Patents

Literature

13790 results about "Nanofiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

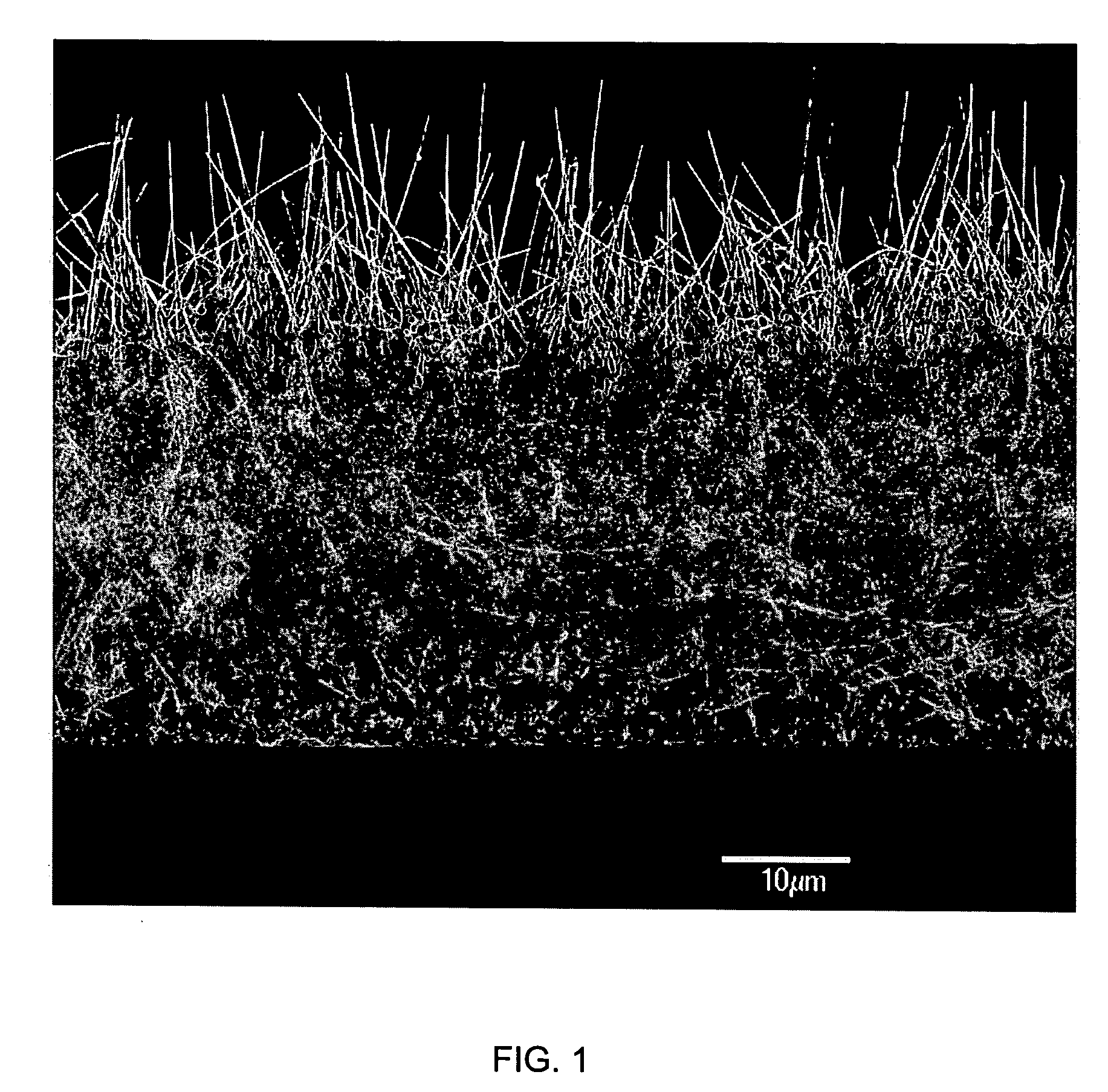

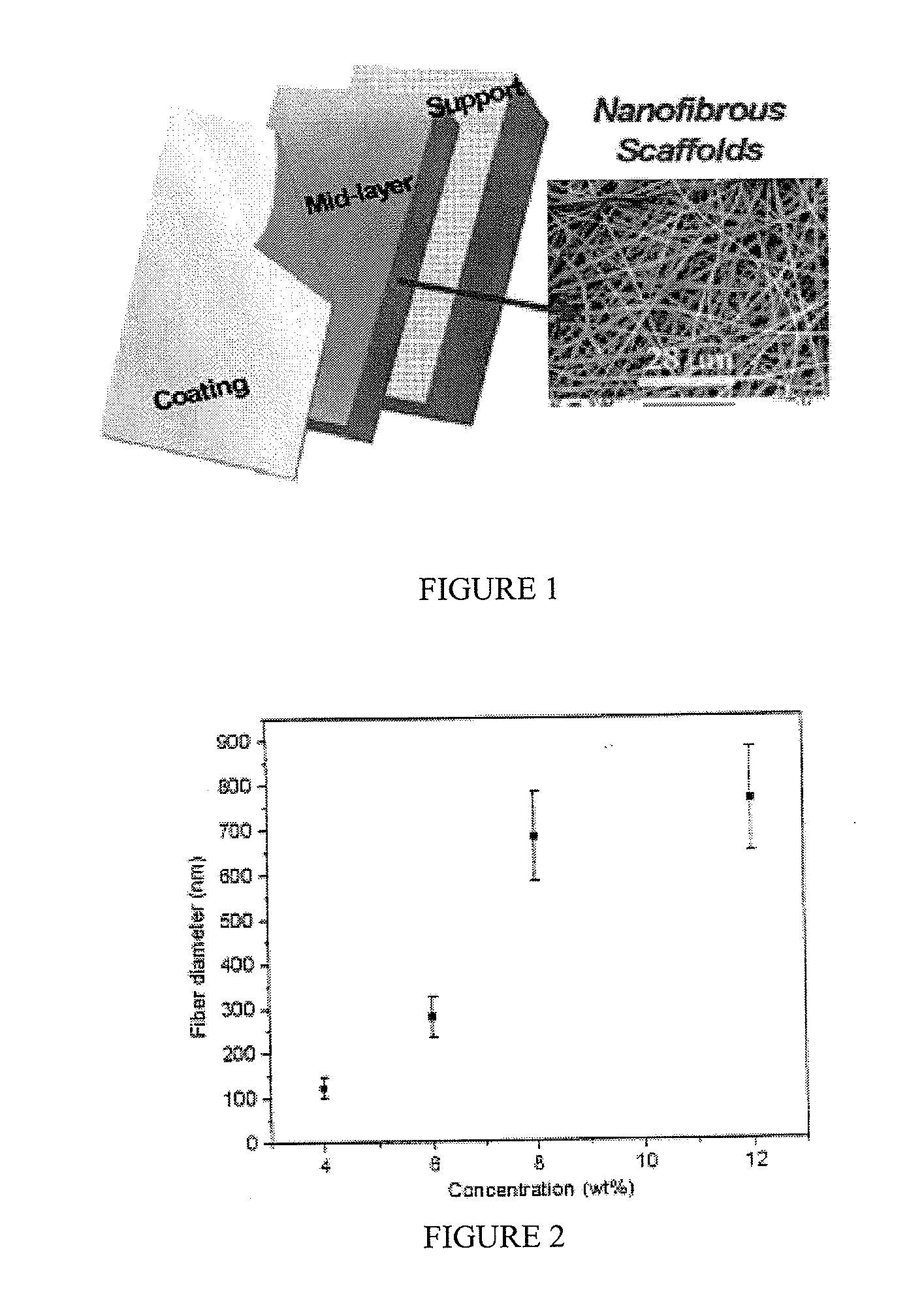

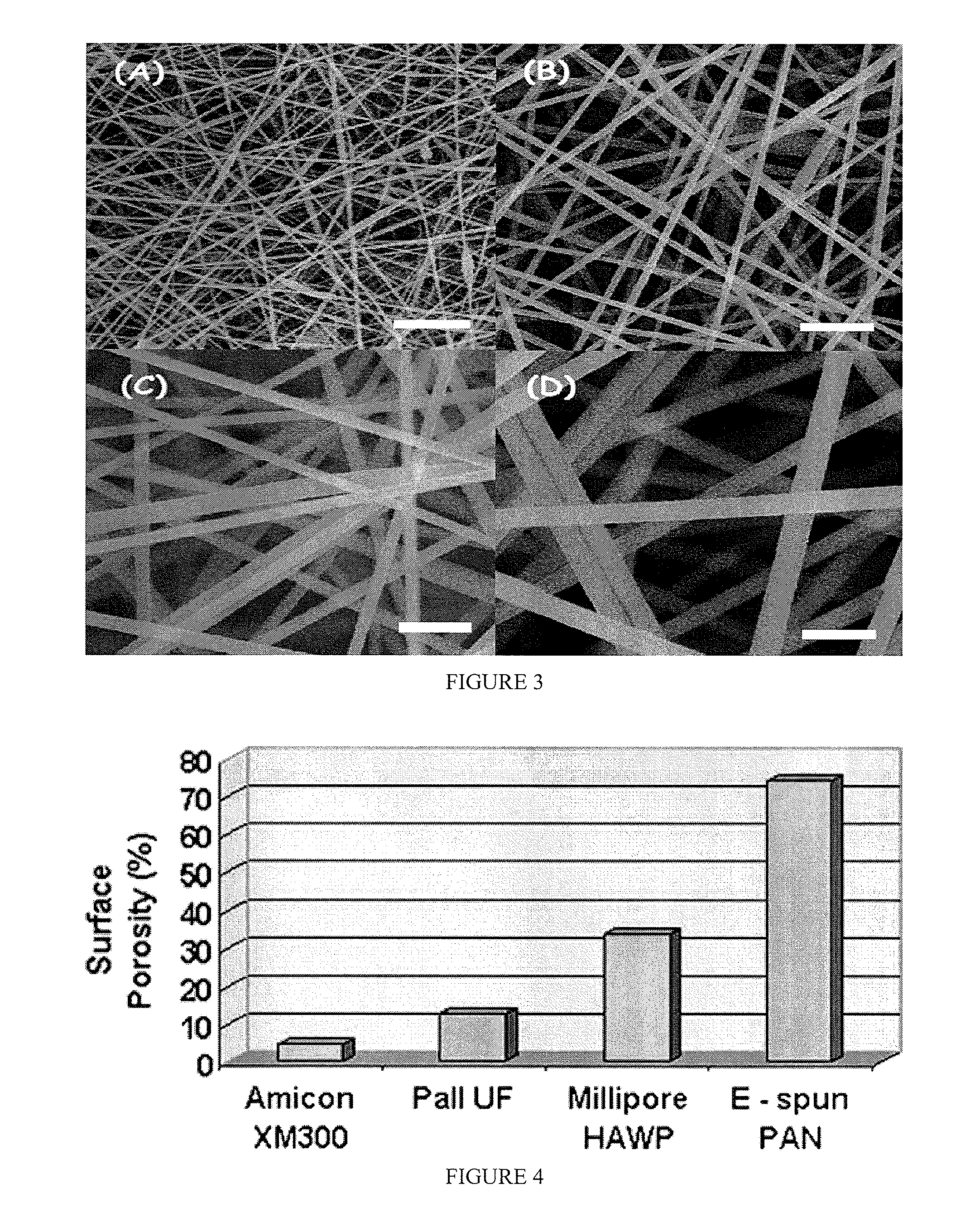

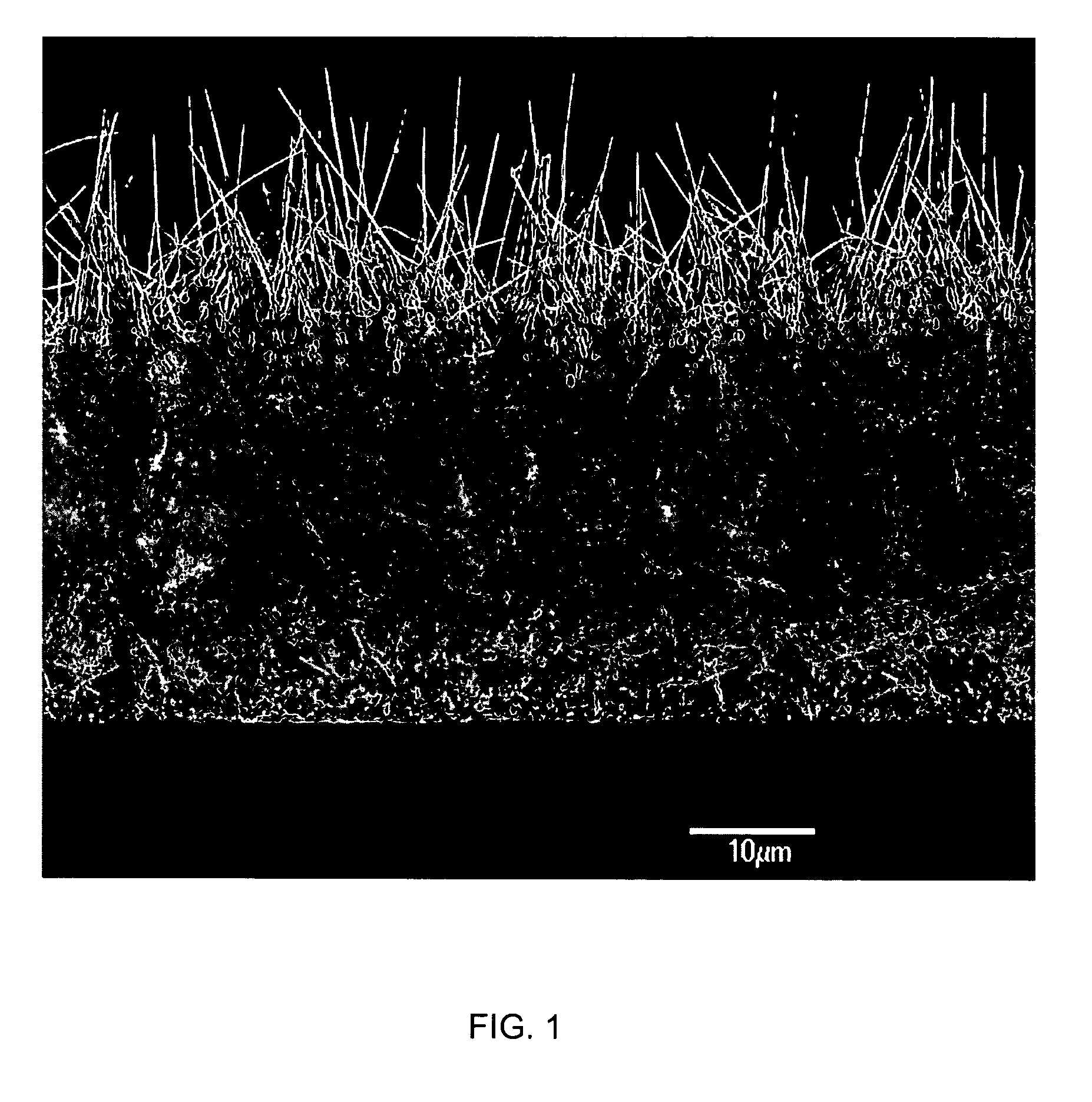

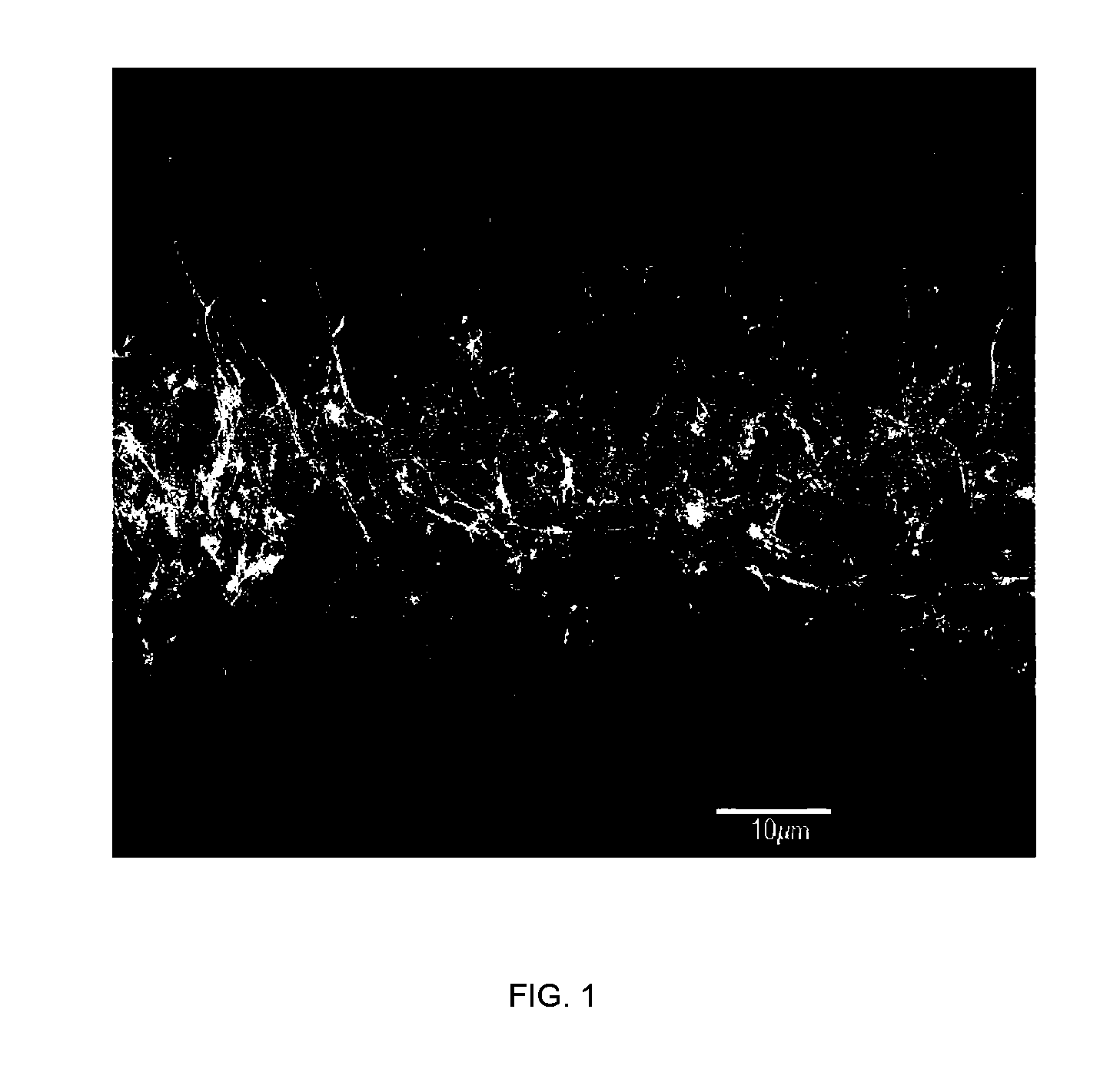

Nanofibers are fibers with diameters in the nanometer range. Nanofibers can be generated from different polymers and hence have different physical properties and application potentials. Examples of natural polymers include collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate. Examples of synthetic polymers include poly(lactic acid) (PLA), polycaprolactone (PCL), polyurethane (PU), poly(lactic-co-glycolic acid) (PLGA), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly(ethylene-co-vinylacetate) (PEVA). Polymer chains are connected via covalent bonds. The diameters of nanofibers depend on the type of polymer used and the method of production. All polymer nanofibers are unique for their large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility in functionalization compared to their microfiber counterparts.

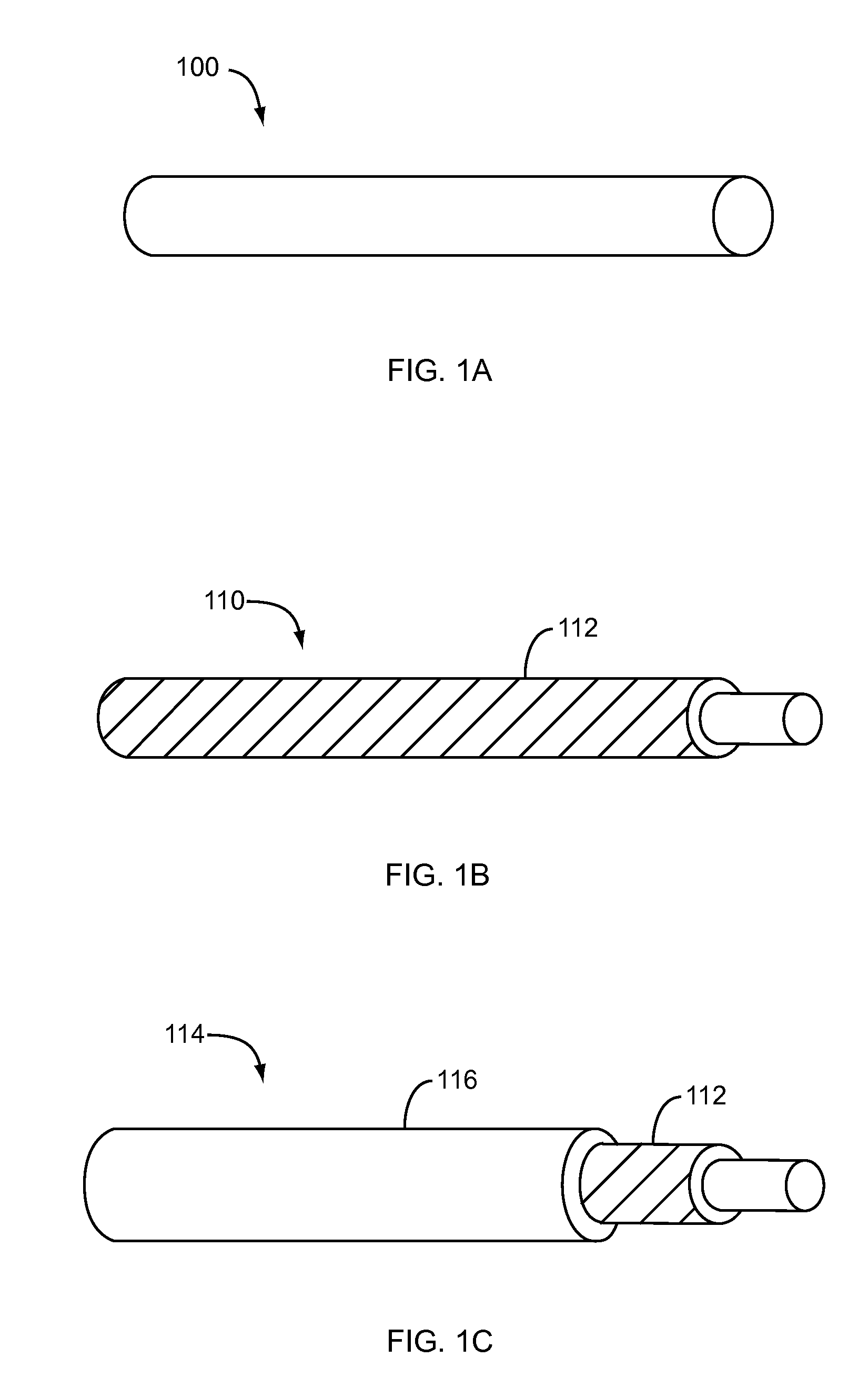

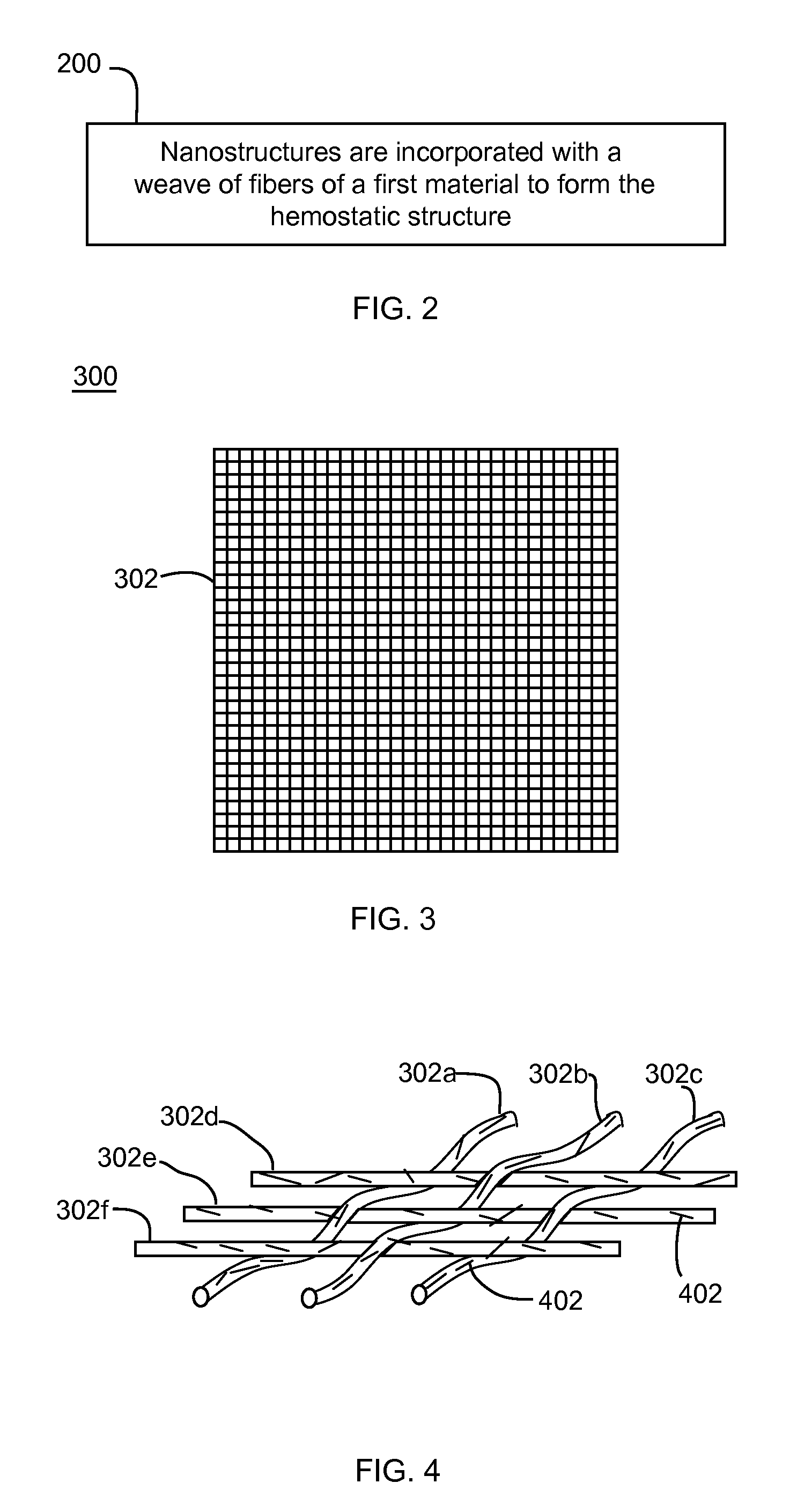

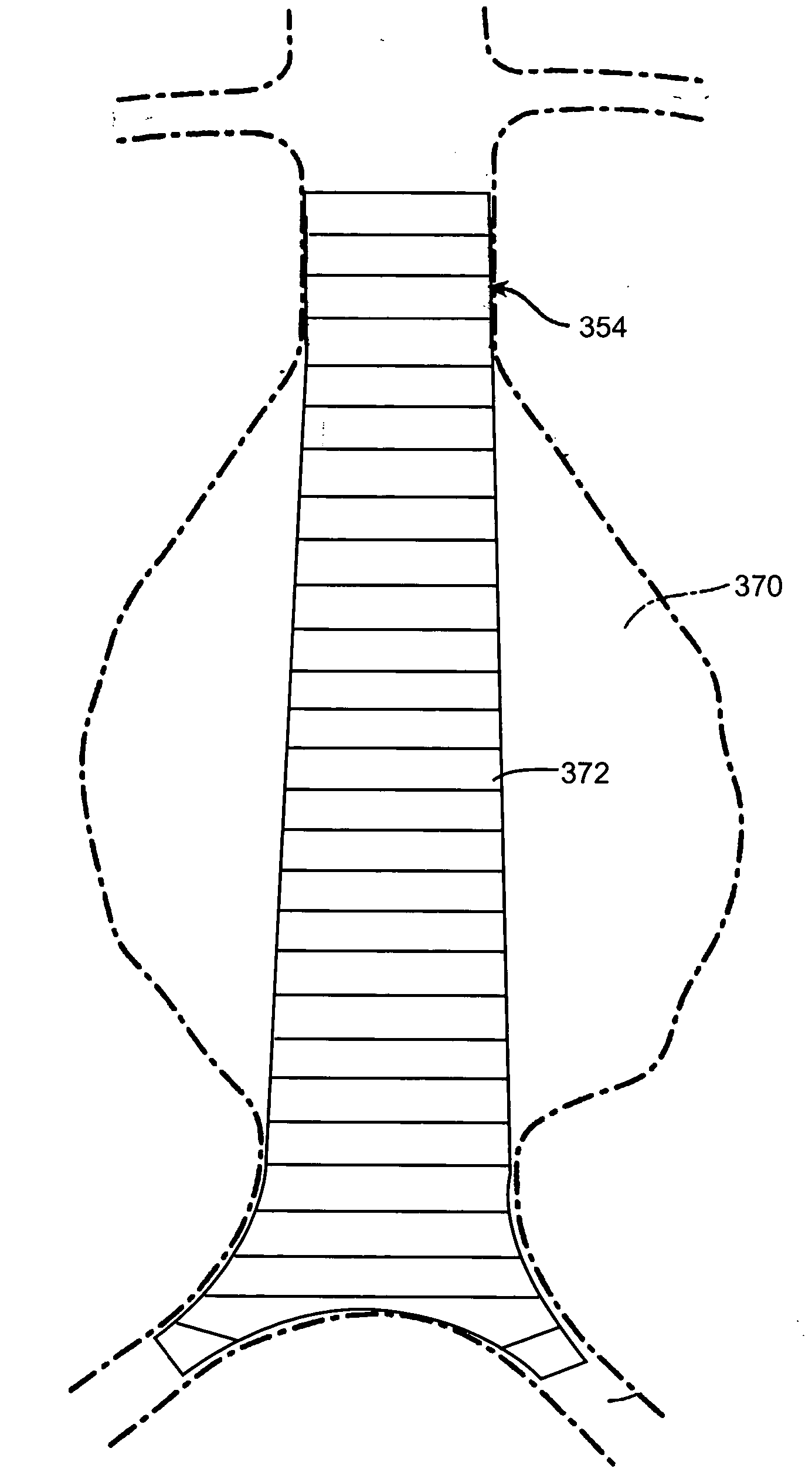

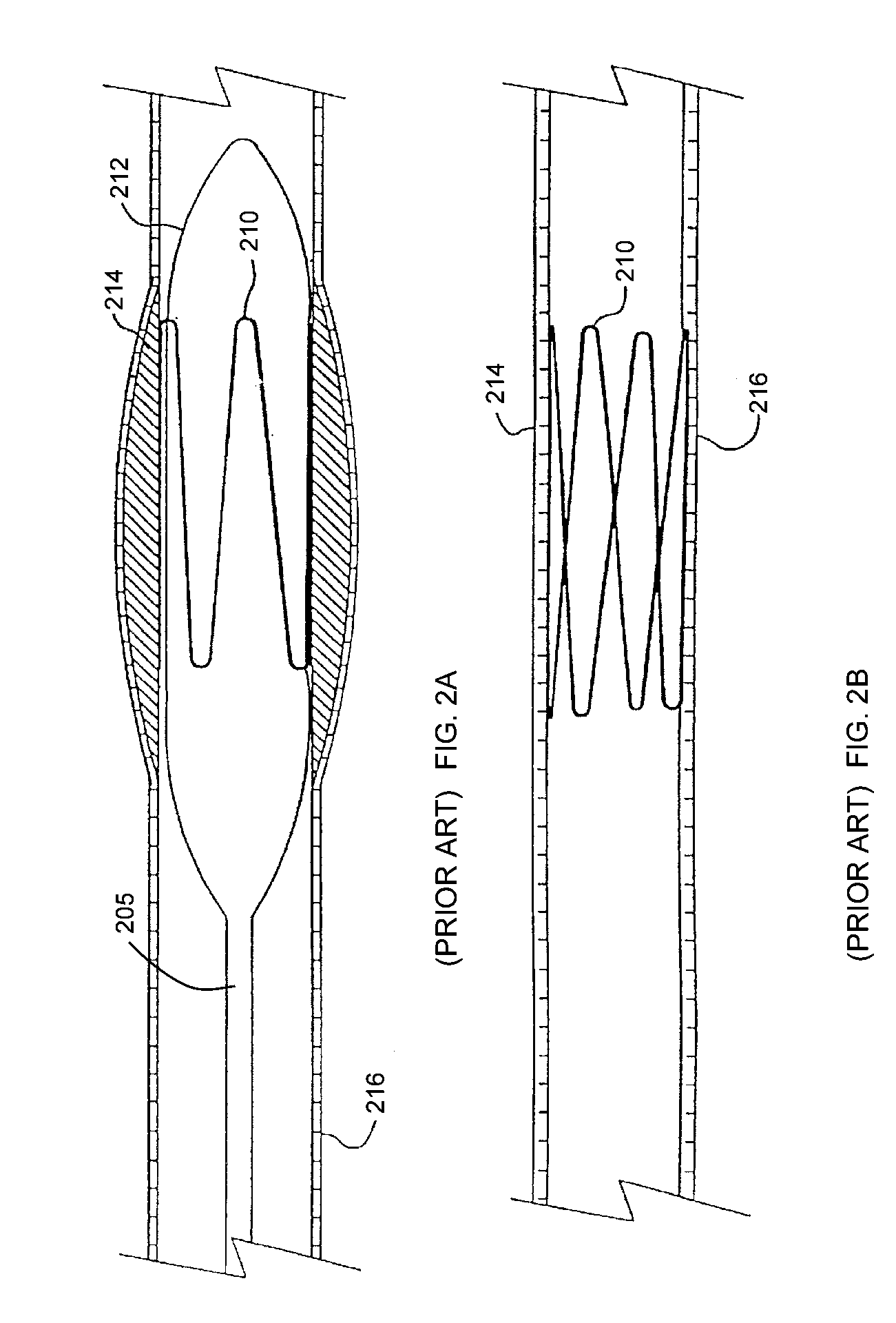

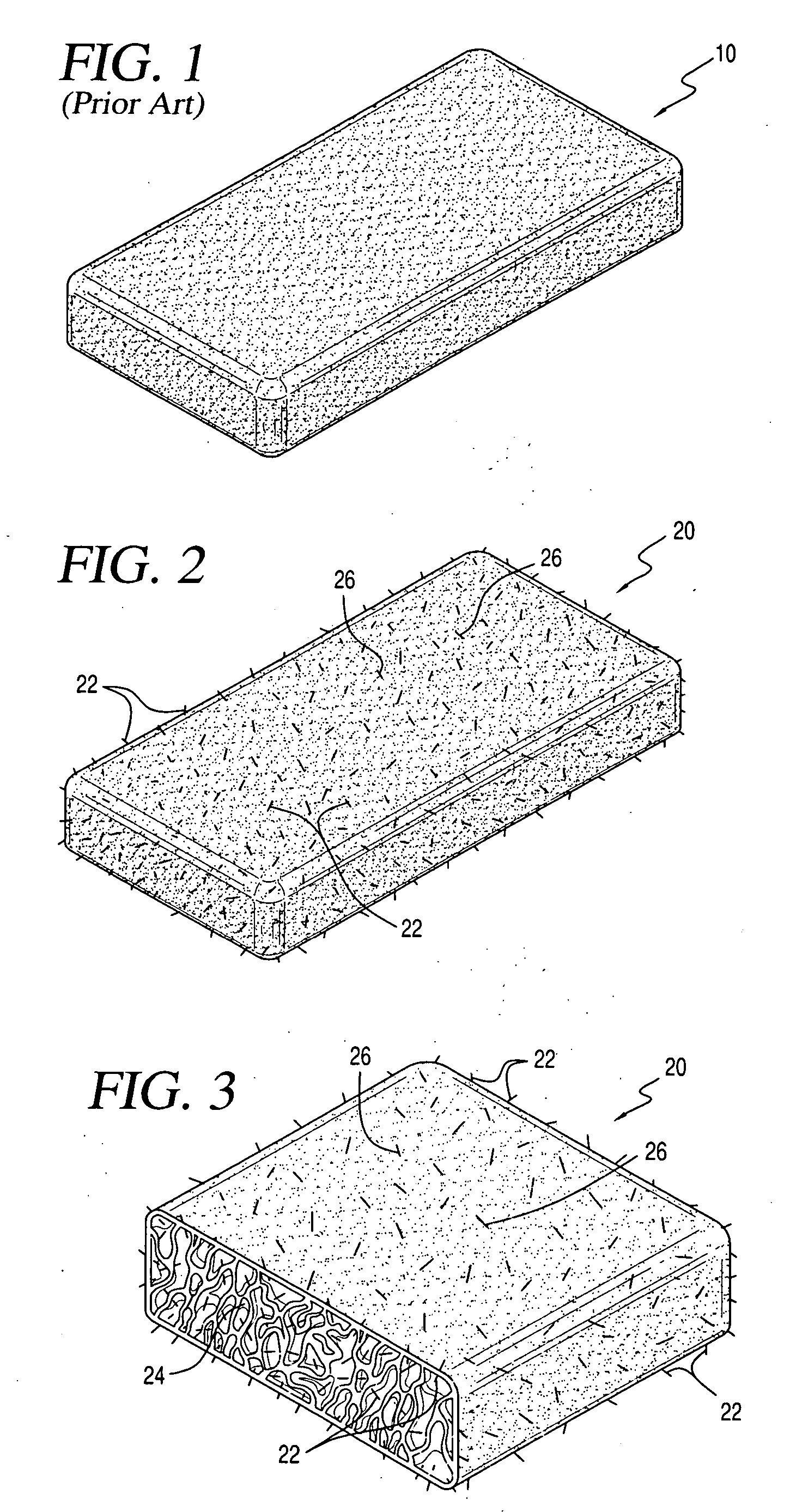

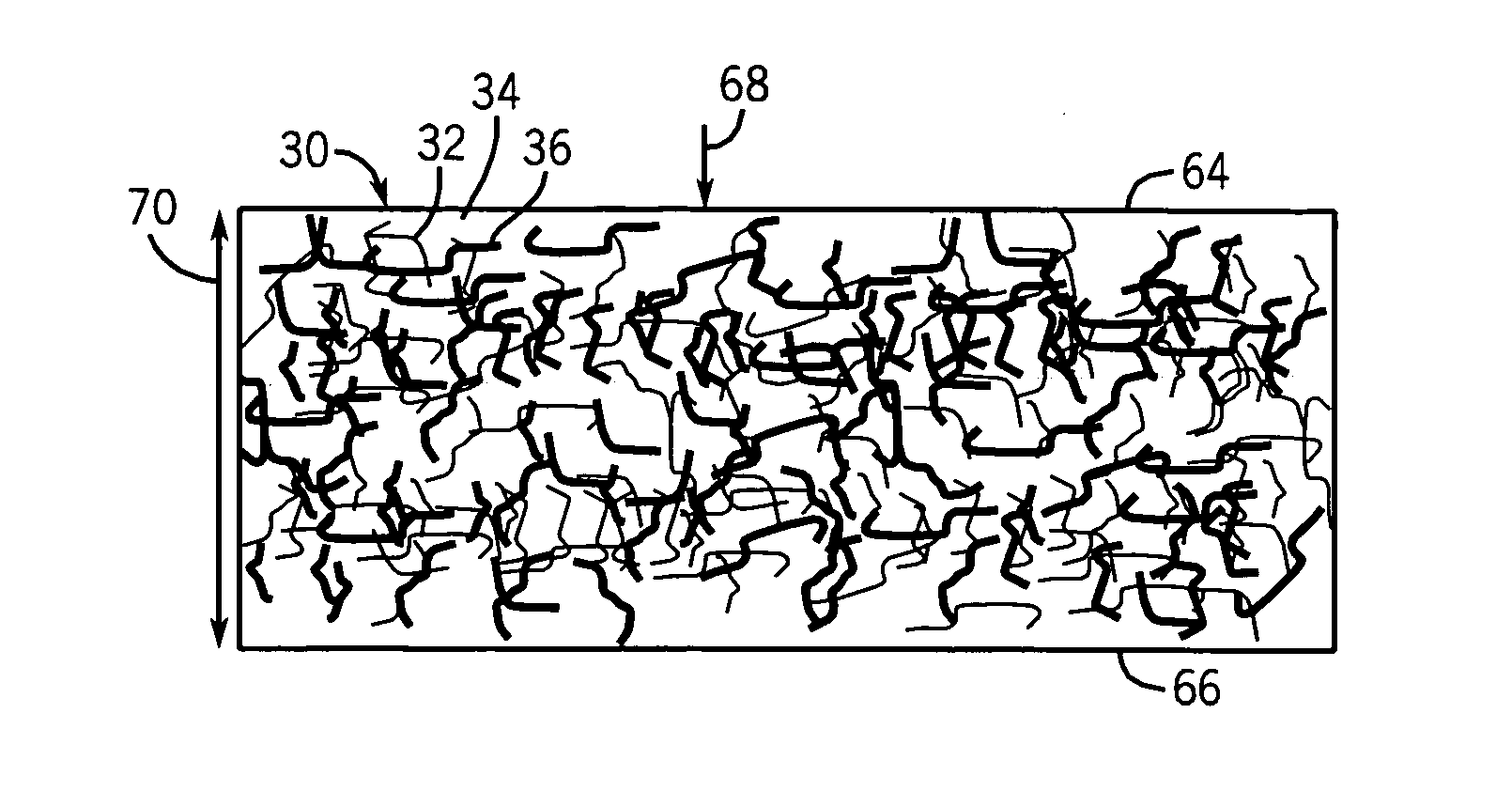

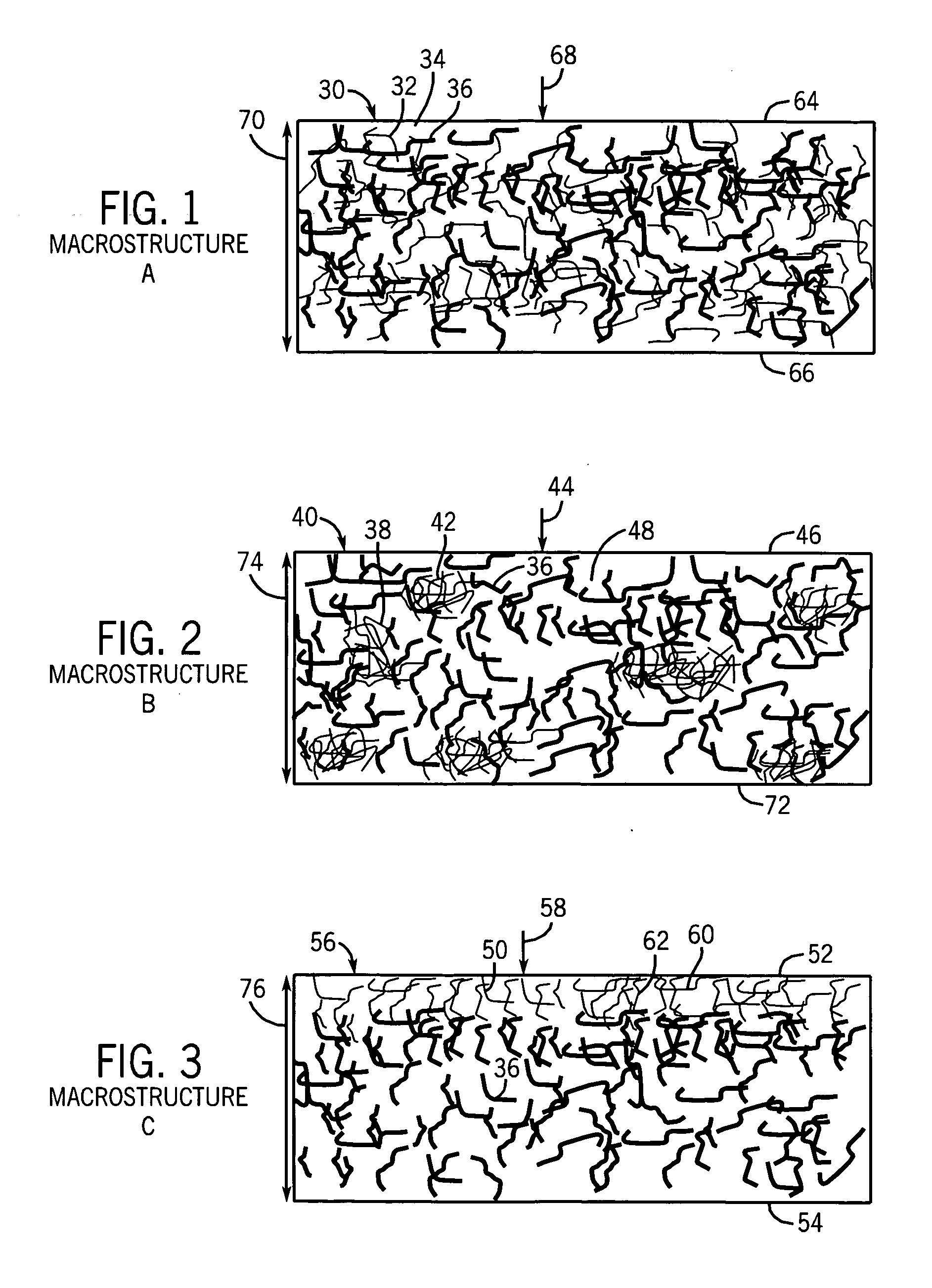

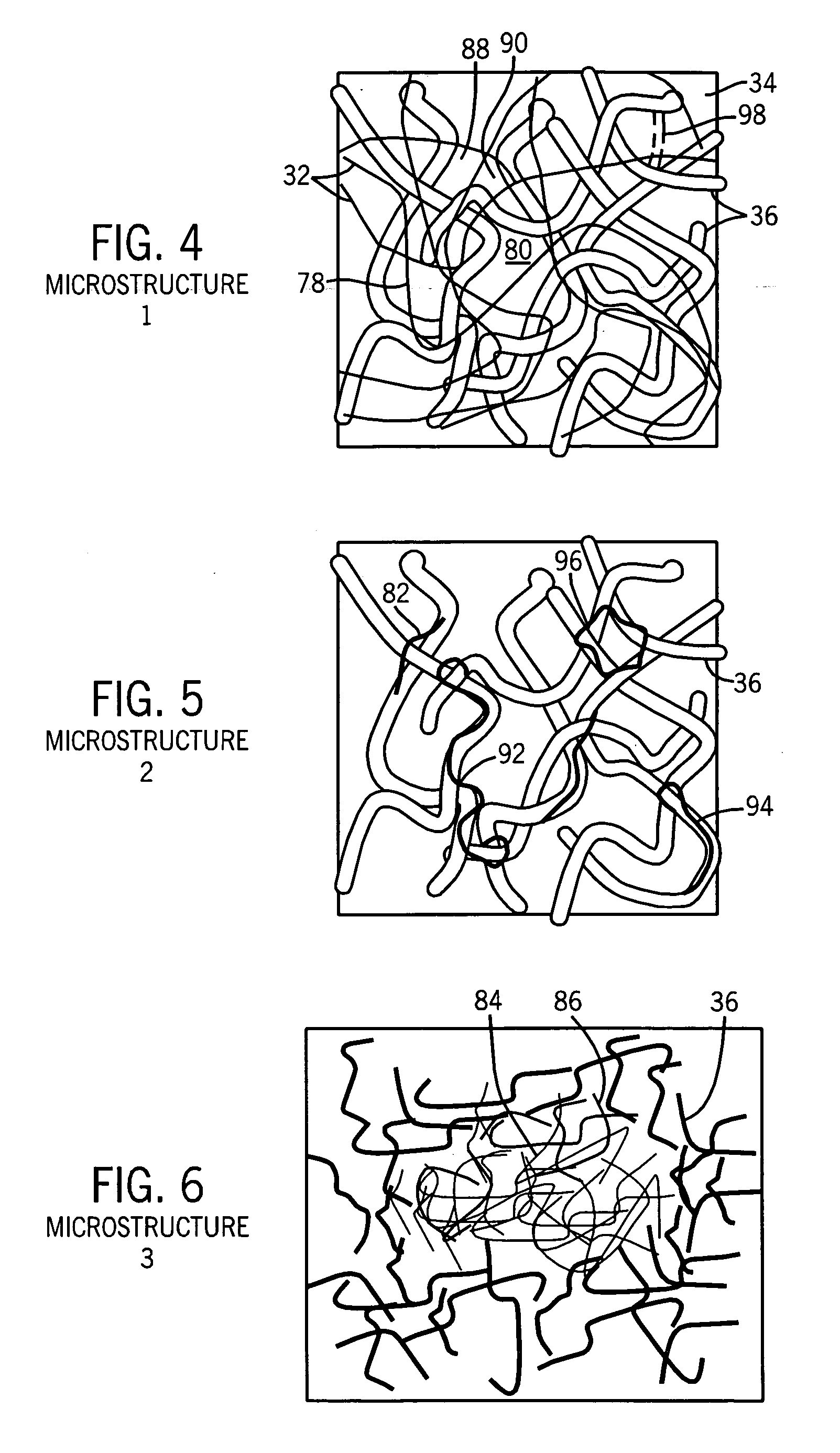

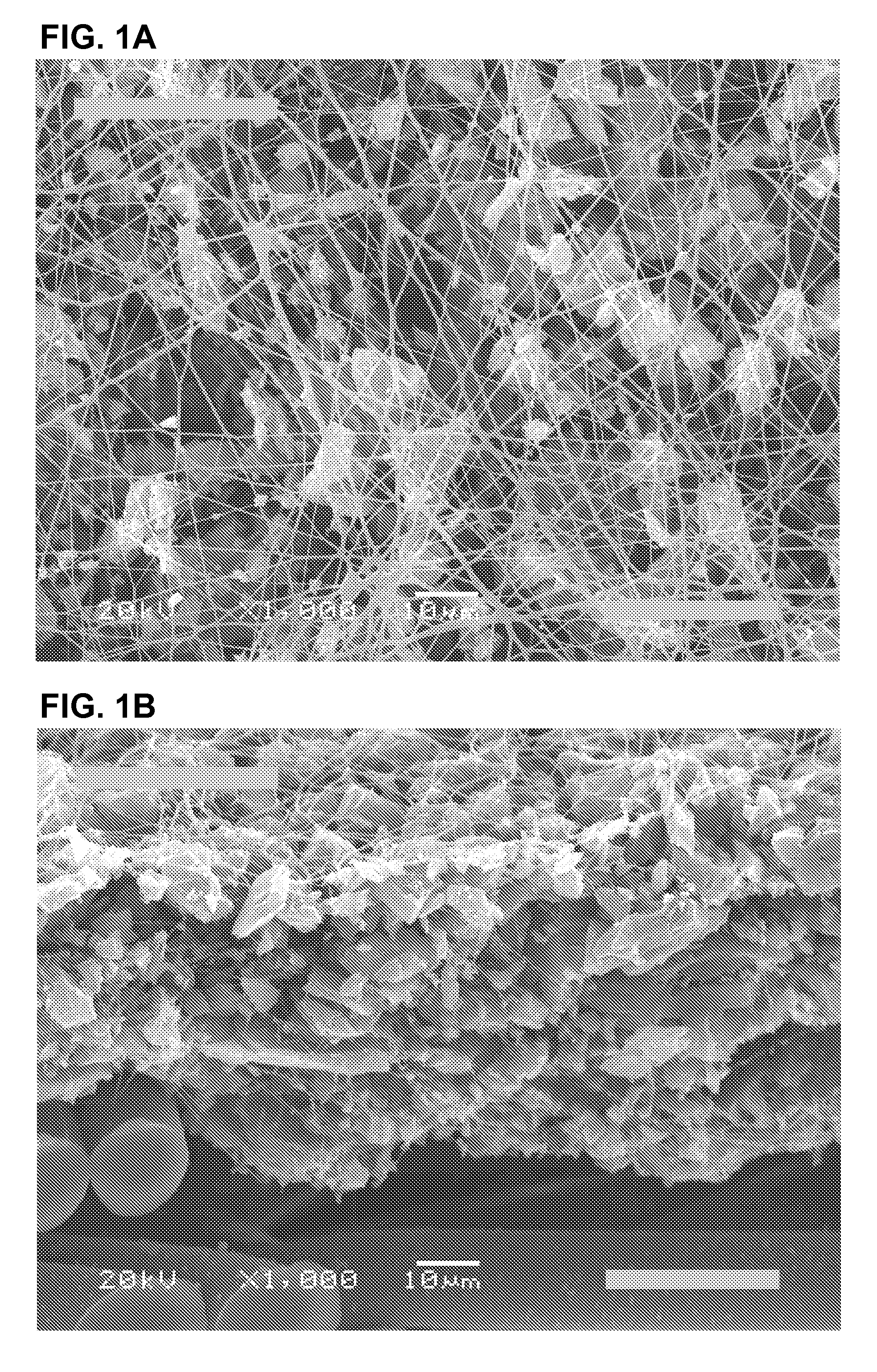

Nanostructure-enhanced platelet binding and hemostatic structures

InactiveUS8319002B2Enhancing overall rate and strengthInduce platelet binding and efficient hemostasisBiocideSurgical adhesivesPlateletNanofiber

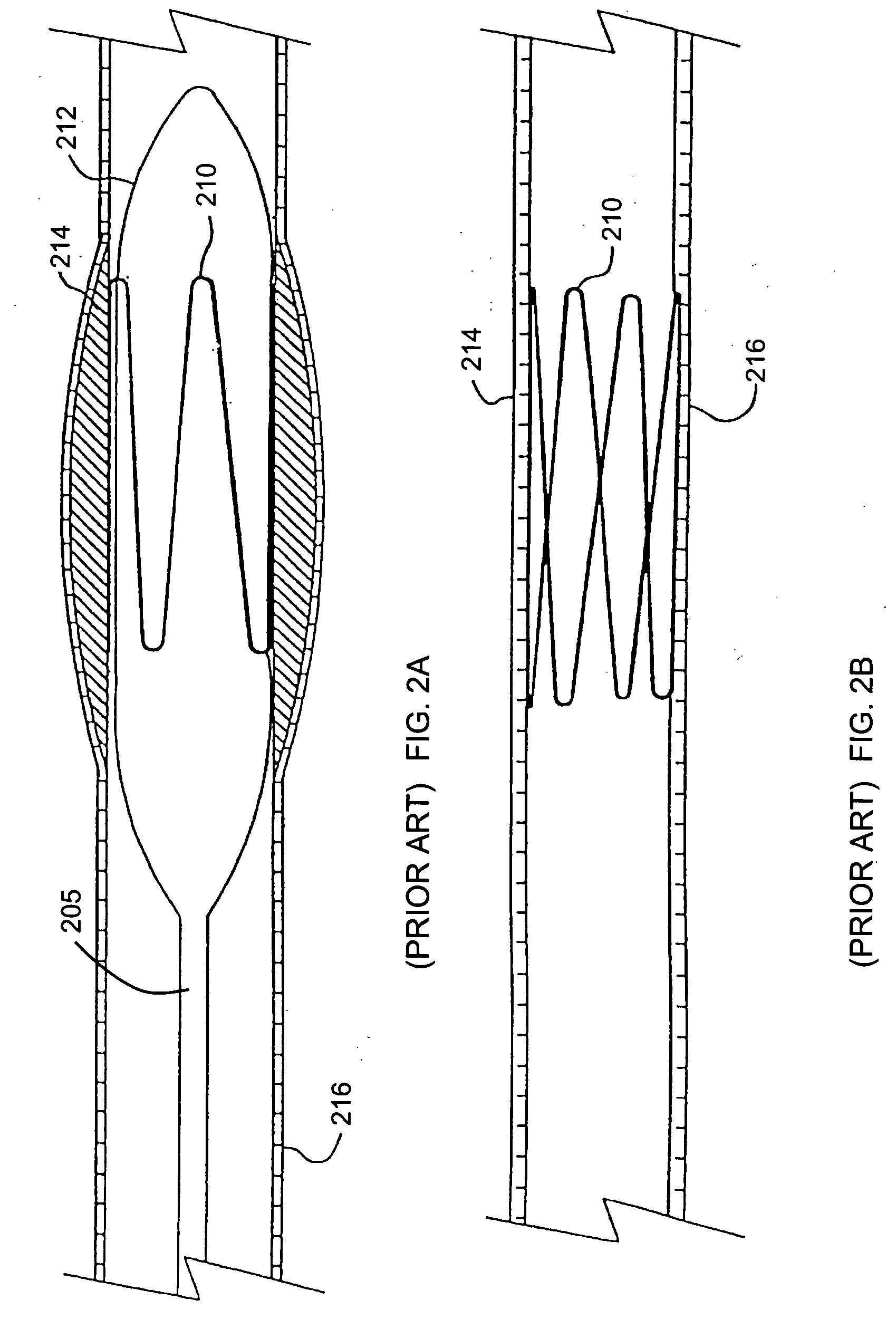

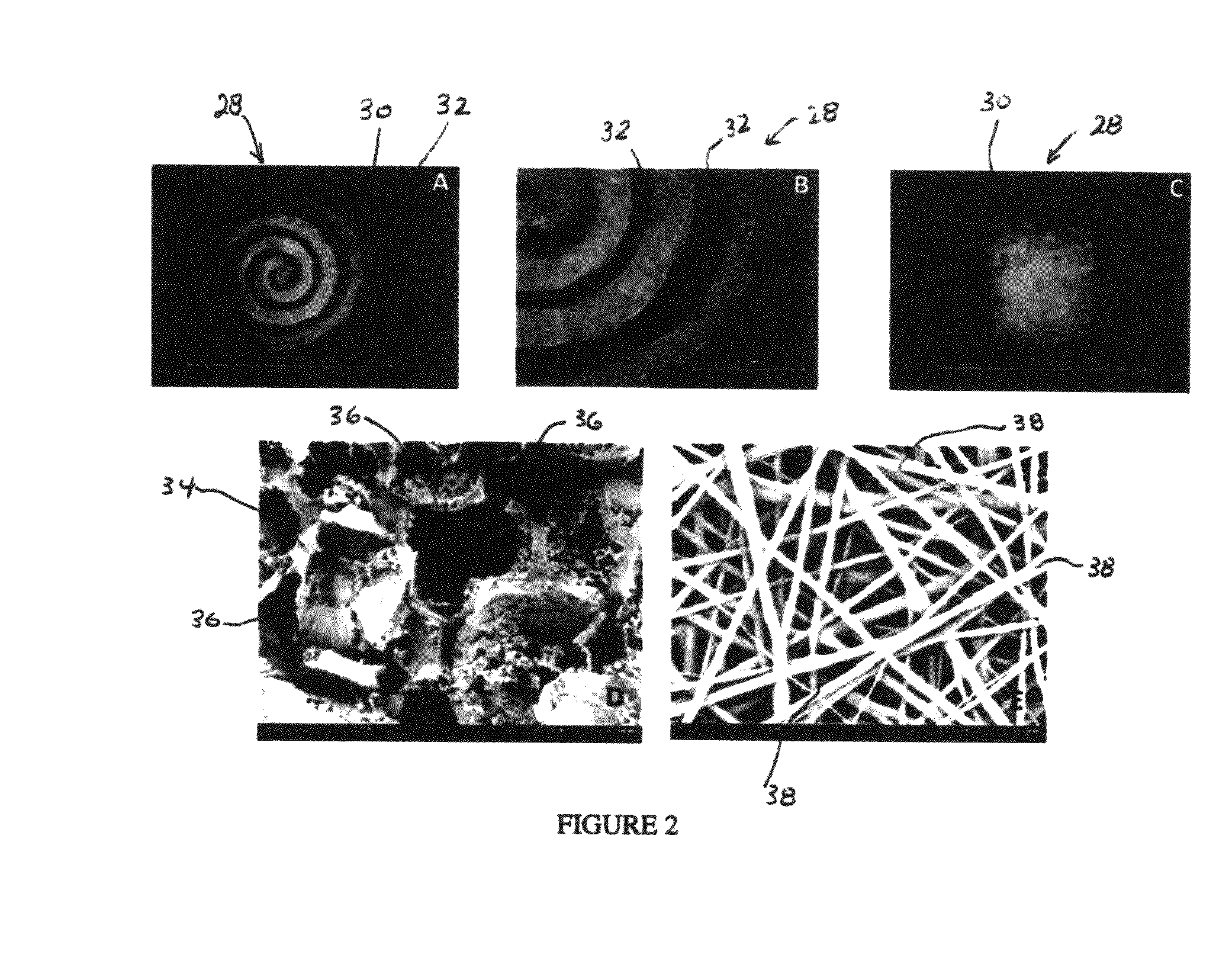

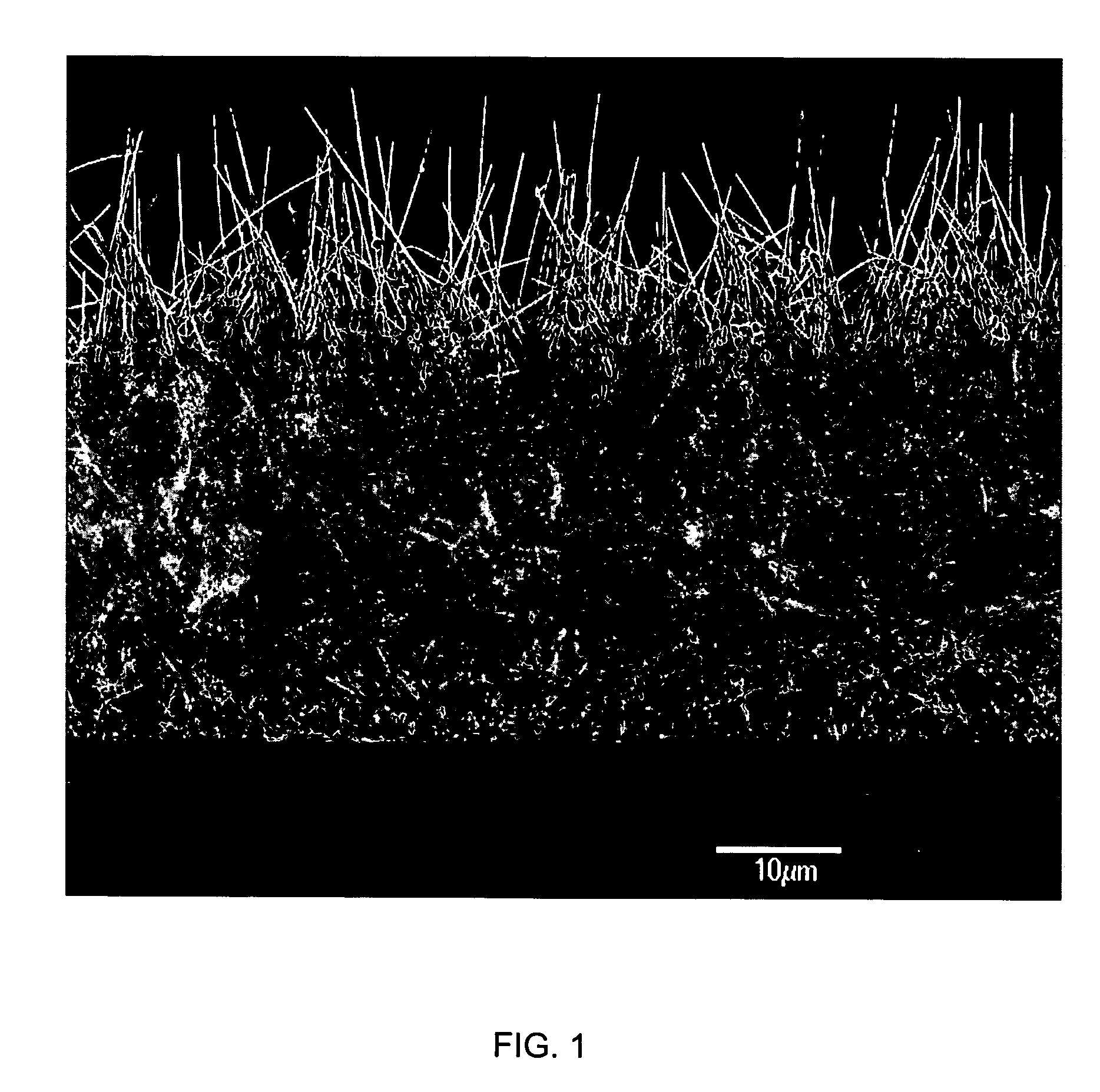

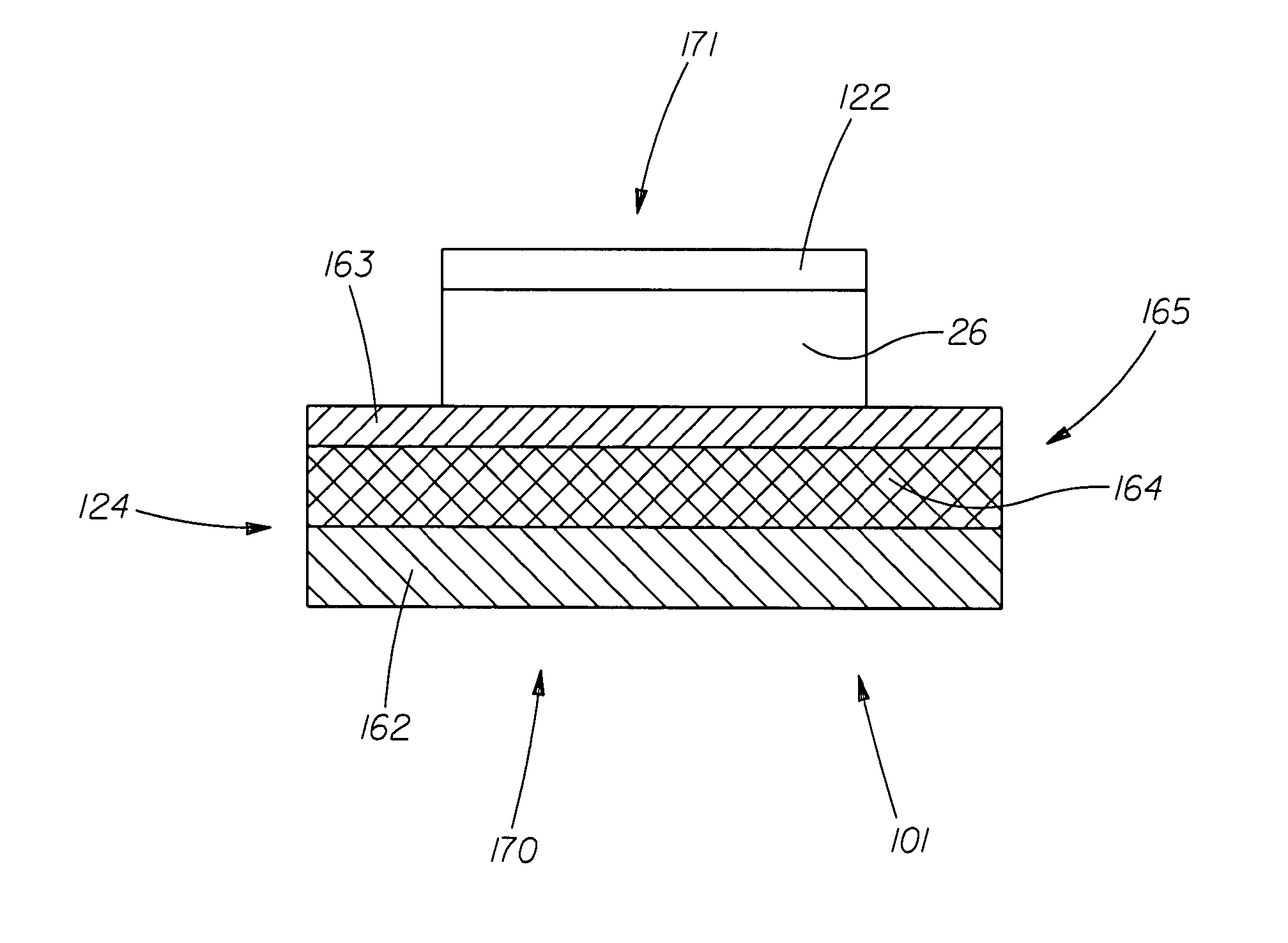

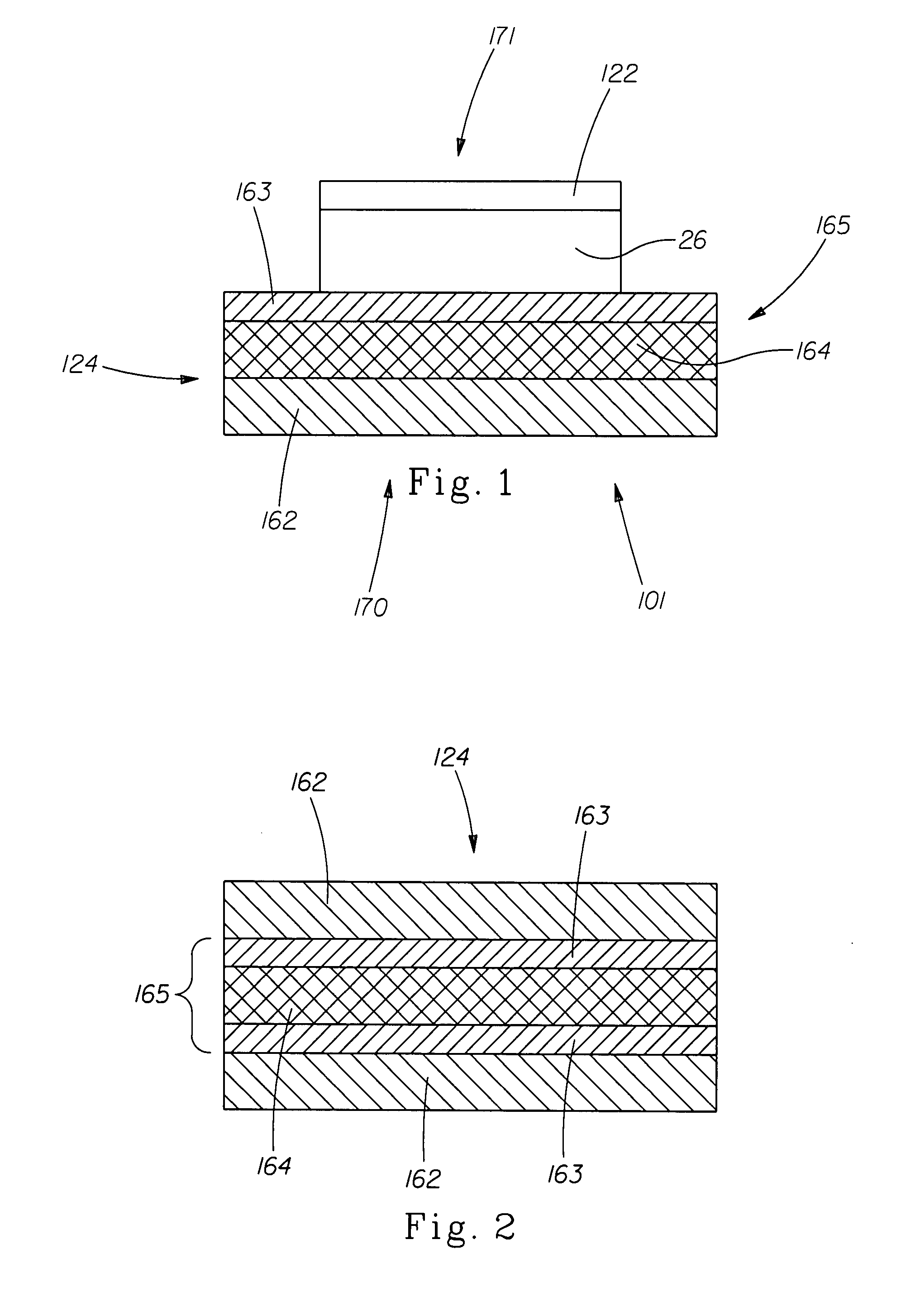

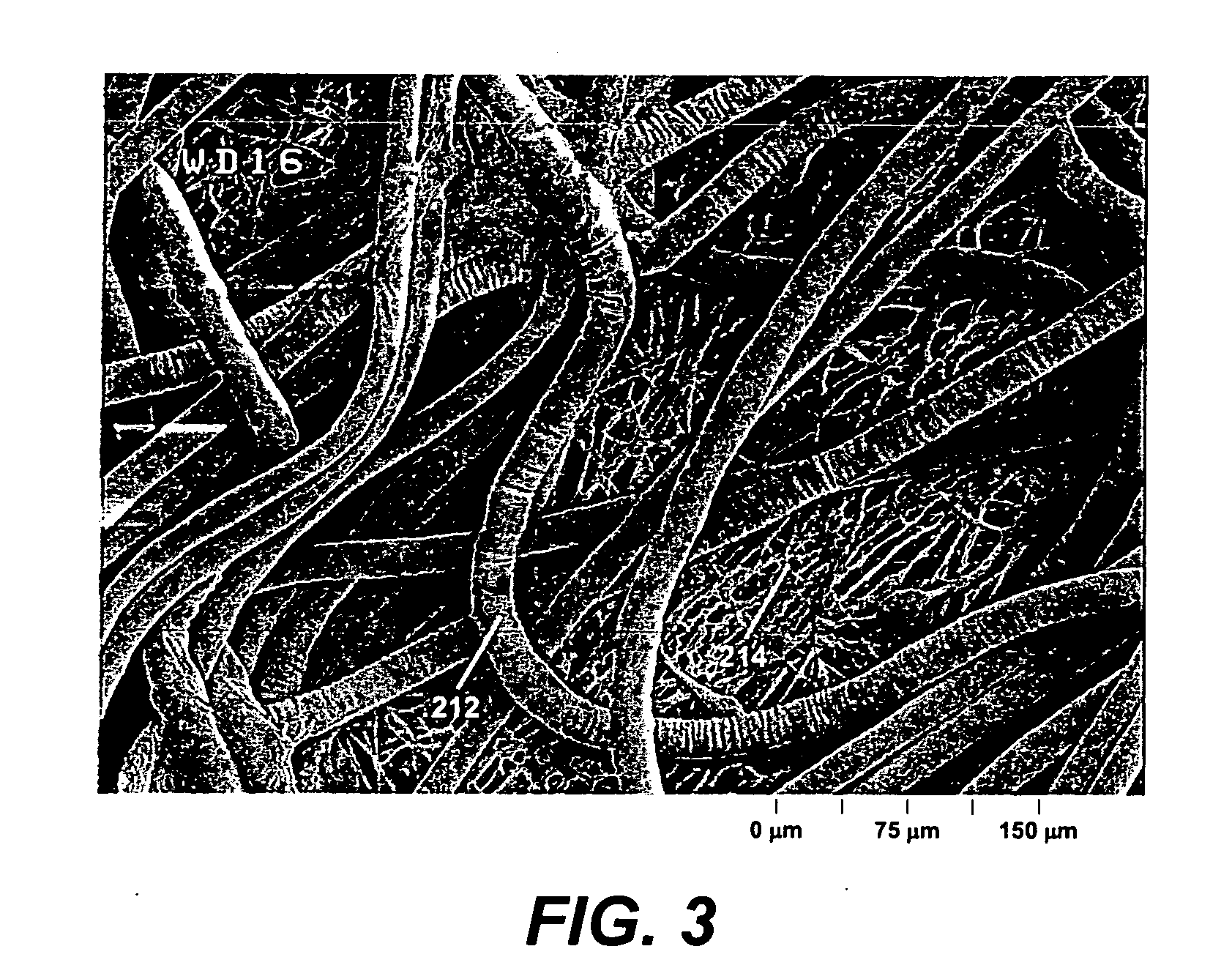

Methods, systems, and apparatuses for nanomaterial-enhanced platelet binding and hemostatic medical devices are provided. Hemostatic materials and structures are provided that induce platelet binding, including platelet binding and the coagulation of blood at a wound / opening caused by trauma, a surgical procedure, ulceration, or other cause. Example embodiments include platelet binding devices, hemostatic bandages, hemostatic plugs, and hemostatic formulations. The hemostatic materials and structures may incorporate nanostructures and / or further hemostatic elements such as polymers, silicon nanofibers, silicon dioxide nanofibers, and / or glass beads into a highly absorbent, gelling scaffold. The hemostatic materials and structures may be resorbable.

Owner:NANOSYS INC

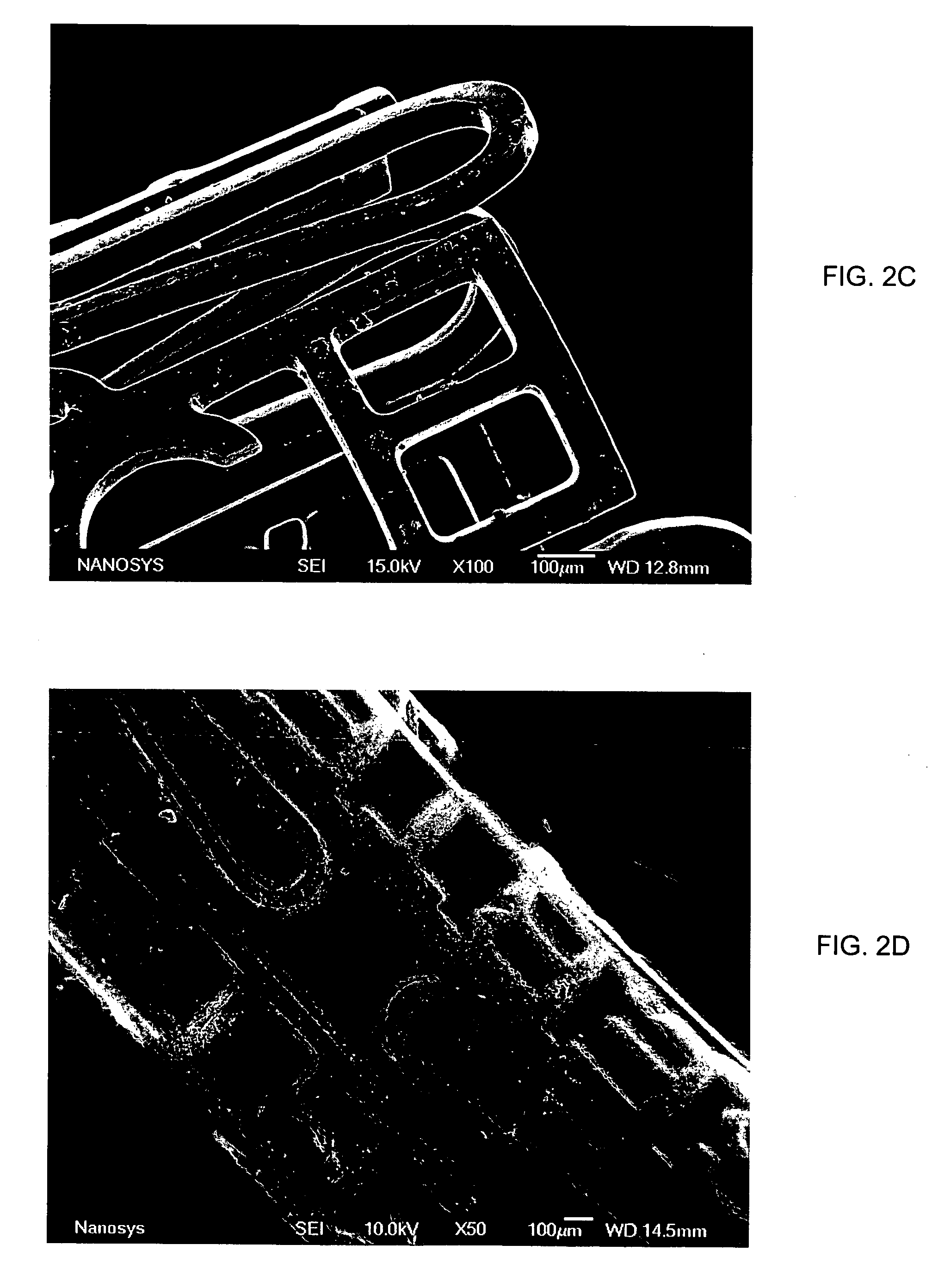

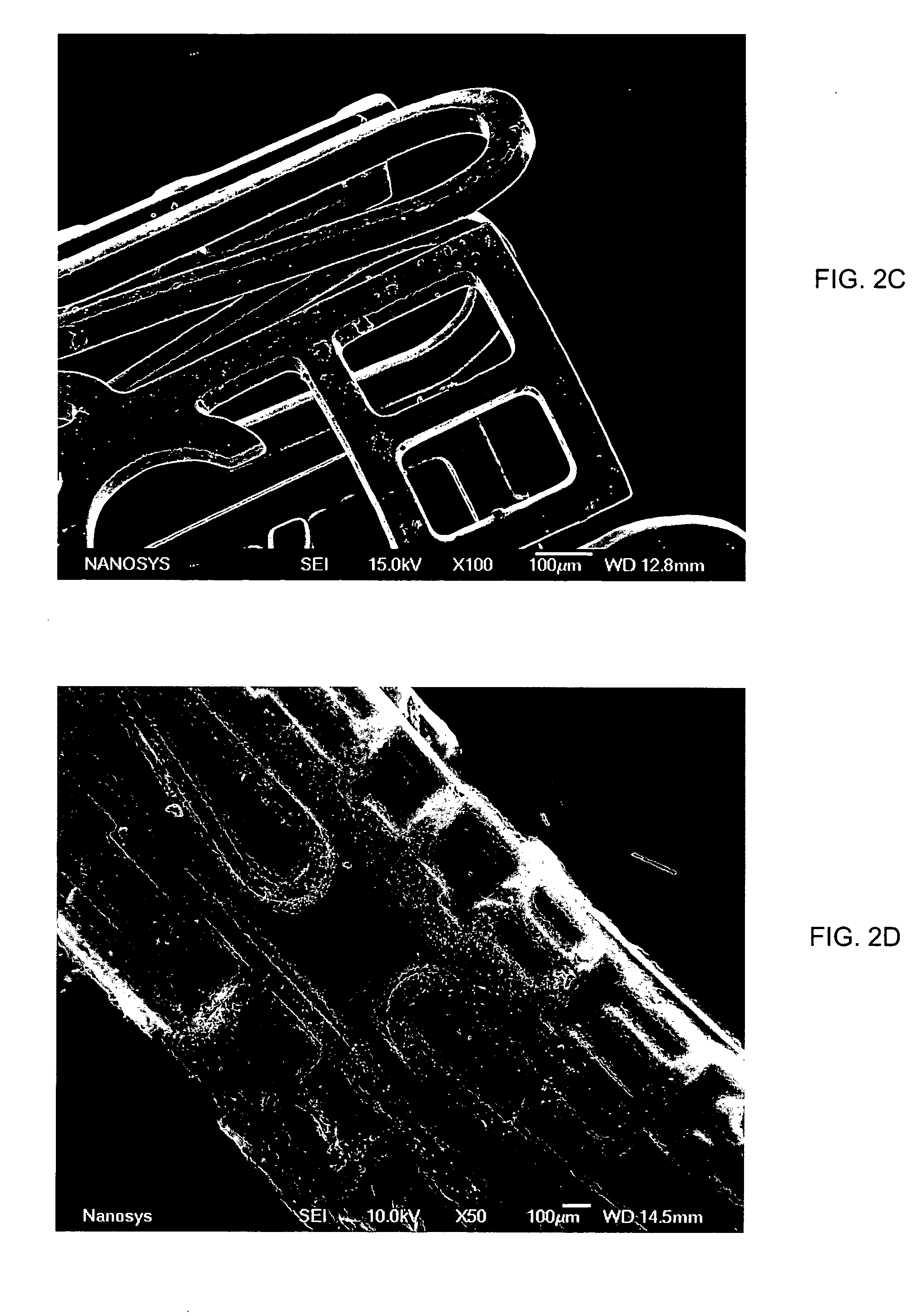

Medical device applications of nanostructured surfaces

InactiveUS20050038498A1Fine surfacePrevent/reduce bio-foulingAntibacterial agentsMaterial nanotechnologyFiberNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices.

Owner:NANOSYS INC

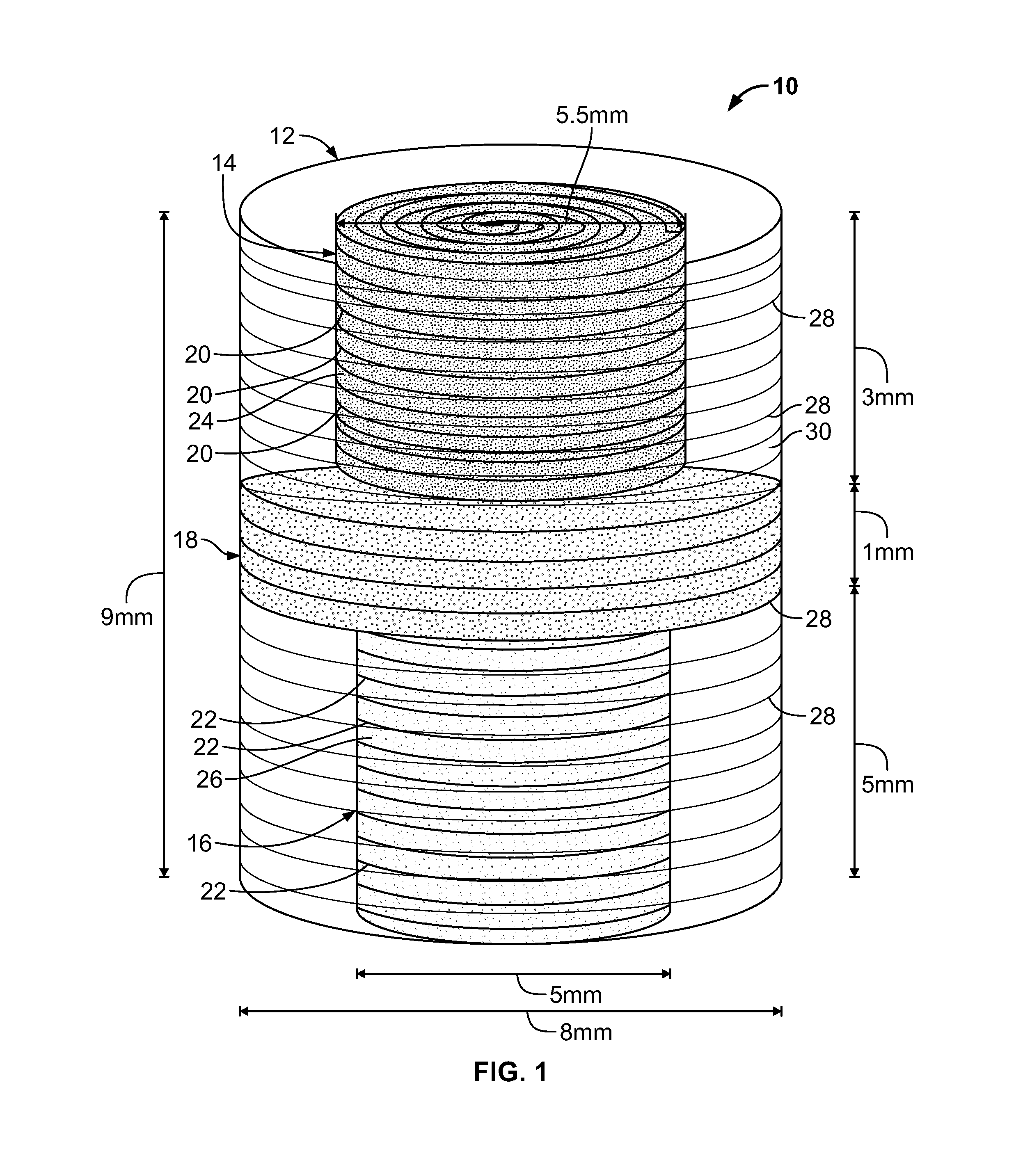

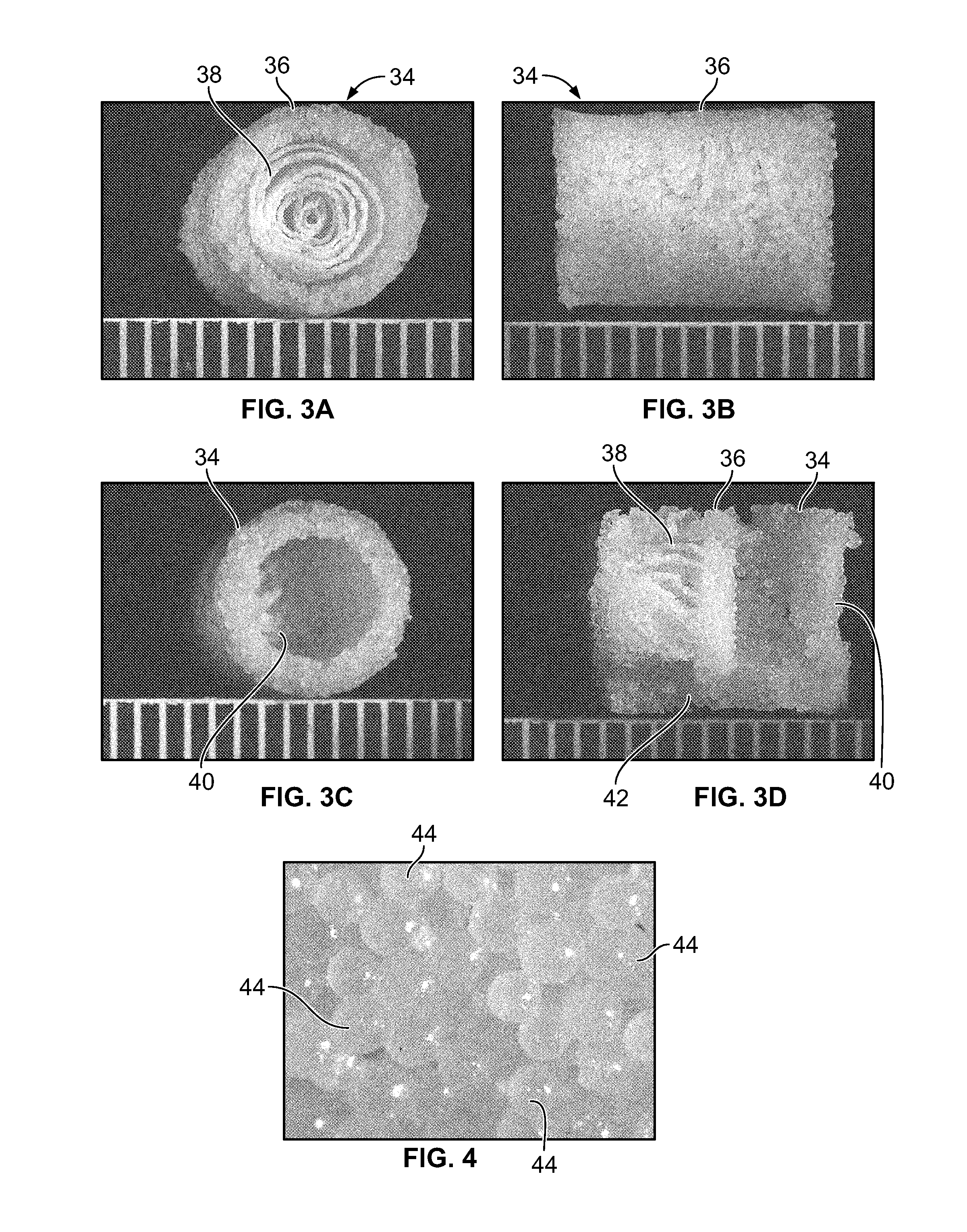

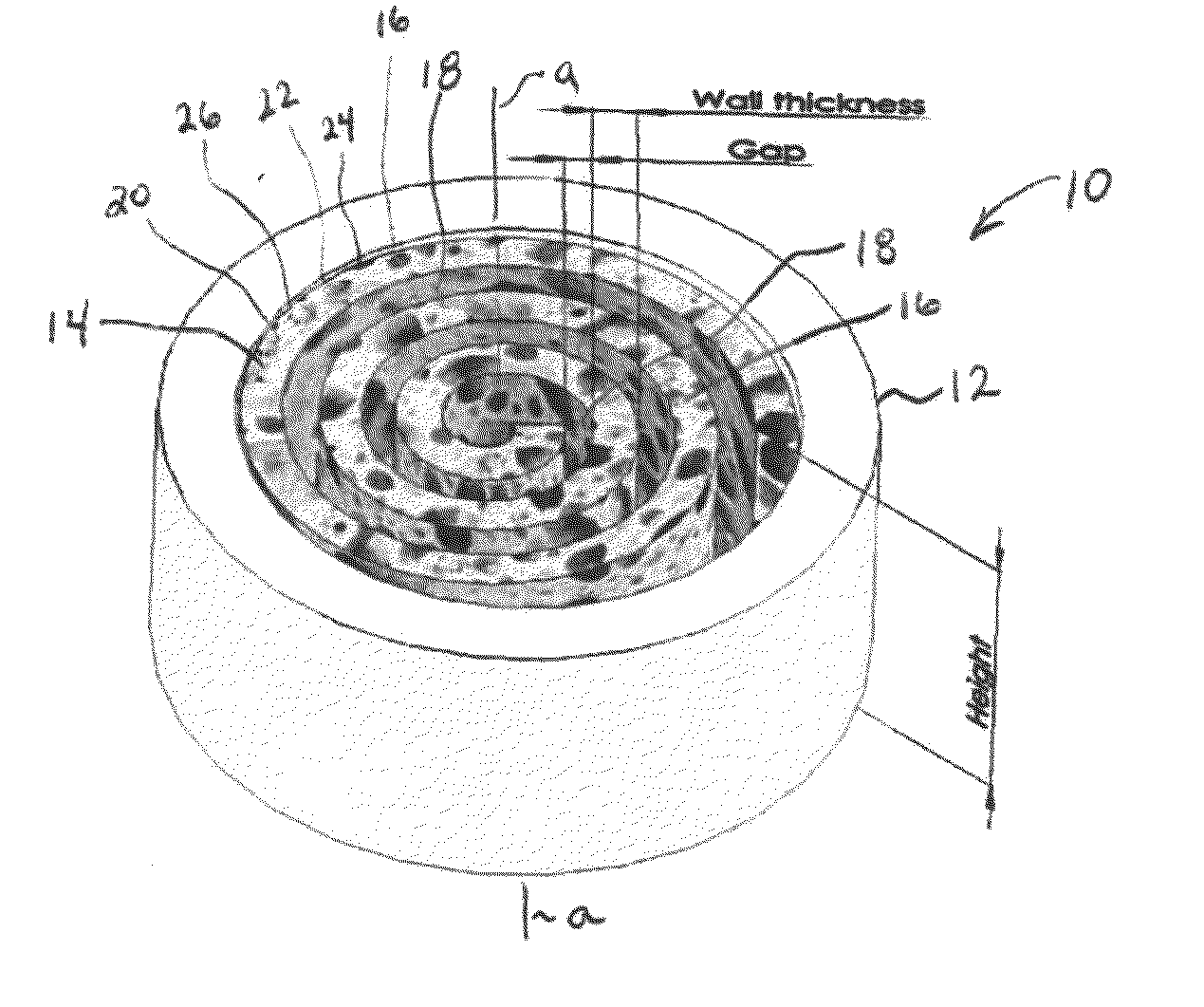

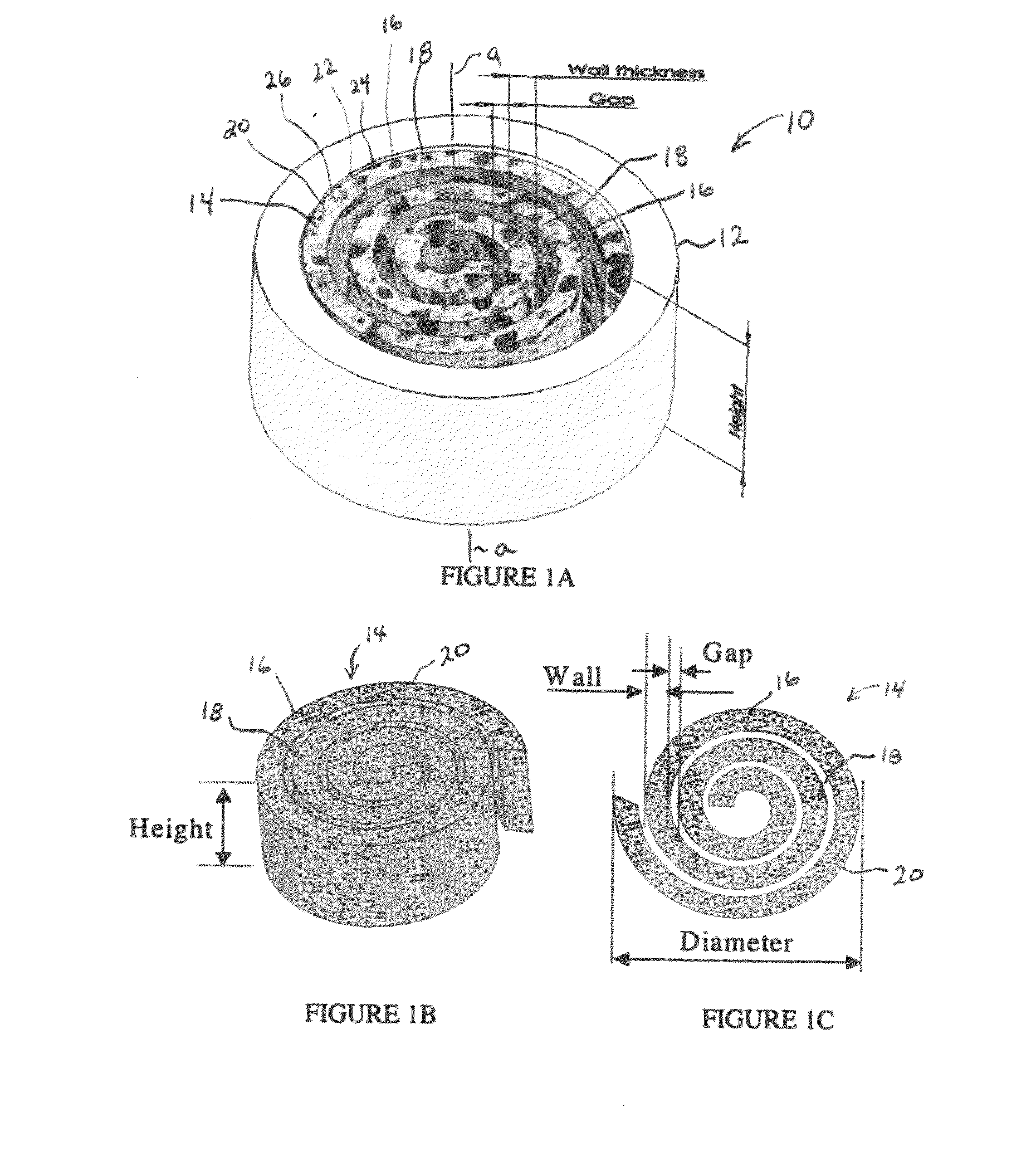

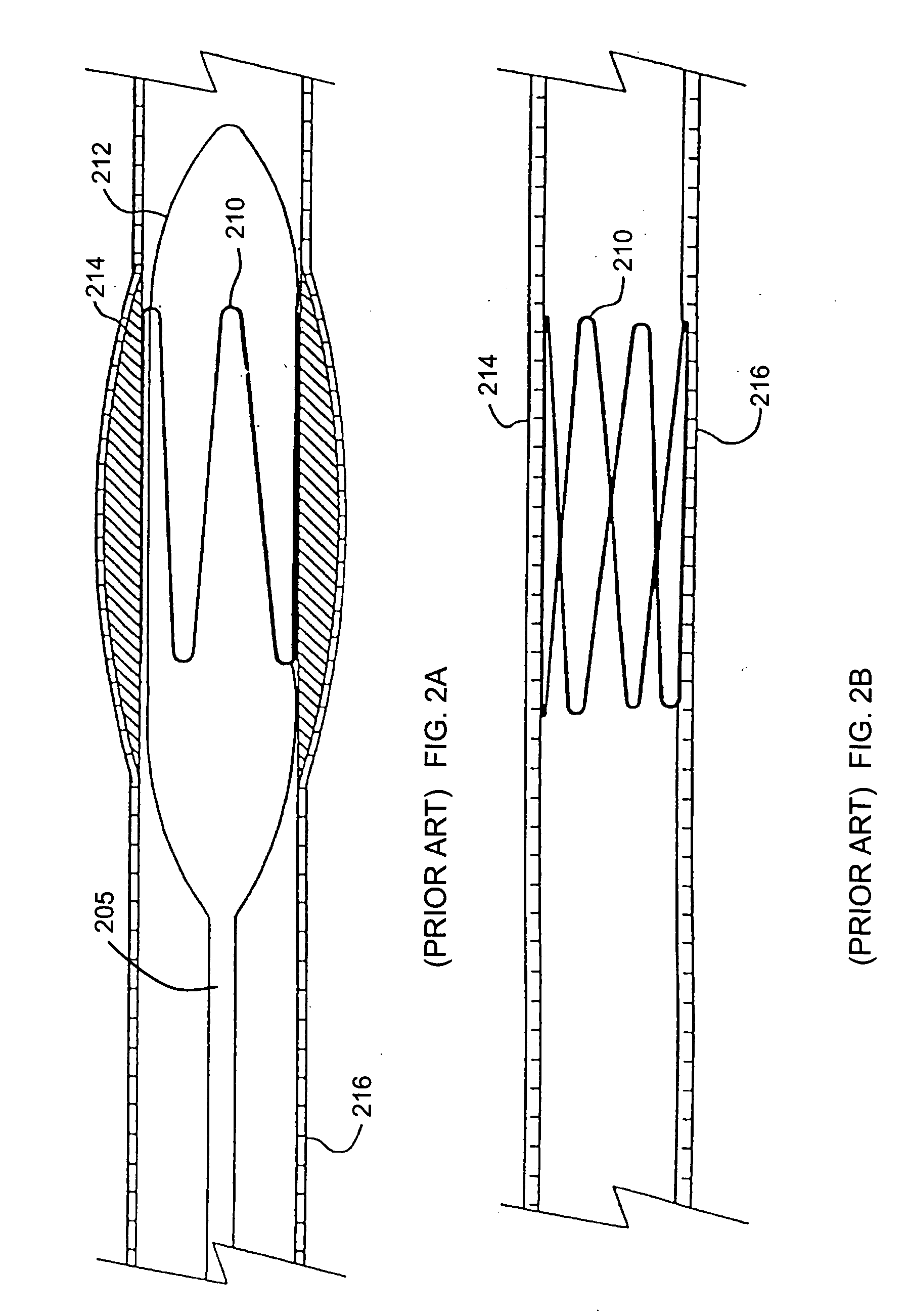

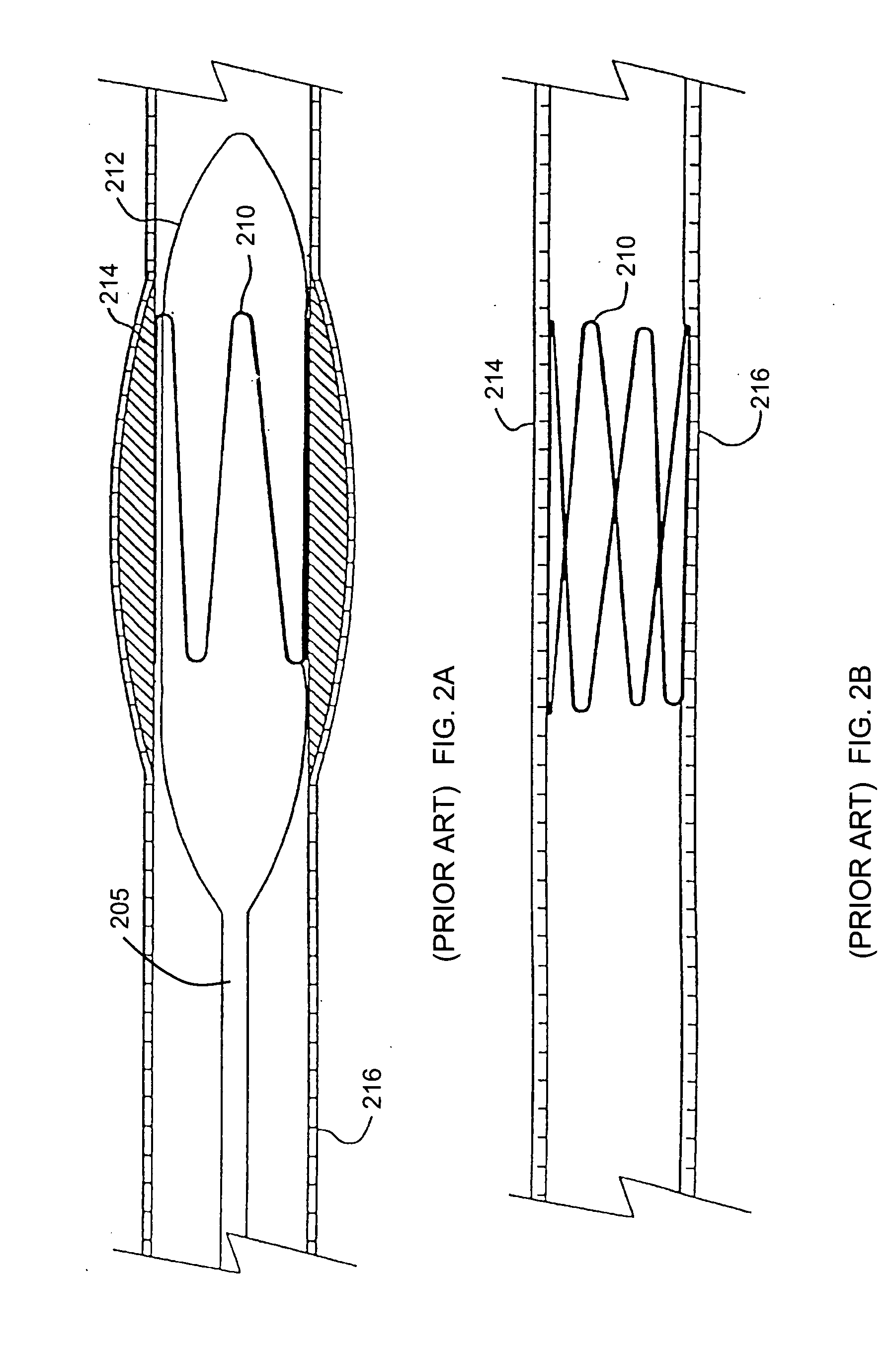

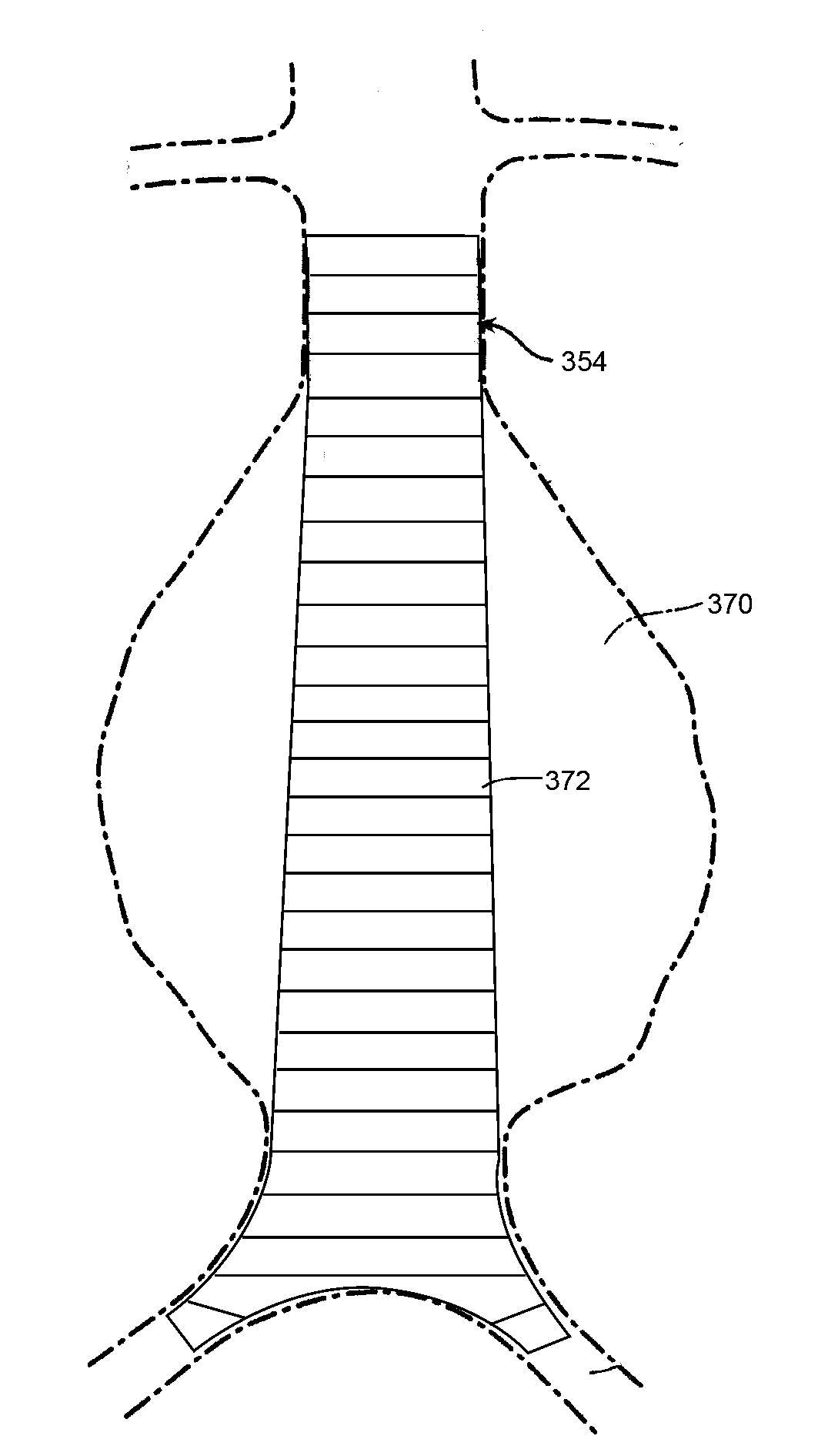

Biphasic osteochondral scaffold for reconstruction of articular cartilage

An osteochondral scaffold has a chondrogenic spiral scaffold in one end of an outer shell made of sintered microspheres, and an osteogenic spiral scaffold in the other end of the outer shell. Each spiral scaffold has nanofibers of a composition selected to promote attachment and proliferation of the desired types of cells. The nanofibers for the chondrogenic spiral scaffold have a different composition than the nanofibers for the osteogenic spiral scaffold. The nanofibers of each spiral scaffold are aligned to orient the attached cells so as to recreate the structure of the native tissue.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

Synergetic functionalized spiral-in-tubular bone scaffolds

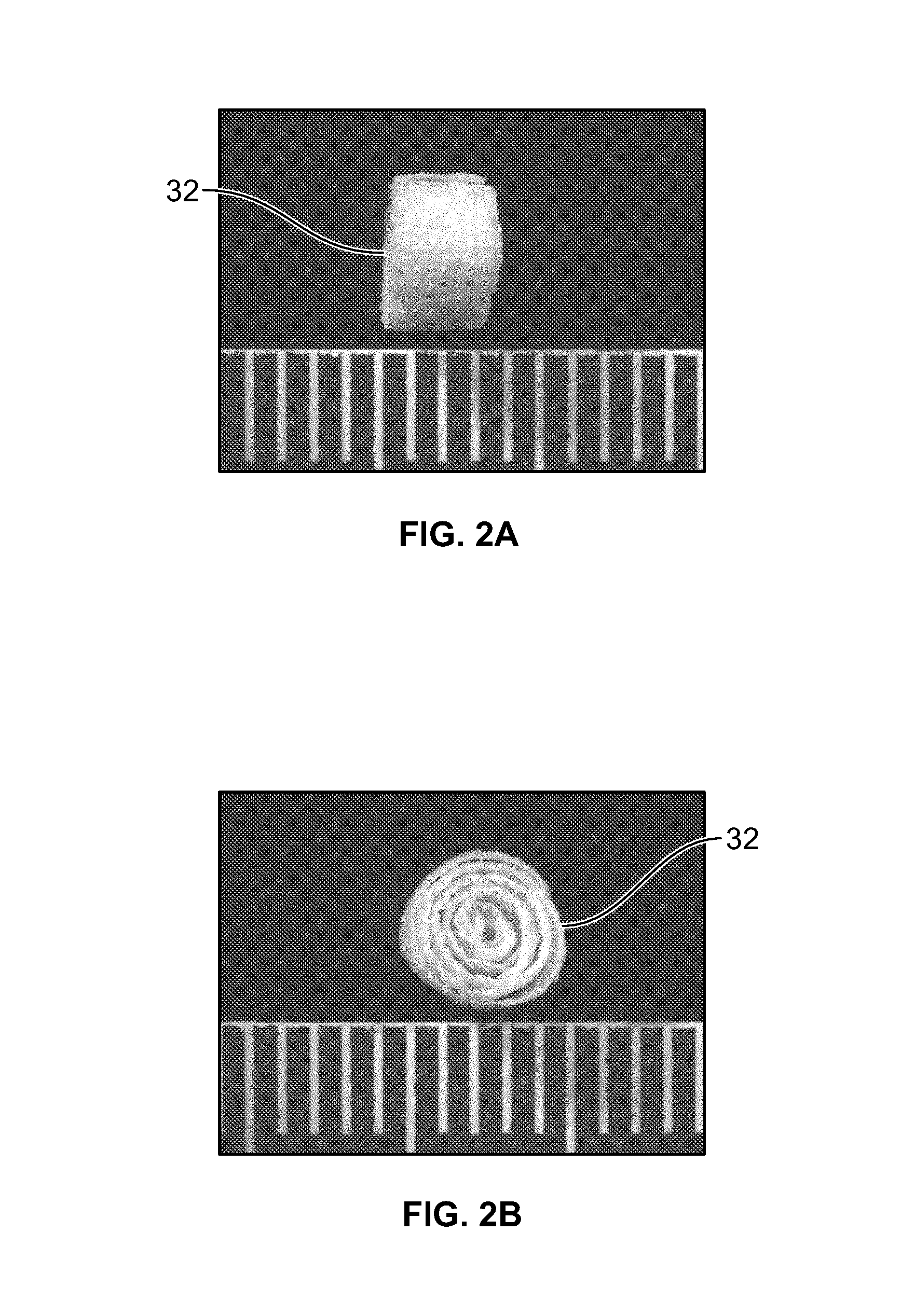

InactiveUS20100310623A1Increase the number ofIncrease alkaline phosphatase activityPeptide/protein ingredientsBone implantPorous sheetCell seeding

An integrated scaffold for bone tissue engineering has a tubular outer shell and a spiral scaffold made of a porous sheet. The spiral scaffold is formed such that the porous sheet defines a series of spiral coils with gaps of controlled width between the coils to provide an open geometry for enhanced cell growth. The spiral scaffold resides within the bore of the shell and is integrated with the shell to fix the geometry of the spiral scaffold. Nanofibers may be deposited on the porous sheet to enhance cell penetration into the spiral scaffold. The spiral scaffold may have alternating layers of polymer and ceramic on the porous sheet that have been built up using a layer-by-layer method. The spiral scaffold may be seeded with cells by growing a cell sheet and placing the cell sheet on the porous sheet before it is rolled.

Owner:UNIV OF CONNECTICUT

Medical device applications of nanostructured surfaces

InactiveUS20060204738A1Improve adhesionIncrease frictionBiocideMaterial nanotechnologyOsteoblastNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:GLO TECH LLC

Synthetically spun silk nanofibers and a process for making the same

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

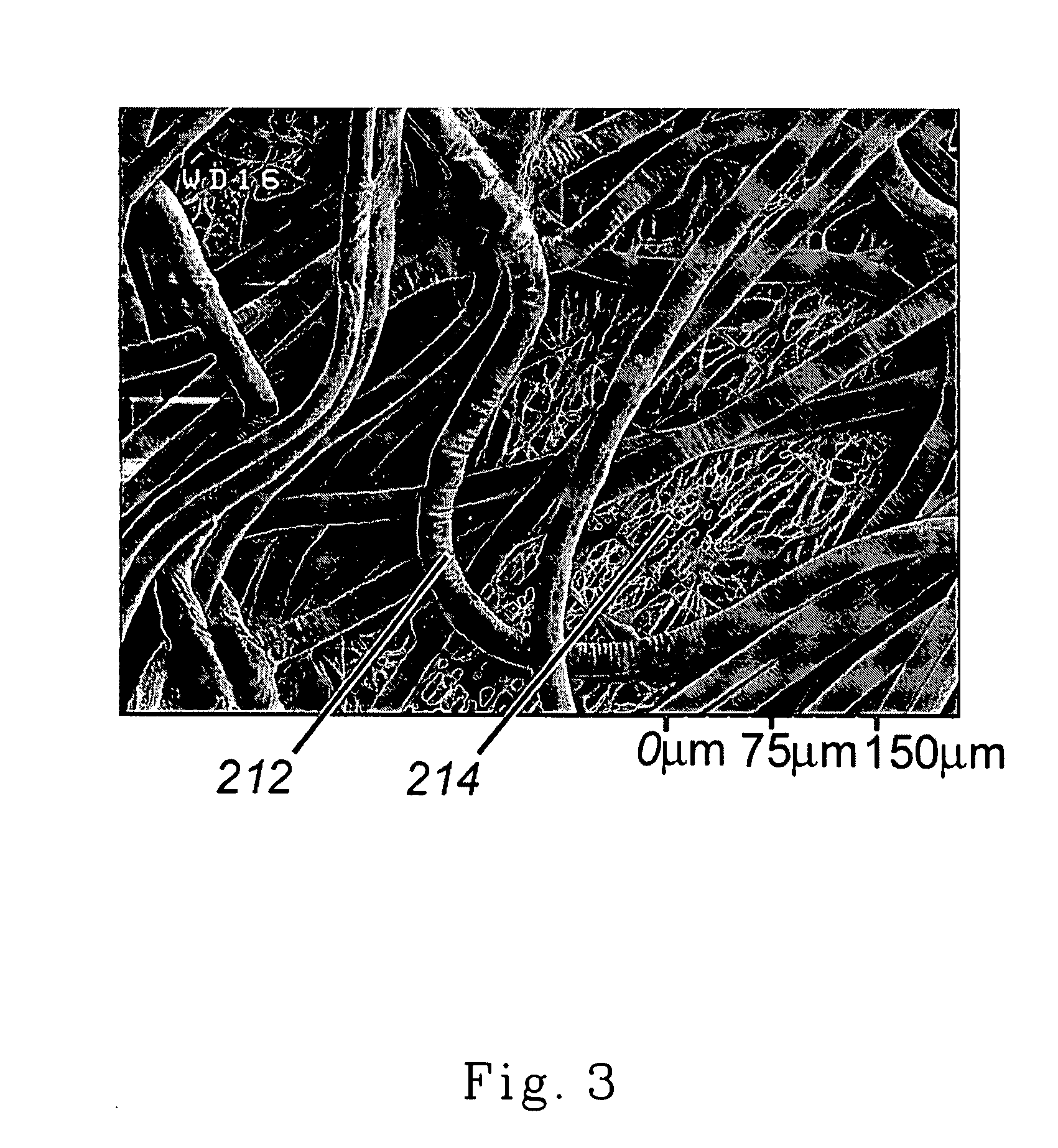

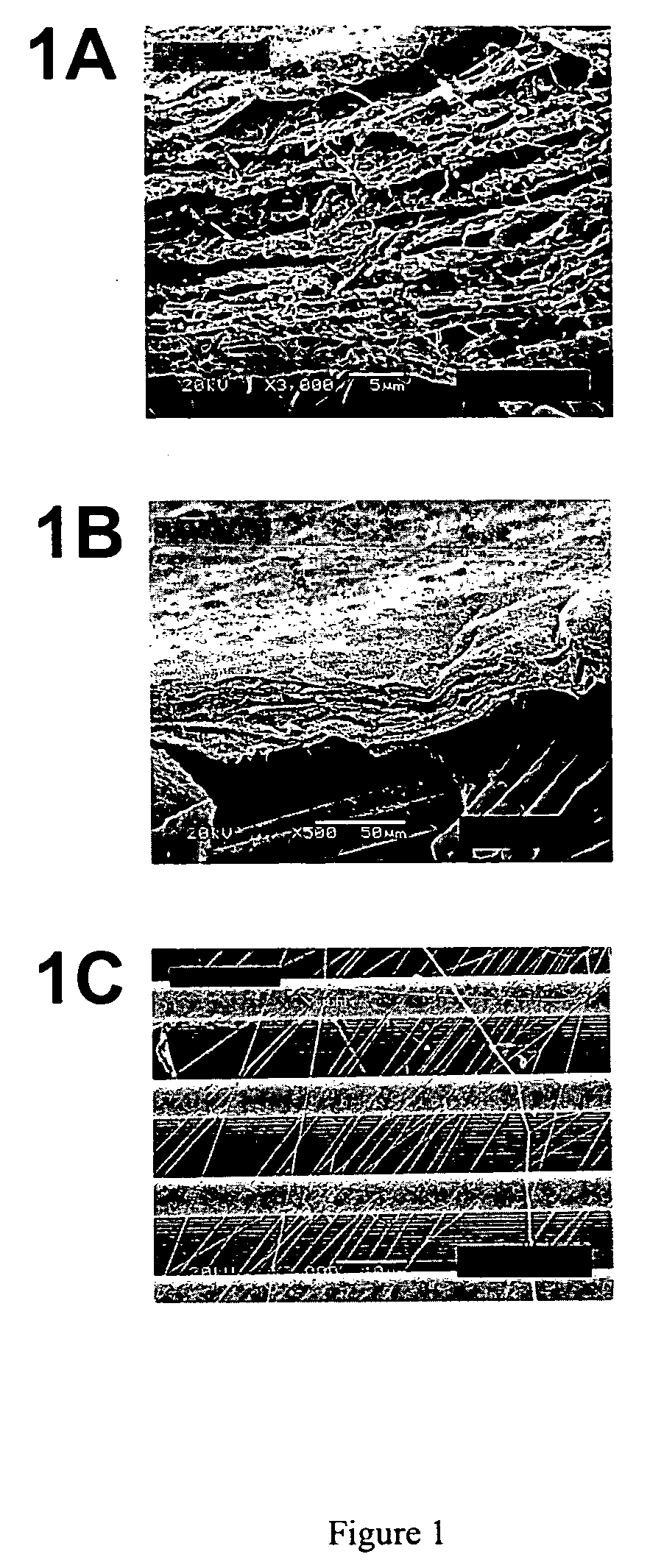

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

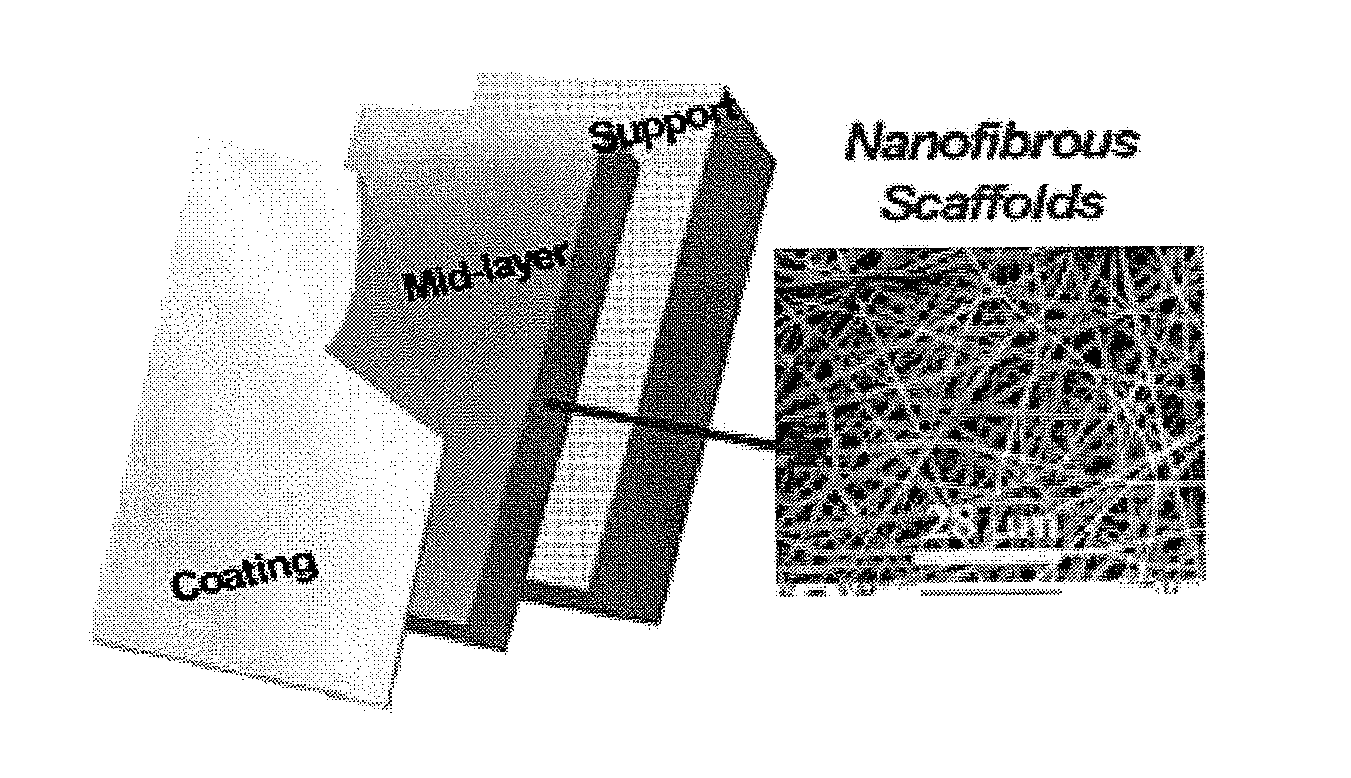

Articles Comprising a Fibrous Support

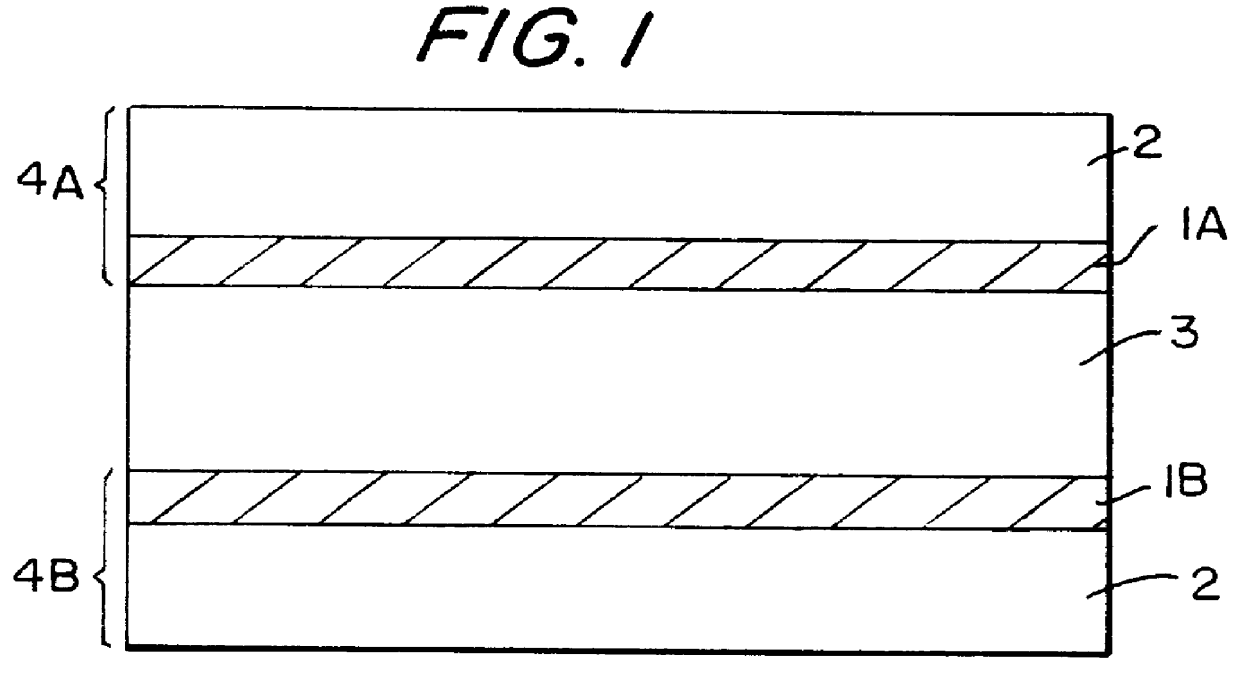

Articles comprising a fibrous support of nanofibers and an interfacially polymerized polymer layer disposed on a surface of the fibrous support are useful, e.g., as fluid separation membranes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

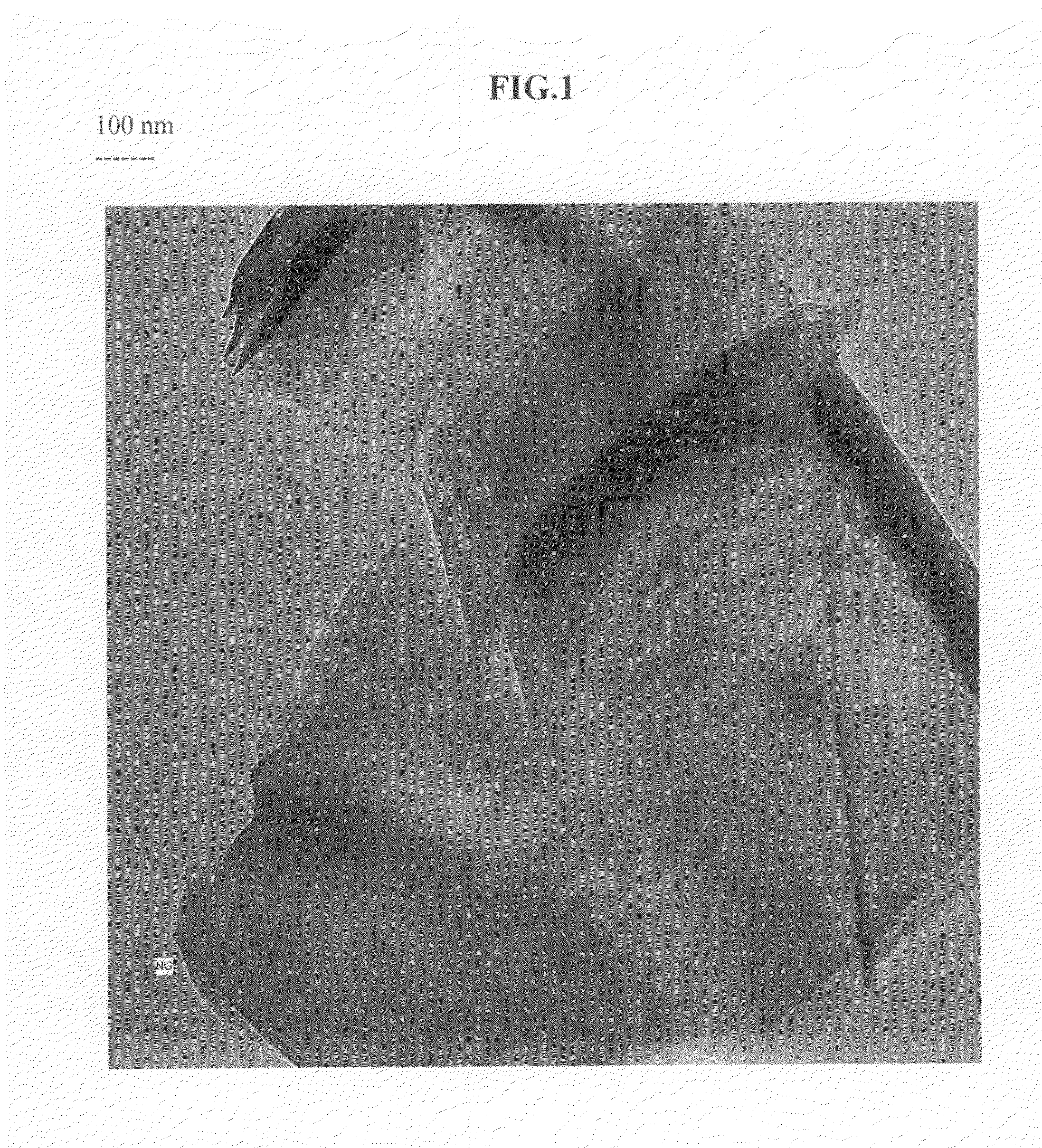

Graphitic nanofibers in electrochemical capacitors

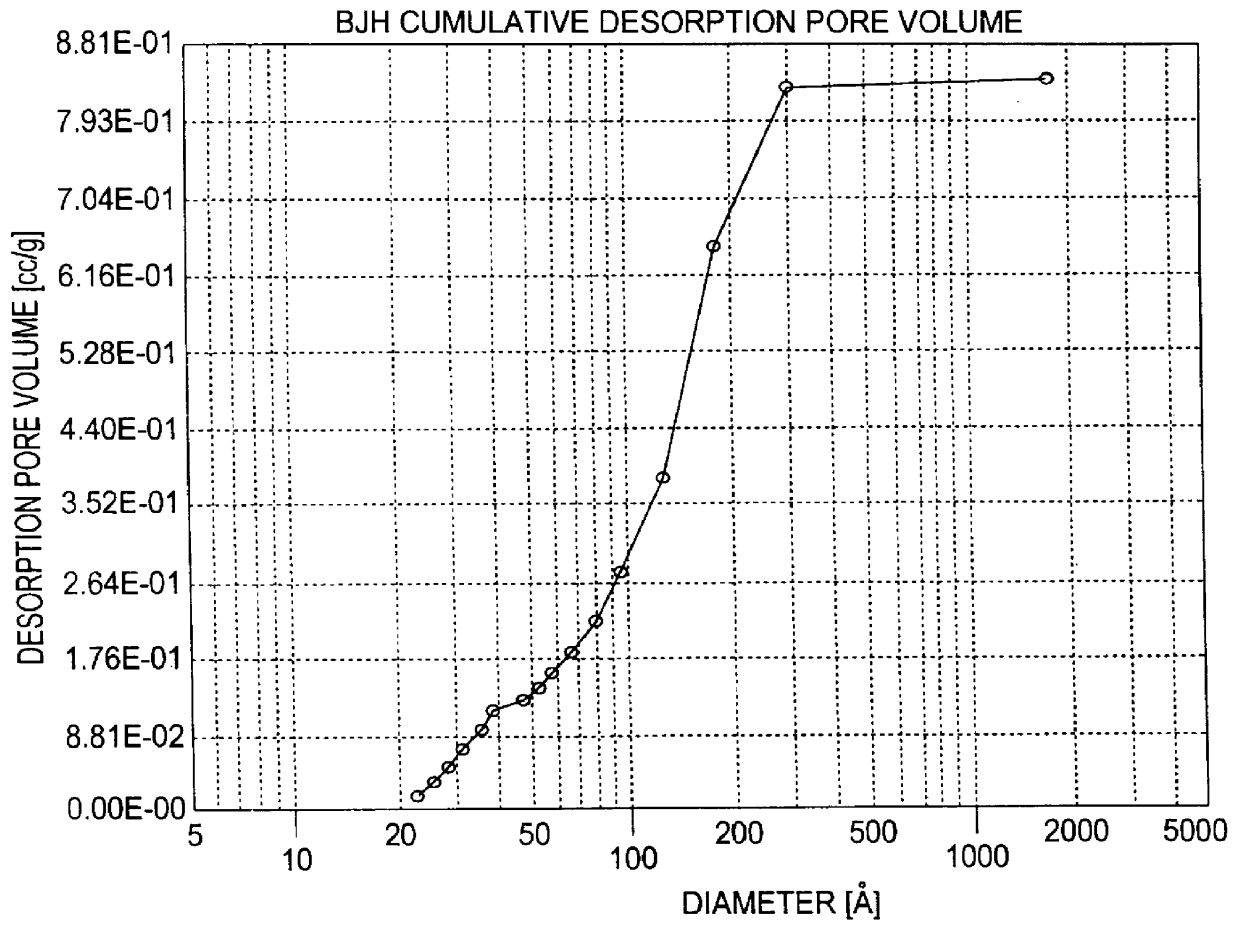

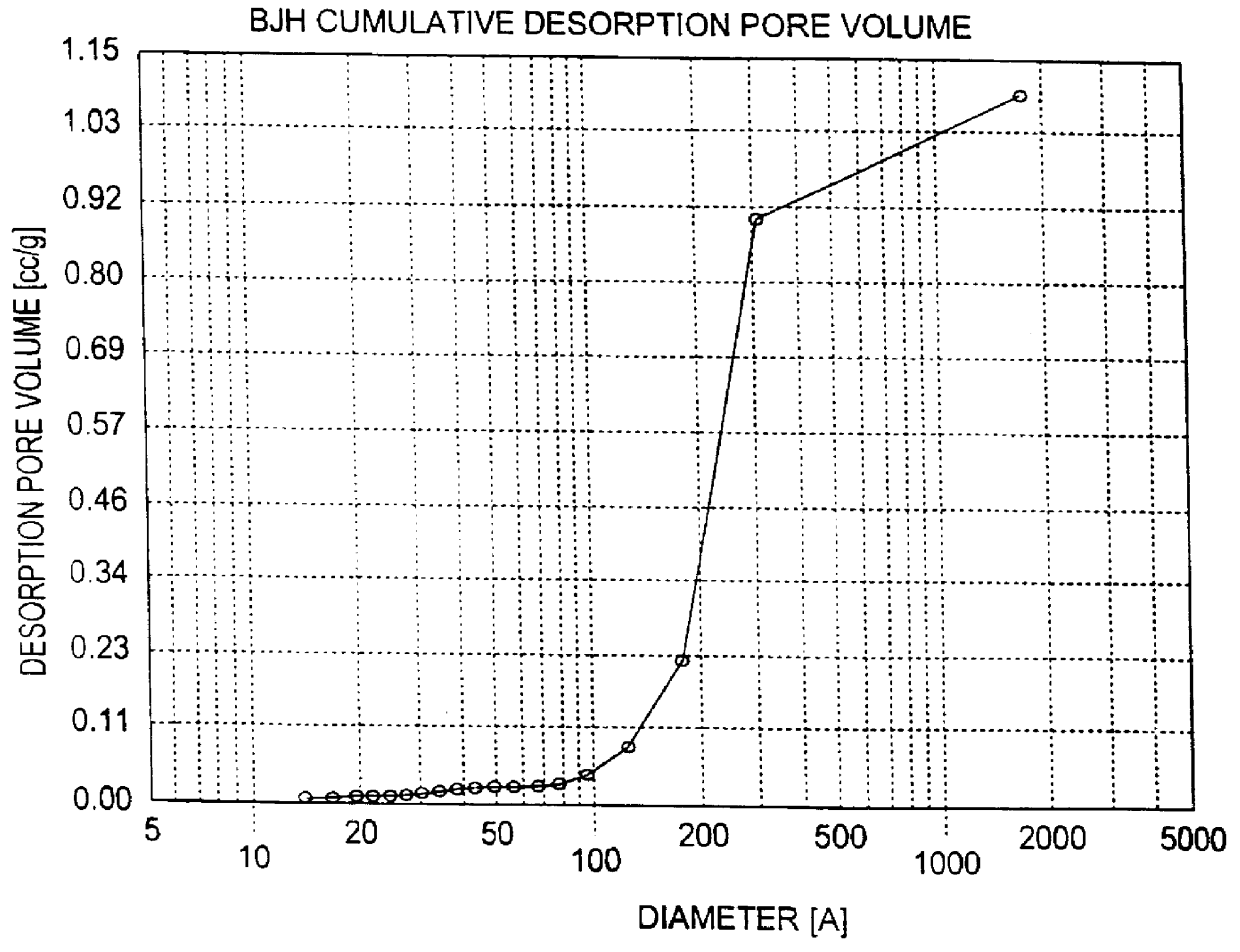

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors. Preferred nanofibers have a surface area greater than about 200 m2 / gm and are substantially free of micropores.

Owner:HYPERION CATALYSIS INT

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

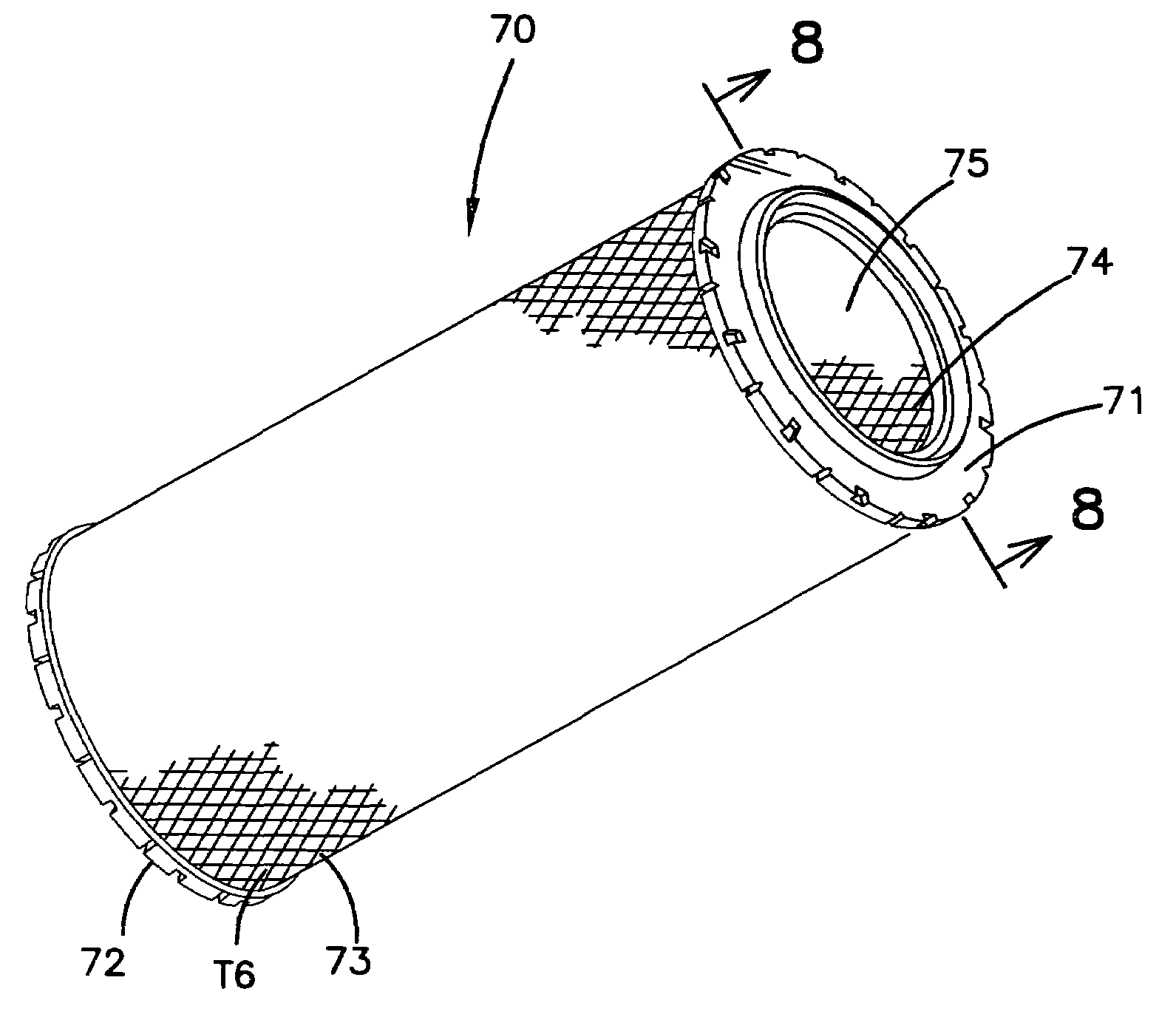

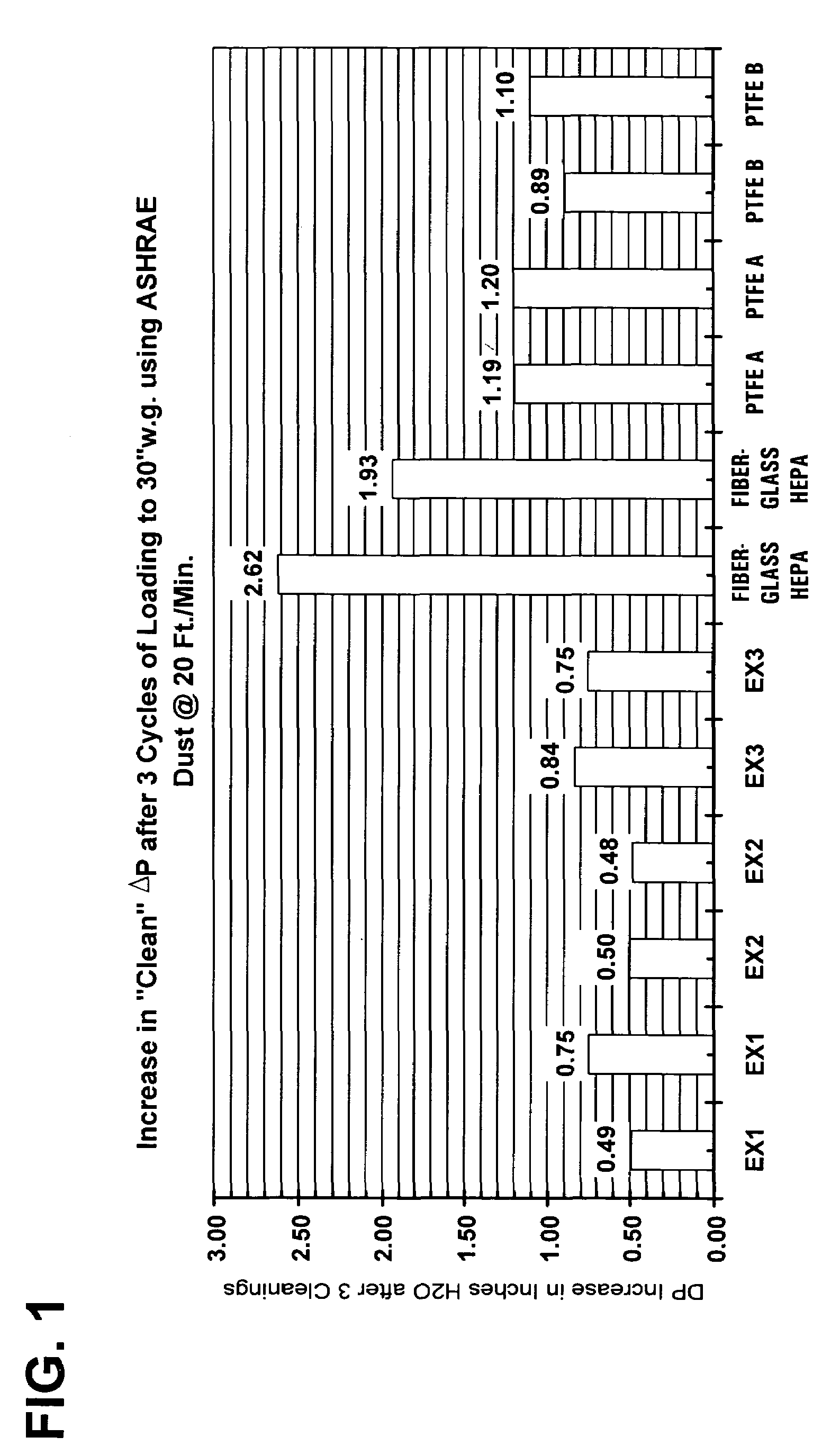

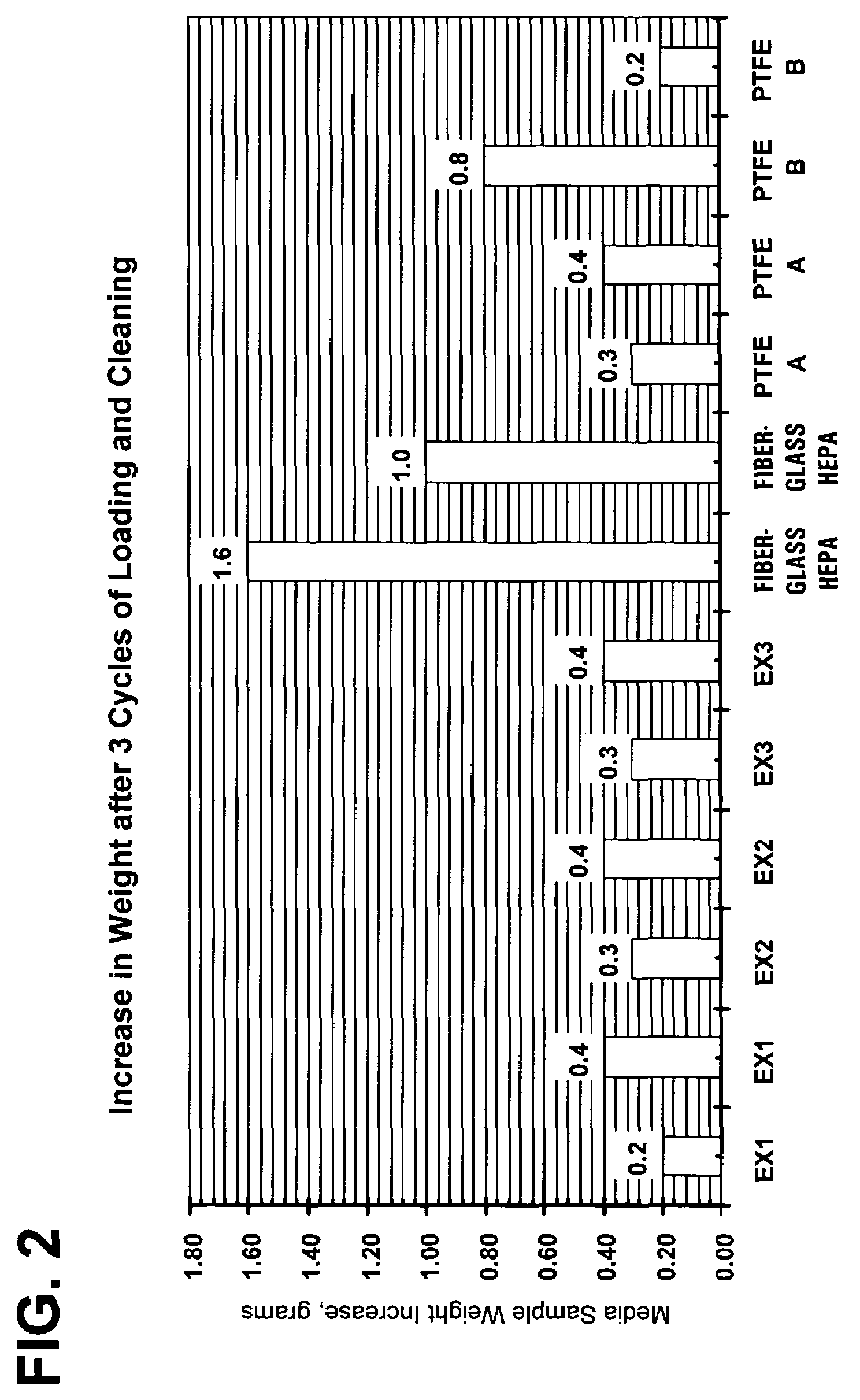

Cleanable high efficiency filter media structure and applications for use

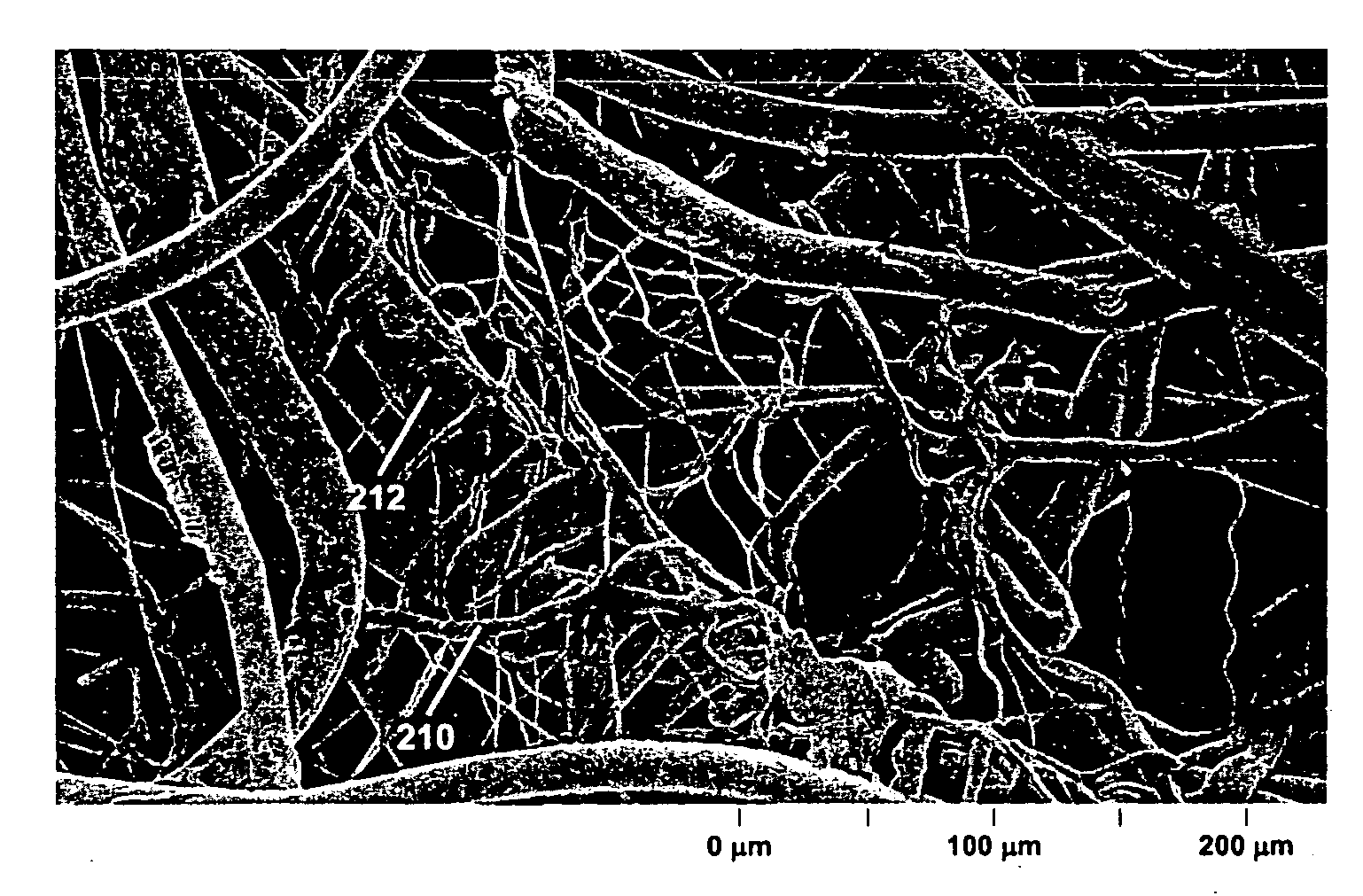

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

Medical device applications of nanostructured surfaces

InactiveUS20050221072A1Fine surfacePrevent/reduce bio-foulingNanomedicinePharmaceutical delivery mechanismMedicineOsteoblast

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:NANOSYS INC

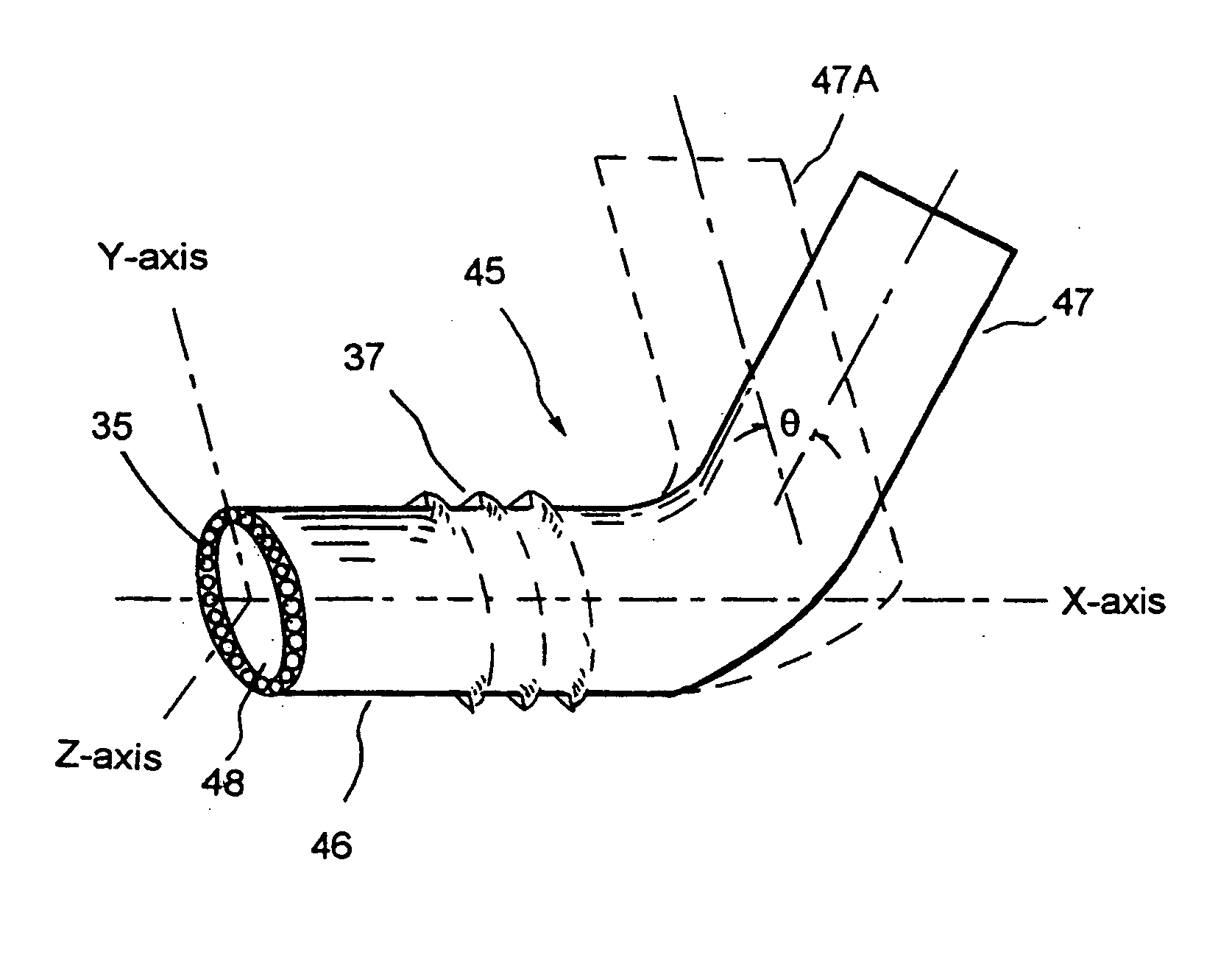

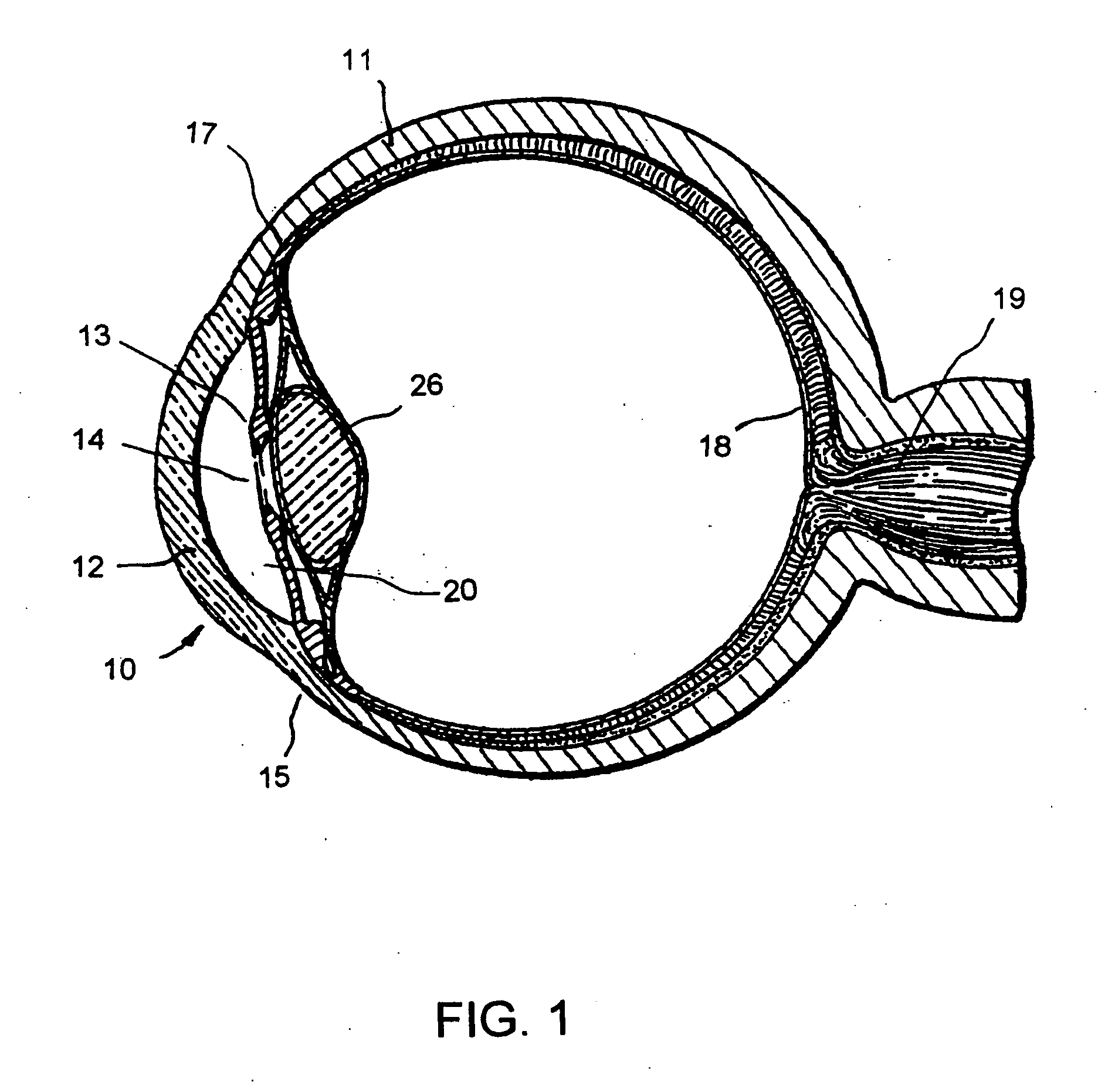

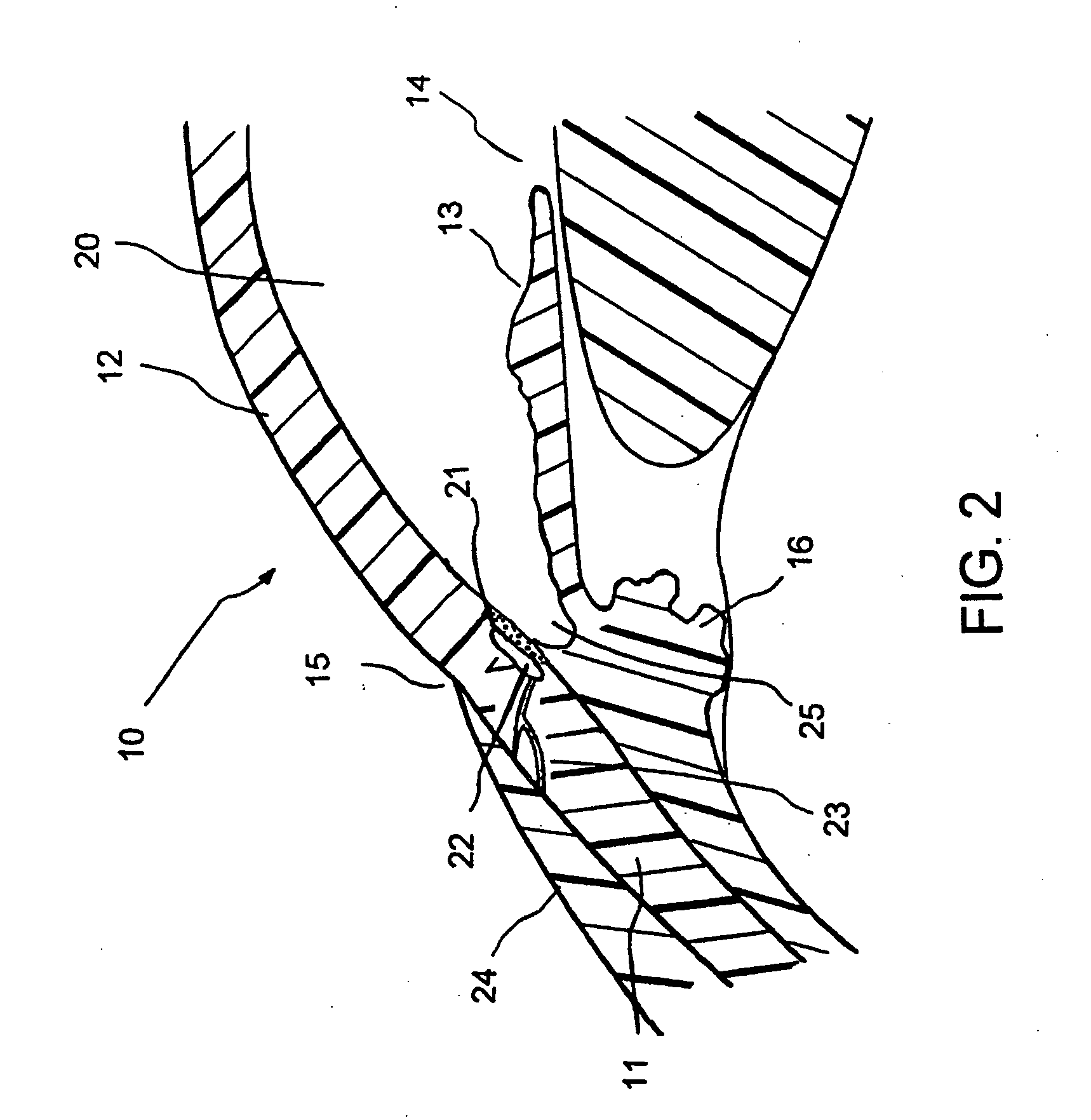

Ophthalmology implants and methods of manufacture

The present disclosure provides an ophthalmology implant and methods for treating glaucoma or optic neural transmission deficiency, wherein at least a portion of the implant is made of or includes a nanometer-sized substance, such as nanotubes, nanofibers, sheets from nanotubes, nanowires, nanofibrous mesh and the like.

Owner:GLAUKOS CORP

Stretchable outer cover for an absorbent article and process for making the same

A stretchable outer cover for use with an absorbent article including an elastomeric film. The elastomeric film includes at least one skin layer that is less tacky than at least one core layer. The outer cover can include a nonwoven layer different structural combinations of spunbond fibers, meltblown fibers, and / or nanofibers. The combination of plastic and elastic components results in an outer cover that has favorable mechanical, physical, and aesthetic properties. The outer cover can be rendered either uniaxially or biaxially stretchable via a mechanical activation process.

Owner:THE PROCTER & GAMBLE COMPANY

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

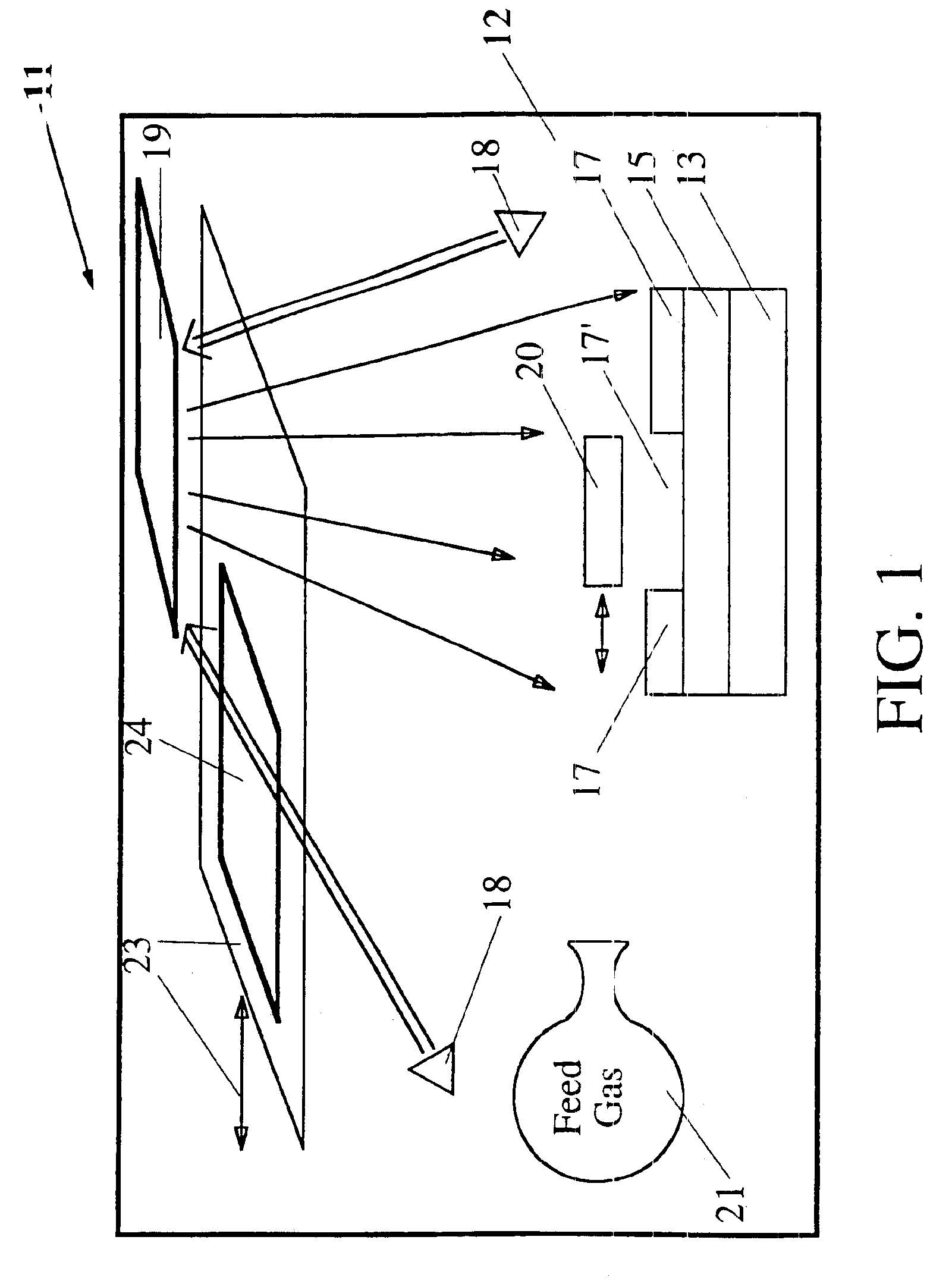

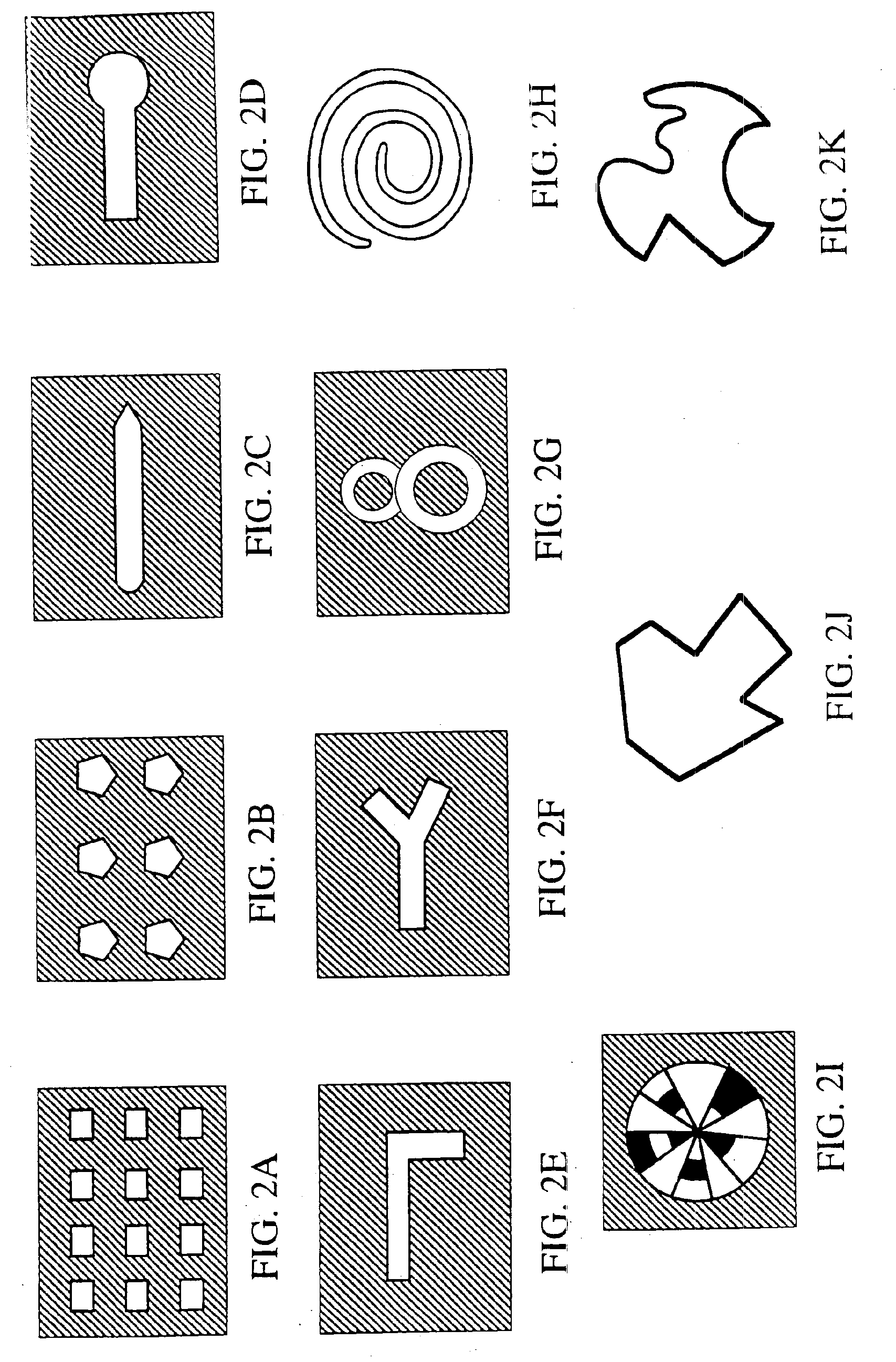

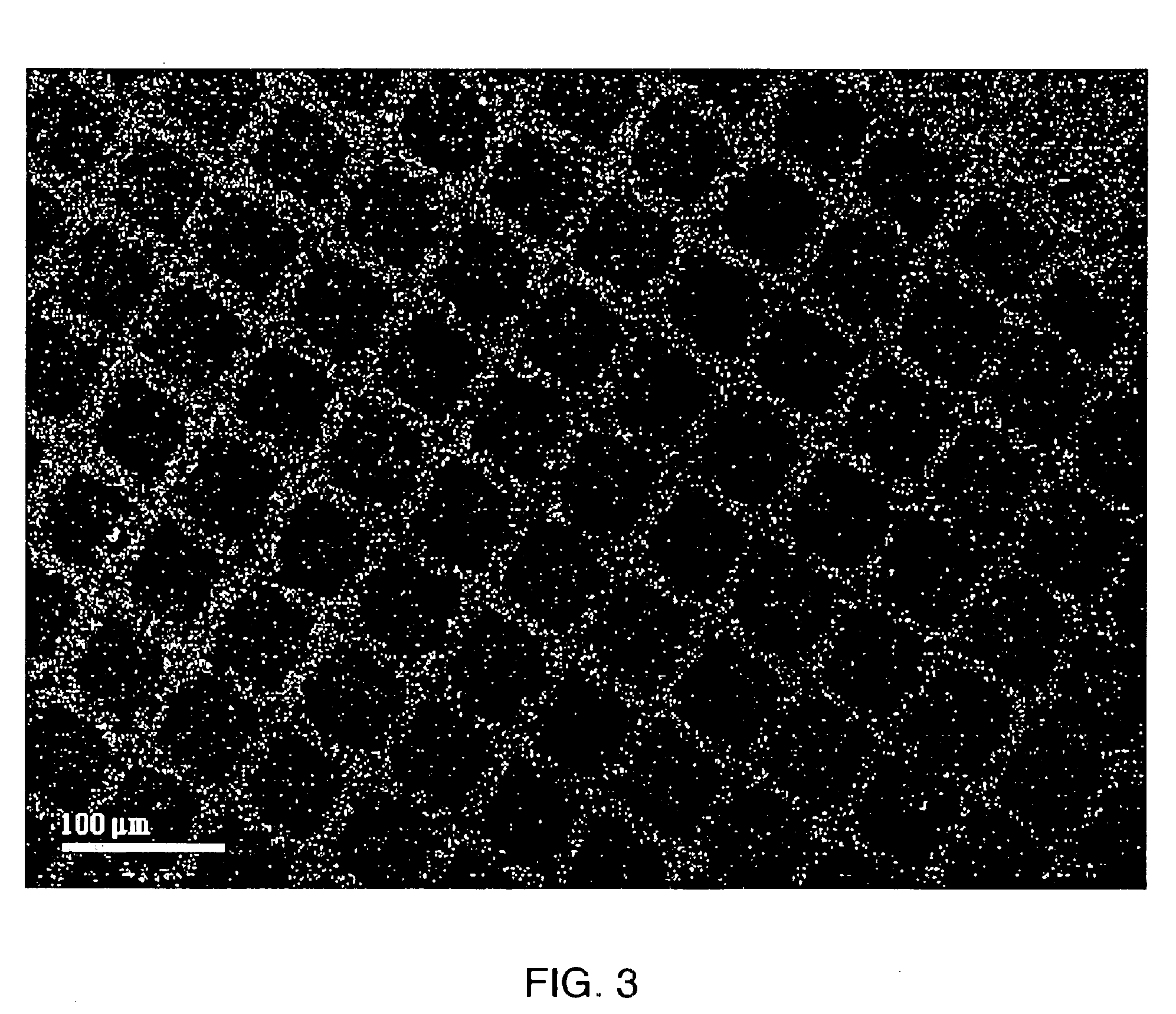

Controlled patterning and growth of single wall and multi-wall carbon nanotubes

Method and system for producing a selected pattern or array of at least one of a single wall nanotube and / or a multi-wall nanotube containing primarily carbon. A substrate is coated with a first layer (optional) of a first selected metal (e.g., Al and / or Ir) and with a second layer of a catalyst (e.g., Fe, Co, Ni and / or Mo), having selected first and second layer thicknesses provided by ion sputtering, arc discharge, laser ablation, evaporation or CVD. The first layer and / or the second layer may be formed in a desired non-uniform pattern, using a mask with suitable aperture(s), to promote growth of carbon nanotubes in a corresponding pattern. A selected heated feed gas (primarily CH4 or C2Hn with n=2 and / or 4) is passed over the coated substrate and forms primarily single wall nanotubes or multiple wall nanotubes, depending upon the selected feed gas and its temperature. Nanofibers, as well as single wall and multi-wall nanotubes, are produced using plasma-aided growth from the second (catalyst) layer. An overcoating of a selected metal or alloy can be deposited, over the second layer, to provide a coating for the carbon nanotubes grown in this manner.

Owner:NASA +1

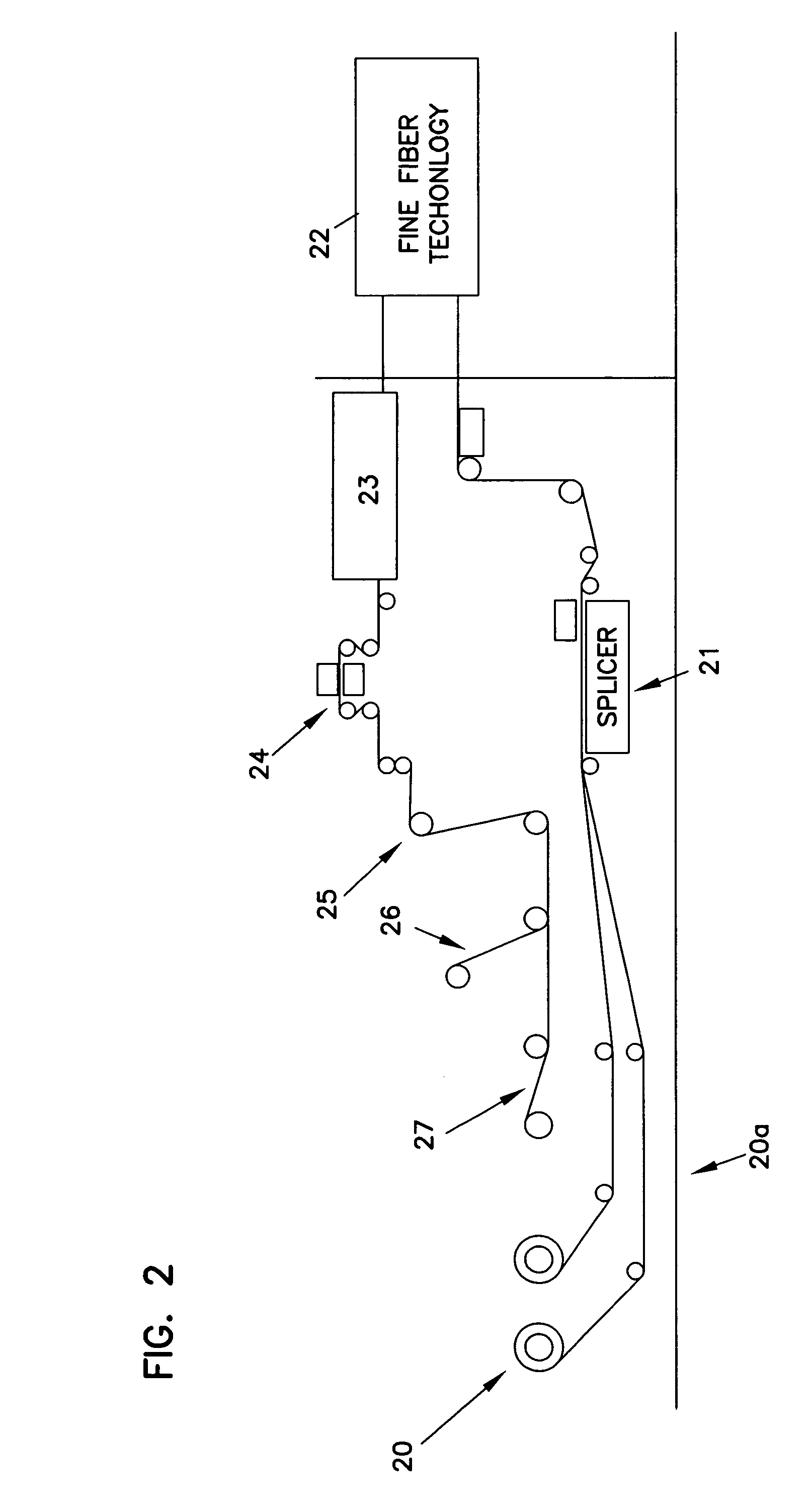

Process if making fine fiber material

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Biaxially stretchable outer cover for an absorbent article

ActiveUS20070287348A1Improve versatilityImprove fitPersonal careSynthetic resin layered productsFiberElastic component

An outer cover for use with an absorbent article having a layer of nonwoven fibrous material and optionally including a polymeric layer laminated or printed onto the layer of nonwoven fibrous material. The outer cover includes at least one plastic component and at least one elastic component in the nonwoven fibrous material and / or optional polymeric layer. The outer cover can have different structural combinations of spunbond fibers, meltblown fibers, and / or nanofibers. The combination of plastic and elastic components results in an outer cover that has favorable mechanical, physical, and aesthetic properties. The outer cover can be rendered either uniaxially or biaxially stretchable via a mechanical activation process.

Owner:THE PROCTER & GAMBLE COMPANY

Medical Device Applications of Nanostructured Surfaces

ActiveUS20070282247A1Increase heightPrevent/reduce bio-foulingNanotechElectrotherapyMedicineNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, a method of administering a composition to a patient is disclosed which comprises providing a composition-eluting device, said composition-eluting device comprising at least a first surface and a plurality of nanostructures attached to the first surface, and introducing the composition-eluting device into the body of the patient.

Owner:RGT UNIV OF CALIFORNIA +1

Nanofibrillar structure and applications including cell and tissue culture

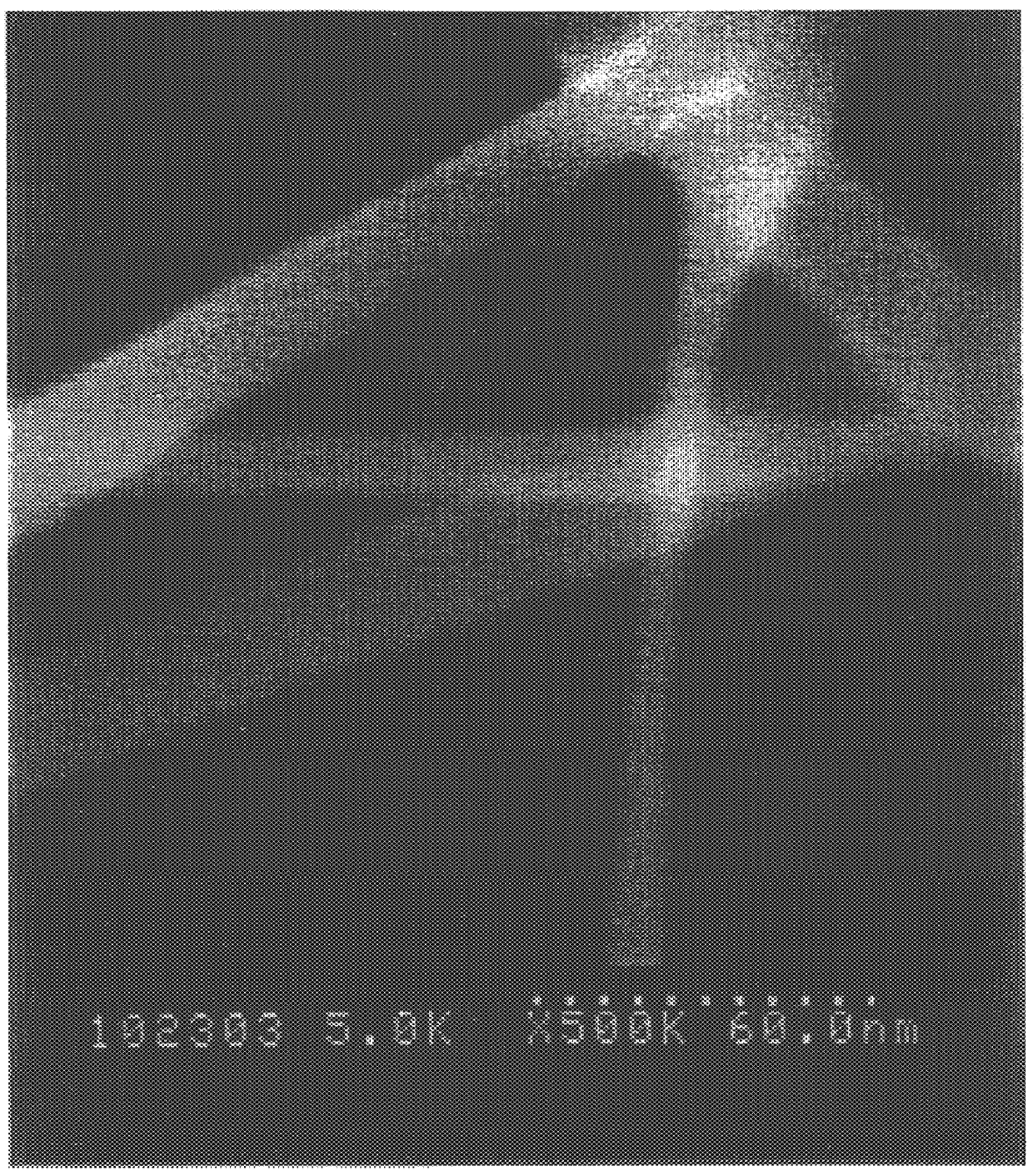

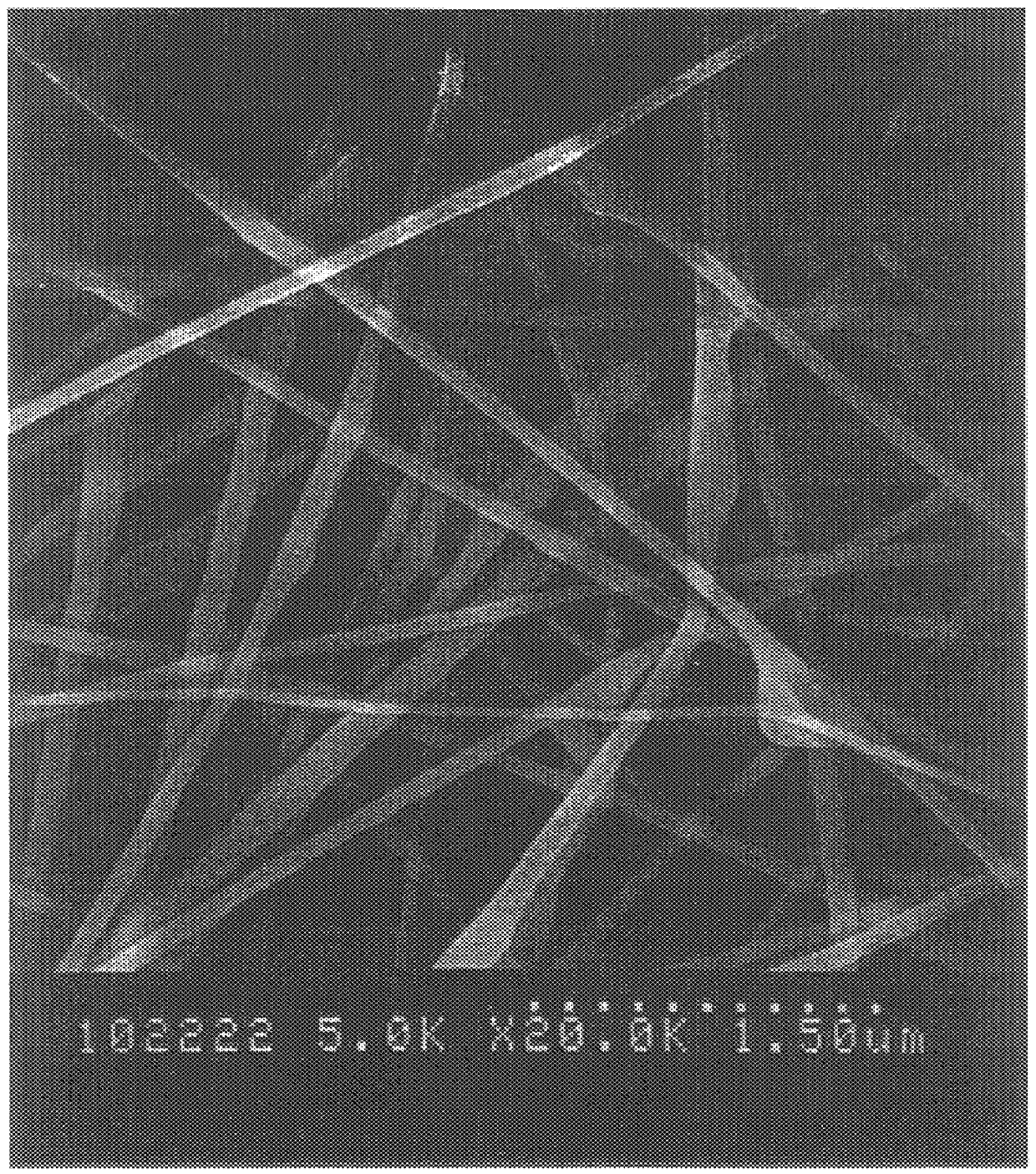

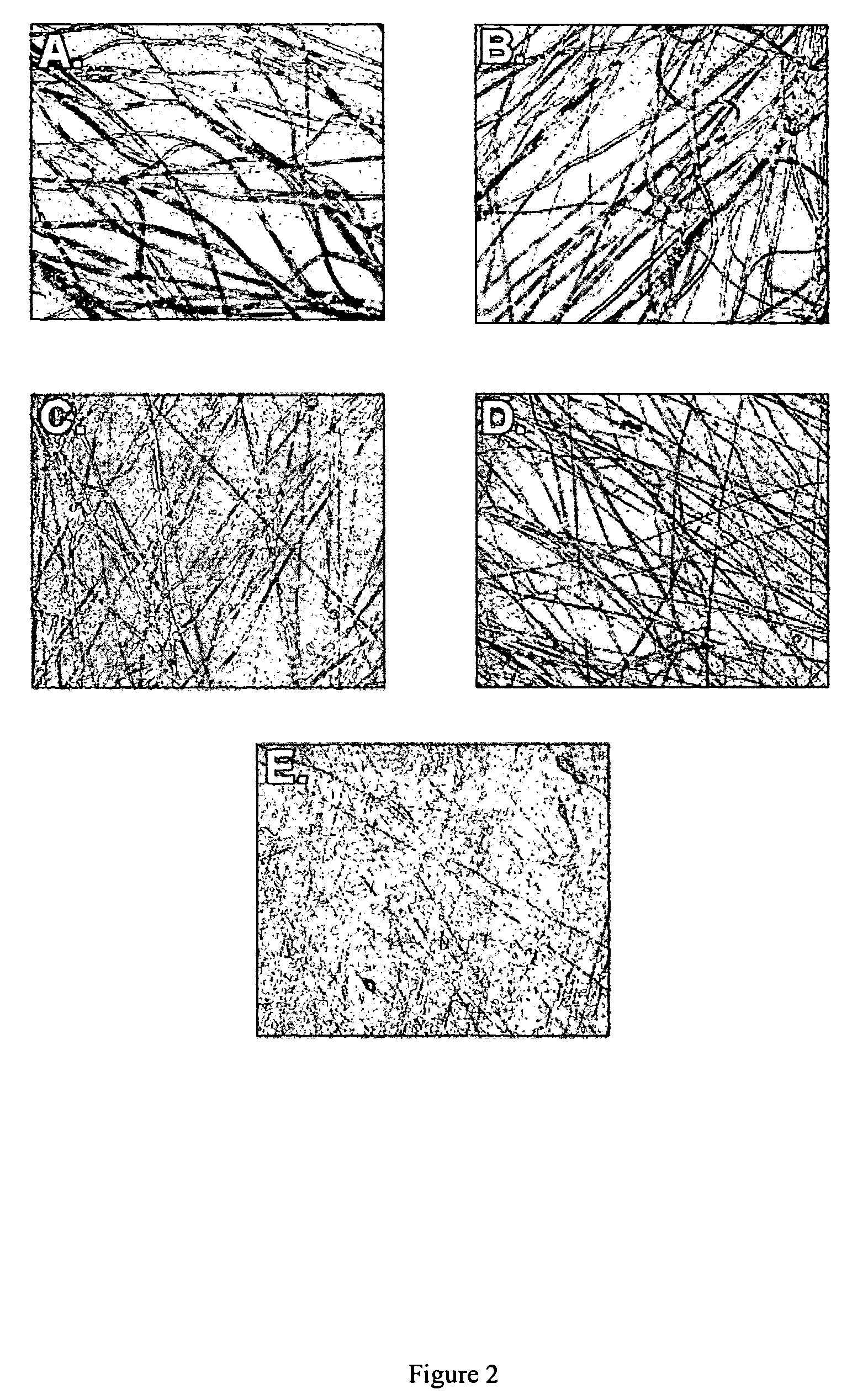

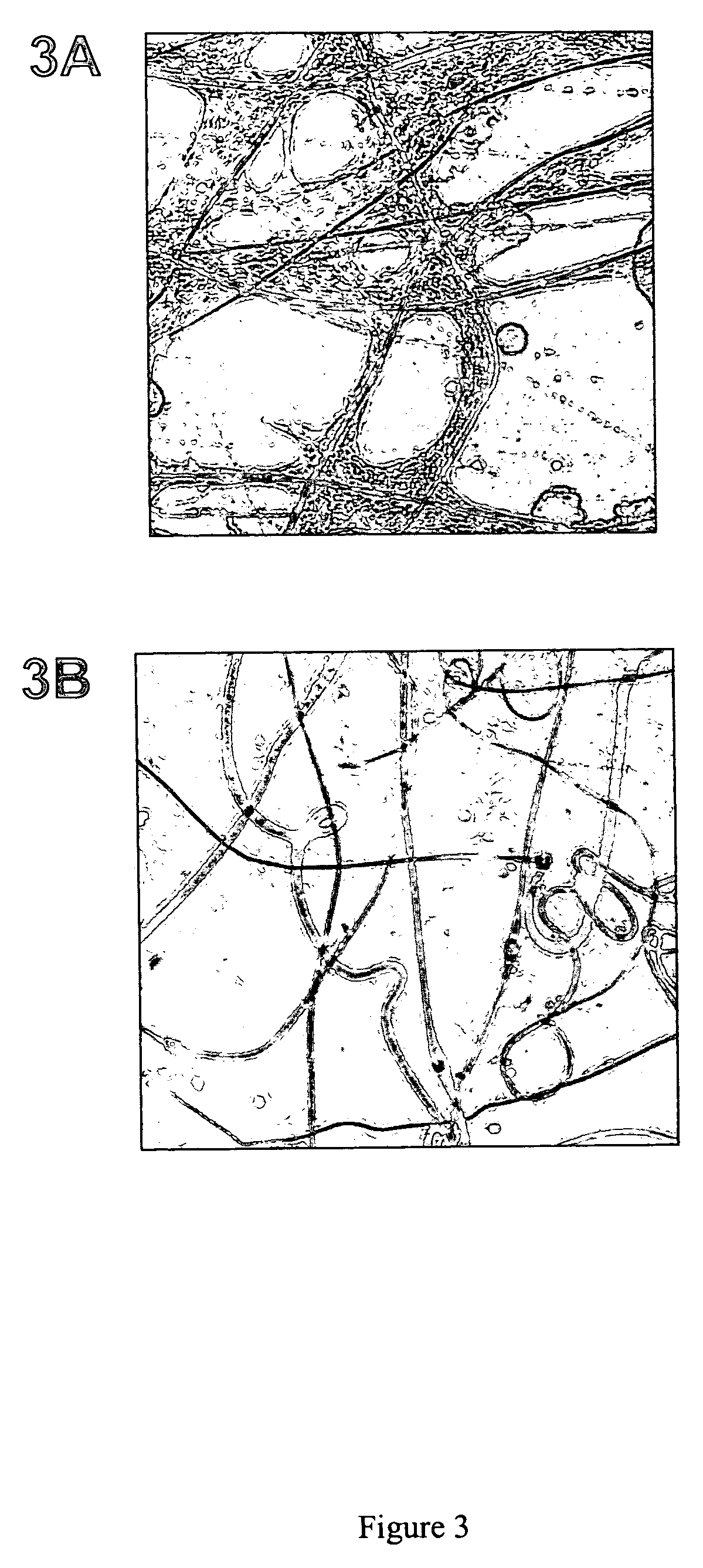

ActiveUS20050095695A1Reduce usageBioreactor/fermenter combinationsNanostructure manufactureLipid formationNanofiber

A nanofibrillar structure for cell culture and tissue engineering is disclosed. The nanofibrillar structure can be used in a variety of applications including methods for proliferating and / or differentiating cells and manufacturing a tissue. Also disclosed is an improved nanofiber comprising a lipid, lipophilic molecule, or chemically modified surface. The nanofibers can be used in a variety of applications including the formation of nanofibrillar structures for cell culture and tissue engineering.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

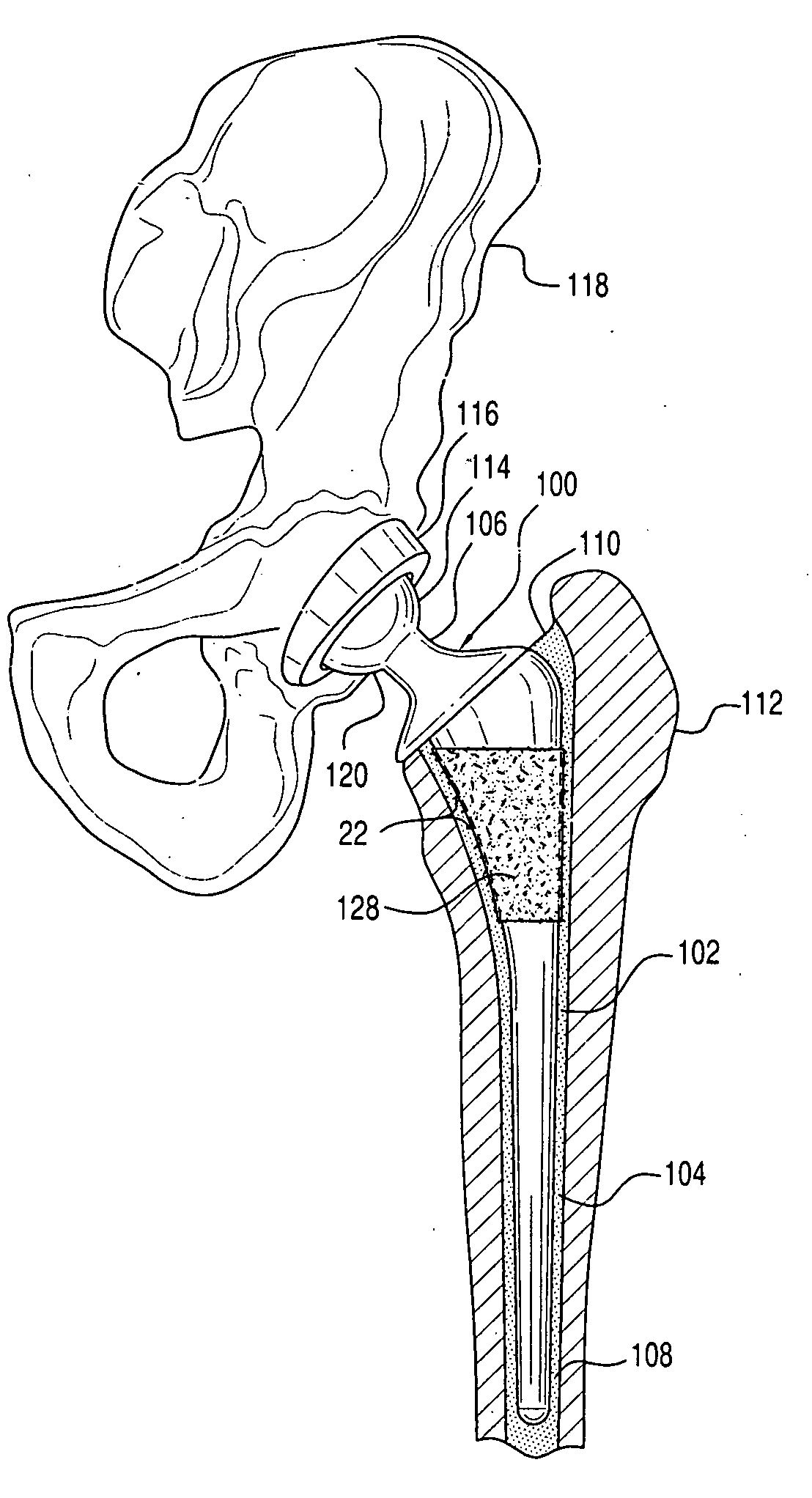

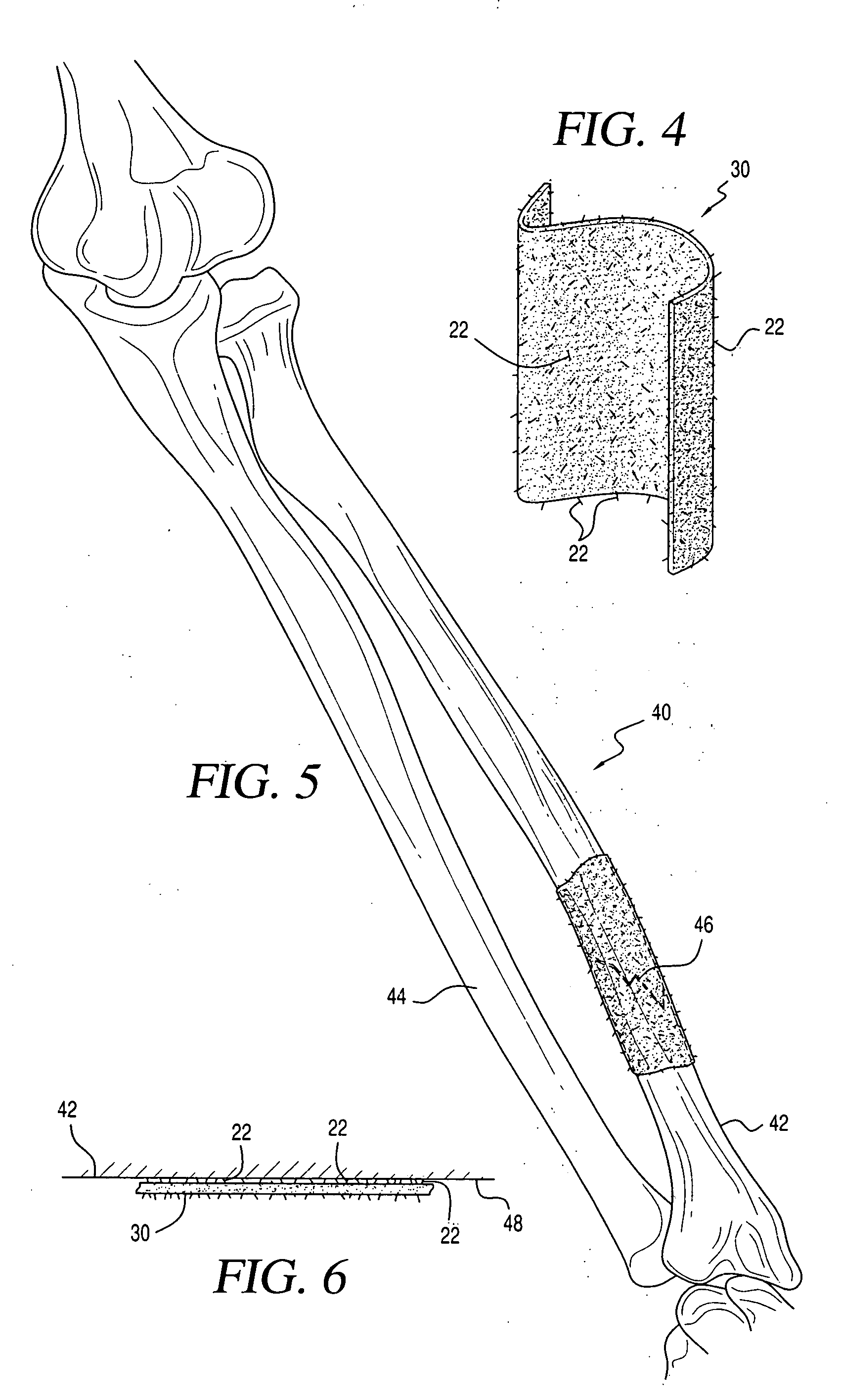

Bone graft composition, method and implant

ActiveUS20070142916A1Simple compositionHigh mechanical strengthMaterial nanotechnologyBone implantFiberNanofiber

A bone regenerative composition includes a resorbable osteoconductive matrix and a multiplicity of substantially rigid nanofibers dispersed within structure of the matrix to impart structural integrity with nanofiber ends projecting out of a surface of the matrix to provide differential load bearing surface bristles.

Owner:WARSAW ORTHOPEDIC INC

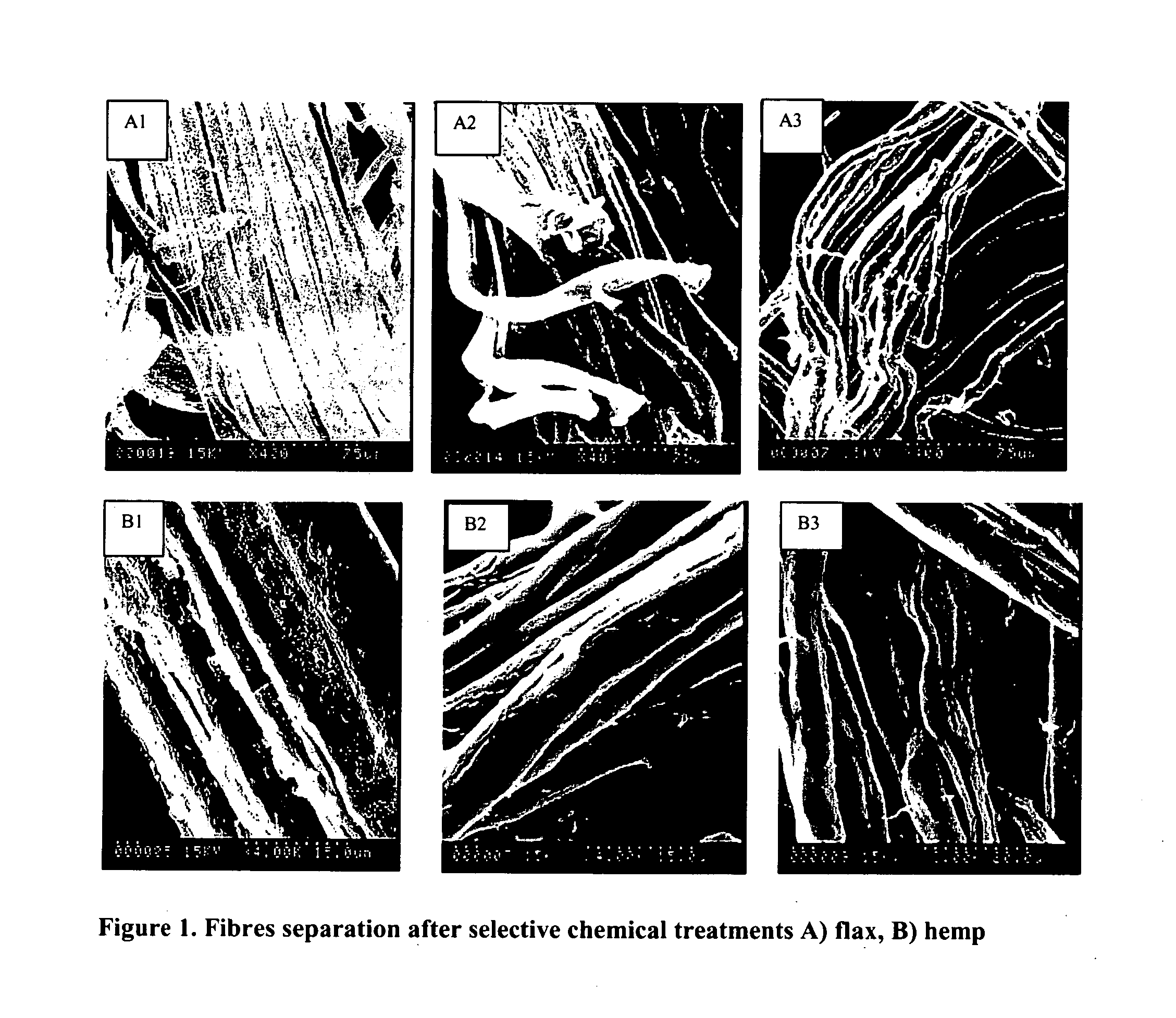

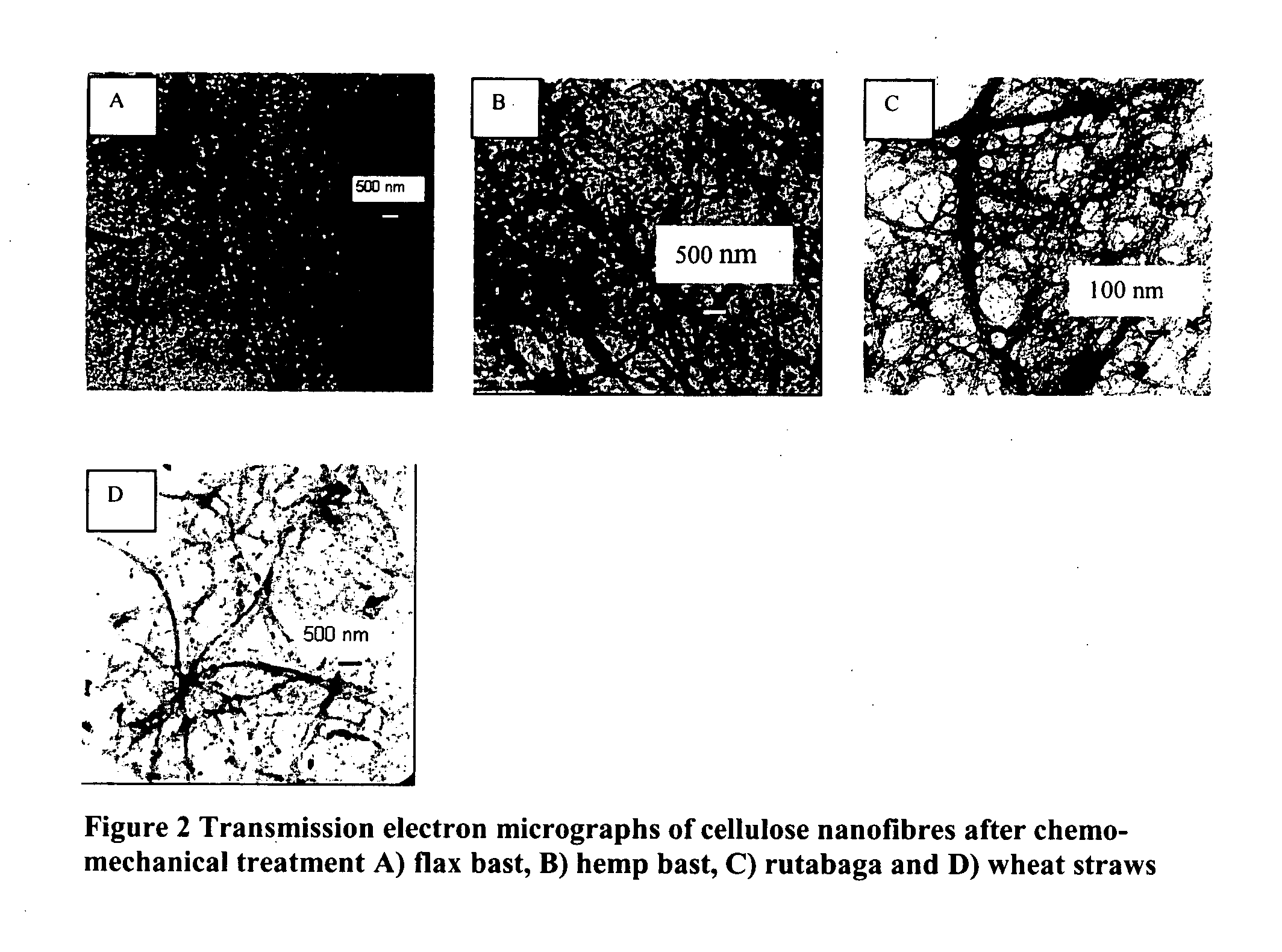

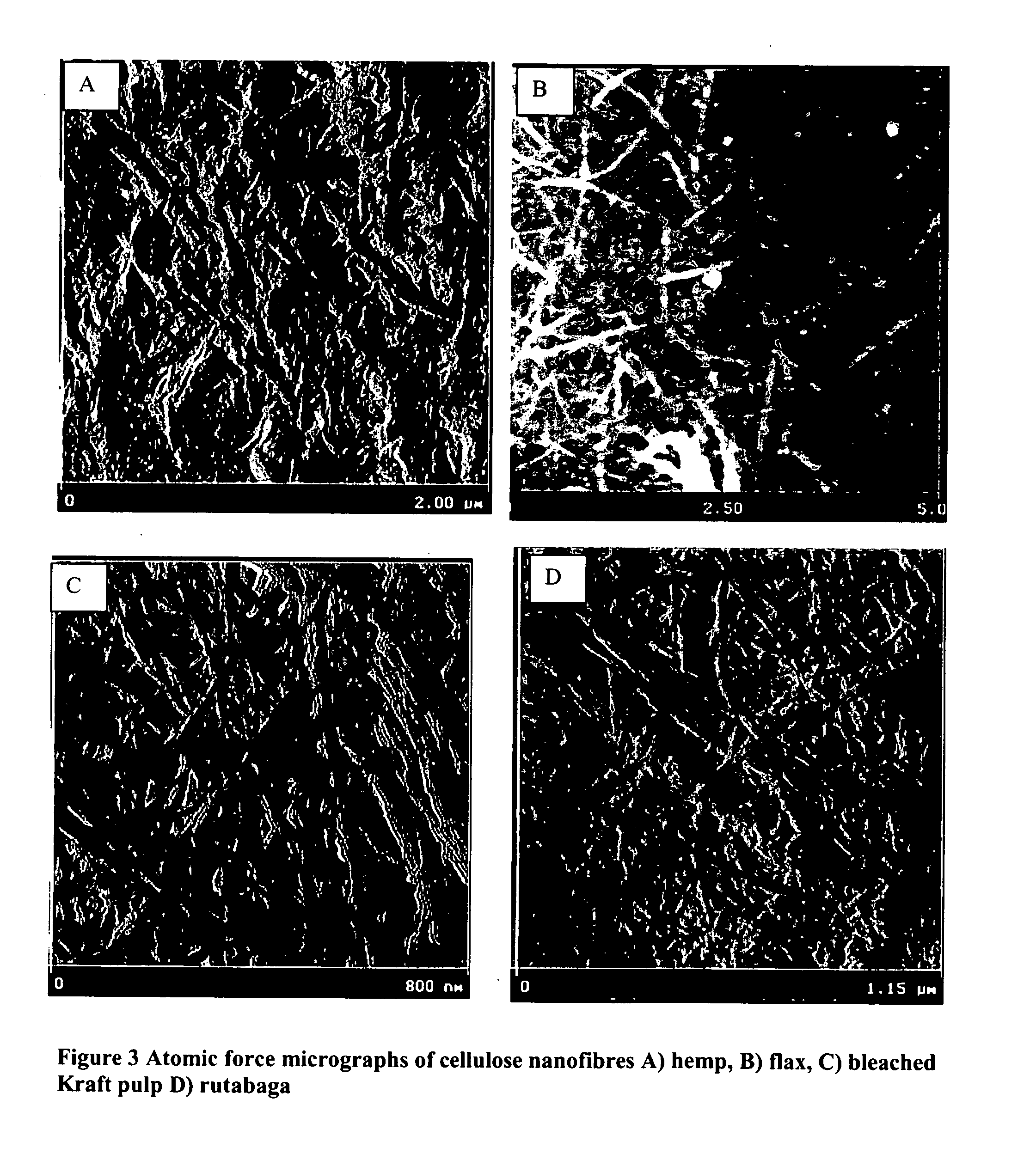

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

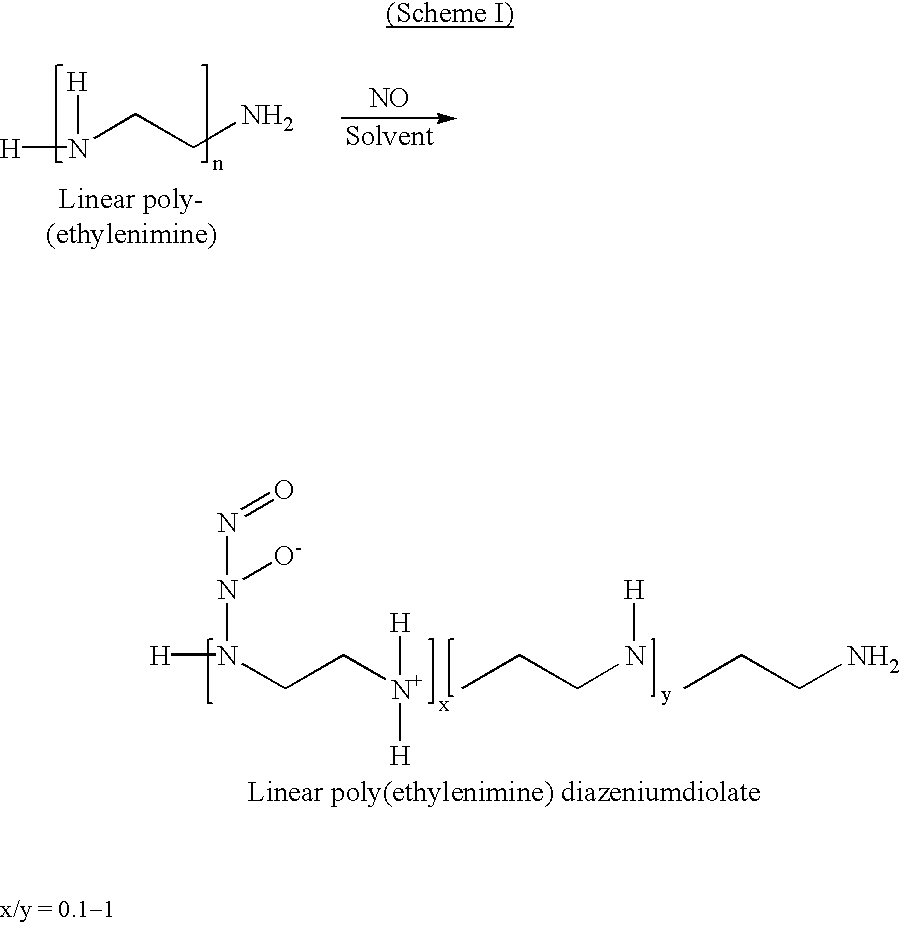

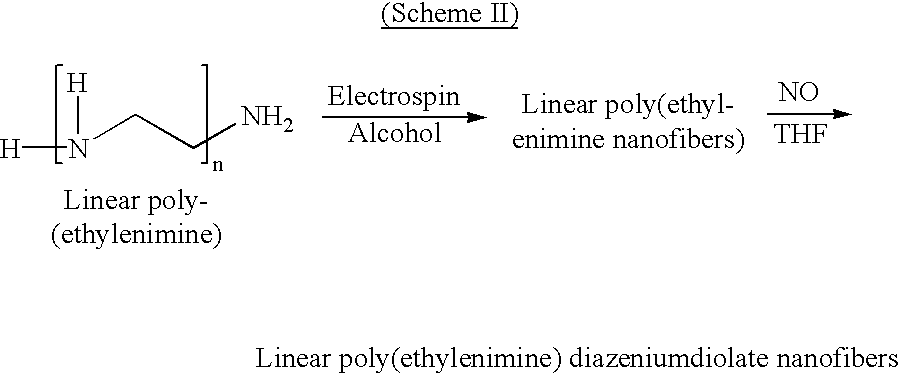

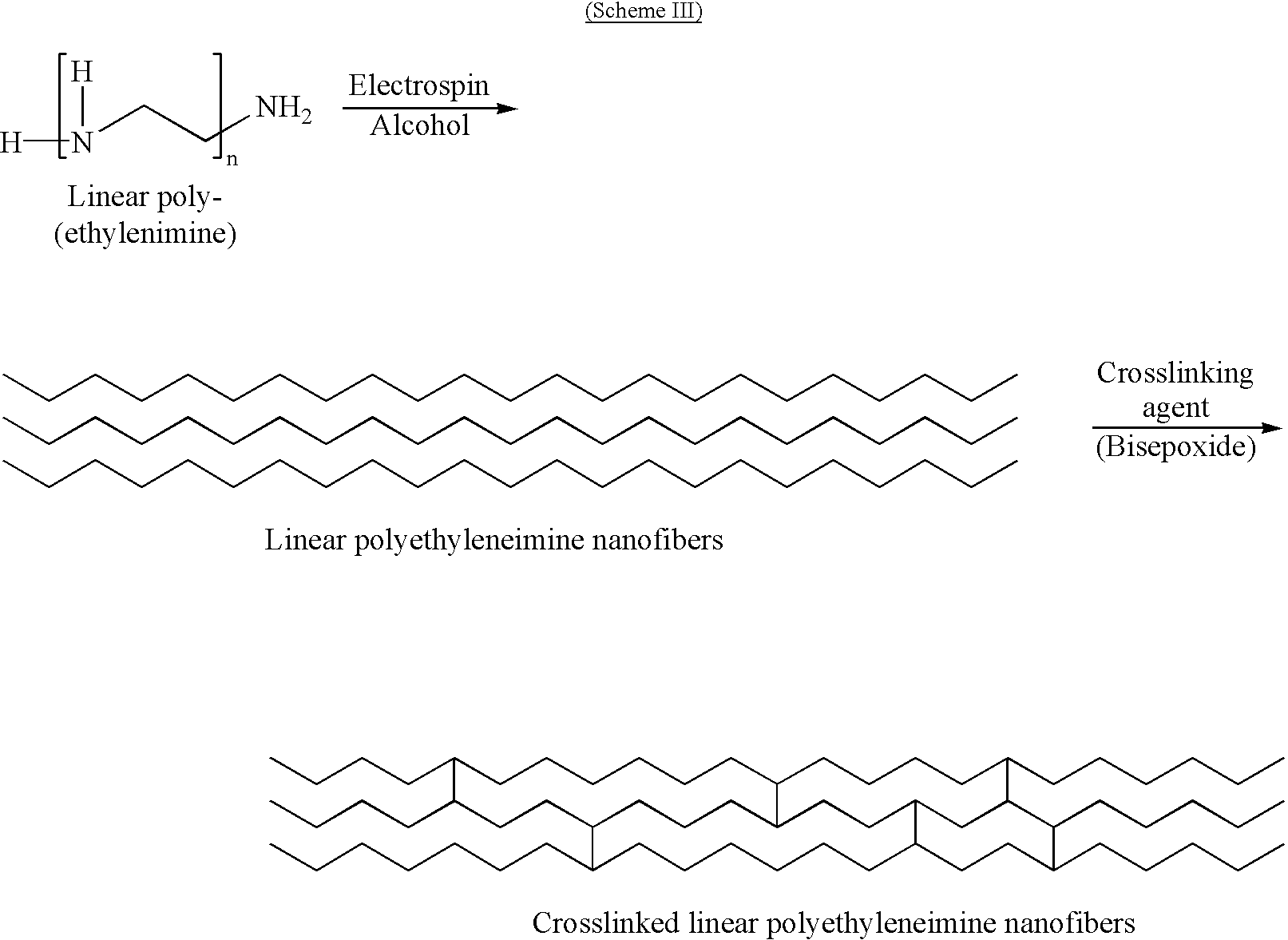

Nitric oxide-modified linear poly(ethylenimine) fibers and uses thereof

A novel coating for medical devices provides nitric oxide delivery using nanofibers of linear poly(ethylenimine)diazeniumdiolate. Linear poly(ethylenimine)diazeniumdiolate releases nitric oxide (NO) in a controlled manner to tissues and organs to aid the healing process and to prevent injury to tissues at risk of injury. Electrospun nano-fibers of linear poly(ethylenimine) diazeniumdiolate deliver therapeutic levels of NO to the tissues surrounding a medical device while minimizing the alteration of the properties of the device. A nanofiber coating, because of the small size and large surface area per unit mass of the nanofibers, provides a much larger surface area per unit mass while minimizing changes in other properties of the device.

Owner:AKRON THE UNIV OF

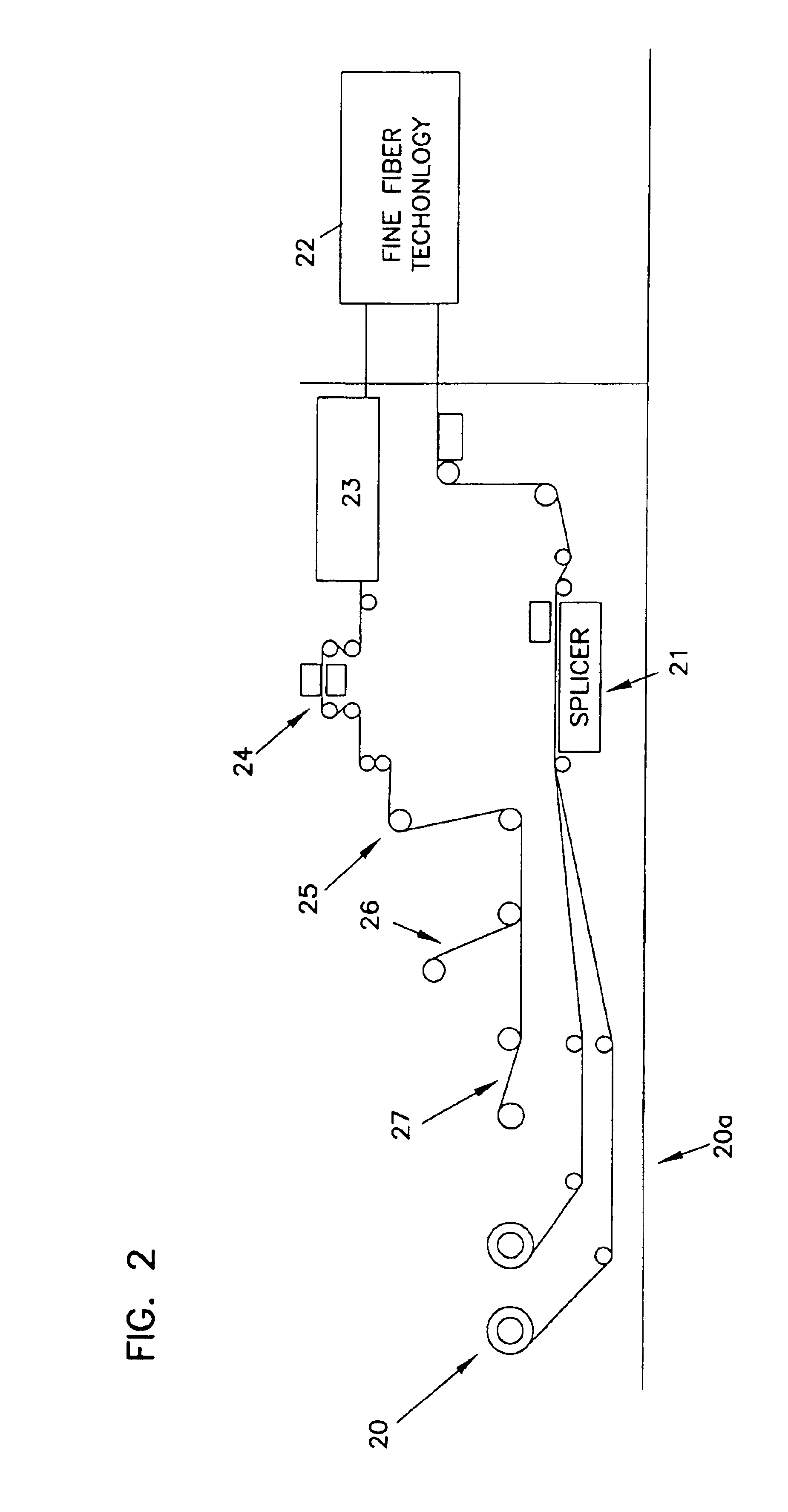

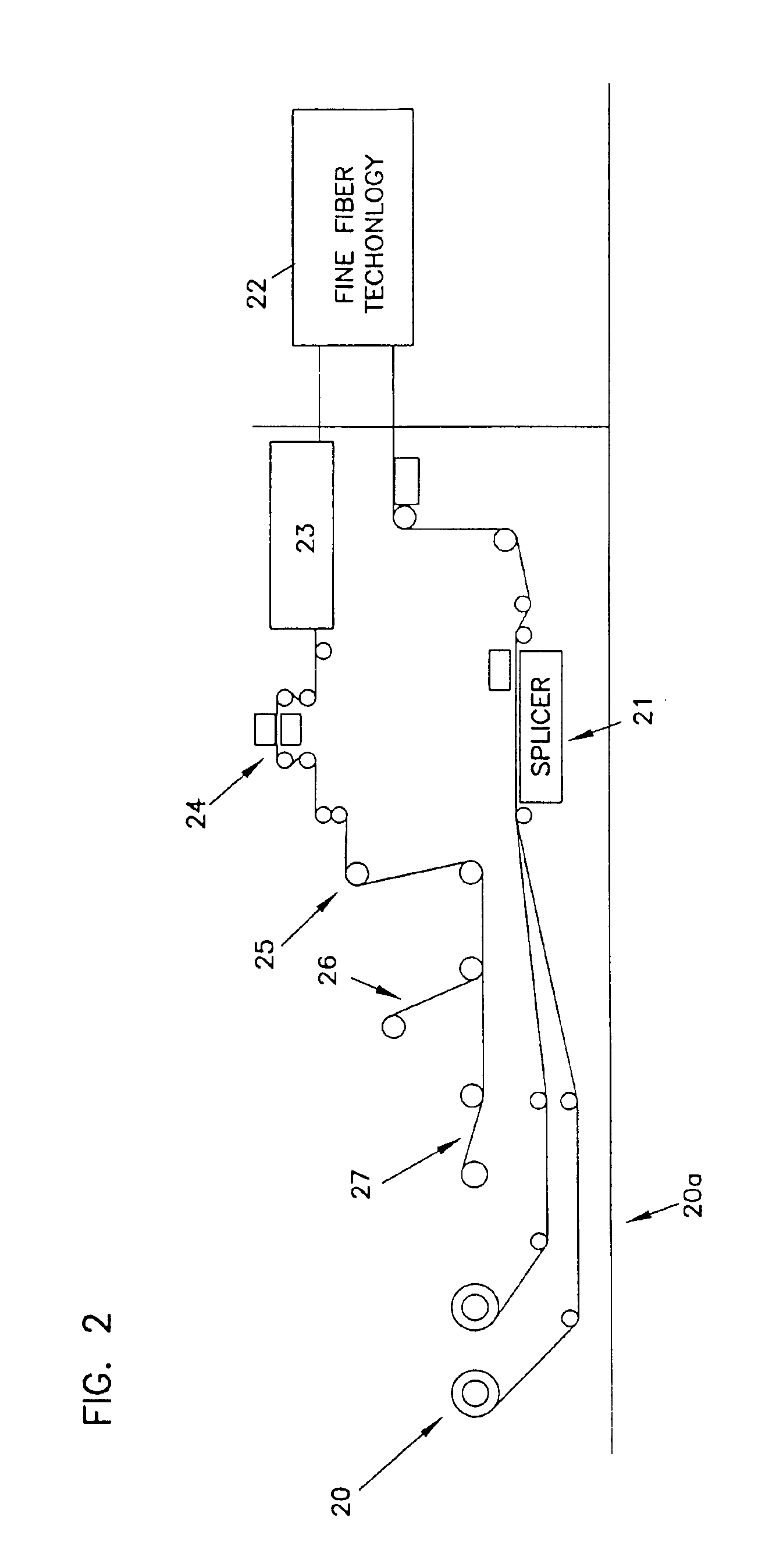

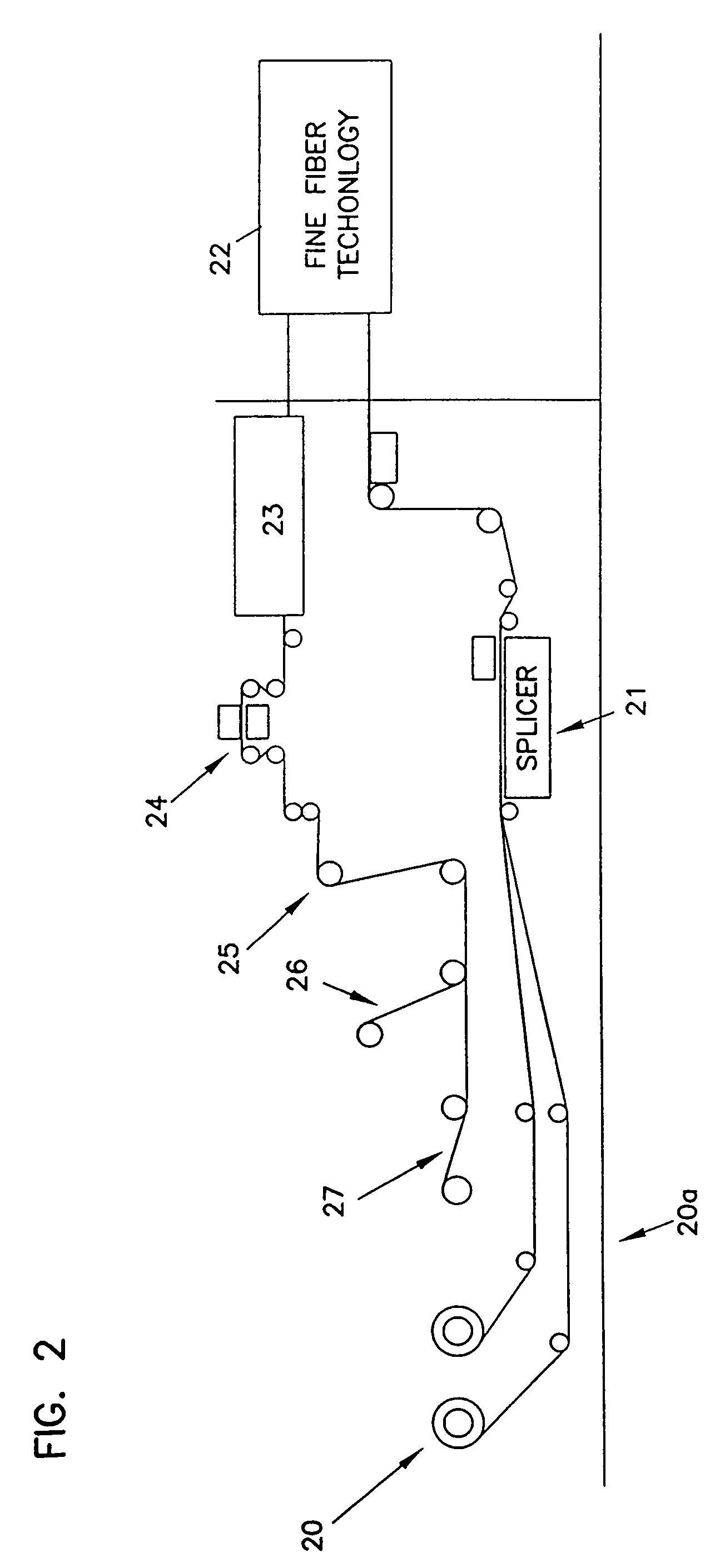

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Air filter with fine fiber and spun bonded media

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

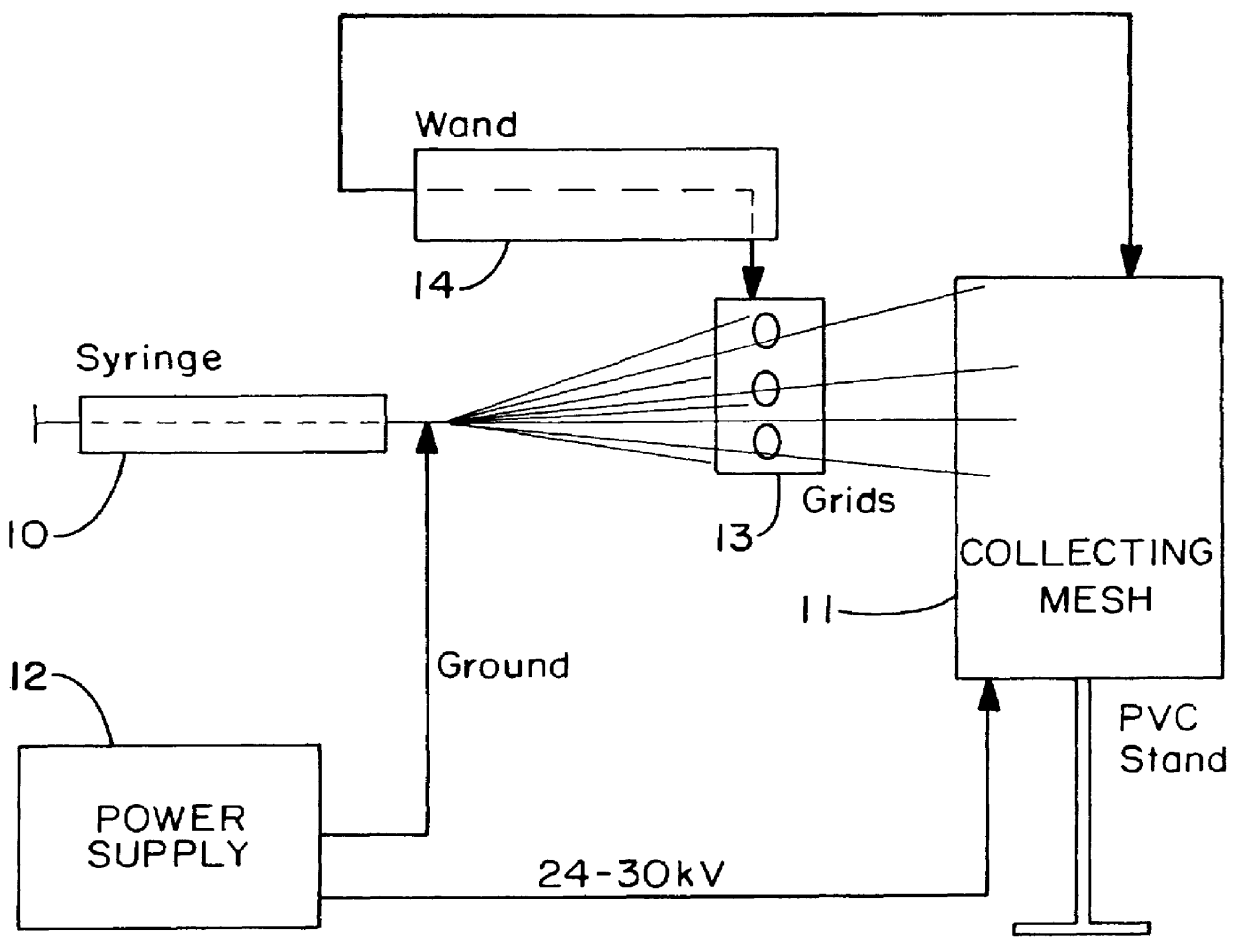

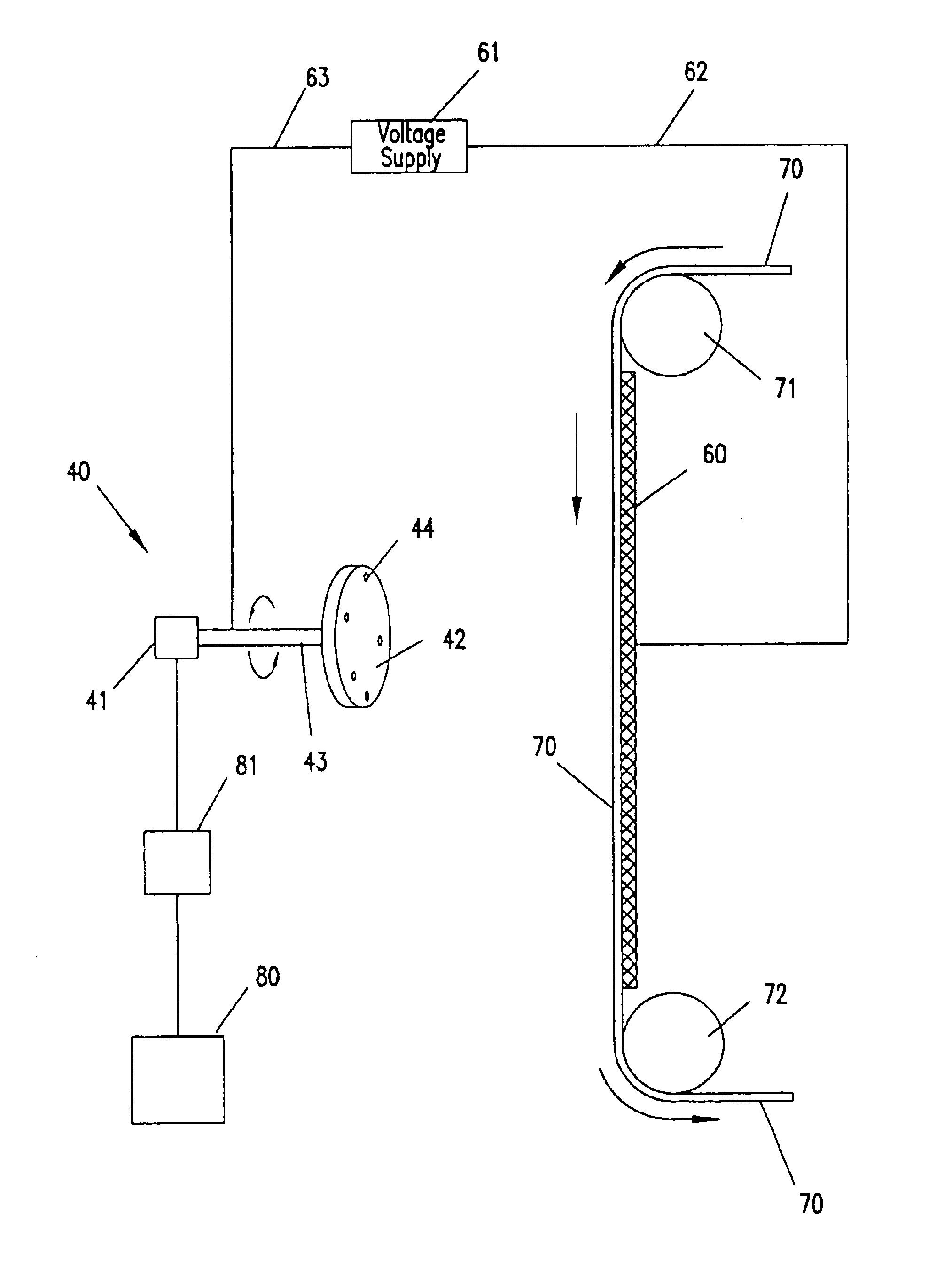

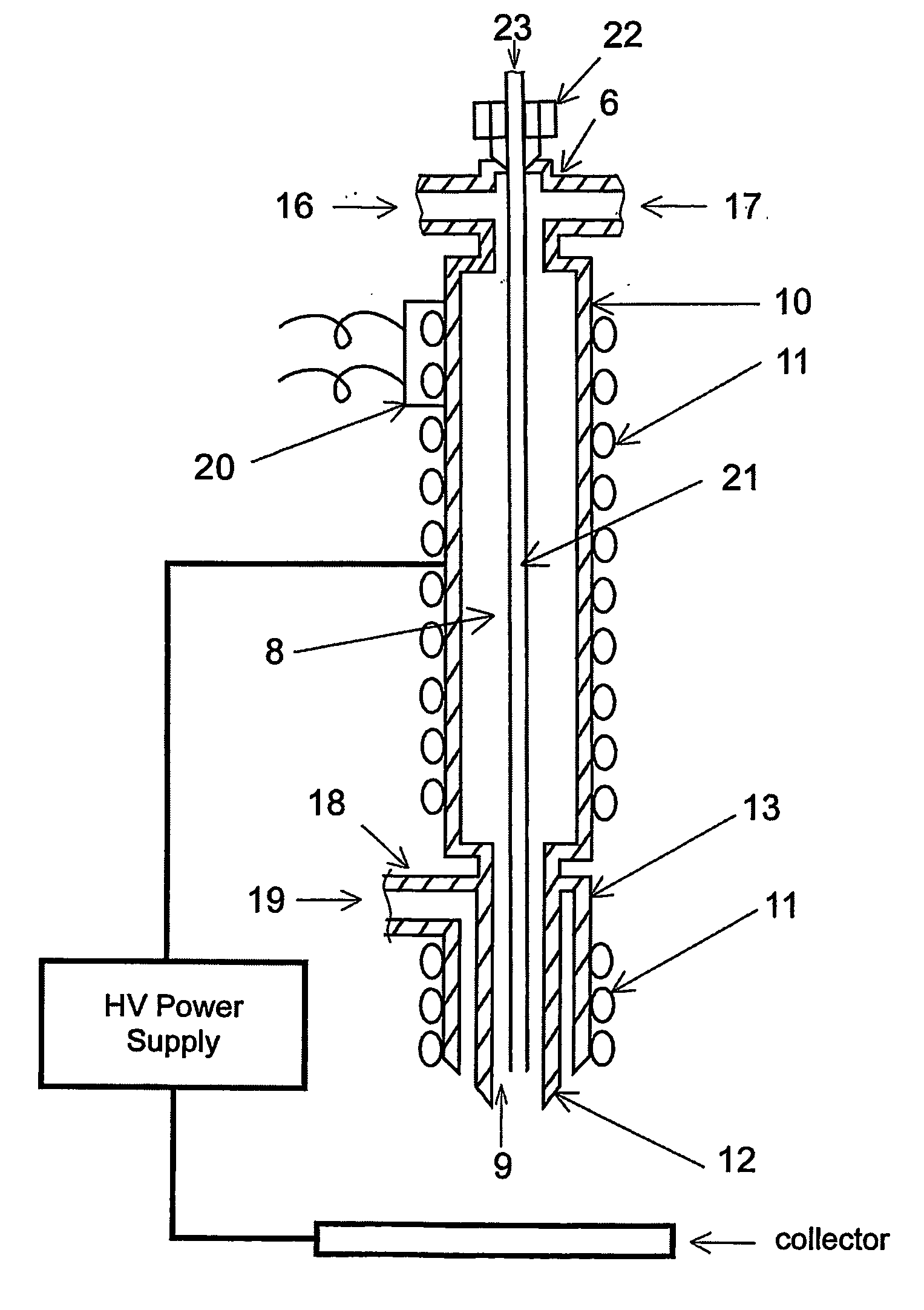

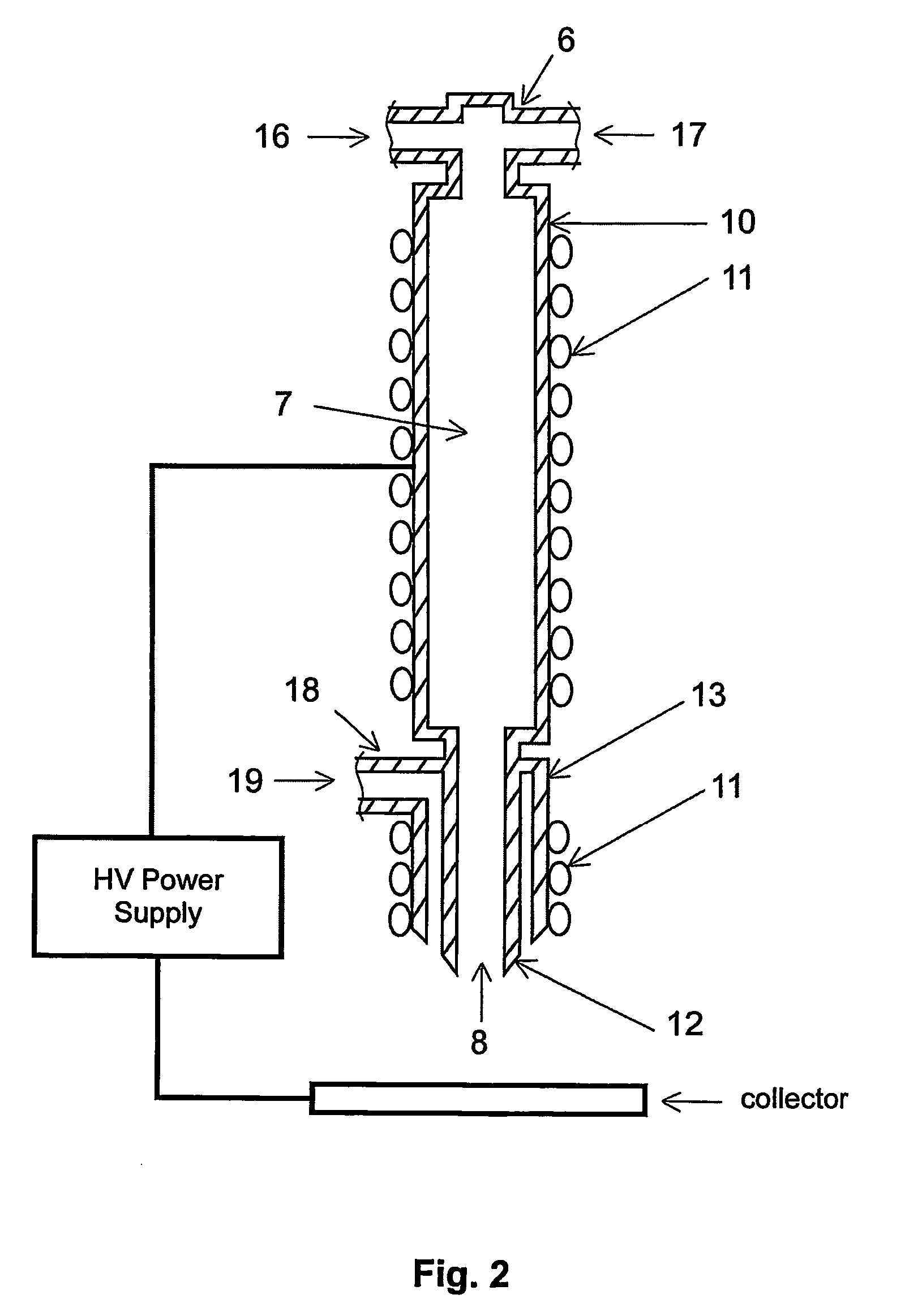

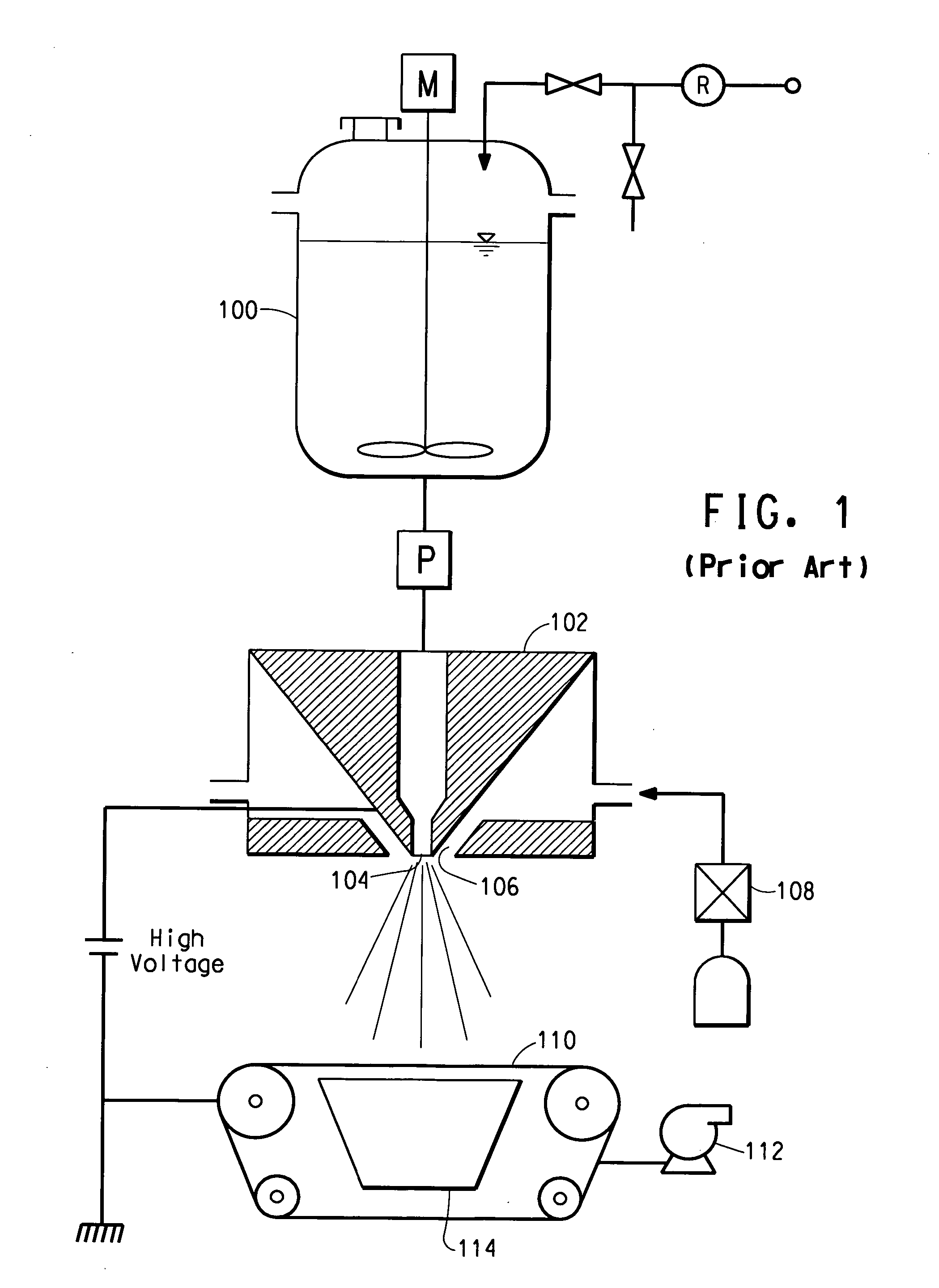

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Owner:DONALDSON CO INC

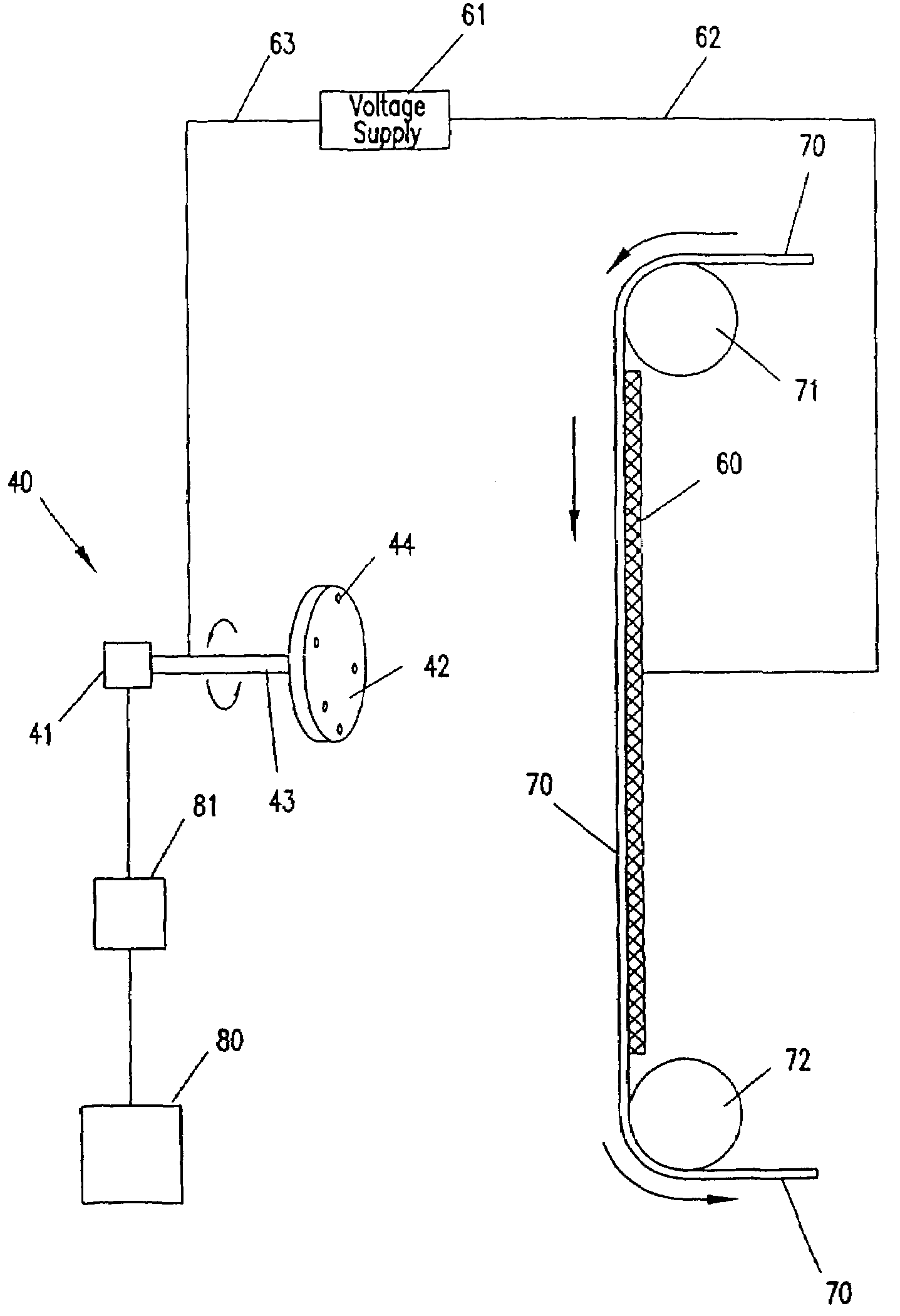

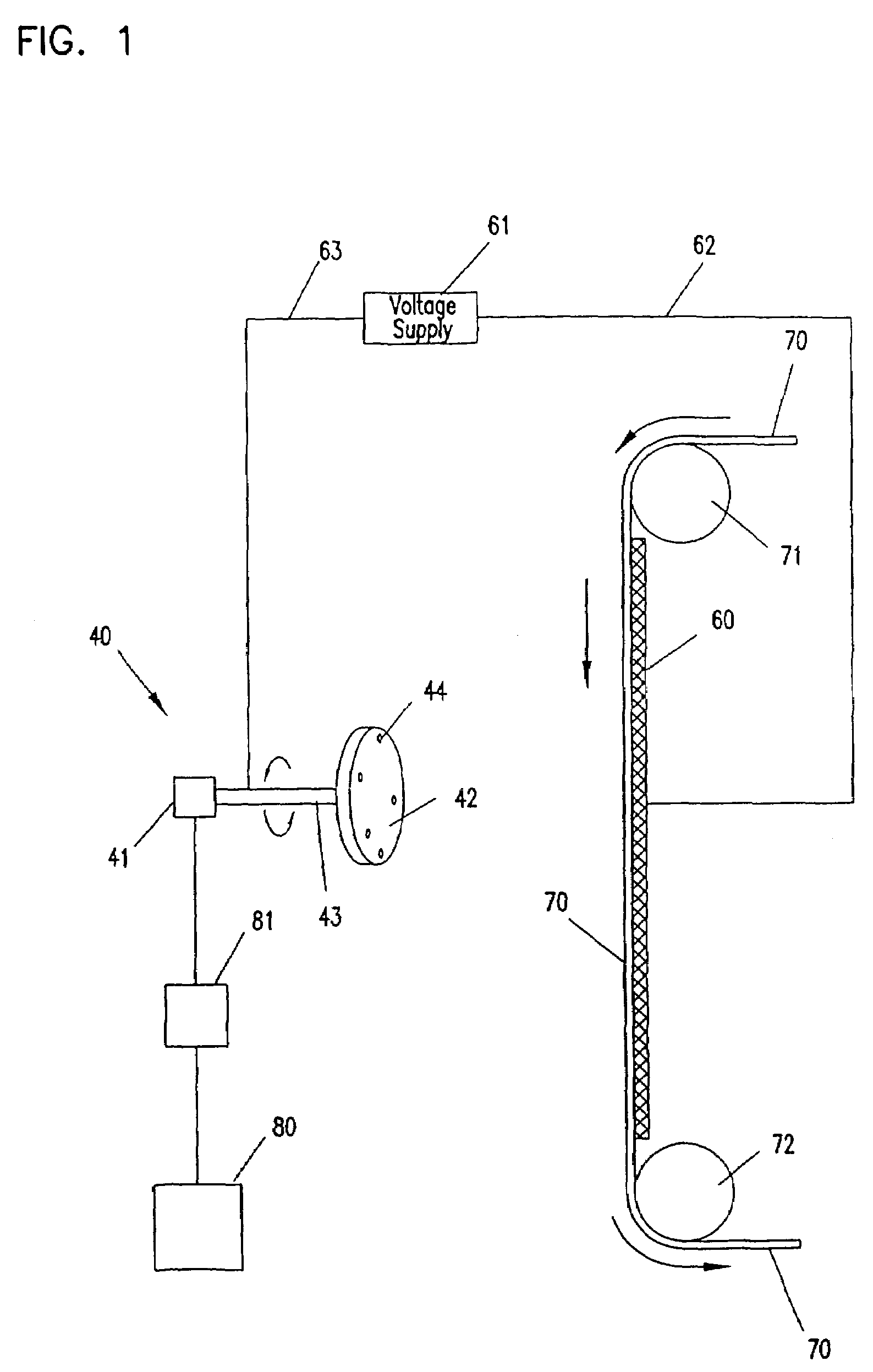

Particle filter system incorporating nanofibers

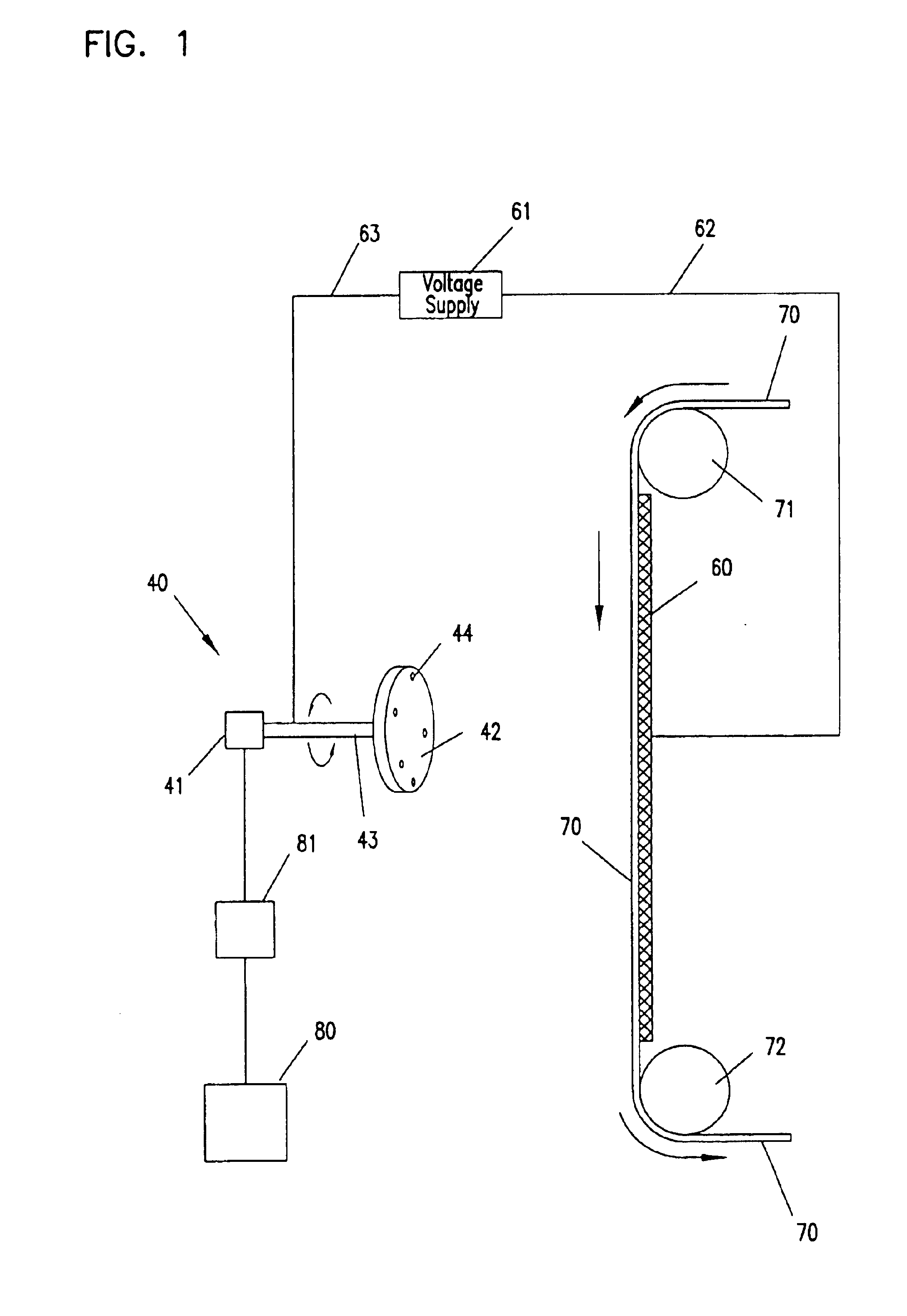

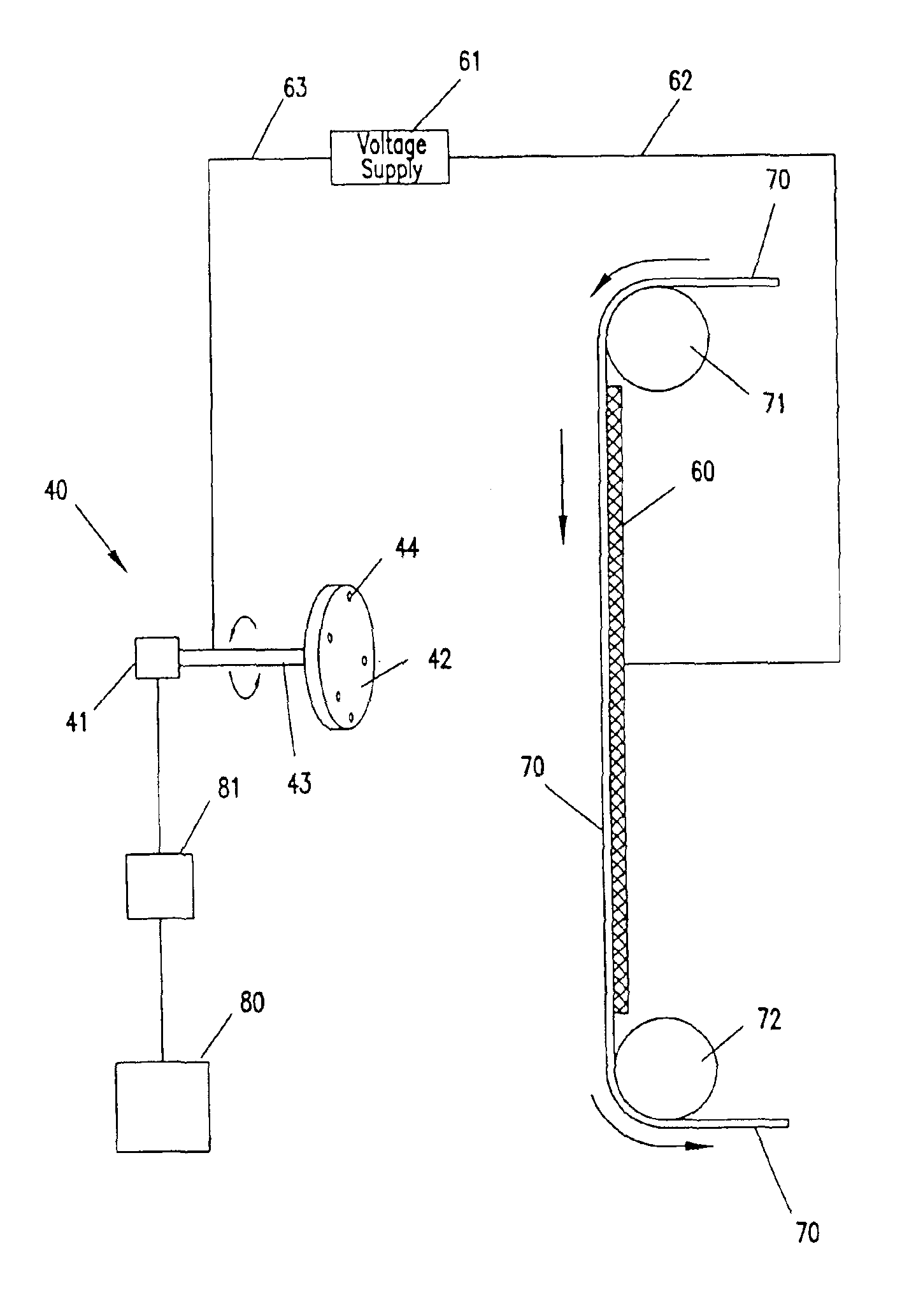

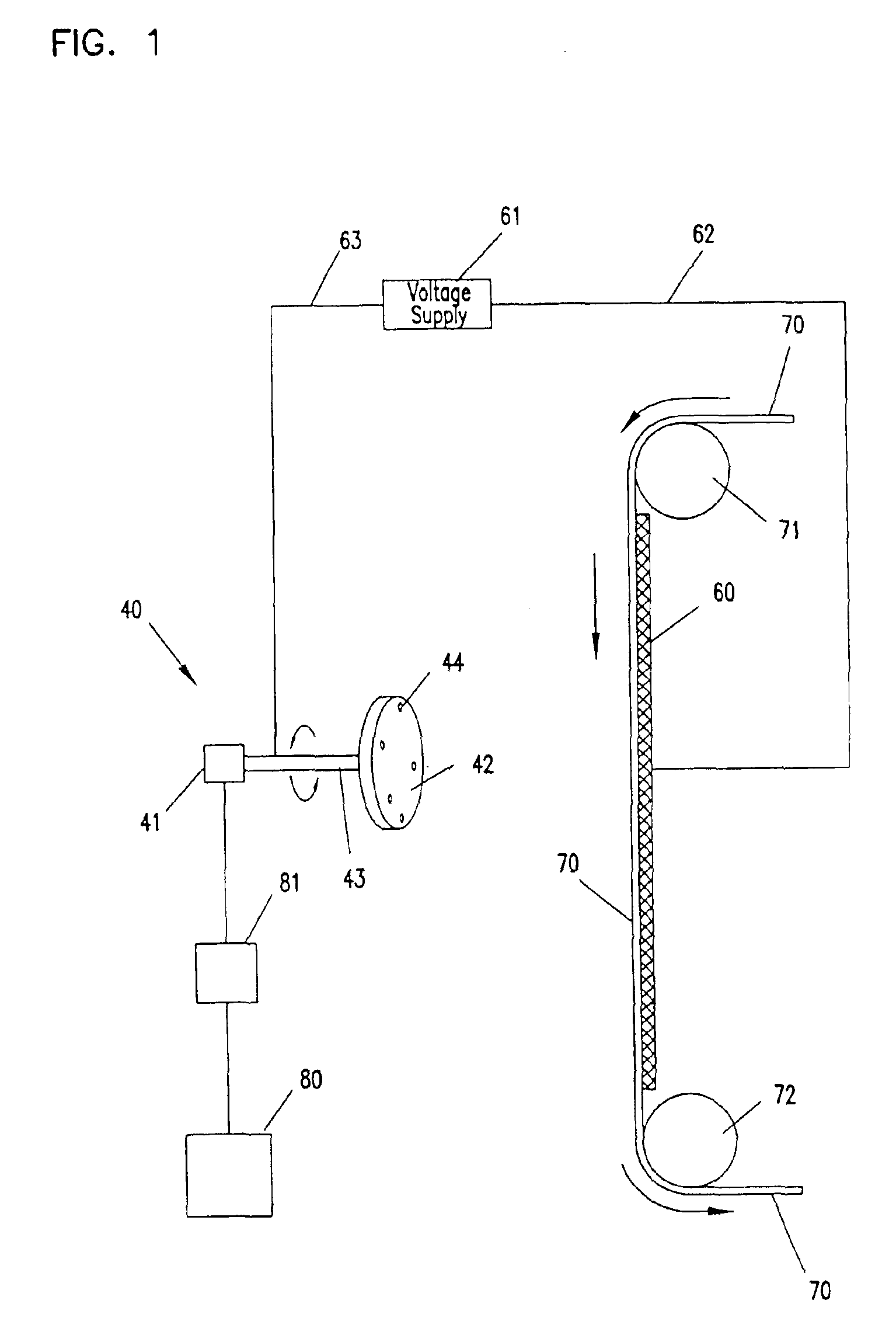

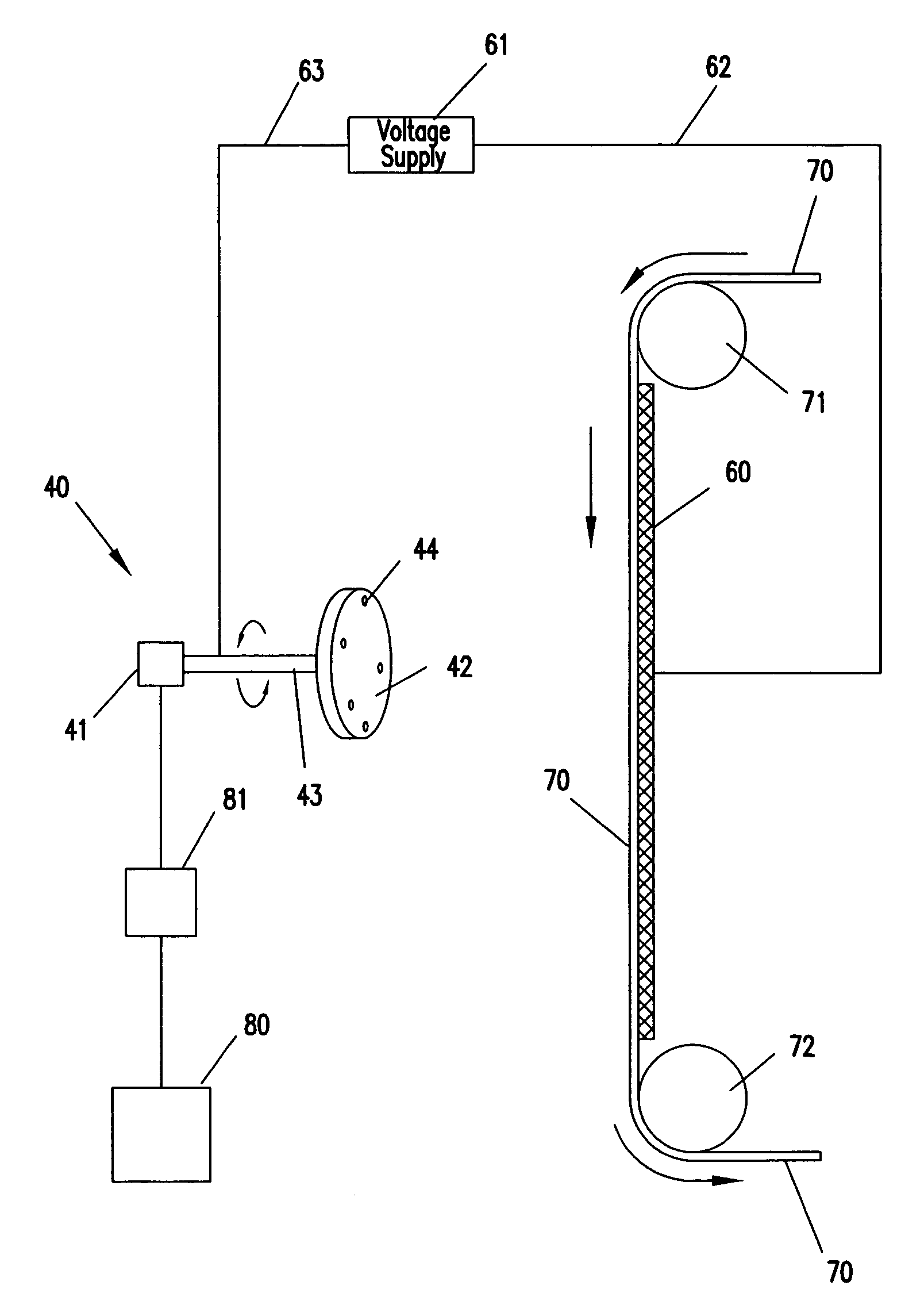

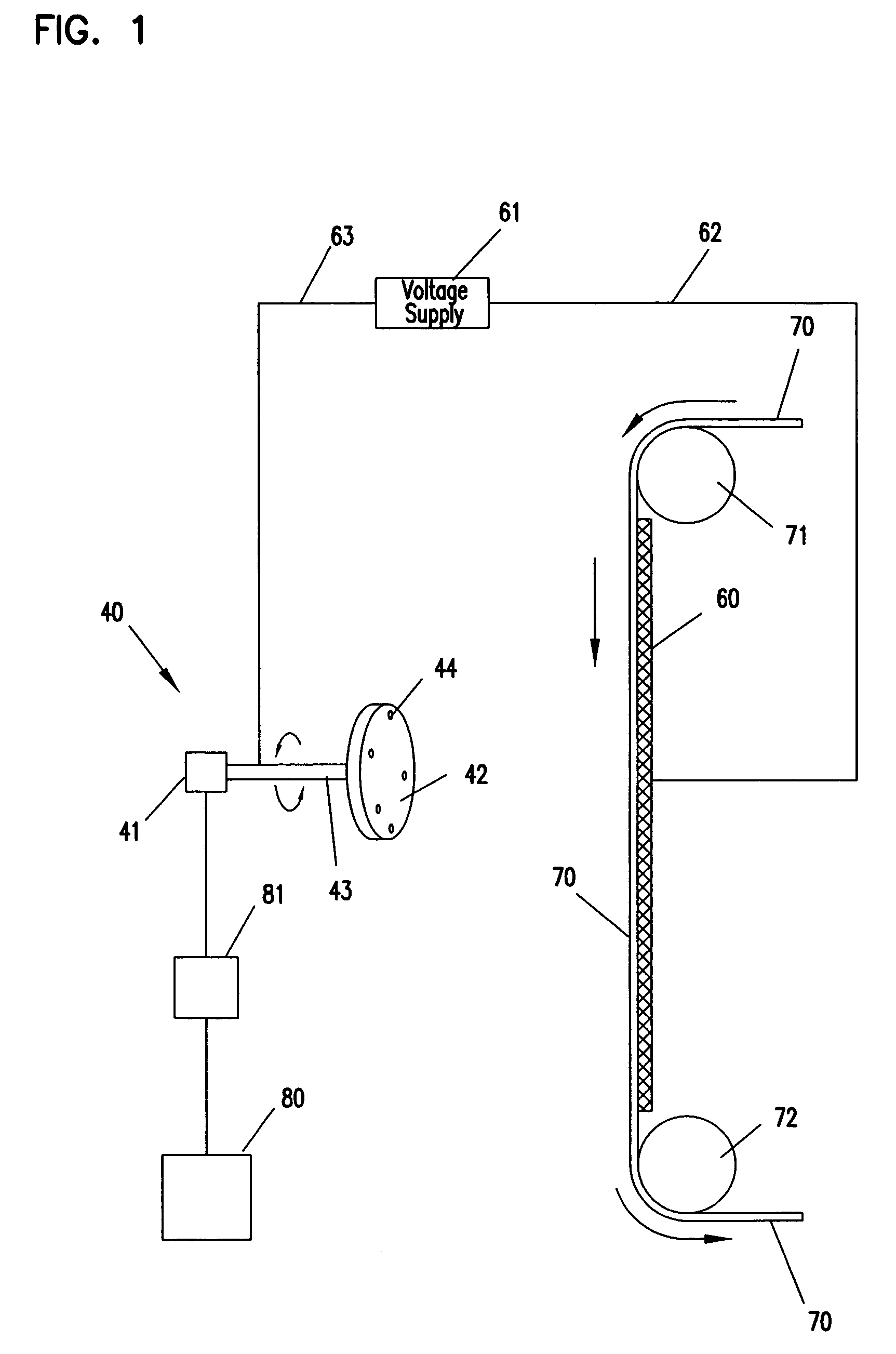

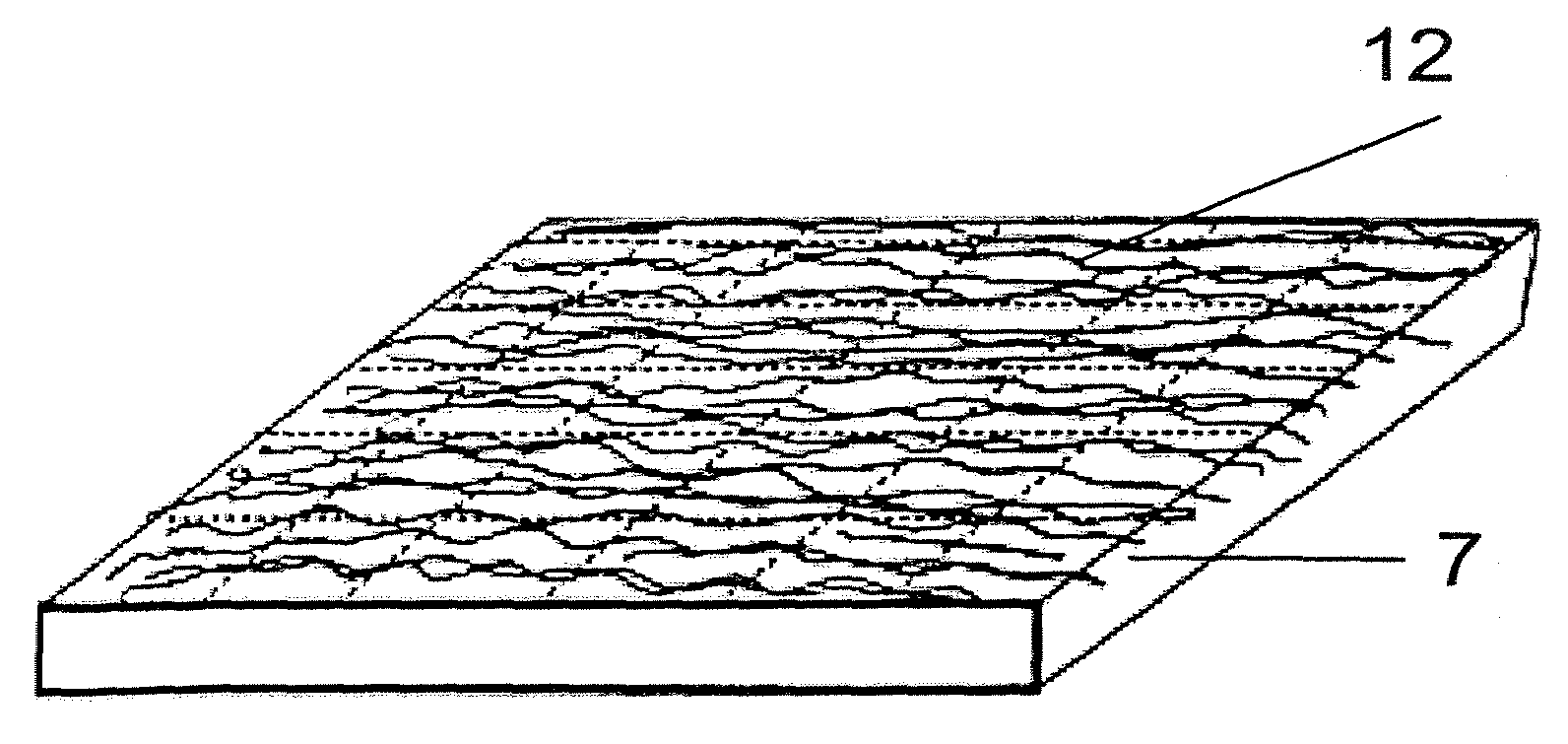

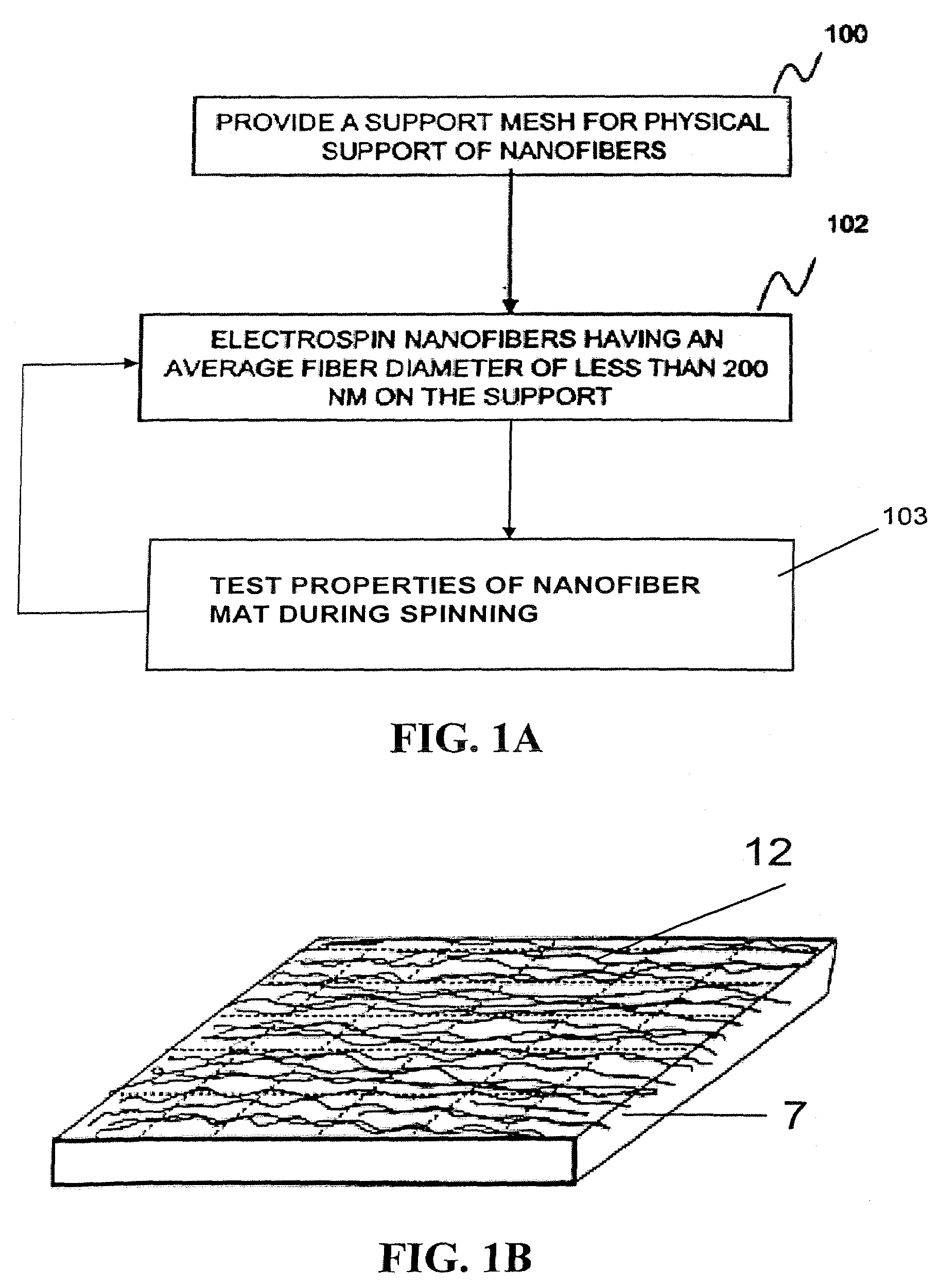

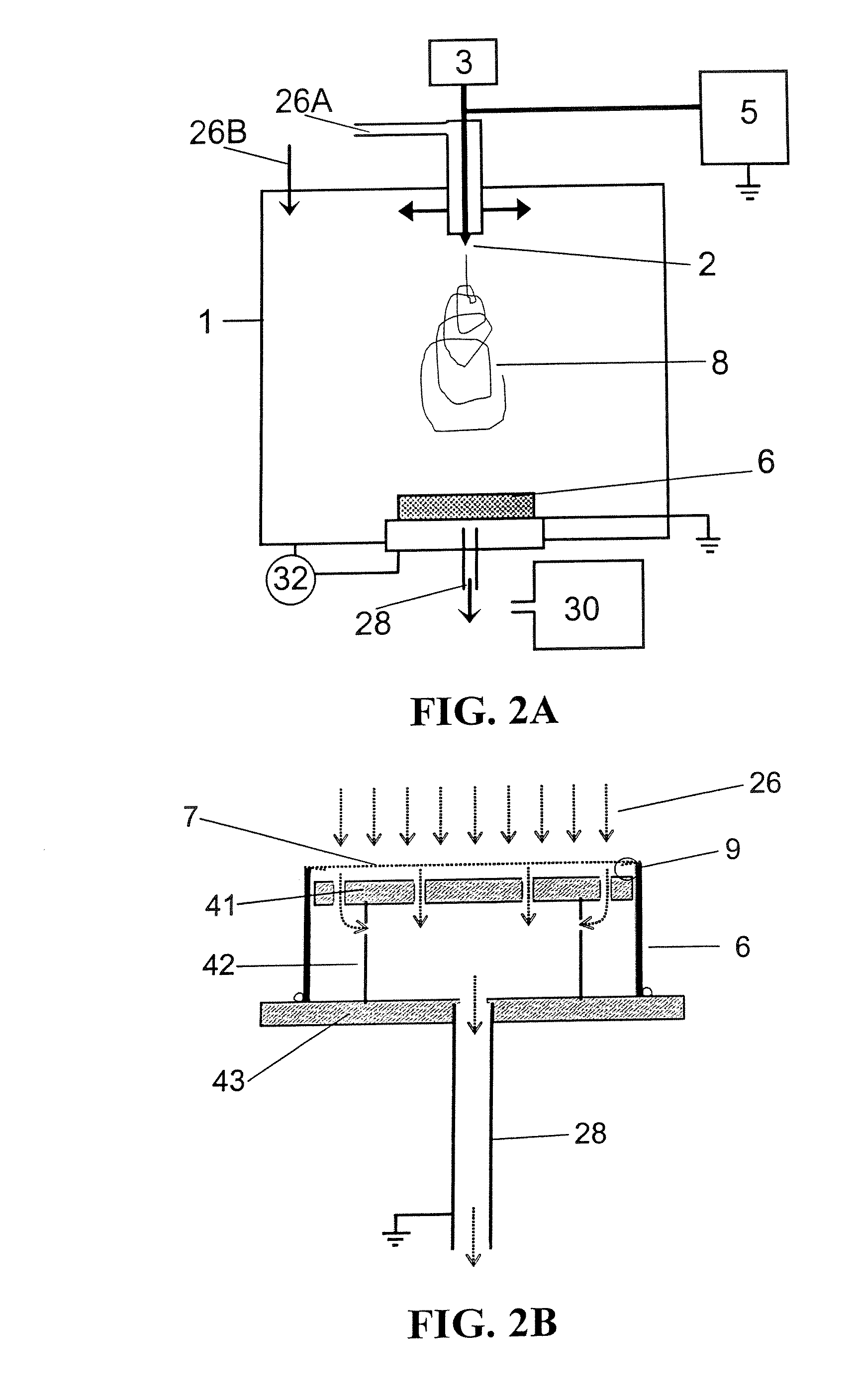

ActiveUS20080110342A1Electric discharge heatingFilament/thread formingElectric field modulationFiber

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

Filtration media for filtering particulate material from gas streams

A filtration medium is disclosed for use in air filters used in heating, ventilating and air conditioning systems. The medium contains at least one nanofiber layer of fibers having diameters less than 1 μm and at least one carrier layer, each nanofiber layer having a basis weight of at least about 2.5 g / m2, and up to about 25 g / m2. The medium has sufficient stiffness to be formed into a pleated configuration.

Owner:EI DU PONT DE NEMOURS & CO

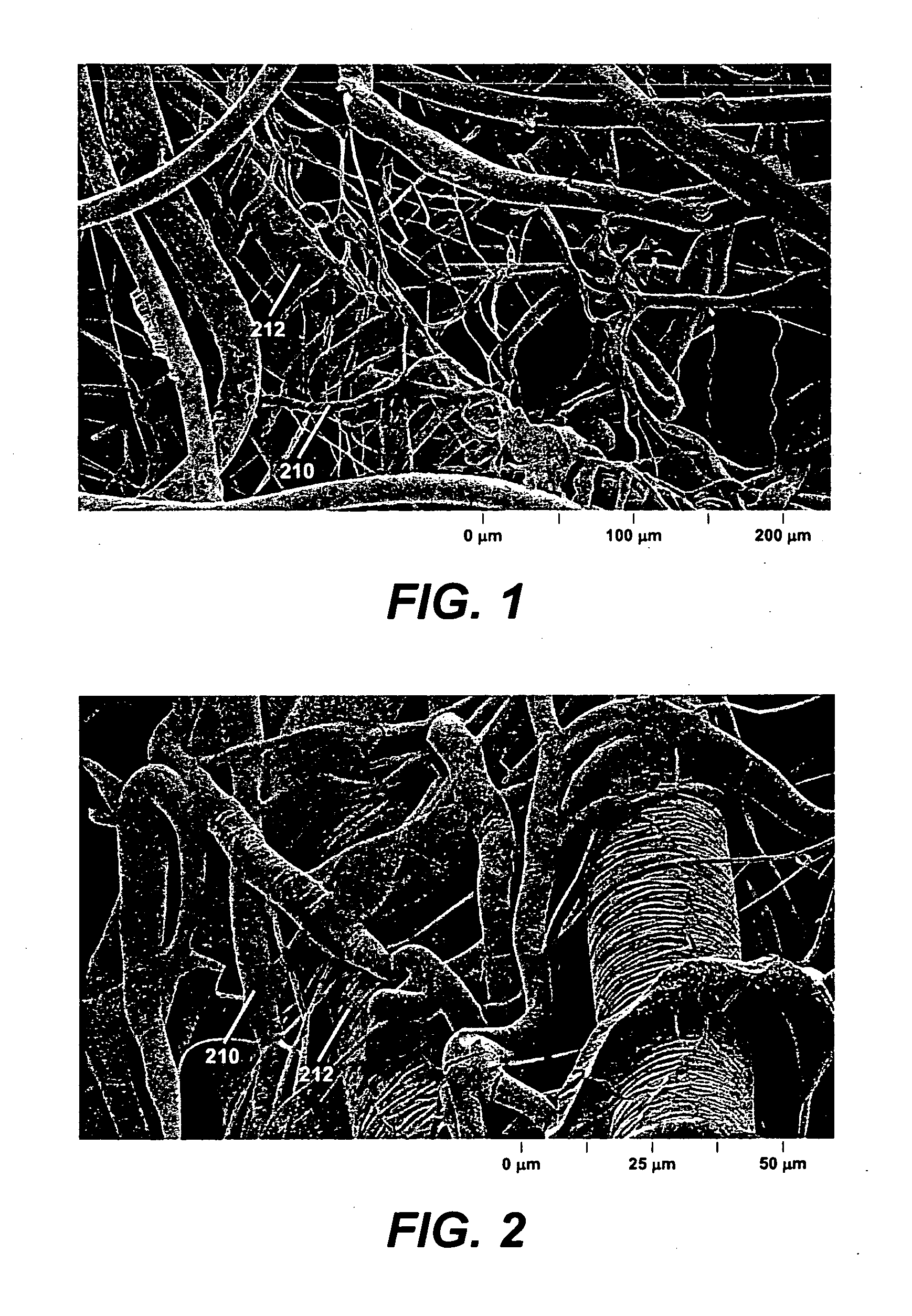

High performance filter media with internal nanofiber structure and manufacturing methodology

InactiveUS20050026526A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberNanofiber

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

Web comprising fine fiber and reactive, adsorptive or absorptive particulate

ActiveUS7655070B1Increase the cross-sectional areaIncreased turbulenceMaterial nanotechnologyUsing liquid separation agentParticulatesFiltration

The assemblies of the invention can comprise a fine fiber layer having dispersed within the fine fiber layer an active particulate material. Fluid that flows through the assemblies of the invention can have any material dispersed or dissolved in the fluid react with, be absorbed by, or adsorbed onto, the active particulate within the nanofiber layer. The structures of the invention can act simply as reactive, absorptive, or adsorptive layers with no filtration properties, or the structures of the invention can be assembled into filters that can filter particulate from a mobile fluid while simultaneously reacting, absorbing, or adsorbing materials from the mobile fluid.

Owner:DONALDSON CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com