Patents

Literature

246results about How to "Abundant sources of raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt-base carbon fiber prepared by coal directly liquefied residues and preparation method thereof

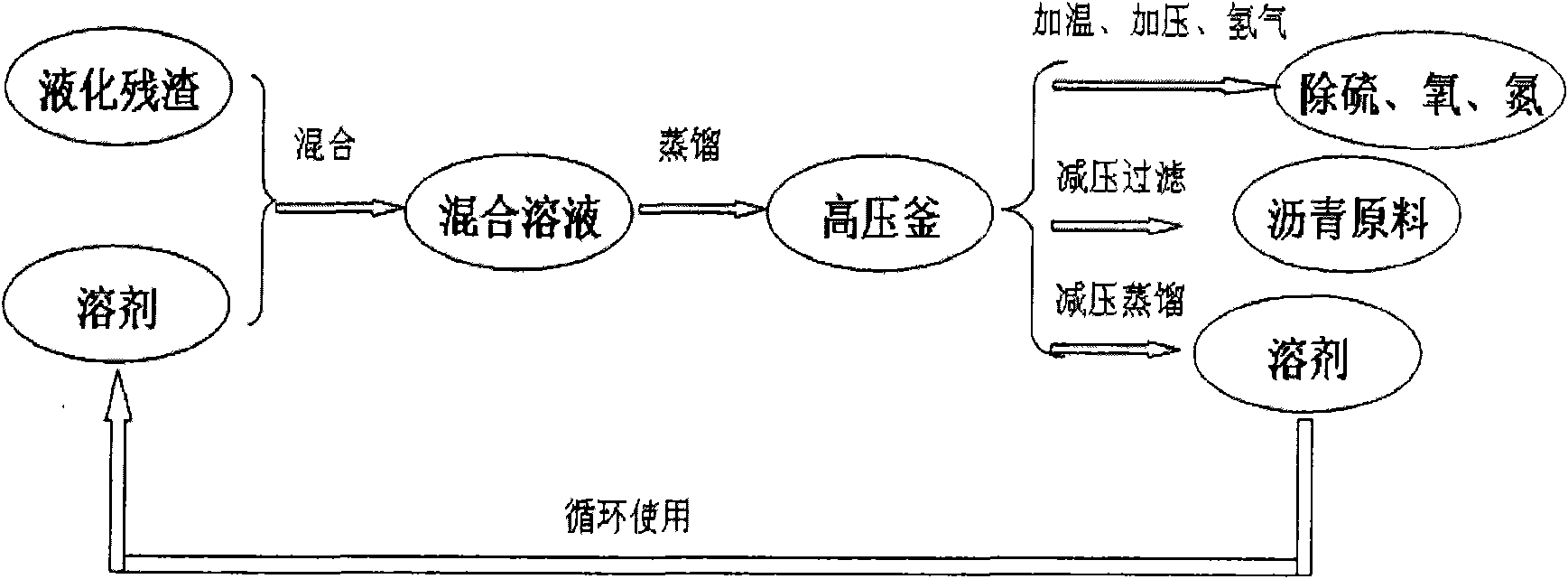

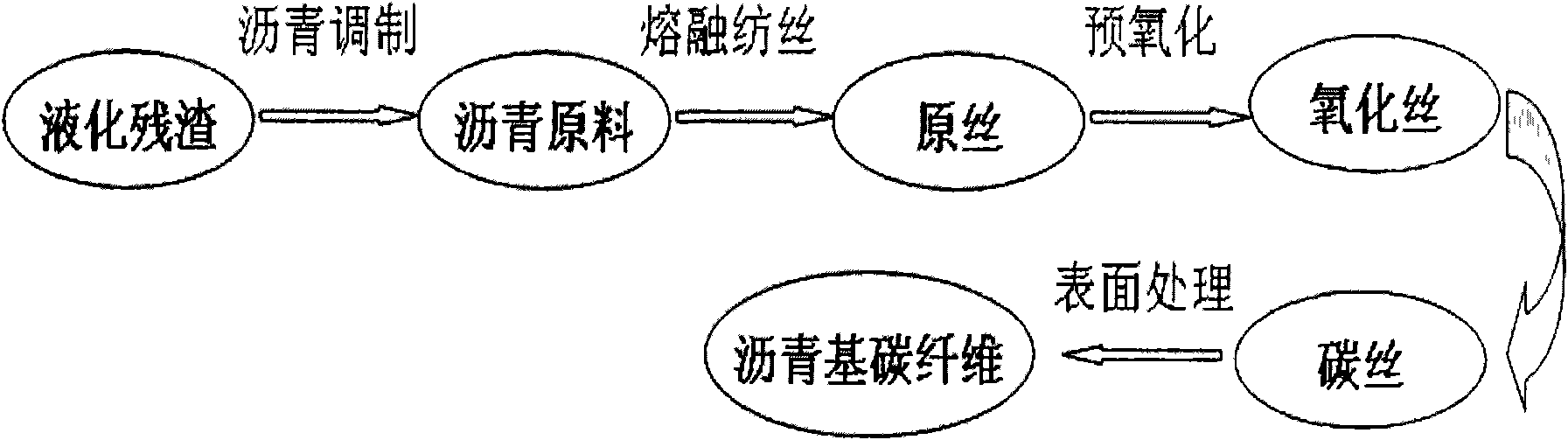

The invention discloses a method for preparing asphalt-base carbon fiber by taking coal directly liquefied residues as a raw material. The method comprises the following steps that: mixed solution of coal directly liquefied residue powder and tetrahydroquinoline solvent is filled into a high pressure autoclave, and is heated to a temperature of between 150 and 400 DEG C after air in the autoclave is replaced by nitrogen; hydrogen is introduced into the autoclave while pressure is increased to 2 to 50MPa; most elements, such as sulfur, oxygen, nitrogen and the like, contained in original residues are removed through distilling under reduced pressure; removing tetrahydroquinoline insoluble substance through filtering under reduced pressure, reclaiming the tetrahydroquinoline solvent through distilling under reduced pressure, and recycling the tetrahydroquinoline solvent; and the obtained tetrahydroquinoline soluble substance can be produced into the asphalt-base carbon fiber through melt spinning, pre-oxidation, low temperature carbonization, high temperature carbonization, superficial treatment, post treatment and other processes.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

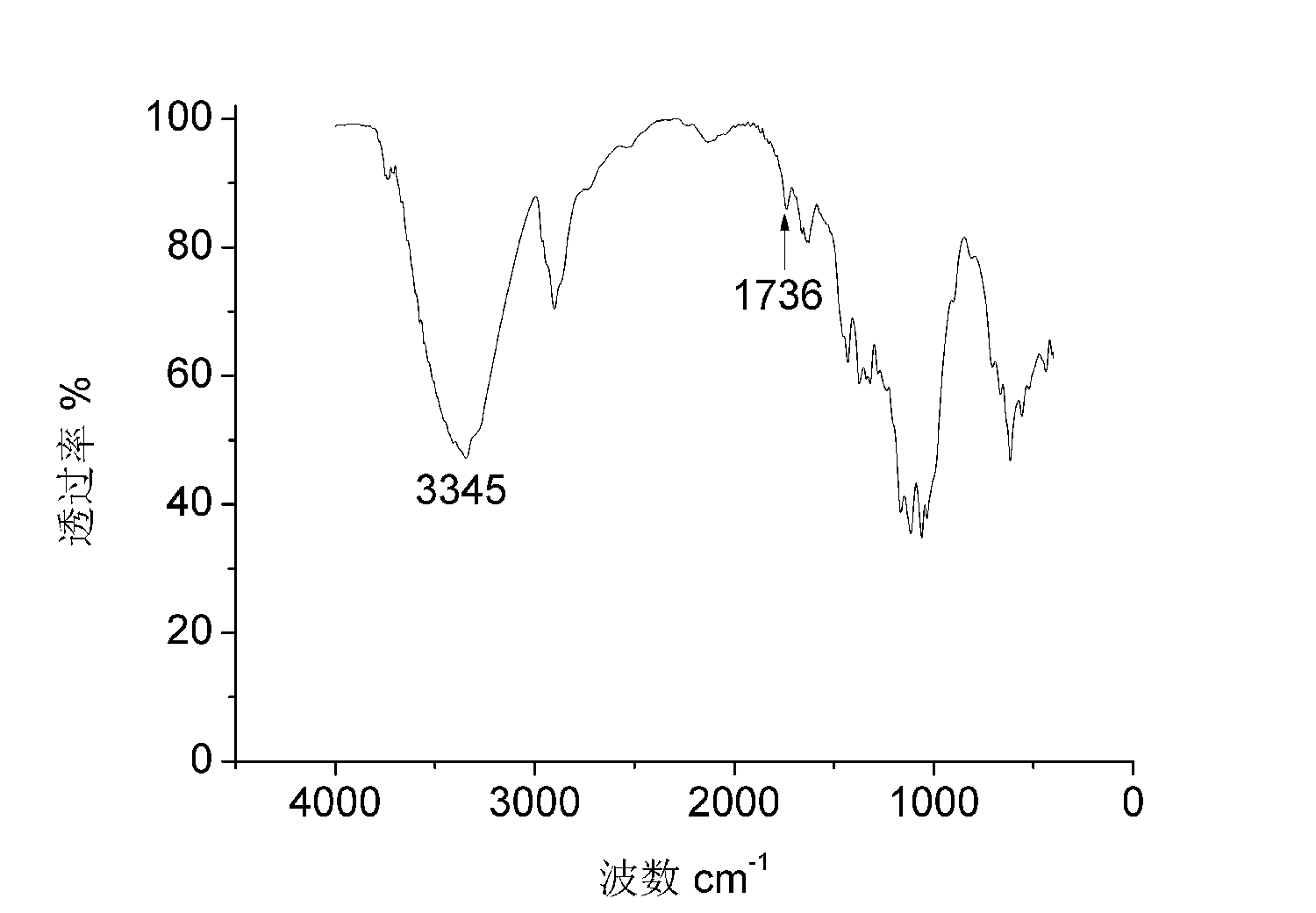

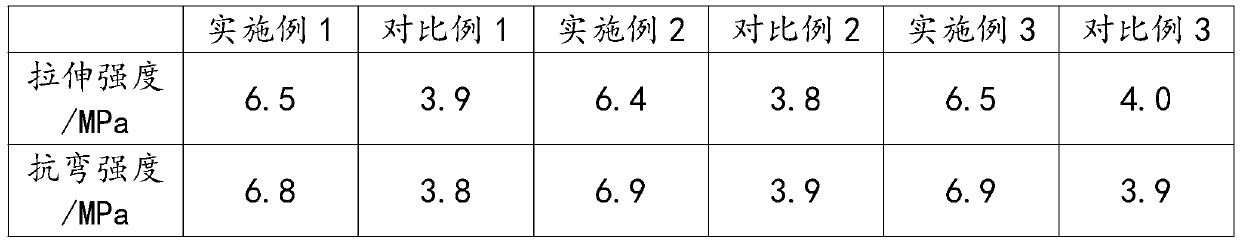

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for producing cellulose ester acetate by using plant cellulose

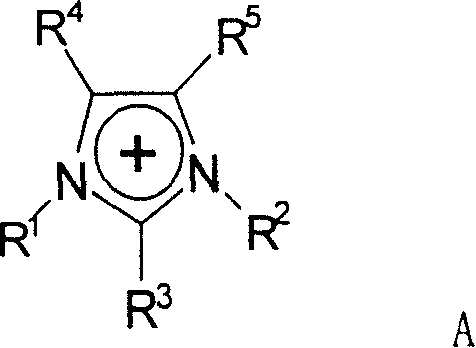

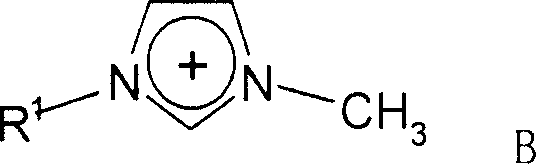

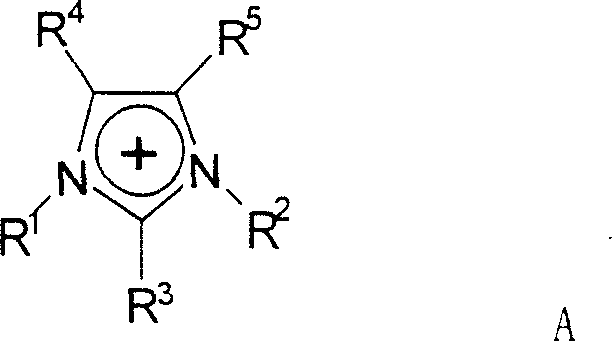

This invention relates to a method for preparing cellulose ester acetate from plant cellulose in ionic liquid. The method comprises: (1) utilizing plant cellulose as the raw material; (2) dissolving plant cellulose in ionic liquid; (3) adding acylation agent into the ionic liquid, performing homogeneous acetylation on plant cellulose, washing the intermediate with water and drying; (4) separating and purifying dried intermediate to obtain cellulose ester acetate. This invention provides a method for homogeneously preparing cellulose ester acetate in clean solvent (ionic liquid) by using low quality plant cellulose as the raw material. The method solves the problem of high cost faced by the present methods.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

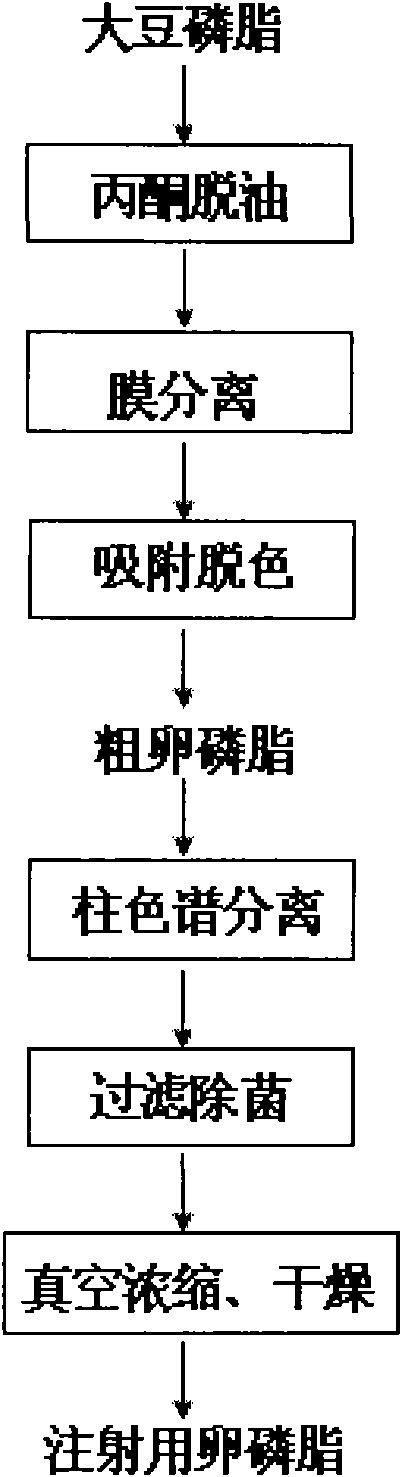

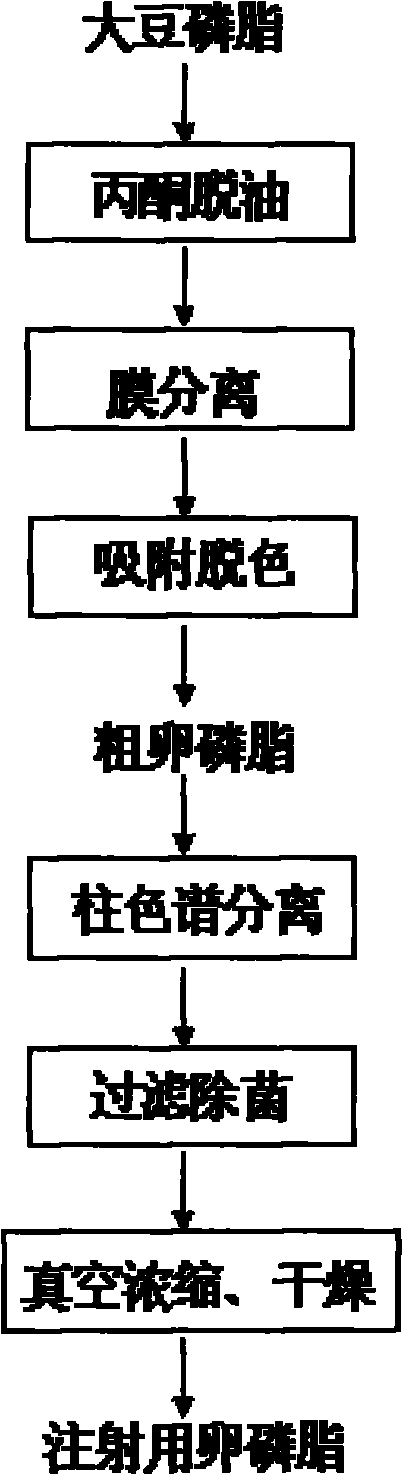

Preparation technology of soybean lecithin for injection

ActiveCN101792461AHigh product purityAbundant sources of raw materialsPhosphatide foodstuff compositionsSolventChemistry

The invention relates to a preparation technology of soybean lecithin for injection. Soybean lecithin is taken as a raw material, crude lecithin is firstly obtained after the treatment of acetone deoiling, membrane separation, adsorption decolorization and the like, then the crude lecithin is undergone column chromatographic fractionation, filtration sterilization, decompression concentration and vacuum drying, and finally the soybean lecithin for injection is obtained. The invention adopts membrane separation to replace the traditional solvent extraction, so the operation is easy. A polar compound with surface hydroxyl groups is taken as a stationary phase, mixed solvent composed of weak polar solvent and strong polar solvent is firstly used as eluent to carry out gradient elution, after all the cephalin flows out, the strong polar solvent is taken as the eluent, thereby not only the separation selectivity is high, but also the usage of the eluent is greatly reduced, and meanwhile, the extraction efficiency of lecithin is high, the product quality is stable, and the industrial mass production is benefited.

Owner:NANJING UNIV OF TECH +1

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

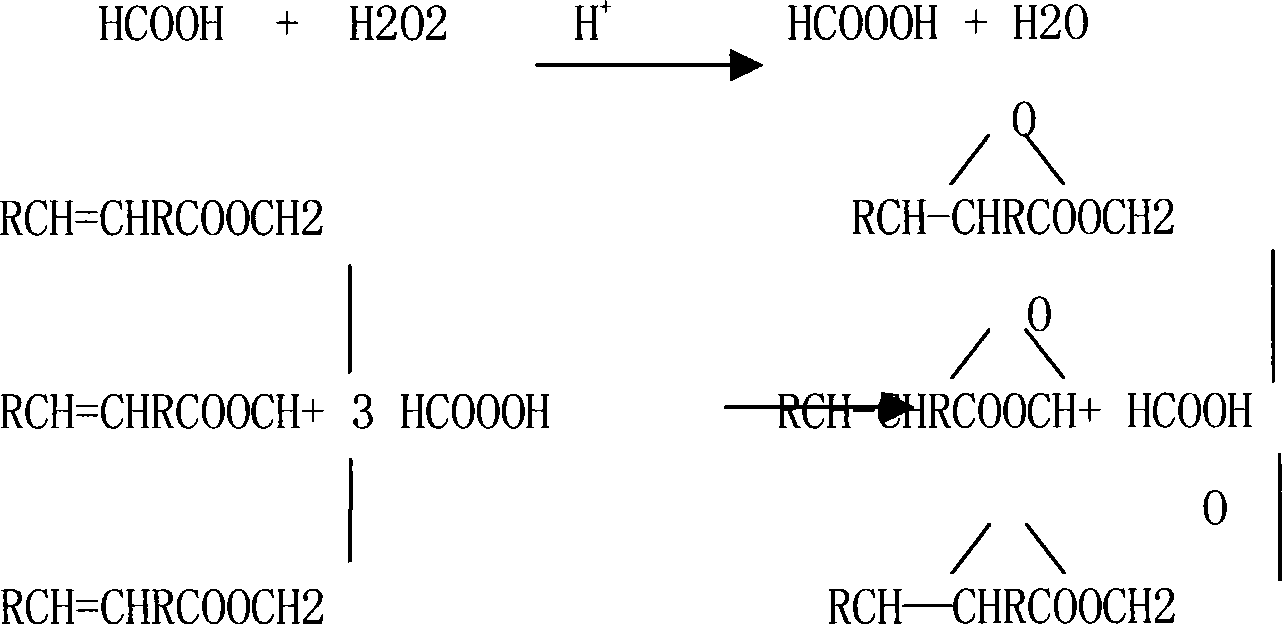

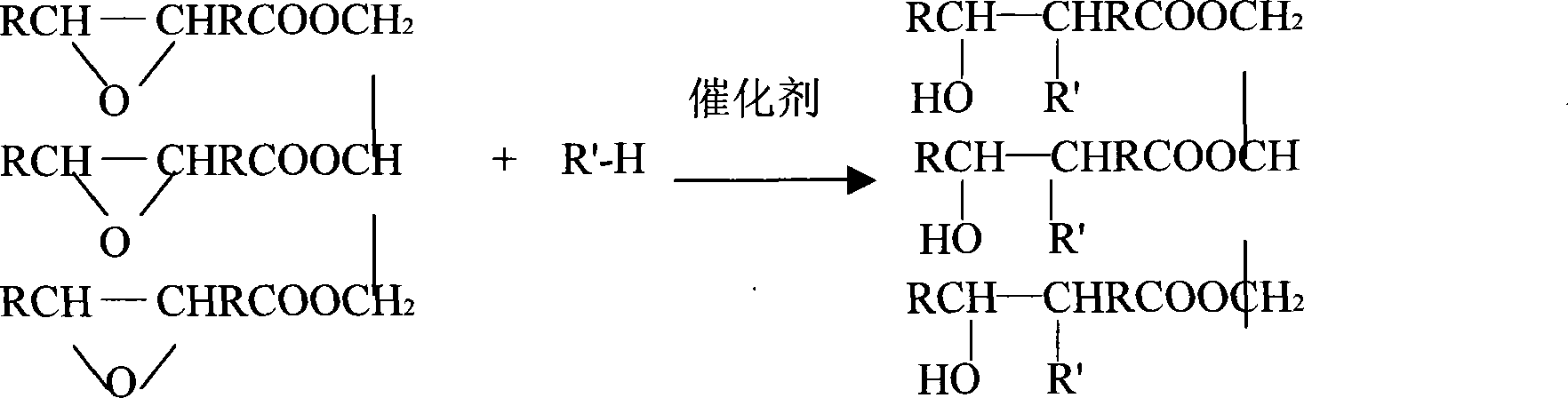

Polyurethane foam plastic prepared from barbadosnut oil

InactiveCN101125912AAbundant sources of raw materialsIncrease replacement rateFatty acid esterificationIsocyanatePolymer chemistry

The invention relates to a polyurethane foam plastic prepared by little tung oil. The biologic group polylol is prepared by epoxidation, ring cleavage, alcoholysis and addition of the tung oil, then the biologic group polylol and polyether glycol are used as basic raw materials to prepare compound materials with assistant agent; finally the compound materials are mixed evenly with blowing catalyst, then react with polyisocyanate with the yield of effervescence, thus obtaining the polyurethane foam plastic. The invention has the advantages that: 1. the little tung oil of the raw material of the biologic group polylol is renewable resource and the little tung is abundant with low cost and is unnecessary to get resources from people; 2. the preparation technique of the biologic group polylol has simple operation, good adjustability of product functionality, comparatively good property and high rate of petrified polyether glycol substation reducing dependence to petrified products; 3. the biologic degradability of polyurethane foam plastic prepared by the little tung oil and biologic group polylol is comparatively good and friendly to environment.

Owner:HONGBAOLI GRP CO LTD

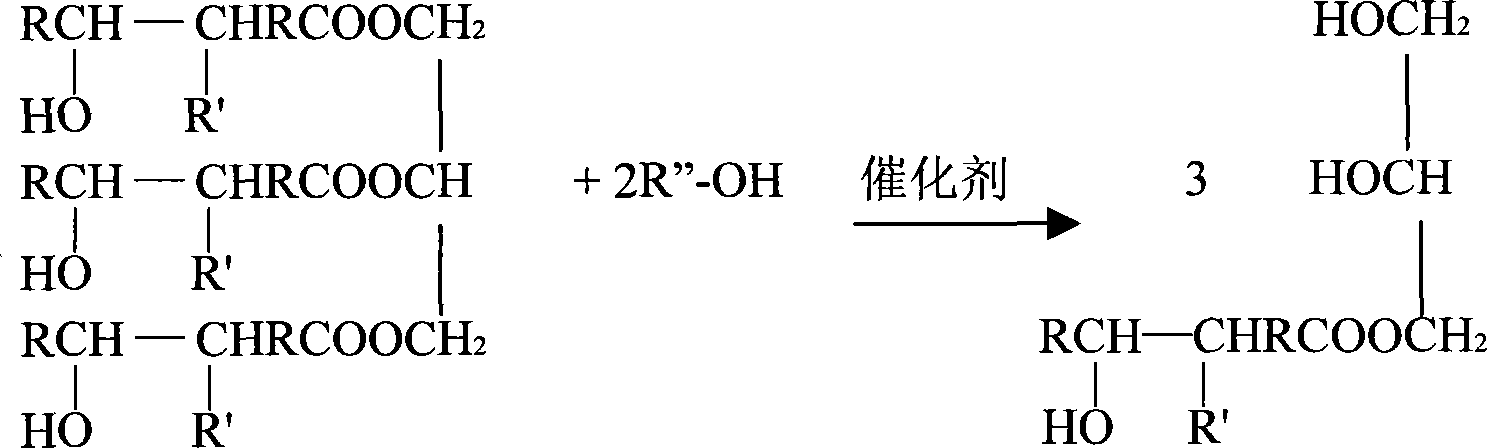

Ferroboron-containing alloy wear-resistant material and preparation method thereof

InactiveCN102534398AAbundant sources of raw materialsSimple production processElectric furnaceProcess efficiency improvementScrapHardness

The invention relates to a ferroboron-containing alloy wear-resistant material and a preparation method thereof, belonging to the technical field of wear-resistant metallic materials. The ferroboron-containing alloy wear-resistant material contains 40-45% of high-manganese steel melt-down material, 3-5% of ferroboron, 10-12% of medium carbon ferrochrome, 0.6-0.9% of ferrotitanium, 1.2-1.5% of calcium silicate barium alloy, 0.3-0.5% of ferrozirconium, 0.4-0.6% of nitrogen ferromanganese and 37-42% of Q235 scrap steel. The wear-resistant material provided by the invention can be produced by using an electric furnace and is prepared by adopting a process that a ventilation plug is mounted at the bottom of a steel ladle so as to insufflate argon gas and carrying out oil hardening; the ferroboron-containing alloy wear-resistant material provided by the invention consists of martensite, austenite, bainite and carbon-boron compounds of Cr7(C,B)3 and Cr3(B,C), has the characteristics of high strength and hardness, good toughness and wear resistance and the like, and has a good use effect in the manufacture of a lining board of a stirring machine and a hammer of a crusher.

Owner:BEIJING UNIV OF TECH

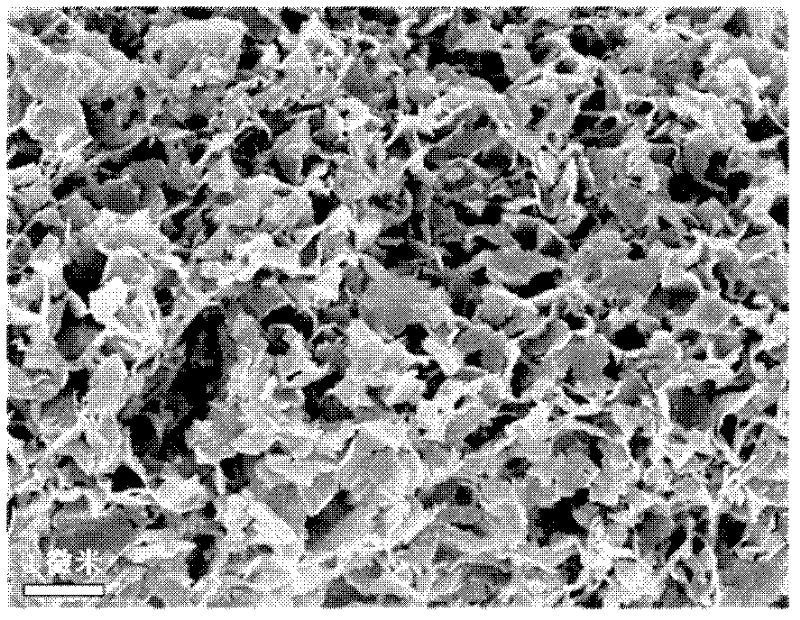

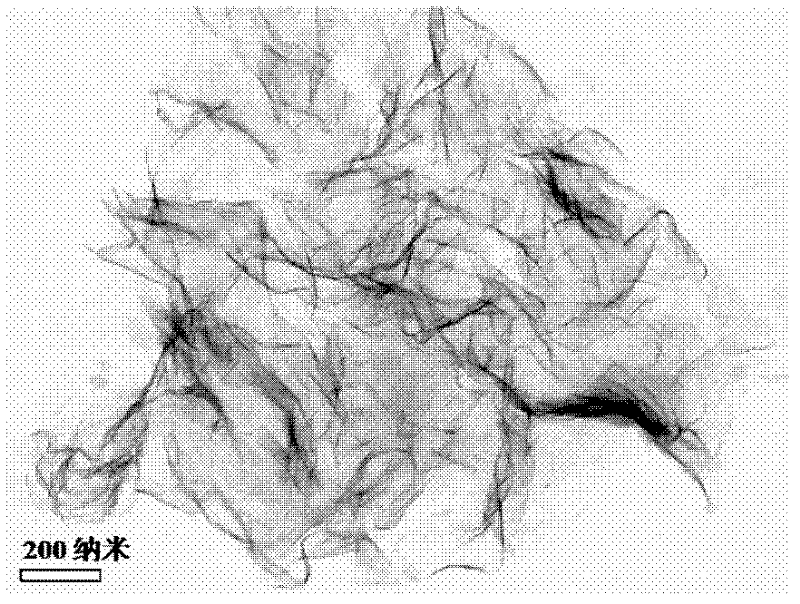

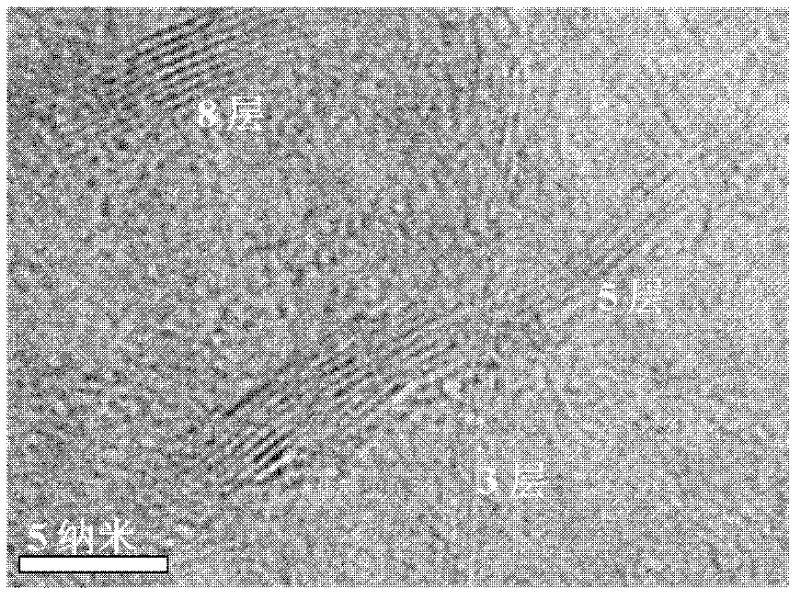

Method for preparing multilayer graphene

ActiveCN102351172AAbundant sources of raw materialsThe reaction process is mild and controllableCvd grapheneBulk polymerization

The invention discloses a method for preparing multilayer graphene. The method is characterized in that: a compound of a vinyl polymer is prepared through carrying out bulk polymerization or in situ polymerization on raw materials consisting of 85-98.5 wt% of a vinyl monomer, 1-10 wt% of a layered compound and 0.5-5 wt% of an aromatization catalyst, a mixture containing the multilayer graphene isprepared through heating the compound of the vinyl polymer for 1min-10h at 700-1500DEG C in an inert atmosphere, and the purified multilayer graphene with the thickness of 0.35-15nm is prepared through immersing the mixture containing the multilayer graphene in a solution containing 10-30% by mass of hydrofluoric acid for 1-48h, separating to obtain a solid, and immersing the separated solid in amixed solution which comprises concentrated sulfuric acid and concentrated nitric acid according to a volume ratio of 1:1 for 1-48h, and separating. The method of the invention has the following advantages: the vinyl polymer is used as a carbon source, so the raw material source is abundant; the aromatization catalyst used in the invention can be directly obtained from the market; reaction processes are mild and controllable, and operations are convenient; and the low cost and large scale preparation of graphene can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of modified fungus bran adsorbent for discoloring dye waste water

InactiveCN101733075AEliminate sources of pollutionAbundant sources of raw materialsOther chemical processesWater/sewage treatment by sorptionChemistryAbsorption effect

The invention relates to a preparation method of a modified fungus bran adsorbent for discoloring dye waste water, belonging to the technical field of environmental protection. The preparation method comprises the following concrete steps: alkalizing and swelling the edible fungus bran which is dried and crushed in an excess NaOH solution at 50-120 DEG C for 1-12 hours, carrying out cationic modification on the swollen edible fungus bran, washing the swollen edible fungus bran with water, and drying the swollen edible fungus bran to obtain the modified fungus bran adsorbent for discoloring dye waste water. In the invention, the processed edible fungus bran is used as a raw material for preparing the adsorbent, wherein celluloses and thalli contained in the fungus bran are mainly used. By using the fungus bran for preparing the adsorbent, agricultural wastes are reasonably used, and pollution sources are eliminated. The invention has the advantages of simple process, low cost, economy,practicability and the like. After cationic modification, active groups in the fungus bran are increased, and the adsorbent has high stability, good absorption effect and wide application range, is renewable and can be widely used for treating dye waste water.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

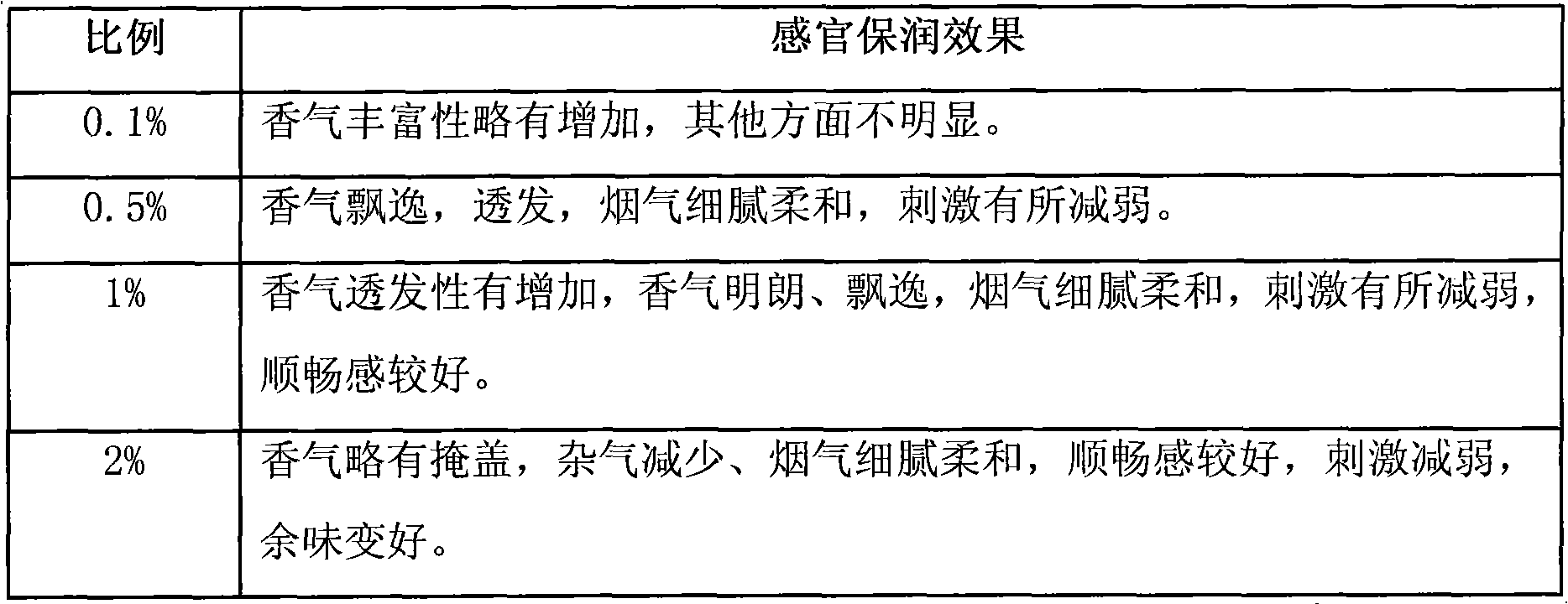

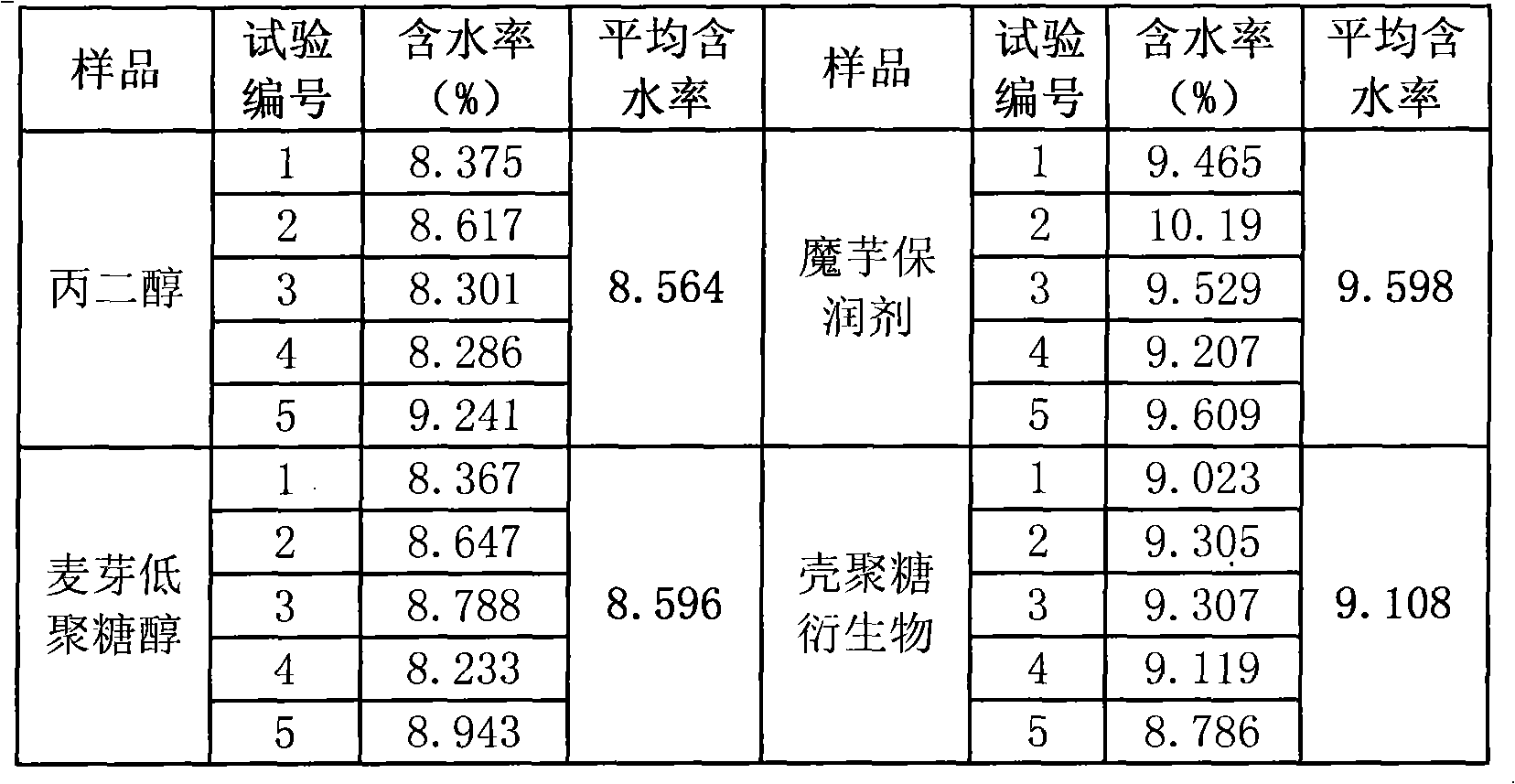

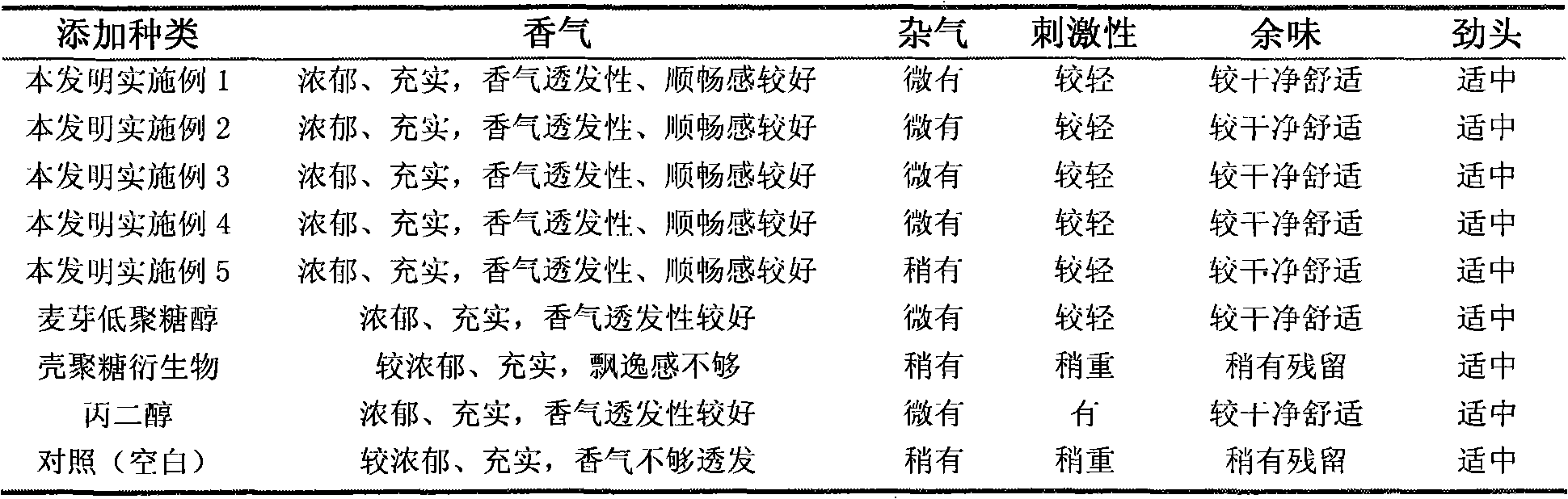

Konjac humectant and application thereof in cigarettes

InactiveCN101878954AAbundant sources of raw materialsPhysical PreservativeTobacco treatmentChemistryHumectant

The invention discloses a konjac humectant and an application thereof in cigarettes, belonging to the technical field of cigarettes. The konjac humectant is prepared by the following steps: adding 20-50% ethanol in konjac powder, soaking and extracting; (2) soaking and extracting filter residue for 2-6 times; (3) eluting by utilizing 95% ethanol or absolute ethyl alcohol; (4) drying at the temperature of 60-80 DEG C; and (5) grinding until the particles can pass through a 60-80 meshed sieve. The konjac humectant is dissolved into konjac humectant solution by utilizing distilled water the weight of which is 1000-10000 times of the konjac humectant, and then the konjac humectant solution is sprayed on tobacco leaves evenly based on the mass ratio of the konjac humectant solution to the tobacco leaves of (0.5-1.5):100 in the tobacco leaf charging process. The konjac humectant in the invention can greatly lower the tobacco production cost, improve physical and sensory moisture-keeping effects, and has simple and feasible method, thereby having wide application prospect in tobacco industry.

Owner:HUBEI CHINA TOBACCO IND

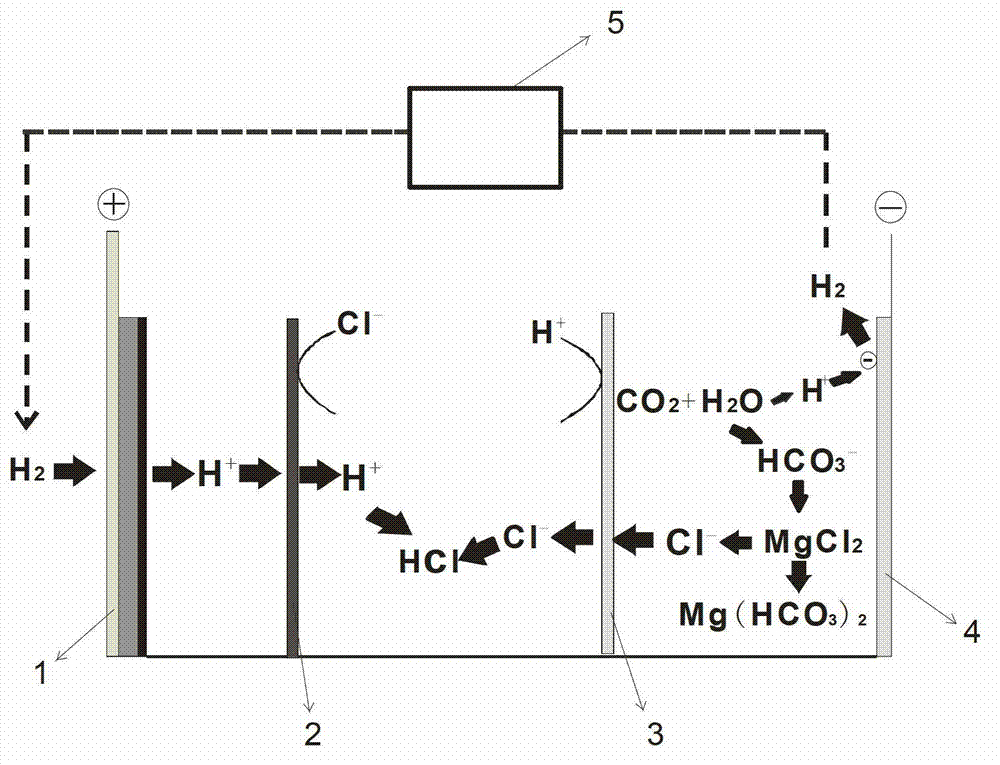

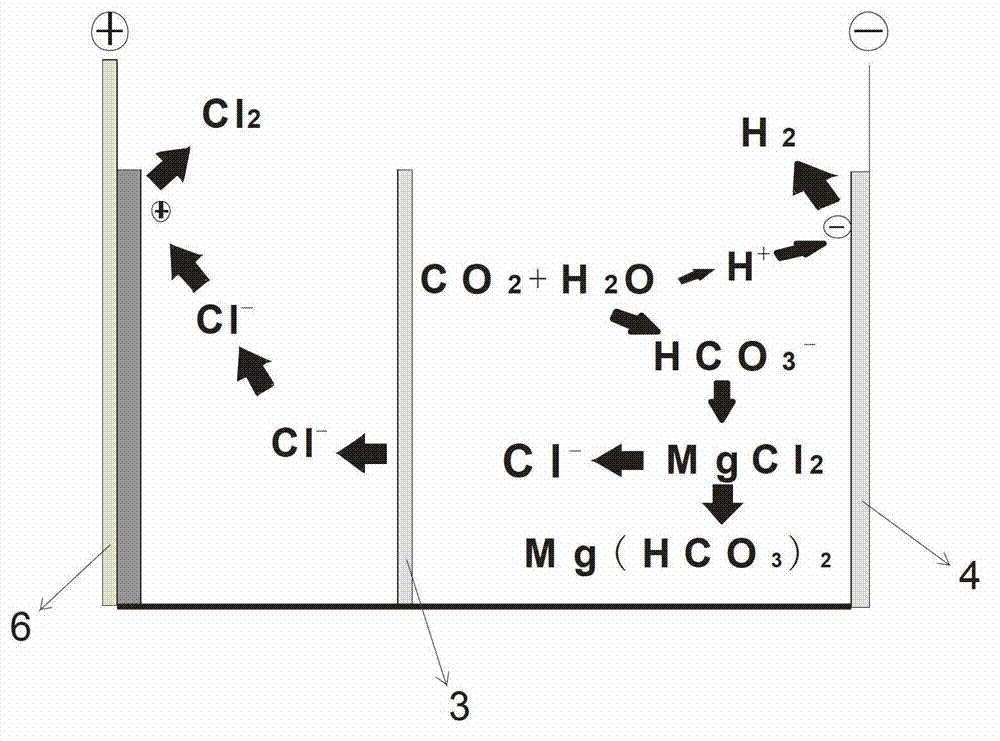

Method for preparing basic magnesium carbonate and coproducing hydrochloric acid by mineralizing CO2 (carbon dioxide) via magnesium chloride

InactiveCN103173782AAbundant sources of raw materialsImprove product added valueCellsChlorine/hydrogen-chlorideIon-exchange membranesChemistry

The invention discloses a method for preparing basic magnesium carbonate and coproducing hydrochloric acid by mineralizing CO2 (carbon dioxide) via magnesium chloride. The method comprises the following steps: standing an anion-exchange membrane in an electrolytic bath and dividing into a positive electrode area and a negative electrode area; adding a conducting solution serving as a positive electrode electrolyte into the positive electrode area; adding a magnesium chloride solution serving as a negative electrode electrolyte into the negative electrode area; filling carbon dioxide gas; applying a direct current power supply between the positive electrode and the positive electrode; reducing a hydrogen ion in the negative electrode electrolyte to form hydrogen on the negative electrode; converting carbon dioxide in the negative electrode electrolyte to form a bicarbonate radical; enabling the chloride ion replaced when bicarbonate radical and magnesium chloride generate magnesium bicarbonate to reach the positive electrode area through the anion-exchange membrane under the action of current, and oxidizing the chloride ion to form chlorine on the positive electrode; carrying out a reaction on chlorine and hydrogen which are generated by the electrolysis to generate hydrochloric acid; moving out the magnesium bicarbonate generated by the electrolytic reaction in the negative electrode area; and heating, filtering and drying the magnesium bicarbonate, thereby obtaining the basic magnesium carbonate. According to the method, when the carbon dioxide is mineralized, the basic magnesium carbonate and hydrochloric acid which have high added values are generated at the same time.

Owner:SICHUAN UNIV

Preparation method of surface-grafted modified nanocellulose crystal

InactiveCN103214623AExpand the scope of applicationAbundant sources of raw materialsMaleic anhydrideDouble bond

The invention belongs to the field of cellulose modification and utilization and in particular relates to a preparation method of a surface-grafted modified nanocellulose crystal. The preparation method of the surface-grafted modified nanocellulose crystal comprises the following steps of: dispersing nanocellulose crystal in an organic solvent; introducing an unsaturated double bond onto the surface of the nanocellulose crystal through a reaction of maleic anhydride and hydroxyl groups on the surface of the nanocellulose crystal; and introducing an initiator and an unsaturated monomer to prepare the surface-grafted modified nanocellulose crystal through a radical polymerization reaction. The surface-grafted modified nanocellulose crystal is uniformly dispersed in a polymer matrix and good in compatibility with the interface of the polymer matrix, and therefore, the prepared polymer nanometer composite material has higher tensile strength and elongation at break. The preparation method of the surface-grafted modified nanocellulose crystal has the advantages of rich raw material resource, simple process, completely biodegradable product, high mechanical performance and the like, and can be used for a plurality of fields including the packaging field, the biological field, the medical field, the engineering plastic field and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Novel wood-plastic composite material

The invention discloses a novel wood-plastic composite material, which is prepared from a wood meal raw material, waste fiber textiles, solid wastes and thermoplastics by the processes of crushing, blending, granulation, extrusion molding and the like. According to the novel wood-plastic composite material, waste mushroom stems, the waste fiber textiles, the solid wastes and the like can be comprehensively utilized, and the wood-plastic composite material prepared from the waste mushroom stems, the waste fiber textiles and the solid wastes is low in cost and high in mechanical performance and service performance, and has the characteristics of low cost and strong strength; in addition, a production method is easy to operate, has lower requirements on a process condition and production equipment, and has broad market application prospect, and large-scale production can be implemented.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

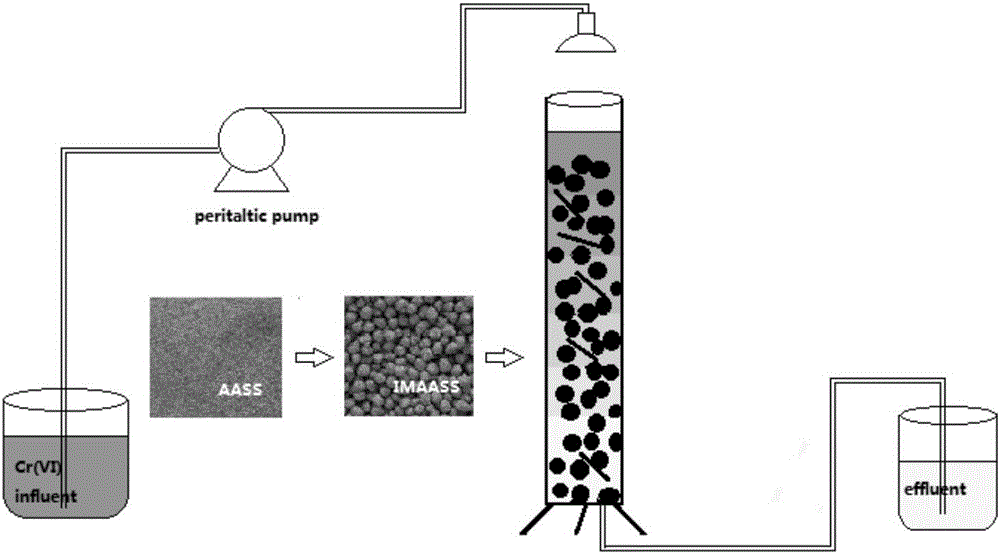

Hexavalent chromium adsorbent and preparation method and application thereof

ActiveCN106179247AAbundant sources of raw materialsLow costOther chemical processesWater contaminantsIndustrial waste waterResource recovery

The invention discloses a hexavalent chromium adsorbent and a preparation method and application thereof, and belongs to the technical field of environmental protection. According to the hexavalent chromium adsorbent and the preparation method and application thereof, edible fungus waste matrix-fungus chaff serves as the material, the advantages that the fungus chaff is loose and porous, large in specific surface area and rich in active group are utilized, and the fungus chaff is modified and prepared into an anion adsorbent and used for adsorbing hexavalent chromium which exists in an anionic form in electroplating wastewater. The fungus chaff modified adsorbent is used for treating hexavalent chromium wastewater, and on the condition that the pH is 5.5, the initial concentration of hexavalent chromium is 100 mg / L, the dosage of the adsorbent is 3 g / L, the adsorption time is 120 min, the temperature is 25 DEG C, and the rotating speed is 150 r / min, the adsorption quantity can reach 31.5 mg / g. The hexavalent chromium adsorbent and the preparation method and application thereof have the main advantages that agricultural solid waste resource recovery is achieved, contamination of waste fungus chaff to environment is reduced, the fungus chaff is applied to water pollution treatment simultaneously, resource utilization of agricultural solid waste is achieved, and the hexavalent chromium adsorbent has the advantages of being wide in material resource, low in preparation cost, easy to operate, high in adsorption efficiency and the like and can be widely applied to treatment of industrial wastewater in electroplating, printing and dyeing, tanning, metallurgy and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

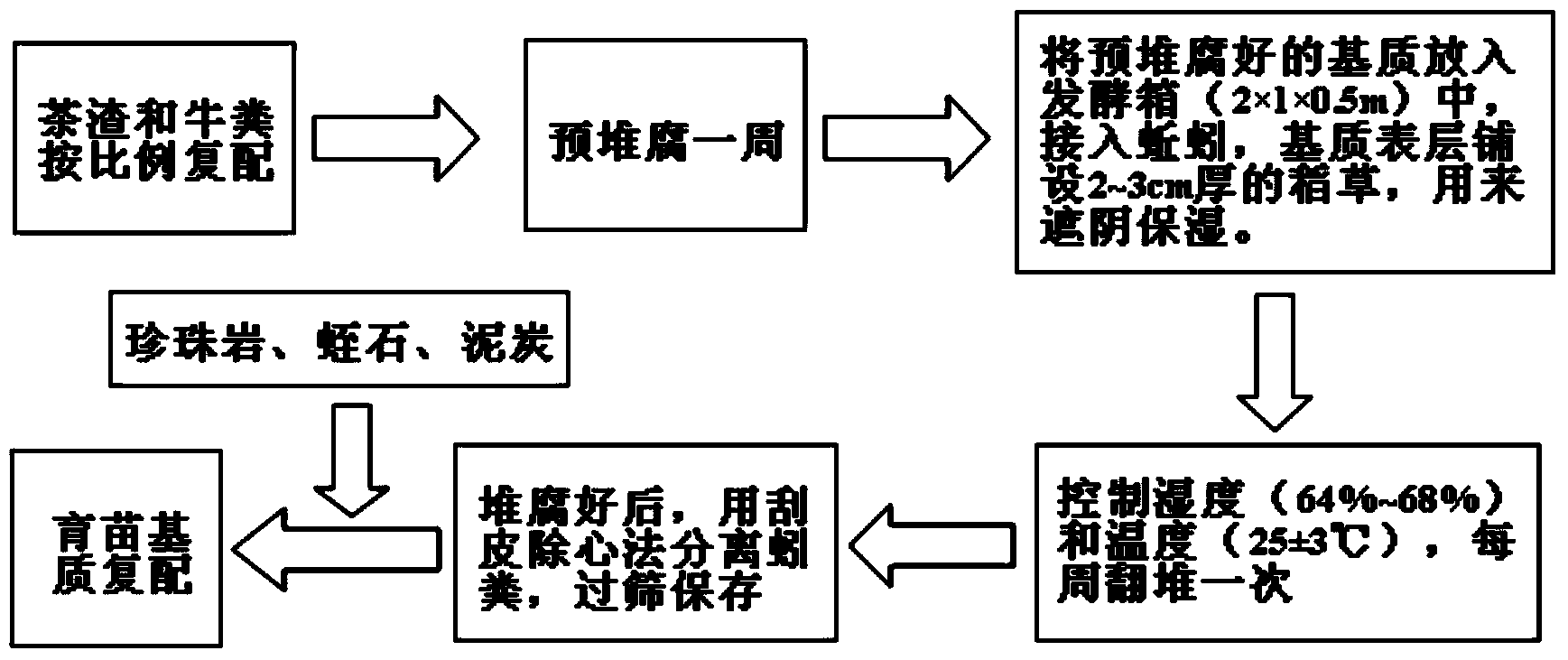

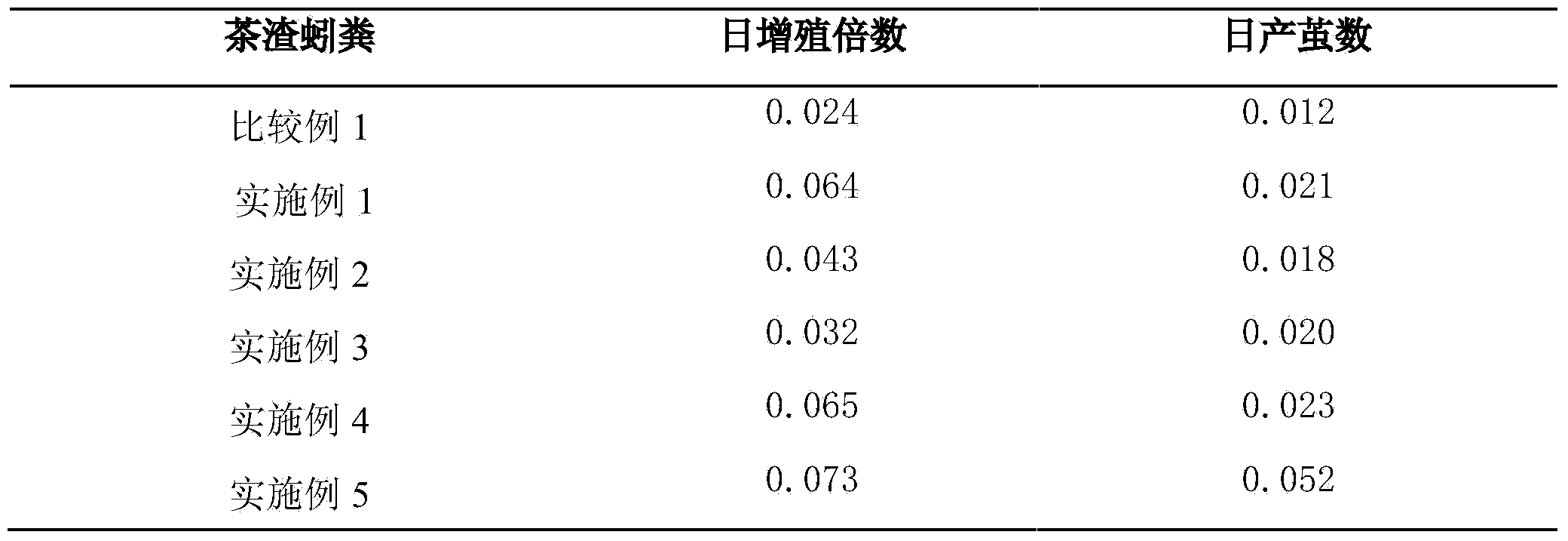

Tea residue wormcast substrate suitable for leafy vegetable seedling and manufacturing method thereof

InactiveCN104365461AHigh nutrient contentOptimize compounding methodExcrement fertilisersGrowth substratesLeafy vegetablesEconomic benefits

The invention discloses a tea residue wormcast substrate suitable for leafy vegetable seedling and a manufacturing method thereof. The substrate comprises, by volume, 20-40% of tea residue wormcast, 10-30% of perlite, 10-30% of vermiculite and 20-40% of peat. The tea residue wormcast is wormcast generated in the mode that earthworms digest tea residues and cow dung serving as an earthworm cultivation substrate. A traditional single mode that the earthworms are cultured through pure cow dung is broken through, earthworm composting reasonably combining the cow dung and the tea residues is achieved, the nutrition content of the wormcast is improved, and the role of the peat in a traditional soilless culture technology is weakened to a large extent when the wormcast serves as a leafy vegetable seedling substrate. The compound method of the leafy vegetable seedling substrate is optimized, quality of leafy vegetable seedling is improved, economic benefits are improved, and a way for recycling the tea residues is developed at the same time. A new method for breeding the earthworms through the tea residues is developed, and ways for earthworm culture and wormcast production are increased.

Owner:NANJING INST OF VEGETABLE SCI

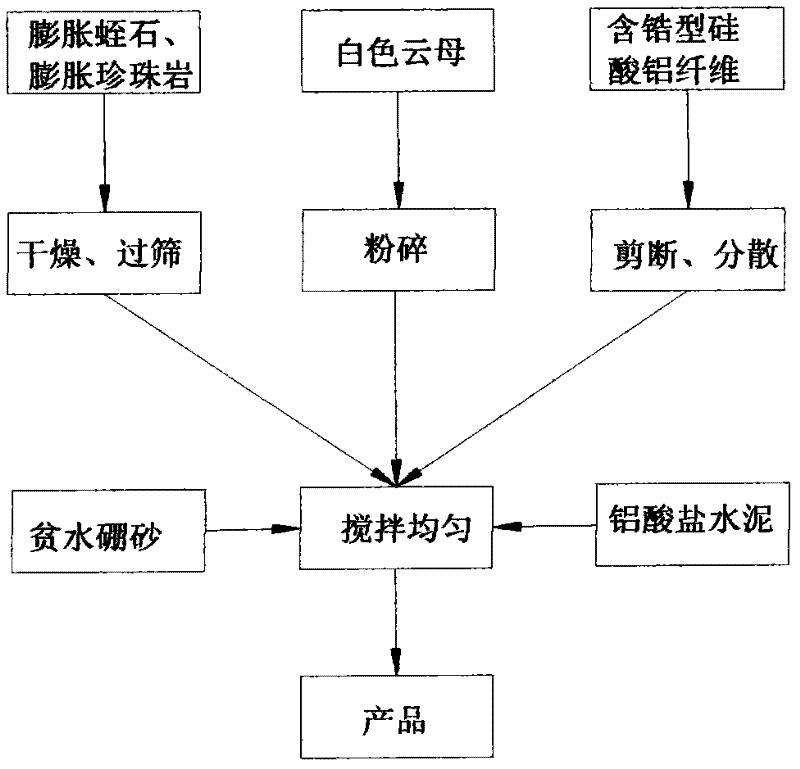

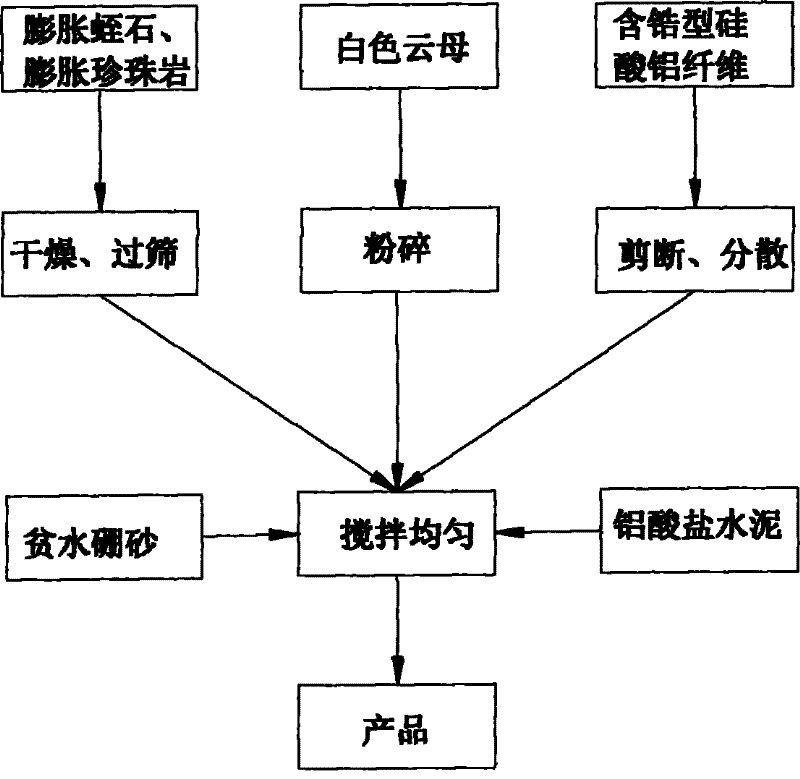

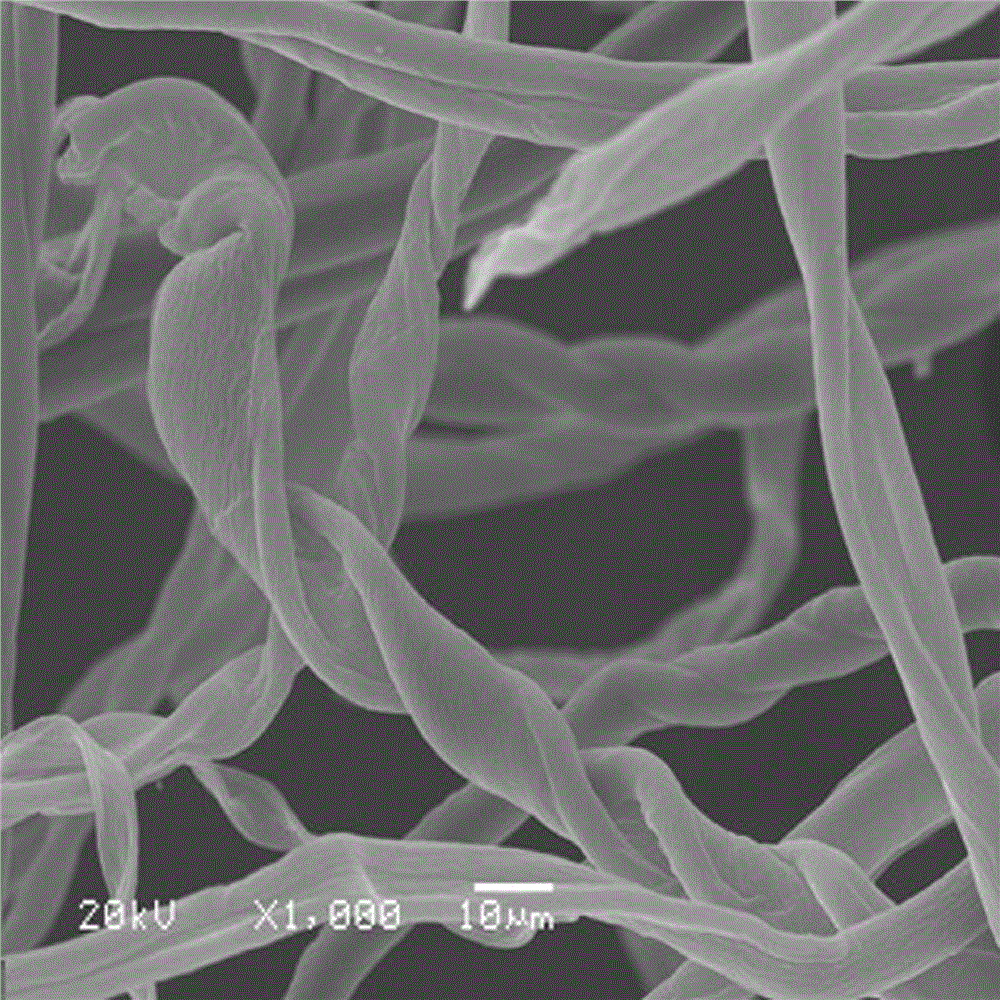

Outdoor thick type fireproof coating for steel structure and its manufacturing method

An outdoor thick type fireproof coating for steel structure relates to a fireproof coating. Provided are an aluminate cement-based thick type fireproof coating for steel structure with an inorganic mineral thermal insulation combination material as main material, and a manufacturing method of the fireproof coating. The fireproof coating consists of a binder, a modifier, an aggregate and an enhancement material. The manufacturing method comprises sieving and drying the aggregate; pulverizing and sieving sheet-like mica; cutting off and dispersing the enhancement material; and well stirring the raw and auxiliary materials composed of the binder, the modifier, the aggregate and the enhancement material. The ratio of the modifier to each component of the aggregate and the enhancement material can be adjusted to promote full hydration of the aluminate cement binder and formation of a zirconia-containing aluminum silicate fiber interconnection net-like structure, change component viscosity and improve integrity of the coating. At the same time, a large amount of light fireproof components with different particle sizes are adopted to compact the coating and reduce the coating density. In addition, the coating has high adhesiveness, water resistance and flexibility, is free from cracking, falloff, chalking and wetting, and has good adhesion.

Owner:高建业

High-fiber instant asparagus ultramicro-powder beverage and preparation method thereof

InactiveCN102551168AAbundant sources of raw materialsLow costFood preparationNutrientNutritional composition

The invention provides a high-fiber instant asparagus ultramicro-powder beverage and a preparation method thereof. The asparagus ultramicro-powder beverage contains 60% to 75% of asparagus ultramicro-powders, 15% to 20% of stabilizers and 5% to 25% of flavorings. The product is prepared by the following steps: subjecting asparagus processing leftovers to vacuum freeze-drying treatment and micronization, adding stabilizers and flavorings, and mixing thoroughly; and the product is soluble in both cold and hot water. The high-fiber instant asparagus ultramicro-powder beverage is rich in dietary fiber, saponins and flavonoids and has hypolipidemic and anti-tumor functions. The method adopts the vacuum freeze-drying treatment and micronization techniques to retain the effective components of asparagus to the greatest extent and improves dissolution and digestion / absorption of nutrients of the product. The beverage and the preparation method have reasonable designs and abundant raw materials, are favorable to asparagus waste utilization, and increase the economic benefits of asparagus industry.

Owner:QINGDAO AGRI UNIV

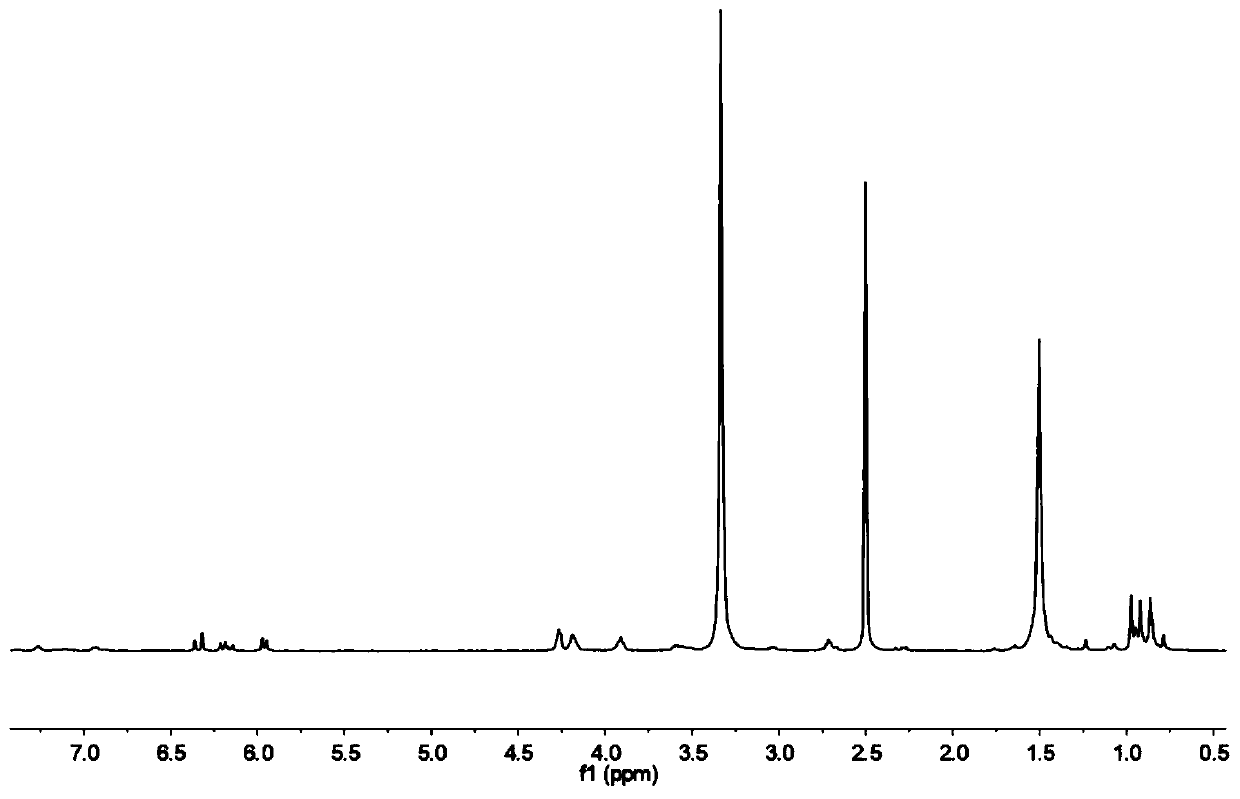

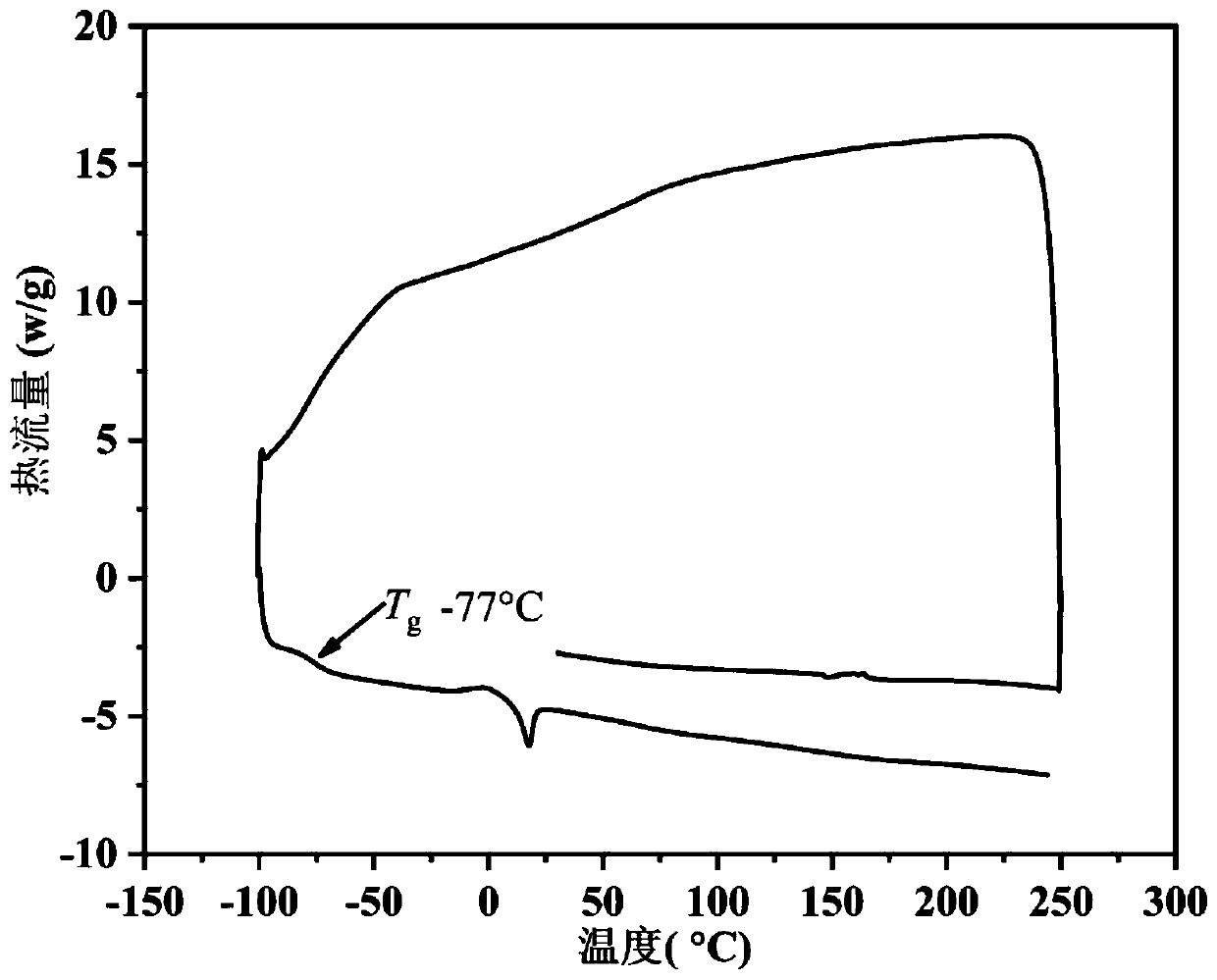

Photosensitive resin and preparation method and application thereof

InactiveCN111040102ALow viscosityIncrease elasticityAdditive manufacturing apparatusElastomerMethacrylate

The invention relates to a photosensitive resin and a preparation method and application thereof, and belongs to the field of intelligent high polymer materials. The photosensitive resin is prepared by reacting polyurethane (methyl) acrylate resin with a monofunctional reactive diluent, a photoinitiator, a leveling agent and a light absorber in a dark environment. An elastomer material formed fromthe photosensitive resin through 3D printing has good elasticity, high tensile strength, high elongation at break and compression resistance, the glass-transition temperature of lower than -50 DEG C,and excellent elasticity at a low temperature.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing N ¿C acetyl ¿C D - glucosamine ú¿NAG)

InactiveCN1796395AAbundant sources of raw materialsGood biocompatibilitySugar derivativesAminosugarsChemistryChitin

This invention relates to a preparation method for N-acetyl-D-aminoglucose (NAG), which includes: a) raw materials chitin and hydrochloric acid (20~35%) are mixed with a mass ratio of 1:3~1:6 and react with each other at a temperature of 60~100 deg.C for 3~6 hours. The mixture is then decolorized, filtered, condensed, crystallized, separated and dried to obtain GAH solution; b) composite catalysts are added; c) AC2O is added with a GAH / AC2O mole ratio of 1:2~1:6 and the pH value is adjusted to 6~10. The solution is stirred and the reaction is kept at a temperature of 0~50 deg.C for 1~4 hours; d) the mixture is filtered with 2~5ª–m microfiltration membrane, crystallized and filtered again. The filtrate is heated, condensed with reverse osmotic membrane and crystallized. The consequent crystals are washed with methanol, ethanol and acetone, purified and dried so as to obtain product NAG.

Owner:济南海得贝海洋生物工程有限公司

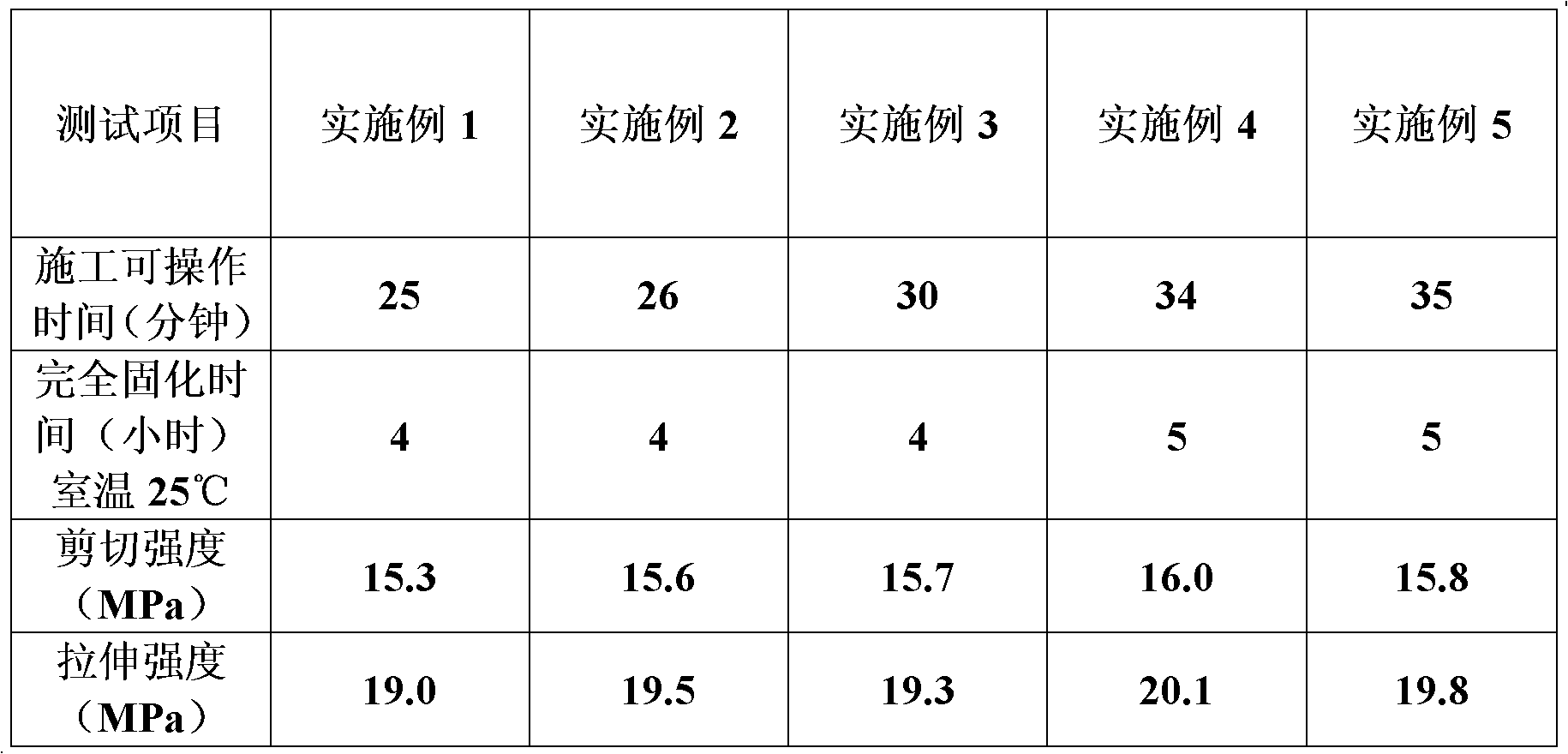

Preparation method of single component room temperature curing epoxy construction glue

InactiveCN103131364AAbundant sources of raw materialsReasonable formulaNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryDiluent

The invention provides a preparation method of single component room temperature curing epoxy construction glue and belongs to the technical field of construction adhesive preparation. Epoxy resin and diluent are added in a reactor first and mixed evenly, then curing agent, accelerant, coupling agent and filler are sequentially added to be mixed, meanwhile, mixing time is controlled, and finally vacuum defoamation, discharge and canning are carried out to form the single component room temperature curing epoxy construction glue. The proportion of weight parts of the epoxy resin, the diluent, the curing agent, the accelerant, the coupling agent and the filler is as follows: 80-100 parts of the epoxy resin, 5-25 parts of the diluent, 10-20 parts of the curing agent, 3.0-5.0 parts of the coupling agent, 0.5-2.0 parts of the accelerant, and 1.0-8.0 parts of the filler. The preparation method of the single component room temperature curing epoxy construction glue has the advantages that raw materials are rich in source and low in price; formula is reasonable and process is simple, complicated devices and complicated operation are not needed; and produced products are convenient to construct, and waste can be avoided.

Owner:常熟市辛庄镇前进五金厂

Culture medium formula and cultivation method for brown hypsizigus marmoreus

InactiveCN103030457AAbundant sources of raw materialsLow priceHorticultureFertilizer mixturesCulture mediumsSoya bean

The invention discloses a culture medium formula for brown hypsizigus marmoreus. The culture medium formula comprises the following raw materials in percentage by weight: 30 to 40 percent of sawdust, 15 to 25 percent of corncob, 15 to 25 percent of soybean hulls, 5 to 10 percent of rice bran, 5 to 10 percent of wheat bran and 5 to 15 percent of cotton seed hulls. The invention also discloses a method for cultivating the hypsizigus marmoreus by using the culture medium formula.

Owner:青岛丰科生物科技有限公司

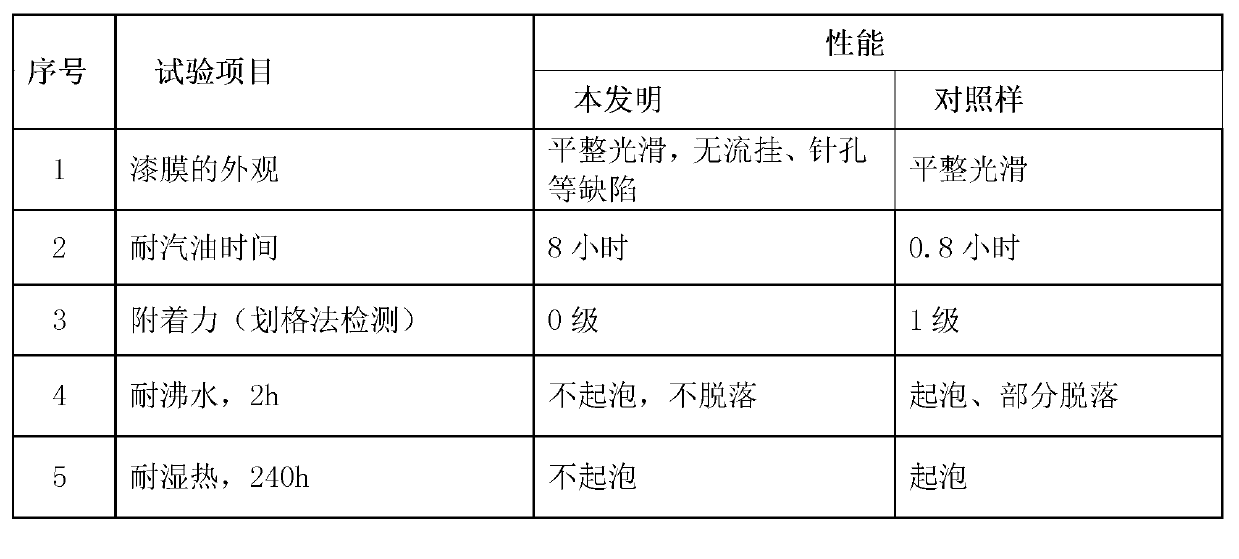

Middle coating paint for polypropylene plastic and preparation method thereof

InactiveCN103342933AImprove storage stabilityAbundant sources of raw materialsCoatingsChemistryPolypropylene

The invention provides a middle coating paint for a polypropylene plastic, which consists of chlorinated polypropylene modified acrylic resin, modified chlorinated polypropylene, a curing agent, pigment, filler, a dispersing agent, an auxiliary and the like. The invention also provides a preparation method of the middle coating paint, which comprises the following steps of: mixing the chlorinated polypropylene modified acrylic resin with the auxiliary, putting the mixture into a sand mill and uniformly dispersing; and adding the modified chlorinated polypropylene and the curing agent, and uniformly mixing to obtain the paint. The middle coating paint provided by the invention has the advantages of low cost, simple preparation technology, wide application and great market potential; when in use, the paint can be coated through special treatment on substrates, the coated paint does not need roasting and can be naturally dried, the construction is convenient, and the energy is saved; and the obtained composite paint film is resistant to ethanol gasoline for 8 hours.

Owner:TIANCHANG JULONG TRAVEL PAINT

Method for producing SiF4 from Na2SiF6 through pyrolysis

ActiveCN102398906ASolve the waste of fluorine resourcesAbundant sources of raw materialsHalogenated silanesChemistryActivated carbon

The invention discloses a method for producing SiF4 from a phosphorus fertilizer industry by-product Na2SiF6 through pyrolysis. The method comprises steps that: Na2SiF6 is dried in a vacuum dryer, and is delivered into a fixed-quantity feeder through a material guiding groove; Na2SiF6 is mixed with NaF in the fixed-quantity feeder, and the mixture is delivered into a high-temperature reaction vessel or a high-temperature circulating fluidized bed; the mixture is subject to pyrolysis for 1-3 hours under a temperature of 600-750 DEG C, wherein the pressure in the high-temperature reaction vessel or the high-temperature circulating fluidized bed is controlled at 10-50mmH2O, such that NaF and SiF4 gases are produced through pyrolysis; NaF is delivered back into the fixed-quantity feeder and is reused; the SiF4 gas is condensed in a condenser, processed though a dust-removing treatment, and purified by using two stages of activated carbon adsorbing columns; the SiF4 gas is then processed through refrigeration compression; the SiF4 gas is delivered into a cylinder, and is stored in the cylinder. The production method provided by the invention is advantaged in low production cost. No waste is generated during the production process, such that clean production is realized. The quality of the produced silicon tetrafluoride gas is stable, and the purity of the silicon tetrafluoride gas reaches 99.9%.

Owner:河南省氟基新材料科技有限公司

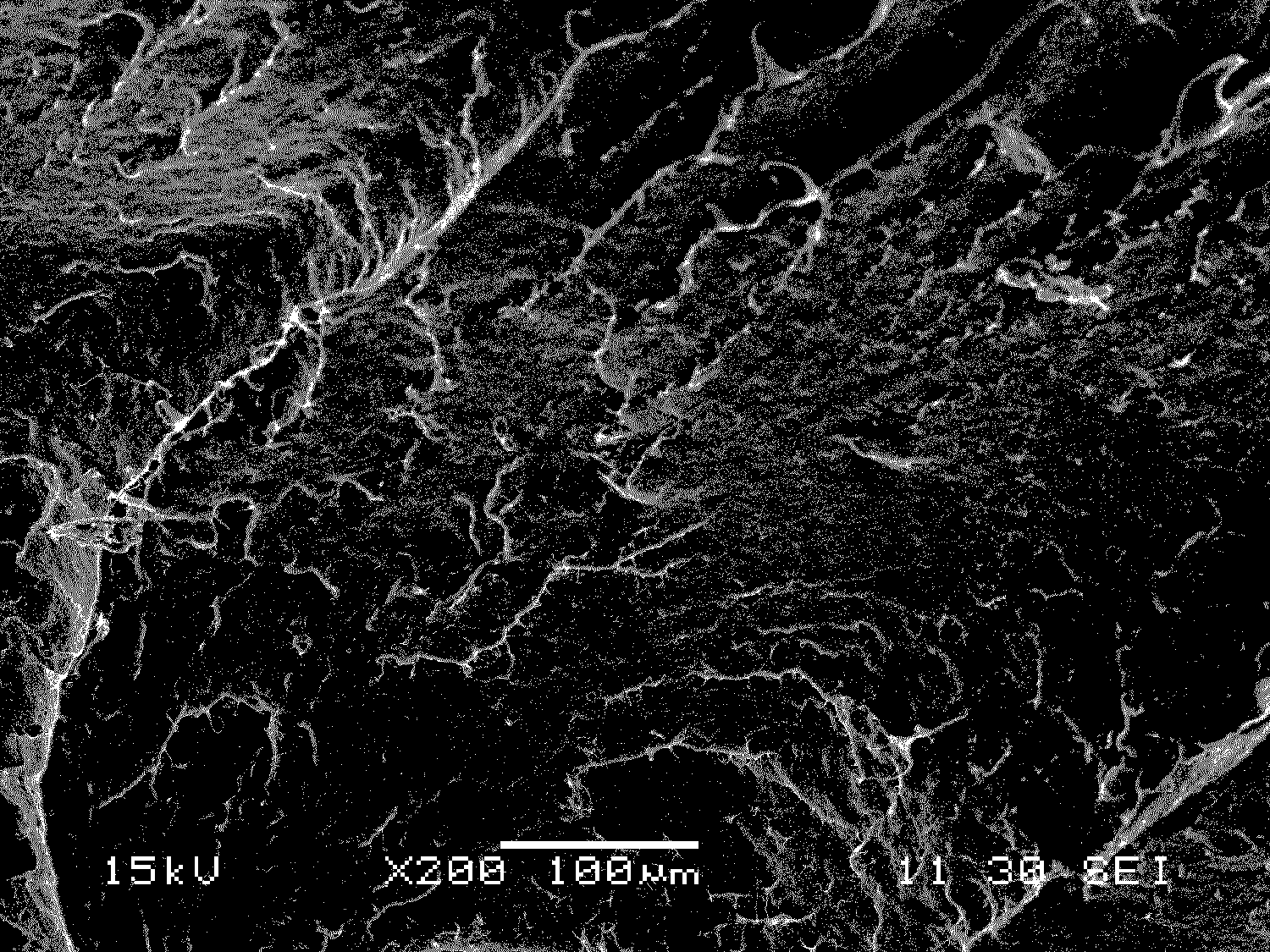

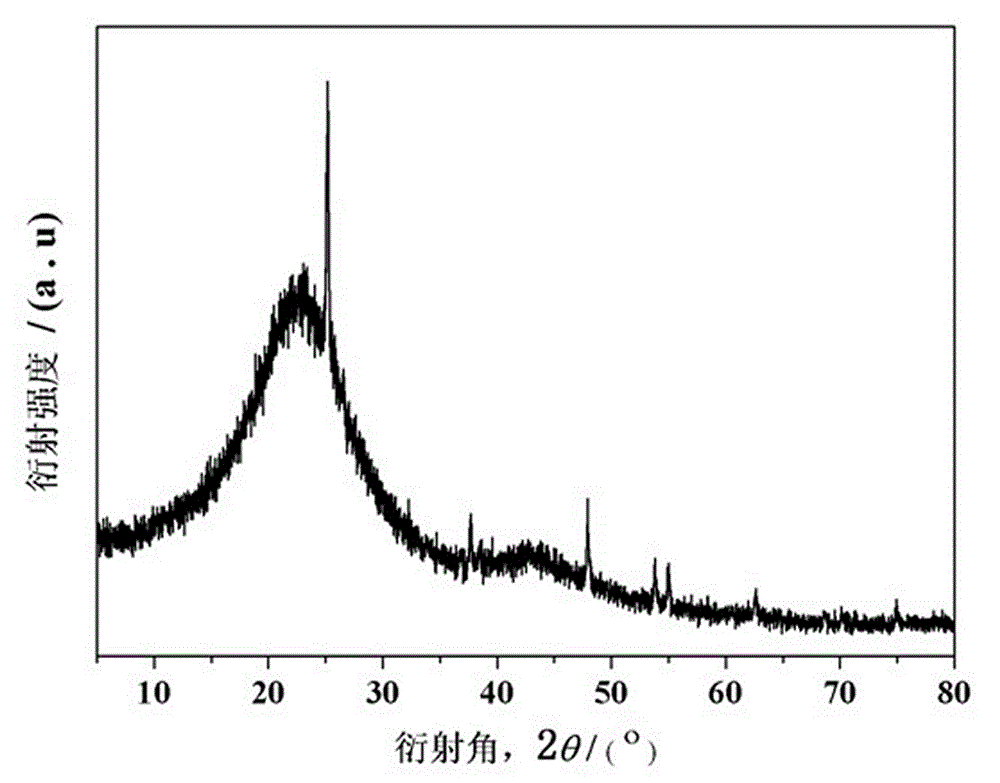

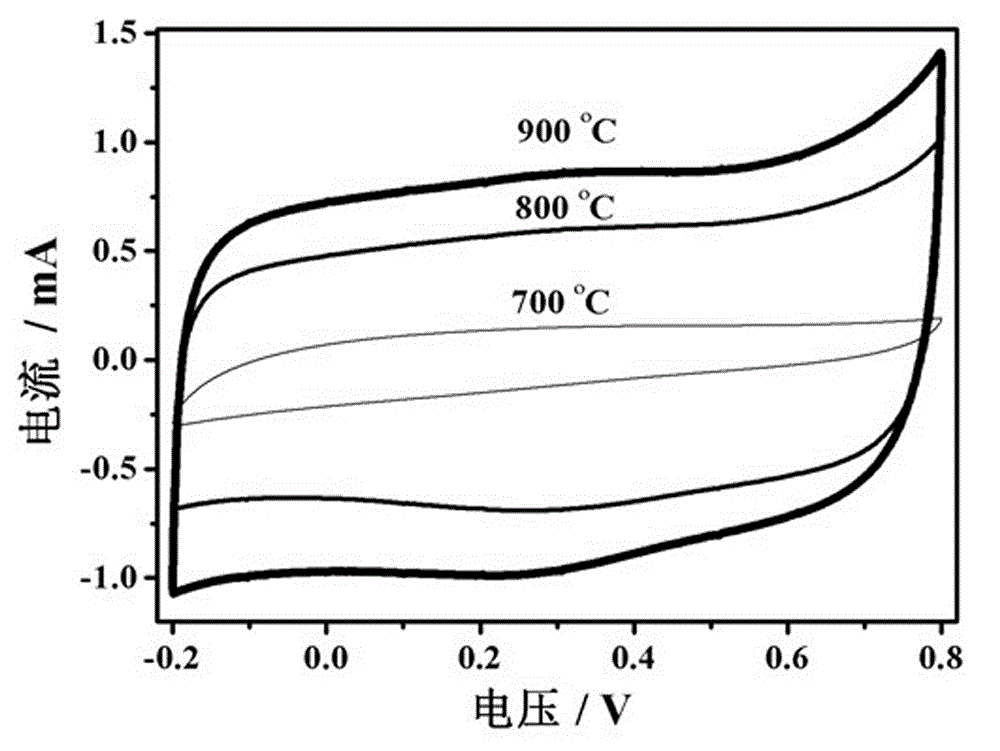

Preparation method of cotton fiber coal-base material, and application thereof as electrode material of supercapacitor

InactiveCN102942176AHigh specific capacitanceAbundant sources of raw materialsElectrolytic capacitorsCarbon preparation/purificationFiberCapacitance

The invention provides a preparation method of a cotton fiber coal-base material, which comprises the steps of: washing cotton fiber respectively with deionized water and ethanol, and then drying; maintaining the dried cotton fiber at the temperature of 300-350 DEG C for 3-5 hours, and carrying out pre-carbonization; under the protection of N2, carrying out carbonization for 3-6 hours at the temperature of 700-900 DEG C; after that, soaking the carbonized cotton fiber into KOH solution with the mass concentration of 10-30% for 2-5 hours at the temperature of 50-80 DEG C; cooling to the room temperature, filtering and soaking the product in 1-3M of HCl for 6-18 hours; and finally, washing the product to be neutral with deionized water, and drying to obtain the cotton fiber coal-base material. The experiments prove that the cotton fiber coal-base material has higher specific capacitance so as to be used as electrode material of a supercapacitor, and has the characteristics of being rich in material source, simple in preparation technology, low in cost, environment-friendly, excellent in conductivity and other electrochemical performances, and the like, thus being an ideal electrode material of the supercapacitor.

Owner:NORTHWEST NORMAL UNIVERSITY

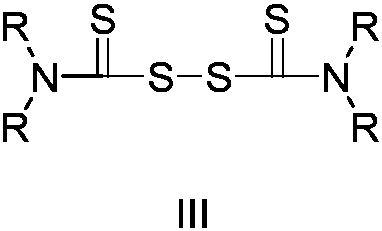

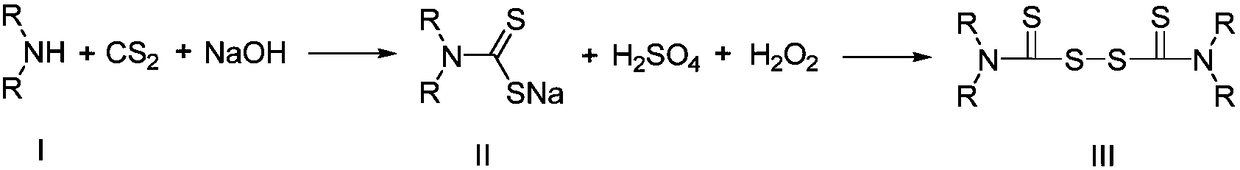

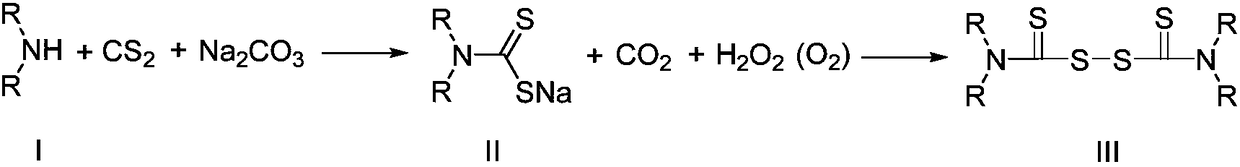

Green synthesizing method for thiuram rubber vulcanizing accelerant

InactiveCN108395393AAbundant sources of raw materialsLow costOrganic chemistryCarbon disulfideChemistry

The invention belongs to the technical field of chemistry and chemical engineering and discloses a synthesizing method of a thiuram(bi(amino thiocarbonyl)disulfide) rubber vulcanizing accelerant. According to the method, parahelium, carbon disulfide and alkali carbonate water solution are utilized as reactants to obtain dithiocar-bamate; then carbon dioxide is utilized as an acidifying agent; hydrogen peroxide, oxygen or air is utilized as an oxidizing agent to oxidize the dithiocar-bamate to generate thiuram compound and the alkali carbonate water solution. The method has the advantages thatthe carbon dioxide is utilized as the acidifying agent, the raw materials has rich source, and cost is low; the carbonate is utilized for replacing traditional sodium hydroxide as an alkaline medium,the carbonate is recycled in a reaction process, and generation of wastewater and waste inorganic salt is obviously reduced.

Owner:TSINGHUA UNIV

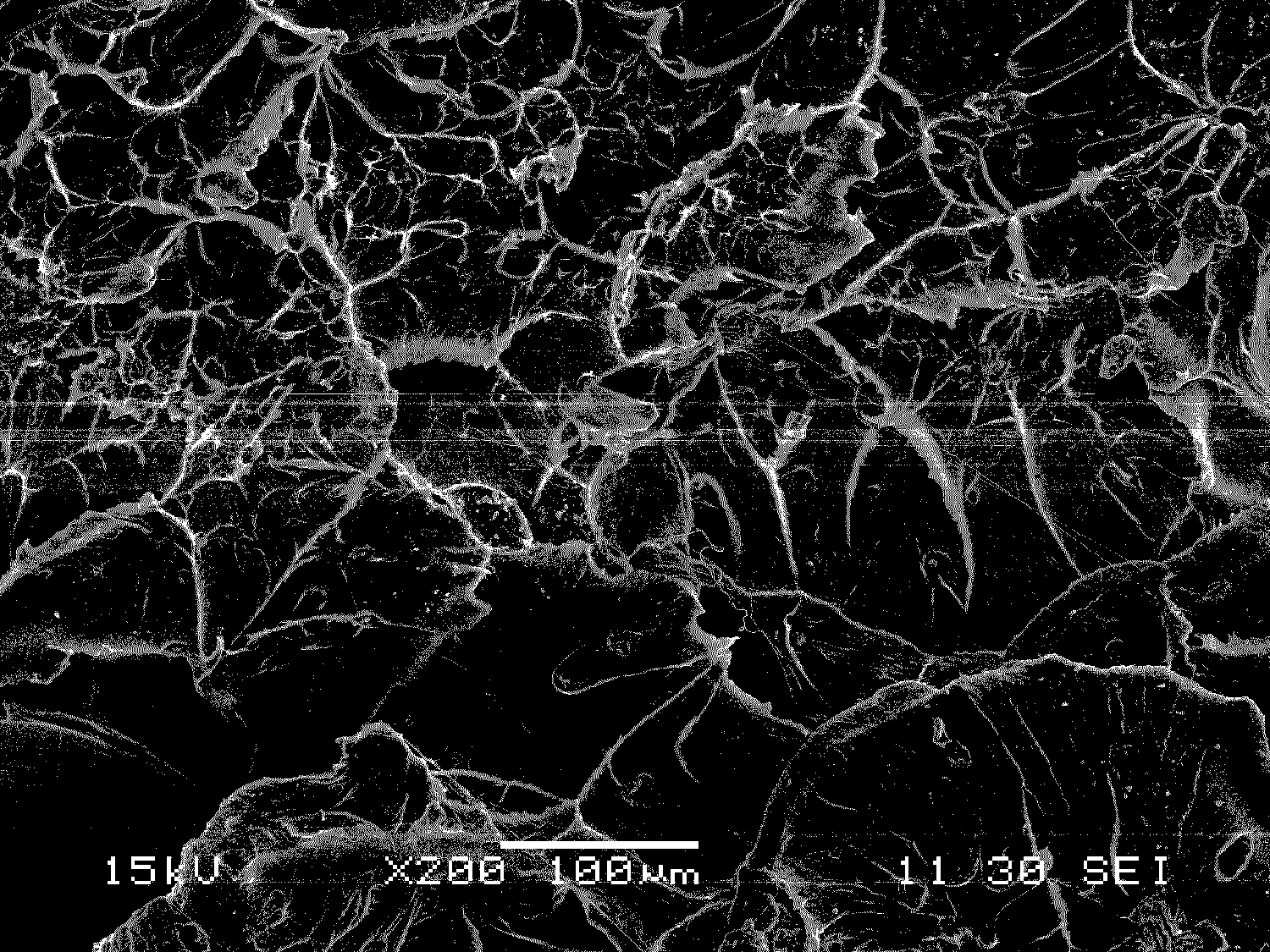

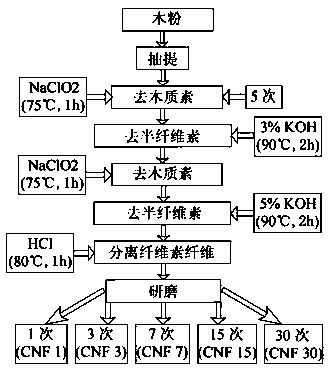

Cellulose nano-fiber/polymethyl methacrylate composite film preparation method

InactiveCN103396571AAbundant sources of raw materialsLow costPulping with organic solventsTransmittanceNanofiber

The present invention relates to a cellulose nano-fiber / polymethyl methacrylate composite film preparation method, which is characterized by comprising the following steps: 1) a raw material treatment, 2) a chemical treatment, 3) a mechanical treatment, 4) cellulose nano-fiber film preparation, and 5) cellulose nano-fiber / polymethyl methacrylate nanometer composite material preparation. According to the present invention, an average diameter of the prepared cellulose nano-fibers is less than 100 nm, the cellulose nano-fiber film has a tensile elastic modulus of 6.06 GPa, a tensile strength of 148.8 MPa, a thermal expansion coefficient of 16.72*10<-6> / K, and light transmittance of 82.1%, and the nanometer composite material film after compounding with the polymethyl methacrylate has a tensile elastic modulus of 3.61 GPa, a tensile strength of 92 MPa, a thermal expansion coefficient of 21.58*10<-6> / K, and light transmittance of 86.3%.

Owner:NANJING FORESTRY UNIV

Environment-friendly bamboo fiber material and preparation method thereof

InactiveCN109705549AIncrease the effective contact areaEnhanced mechanical adhesionPlasticizerHot pressing

The invention discloses an environment-friendly bamboo fiber material which is prepared from the following raw materials in parts by weight: 30-40 parts of polylactic acid, 10-18 parts of poly (butylene succinate), 20-30 parts of modified bamboo fiber, 10-15 parts of a plasticizer and 2-3 parts of an antibacterial agent; the invention further discloses a preparation method of the environment-friendly bamboo fiber material, and the preparation method comprises: step 1, sealing and placing; step 2, mixing; step 3, after being cooled, crushing the mixture into particles through a strong crusher,and pouring the particles into a hot-pressing mold; and step 4, carrying out hot pressing. According to the invention, the polylactic acid and the poly (butylene succinate) are used as a matrix of materials, and are both biodegradable resin, and the mechanical property and the heat resistance of the composite material can be improved by enhancing effect of the modified bamboo fiber; meanwhile, dueto the addition of the plasticizer, the composite material not only has relatively high strength, and the elongation at break and the water resistance are good; due to the addition of the antibacterial agent, the composite material is not easy to mildew, and the service life of the composite material can be effectively prolonged.

Owner:金华市秸和环保技术咨询有限公司

Environment-friendly type shaving board and producing method thereof

InactiveCN101254608ALow costAbundant sources of raw materialsDomestic articlesFlat articlesEtherIsocyanate compound

The invention discloses an environment-friendly shaving board and a manufacture method thereof. The environment-friendly shaving board comprises plant fiber materials 850 to 1,100 weight parts, plant fiber poly(ether-ester) polyol 60 to 80 weight parts and isocyanate 25 to 45 weight parts. The manufacture method comprises the following steps: mixing plant fiber poly(ether-ester) polyol with isocyanate to obtain an adhesive; directly spraying the adhesive on the surface of the plant fiber material, and permeating into the plant fiber material, spreading, hot-pressing, mold-pressing the plant fiber material mixed with the adhesive at high temperature, reacting, curing, molding, de-molding, sawing, and sanding to obtain the shaving board. The shaving board is free of toxic and harmful substances such as free formaldehyde, and is an environment-friendly green building material. The shaving board has low cost, simple manufacture method and excellent performance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

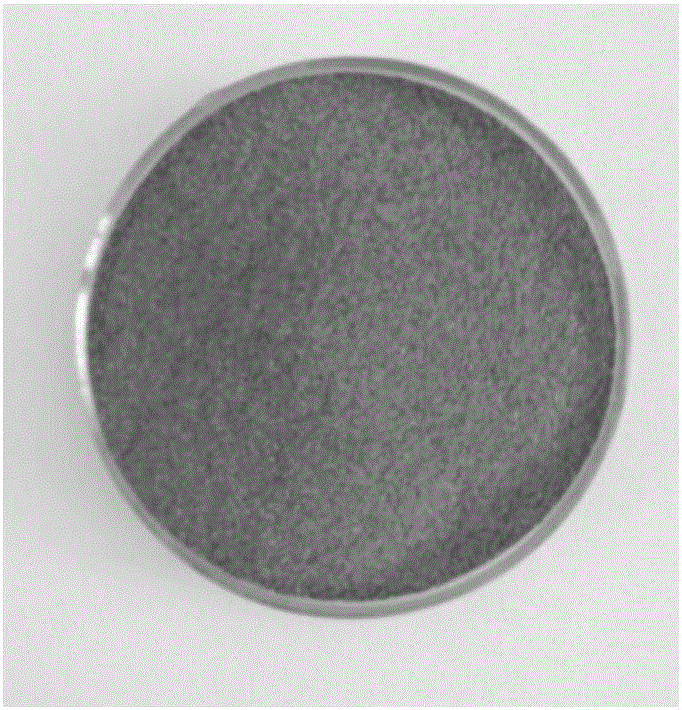

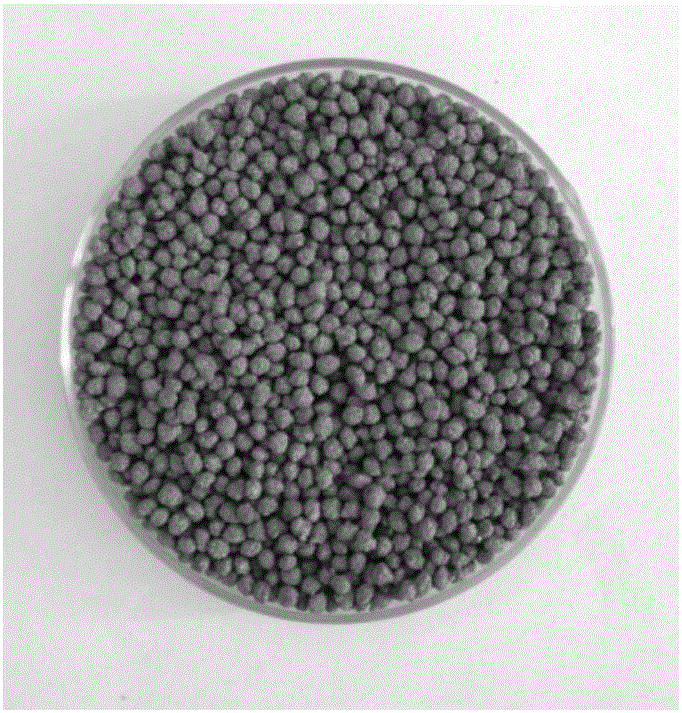

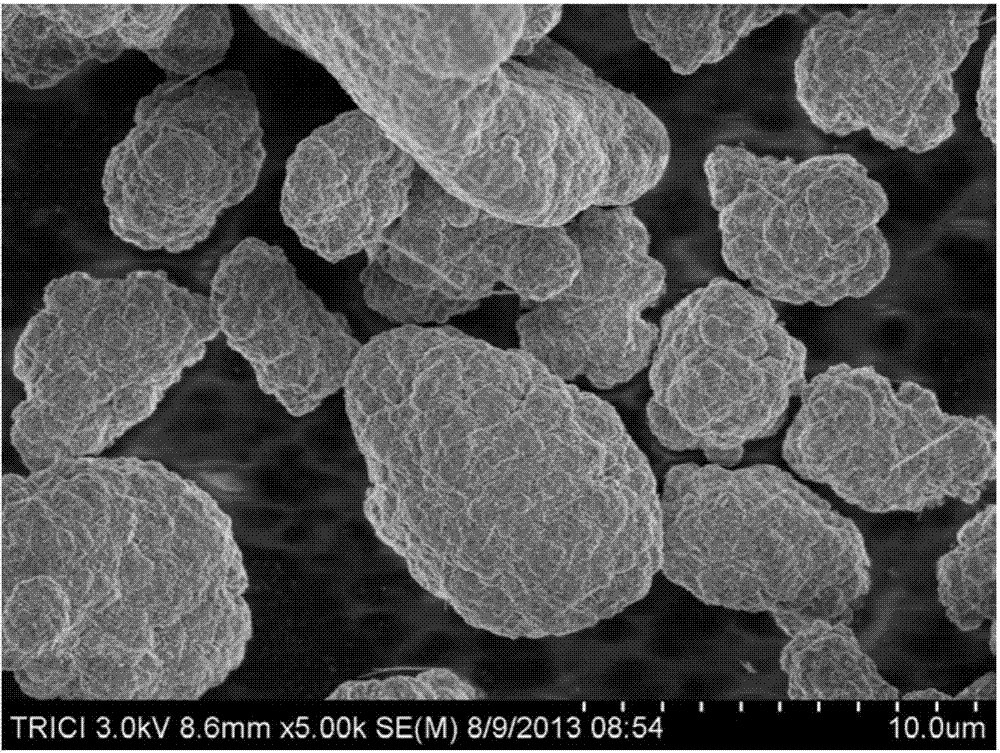

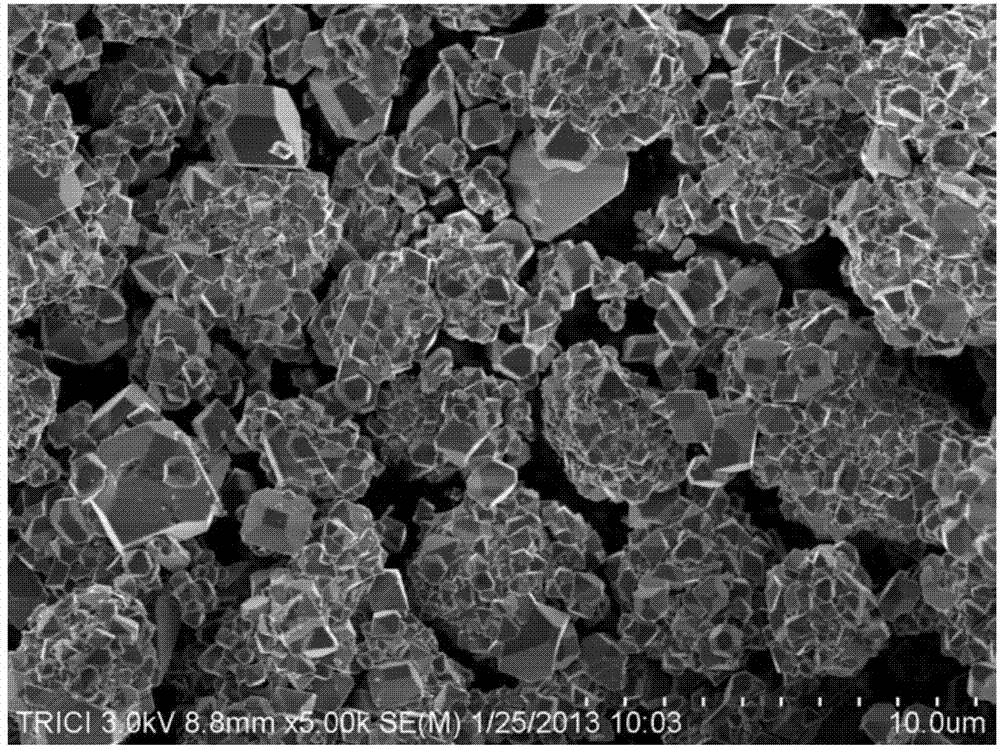

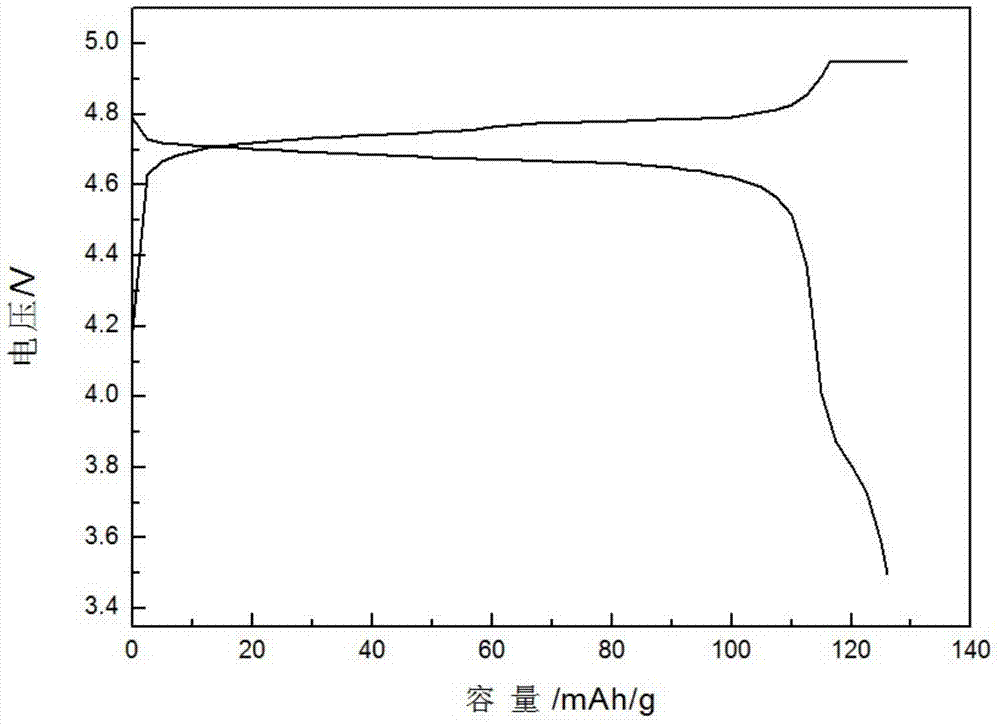

Preparation method of spherical nickel-lithium manganate anode material

ActiveCN103579607AAbundant sources of raw materialsSimple processCell electrodesSecondary cellsMetalWater baths

The invention discloses a preparation method of a spherical nickel-lithium manganate anode material. The preparation method is characterized by comprising the following steps: weighing a lithium source compound, a nickel source compound and spherical manganous-manganic oxide by a mol ratio of 2:1:1; dissolving the lithium source compound and the nickel source compound in ethanol to prepare a solution of which the total concentration of metal cation is 0.1-0.3 mol / L; adding the spherical manganous-manganic oxide into the solution; heating the solution in a water bath with stirring until a paste-like mixture is formed; drying the paste-like mixture at 90-110 DEG C to obtain gray black powder; roasting the obtained powder at 750-950 DEG C for 6-36 hours; annealing at 615-675 DEG C for 2-6 hours; cooling, directly sieving, and then obtaining the nickel-lithium manganate anode material. The lithium source compound is lithium acetate or lithium nitrate, and the nickel source compound is nickel acetate or nickel nitrate. The water-bath heating temperature is 50-70 DEG C.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

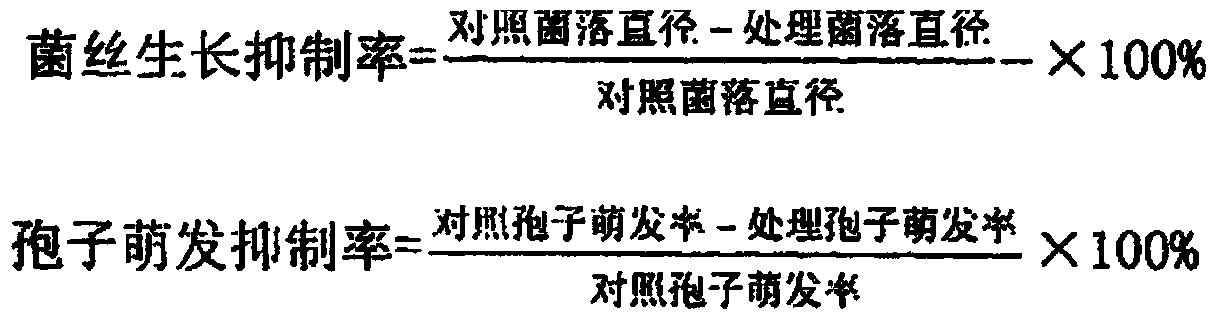

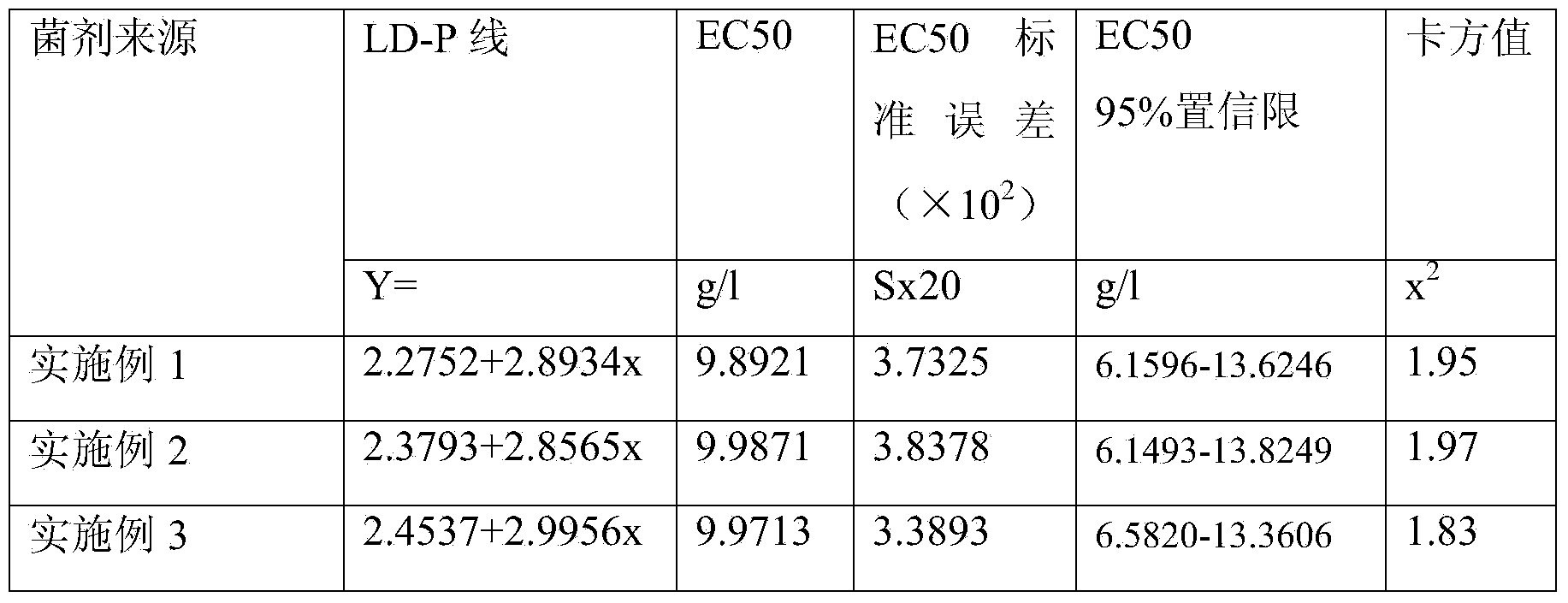

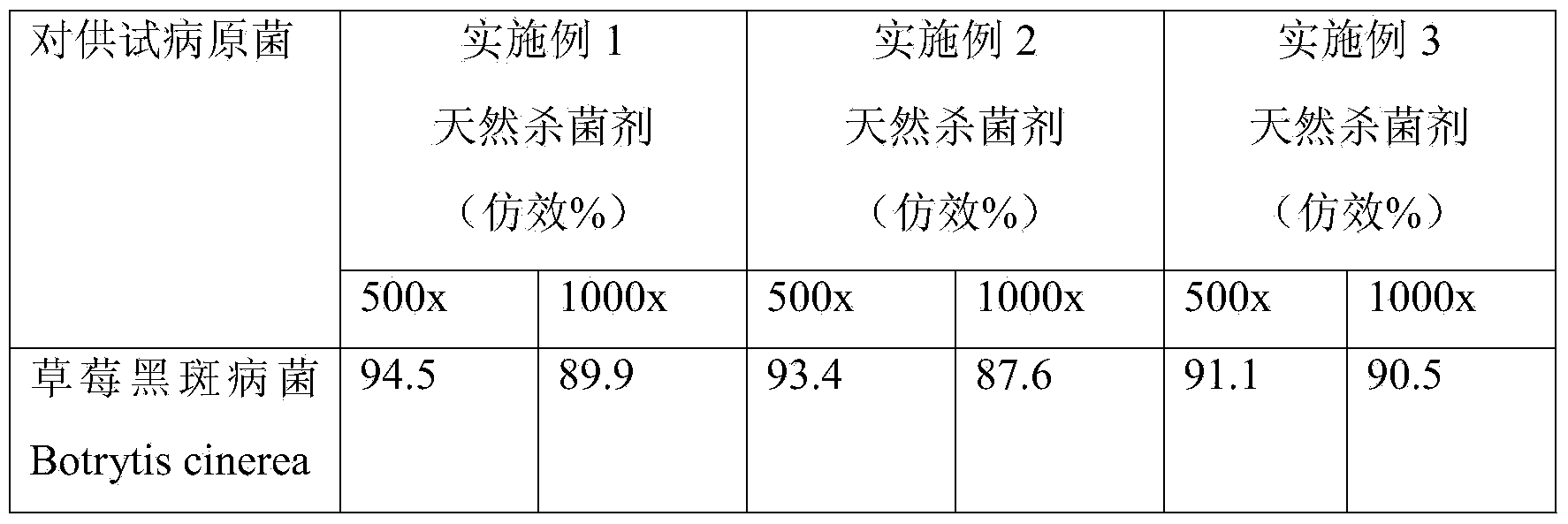

Natural fungicide for prevention and control of strawberry black spot and preparation method thereof

A provided natural fungicide for prevention and control of strawberry black spot is prepared from the following components: garlic, mint, lotus leaf, herba schizonepetae, terminalia chebula, artemsia argyi, cassia bark, cornus officinalis, phryma leptostachya, and myrrh. The natural fungicide for prevention and control of strawberry black spot is rich in raw material sources and low in cost, is prepared by adopting the pure natural components, not only is non-toxic and pollution-free, but also can effectively prevent and control strawberry black spot.

Owner:赵兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com