Patents

Literature

8089results about How to "Rich sources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

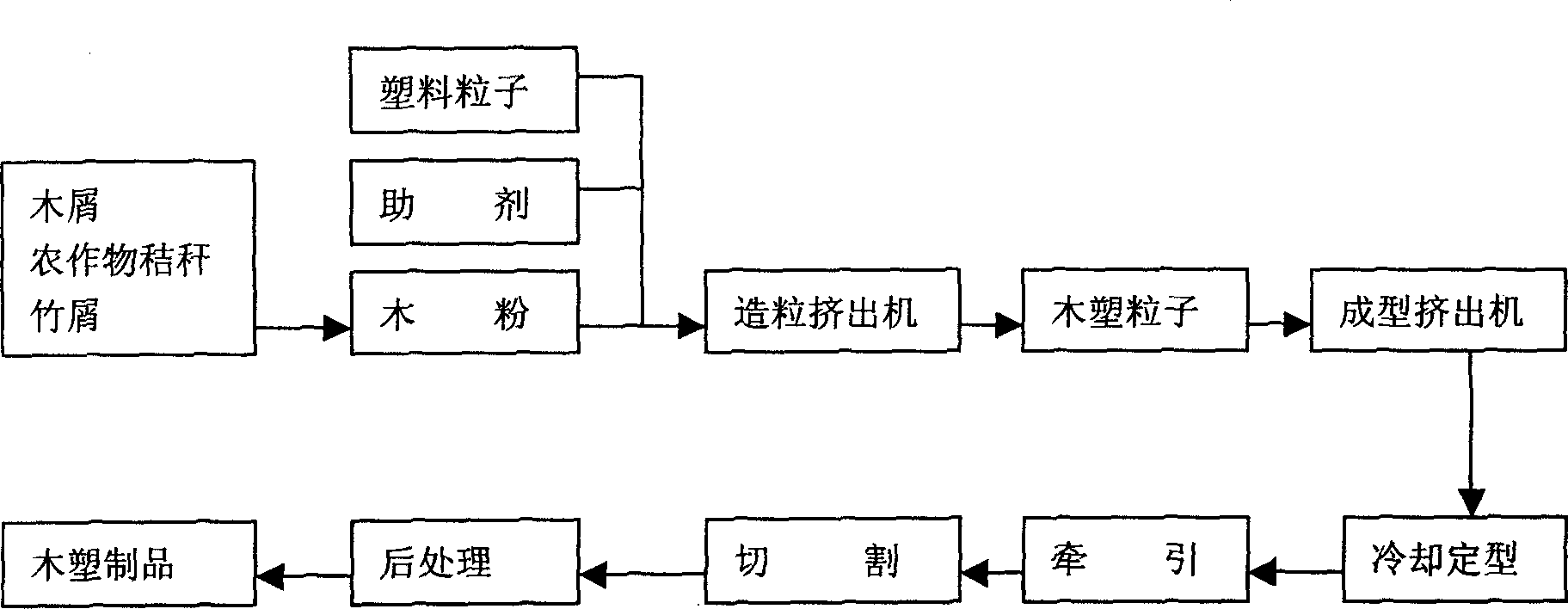

Making process of compound wood-plastic material product

The present invention discloses the making process of compound wood-plastic material product. Un-dried wood powder, plastic grain, compatibilizing agent, coupler, antioxidant, reinforcer, color powder and lubricant in certain proportion are fed to a pelletizing extruder for form granular material; and the granular material is extruded in a forming extruder and further processed through cooling to settle, drawing, cutting and decorating to produce the wood-plastic product. The present invention has the advantages of simple process, high production effect and rich material resource, and the product has timber-like texture, excellent performance and environment friendship.

Owner:浙江诚信包装有限公司

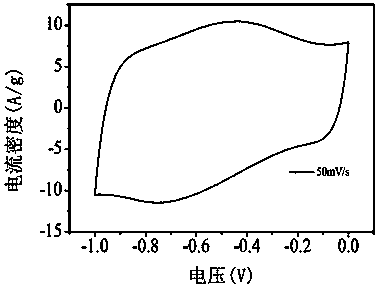

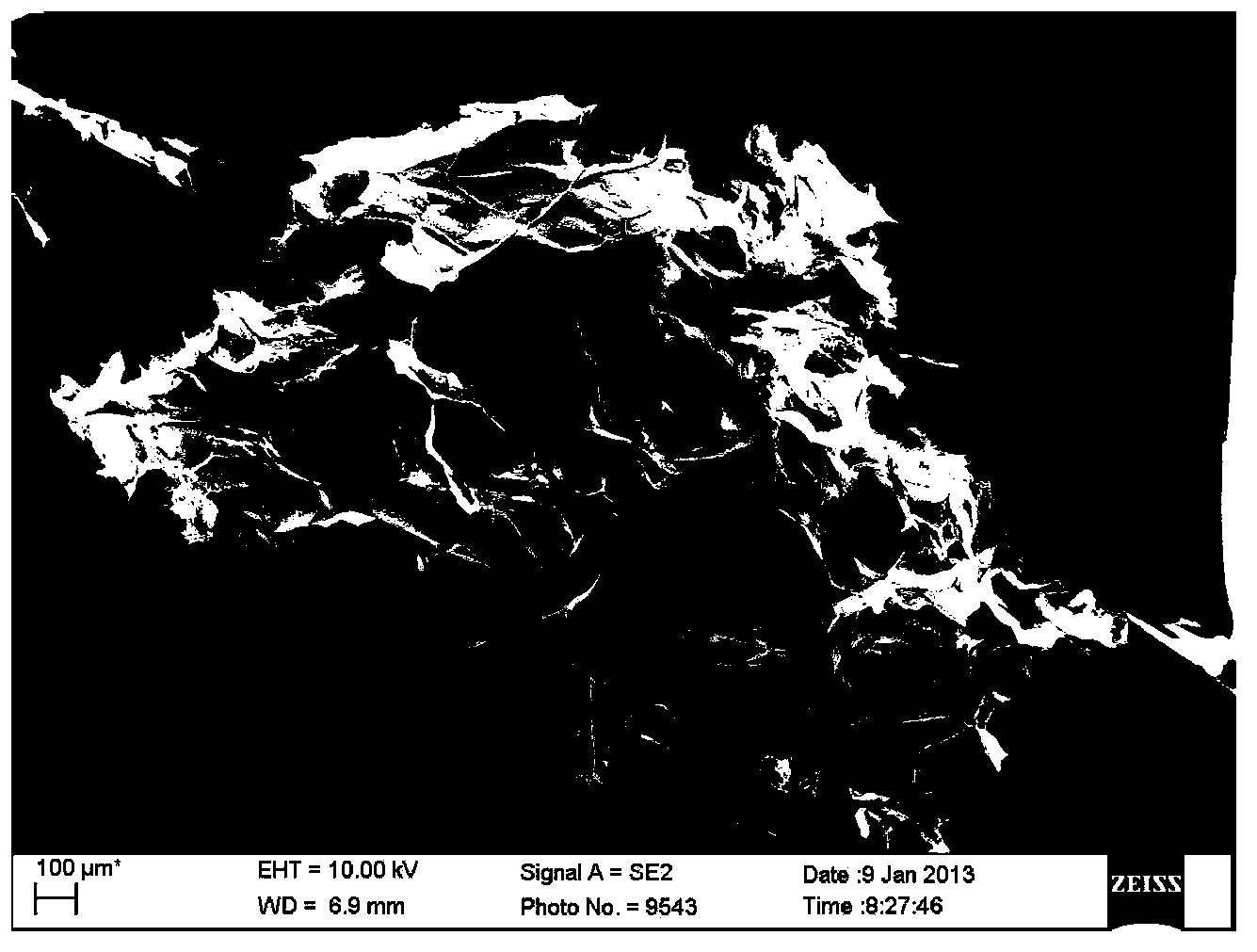

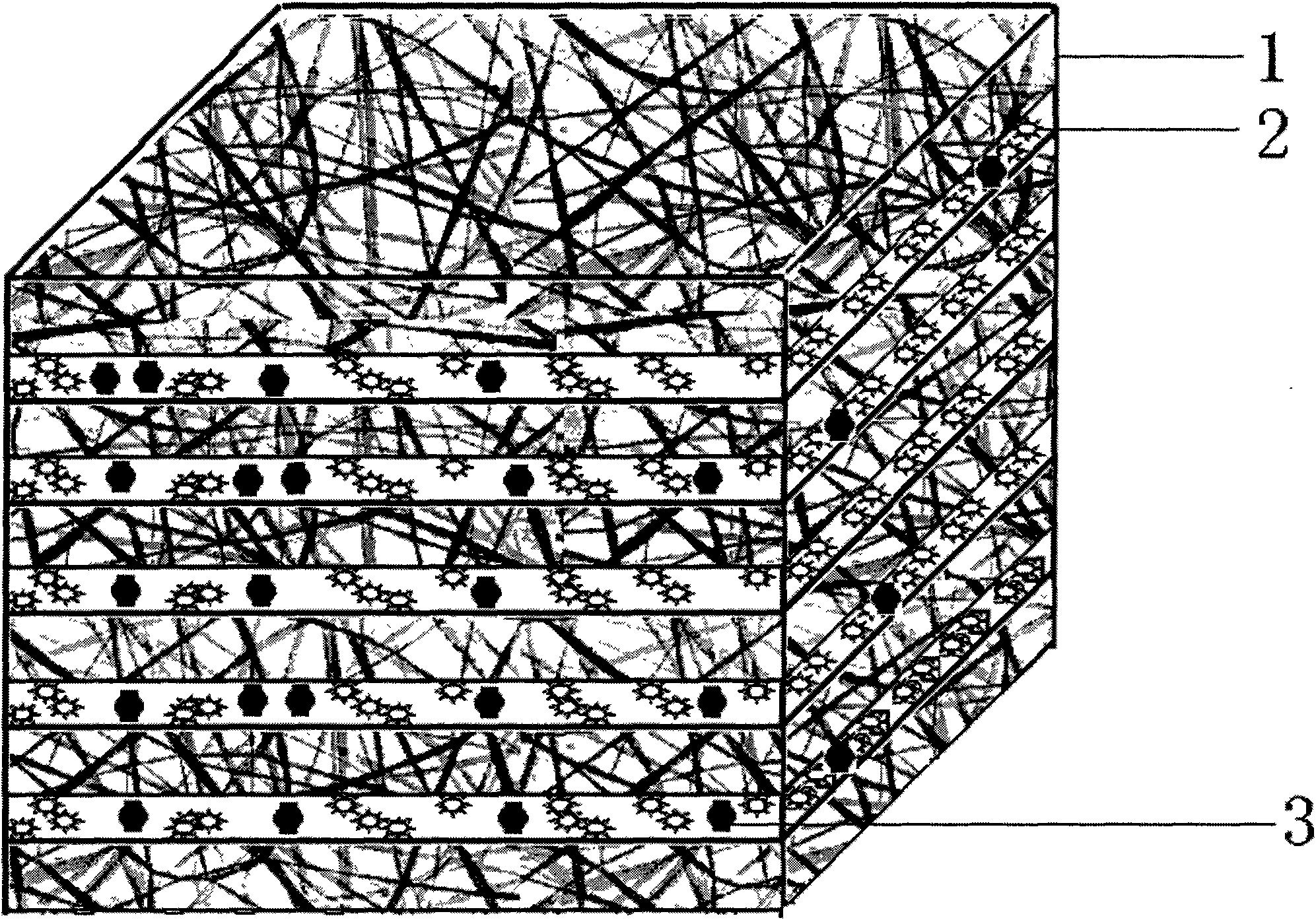

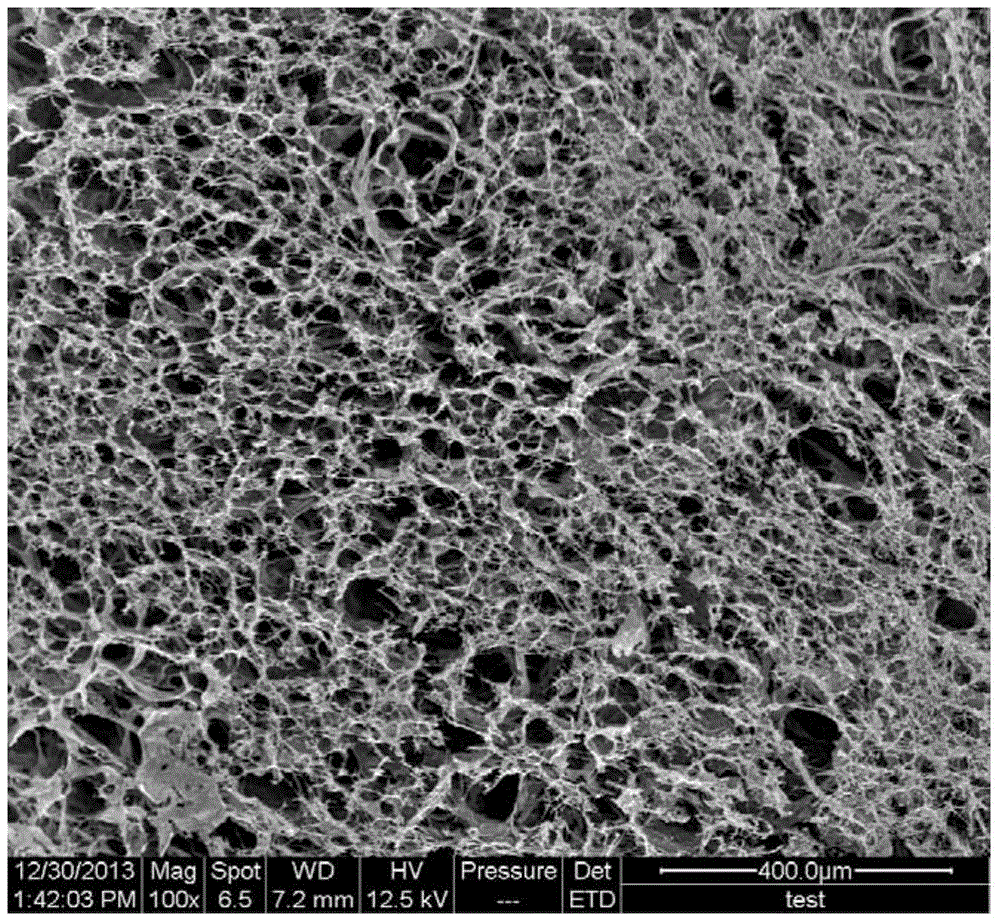

Method for preparing graphene aerogel and graphene/ metallic oxide aerogel

InactiveCN103413689ARich sourcesLow priceHybrid capacitor electrodesGrapheneSupercritical dryingCross-link

The invention discloses a method for preparing graphene aerogel and graphene / metallic oxide aerogel. The method is characterized in that graphite oxide aqueous solution serves as a raw material, alcohol serves as a cross-linking agent, a precursor solution is obtained through the simple mixing and dispersing processes, the hydrothermal method is adopted, the freeze drying method or a supercritical drying method is adopted, and then the graphene aerogel is obtained . The graphene / metallic oxide aerogel can be prepared by adding metallic oxide into the polymeric precursor solution. On one hand, the graphene vinyl aerogel material has the characteristic of the graphene aerogel, and on the other hand, the graphene vinyl aerogel material can have the physicochemical characteristic of the metallic oxide. In addition, the aerogel material has a large specific surface and good electrical conductivity, can directly serve as a supercapacitor electrode, and has large specific capacity, good rate capability and cycling stability. The materials used in the method are low in cost, the industrial process is simple, and the method is friendly to the environment.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting lithium salts in lithium-containing brine

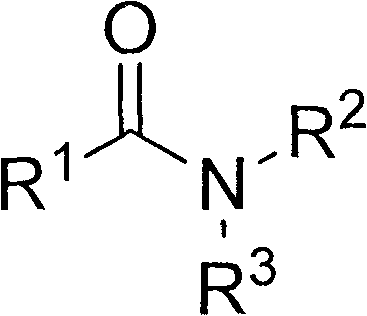

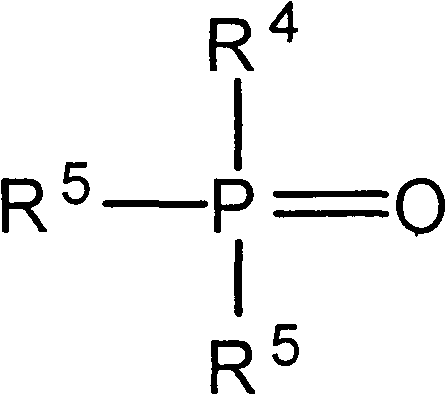

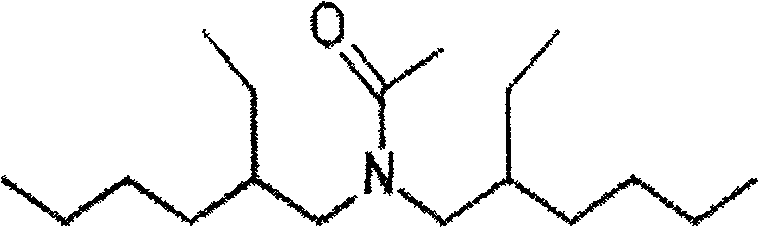

ActiveCN103055539AReduce dosageReduce corrosionLithium compoundsLiquid solutions solvent extractionLithiumStructural formula

The invention provides a method for extracting lithium salts in lithium-containing brine. Lithium is extracted through a co-extraction agent, an extraction agent and a diluent, wherein the extract is a mixture of an amide compound and a neutral phosphorus oxide compound, the structural formula of the amide compound is shown in the specification, and the structural formula of the neutral phosphorus oxide compound is shown in the specification. The method provided by the invention further optimizes the properties of extracted lithium, so that the method is more applicable to the industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

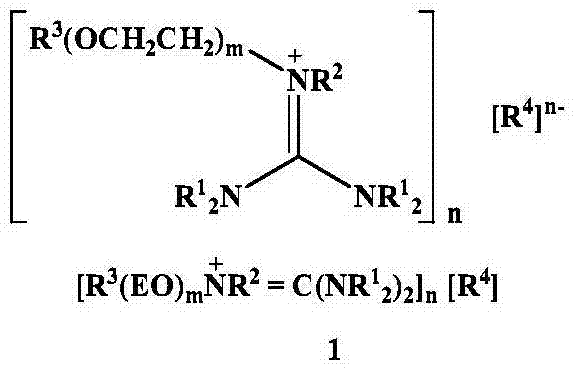

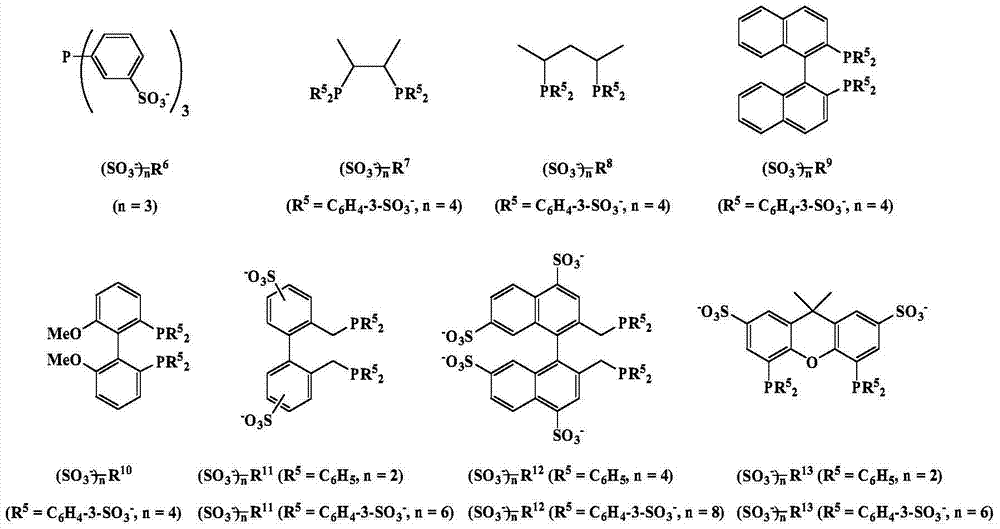

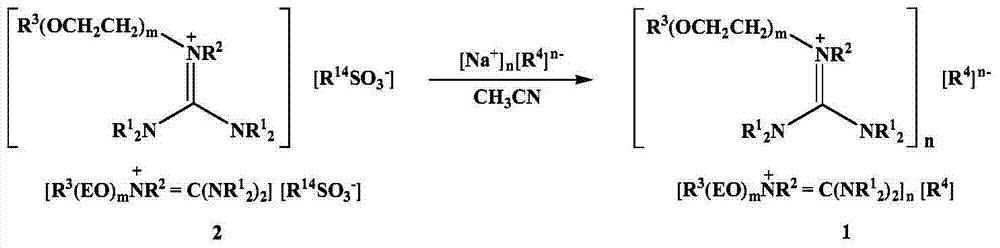

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

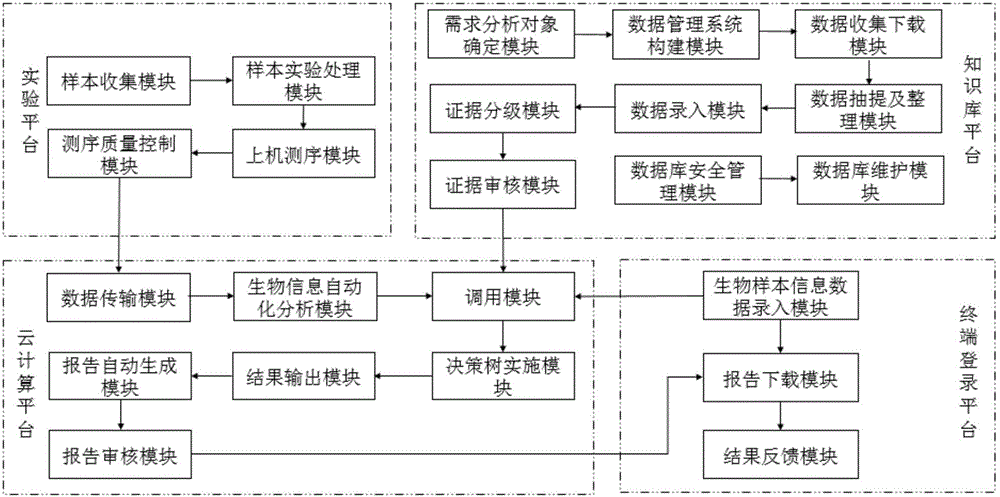

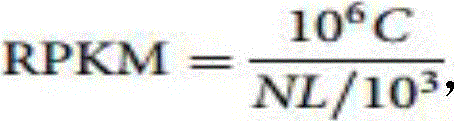

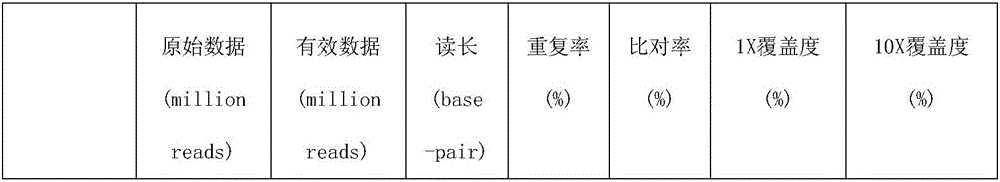

System used for intelligently analyzing individualized tumor gene detection

ActiveCN107437004ARich source of informationComprehensive coverageSequence analysisSpecial data processing applicationsInformation transferGenetic testing

The invention relates to a system used for intelligently analyzing the individualized tumor gene detection. The system comprises a test platform, a knowledge base platform, a cloud computing platform and a terminal entry platform. After a collected biological sample is subjected to computer sequencing through the test platform, the sequencing data is transmitted to the cloud computing platform, and meanwhile, after a user inputs sample information and analysis requirements on the terminal entry platform, the information is transmitted to the cloud computing platform; the knowledge base platform is used for collecting analysis knowledge data; the sample sequencing data is subjected to biological information analysis through the cloud computing platform, and after calling the data analysis in the knowledge base platform, the cloud computing platform transmits the generated analysis report to the terminal entry platform; report downloading and feedback are conducted through the terminal entry platform. By means of the system, more accurate treatment information can be better provided for patients according to the individualized tumor analysis of large-scale sequencing results, and the treatment cost is saved.

Owner:SHENZHEN HUADA GENE INST

Freezing beverage containing isomalt oligosaccharide and its preparation method

InactiveCN101057628AImprove gastrointestinal environmentHas a comprehensive nutritional effectFrozen sweetsIsomaltooligosaccharideFlavoring essences

The invention discloses a freeze beverage containing isomaltose hypgather and process for preparation, wherein the raw materials comprise the following constituents (by weight ratio): cow's milk and / or dairy product and / or dairy product analogues 0-90%, isomaltose hypgather 0. 01-10. 0%, sugar 4. 0-16. 0%, stabilizing agent 0. 1-1. 0%, sour flavor agent 0-0. 7%, edible flavoring essence 0. 01-0. 4% and balancing water.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

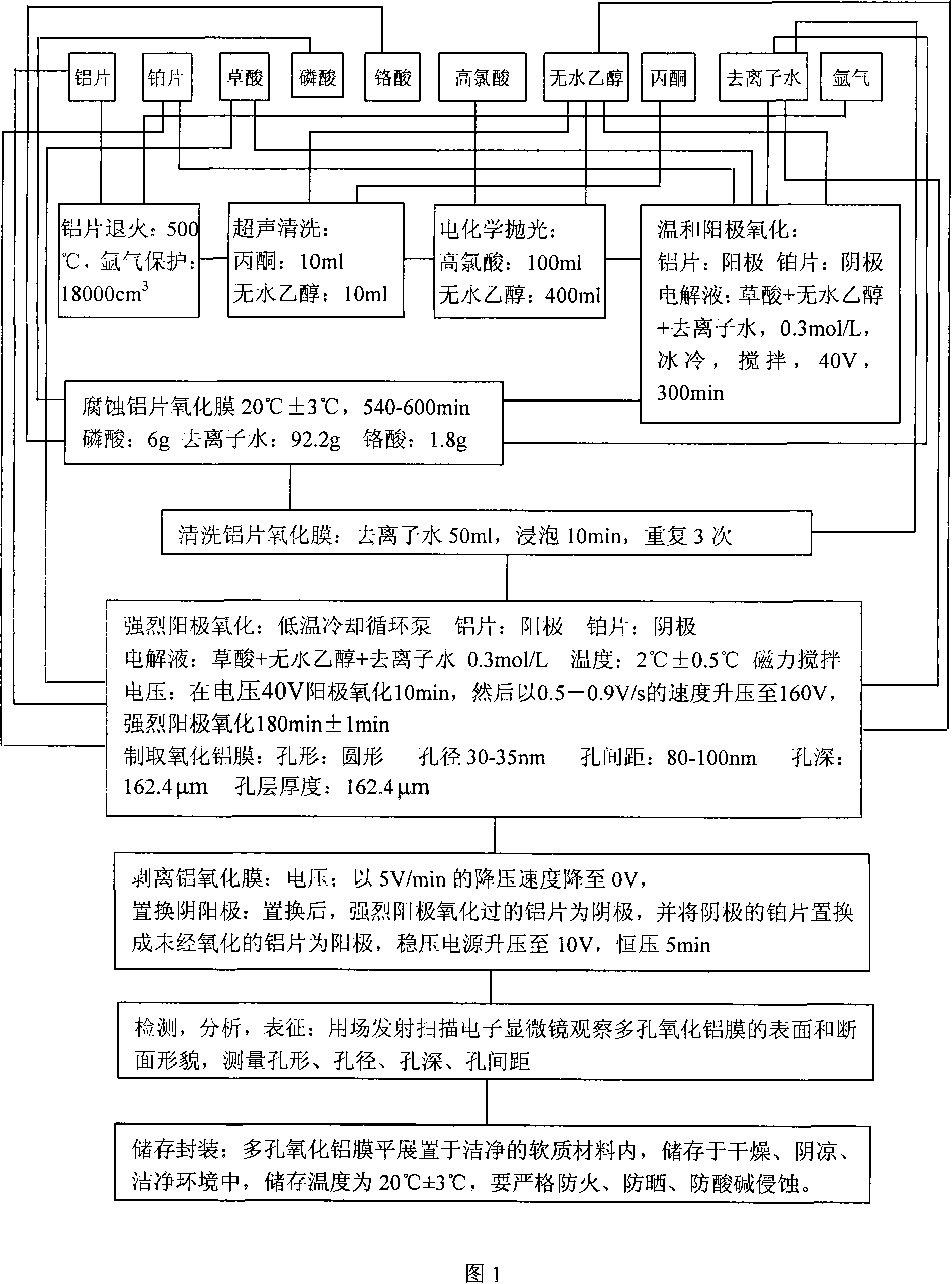

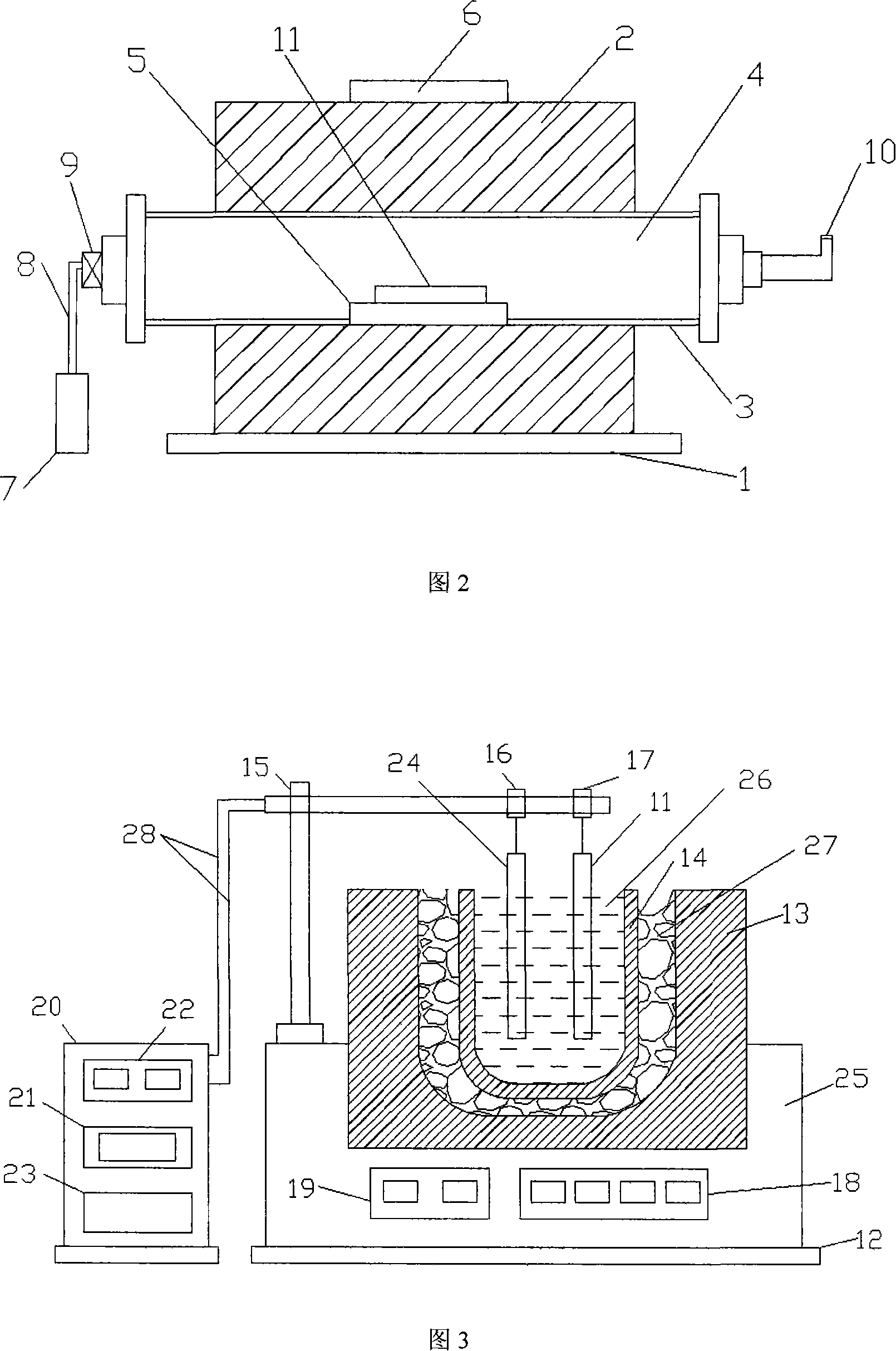

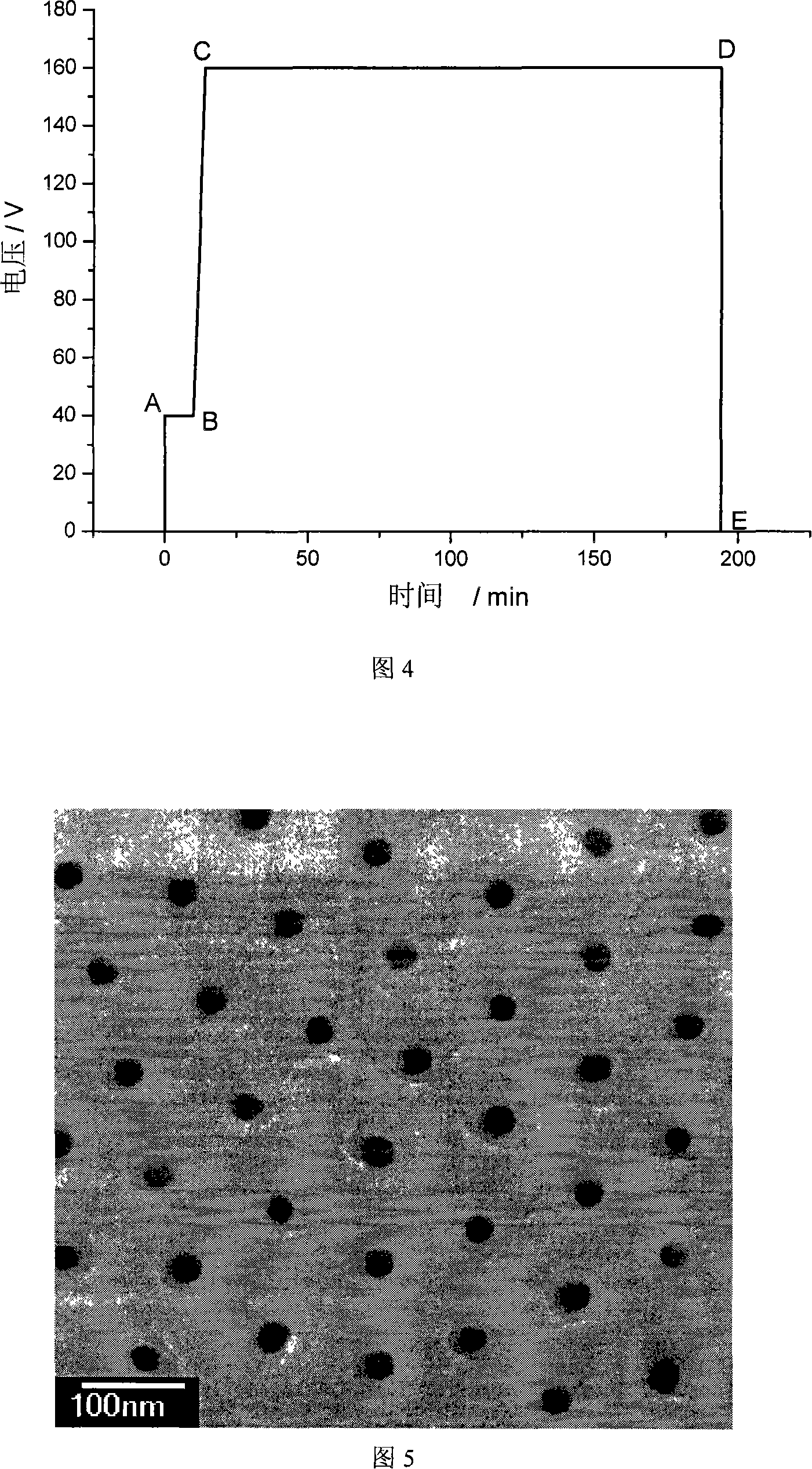

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

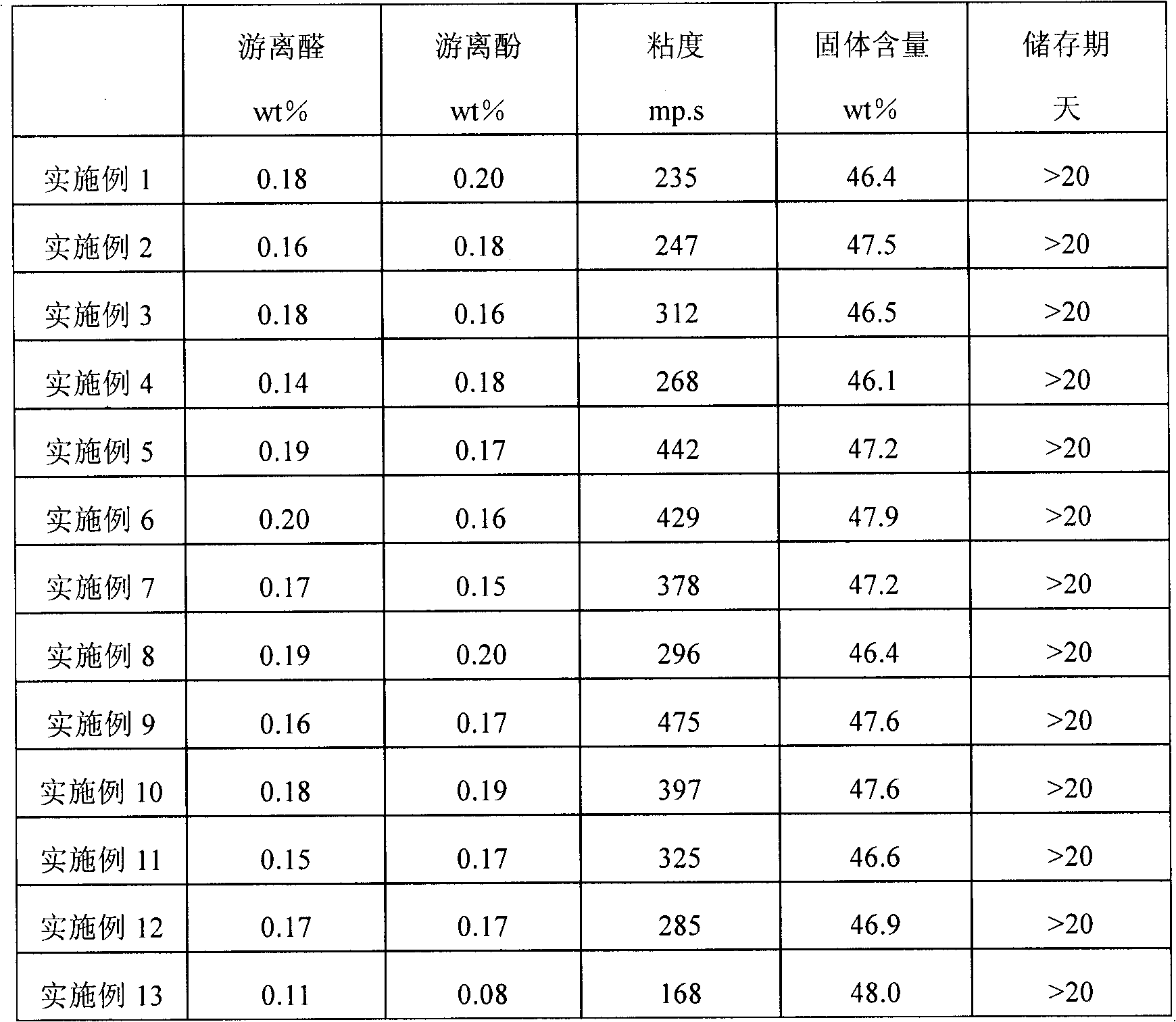

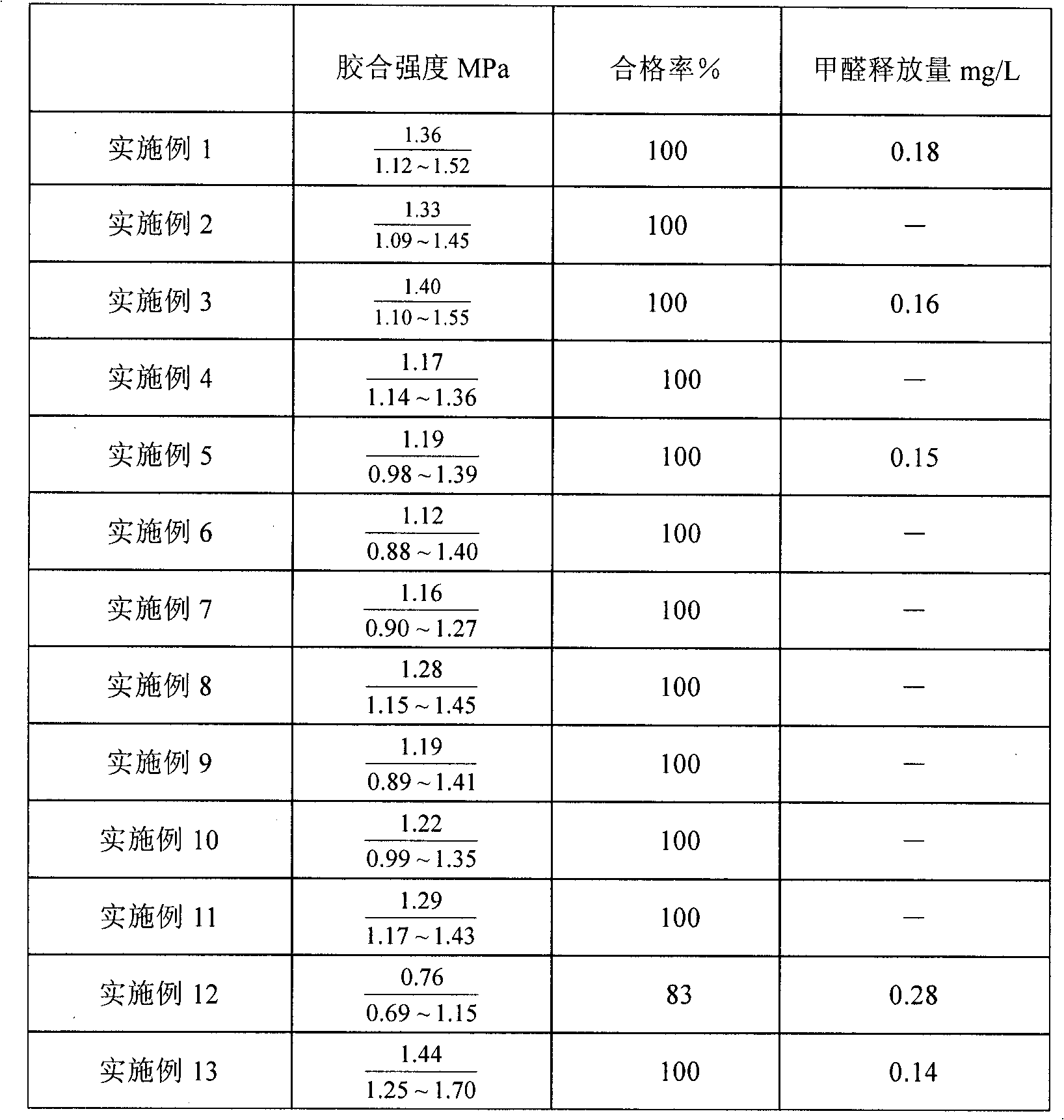

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

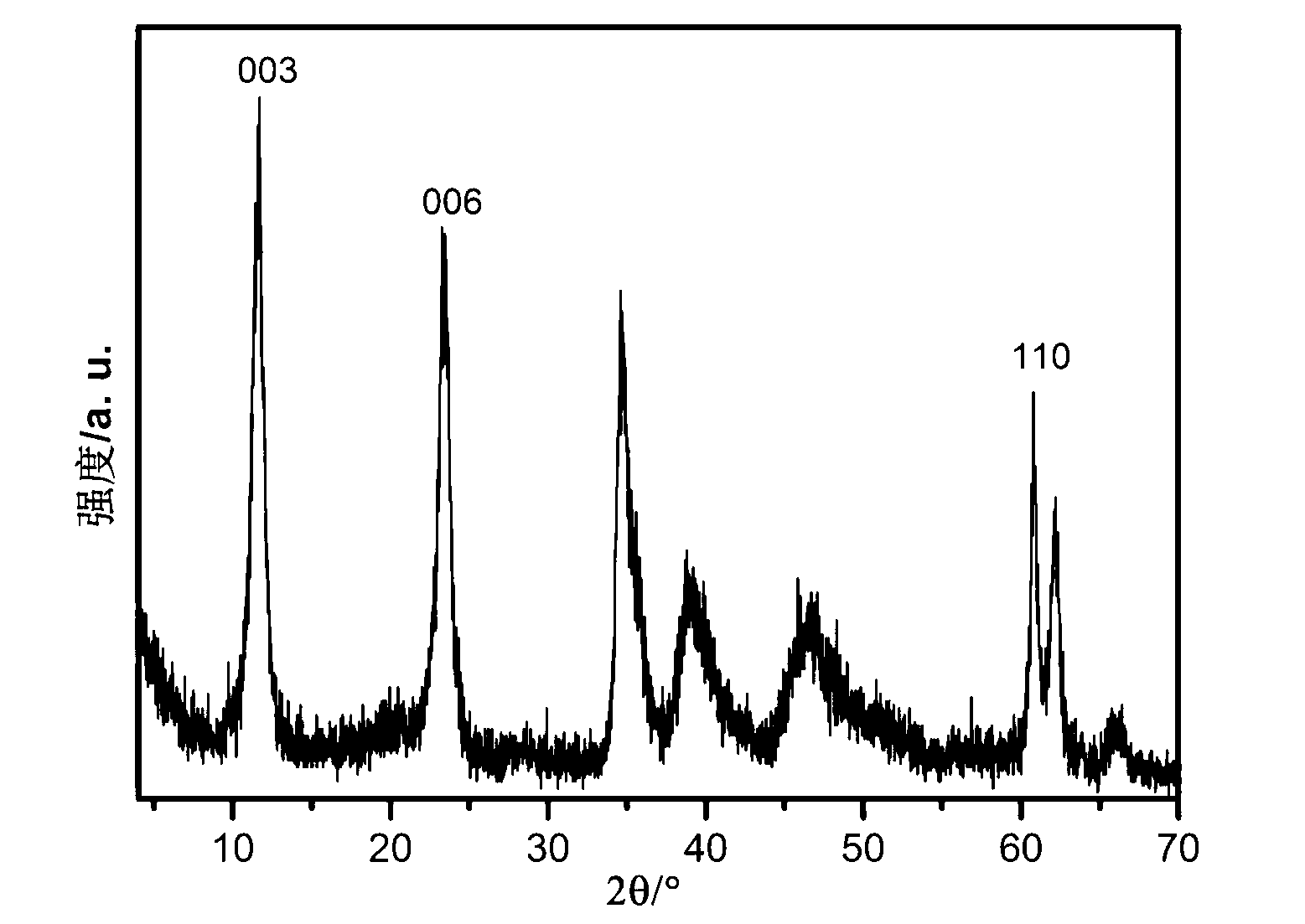

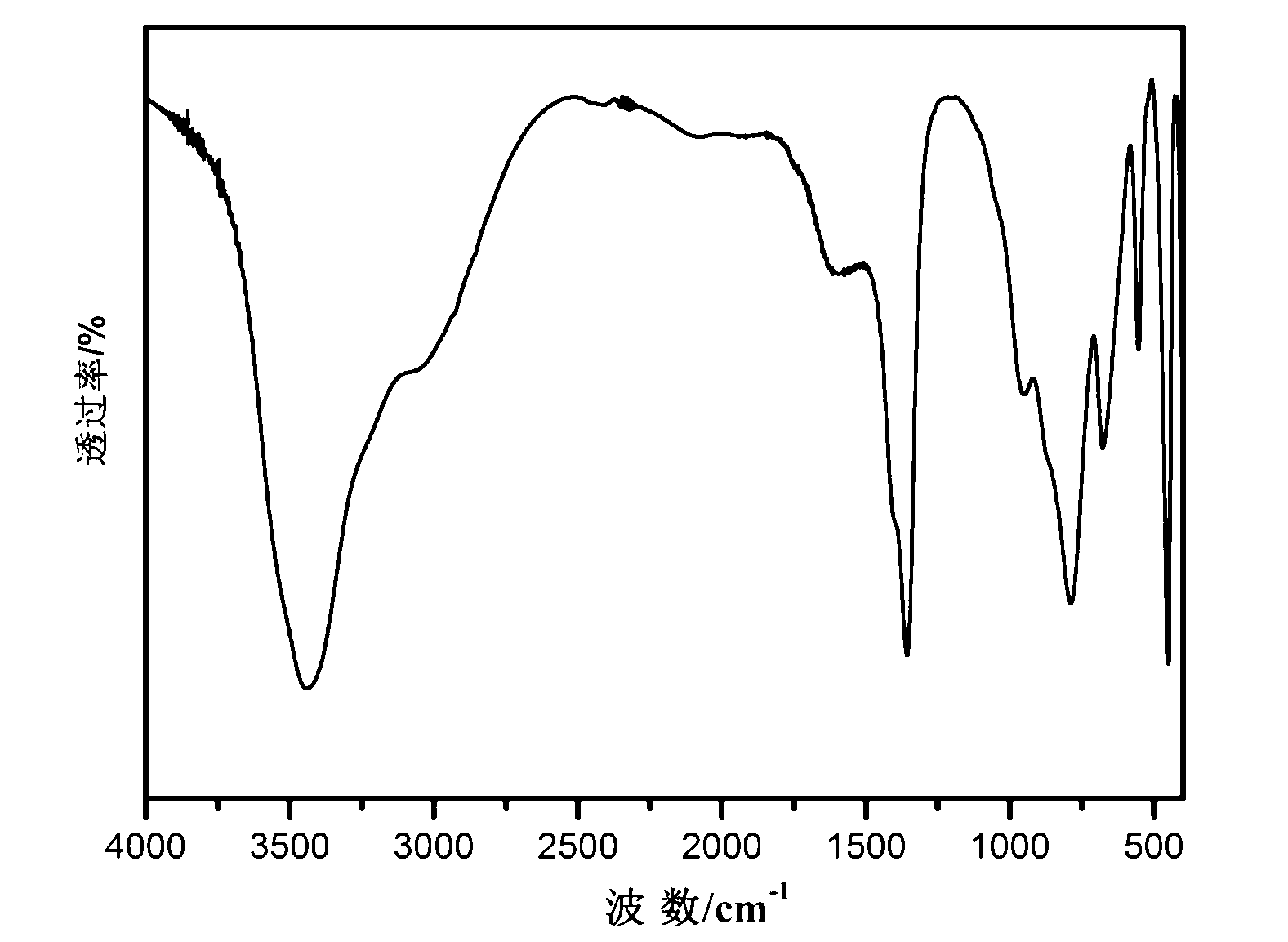

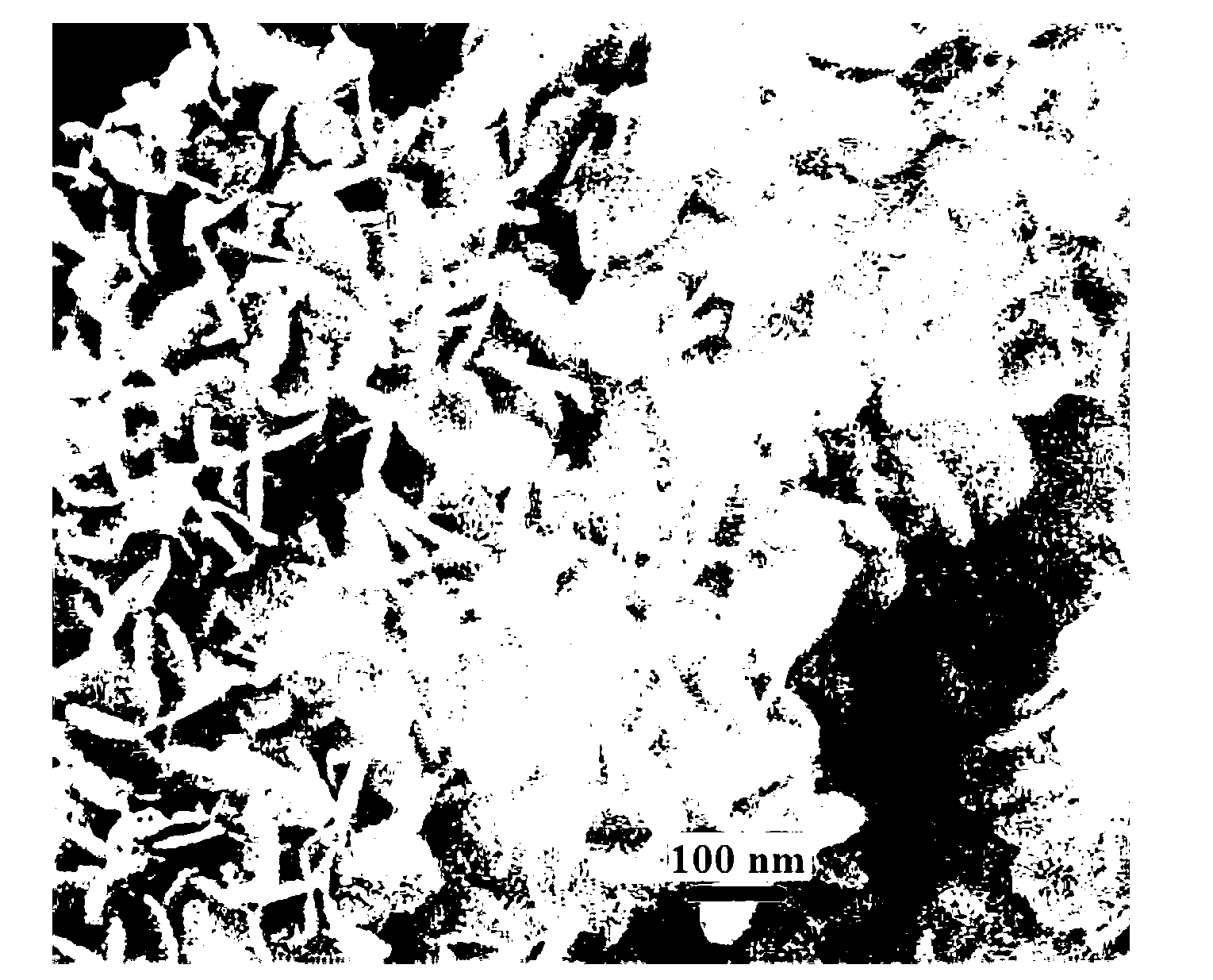

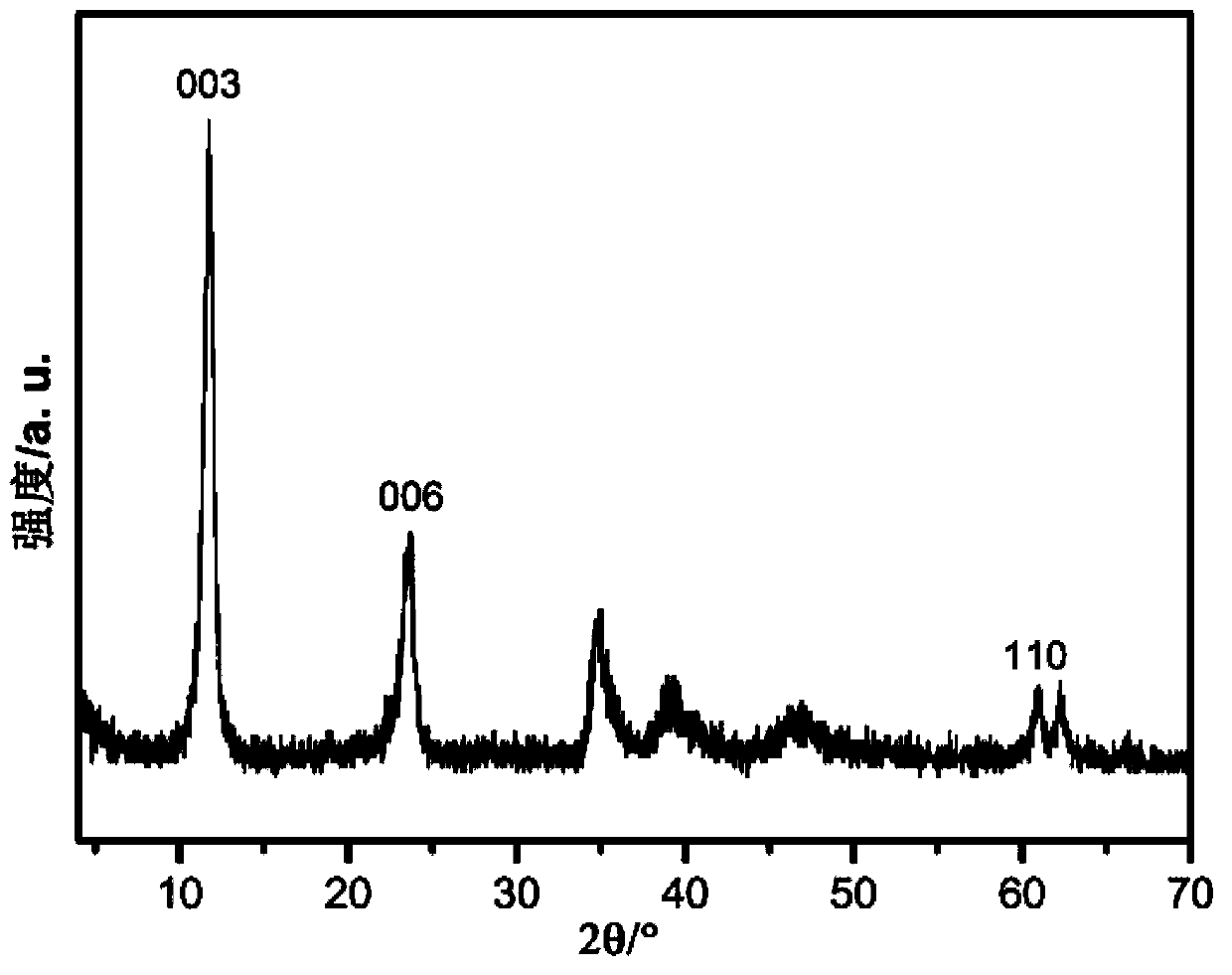

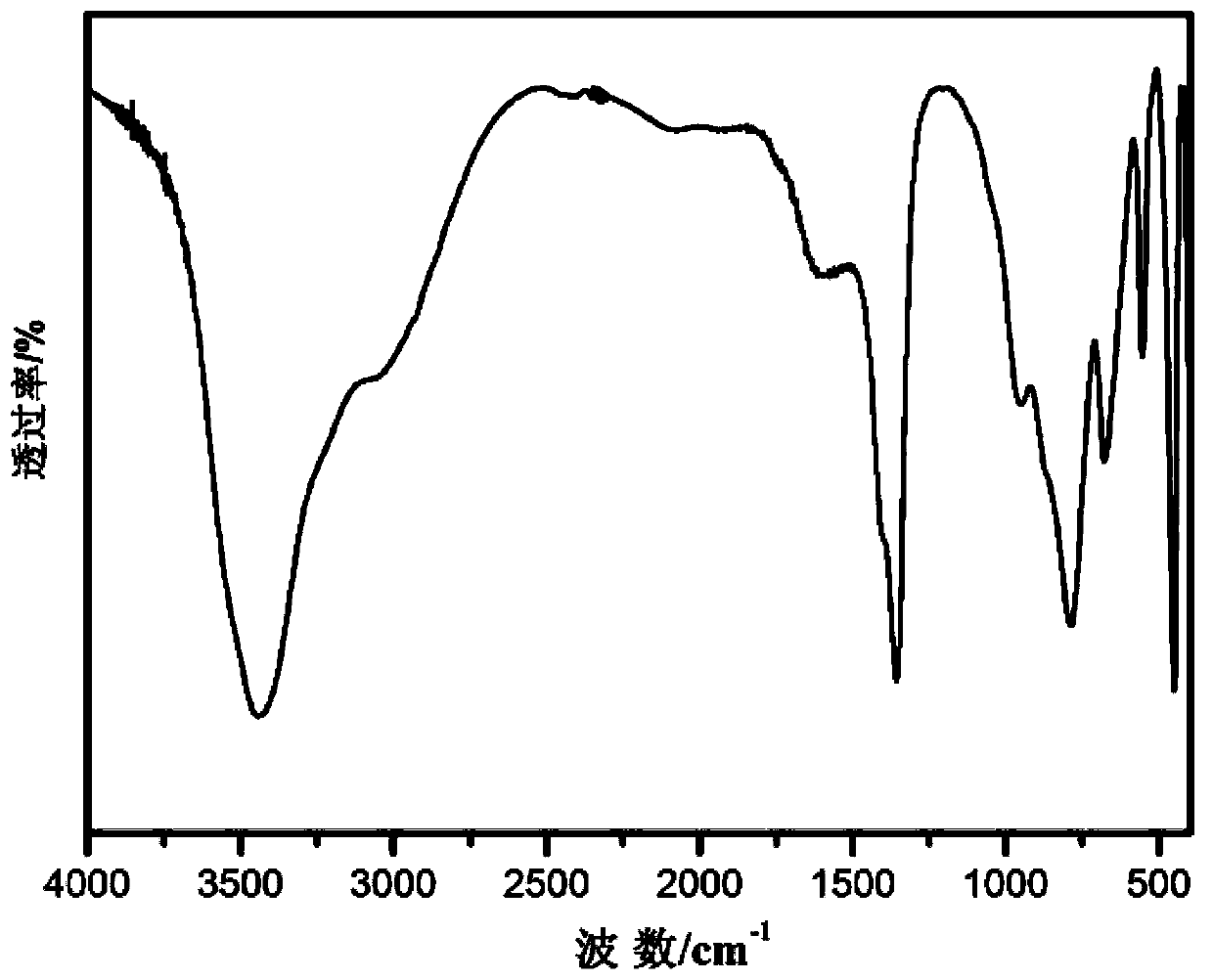

Nano-size layered double hydroxide and step-by-step precipitation preparation method thereof

InactiveCN103159238ARich sourcesLow costMaterial nanotechnologyTitanium compoundsPhysical chemistryAdsorption separation

The invention provides a nano-size layered double hydroxide and a step-by-step precipitation preparation method thereof. The preparation method comprises the following steps: based on a soluble salt of a metal and an alkali as raw materials, respectively precipitating metal ions constituting an LDH (layered double hydroxide) layer plate through step-by-step precipitation reaction and generating the LDH during the second-step precipitation process. As the activity of the hydroxide prepared by the first-step precipitation reaction is high, the LDH can fast nucleate and grow during the second-step precipitation, an obtained LDH sheet is thinner, the thickness of the layer plate is 5-15nm, the length of the layer plate is 50-150nm, and the specific surface area of a BET (Brunauer-Emmett-Teller) is 140-280m<2> / g, which is much larger than the specific surface area of the common LDH. By adopting the method, the shortcoming of small specific surface area during the preparation of the LDH through a co-precipitation method can be overcome. The preparation method adopted by the invention is simple and convenient, high temperature and high pressure are not required, special equipment is not required, sources of the raw materials are rich, and the cost is low. The layered double hydroxide can be widely applied to the fields of adsorption separation, catalysis, high polymer materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for plant source active component nano-scale membrane type vesicle

The present invention provides a preparation method for a plant source active component nano-scale membrane type vesicle. The preparation method comprises the following steps: (1) extracting a plant raw material raw liquid; (2) extracting the supernatant or the concentrate; (3) precipitating and resuspending membrane type vesicle; and (4) carrying out a nano-scale homogenization treatment to obtain nanoparticles, wherein the nanoparticles are the plant source active component nano-scale membrane type vesicles. The present invention further provides a preparation method for the plant source active component nanoparticles with different densities. According to the present invention, the plant raw material is adopted to prepare the nano-scale membrane type vesicle, advantages of rich raw material source, low cost, mass production and the like are provided, and scalization vesicle utilization is achieved.

Owner:居颂光

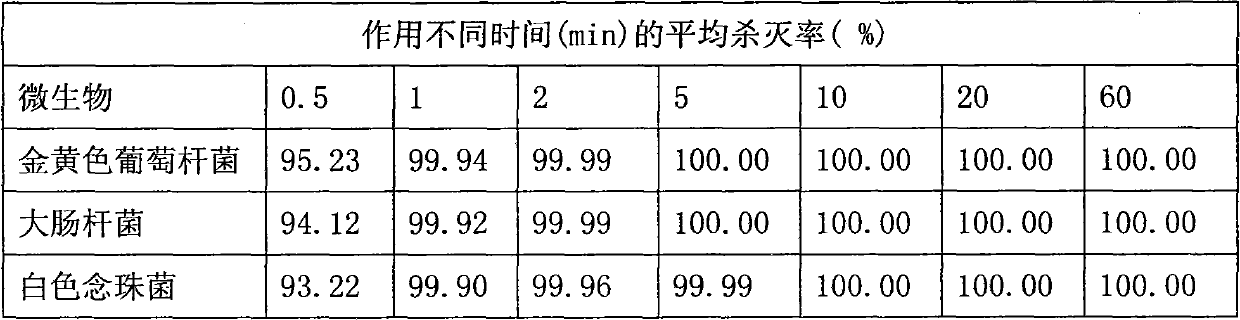

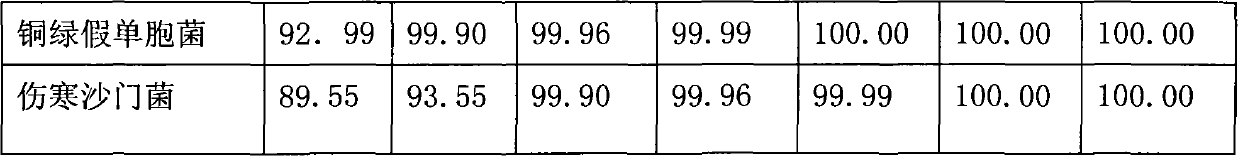

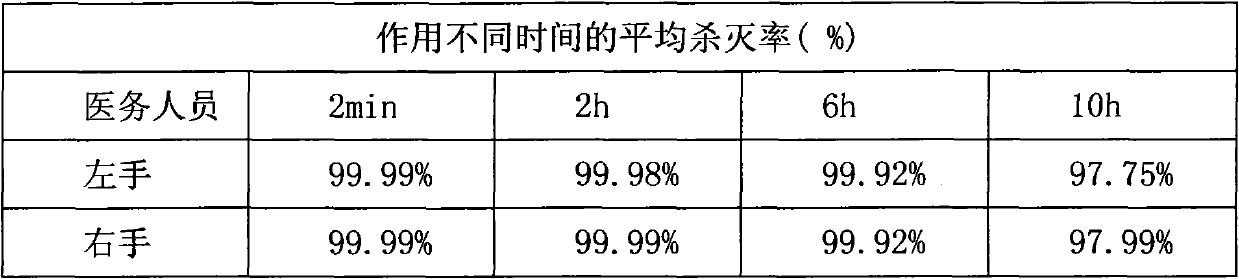

Washing-free antibacterial hand sanitizer and preparation method thereof

InactiveCN101766552AAvoid damageSimple processAntibacterial agentsCosmetic preparationsHand sanitizerChlorhexidine

The invention discloses a washing-free antibacterial hand sanitizer and a preparation method thereof. Raw materials of the washing-free antibacterial hand sanitizer calculated at 100ml include 1-10g of chlorhexidine salt, 5-1,000ug of silver nitrate, 30-90ml of alcohol, 2-50g of skin care agent, 0.5-3g of tackifier, 0.5-3g of surfactant, 0.5-5g of p+H regulator and 15-50ml of deionized water. In the preparation method, the skin care agent and the chlorhexidine salt are added to the alcohol and dissolved under the temperature of 30-70 DEG C to form alcoholic solution; the tackifier, the surfactant and the silver nitrate are added to the deionized water to form aqueous solution; finally, the aqueous solution and the pH regulator are added to the alcoholic solution to prepare the washing-free antibacterial hand sanitizer. The washing-free antibacterial hand sanitizer contains various antibacterial components, has very strong broad-spectrum antibacterial and bactericidal effects on various bacteria and fungi, and has long-acting antibacterial effect.

Owner:ZHEJIANG KUNZHILIN BIOMEDICINE TECH

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

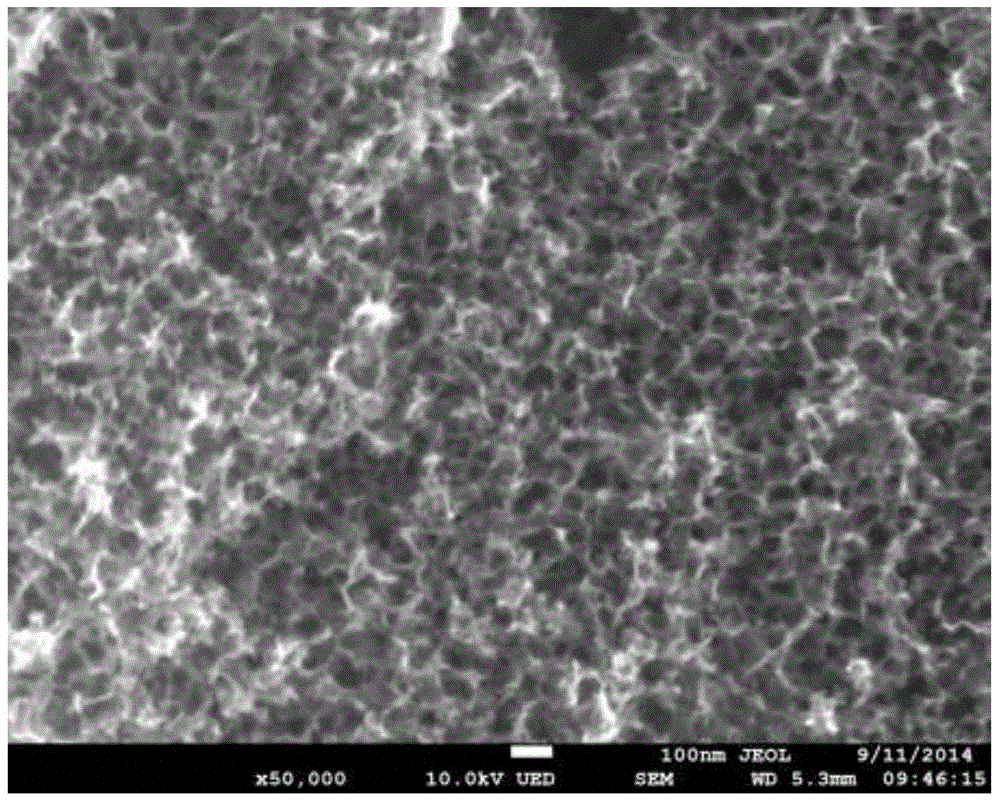

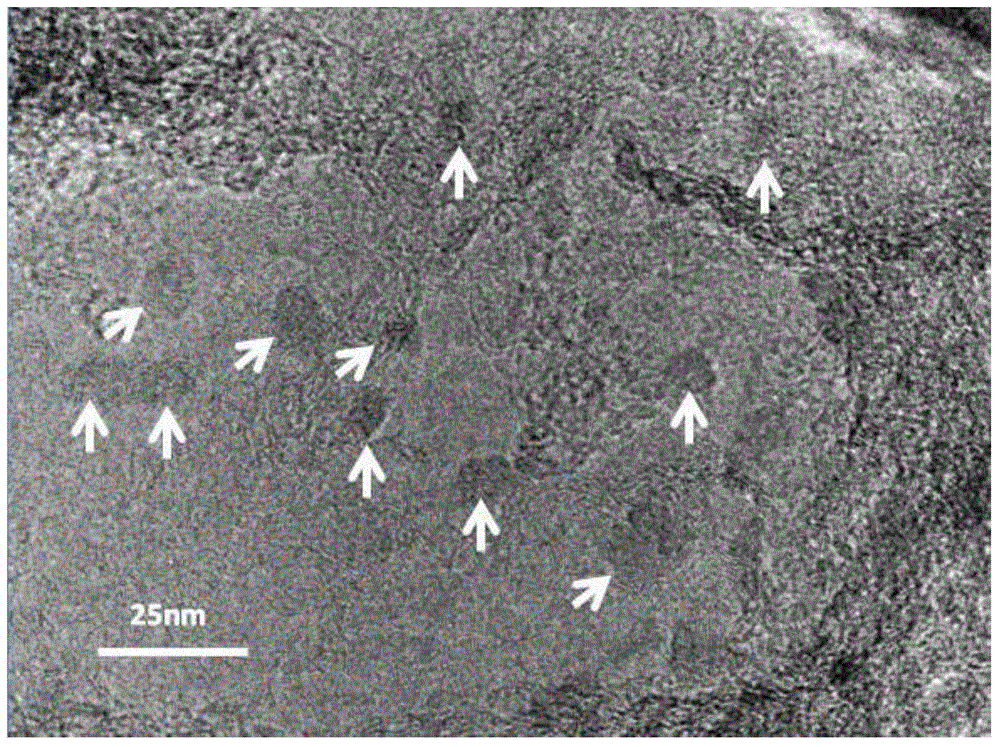

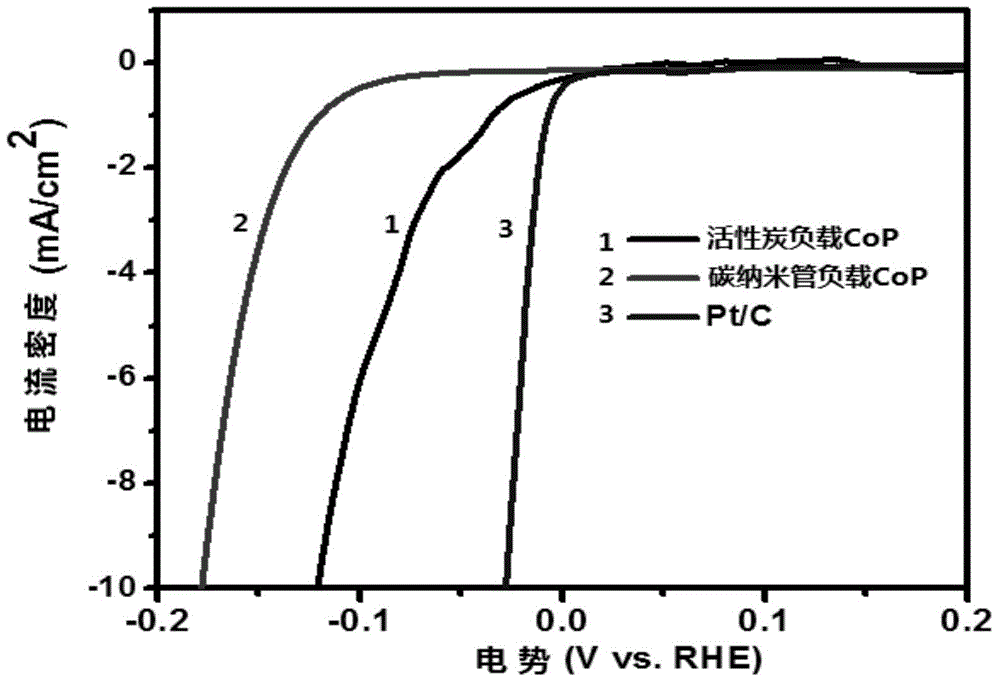

Catalyst for loading cobalt phosphide on activated carbon as well as preparation and application of catalyst

ActiveCN104941674AExcellent hydrogen evolution catalytic performanceRich sourcesCatalyst carriersElectrolysis componentsFiltrationCobalt

The invention relates to a catalyst for loading cobalt phosphide on activated carbon as well as preparation and application of the catalyst. The catalyst is prepared by taking multilayer nanoporous activated carbon (HNC) as a carrier and loading cobalt phosphide (CoP) on the surface of the activated carbon. The preparation method comprises the following steps: mixing cobalt nitrate hexahydrate (Co(NO3)2.6H2O), urea (CO(NH3)2), ammonium fluoride (NH4F) and deionized water to obtain a reaction mixture raw material; mixing a certain quantity of HNC with the reaction mixture raw material under an ultrasonic condition for hydrothermal reaction; carrying out suction filtration drying to obtain a precursor; conducting annealing on the precursor and sodium hypophosphite under the protecting atmosphere of argon; carrying out cooling. The catalyst prepared according to the preparation method can be used for electrochemical hydrogen evolution, and is excellent in catalytic activity for hydrogen evolution.

Owner:SOUTHWEST UNIV

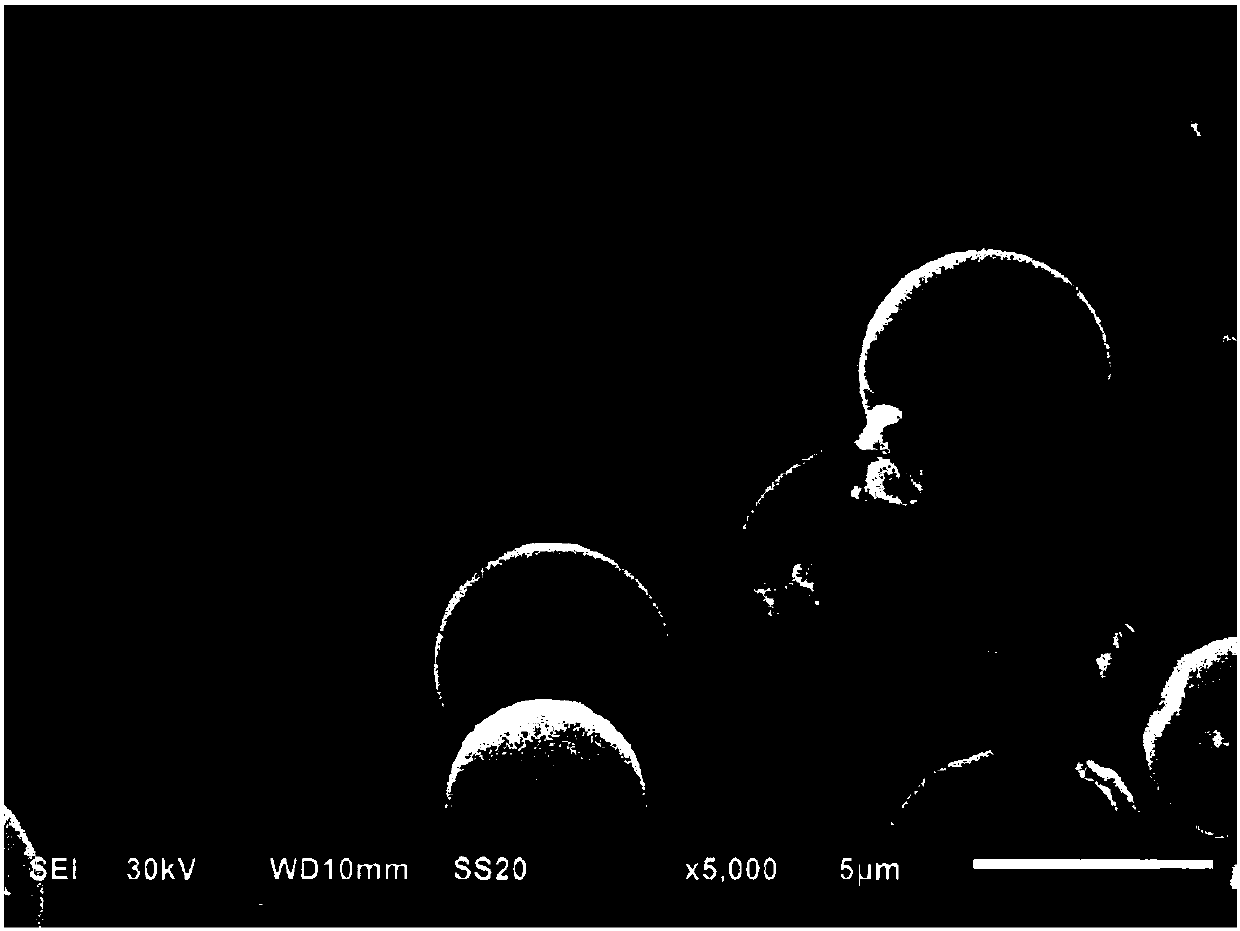

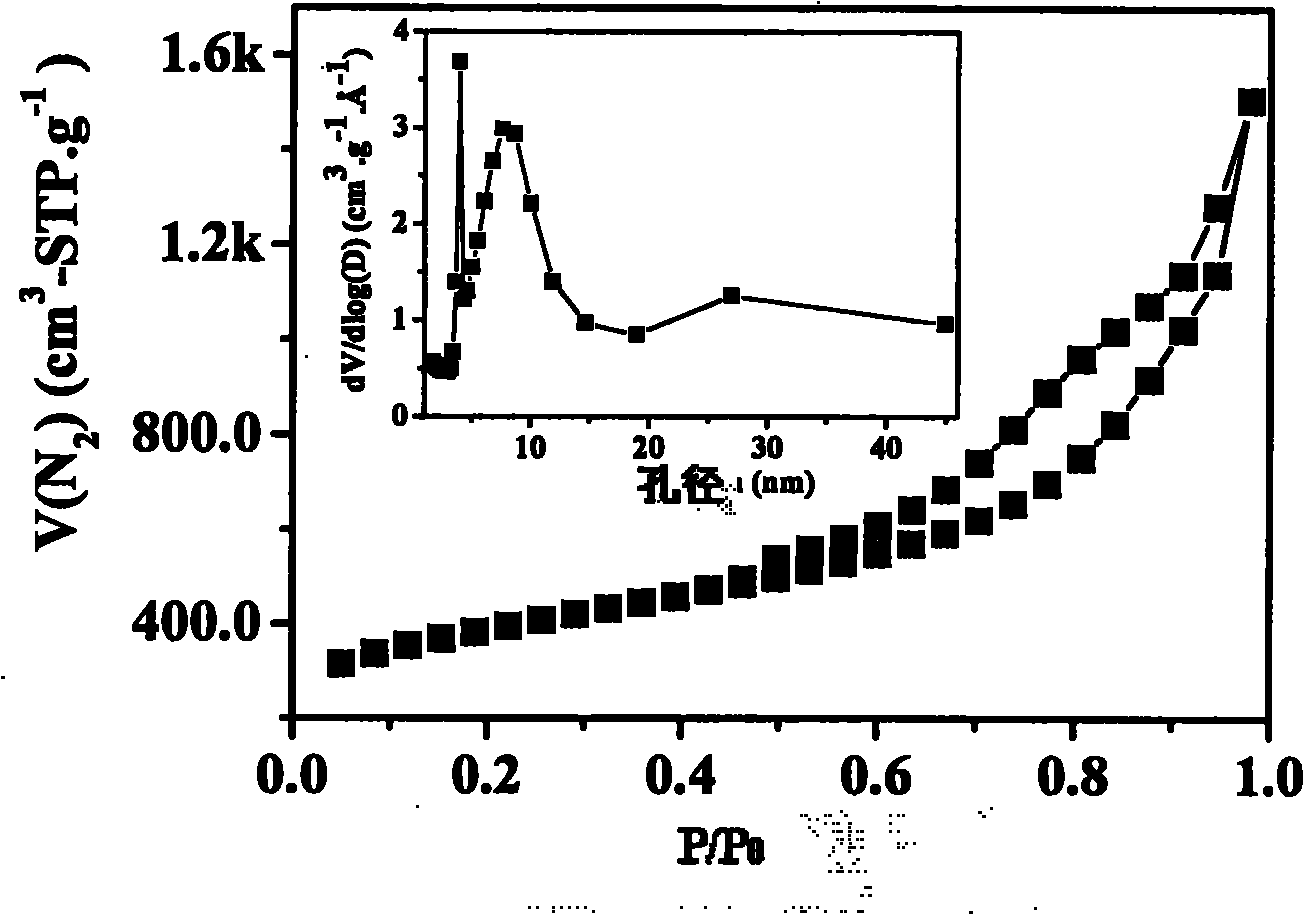

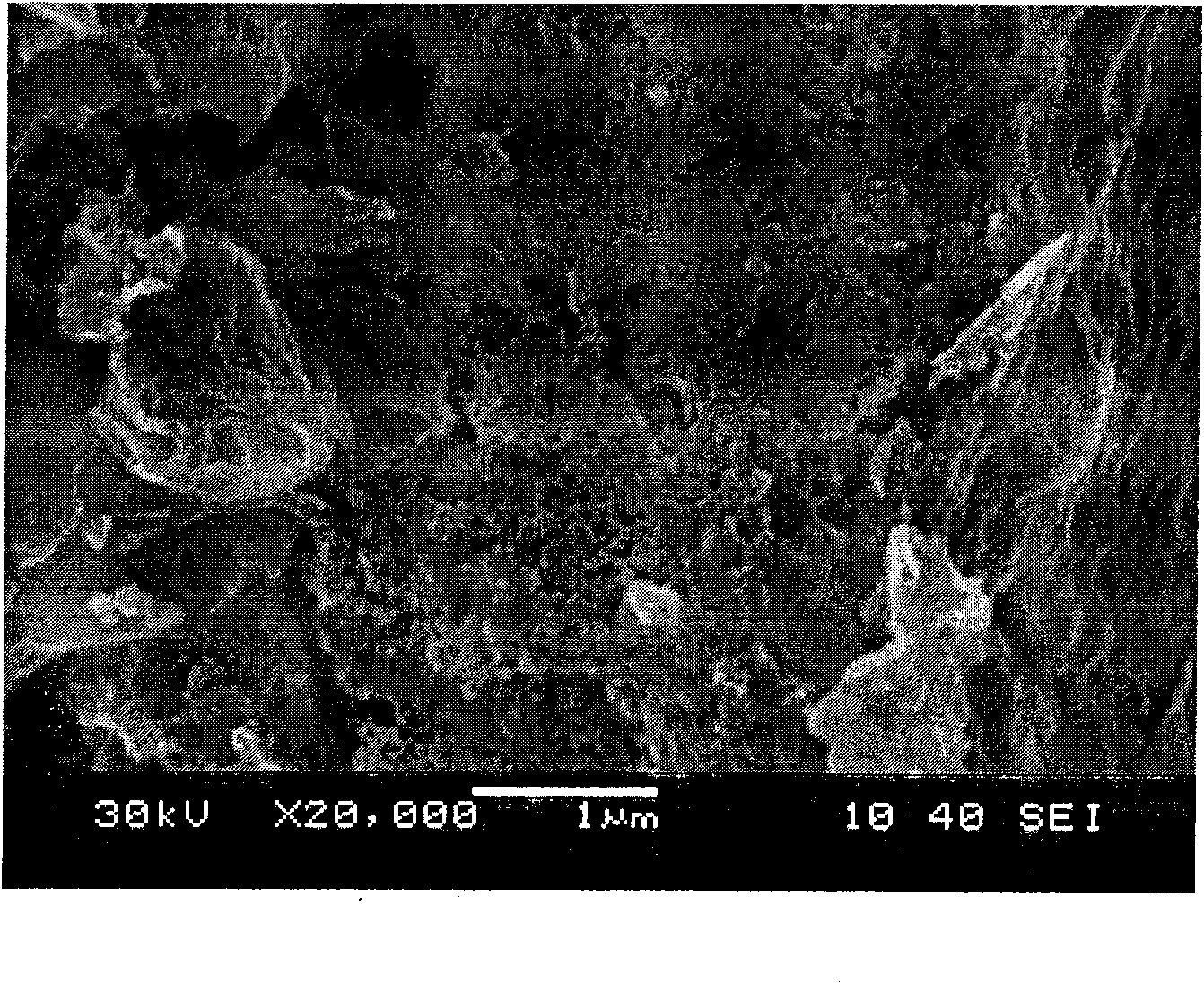

Preparation method and application of nitrogen-doped starch-based activated carbon microsphere material

ActiveCN105948045AMicrostructure is easy to controlGood dispersionHybrid capacitor electrodesDispersityMicrosphere

The invention discloses a preparation method and application of a nitrogen-doped starch-based activated carbon microsphere material. The nitrogen-doped starch-based activated carbon microsphere material is prepared by taking starch as the carbon source and taking a nitrogen-containing compound as the nitrogen source through the steps of gelatinization, hydrothermal treatment, carbonization, activation and the like. The diameters of prepared carbon microspheres range from 0.5 micrometer to 10 micrometers, the particle size is controllable, the dispersity is good, the specific surface area ranges from 1,000 m<2> / g to 3,000 m<2> / g, and the nitrogen content ranges from 0.2% to 15%. The prepared material relates to the application fields of electrochemical energy storage, adsorption separation, catalyst carriers, drug carriers and the like and is particularly applicable to electrochemical energy storage. Green biomass is adopted as the carbon source, sources are wide, the price is low, and the preparation technology is simple, easy to control, environmentally friendly and suitable for large-scale production.

Owner:XIANGTAN UNIV

Yam fish ball and production method thereof

The invention discloses a yam fish ball and a production method thereof. The yam fish ball comprises the following components by weight part: 10 parts of fish mixture, 1-4 parts of Chinese yam rhizome, 0.2-0.4 part of egg white, 0.2-0.6 part of potato starch, 0.2-0.4 part of fat lining, 0.73-0.83 part of modifier and 0.5 part of seasoning. The method comprises the following steps: (1) selecting fresh water fish; (2) poaching, draining, rubbing and straining fish meat; (3) preparing yam mash; (4) mincing the fish meat and producing balls; (5) gelling the yam fish balls; and (6) packaging, quickfreezing and refrigerating. The yam fish ball produced by the method has low cost, full nutrition, delicious taste, white colour and good sense, is easy for digestive absorption and is favorable forhealth of human bodies.

Owner:高翔

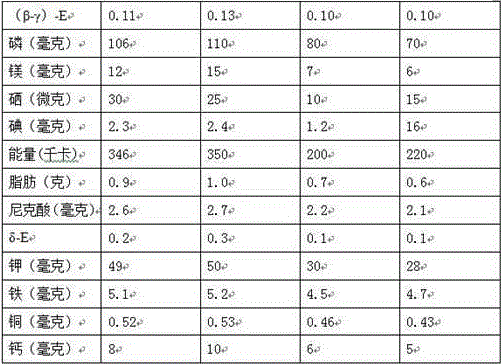

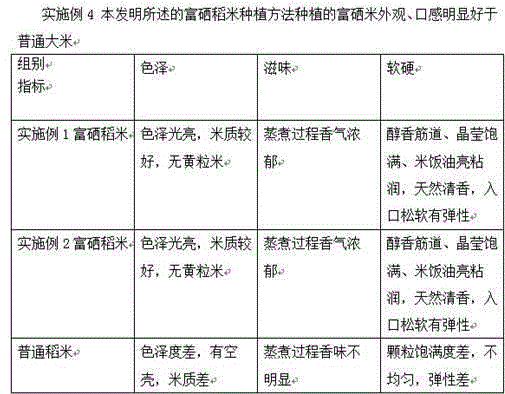

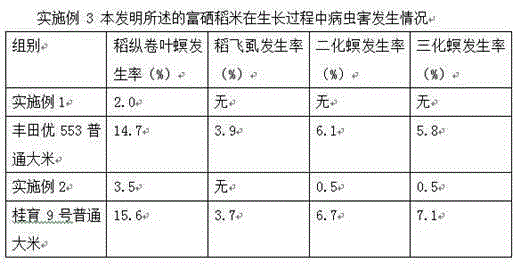

Selenium-enriched rice planting method

InactiveCN105052644AResistant to decompositionLong durationBiocideCalcareous fertilisersPaniclePaddy field

The invention discloses a selenium-enriched rice planting method. The method includes the following steps of land selecting, field finishing, seed treatment, sowing and seedling raising, seedling transplant, fertilizer management in the later period, irrigation treatment and selenium-enriched rice harvesting. Before seedlings are transplanted, selenium-enriched base fertilizer in a complex state is applied in the rice field, and a certain selenium source is provided for rice; at the beginning of panicle emergence and flowering of rice and grouting, the selenium-enriched compound fertilizer is applied in the rice field again, the selenium-enriched fertilizer is evenly distributed around roots of the seedlings in the growth process, the selenium in a complex state from soil is absorbed by the roots of the plants and then enters the inner cycle systems of the plants and participates in synthesis of protein through the path from stems to leaves to flowers and fruits, and finally, the selenium in an ionic condition from soil is stored in the seeds in the form of selenoprotein. The selenium-enriched rice tastes good and is high in nutrient matter content, and the content of the selenium of the rice can reach over 0.2 mg / kg and meets the national selenium-enriched standard.

Owner:GUANGXI XIEJI AGRI DEV CO LTD

Charcoal-containing polyurethane foam composite material

Disclosed is carbon-containing urethane foam composite material, relating to urethane foam composite material. The composite material is carbon-containing soft urethane foam, or carbon-containing slowly-recoverable urethane foam or carbon-containing hard urethane foam. Apart from the necessary foam source and the auxiliary material, the raw material for preparing the urethane foam includes super-thin bamboo powder or charcoal powder. Furthermore, far-infrared powder, sterilized powder, silver ion powder, organic germanium powder, tea powder or Chinese herbal powder can be added into the raw material for preparing the urethane foam. The urethane foam can be made into bath sponge and washing sponge with the capabilities of adsorbing and degrading noxious gas, disinfecting and sterilizing, radiating far infrared rays and adjusting humidity or be made into pillows, cushions, mattresses and indoor decorations with medical and health care functions in daily life.

Owner:林文炳

Long glass fiber reinforced recycled polypropylene material and preparation method thereof

The invention discloses long glass fiber reinforced recycled polypropylene material and a preparation method thereof. The long glass fiber reinforced recycled polypropylene material comprises components according to mass percent: 25-55% of polypropylene, 30-60% of long glass fiber, 0.4-0.8% of coupling agent, 3-8% of graft of thermoplastic elastomer, 0.1-0.3% of fused finger modifier, 0.2-0.4% ofantioxygens, 1-4% of lubricant and 1-3% of selective assistant. The preparation method is as follows: mixing and stirring components except for long glass fiber, and then adding the components exceptfor long glass fiber to a screw extruder; adding long glass fiber, mixing, extruding, cooling, air drying and pelleting; as the fused finger modifier is added, the requirements on polypropylene are reduced; various recycled polypropylene materials can be used as backing material. The preparation method is simple and has low cost; the prepared long glass fiber einforced recycled polypropylene material has good comprehensive performances and can replace a plurality of metal parts to be applied to various fields.

Owner:惠东美化塑胶实业有限公司

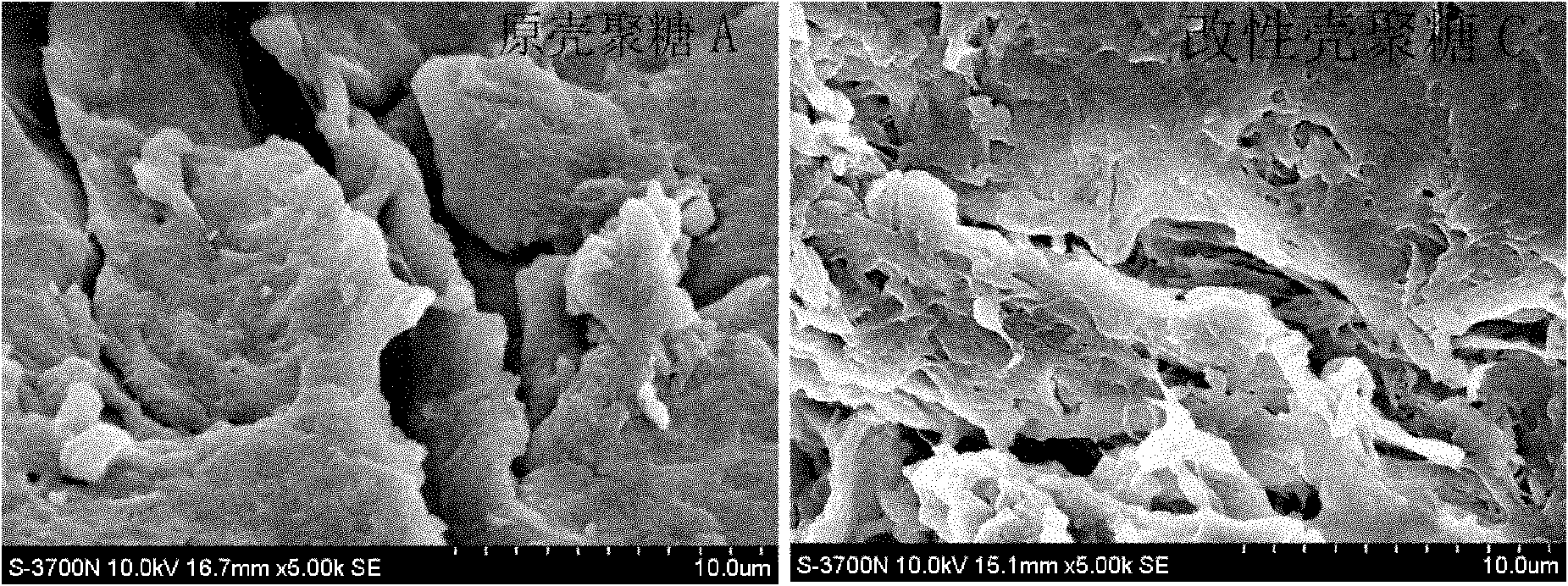

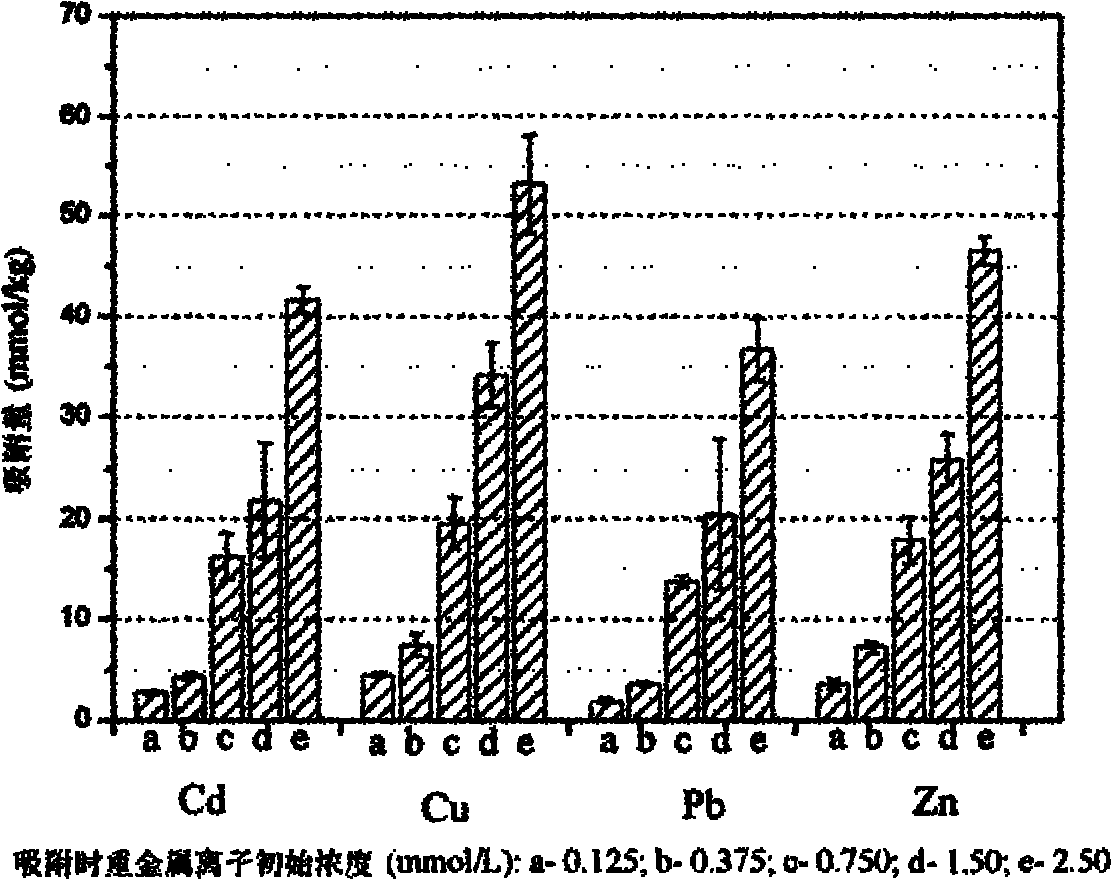

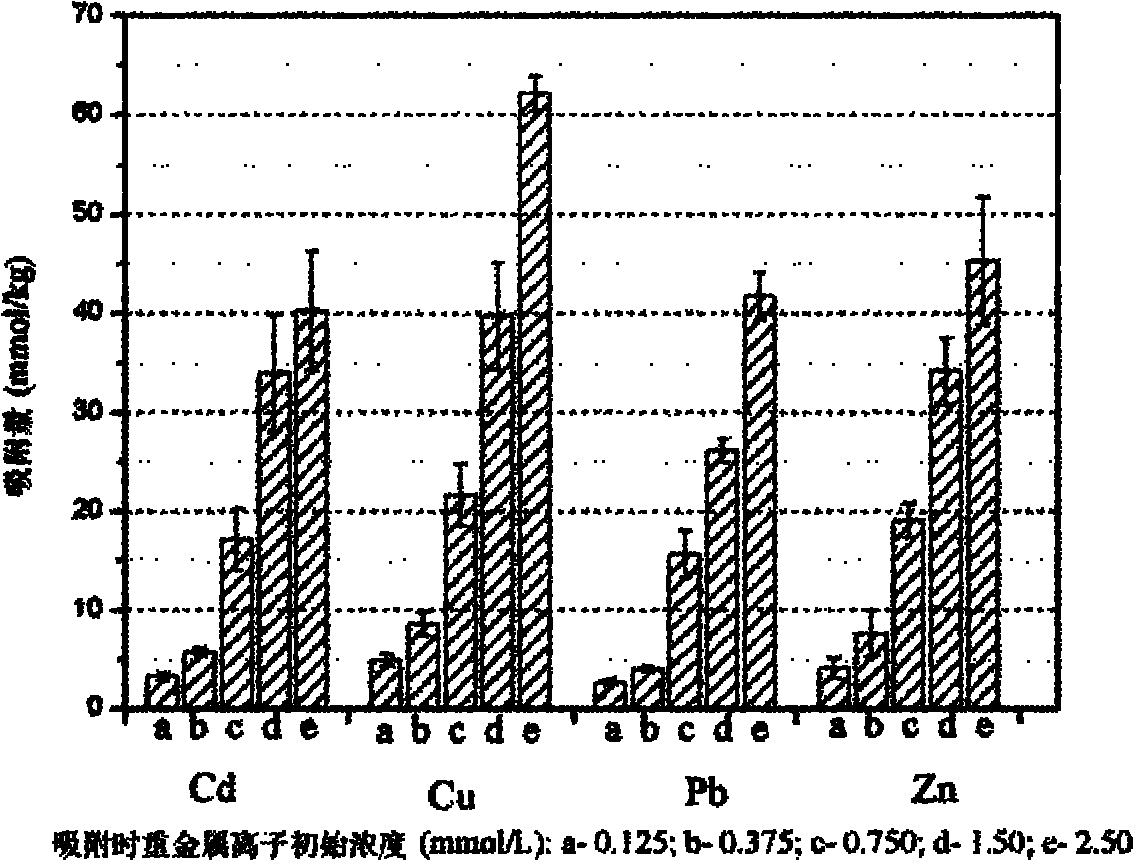

Modified chitosan material capable of absorbing heavy metal ions and preparation method thereof

ActiveCN102161781AEasy to makeEasy to recycleOther chemical processesWater/sewage treatment by sorptionLiquid ratioMass ratio

The invention discloses a modified chitosan material capable of absorbing heavy metal ions and a preparation method thereof. The modified chitosan material is prepared by a method comprising: dissolving the chitosan and sodium alga acid in water respectively to prepare chitosan solution at a concentration of 1.5 mass percent and sodium alga acid solution at a concentration of 2 mass percent; mixing the chitosan solution and sodium alga acid solution uniformly according to a mass ratio of the chitosan and the sodium alga acid of (8-10):1 under a room temperature condition, and dripping calcium chloride solution at a concentration of 1.5 mass percent according to a solid to liquid ratio of the sodium alga acid to the calcium chloride solution of 1:37 with stirring; fully stirring after dripping is finished; regulating the pH value of the solution to 7.2+-0.2 till solid floccules appear; standing till solid gel appears; and filtering, and drying the gel at 35 DEG C to obtain the modified chitosan material.

Owner:INST OF ANALYSIS GUANGDONG ACAD OF SCI (CHINA NAT ANALYTICAL

Electric steel insulating paint, and preparation method and coating method thereof

InactiveCN101659799AImprove insulation performanceConvenient coatingCoatingsElectrical resistance and conductanceElectrical steel

The invention relates to an electric steel insulating paint, and a preparation method and a coating method thereof. The electric steel insulating paint is prepared from the following components by mass percent: 25-65% of aluminium dihydrogen phosphate, 0.5-3% of silica sol, 1-5% of phosphoric acid, 1-5% of magnesium oxide, 0.1-1% of nitrate additive containing rare earth, 1-5% of silane coupling agent and the balance water as a solvent. The thickness of the electric steel insulating paint is 0.3-8 mu m. The electric steel insulating paint has the advantages of favorable insulating property, favorable coating performance, high interface resistance, high breakdown resistance, high corrosion resistance, high adhesion property and the like. The environmental-protection insulating paint does not contain chromium, and thereby being clean and having no pollution. In addition, the electric steel insulating paint also has the advantages of rich material sources, low cost, high performance priceratio, strong market competitiveness and wide application prospects.

Owner:艾宝魁

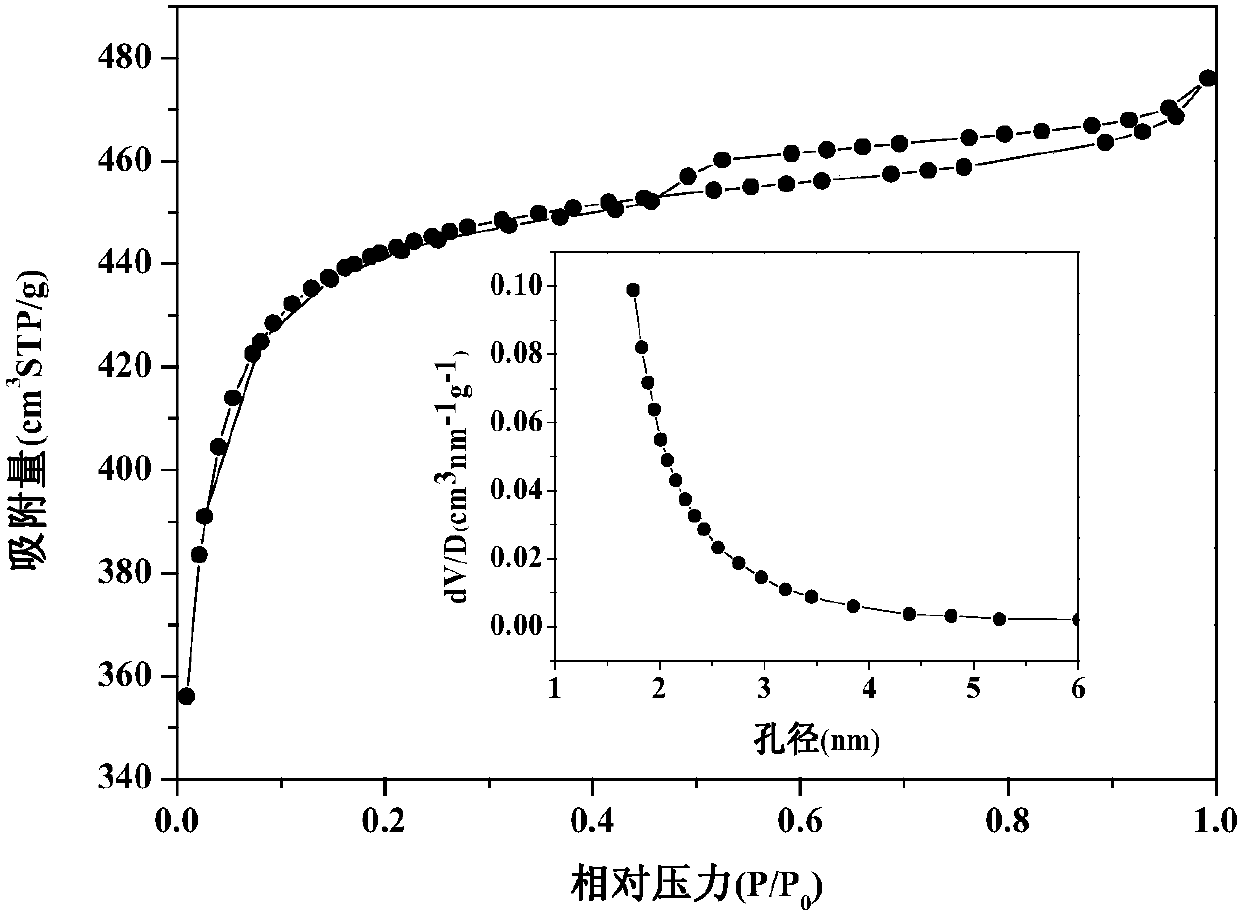

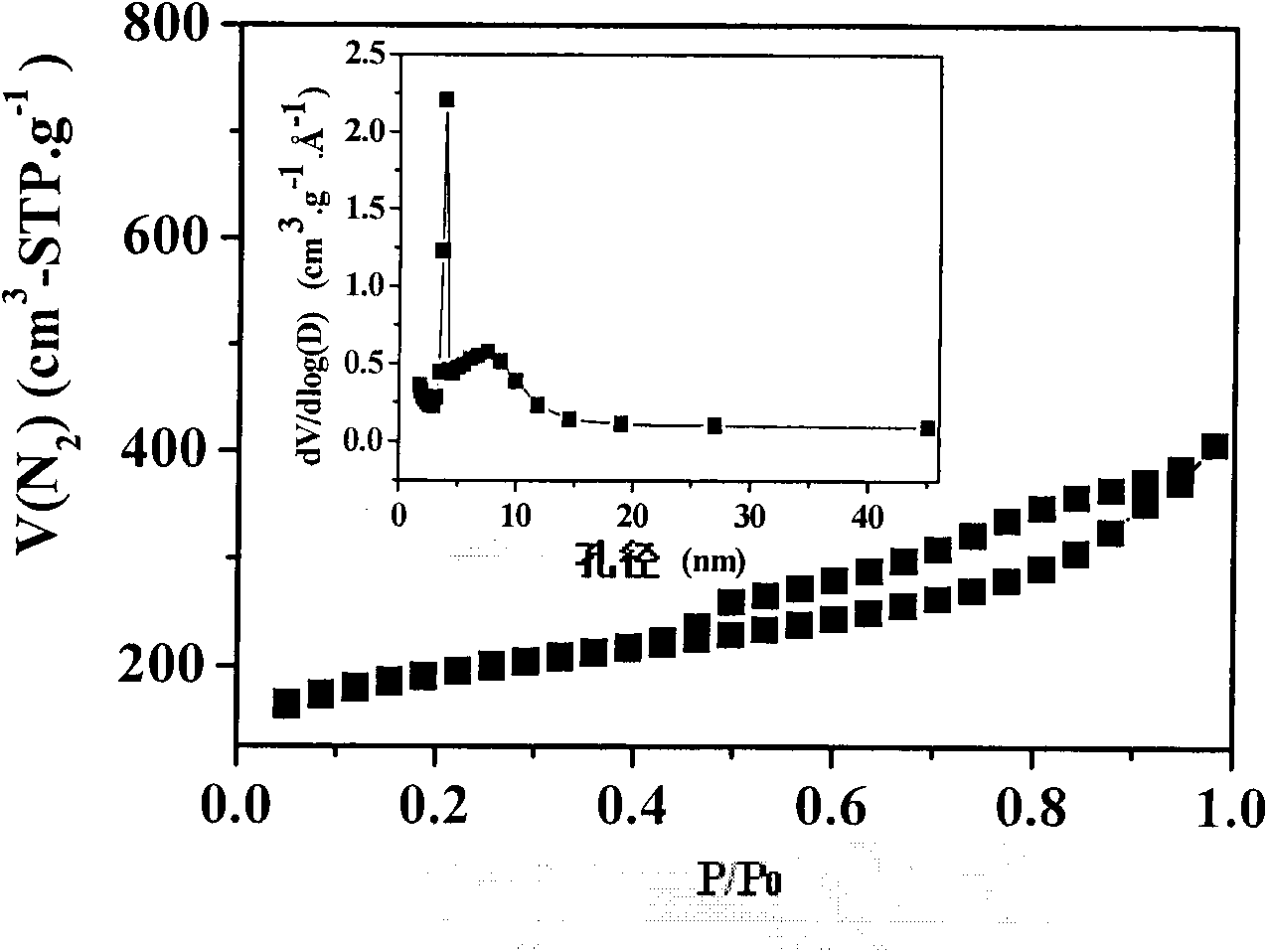

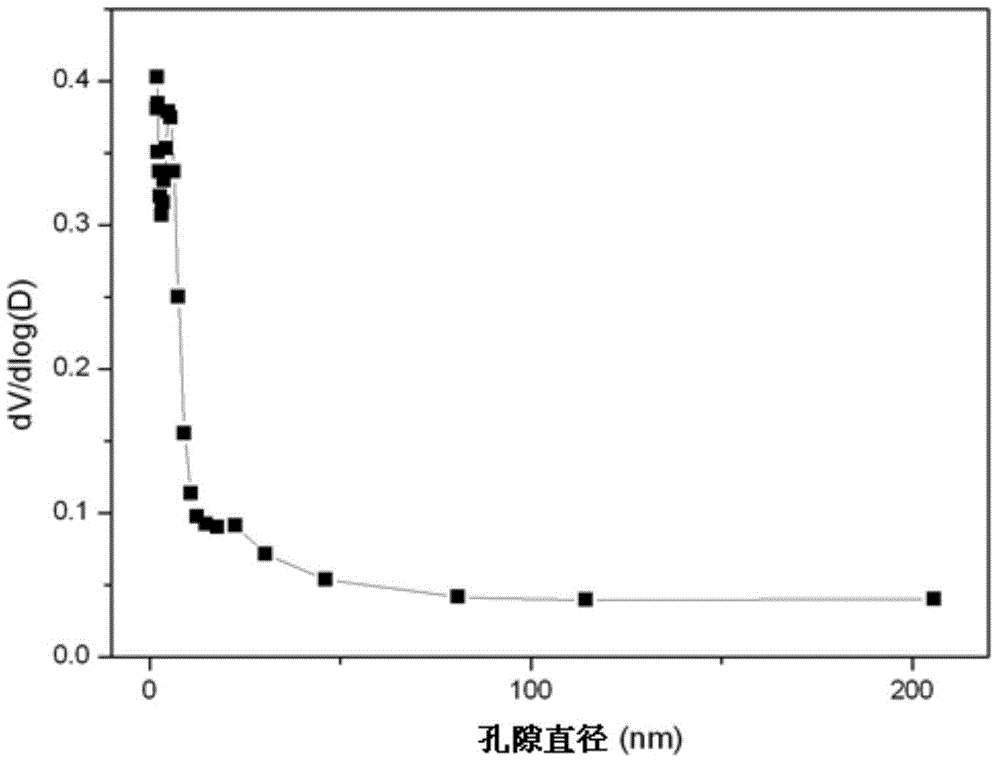

Method for preparing high-surface-area nitrogenous mesoporous carbon material

The invention discloses a method for preparing a high-surface-area nitrogenous mesoporous carbon material. The method prepares the nitrogenous mesoporous carbon material by using melamine, urea and formaldehyde as raw materials, using metal chloride as a template agent and an active agent, and performing the steps of dissolution, polymerization, solidification, carbonization, washing, drying and the like. The raw materials are rich in sources and have low prices; the metal chloride used as the template agent and the active agent has a low price and can be recycled; the whole preparation method is simple and feasible; and the prepared nitrogenous mesoporous carbon material has a specific area of 500 to 1,500 m<2> / g, a total pore volume of 1.0 to 3.0 cm<3> / g, a mesoporous ratio of 80 to 92 percent, an adjustable pore diameter of between 2.5 nm to a plurality of microns and the nitrogen content (atomic percent) of 5 to 28 percent at, and is expected to be widely applied in the fields of adsorbents, catalyst carriers, electrode materials and the like.

Owner:NANJING UNIV

Artificial articular cartilage based on autologous cells and preparation method thereof

ActiveCN101574543AImprove mechanical propertiesAvoid inconvenienceJoint implantsElectrospinningHYDROSOL

The invention provides artificial articular cartilage based on autologous cells and a preparation method thereof. The artificial articular cartilage comprises a nano bionic support and hydrosol adhered to the nano bionic support, wherein one or more cytokines are coated into the hydrosol. The invention also provides the method for preparing the artificial articular cartilage, which comprises the following steps: preparing an electrostatic spinning solution, a cytokine-containing hydrosol solution and a crosslinking agent solution; using the crosslinking agent solution to receive electrostatic spinning so as to prepare the nano bionic support; and using an ink jet printer to print the cytokine-containing hydrosol solution on the nano bionic support, and curing the hydrosol to obtain the artificial articular cartilage. The three-dimensional support adopted by the invention has ideal degradation speed and is degraded after the regeneration of an articular cartilage layer, can meet the requirement of actual clinical application, can be completely degraded, and has good abrasion resistance and lubricity so as to be capable of replacing the cartilage before the regeneration of the articular cartilage layer.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Flaky structure layered composite hydroxide and preparation method thereof

The present invention provides a flaky structure layered composite hydroxide and a preparation method thereof. According to the preparation method, a metal hydroxide, an oxide, a basic carbonate, a metal soluble salt and an alkali are adopted as raw materials, the addition speed of the alkali solution is controlled to prepare the flaky LDH, and the space confinement effect of the metal hydroxide, the oxide or the basic carbonate exists, such that the produced LDH flakes do not easily aggregate so as to finally obtain the LDH with a large specific surface, wherein the BET specific surface area is 130-200 m<2> / g and is much larger than the specific surface area of the ordinary LDH. According to the invention, the preparation method has characteristics of simpleness, no requirement of high temperature, high pressure and special equipment, rich raw material source and low cost; and the flaky structure layered composite hydroxide can be widely used in the fields of absorption separation, catalysis, polymer materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

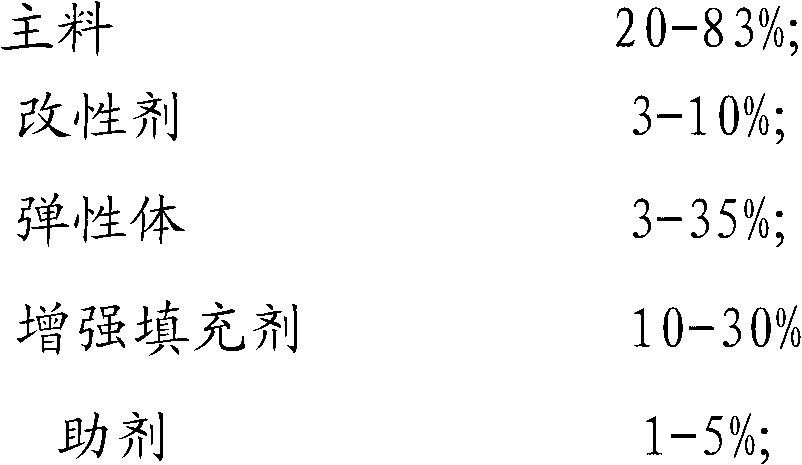

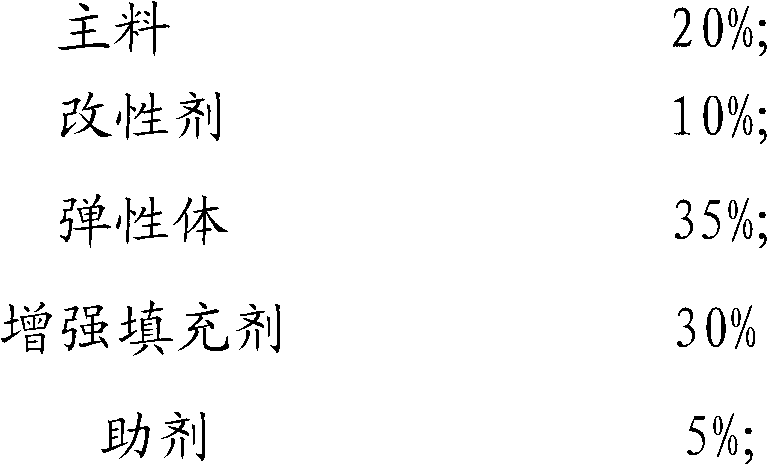

Composite material special for blow molding of reinforced nylon air inlet pipe and preparation method thereof

The invention provides a composite material special for blow molding of a reinforced nylon air inlet pipe. The composite material comprises the following components in percentage by mass: 20-83 percent of main material, 3-10 percent of modifier, 3-35 percent of elastomer, 10-30 percent of enhancing filler and 1-5 percent of auxiliary agent. The composite material special for blow molding of the reinforced nylon air inlet pipe can be used in blow molded products of air inlet pipelines, oil paths or cooling system pipelines at the peripheries of automobile engines. The composite material contains the reinforcing filler; the strength and the high temperature resistance performance of the composite material are improved; and the composite material is rich and cheap in raw materials and is suitable for promotion and application.

Owner:辰东意普万新材料(广东)有限公司

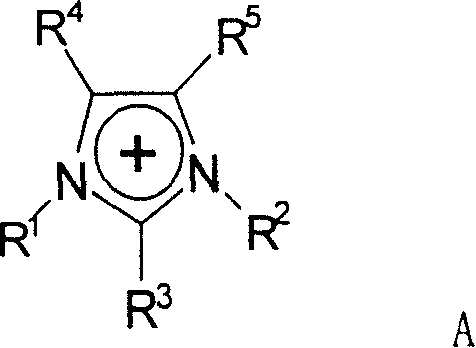

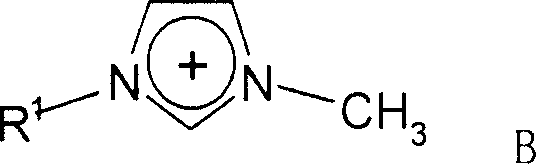

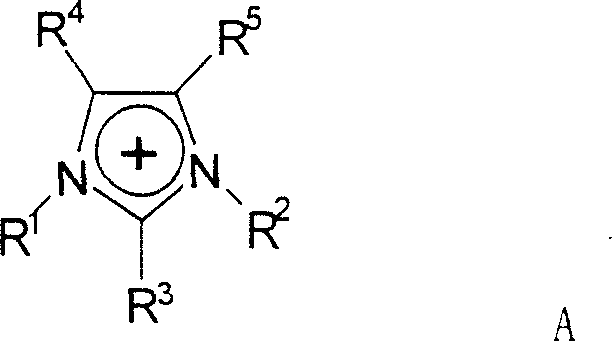

Method for producing cellulose ester acetate by using plant cellulose

This invention relates to a method for preparing cellulose ester acetate from plant cellulose in ionic liquid. The method comprises: (1) utilizing plant cellulose as the raw material; (2) dissolving plant cellulose in ionic liquid; (3) adding acylation agent into the ionic liquid, performing homogeneous acetylation on plant cellulose, washing the intermediate with water and drying; (4) separating and purifying dried intermediate to obtain cellulose ester acetate. This invention provides a method for homogeneously preparing cellulose ester acetate in clean solvent (ionic liquid) by using low quality plant cellulose as the raw material. The method solves the problem of high cost faced by the present methods.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Preparation method of temperature-resistant and salt-tolerant nano oil displacement agent

ActiveCN103725278AWon't fall offImprove performanceMaterial nanotechnologyDrilling compositionActive agentSurface-active agents

The invention provides a preparation method of a temperature-resistant and salt-tolerant nano oil displacement agent. The preparation method comprises the following steps: modifying polyacrylamide to surfaces of silica nanoparticles through chemical bonds to obtain nano-composite particles with stable performance, and then using the nano-composite particles together with alkali and a surfactant to prepare the nano oil displacement agent. The nano oil displacement agent can solve the problem about high possibility of falling off of a polymer on the surface of a traditional nano oil displacement agent in the formation moving process, so as to achieve an excellent oil displacement effect. Especially in the high-temperature and high-salt formation, the nano oil displacement agent can overcome harsh formation conditions and cannot reduce the oil displacement effect.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

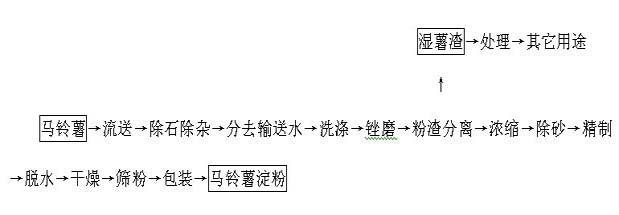

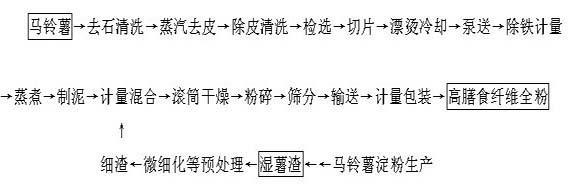

Method for producing potato flake with high dietary fiber content

The invention discloses a method for producing potato flake with high dietary fiber content. The method comprises the following steps: after the byproduct of wet potato residue generated through flour-residue separation during potato starch production is subject to acid base interaction, oxidation or enzymolysis and micronization, the micronized dietary fiber of potato is mixed with mashed potatoes obtained through steaming, boiling and smashing in a certain content ratio, the mixture is dried through a roller dryer, the moisture content in the product is smaller than or equal to 10 percent, and the potato flake rich in dietary fiber is produced after crushing and sieving. The method of the invention is suitable for being implemented in whole potato processing production enterprises, the produced potato flake is rich in an excess amount of dietary fiber and can be used as an auxiliary material for processing other foods, therefore, the economic value of the byproduct of starch production, i.e., wet potato residue is greatly increased, and pollution to the environment is reduced.

Owner:广州华糖食品有限公司 +1

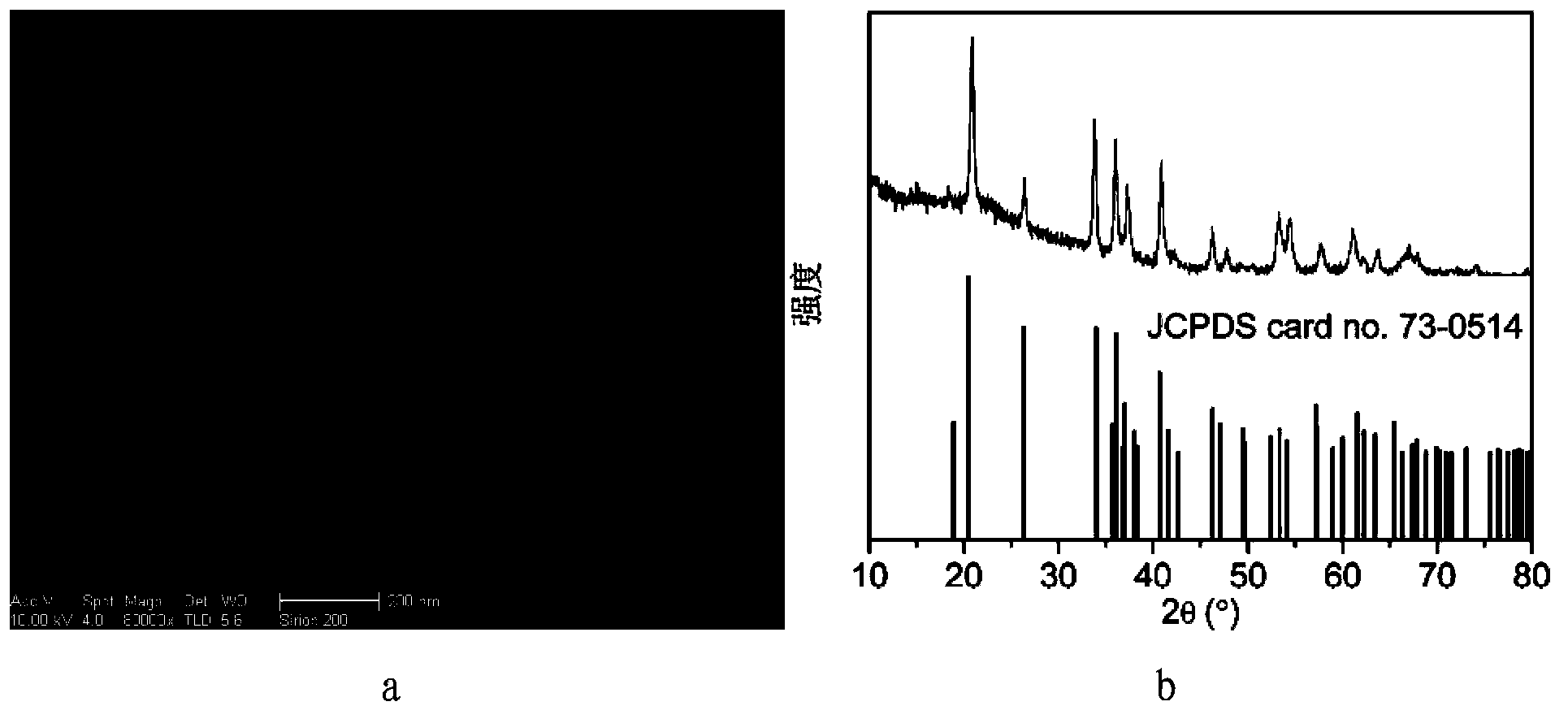

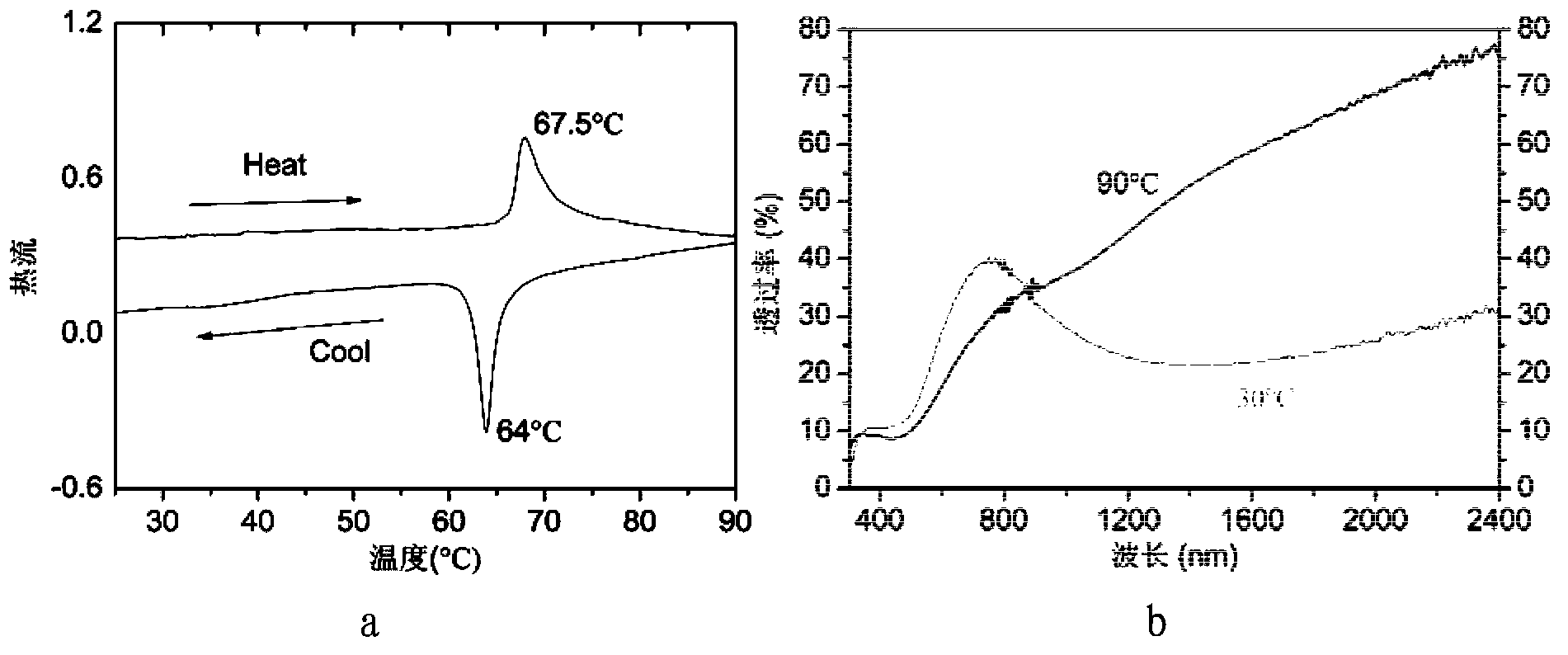

Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

InactiveCN104071843AGood phase change propertiesExcellent infrared control performanceMaterial nanotechnologyVanadium oxidesVanadium dioxideDispersity

The invention discloses a preparation method of monodispersed M-phase vanadium dioxide nanoparticles. The preparation method comprises the following steps: mixing vanadium pentoxide, oxalate dihydrate and water according to a molar ratio of (1-2.5) : 1 : (500-800) to obtain mixed liquid, adding 4%-6% of a surfactant based on the volume of the mixed liquid into the mixed liquid, and stirring for at least 2 hours to obtain a precursor solution; reacting the precursor solution in a sealed state at 200-260 DEG C for at least 1 day to obtain reaction liquid; performing solid-liquid separation and washing on the reaction liquid in sequence to obtain orthogonal vanadium dioxide powder; annealing the orthogonal vanadium dioxide powder in a nitrogen atmosphere at 300-600 DEG C for 0.5 hour to obtain the monodispersed M-phase vanadium dioxide nanoparticles with particle sizes of 60nm-80nm. The preparation method has the advantages of environmental protection and no temperature gradient control during annealing, and can be widely used for preparing the M-phase vanadium dioxide nanoparticles with very good dispersity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preparation method of biomass nano cellulose carbon aerogel

The invention relates to a preparation method of a carbon aerogel, particularly a preparation method of a biomass nano cellulose carbon aerogel, and aims to solve the problems of complex preparation process and lack of raw materials in the traditional carbon aerogel. The method comprises the following steps: 1. treatment of biomass material: treating the biomass material with acidified sodium chlorite, and treating with a 1-10 wt% potassium hydroxide solution to obtain purified cellulose; 2. preparing purified cellulose water solutions with different concentrations; 3. mechanical treatment: carrying out ultrasonic treatment on the purified cellulose water solution, carrying out high-pressure homogenization treatment to obtain a nano cellulose water suspension, and standing the nano cellulose water suspension to obtain the nano cellulose aquagel by self-assembly; 4. drying the nano cellulose aquagel to prepare the nano cellulose aerogel; and 5. carrying out carbonizing treatment on the nano cellulose aerogel in a pipe furnace in an inert gas protective atmosphere to prepare the nano cellulose carbon aerogel. The method is applicable to the field of aerogel materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

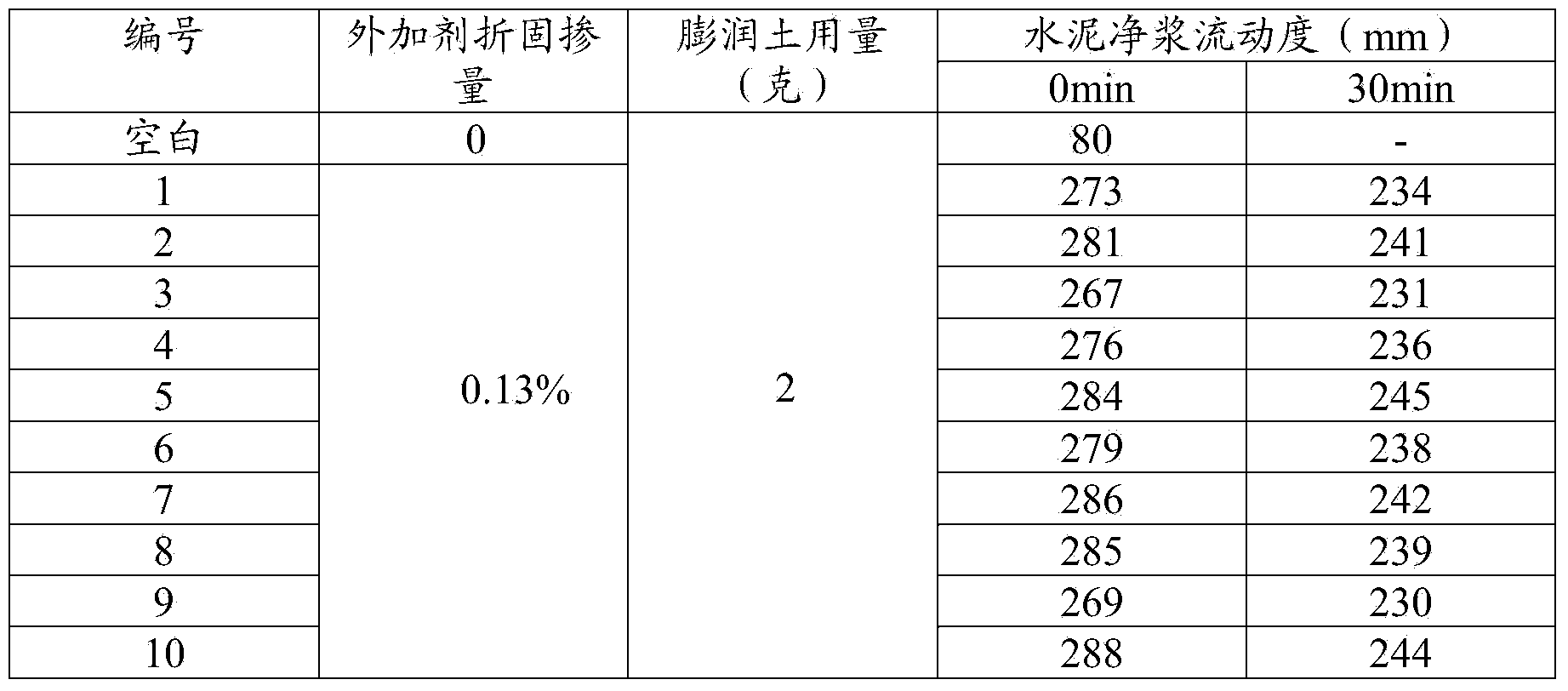

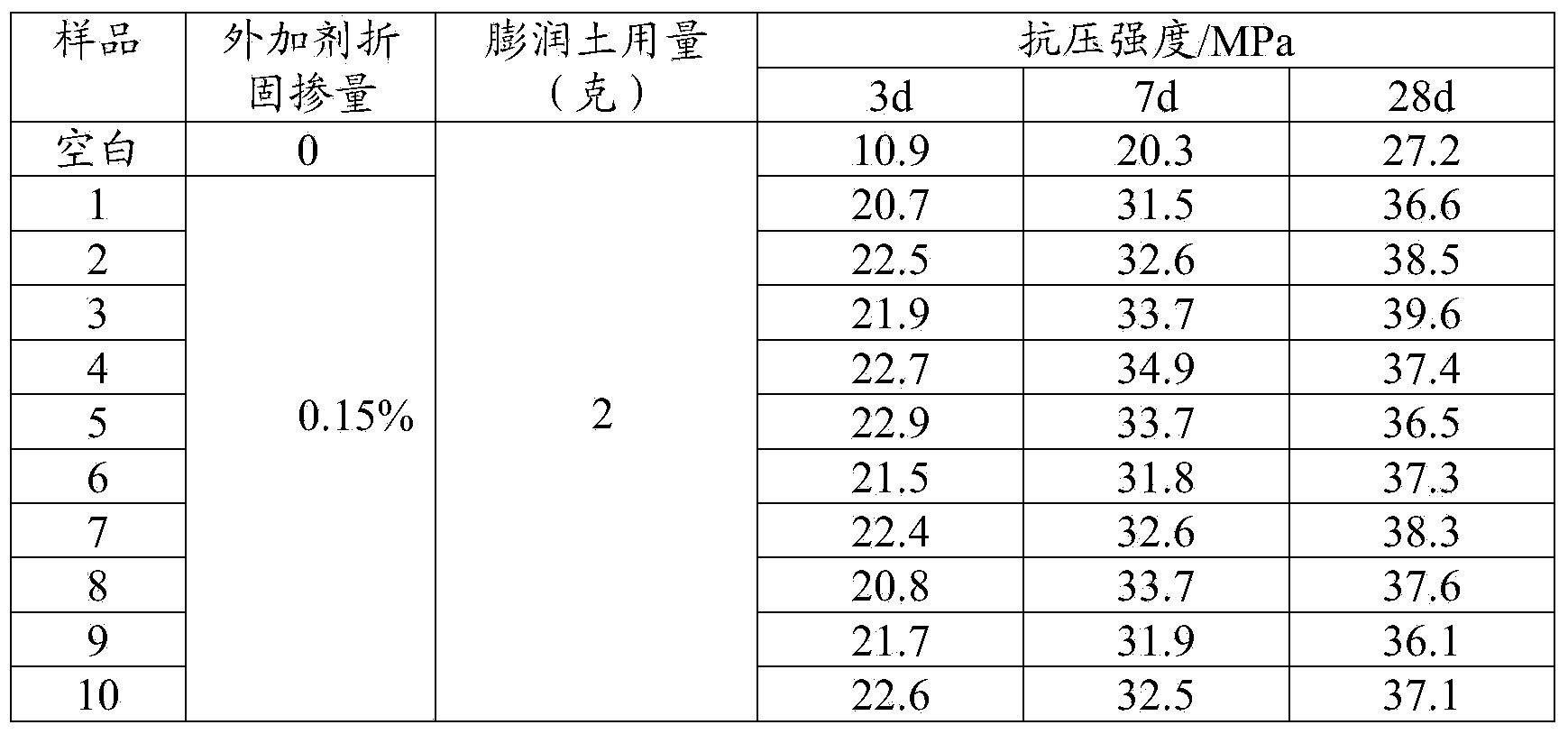

Preparation method of mud-resistant polycarboxylate-type water reducer

The invention relates to a preparation method of a mud-resistant polycarboxylate-type water reducer. The preparation method comprises the following specific steps: stirring an unsaturated small monomer containing an epoxy group, a secondary amine small organic molecule and a small organic molecule containing halogen at certain temperature under the action of a catalyst to obtain a product of quaternary ammonium salt unsaturated small monomer; carrying out water phase free radical polymerization reaction on the quaternary ammonium salt unsaturated small monomer, an unsaturated ester small monomer, an unsaturated sulfoacid small monomer, an unsaturated acid small monomer and an unsaturated polyether large monomer under the combined action of an initiator and a chain transfer agent to obtain a copolymerized product, regulating the pH value after reaction and adding water to obtain the polycarboxylate-type water reducer. The mud-resistant polycarboxylate-type water reducer prepared by the method has the advantages of being simple in reaction, easy to control and low in cost. Besides, adverse effect caused by mud-containing aggregate in the concrete can be avoided, and the problems of insufficient concrete slushing, large slump loss and low strength are solved without increasing the mixing amount of the water reducer.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com