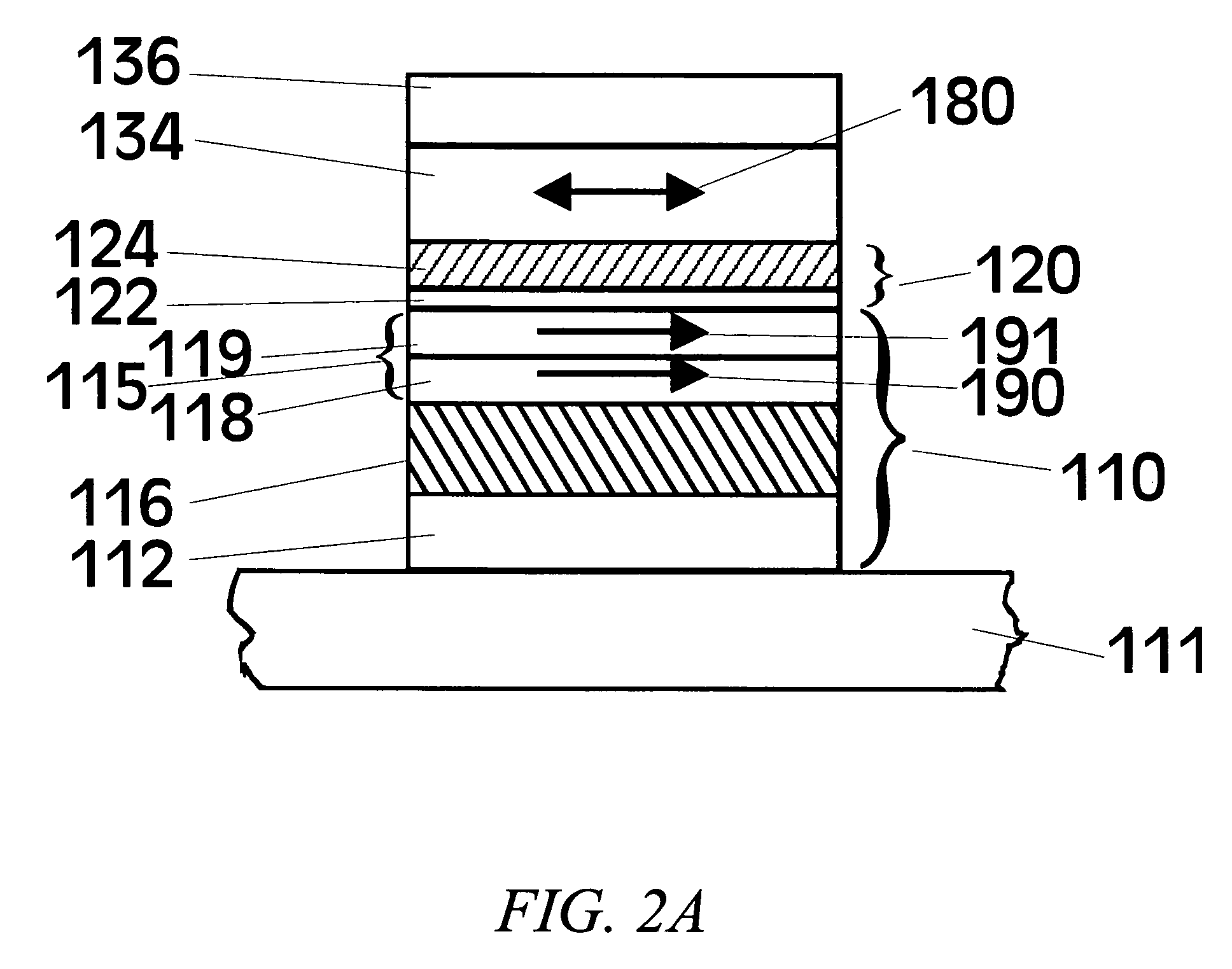

Mg-Zn oxide tunnel barriers and method of formation

ActiveUS7252852B1Not diminishing spin polarizationImprove performanceNanomagnetismMagnetic measurementsOxygenZinc

ZnMg oxide tunnel barriers are grown which, when sandwiched between ferri- or ferromagnetic layers, form magnetic tunnel junctions exhibiting high tunneling magnetoresistance (TMR). The TMR may be increased by annealing the magnetic tunnel junctions. The zinc-magnesium oxide tunnel barriers may be incorporated into a variety of other devices, such as magnetic tunneling transistors and spin injector devices. The ZnMg oxide tunnel barriers are grown by first depositing a zinc and / or magnesium layer onto an underlying substrate in oxygen-poor (or oxygen-free) conditions, and subsequently depositing zinc and / or magnesium onto this layer in the presence of reactive oxygen.

Owner:IBM CORP

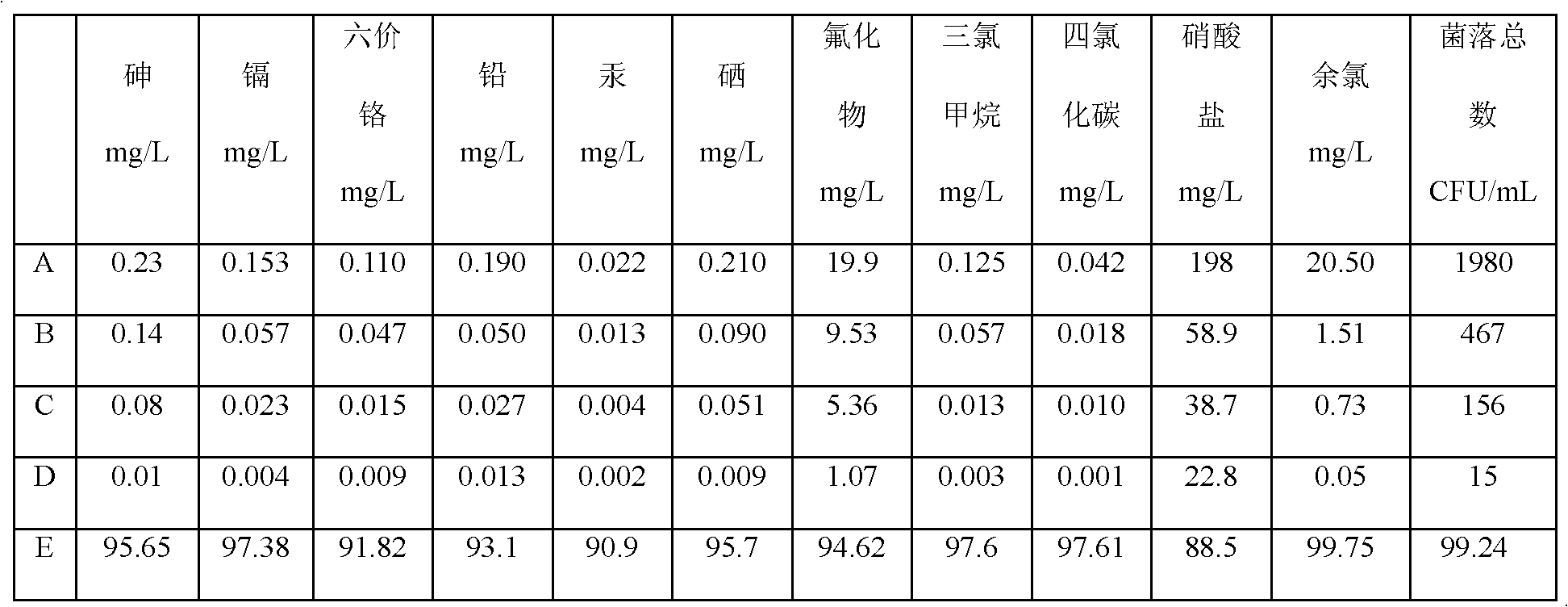

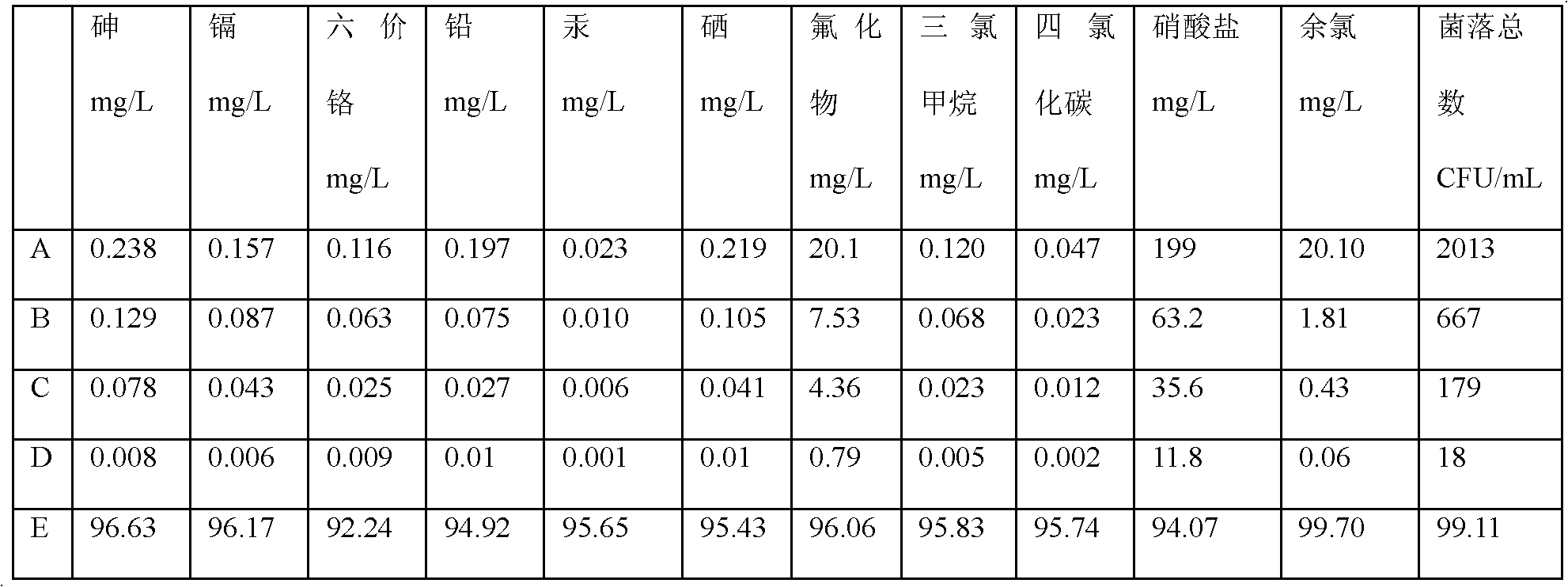

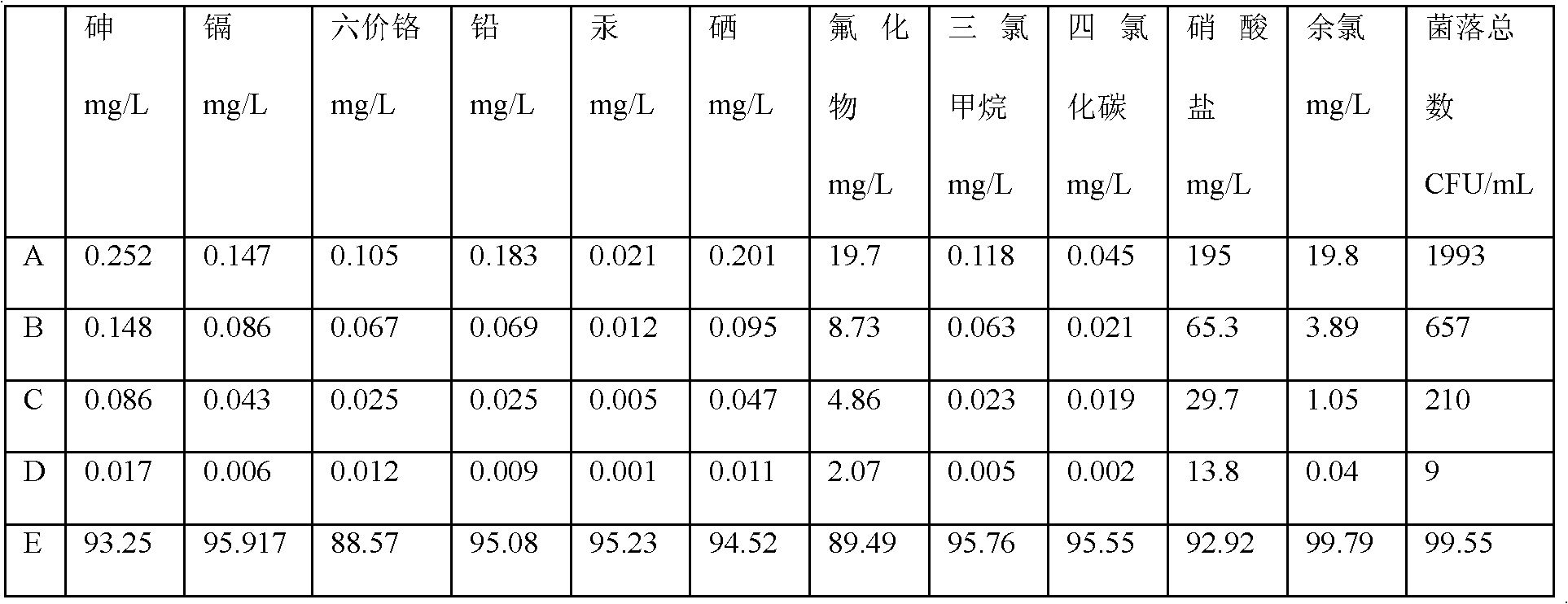

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

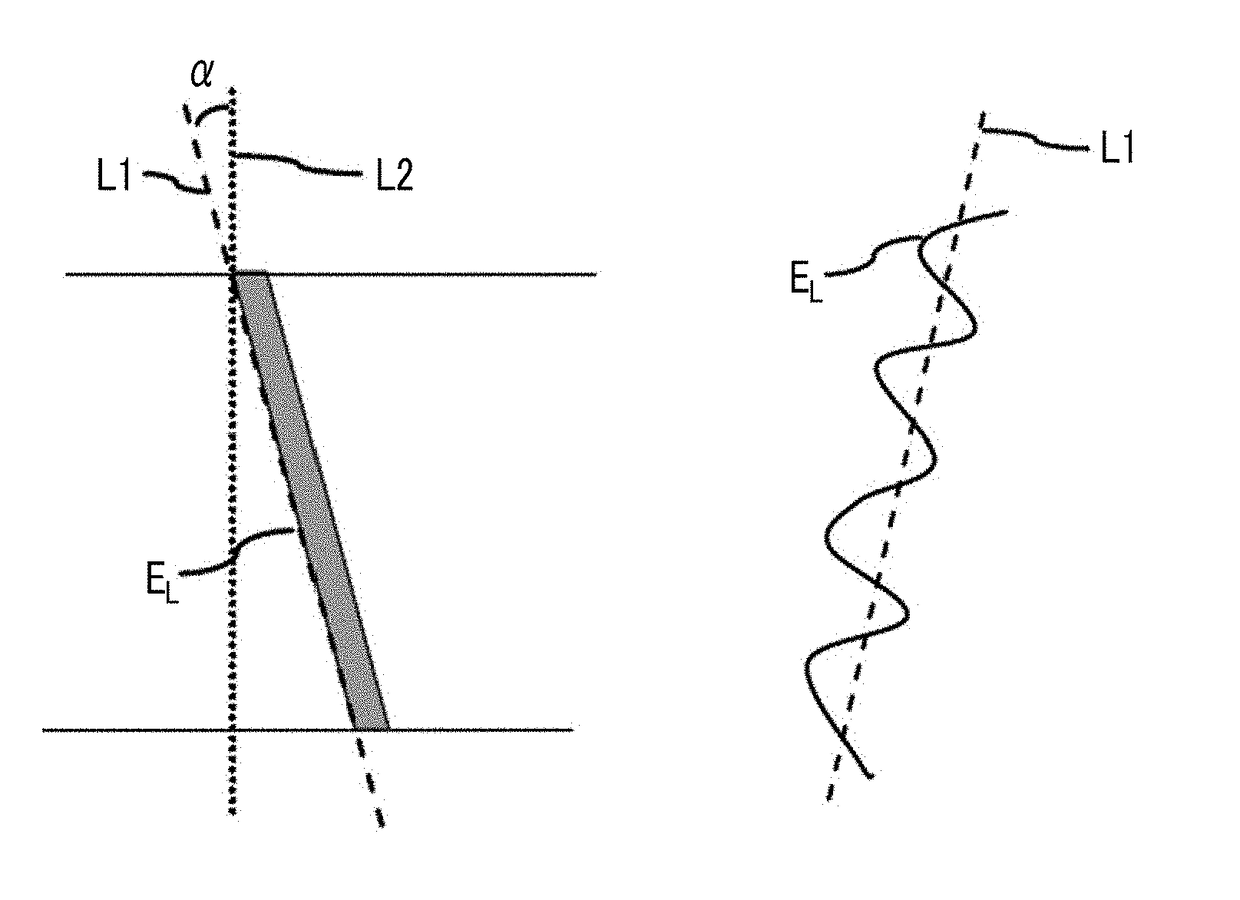

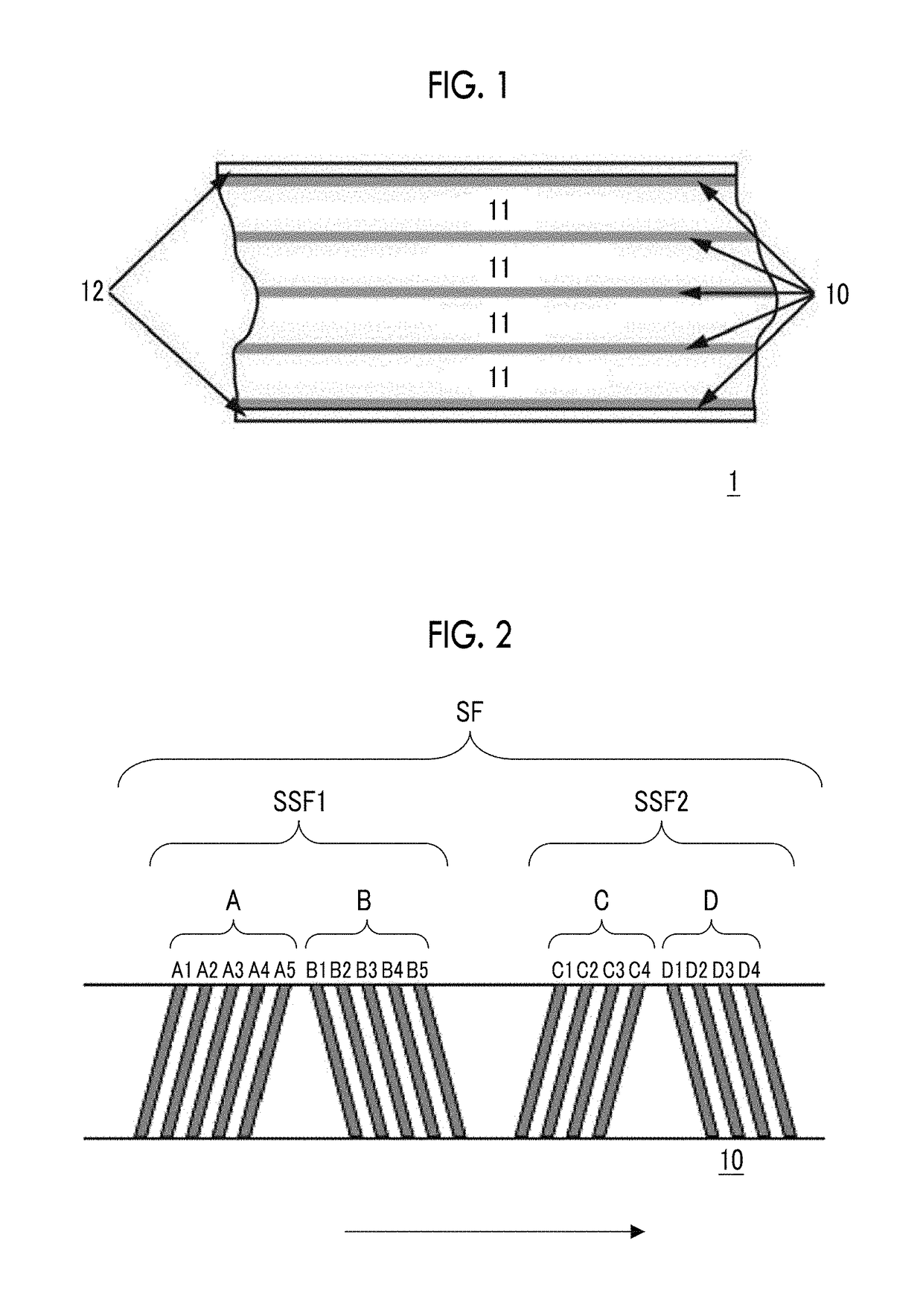

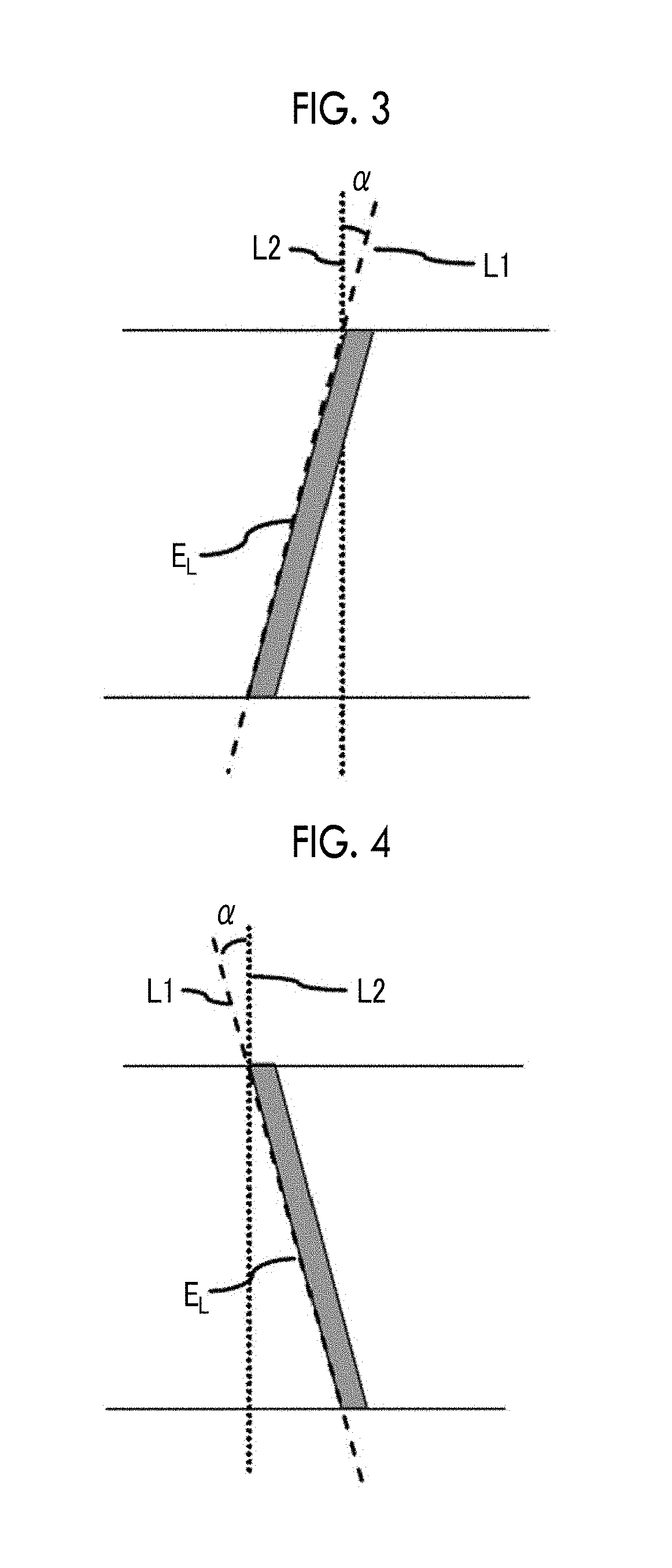

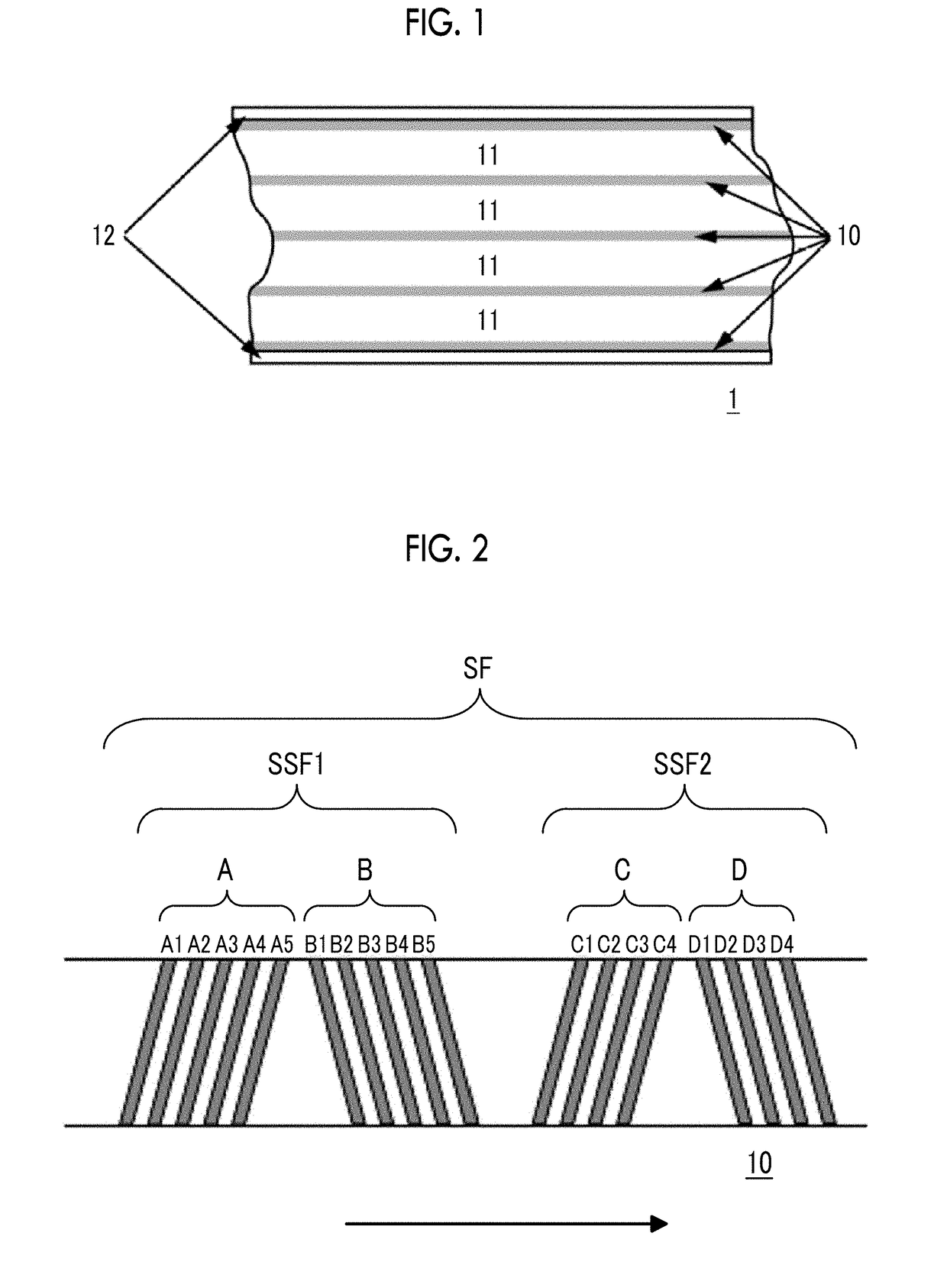

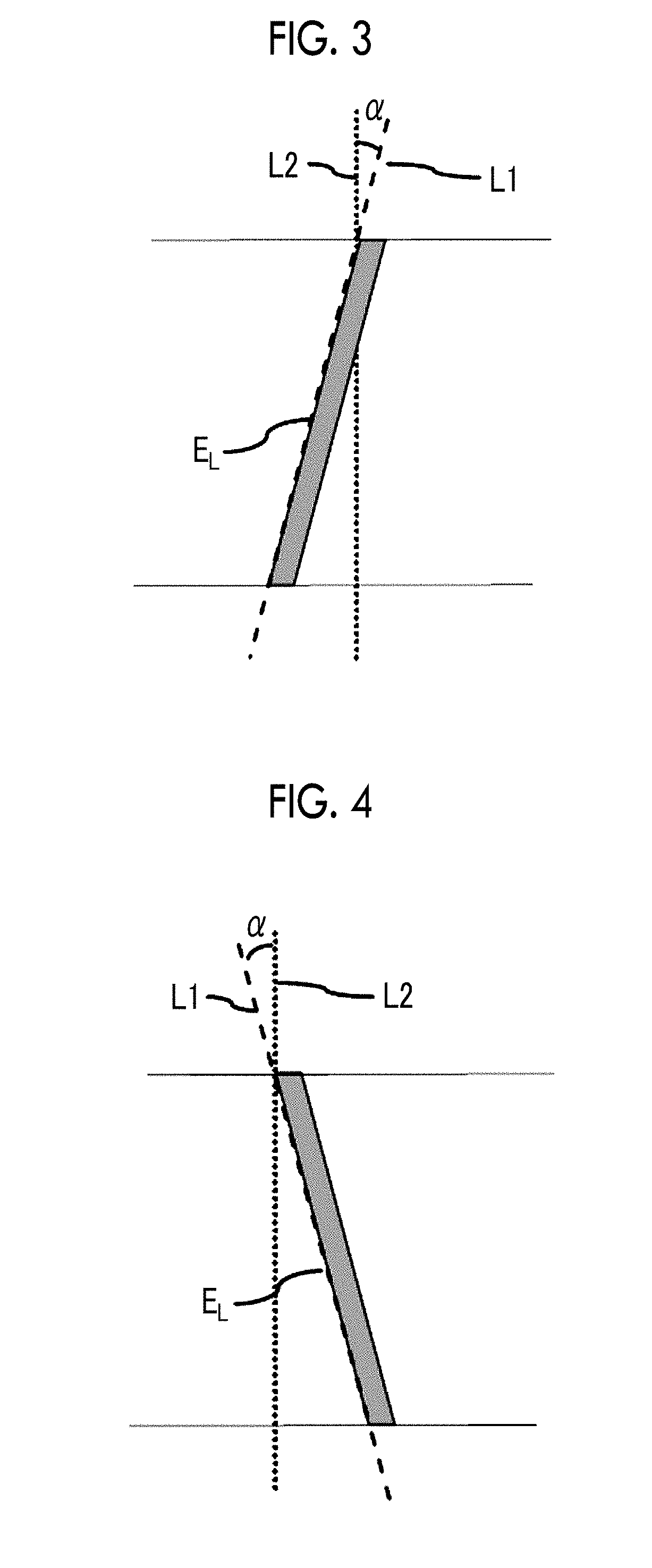

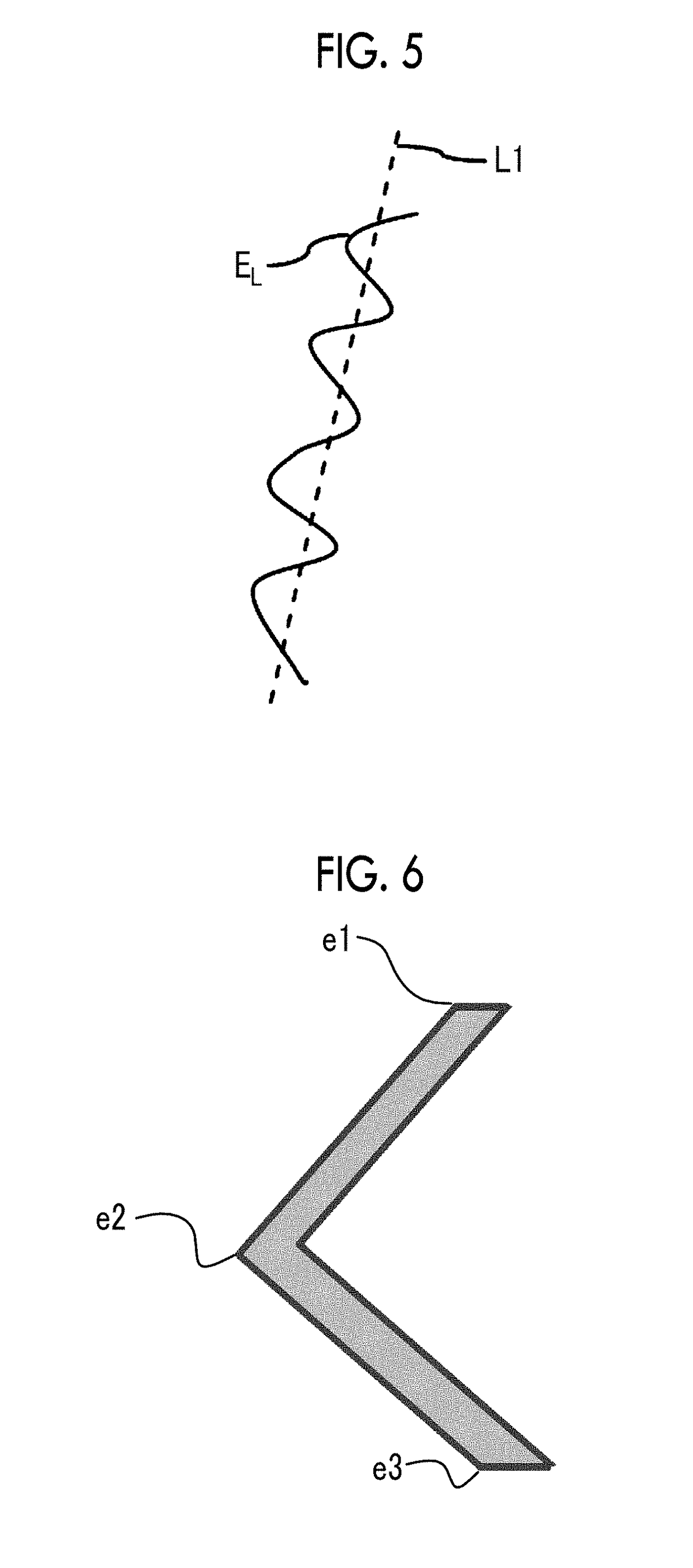

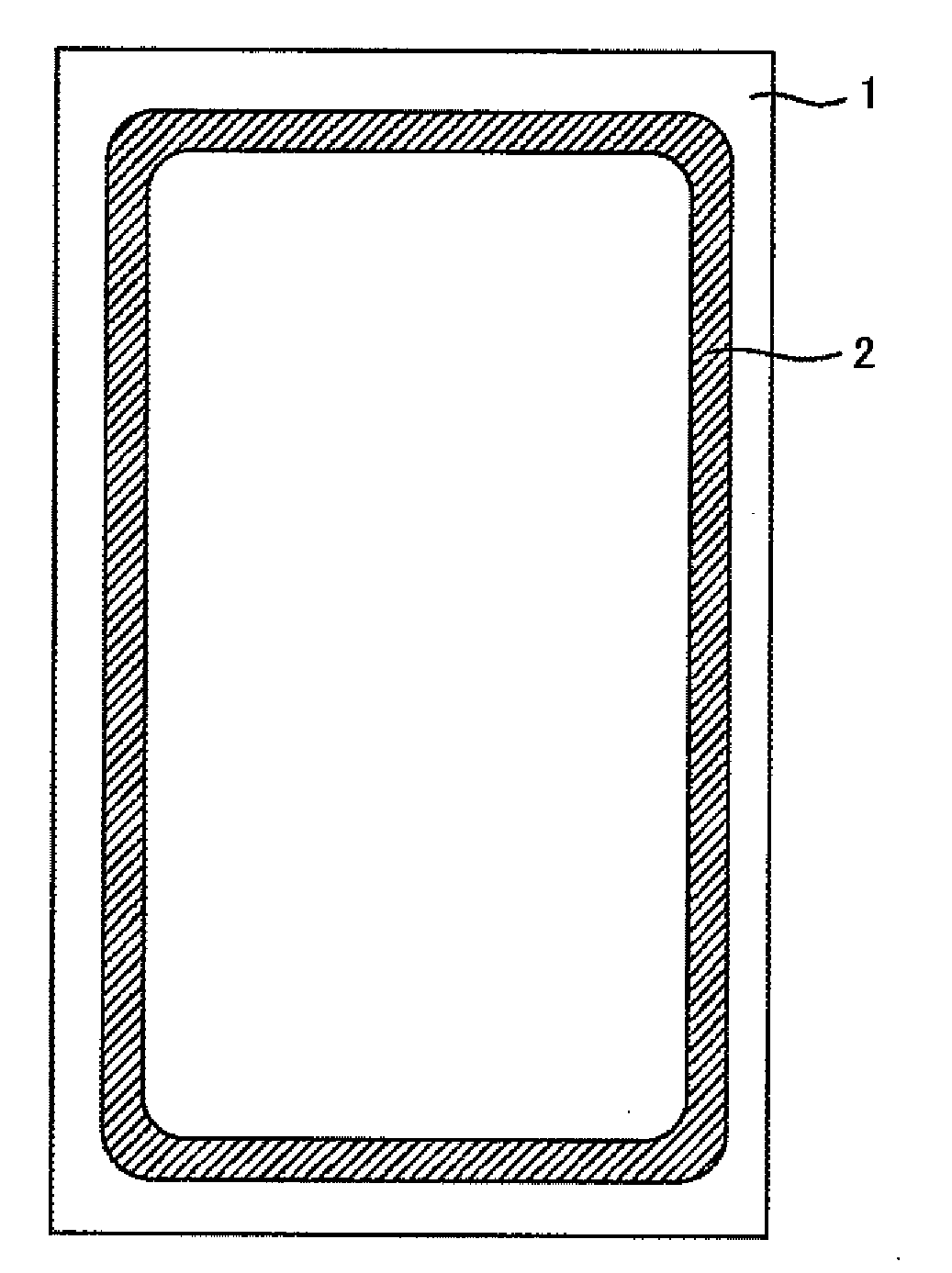

Magnetic tape and magnetic tape device

ActiveUS10074393B2Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic force microscopeMagnetic tension force

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which the magnetic layer includes a timing-based servo pattern, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, and an edge shape of the timing-based servo pattern specified by a magnetic force microscope observation is a shape in which a difference (l99.9−l0.1) between a value l99.9 of a cumulative frequency function of 99.9% of a position deviation width from an ideal shape in a longitudinal direction of the magnetic tape and a value l0.1 of the cumulative frequency function of 0.1% thereof is equal to or smaller than 180 nm.

Owner:FUJIFILM CORP

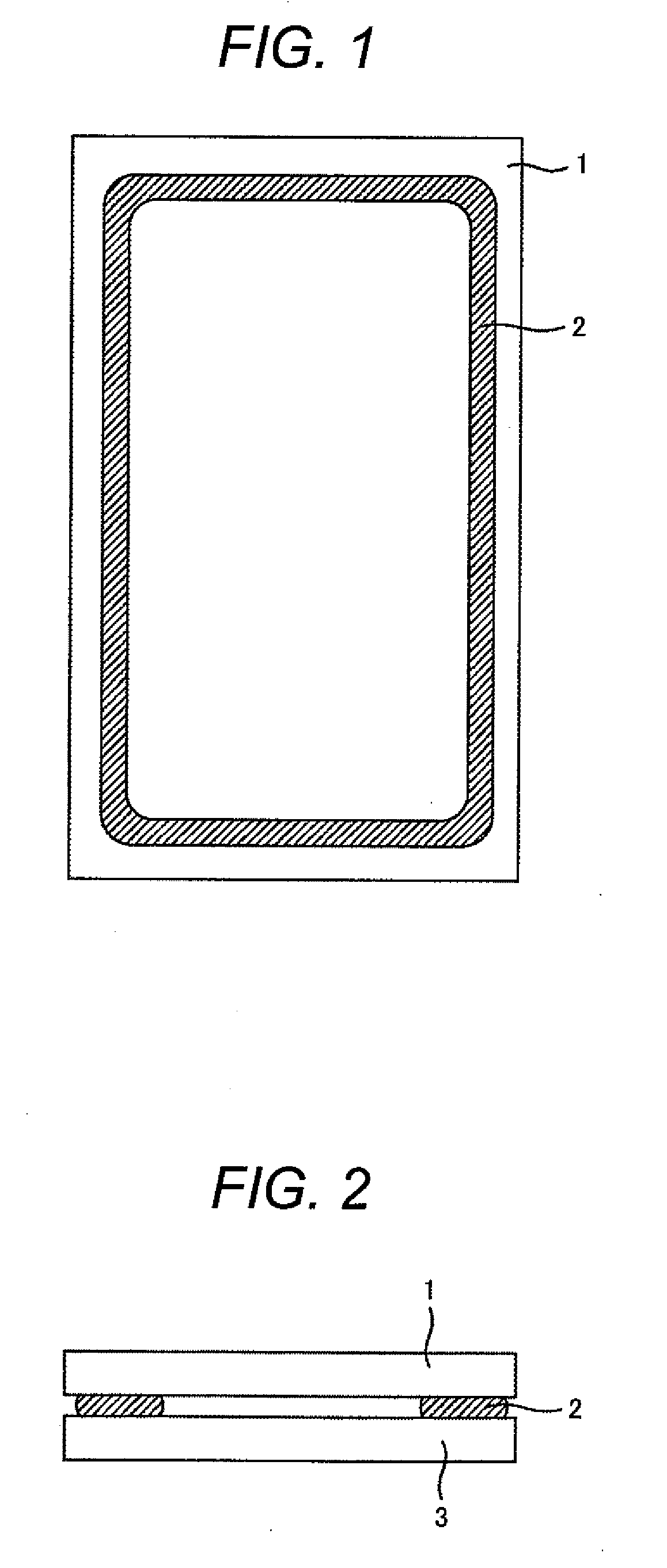

Magnetic recording medium

InactiveUS20100227201A1Excellent reproduction outputReduced particle noiseRecord information storageMagnetic recordingMagnetiteMagnetization

A magnetic recording medium having a nonmagnetic substrate, and a soft magnetic layer and a ferromagnetic layer having a thickness of 5 to 150 nm formed in this order on the nonmagnetic substrate, in which, the ferromagnetic layer contains a spherical, ellipsoidal or plate-form ferromagnetic powder and a binder, and has an axis of easy magnetization substantially in a perpendicular direction, and the soft magnetic layer contains a spherical or ellipsoidal magnetite soft magnetic powder having a particle size of 30 nm or less, a rate of variation in particle size of 20% or less and a saturation magnetization of 10 to 60 Am2 / kg, and a binder.

Owner:HITACHT MAXELL LTD

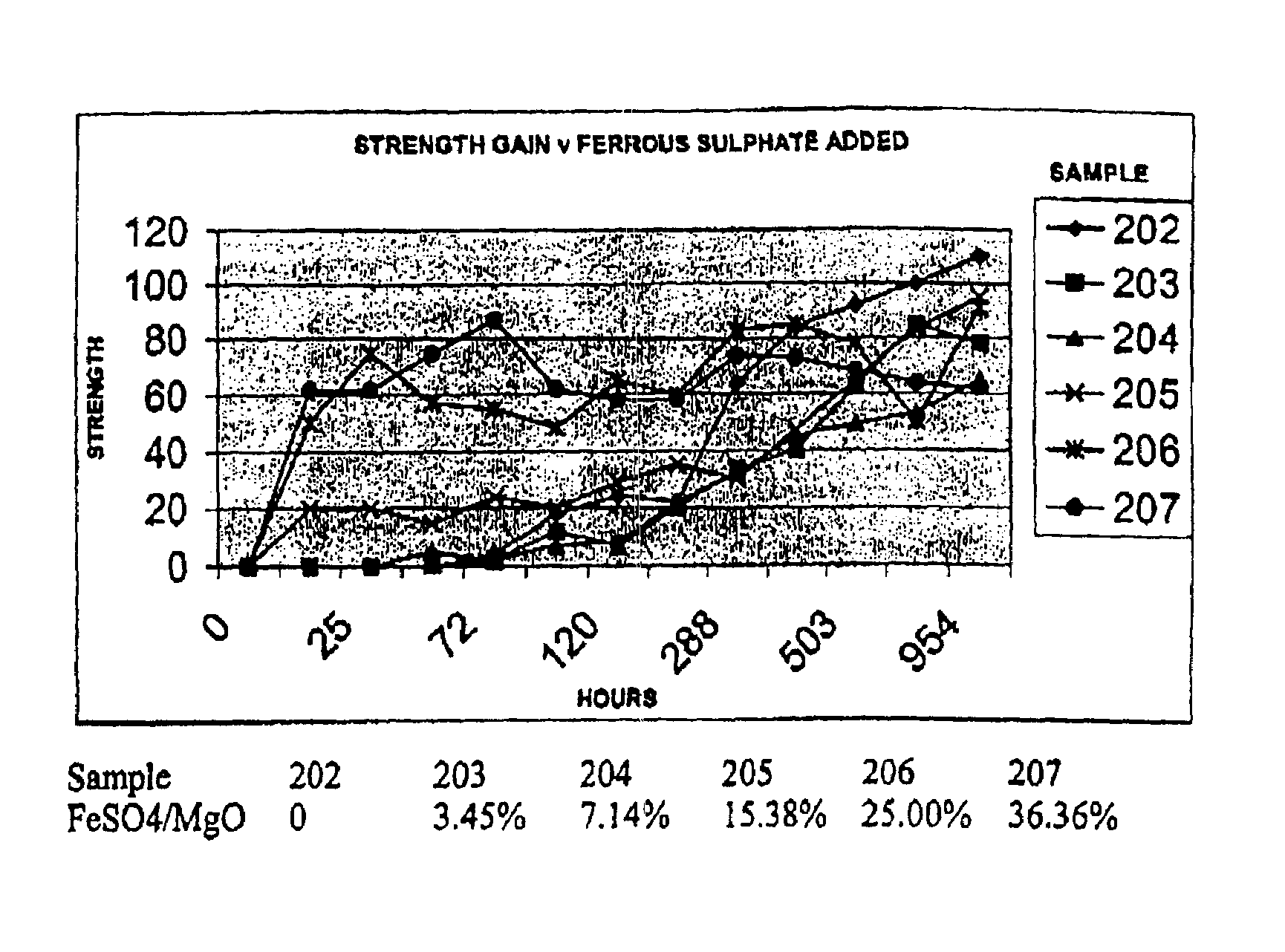

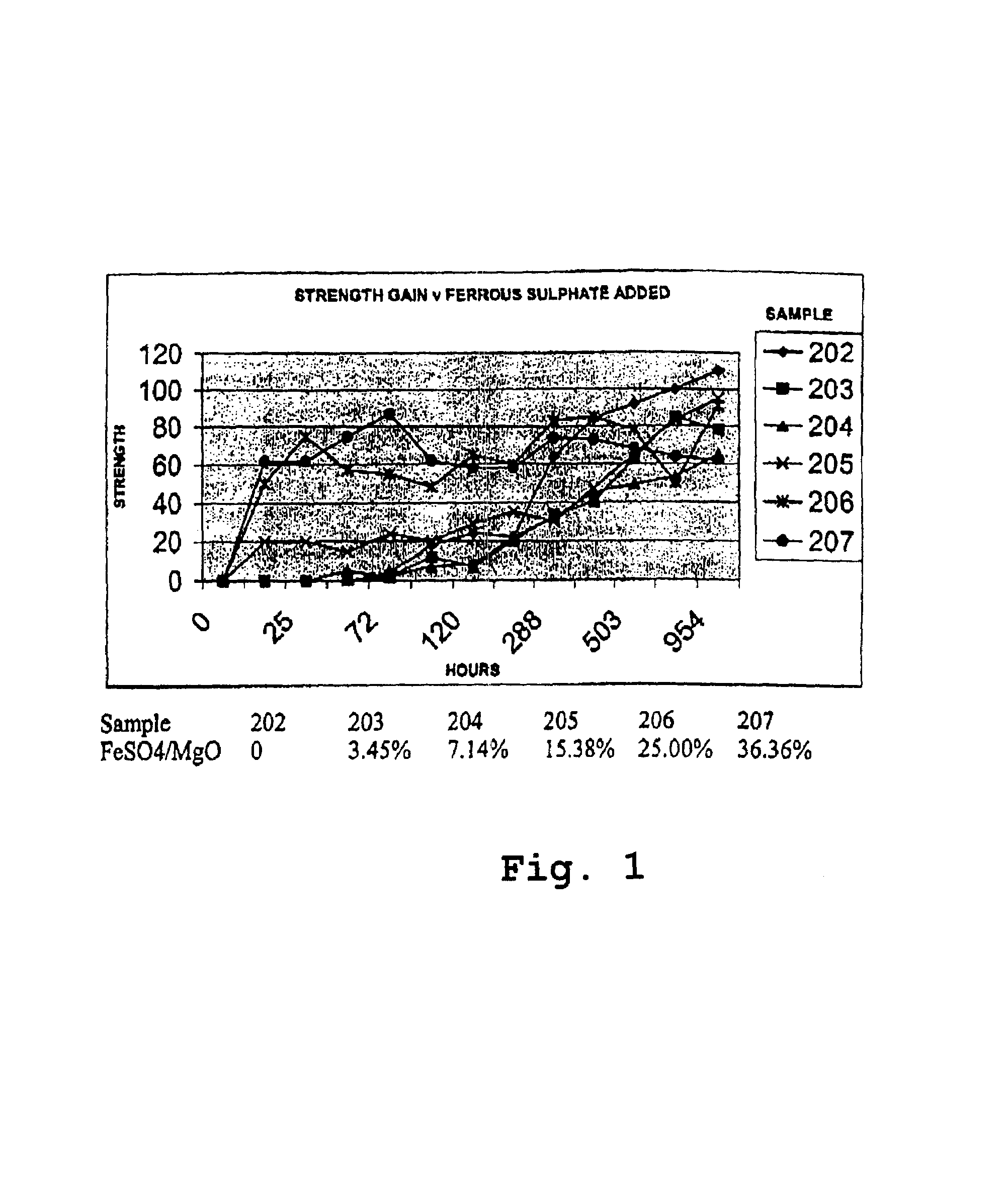

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods.The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

Magnetic tape and magnetic tape device

ActiveUS20180374507A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesIn planeMagnetic force microscope

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, in which the magnetic layer includes a timing-based servo pattern, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, an XRD intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, and an edge shape of the timing-based servo pattern specified by magnetic force microscope observation is a shape in which a difference (L99.9−L0.1) is equal to or smaller than 180 nm, and a magnetic tape device including the magnetic tape.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9530444B2Increased durabilityReduce runningMagnetic materials for record carriersRecord information storageScanning electron microscopeElectron microscope

Owner:FUJIFILM CORP

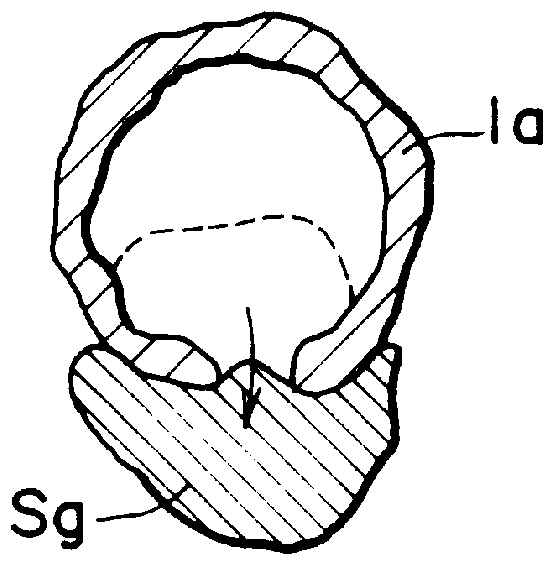

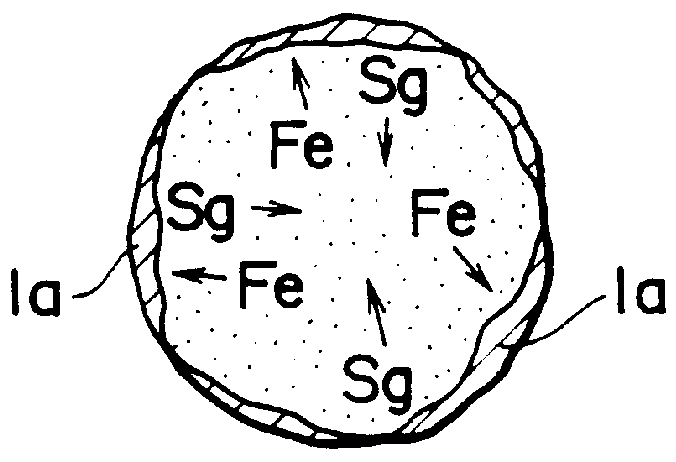

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

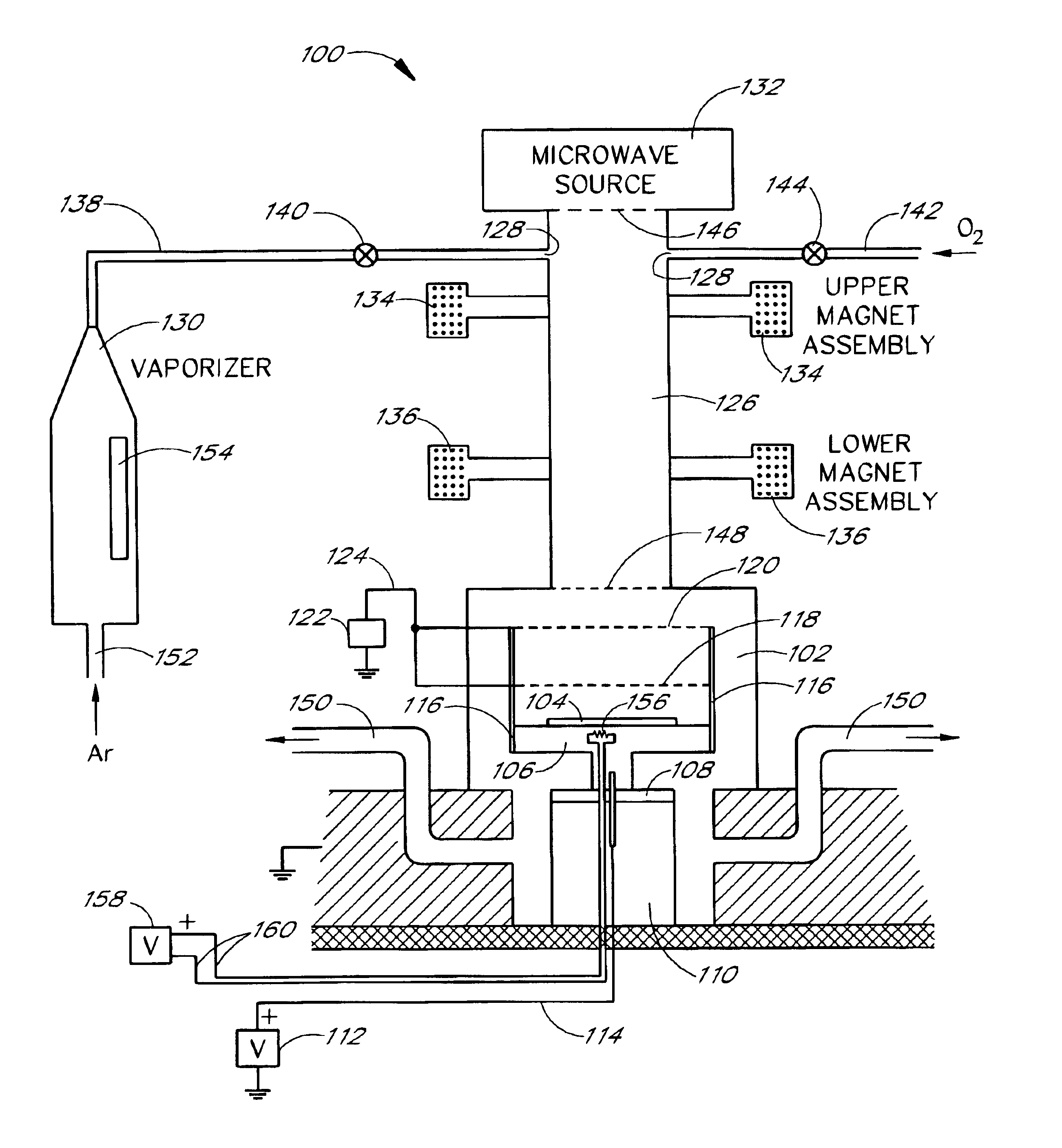

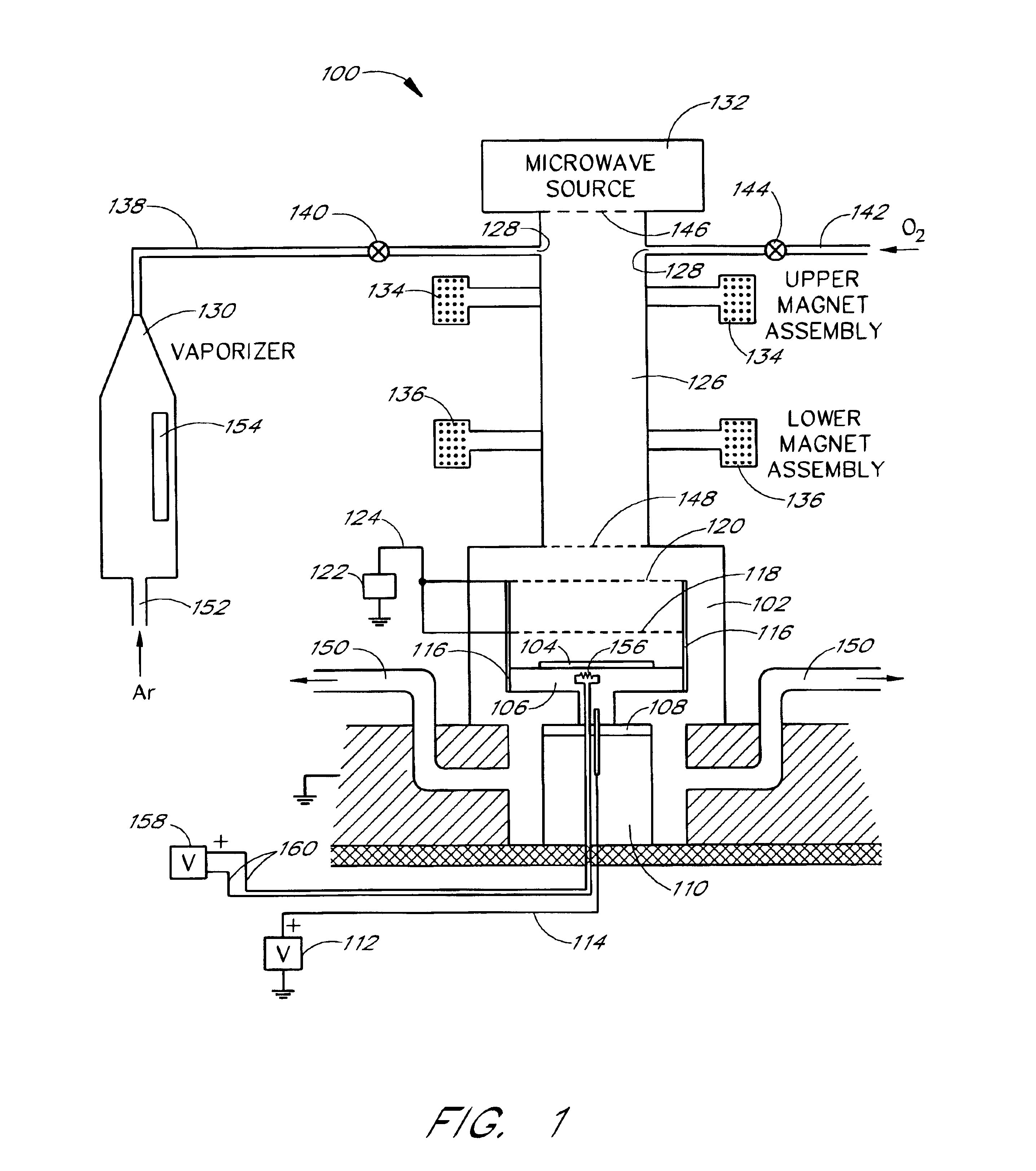

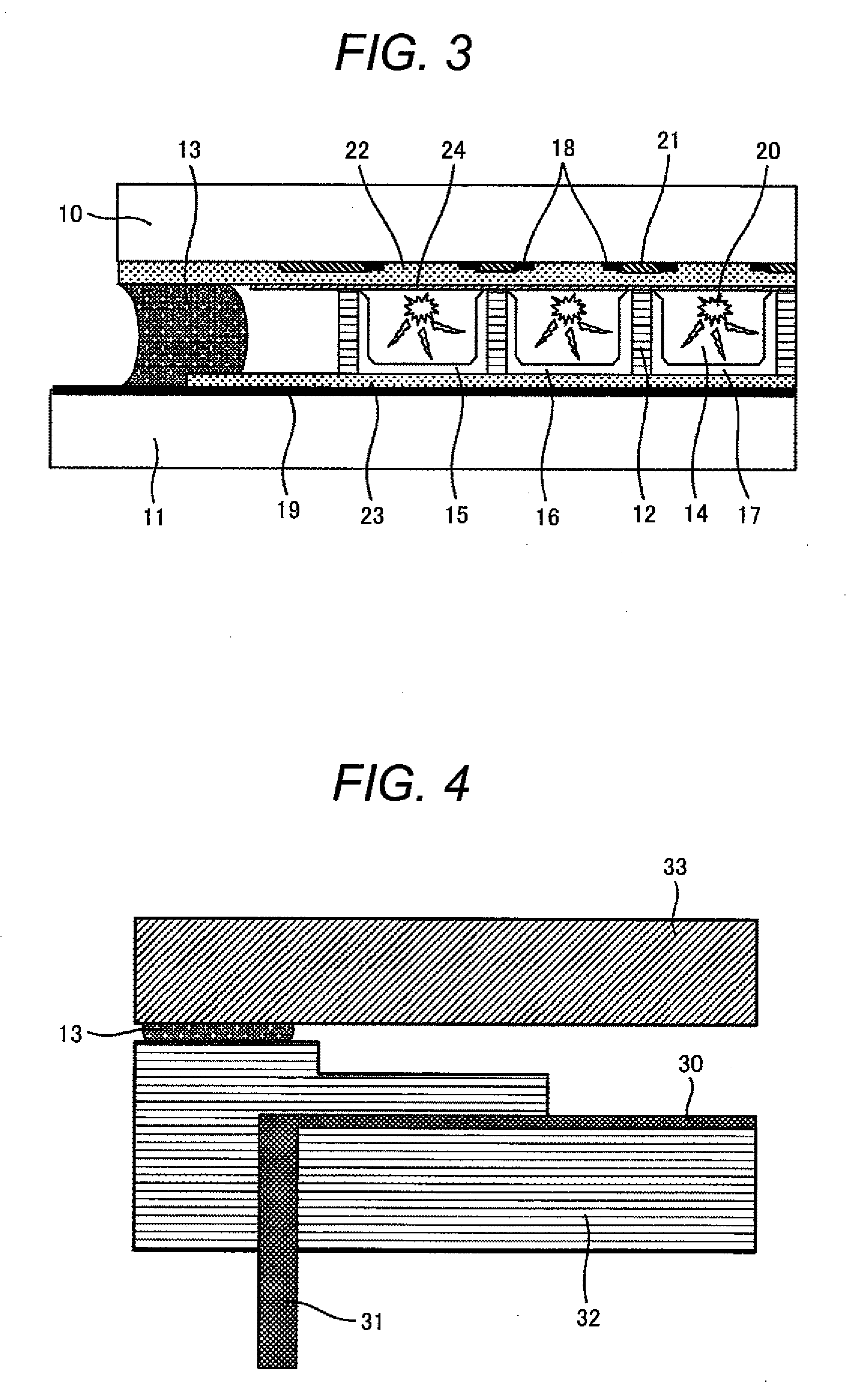

Method and apparatus for the fabrication of ferroelectric films

InactiveUS6858120B2Improve economyEasy to customizeCellsElectric discharge tubesFerroelectric thin filmsOxygen ions

The present invention is related to methods and apparatus for processing weak ferroelectric films on semiconductor substrates, including relatively large substrates, e.g., with 300 millimeter diameter. A ferroelectric film of zinc oxide (ZnO) doped with lithium (Li) and / or magnesium (Mg) is deposited on a substrate in a plasma assisted chemical vapor deposition process such as an electron cyclotron resonance chemical vapor deposition (ECR CVD) process. Zinc is introduced to a chamber through a zinc precursor in a vaporizer. Microwave energy ionizes zinc and oxygen in the chamber to a plasma, which is directed to the substrate with a relatively strong field. Electrically biased control grids control a rate of deposition of the plasma. The control grids also provide Li and / or Mg dopants for the ZnO to create the ferroelectric film. A desired ferroelectric property of the ferroelectric film can be tailored by selecting an appropriate composition of the control grids.

Owner:CONVERSANT INTPROP MANAGEMENT INC

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

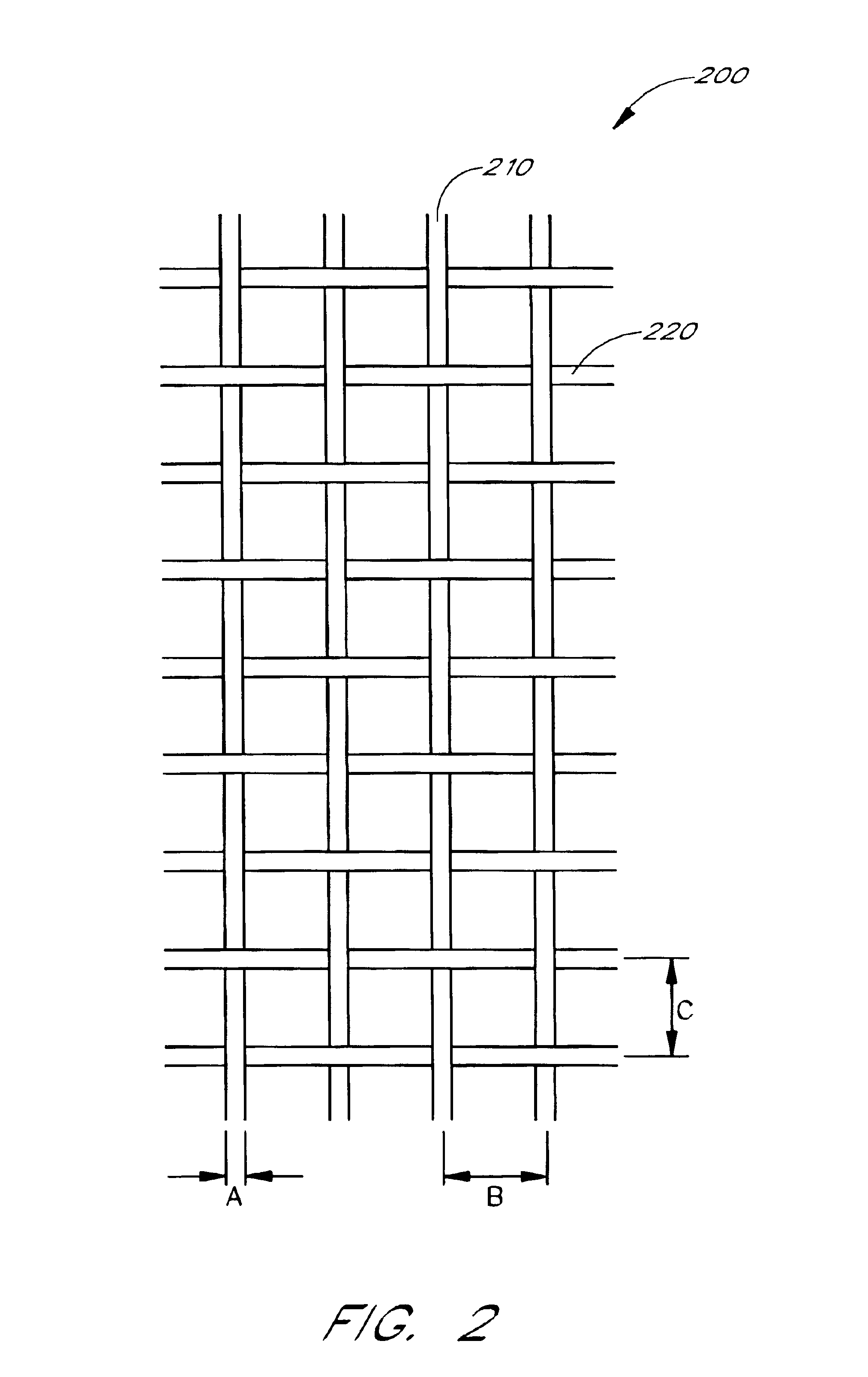

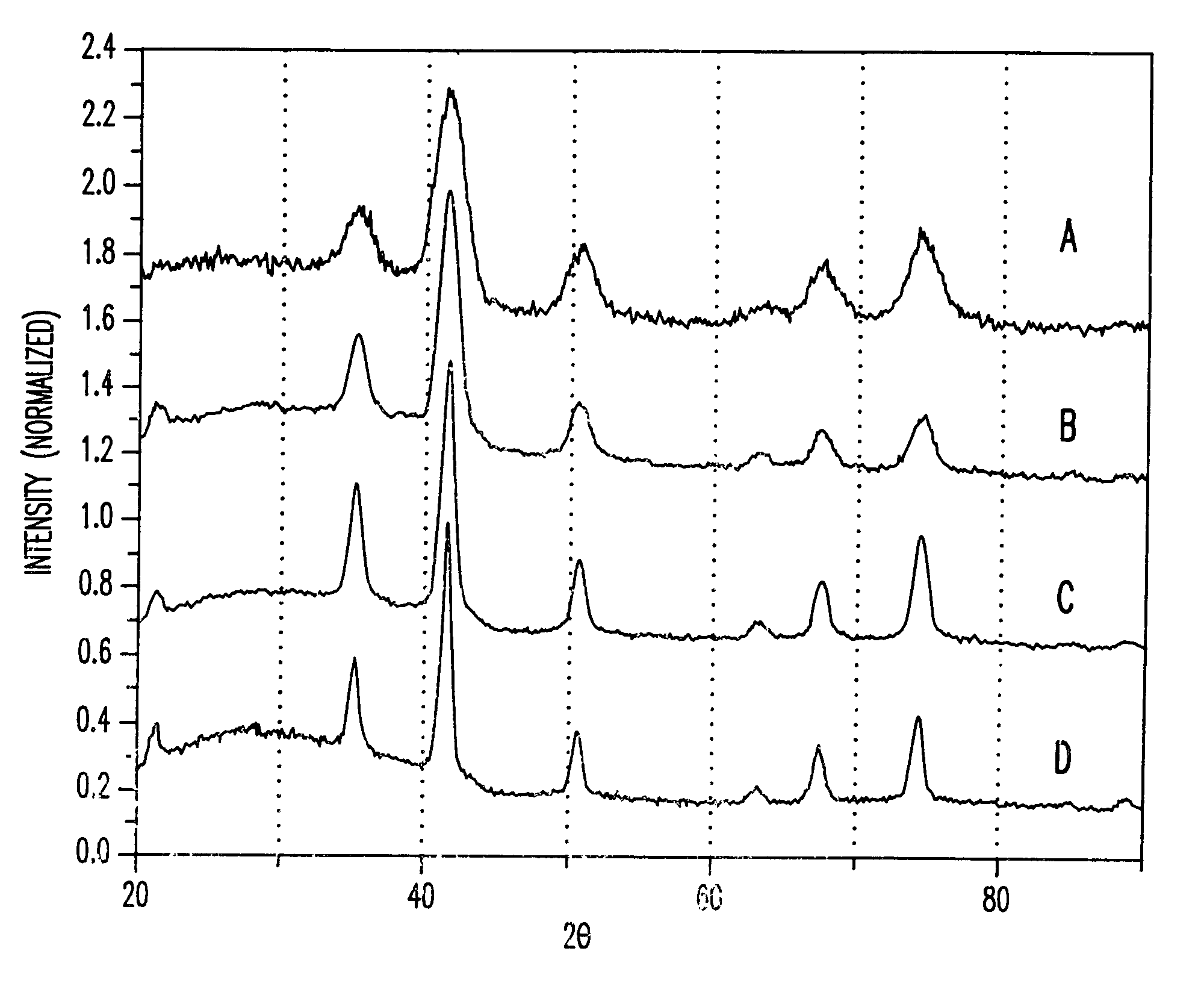

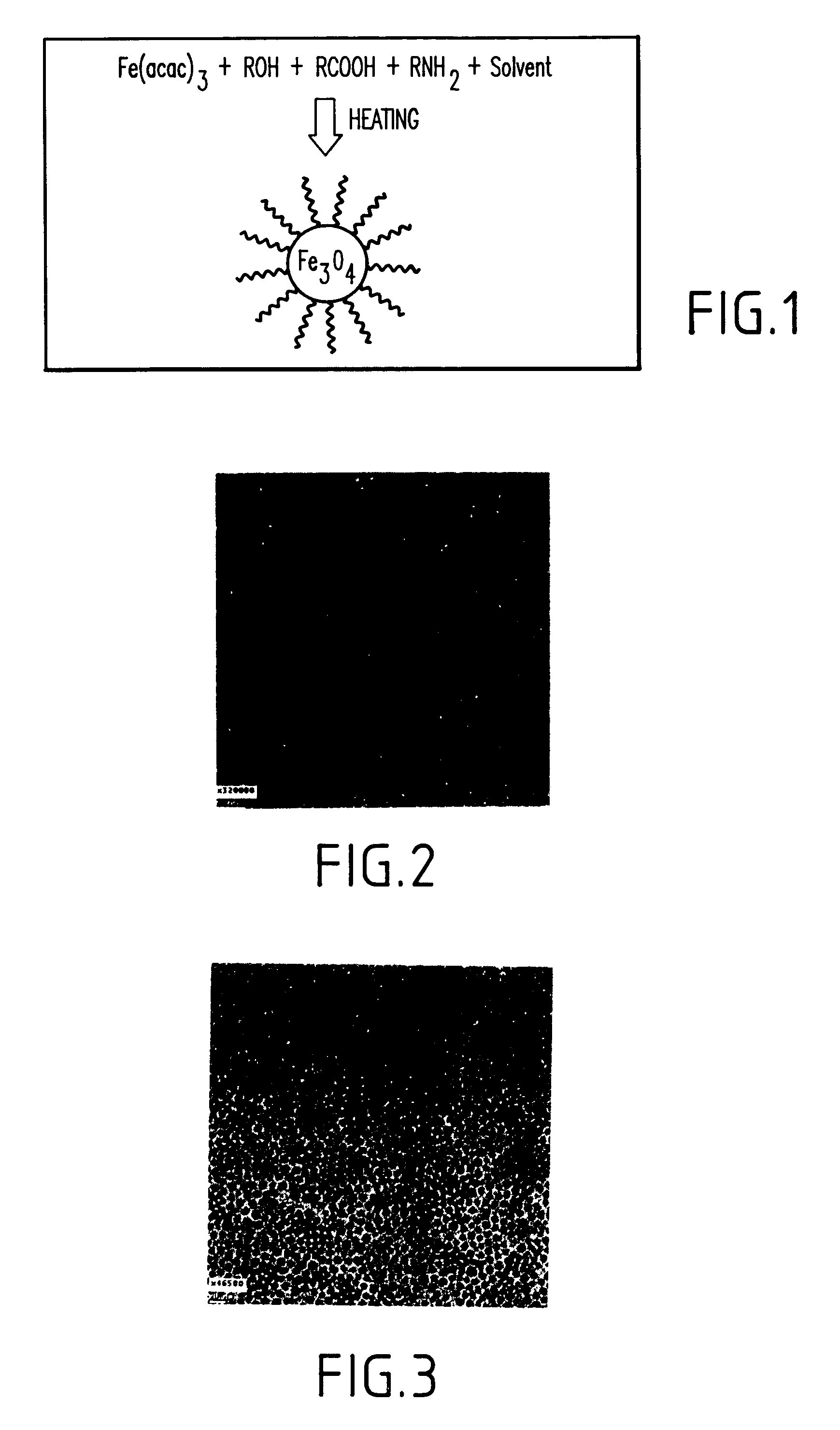

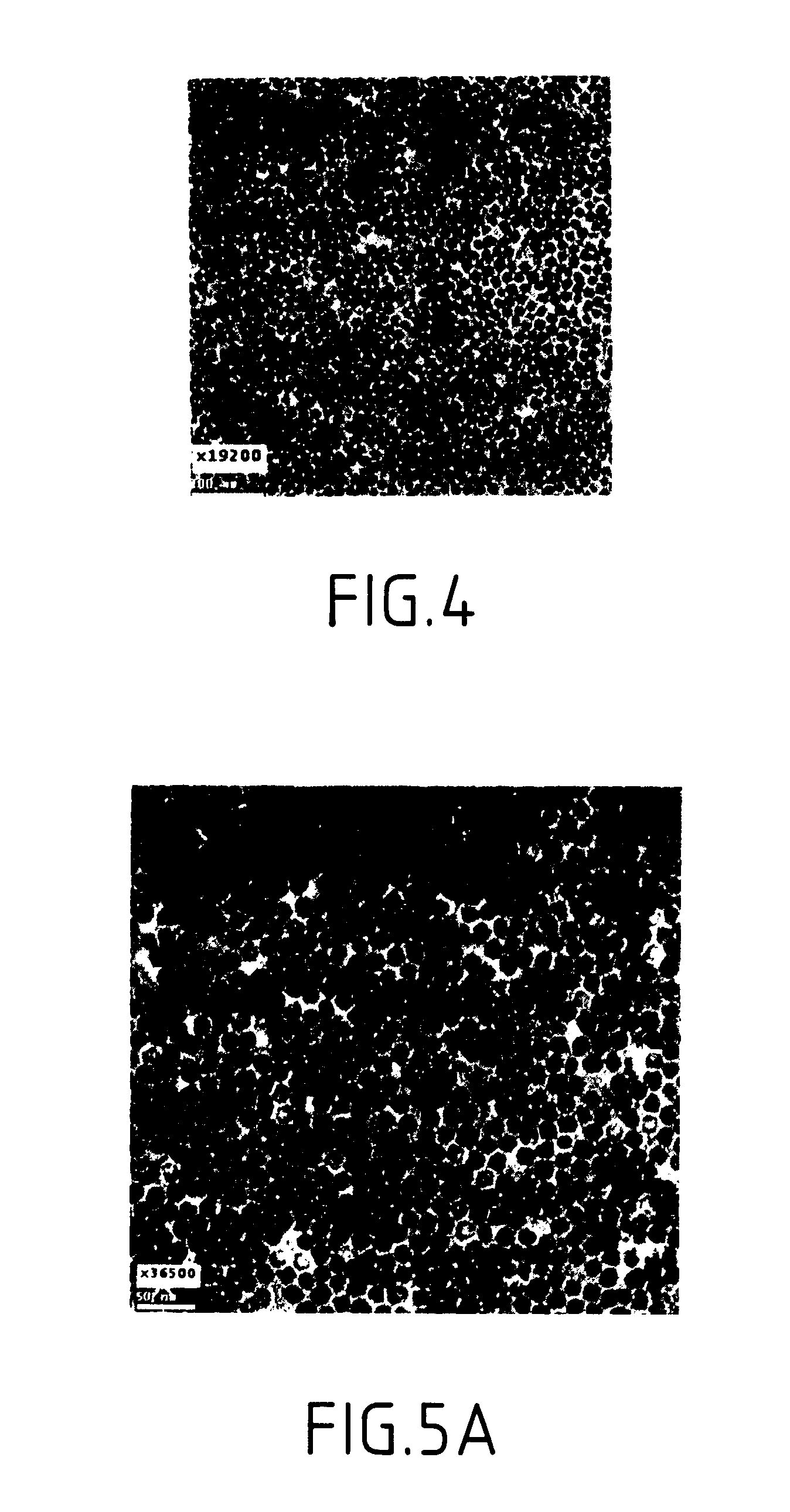

Synthesis of magnetite nanoparticles and the process of forming Fe-based nanomaterials

InactiveUS6962685B2Small sizeNarrow size distributionMaterial nanotechnologyNanomagnetismIron saltsMagnetite Nanoparticles

A method and structure for making magnetite nanoparticle materials by mixing iron salt with alcohol, carboxylic acid and amine in an organic solvent and heating the mixture to 200–360 C is described. The size of the particles can be controlled either by changing the iron salt to acid / amine ratio or by coating small nanoparticles with more iron oxide. Magnetite nanoparticles in the size ranging from 2 nm to 20 nm with a narrow size distribution are obtained with the invention. The invention can be readily extended to other iron oxide based nanoparticle materials, including M Fe2O4 (M=Co, Ni, Cu, Zn, Cr, Ti, Ba, Mg) nanomaterials, and iron oxide coated nanoparticle materials. The invention also leads to the synthesis of iron sulfide based nanoparticle materials by replacing alcohol with thiol in the reaction mixture. The magnetite nanoparticles can be oxidized to γ-Fe2O3, or α-Fe2O3, or can be reduced to bcc-Fe nanoparticles, while iron oxide based materials can be used to make binary iron based metallic nanoparticles, such as CoFe, NiFe, and FeCoSmx nanoparticles.

Owner:INT BUSINESS MASCH CORP

Pretreatment compositions and methods for coating a metal substrate

ActiveUS20090032144A1Sufficient amountElectrophoretic coatingsSolid state diffusion coatingPre treatmentMetal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

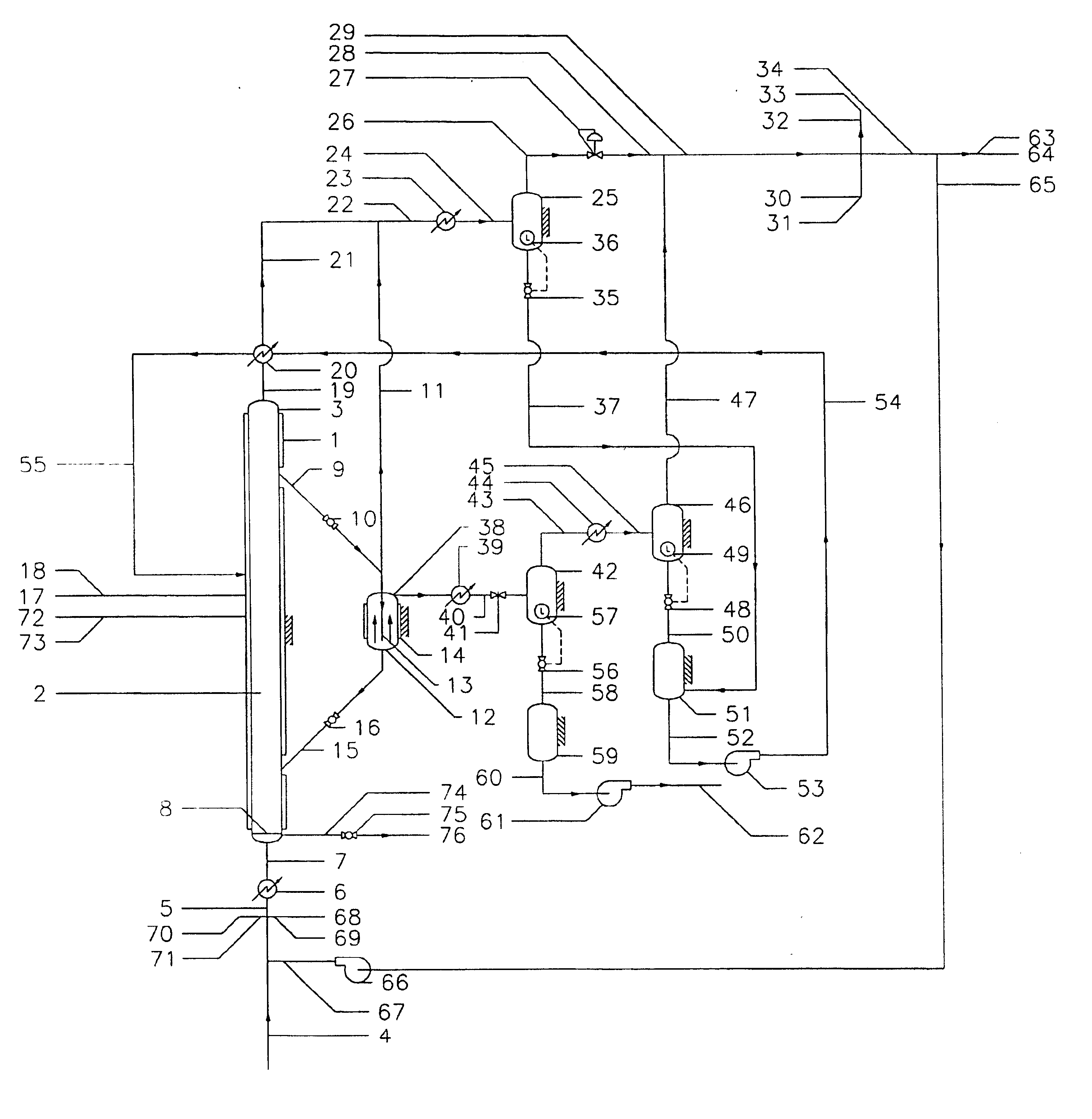

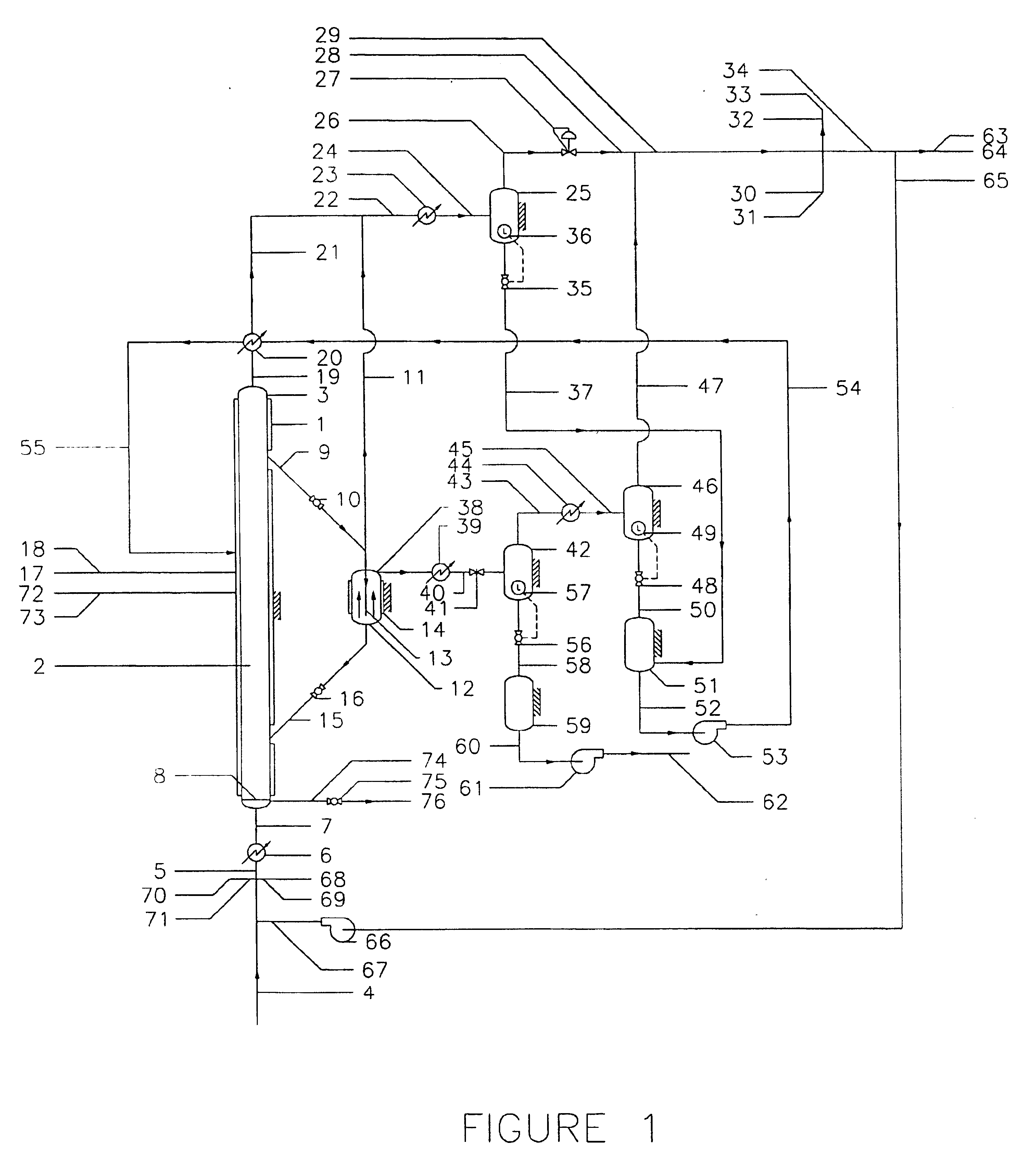

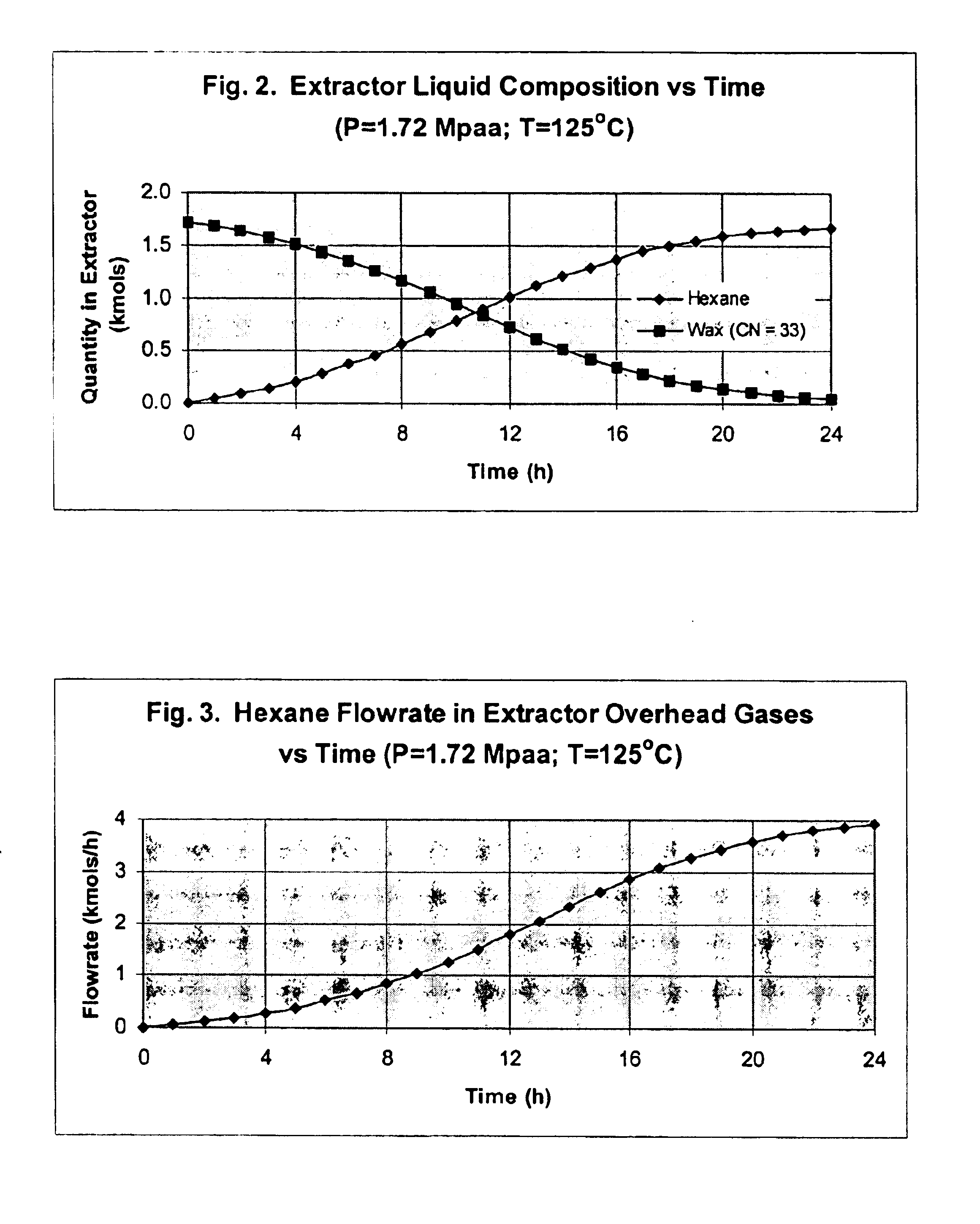

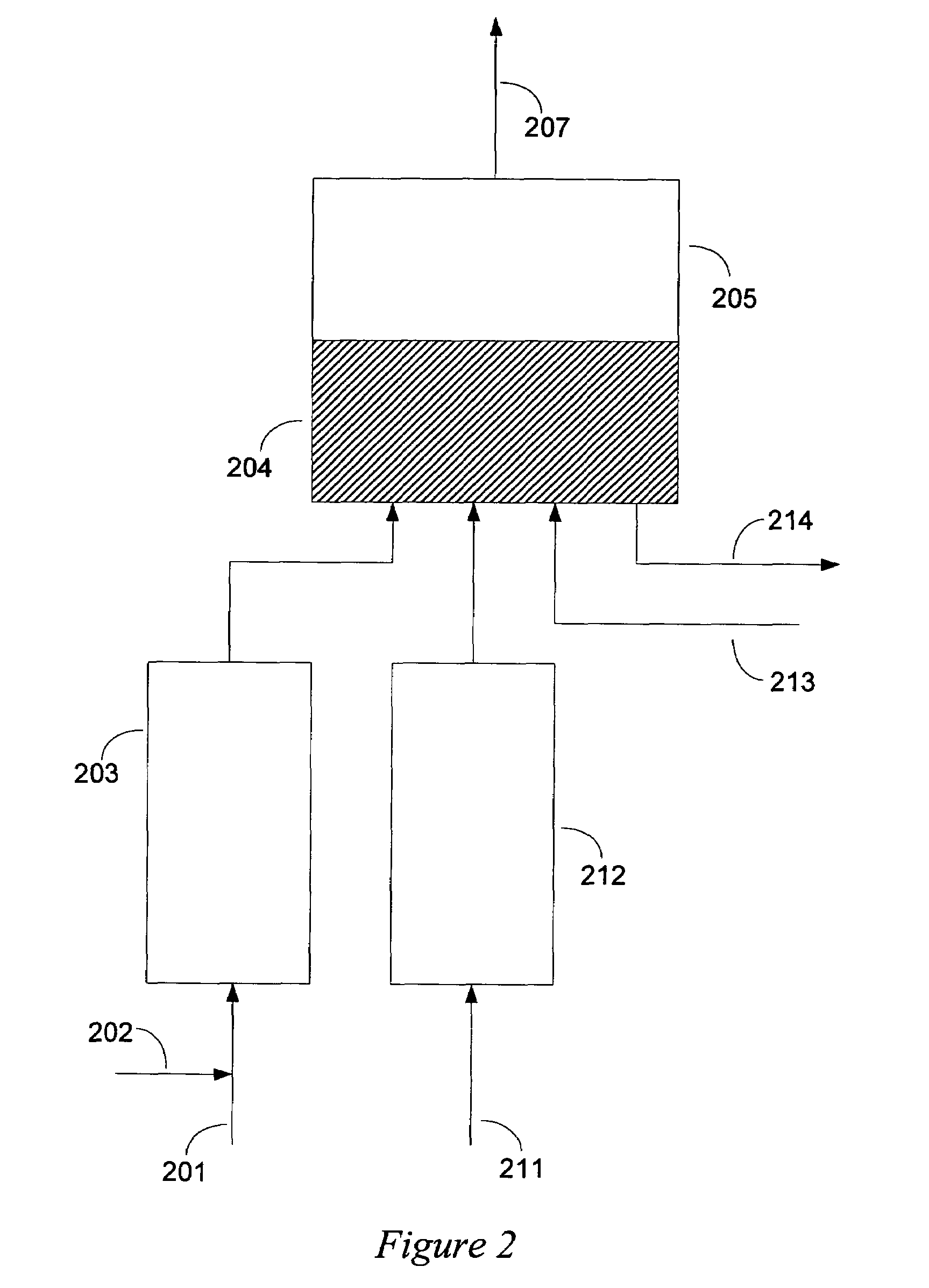

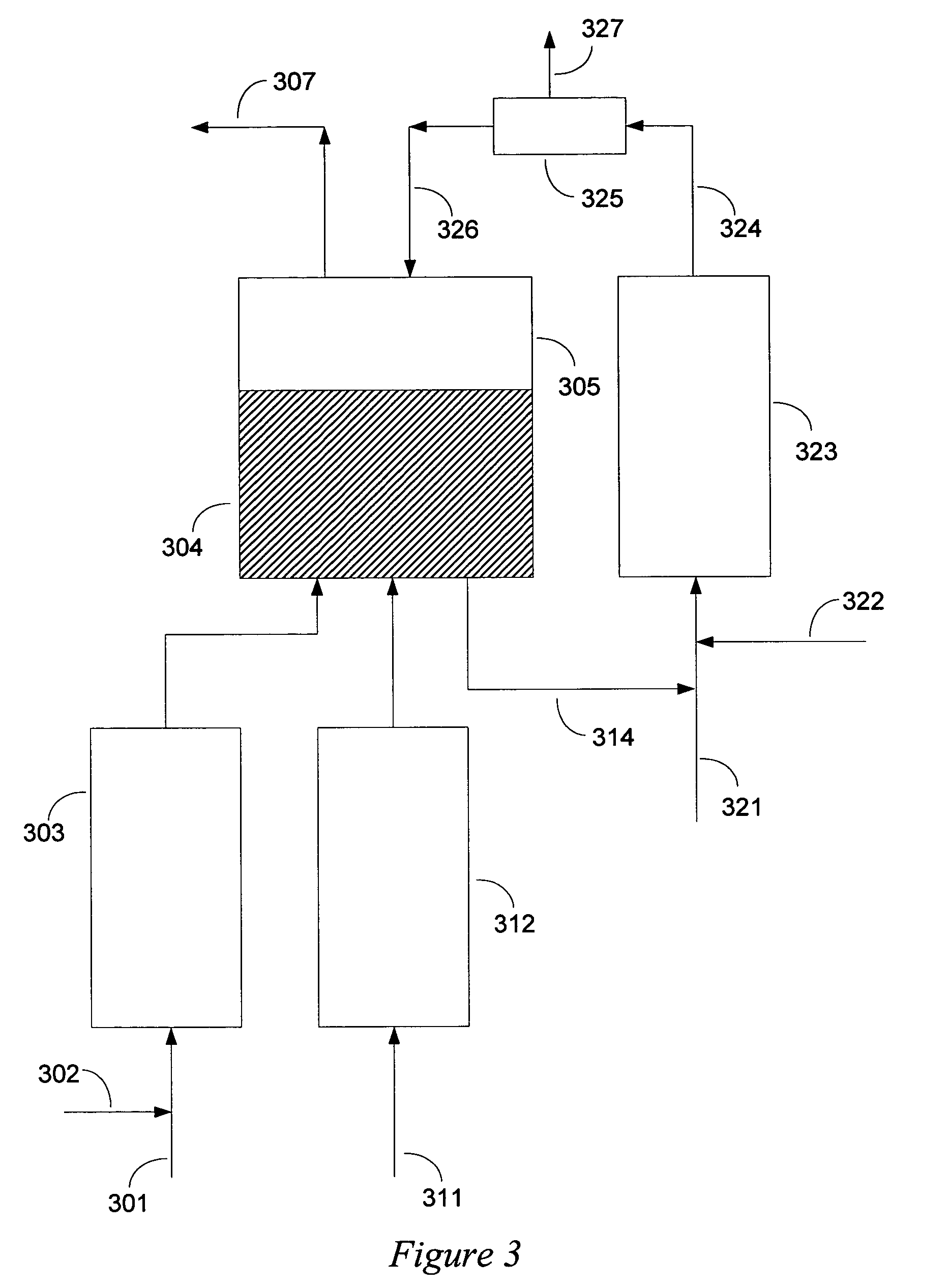

Method and apparatus for regenerating an iron-based Fischer-Tropsch catalyst

ActiveUS6838487B1Reduce concentrationMaintain standardOrganic compound preparationOther chemical processesWaxContinuous flow

Solvent extraction is used to remove wax and contaminants from an iron-based Fischer-Tropsch catalyst in a natural circulation continuous-flow system. The wax-free catalyst is then subjected to controlled oxidation to convert the iron to its initial oxidized state, Fe2O3. Reactivation of the oxide catalyst precursor is carried out by addition of synthesis gas.

Owner:RES USA LLC

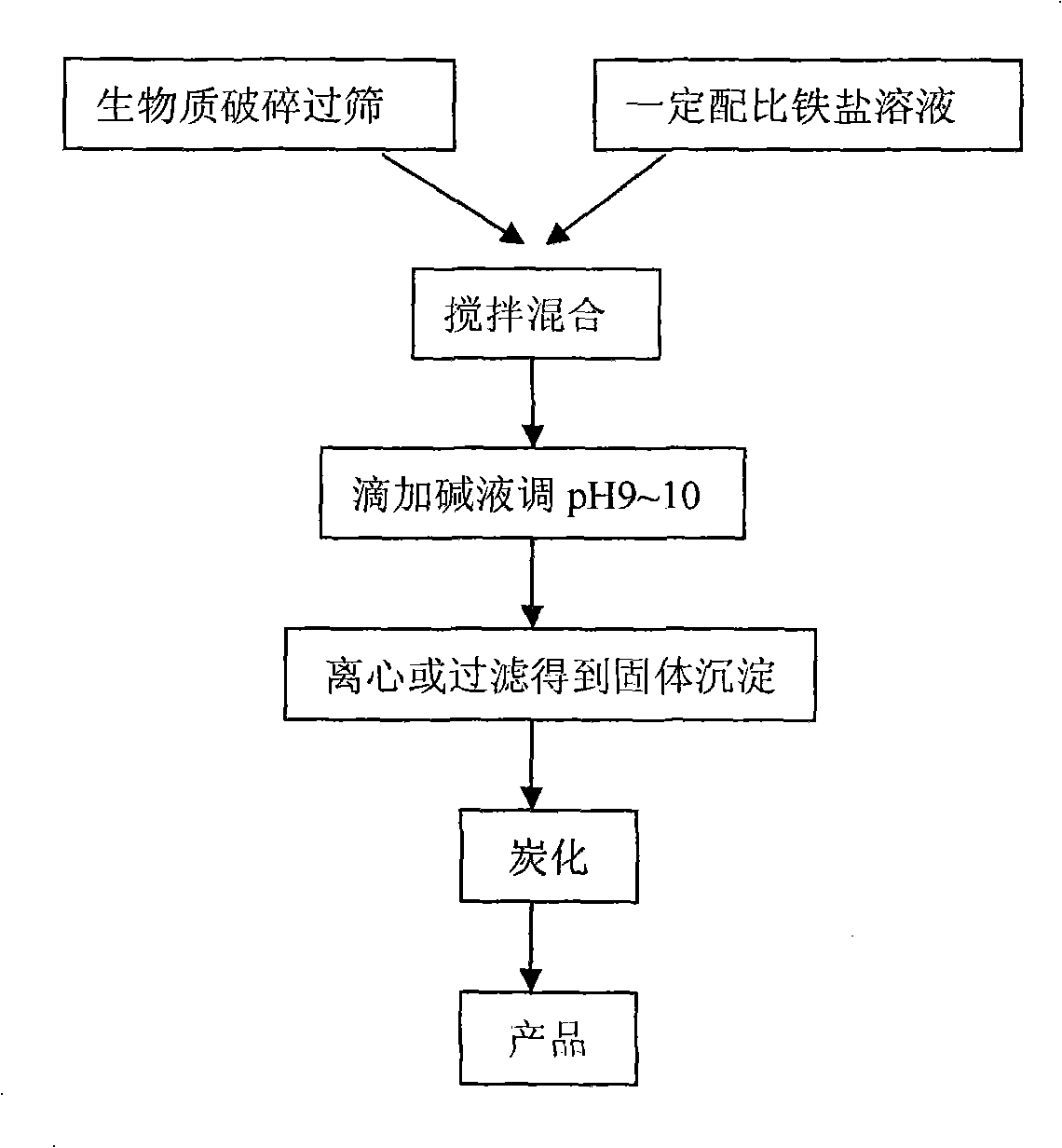

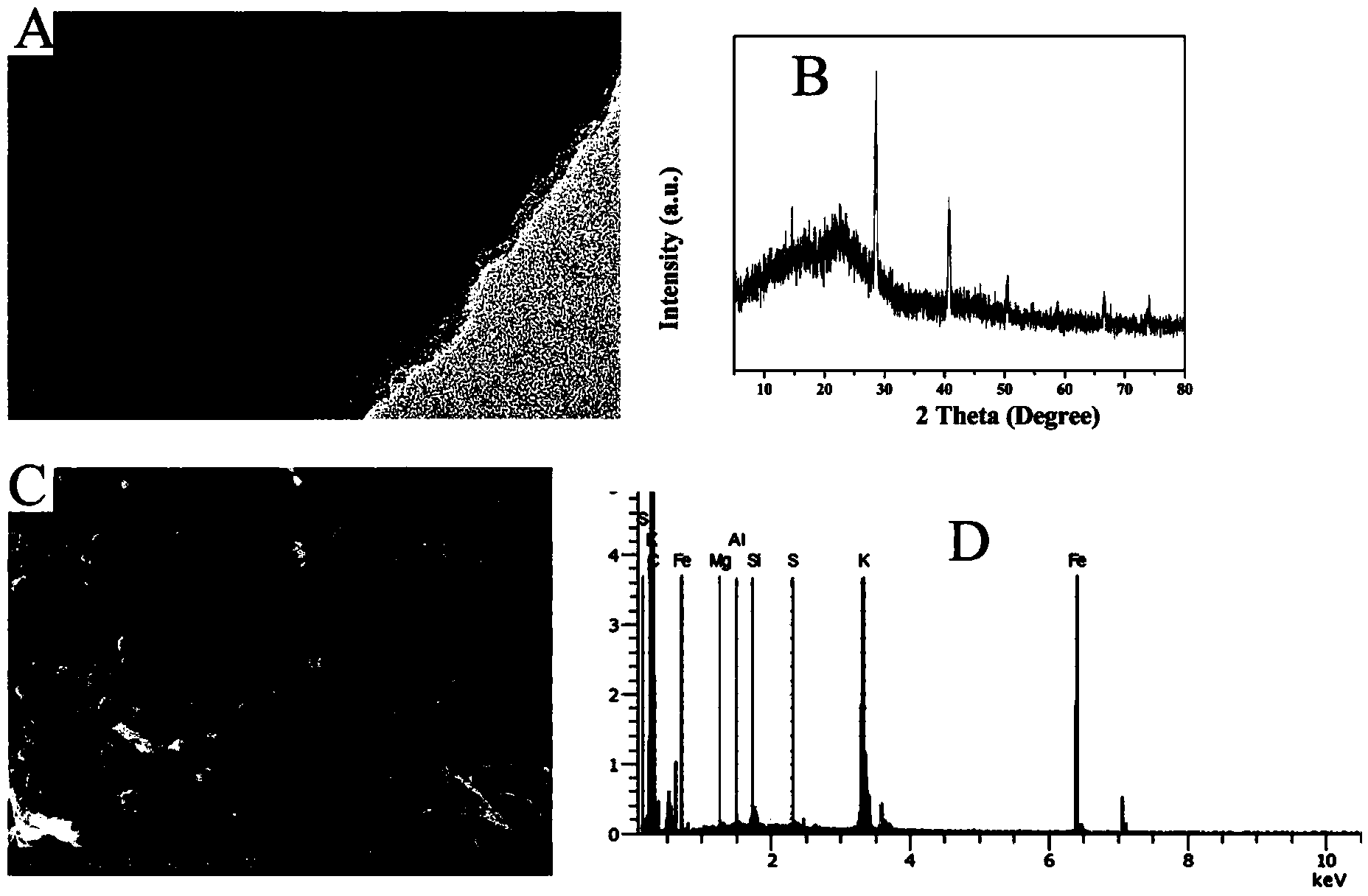

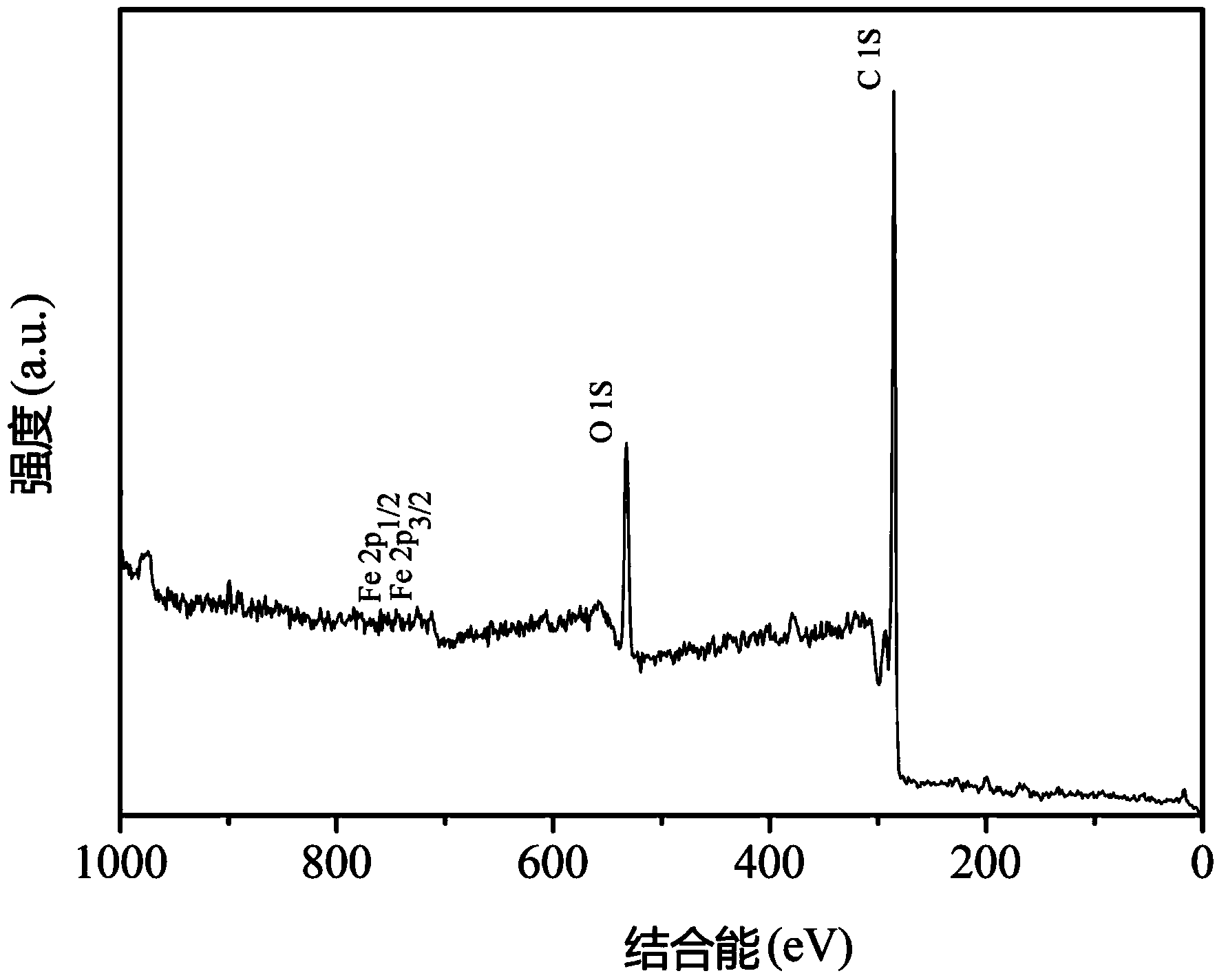

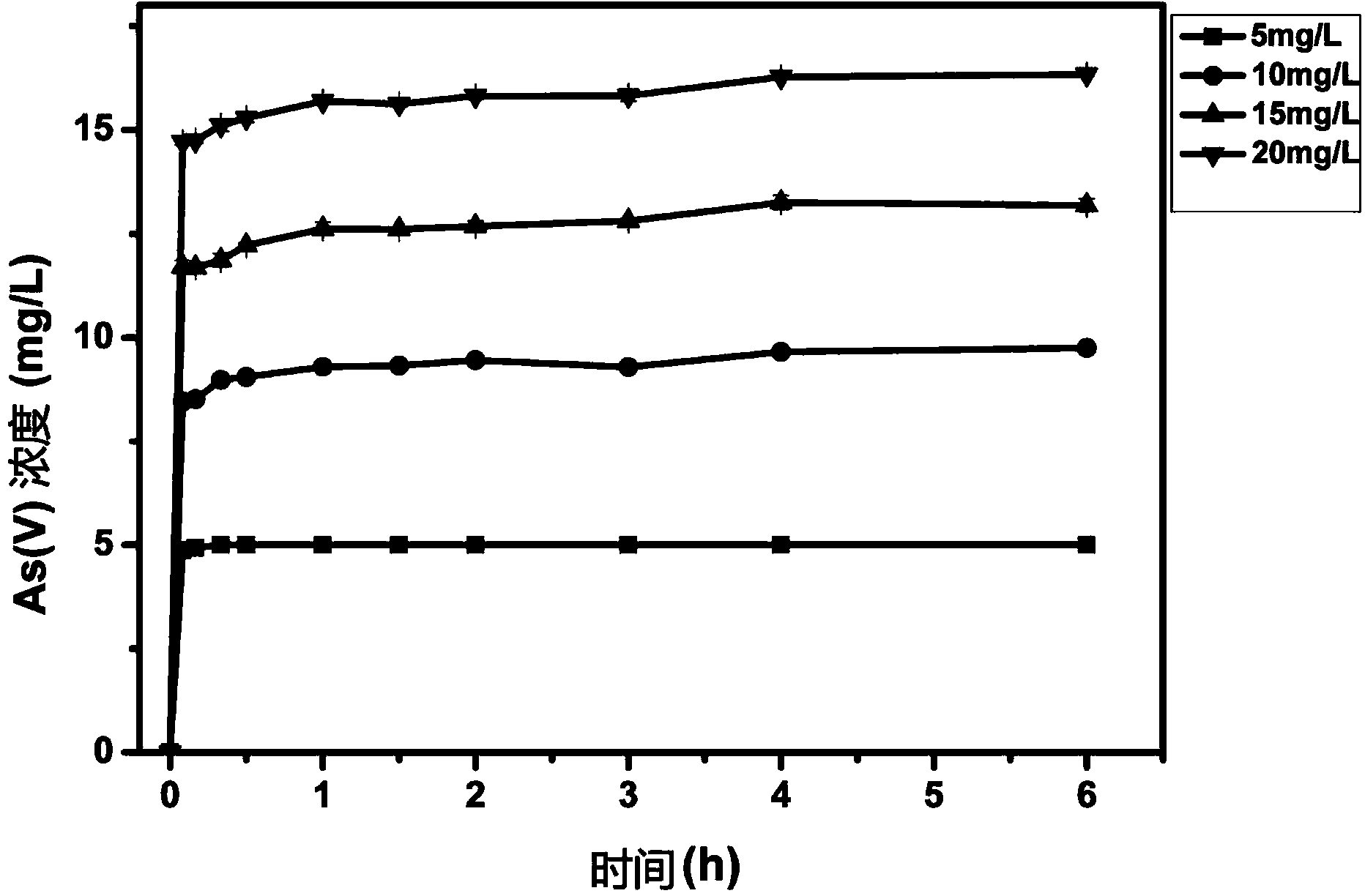

Method for preparing magnetic biological carbon adsorbing material and usage thereof

The invention discloses a method for preparing magnetic biological carbon adsorbing material and the usage thereof. The method comprises the steps: 1) drying and crushing waste biomass, and sieving by20-100 meshes; 2) putting the sieved biomass into 0.1-0.5mol / L of iron salt solution with the weight percent of the biomass being 1-10% of the total quantity; under stirring, dripping 3-6mol / L of NaOH solution until the pH value of the solution is 9-10; 3) filtering, drying and compacting the solid precipitate, and then limiting oxygen carbonizing for 1-5h at the temperature of 100-700 DEG C, thus obtaining the magnetic biological carbon adsorbing material; 4) putting the magnetic biological carbon adsorbing material into waste water, and simultaneously removing organic pollutant and phosphate radical in the waste water. The method realizes synchronization of preparation of the adsorbing material and the process of magnetization, and is simple in preparation process, rich in the source ofthe biomass material and low in cost; furthermore, the prepared magnetic adsorbent is covered by biological carbon or embedded with magnetic nano Fe3O4 granules, has special structure and stable existence, can effectively remove the organic pollutant and phosphate in the waste water, and is easy for magnetic separation.

Owner:ZHEJIANG UNIV

Processing of titanium-aluminum-vanadium alloys and products made thereby

InactiveUS20040221929A1Expensive to produceHigh energy input requirementMetal rolling arrangementsNitrogenTitanium

A method of forming an article from an alpha-beta titanium including, in weight percentages, from about 2.9 to about 5.0 aluminum, from about 2.0 to about 3.0 vanadium, from about 0.4 to about 2.0 iron, from about 0.2 to about 0.3 oxygen, from about 0.005 to about 0.3 carbon, from about 0.001 to about 0.02 nitrogen, and less than about 0.5 of other elements. The method comprises cold working the alpha-beta titanium alloy.

Owner:ATI PROPERTIES

Magnetic recording medium and coating composition for magnetic recording medium

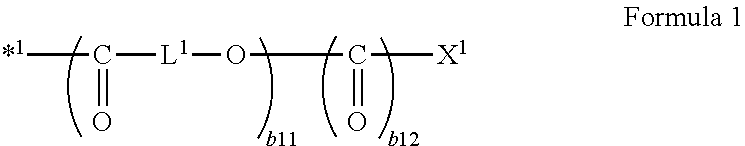

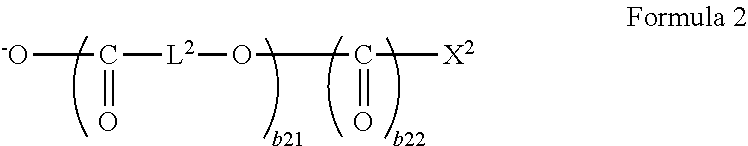

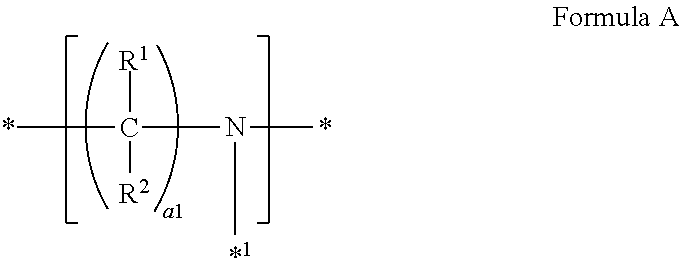

InactiveUS20140374645A1Good dispersionSmall particle sizeInorganic material magnetismRecord information storagePolyesterNon magnetic

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein an average particle size of the ferromagnetic powder is equal to or less than 50 nm, the magnetic layer further comprises a compound, and the compound comprises at least one polyalkyleneimine chain and at least one polyester chain, with a proportion in the compound accounted for by the polyalkyleneimine chain being less than 5.0 weight percent and a number average molecular weight of the polyalkyleneimine chain ranging from 300 to 3,000.

Owner:FUJIFILM CORP

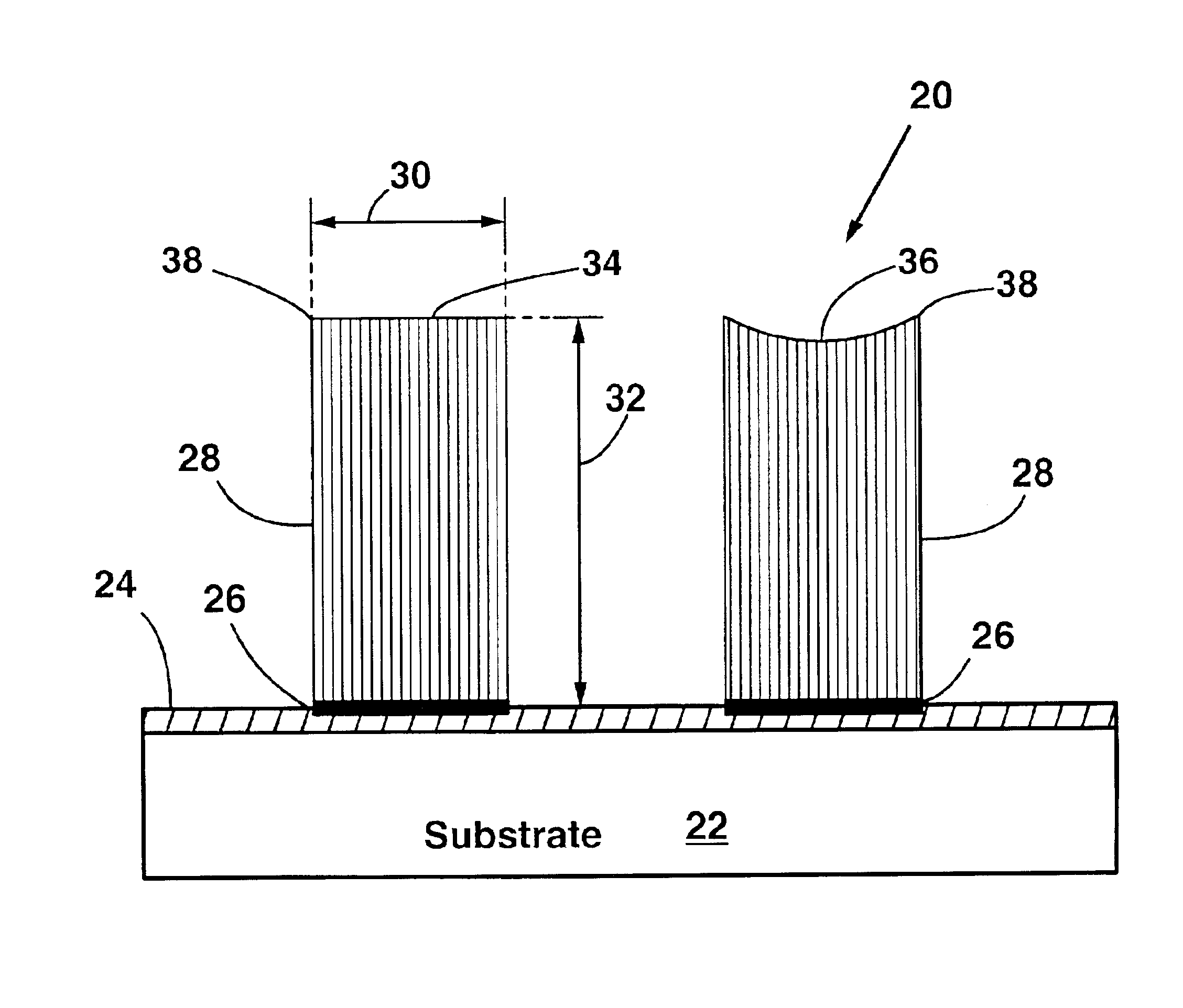

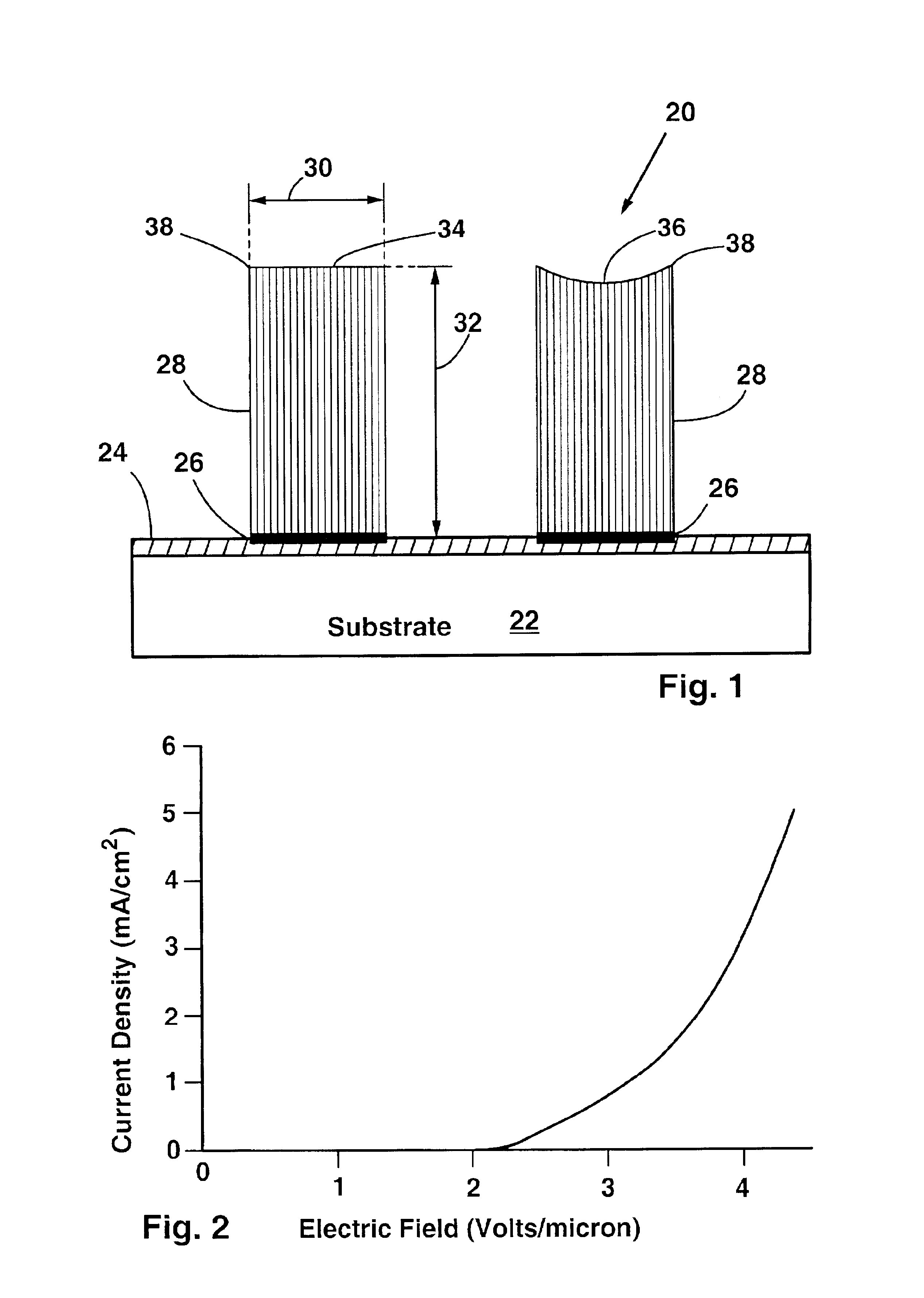

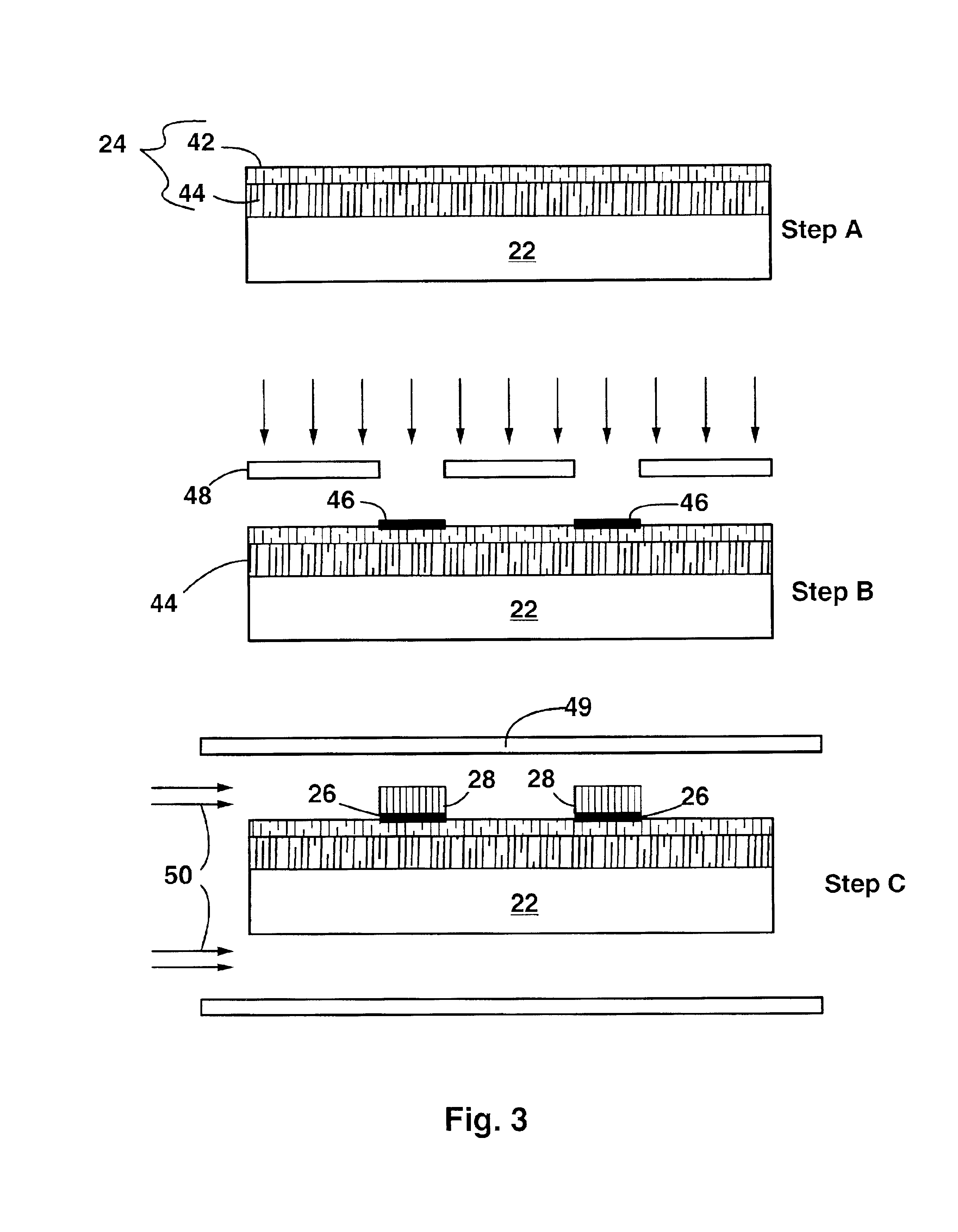

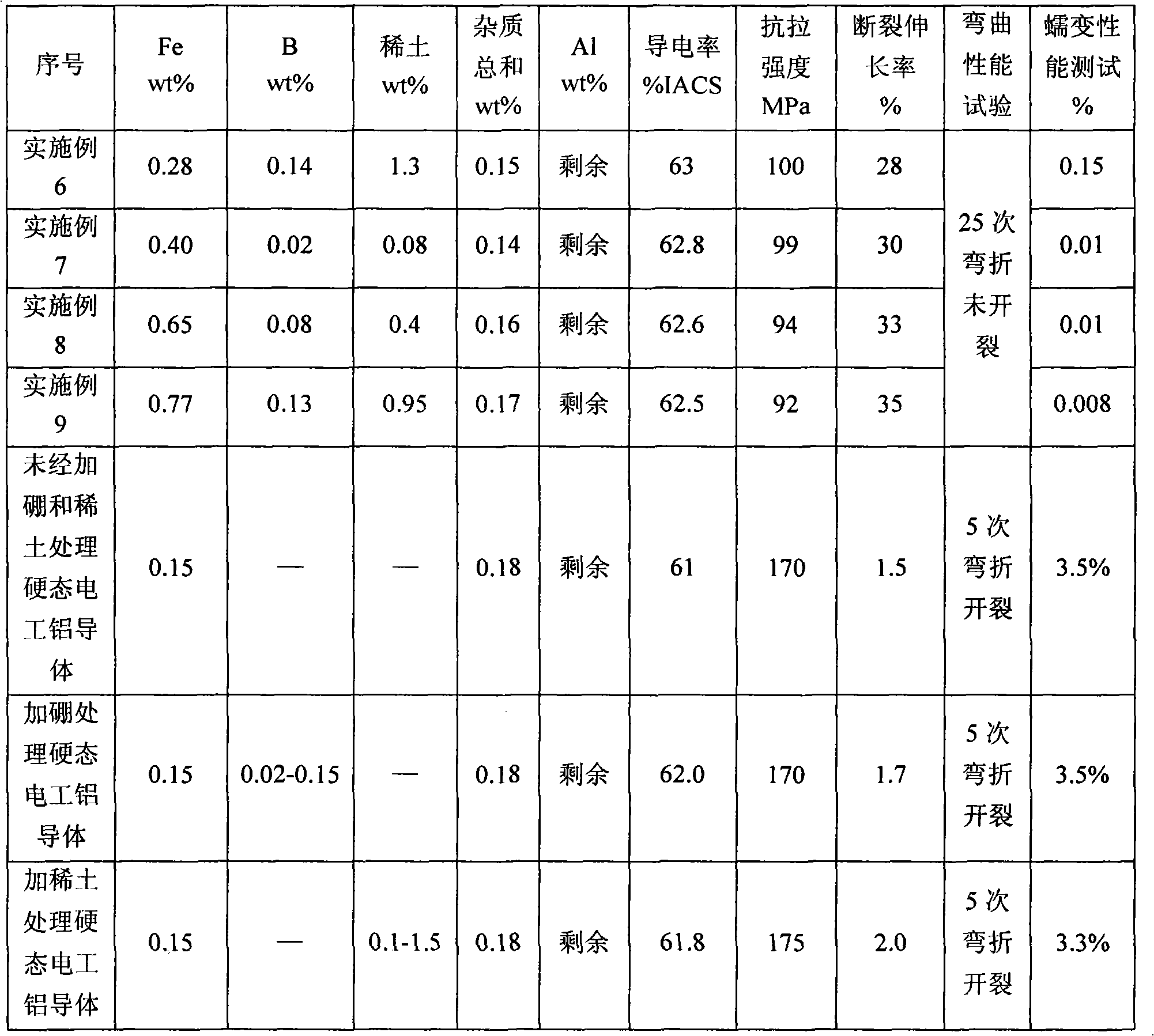

Self-oriented bundles of carbon nanotubes and method of making same

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

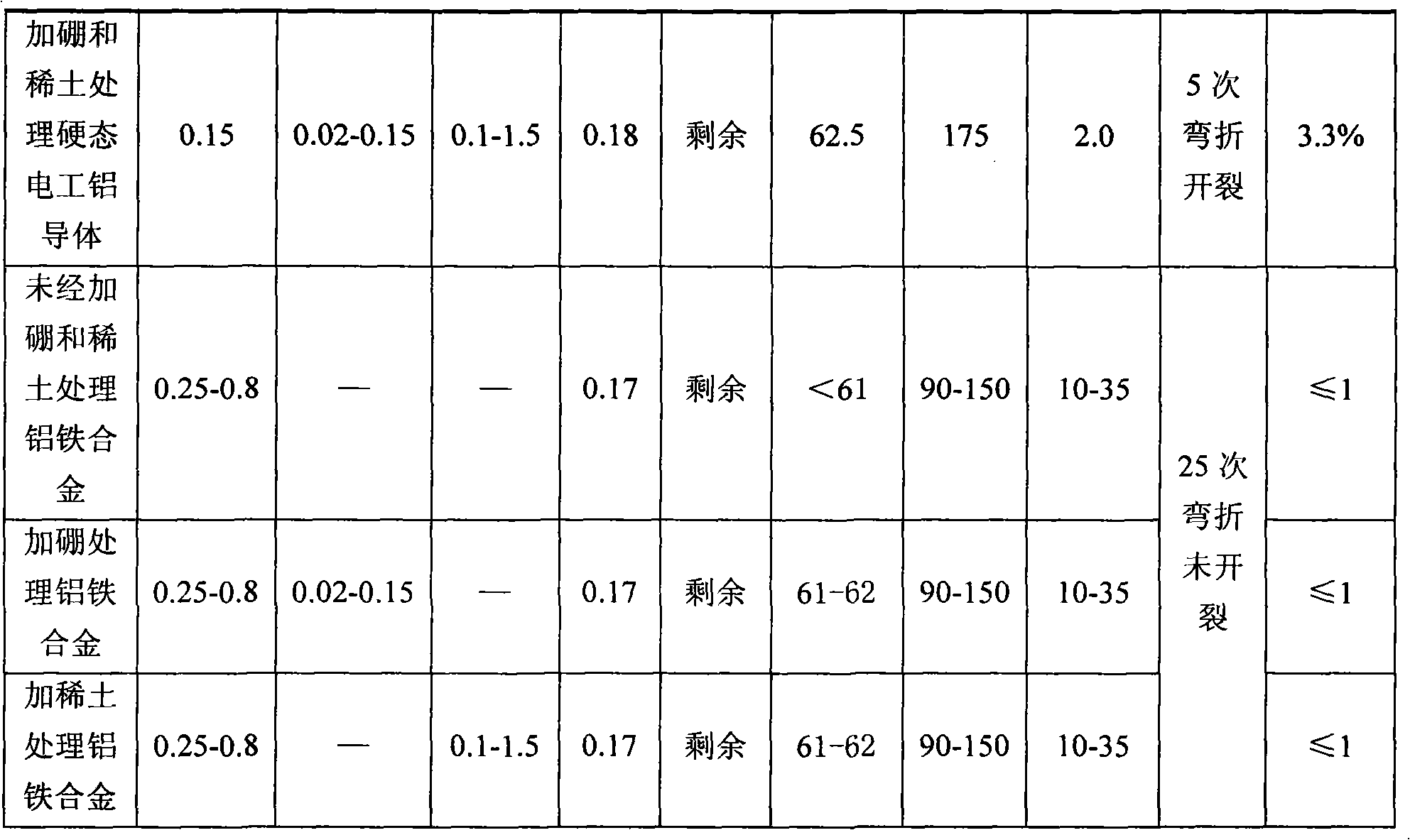

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Method for making single-wall carbon nanotubes using supported catalysts

InactiveUS7250148B2Suitable for growthAppropriate densityMaterial nanotechnologyFibre chemical featuresCarbon nanotubeMoving bed

A method for growing single-wall carbon nanotubes involves preparing a catalyst comprising catalytic metals, iron and molybdenum, and magnesium oxide support material and contacting the catalyst with a gaseous carbon-containing feedstock at a sufficient temperature and for a sufficient contact time to make single-wall carbon nanotubes. The weight ratio of iron and molybdenum can range from about 2 to 1 to about 10 to 1 and the metals loading up to about 10 wt % of the MgO. The catalyst can be sulfided. Methane is a suitable carbon-containing feedstock. The process can be conducted in batch, continuous or semi-continuous modes, in reactors, such as a transport reactor, fluidized bed reactor, moving bed reactors and combinations thereof. The process also includes making single-wall carbon nanotubes with catalysts comprising at least one Group VIB or Group VIIIB metal on supports such as magnesia, zirconia, silica, and alumina, where the catalyst is sulfided.

Owner:UNIDYM

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

Methods to improve heteroatom lattice substitution in large and extra-large pore borosilicate zeolites

InactiveUS6790433B2Controlled catalytic propertyAluminium compoundsMolecular sieve catalystsIron saltsAluminosilicate

The invention, in one embodiment, is a method for preparing crystalline zeolites by (a) contacting a calcined essentially aluminum free borosilicate zeolite with an aqueous acid solution, thereby producing an at least partially deboronated zeolite; (b) contacting said at least partially deboronated zeolite with a solution selected from the group consisting of an aqueous aluminum salt solution, thereby producing an aluminosilicate zeolite; an aqueous gallium salt solution, thereby producing a gallosilicate zeolite; an aqueous iron salt solution, thereby producing a ferrosilicate zeolite; and mixtures thereof; and (c) where the contacting in step (b) occurs at a pH of not greater than about 3.5. In another embodiment, the present invention provides a method for preparing crystalline zeolites by contacting a calcined essentially aluminum free large or extra-large pore borosilicate zeolite with a solution selected from the group consisting of an aqueous aluminum salt solution, thereby producing an aluminosilicate zeolite; an aqueous gallium salt solution, thereby producing a gallosilicate zeolite; an aqueous iron salt solution, thereby producing a ferrosilicate zeolite; and mixtures thereof; and where the contacting occurs at a pH of not greater than about 3.5.

Owner:CHEVROU USA INC

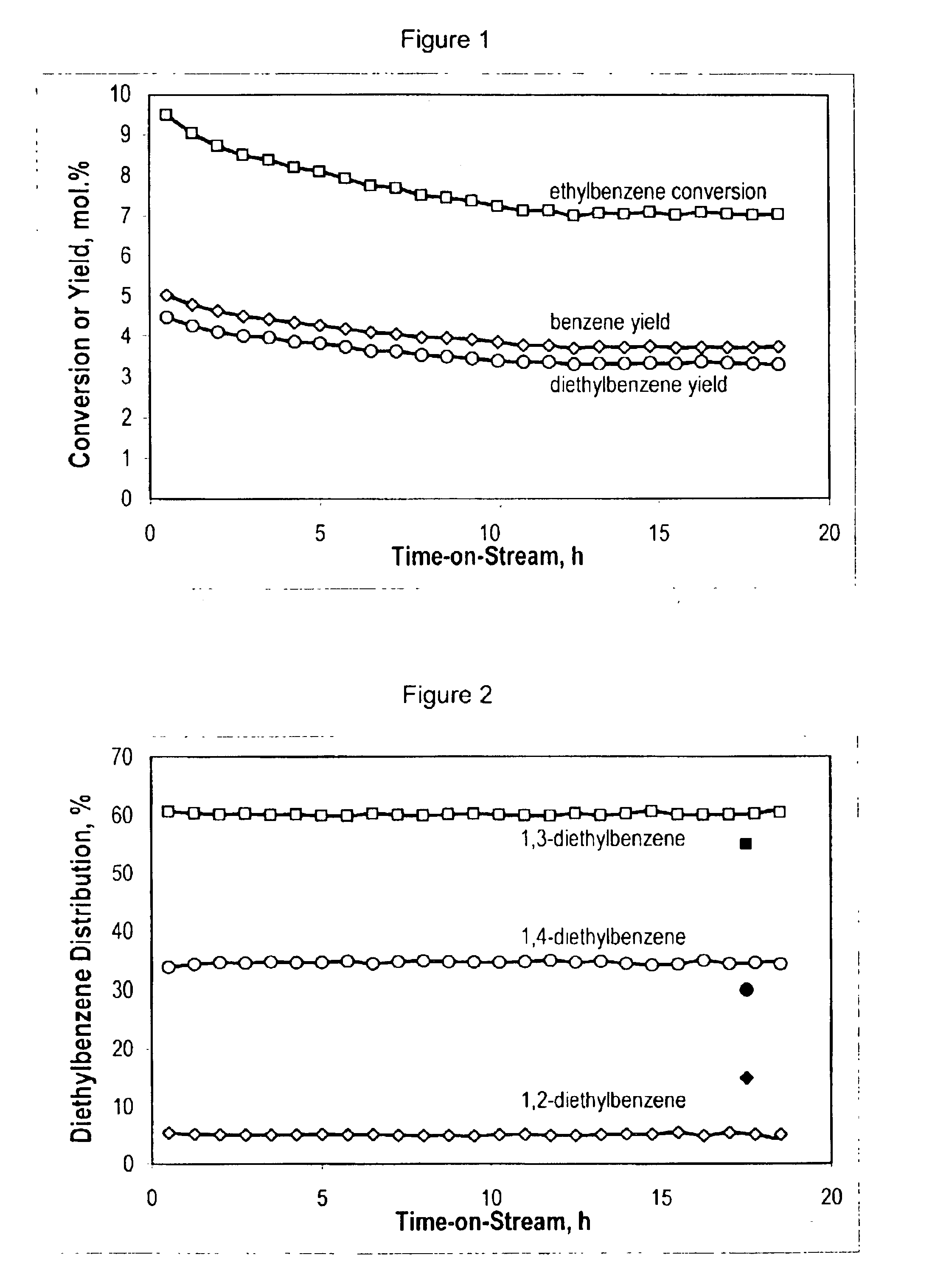

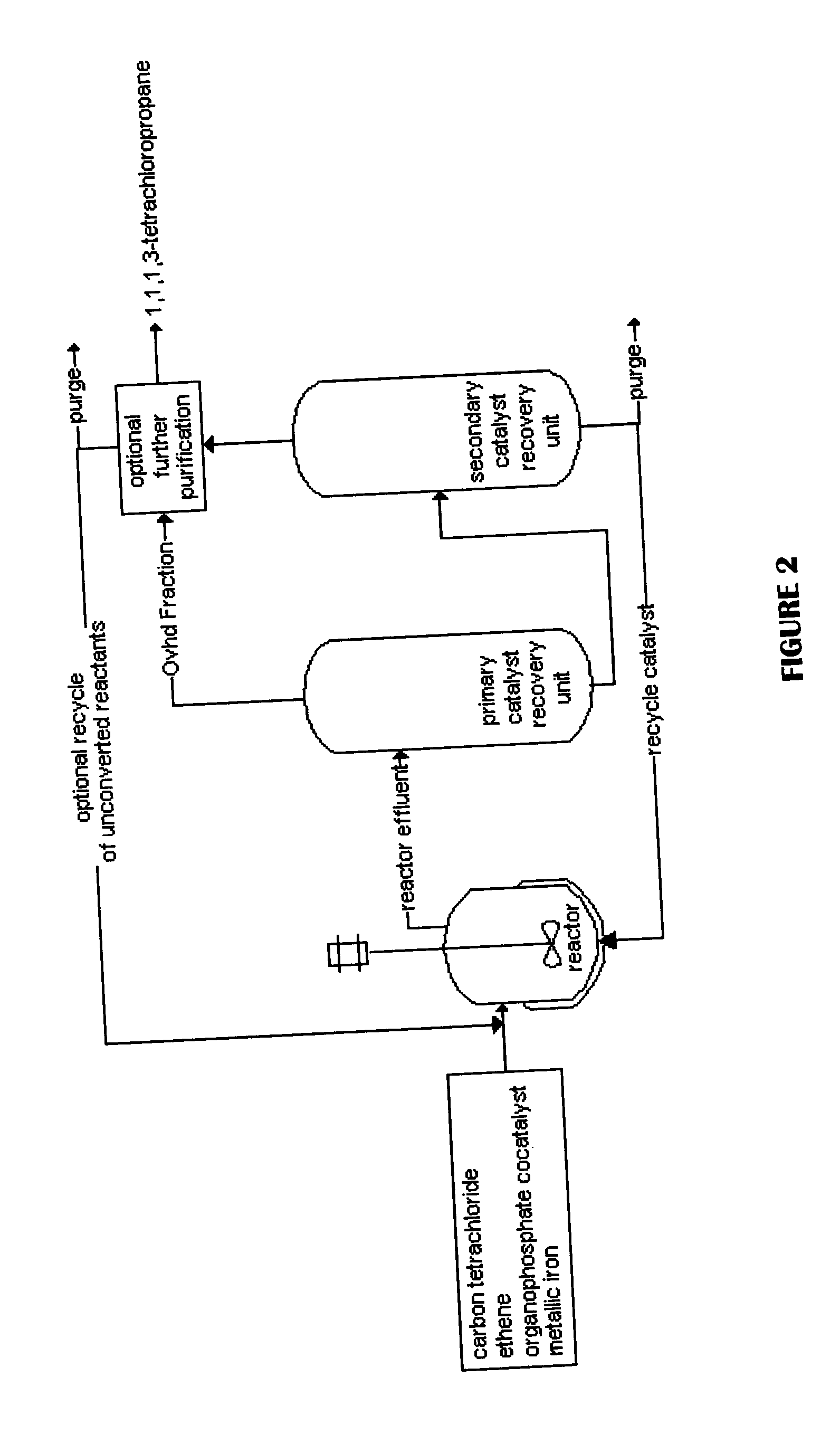

Method for producing 1,1,1,3-tetrachloropropane and other haloalkanes with iron catalyst

InactiveUS20040225166A1Efficient and economical to produceHalogenated hydrocarbon preparationTetrachlorideDistillation

A continuous process is provided for the manufacture of haloalkanes by the reaction of carbon tetrachloride with olefins in the presence of iron metal, trialkylphosphate, and ferric chloride. A fraction of the catalyst and co-catalyst are separated after the reaction and recycled. In a preferred application, the olefin is ethene, and the haloalkane product is 1,1,1,3-tetrachloropropane. Two distillation steps take place in order to enhance the production of 1,1,1,3-tetrachloropropane.

Owner:OCCIDENTAL CHEM CORP

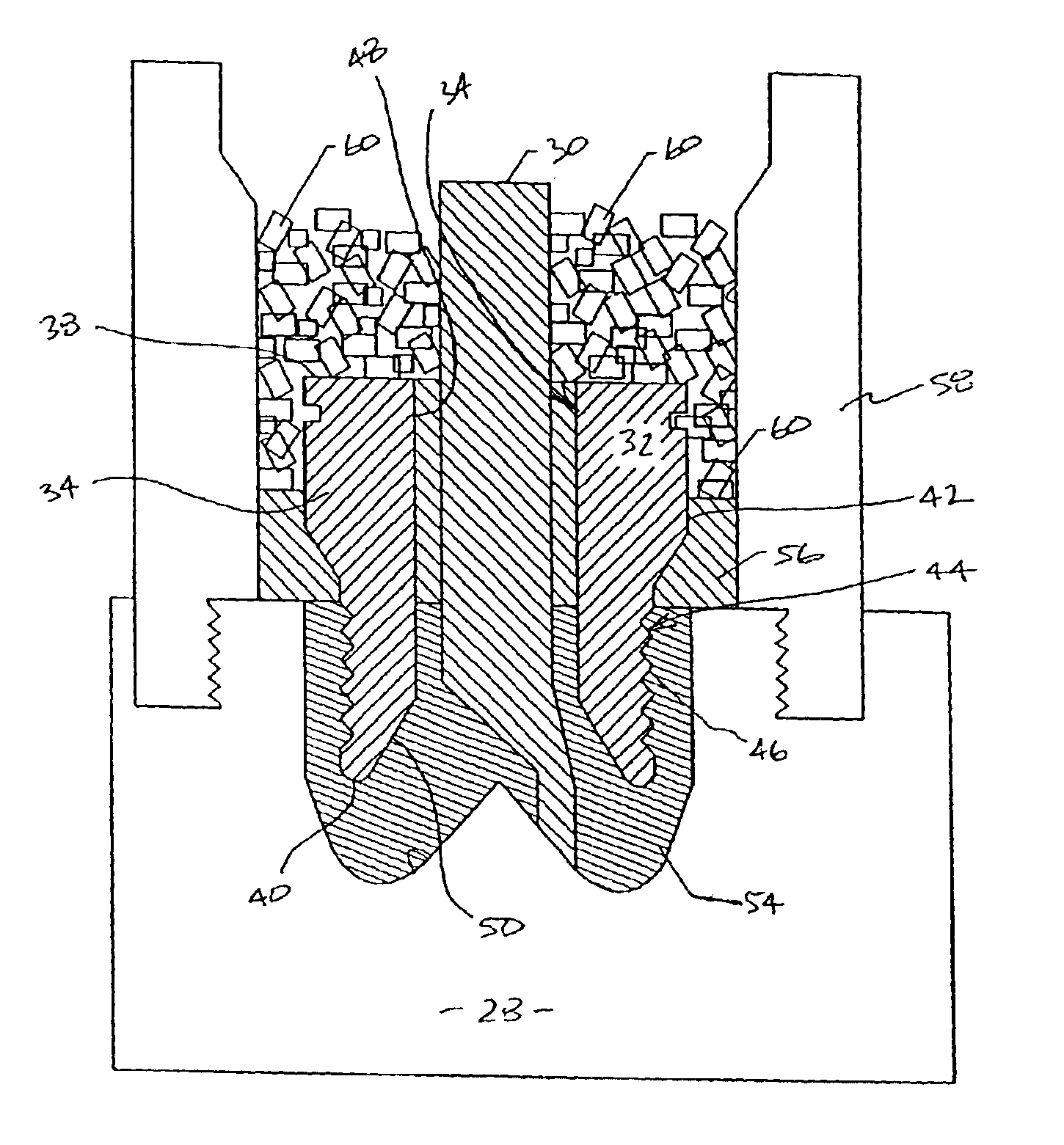

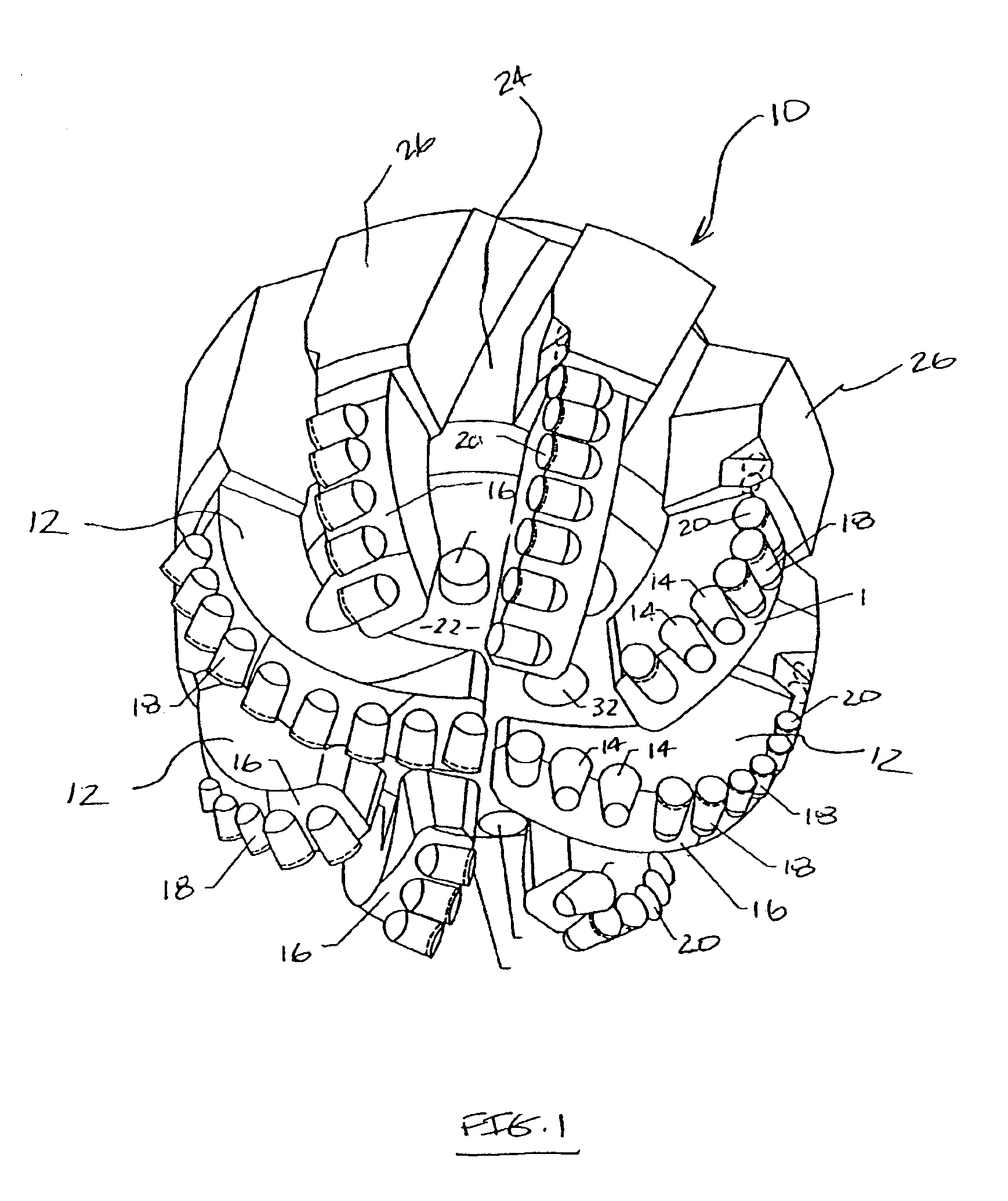

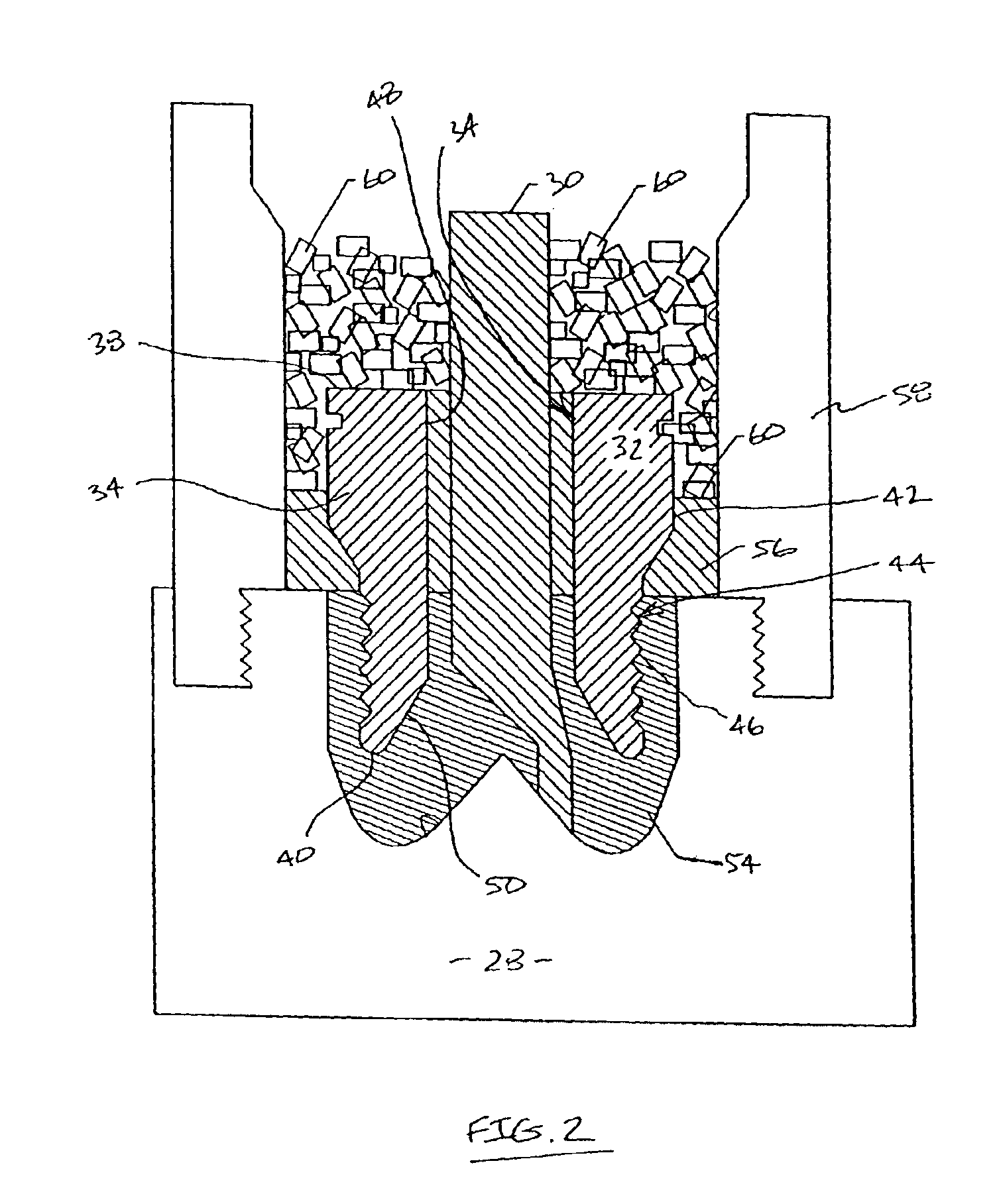

High-strength/high-toughness alloy steel drill bit blank

Drill bit reinforcing members or blanks of this invention are formed from high-strength steels having a carbon content less than about 0.3 percent by weight, a yield strength of at least 55,000 psi, a tensile strength of at least 80,000 psi, a toughness of at least 40 CVN-L, Ft-lb, and a rate of expansion percentage change less than about 0.0025% / ° F. during austenitic to ferritic phase transformation. In one embodiment, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.5 to 1.5 percent by weight manganese, up to about 0.8 percent by weight chromium, 0.05 to 4 percent by weight nickel, and 0.02 to 0.8 percent by weight molybdenum. In another example, such steel comprises in the range of from about 0.1 to 0.3 percent by weight carbon, 0.9 to 1.5 percent by weight manganese, 0.1 to 0.5 percent by weight silicon, and one or more microalloying element selected from the group consisting of vanadium, niobium, titanium, zirconium, aluminum and mixtures thereof.

Owner:SMITH INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com