Patents

Literature

77487results about How to "Improve adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

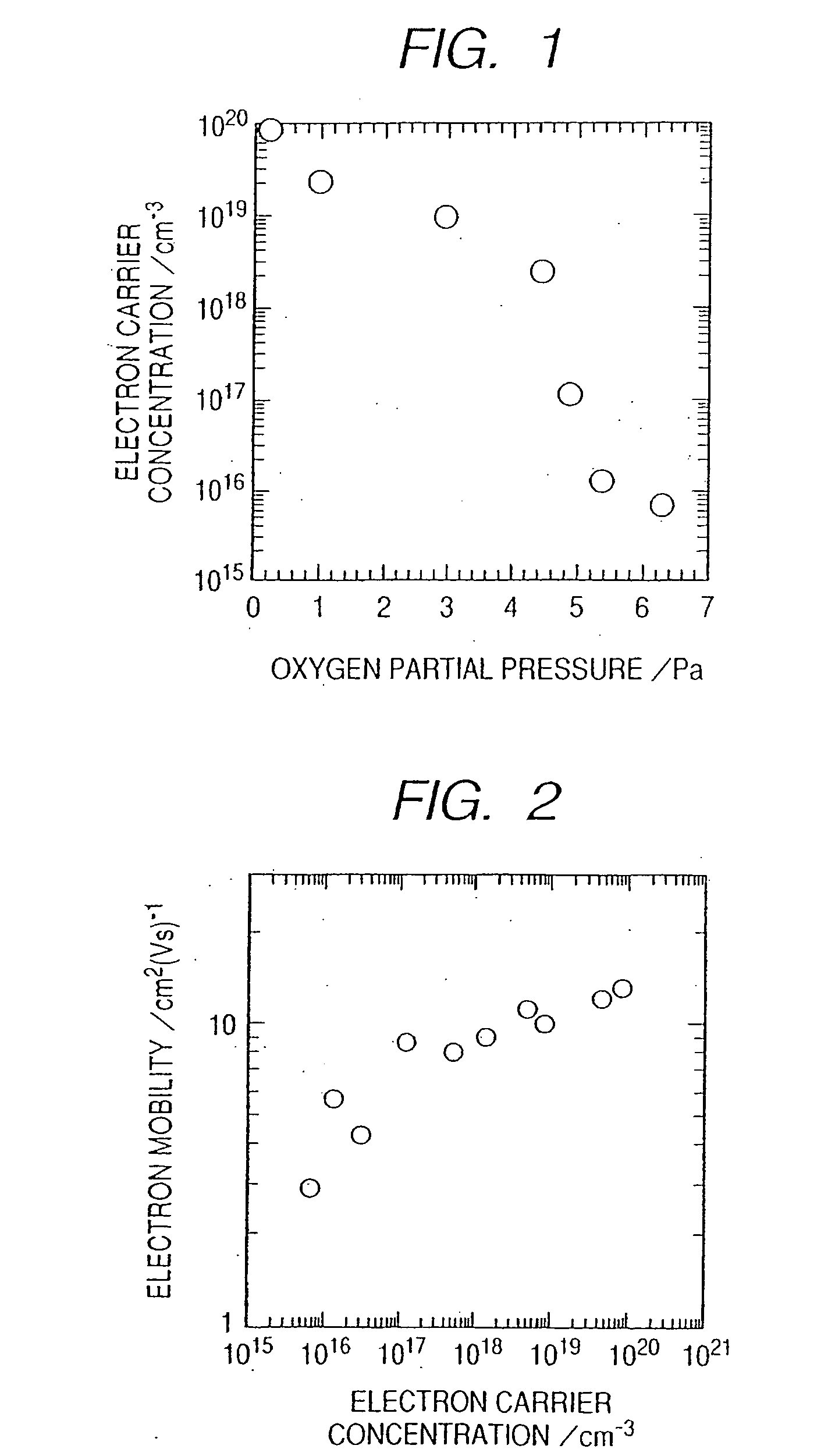

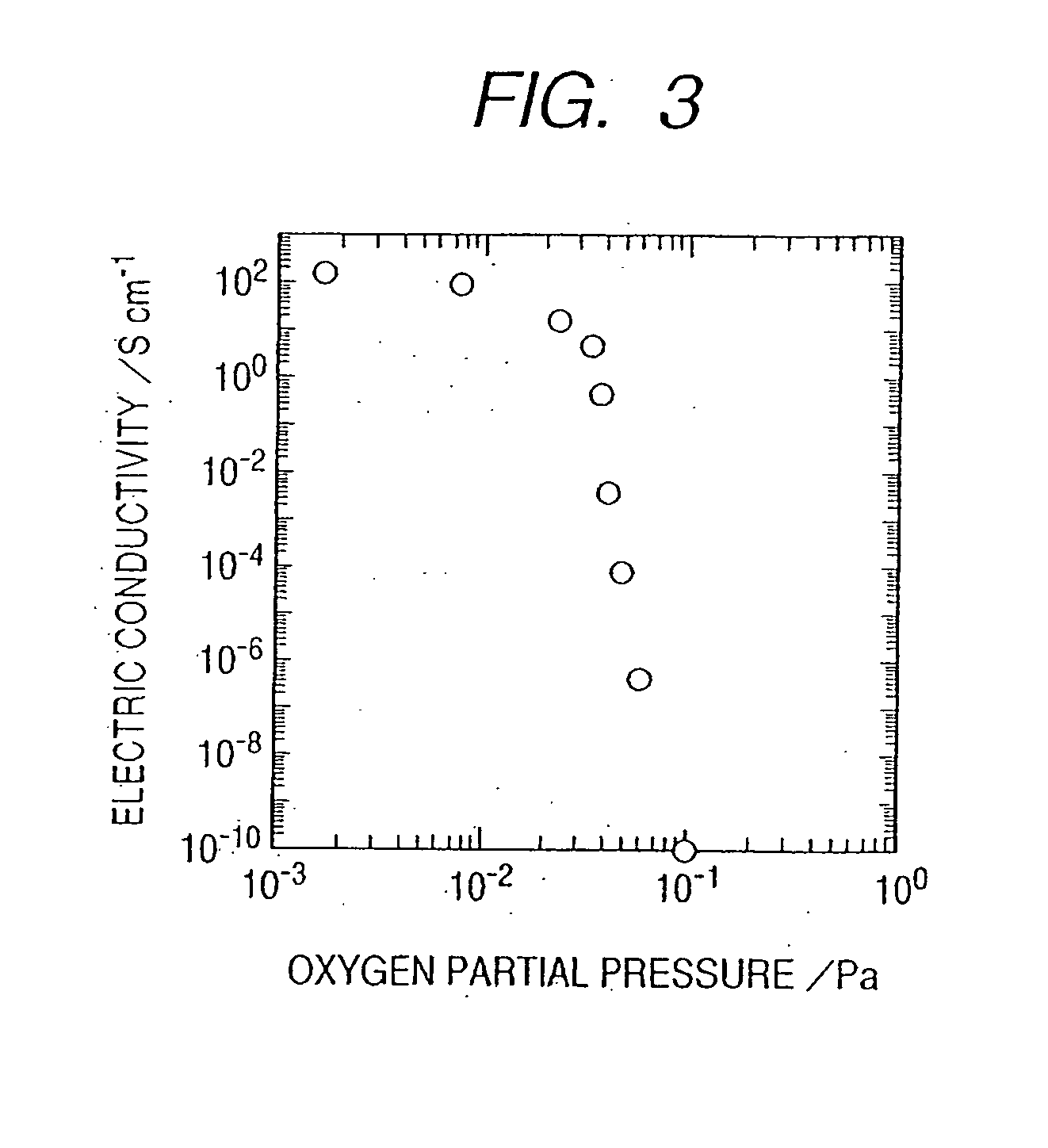

Field effect transistor

ActiveUS20060113539A1Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

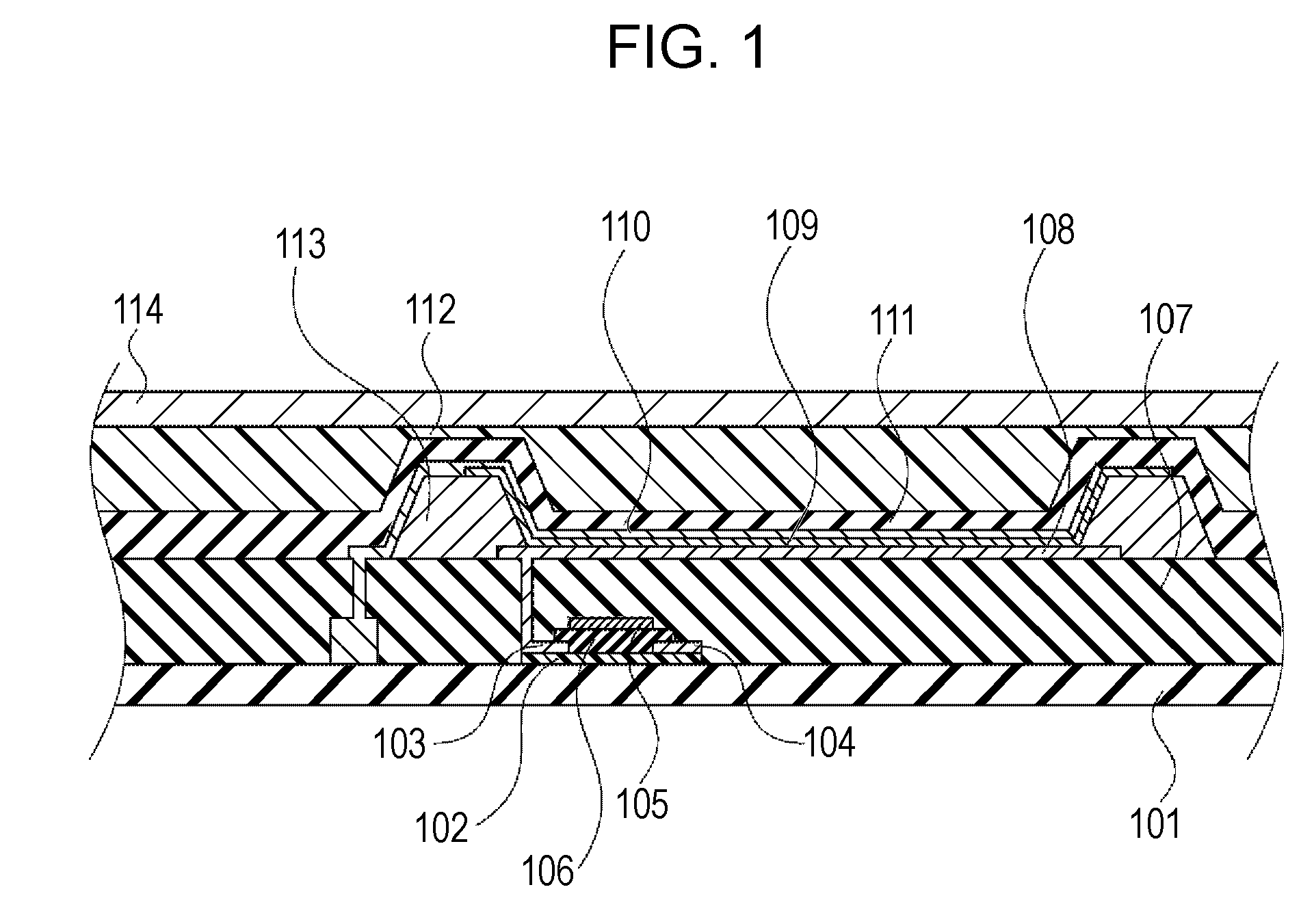

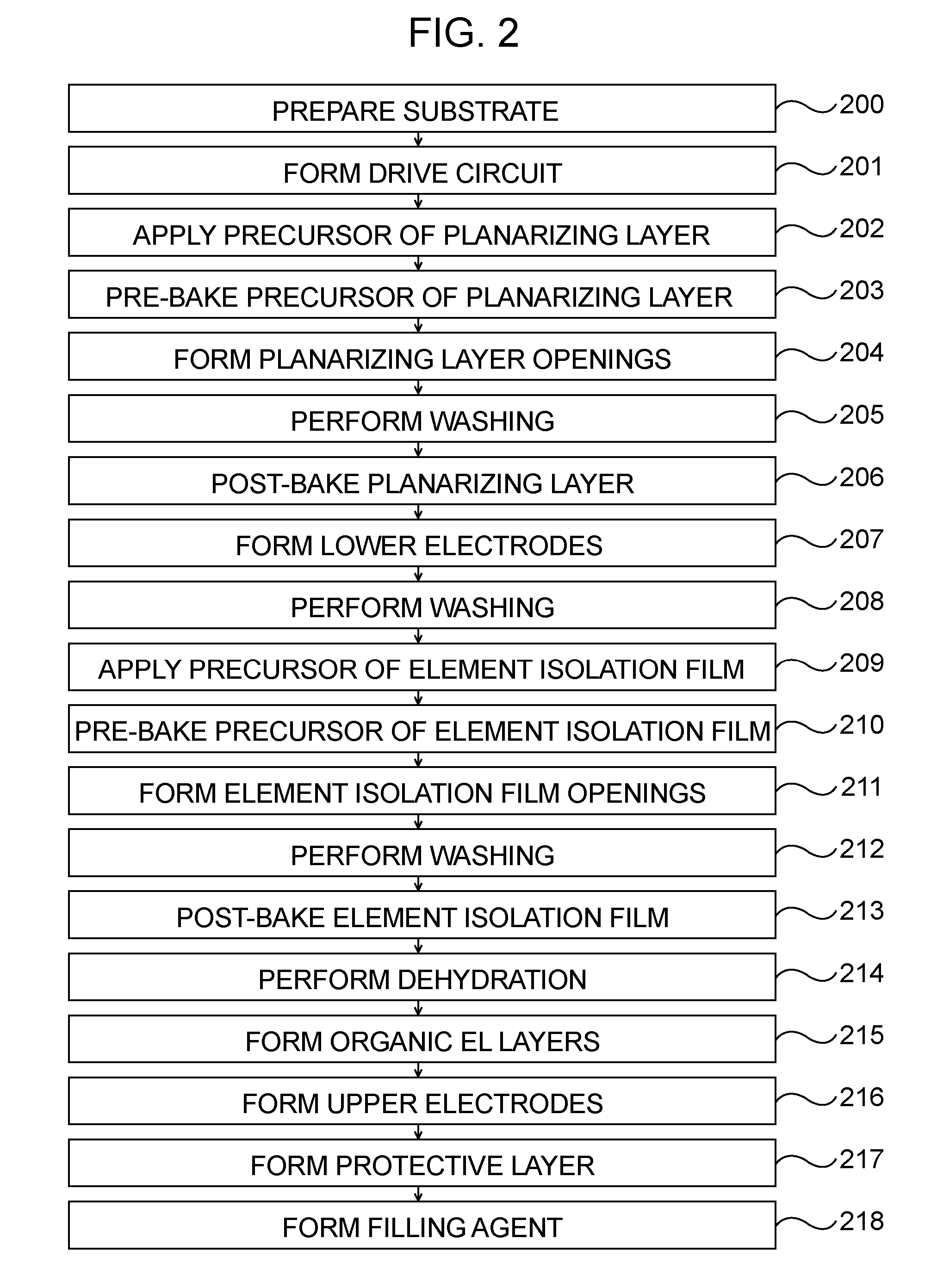

Organic electroluminescent display device and manufacturing method thereof

ActiveUS20070046191A1Maintain its level of performanceEnhance layeringDischarge tube luminescnet screensElectroluminescent light sourcesOligomerEngineering

The present invention provides an organic EL display device having a planarizing layer, which is prevented from being distorted. The above organic EL display device has a planarizing layer, which retains 5% or less the oligomer used to form this layer.

Owner:CANON KK

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

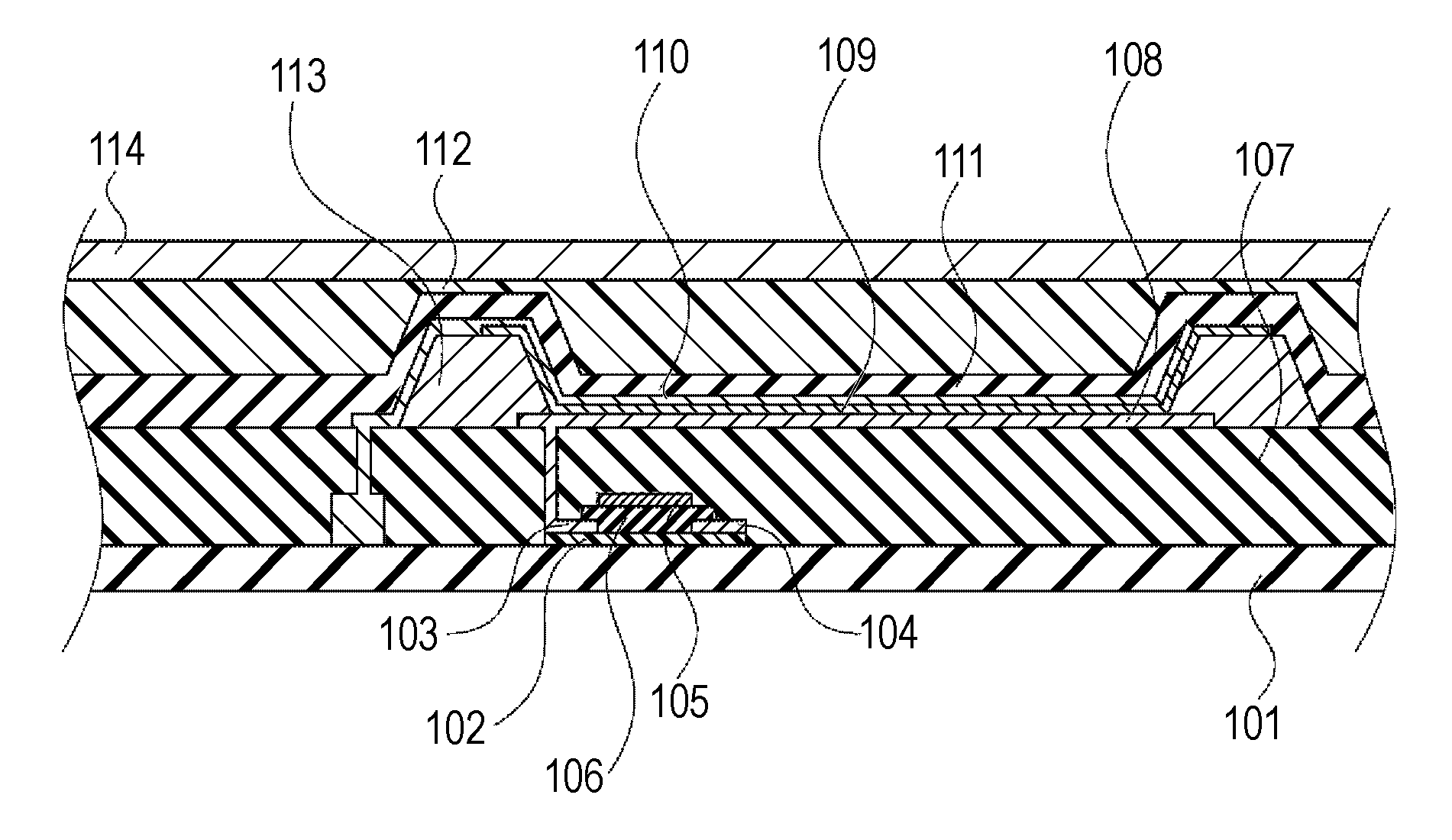

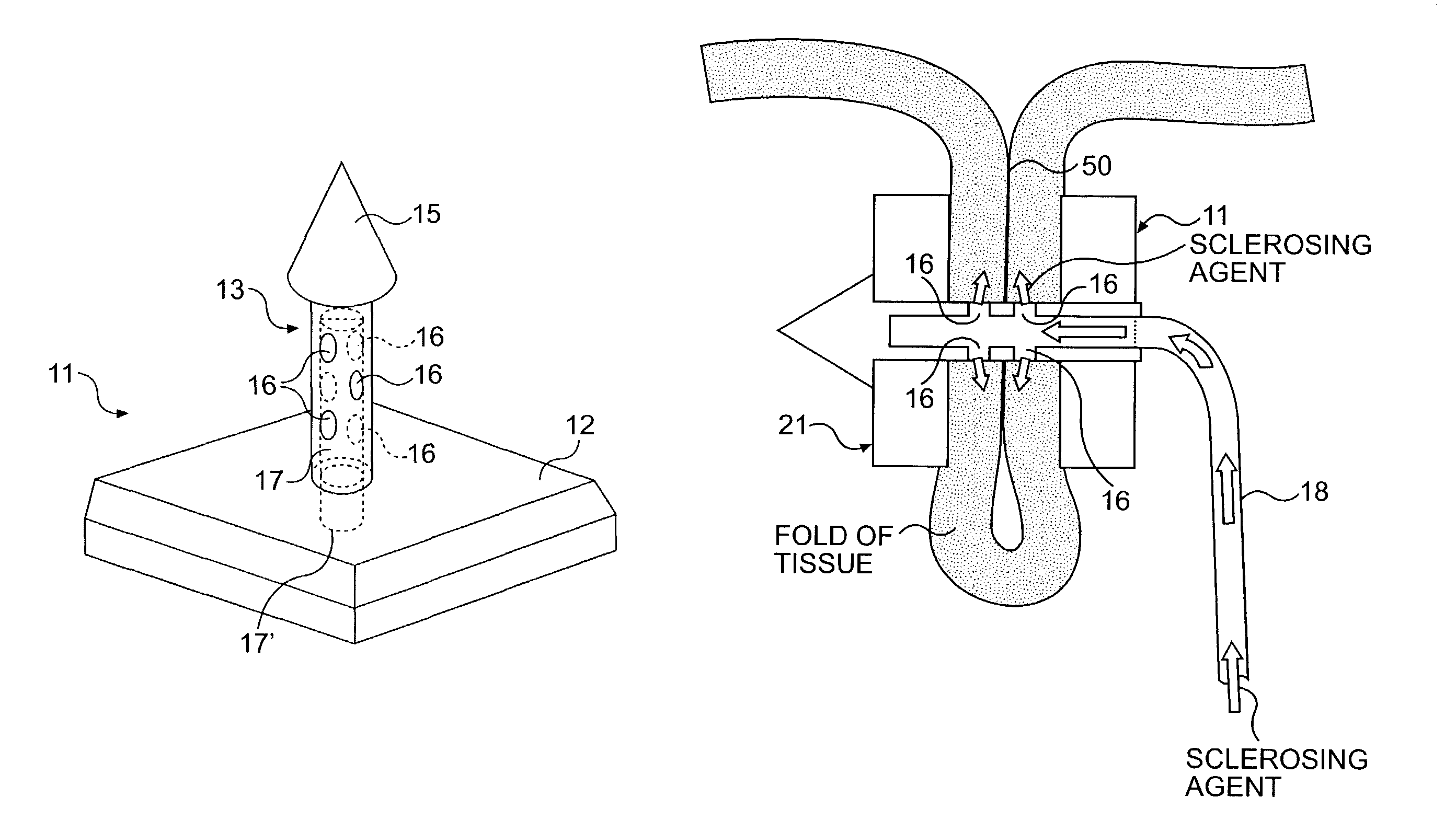

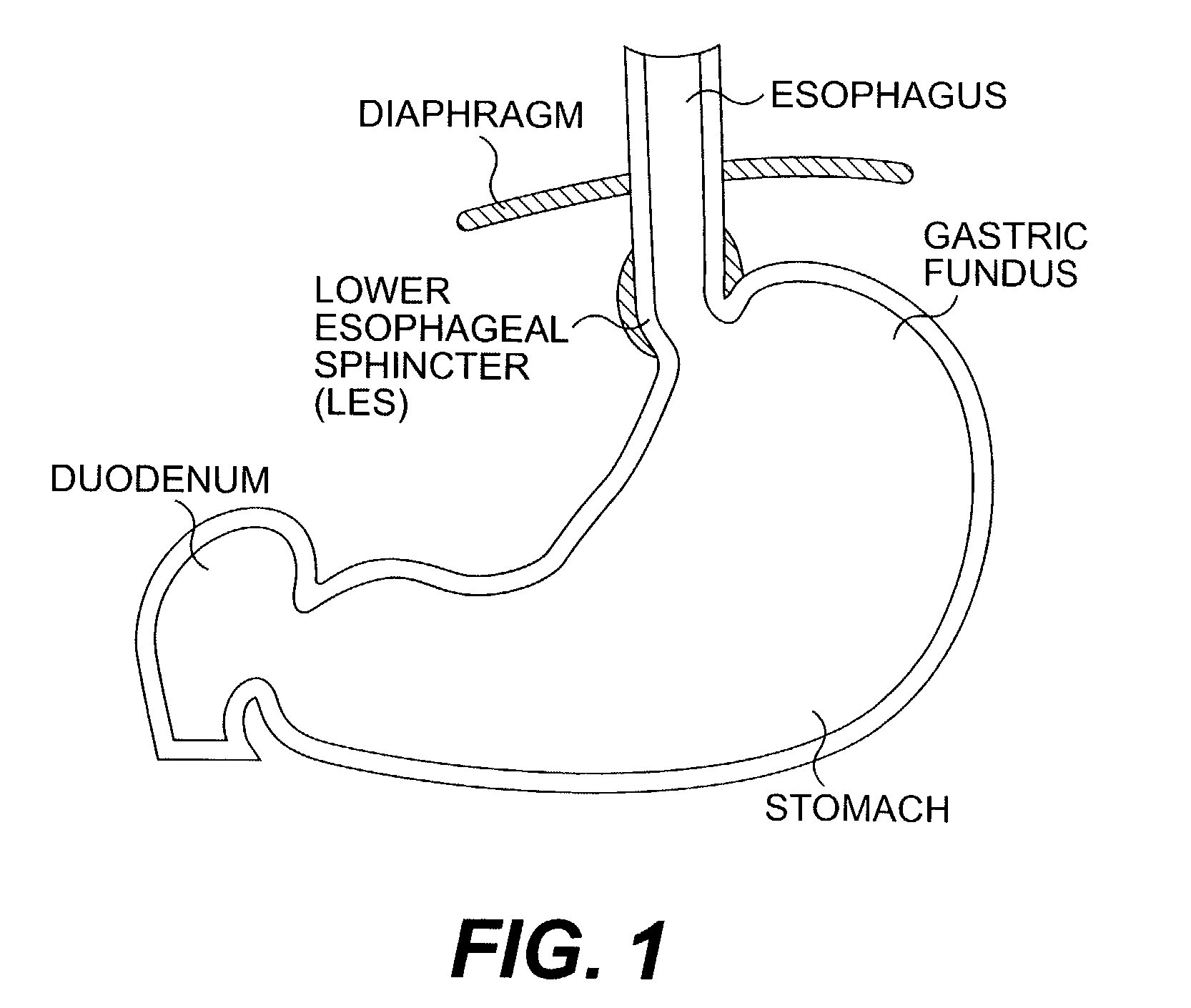

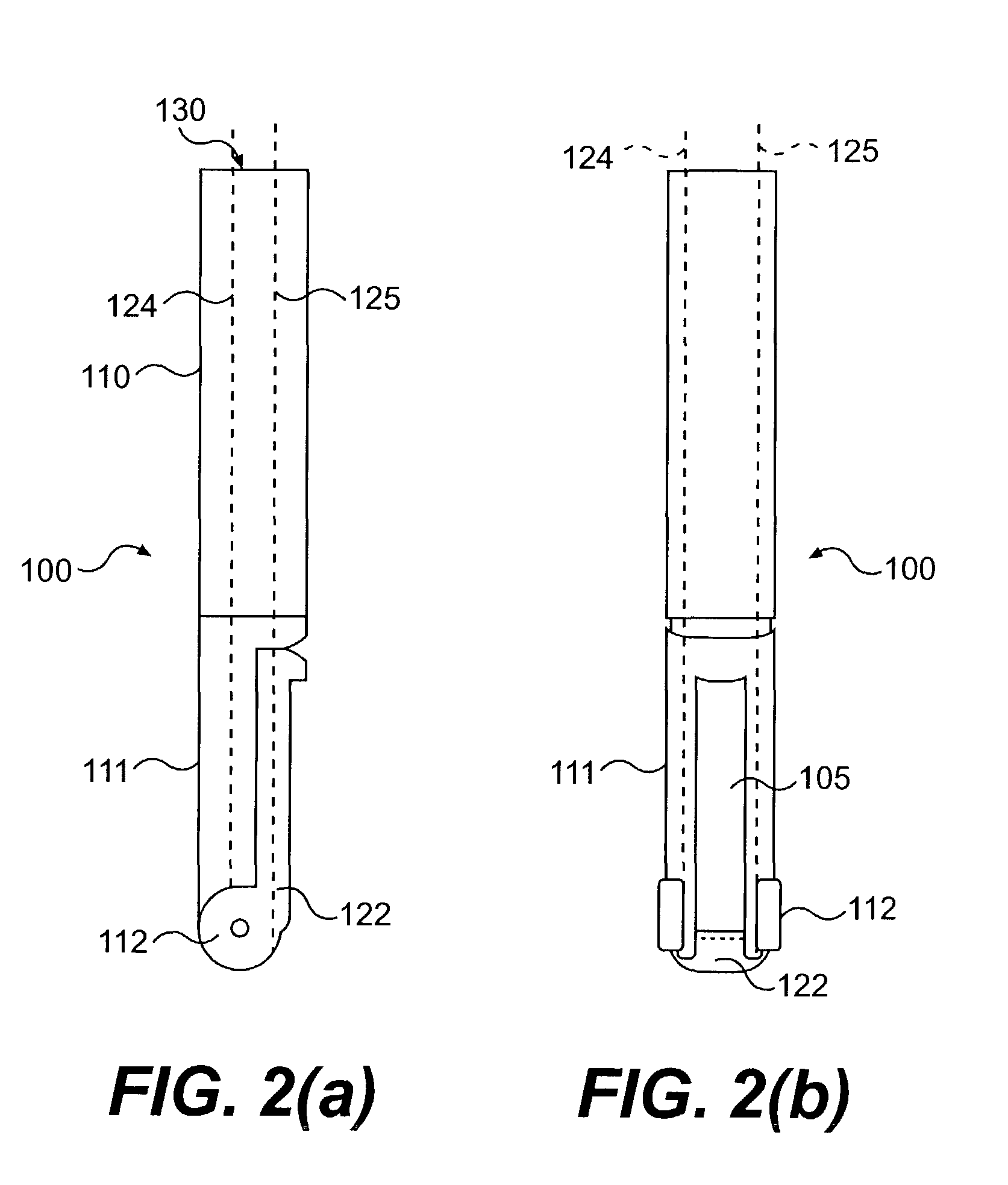

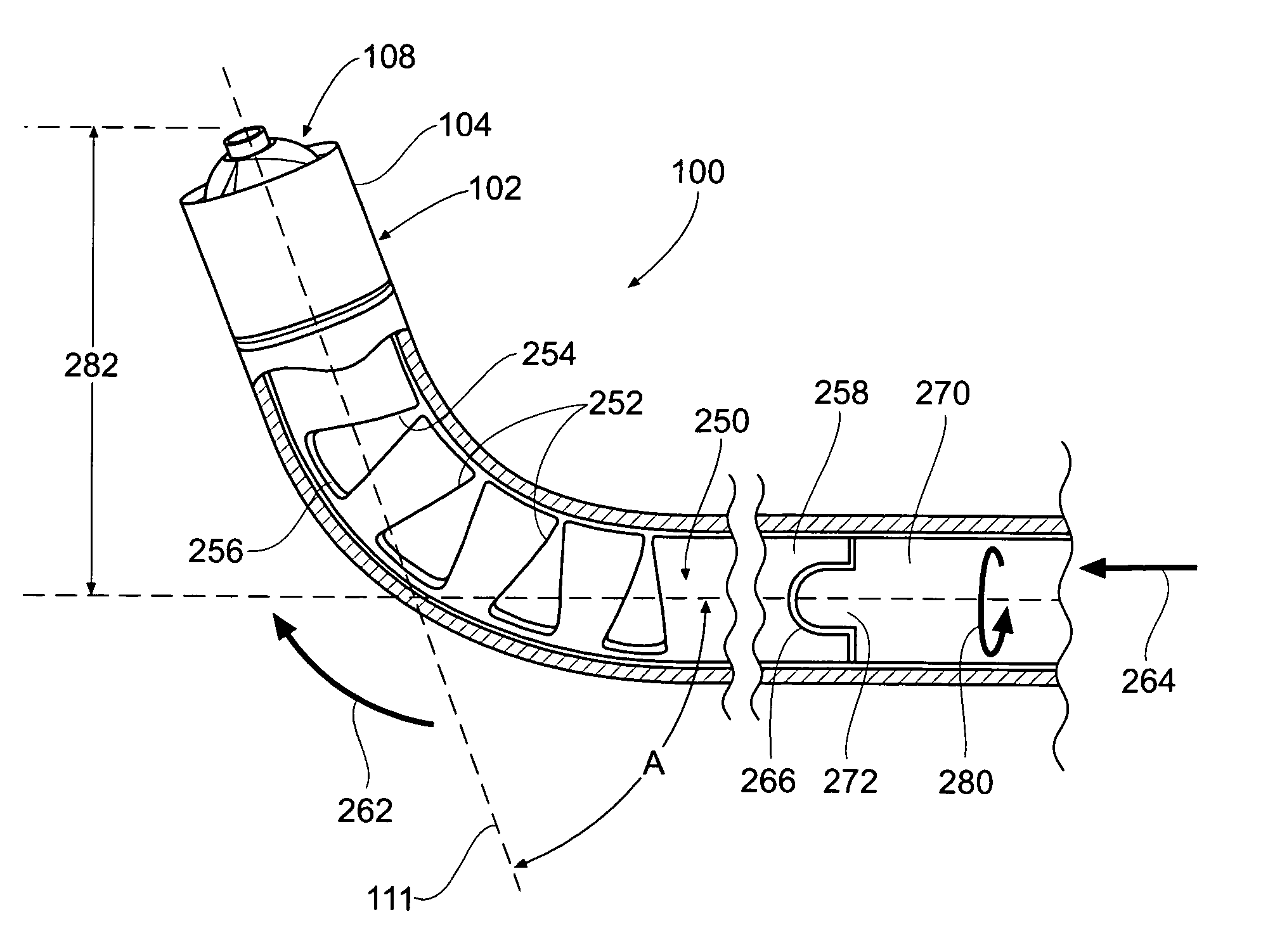

Tissue fastening devices and processes that promote tissue adhesion

ActiveUS8241308B2Improve adhesionOptimize allocationStaplesNailsEndoscopic ProcedureEndoscopic surgery

The invention in certain aspects relates to a surgical fastener for fastening tissue segments having tissue surfaces. The fastener includes a first fastener member having a base and a piercing element connected to the base for piercing the tissue segments to be fastened, a second fastener member having an opening for receiving and retaining the piercing element of the first fastener member such that the tissue segments to be fastened are retained between the first and second fastening members, and means for promoting adhesion between the tissue surfaces. The invention also relates to related methods and devices for promoting adhesion of tissue segments and preventing fastener migration, especially in an endoscopic procedure for the treatment of GERD.

Owner:BOSTON SCI SCIMED INC

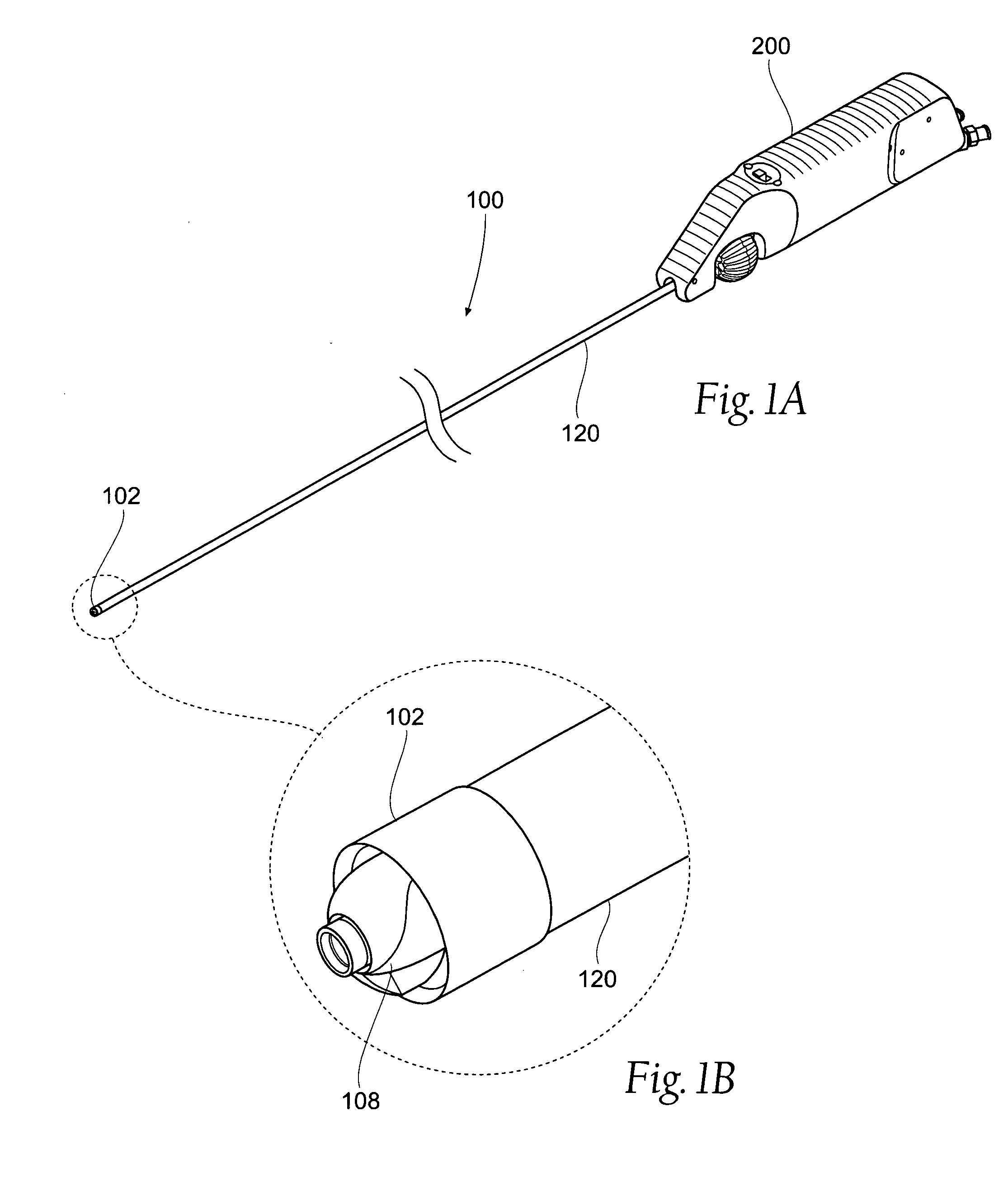

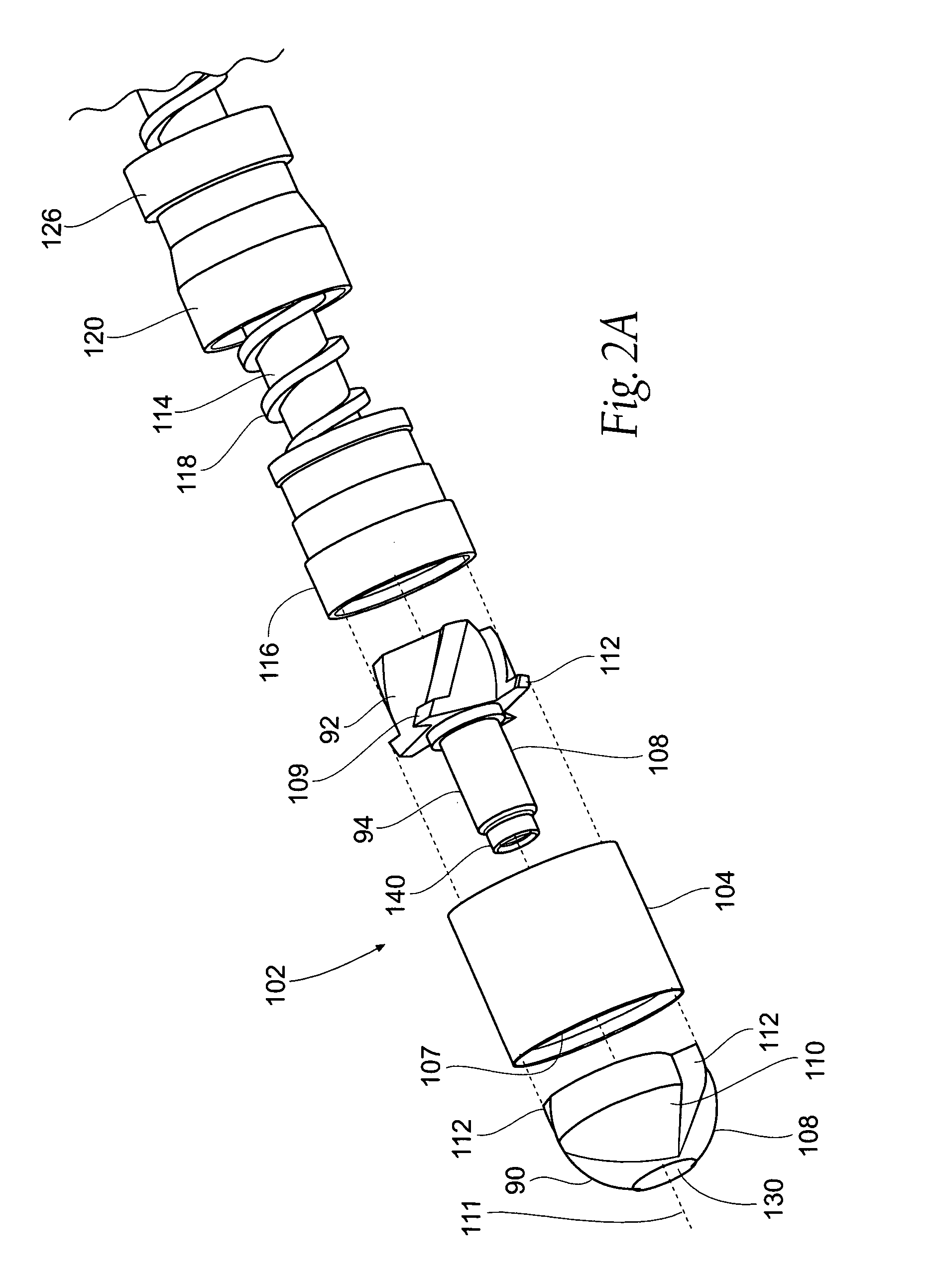

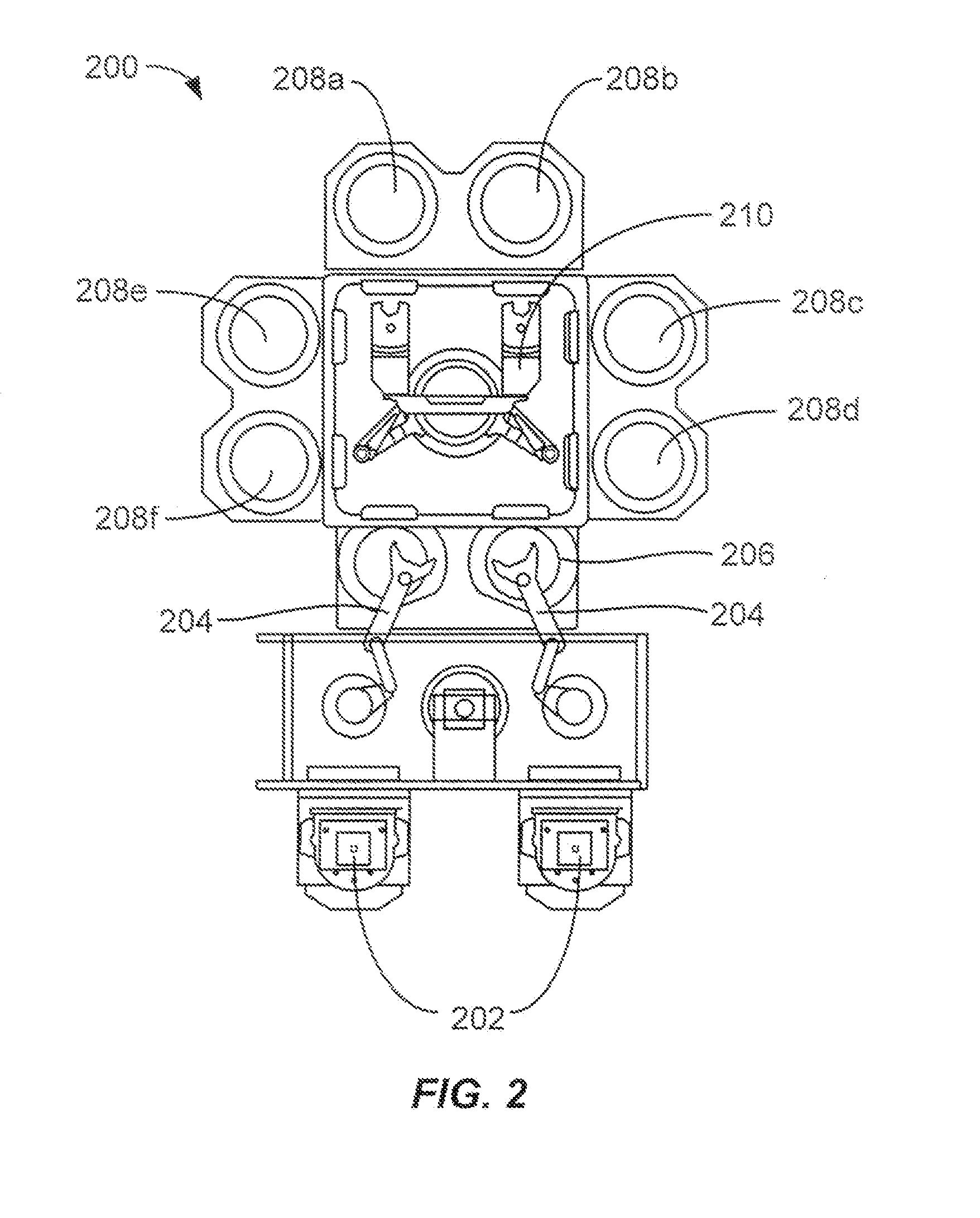

Atherectomy devices, systems, and methods

Owner:ATHEROMED

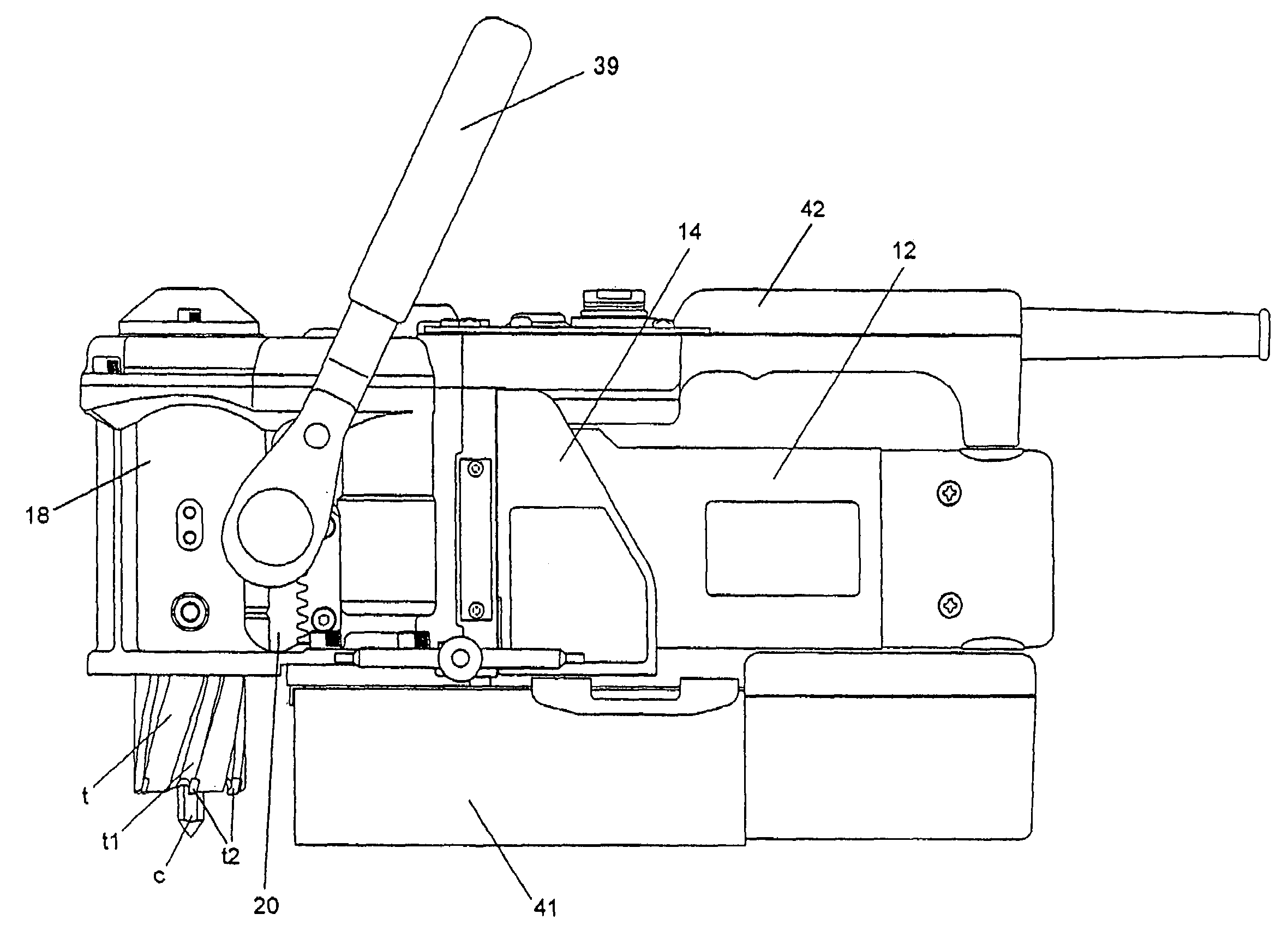

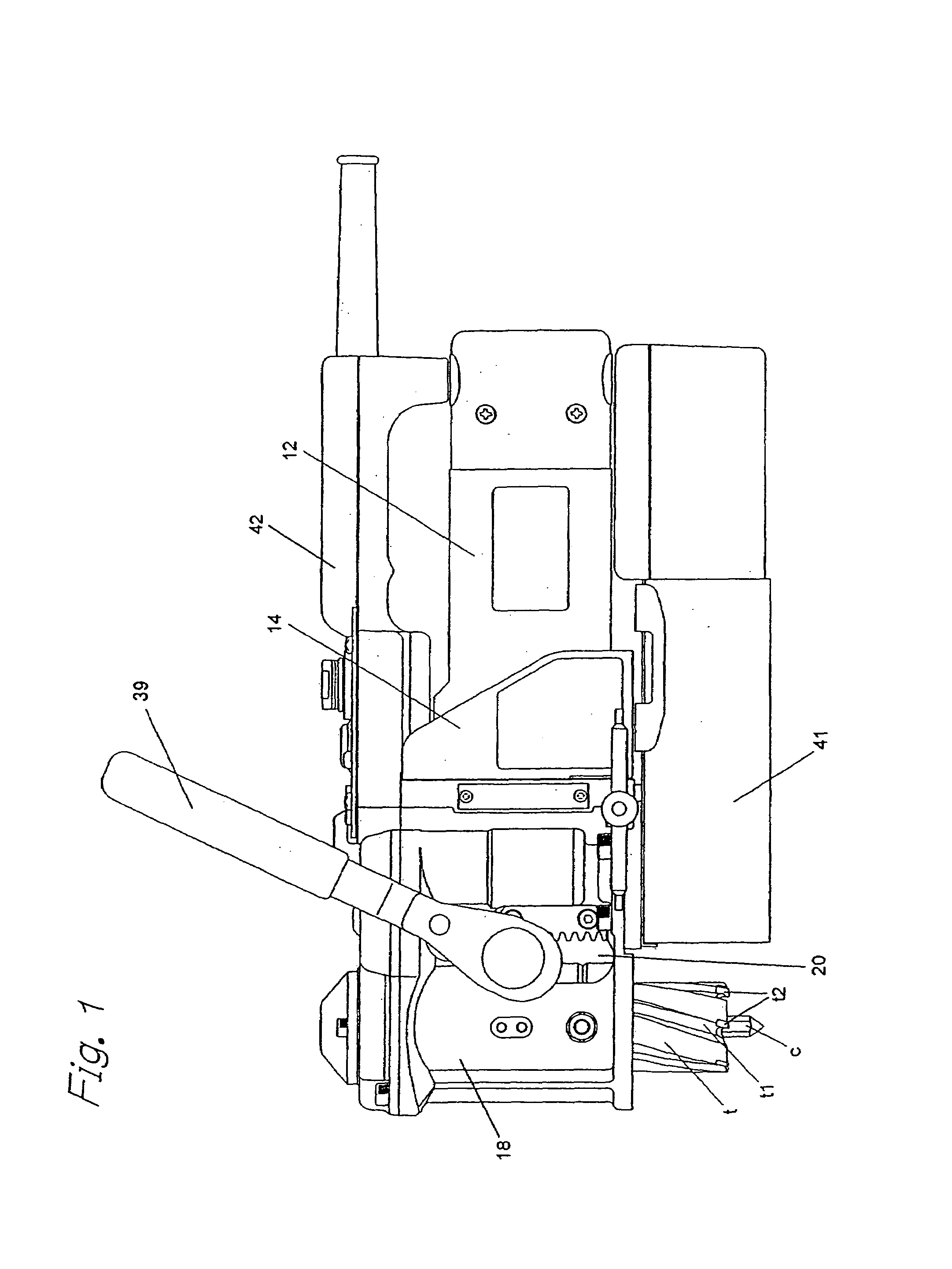

Electric drill apparatus

InactiveUS7121773B2Reduce weight and sizeLow profileDrilling/boring measurement devicesThread cutting machinesRotational axisAnnular cutter

An electric drill apparatus having a low profile is provided which comprises an annular cutter, a motor for rotating the annular cutter, a rotary shaft assembly for rotating the annular cutter attached to its leading end about a rotating, a rotation reduction mechanism disposed between the motor and rotary shaft assembly for transmitting a driving force of the motor to the annular cutter through the rotary shaft assembly, a feed mechanism responsive to an operation of a manual handle, for moving the rotary shaft assembly along with a straight line to advance or retract the annular cutter attached to the rotary shaft assembly with respect to a workpiece, and an adhesion base for securing the electric drill apparatus to the workpiece. The annular cutter has a plurality of cutting blades comprised of cemented carbide tips fixed on its lower end, thereby it is capable of rotating at a high speed. The rotary shaft assembly has a rotating shaft which rotates in a direction different from that of a rotating shaft of the motor, thereby the drill apparatus has a low profile.

Owner:NITTO KOHKI CO LTD

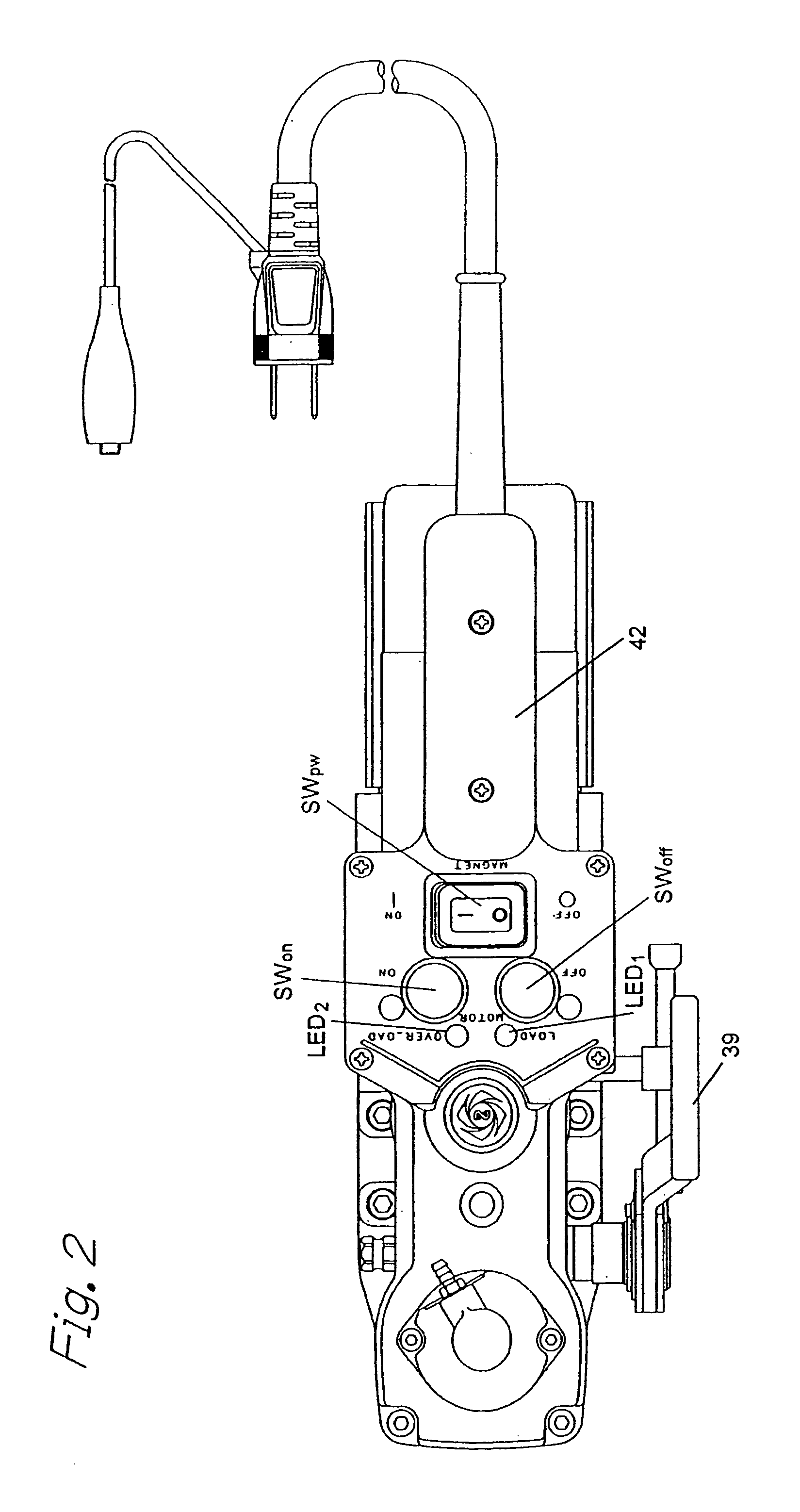

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

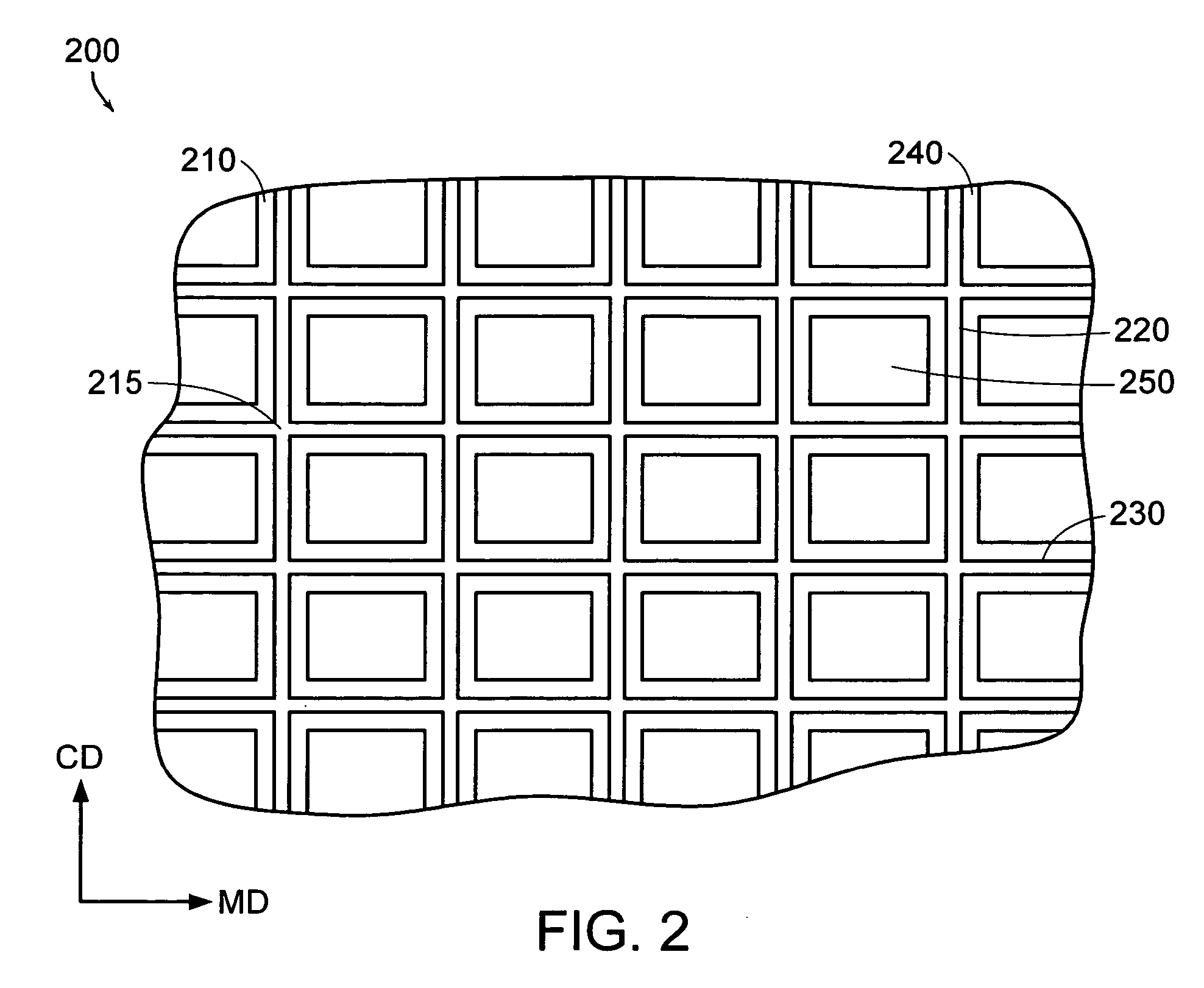

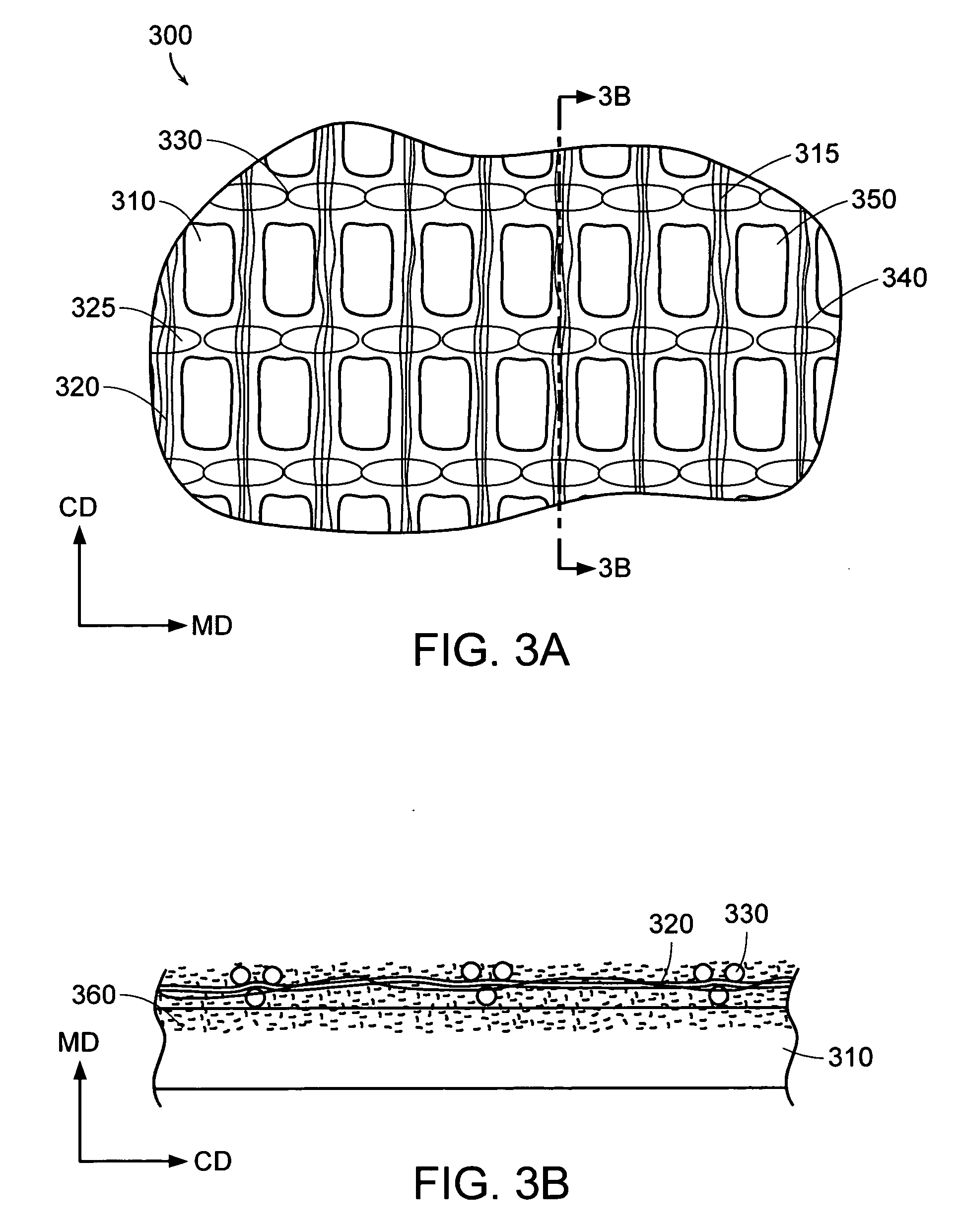

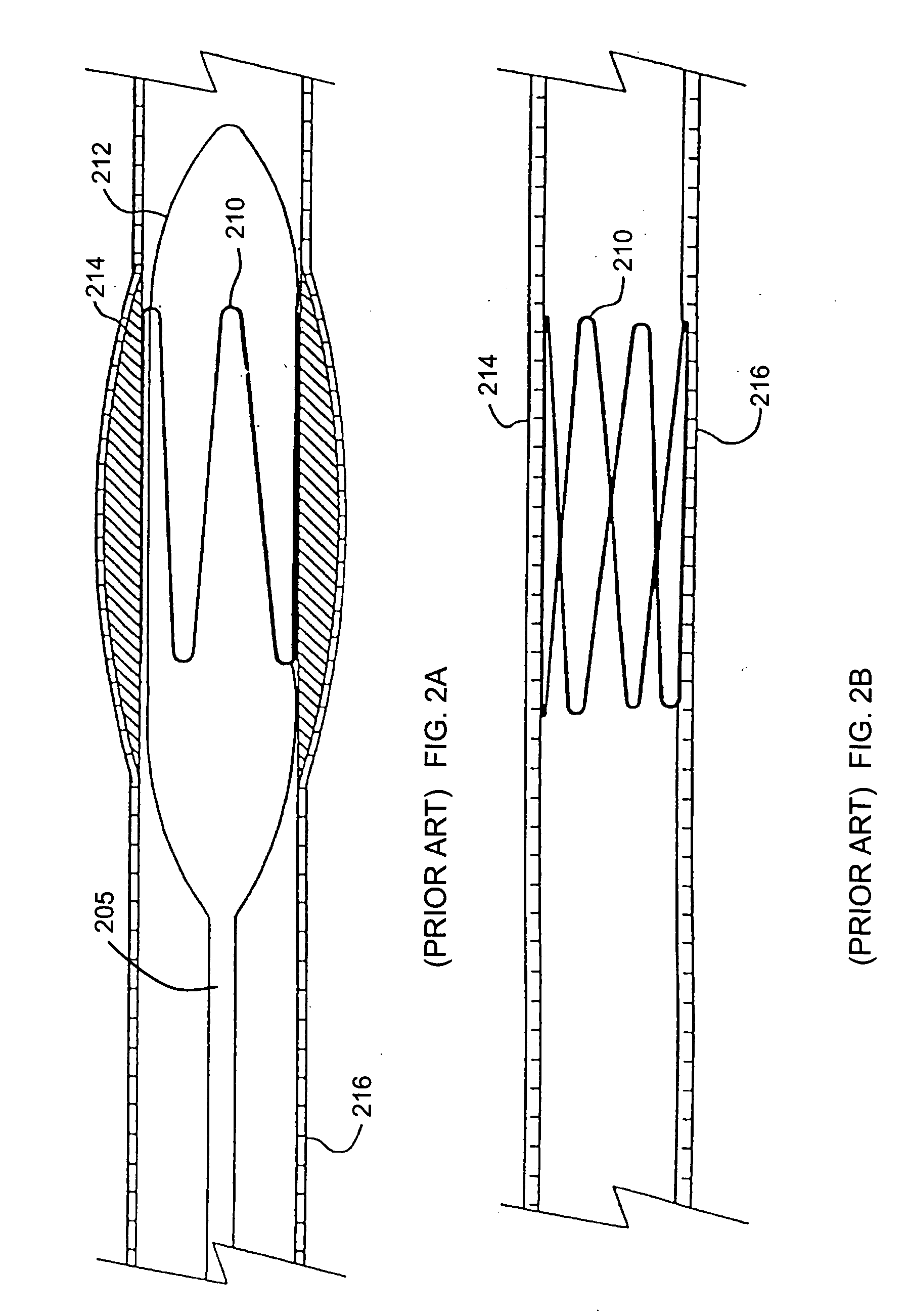

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

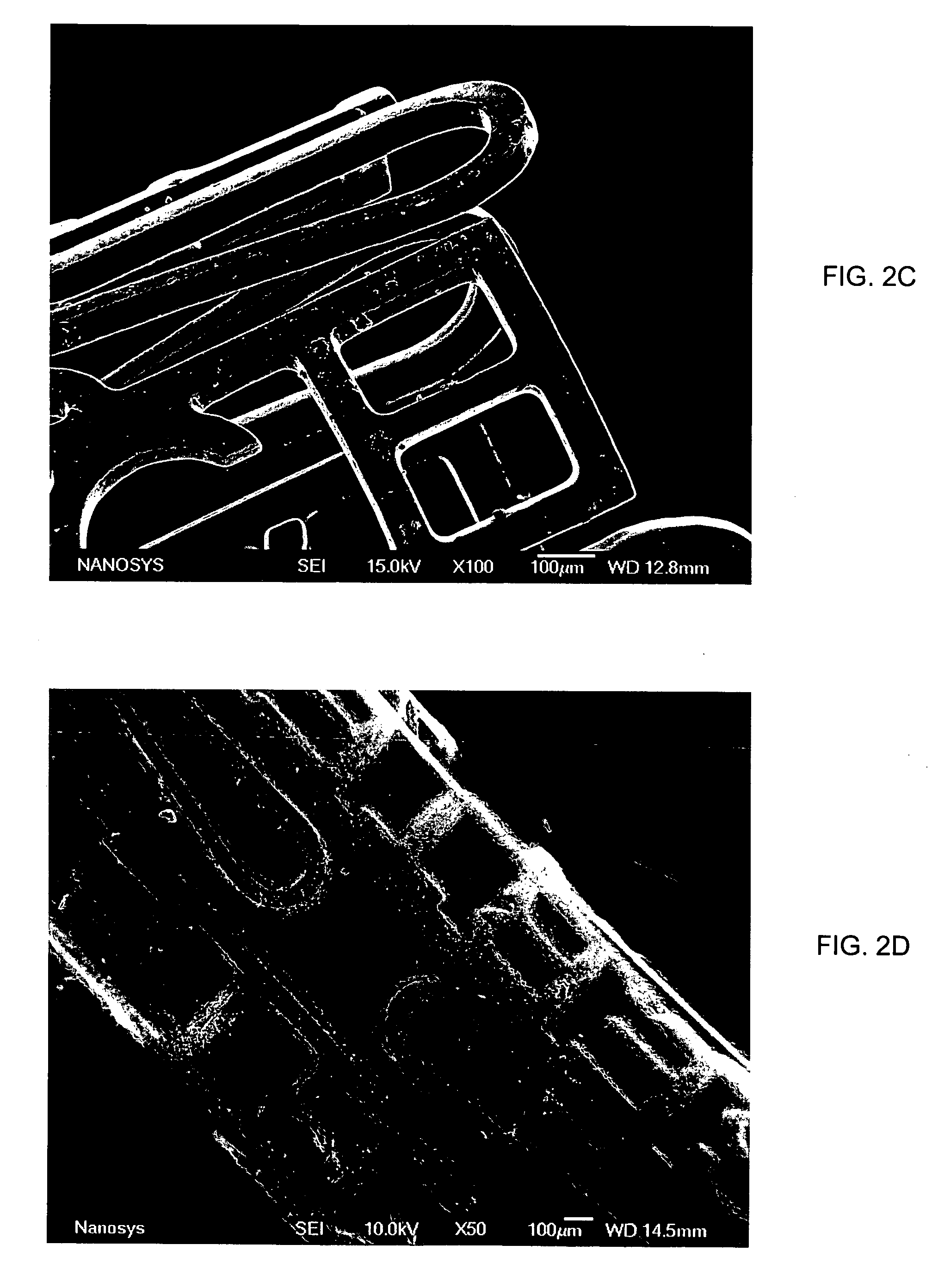

Medical device applications of nanostructured surfaces

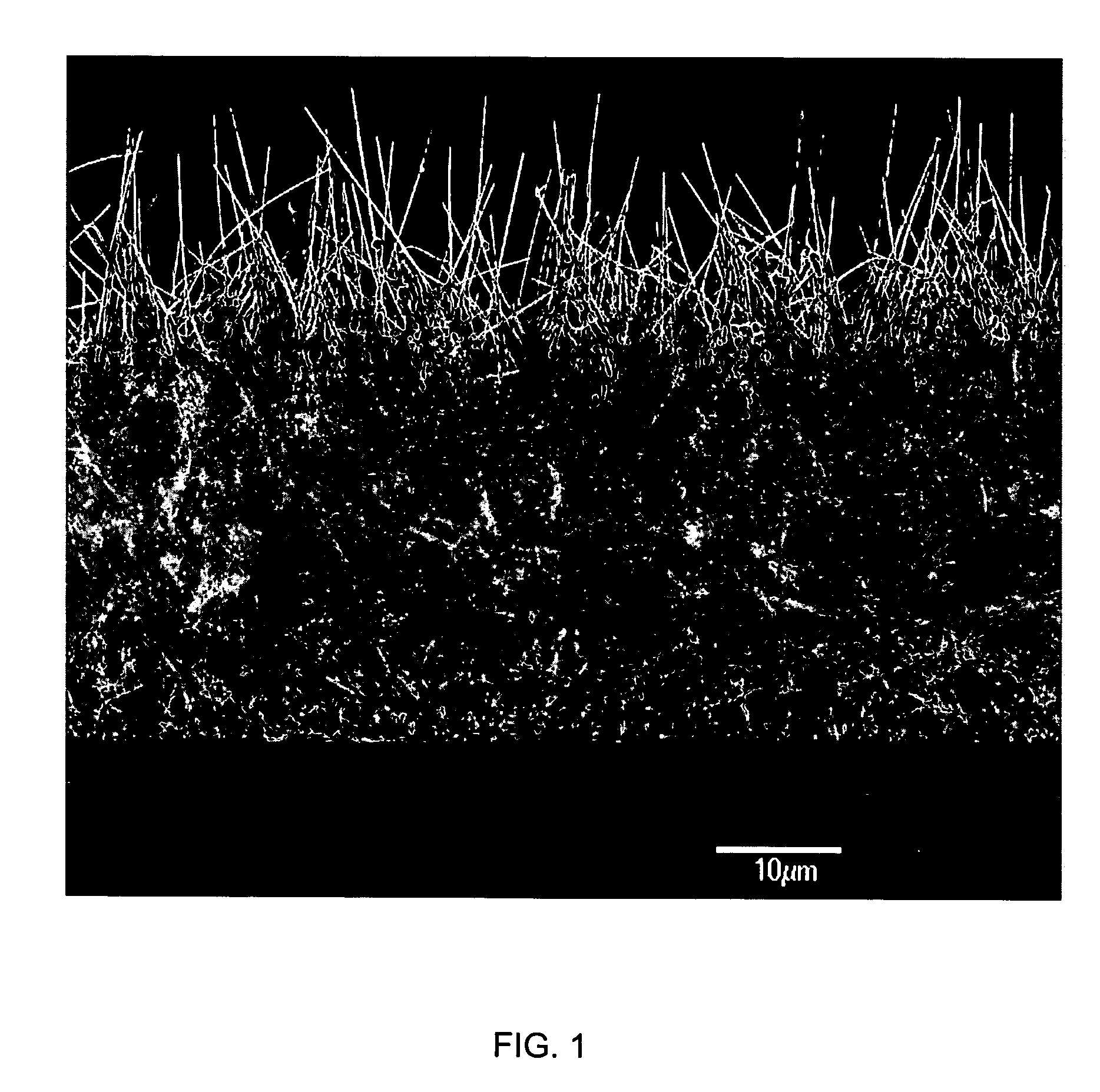

InactiveUS20060204738A1Improve adhesionIncrease frictionBiocideMaterial nanotechnologyOsteoblastNanofiber

This invention provides novel nanofiber enhanced surface area substrates and structures comprising such substrates for use in various medical devices, as well as methods and uses for such substrates and medical devices. In one particular embodiment, methods for enhancing cellular functions on a surface of a medical device implant are disclosed which generally comprise providing a medical device implant comprising a plurality of nanofibers (e.g., nanowires) thereon and exposing the medical device implant to cells such as osteoblasts.

Owner:GLO TECH LLC

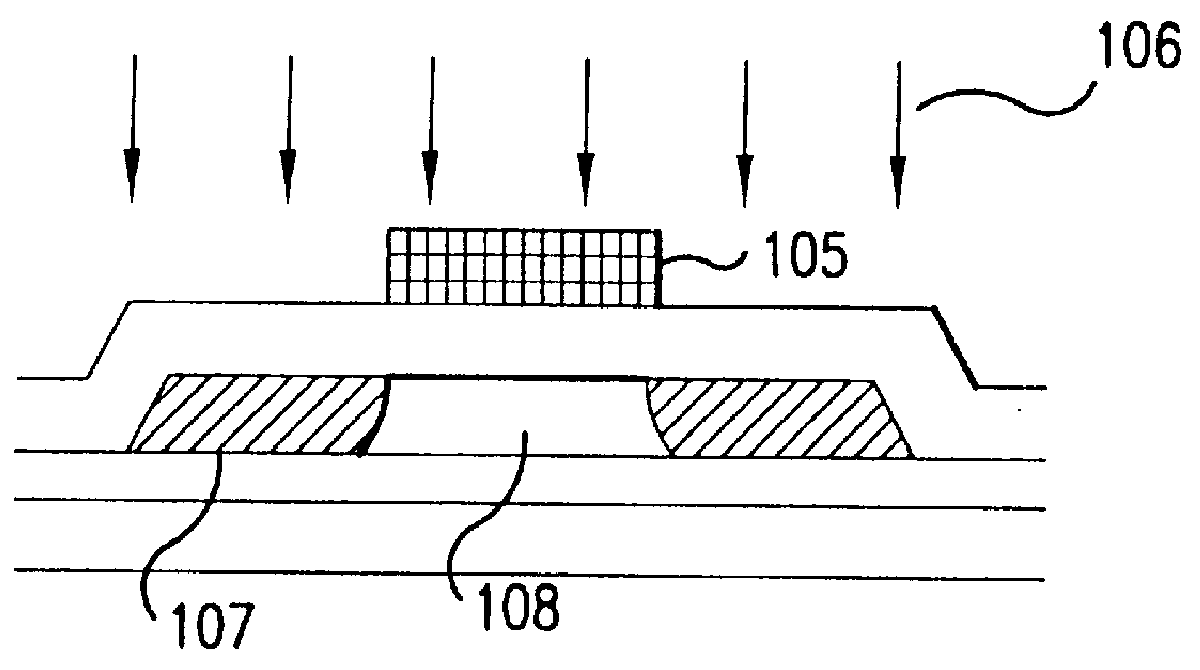

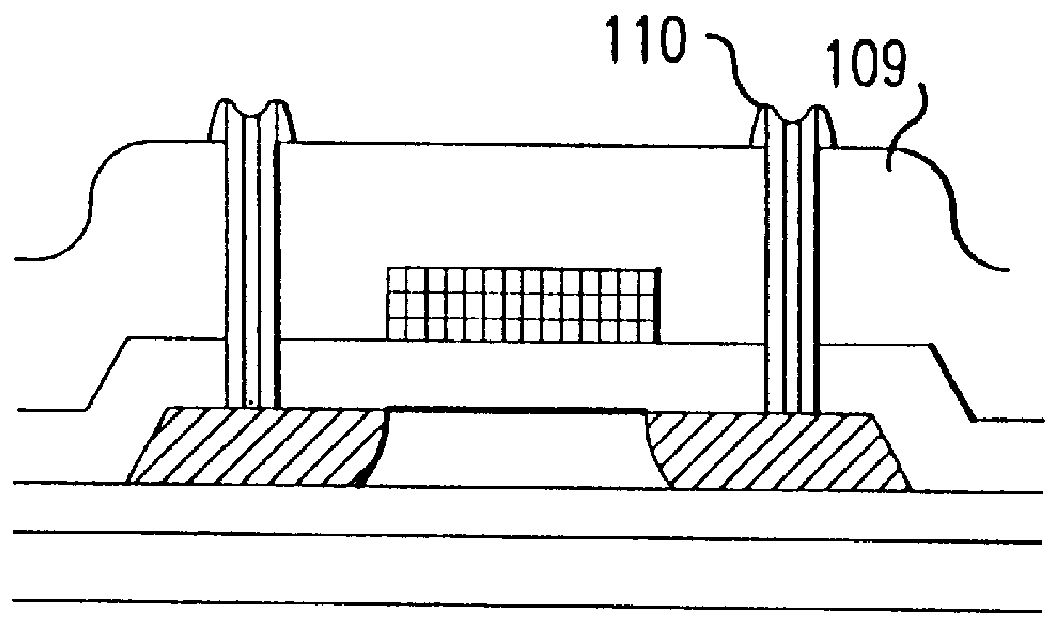

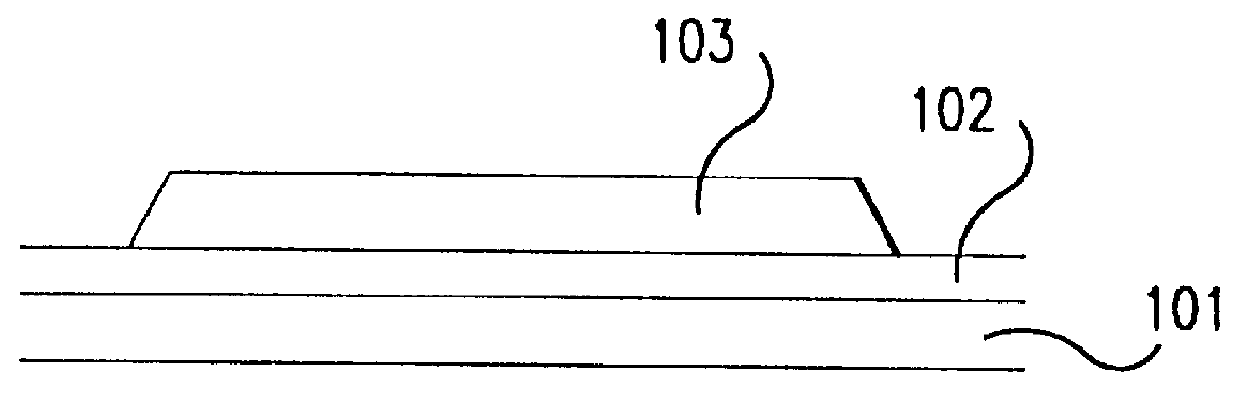

Fabrication method for a thin film semiconductor device, the thin film semiconductor device itself, liquid crystal display, and electronic device

InactiveUS6017779AImprove propertiesWell formedTransistorLinear bearingsElectronic circuitLiquid-crystal display

In order to fabricate a high performance thin film semiconductor device using a low temperature process in which it is possible to use low price glass substrates, a thin film semiconductor device has been fabricated by forming a silicon film at less than 450 DEG C., and, after crystallization, keeping the maximum processing temperature at or below 350 DEG C. In applying the present invention to the fabrication of an active matrix liquid crystal display, it is possible to both easily and reliably fabricate a large, high-quality liquid crystal display. Additionally, in applying the present invention to the fabrication of other electronic circuits as well, it is possible to both easily and reliably fabricate high-quality electronic circuits.

Owner:INTELLECTUAL KEYSTONE TECH

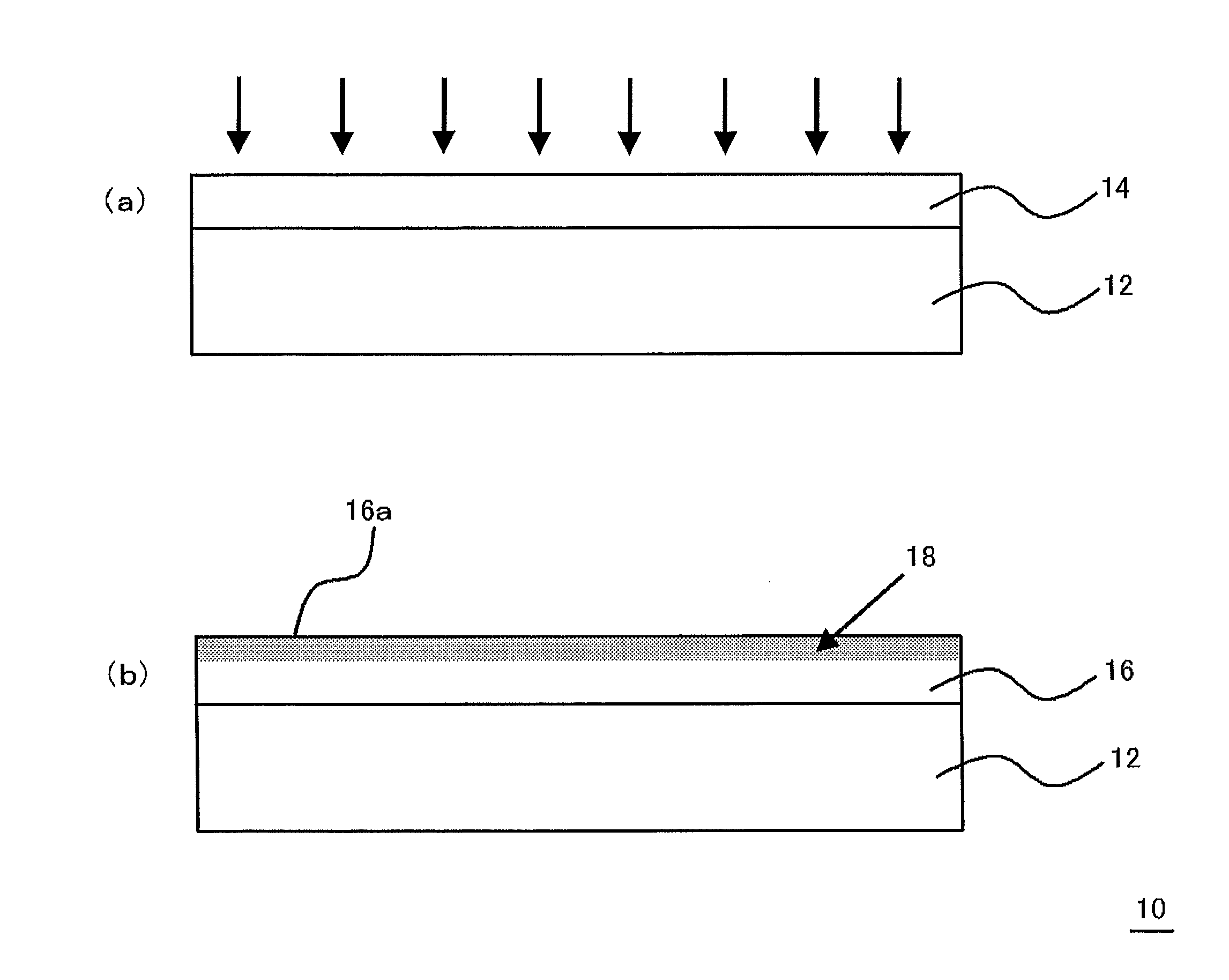

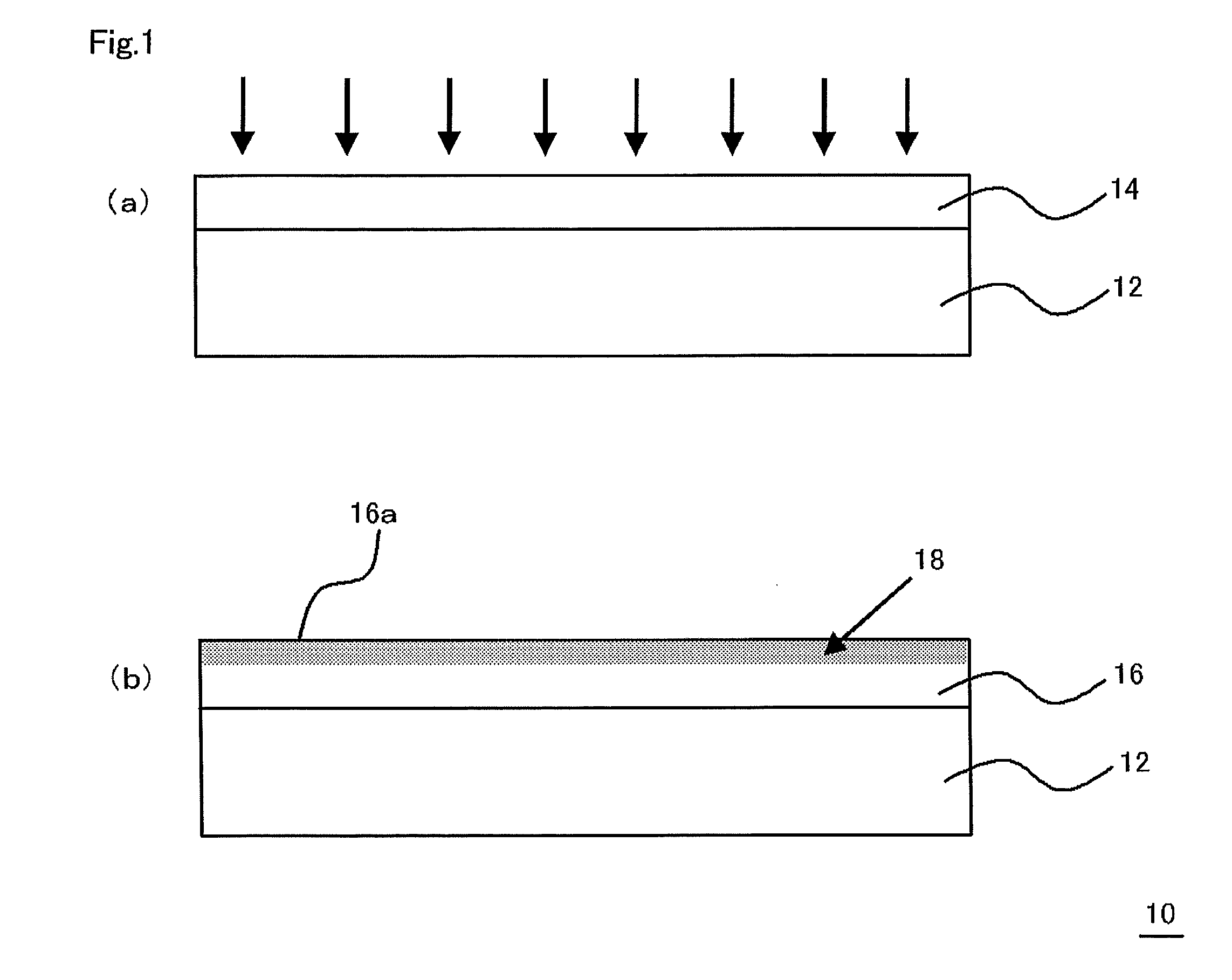

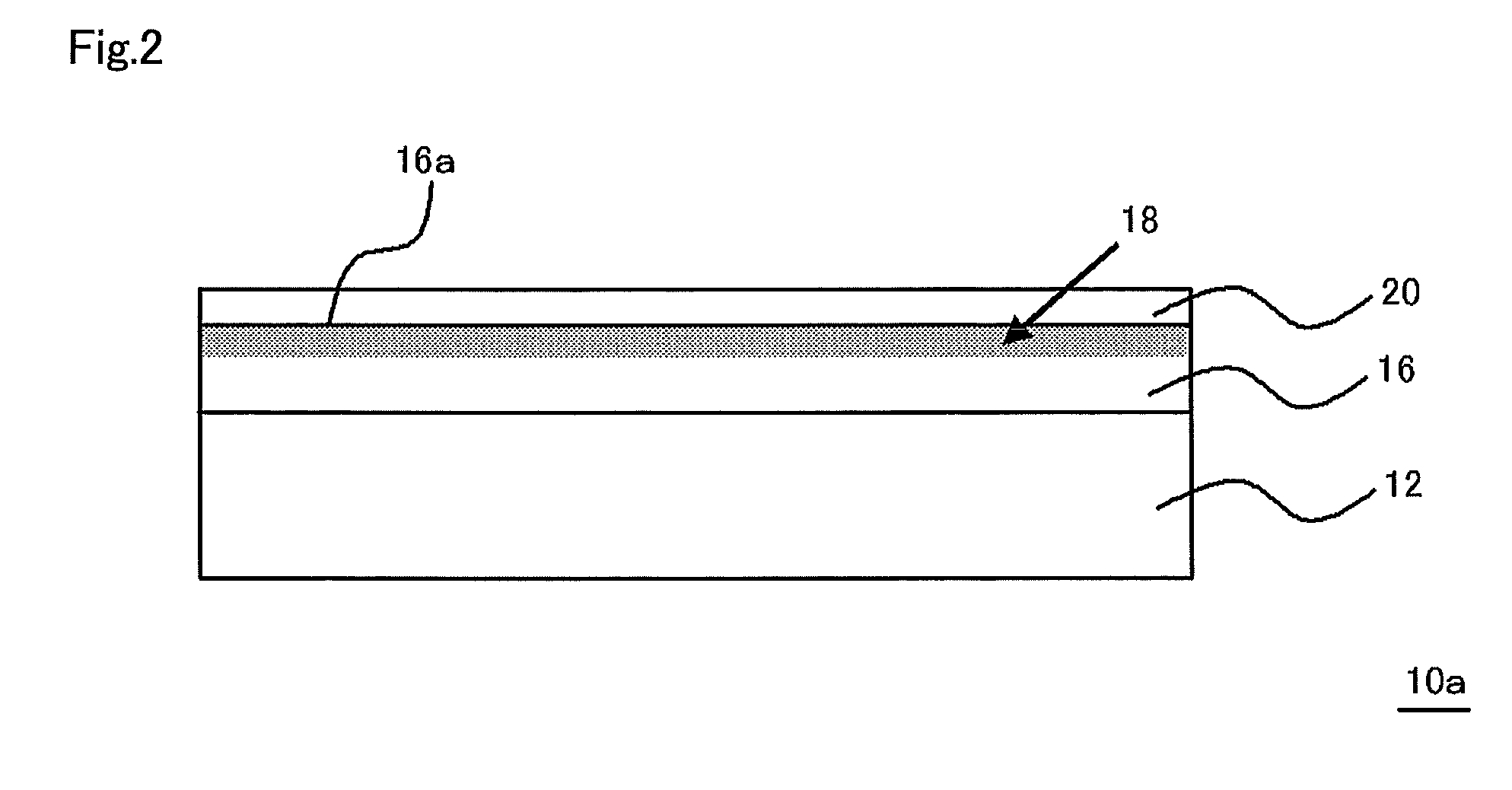

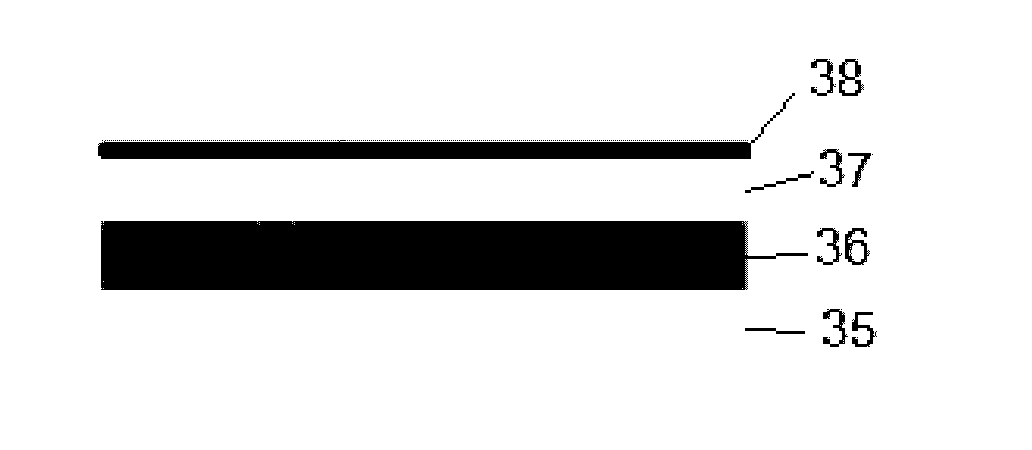

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

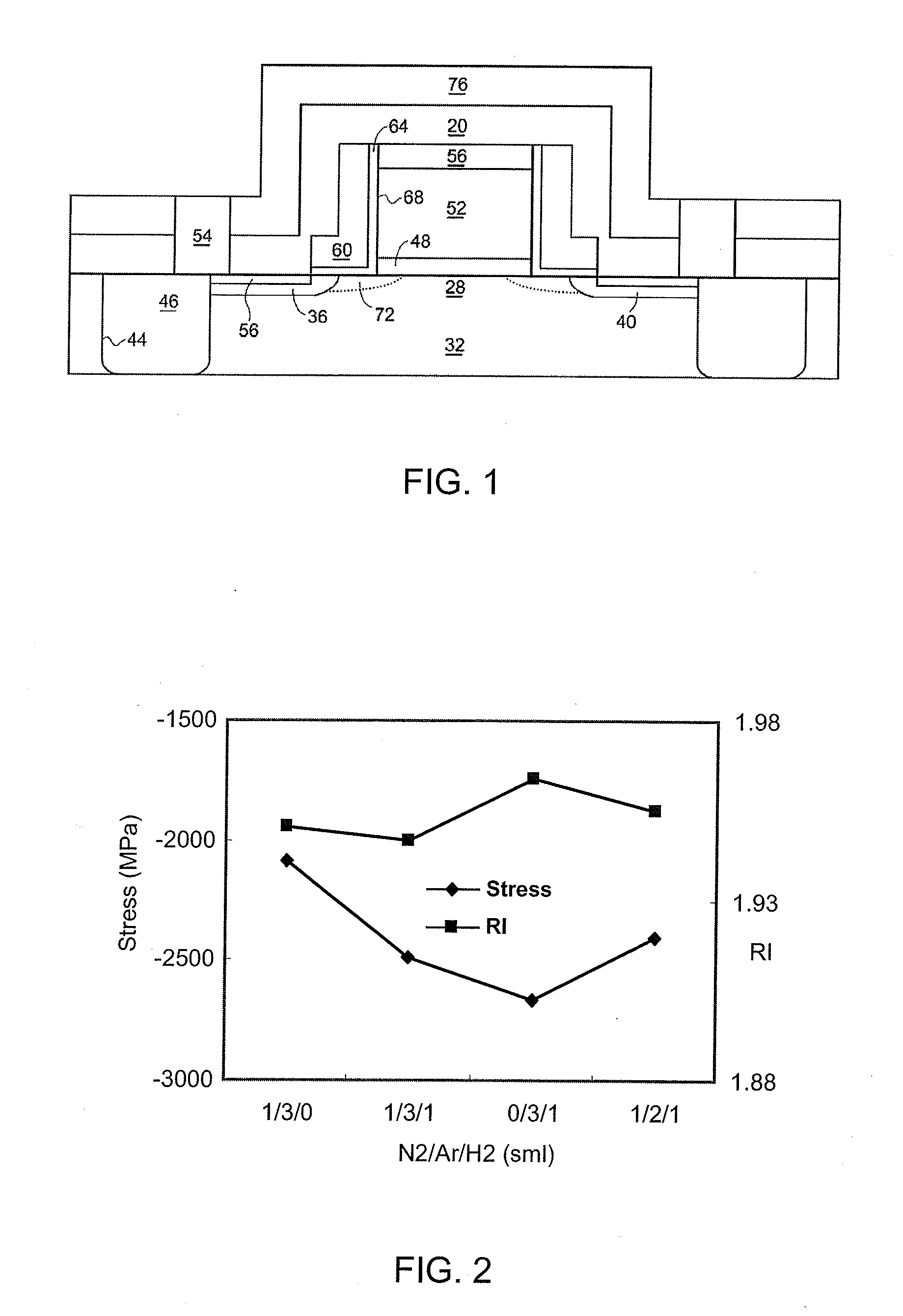

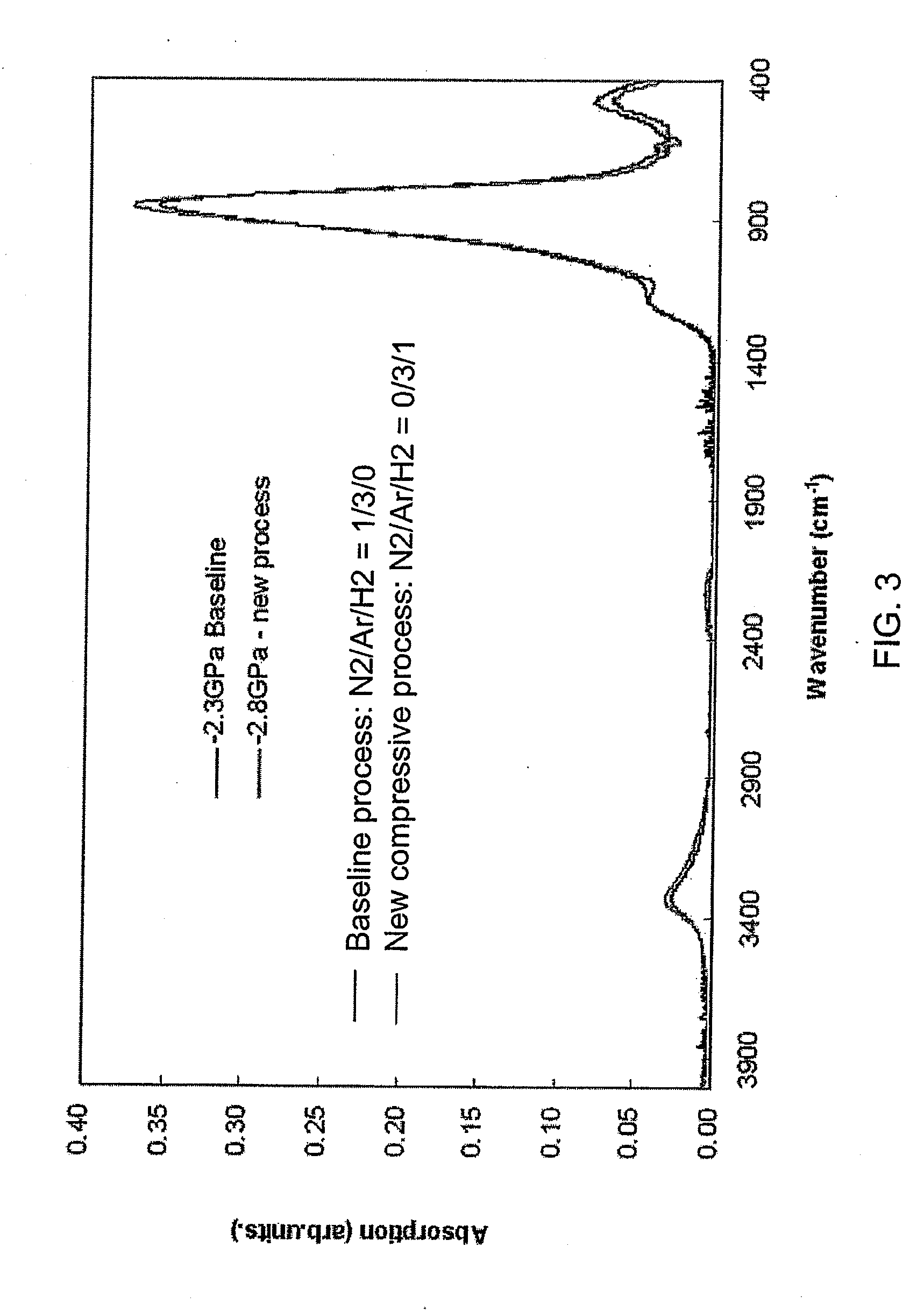

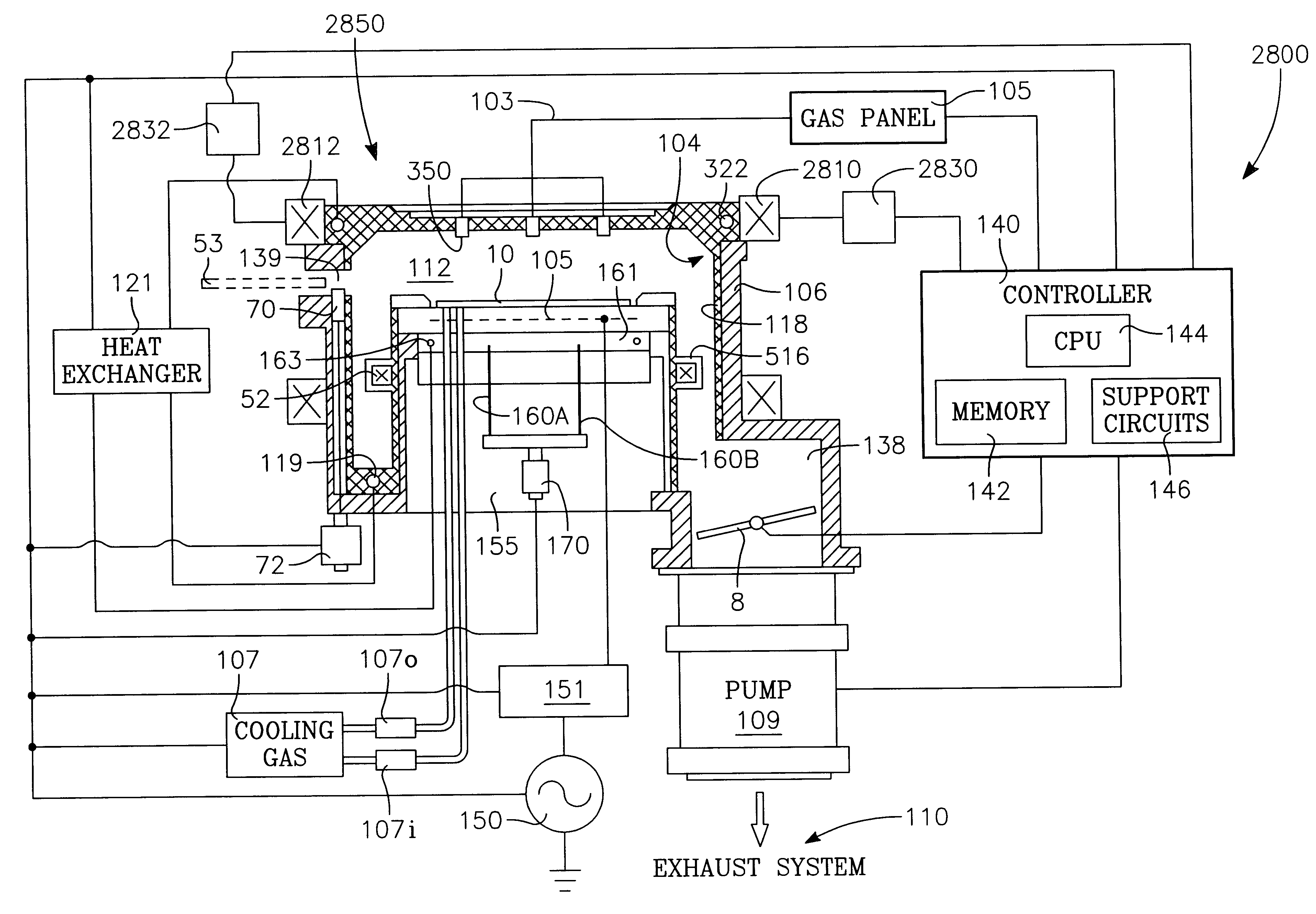

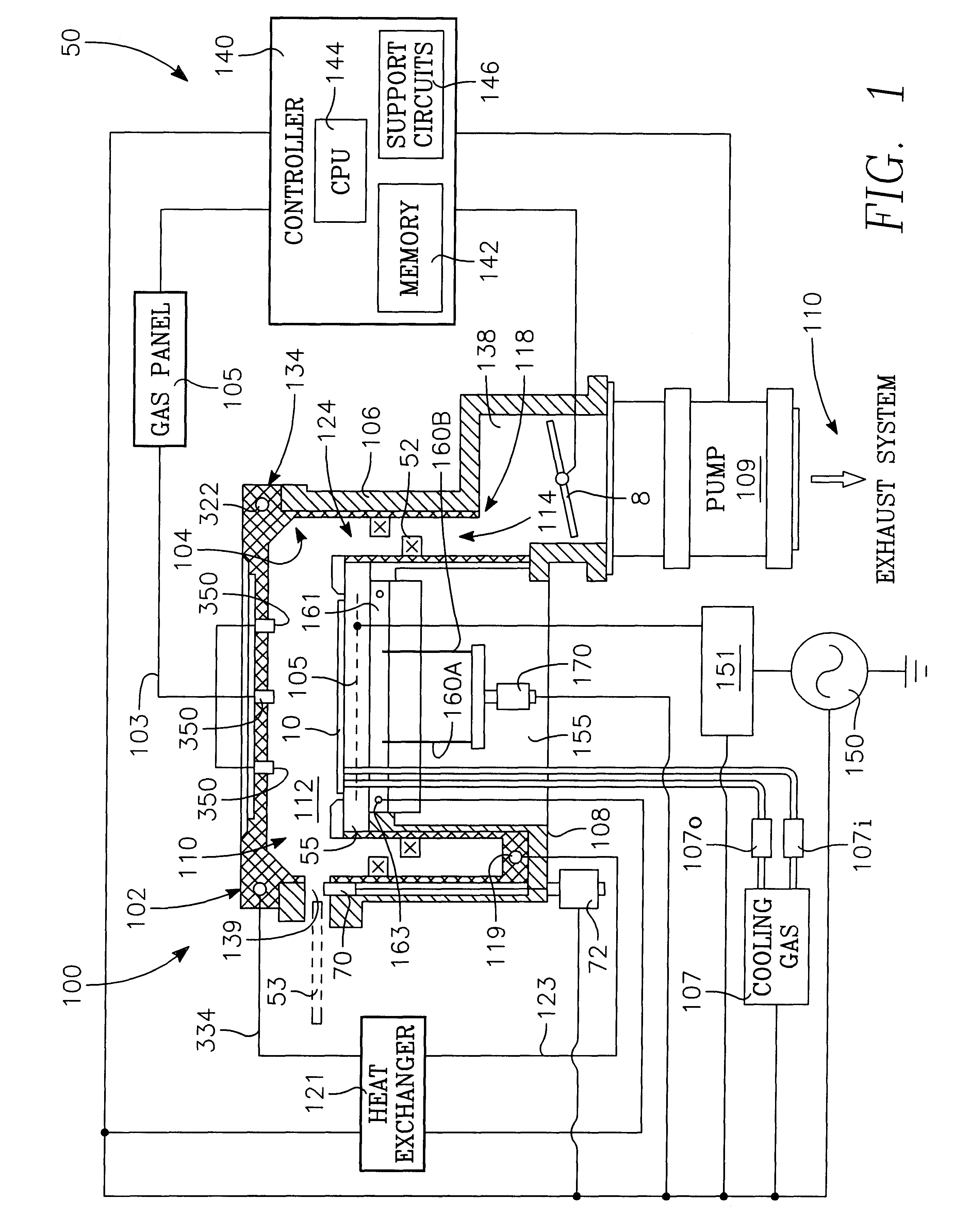

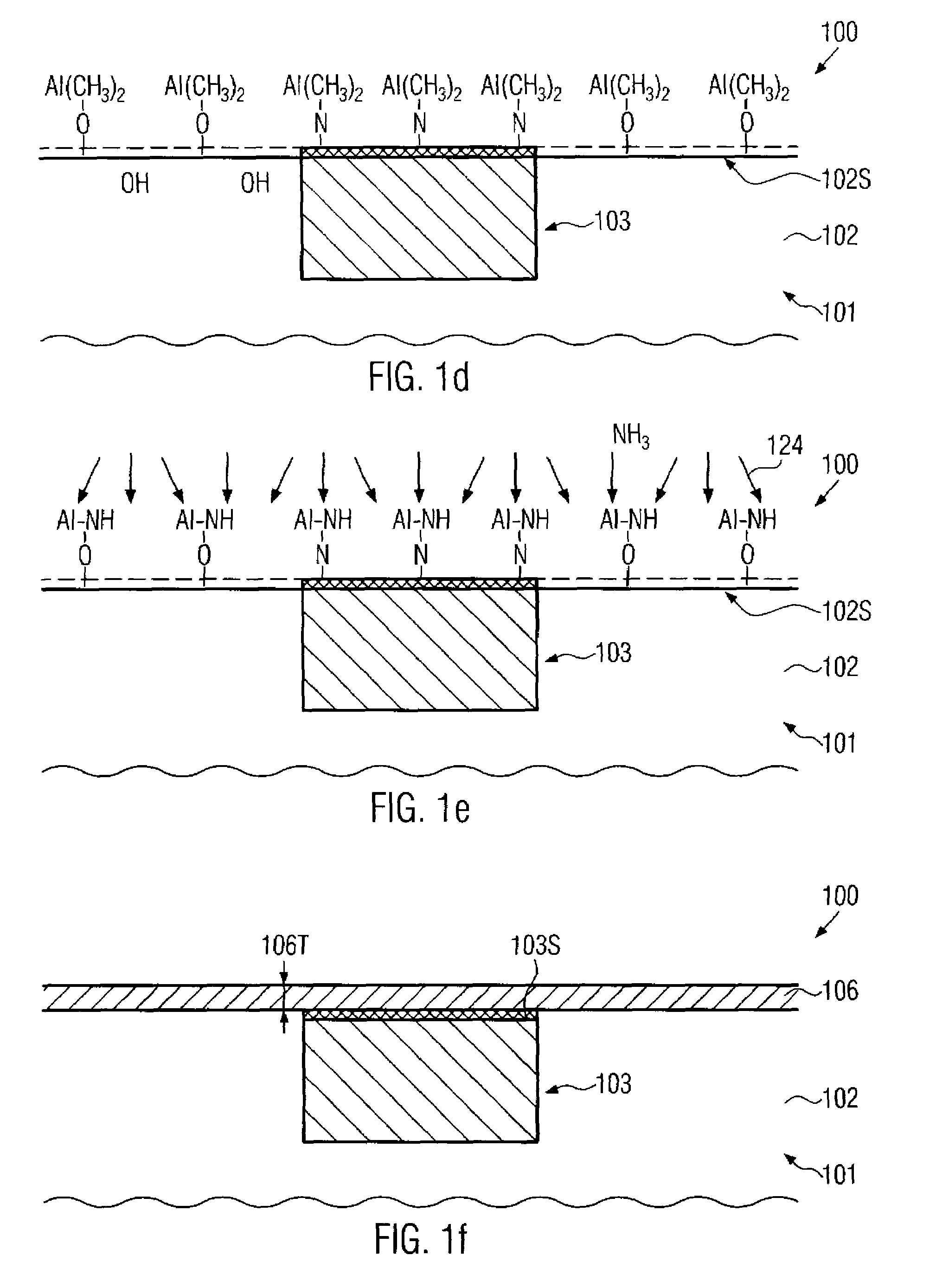

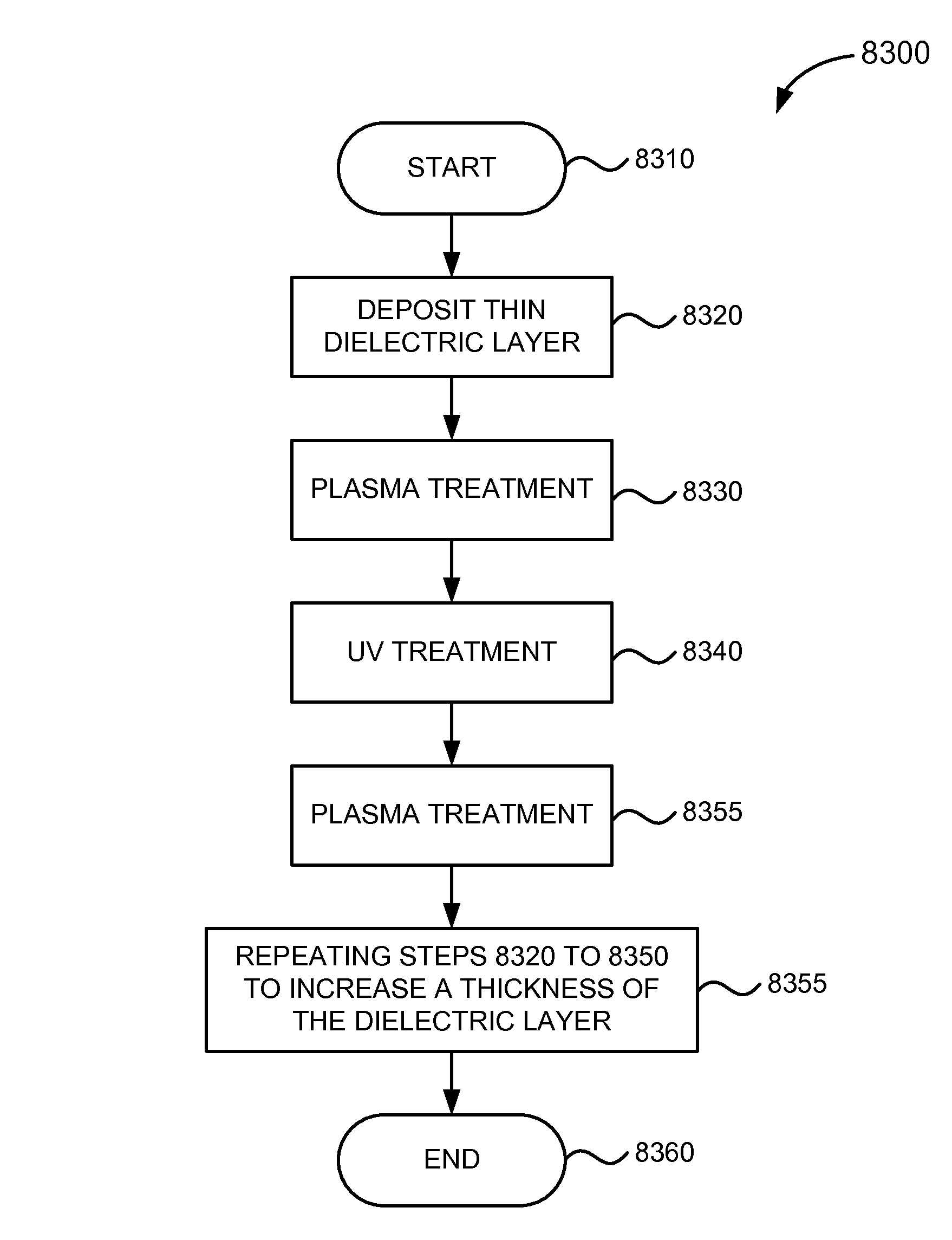

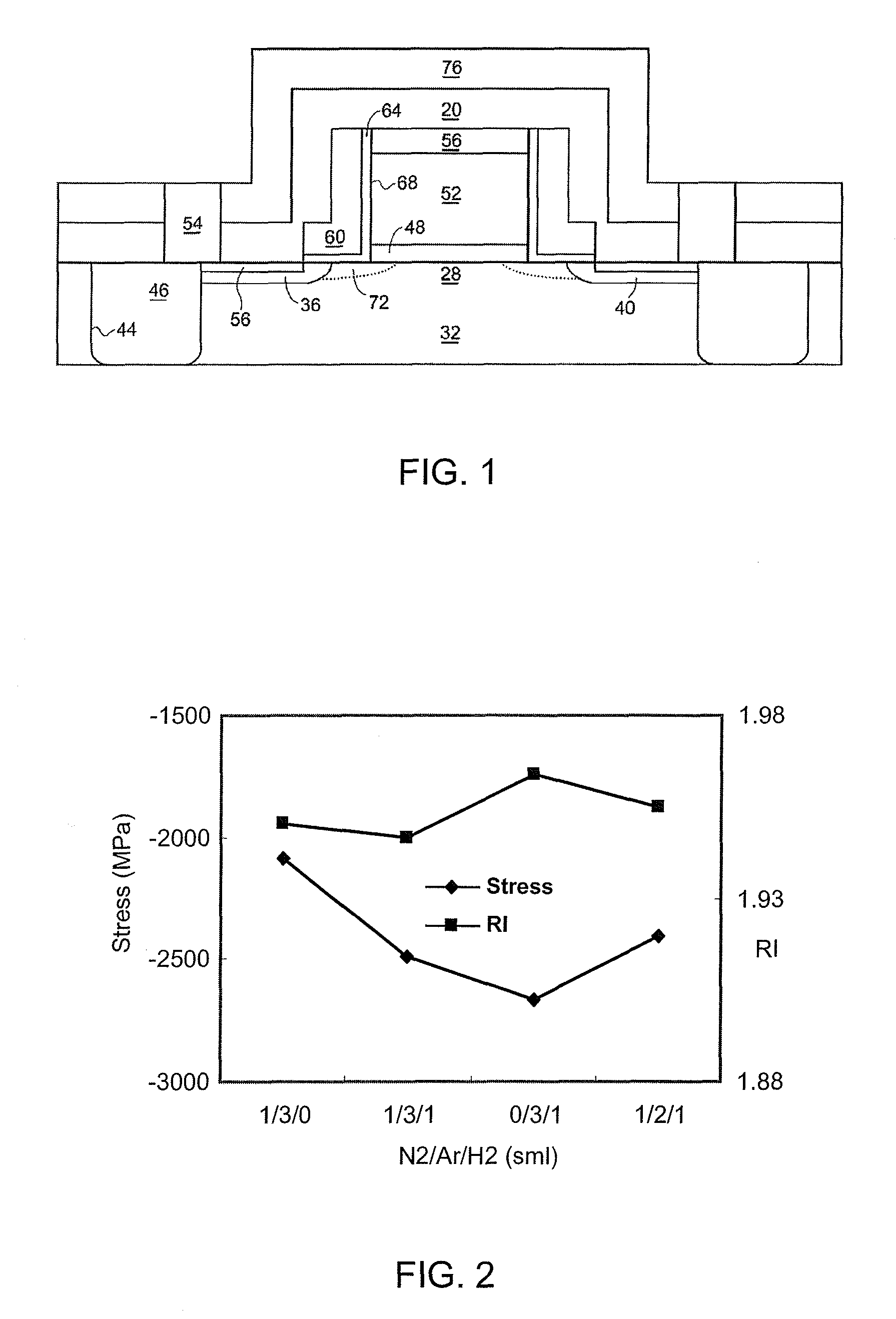

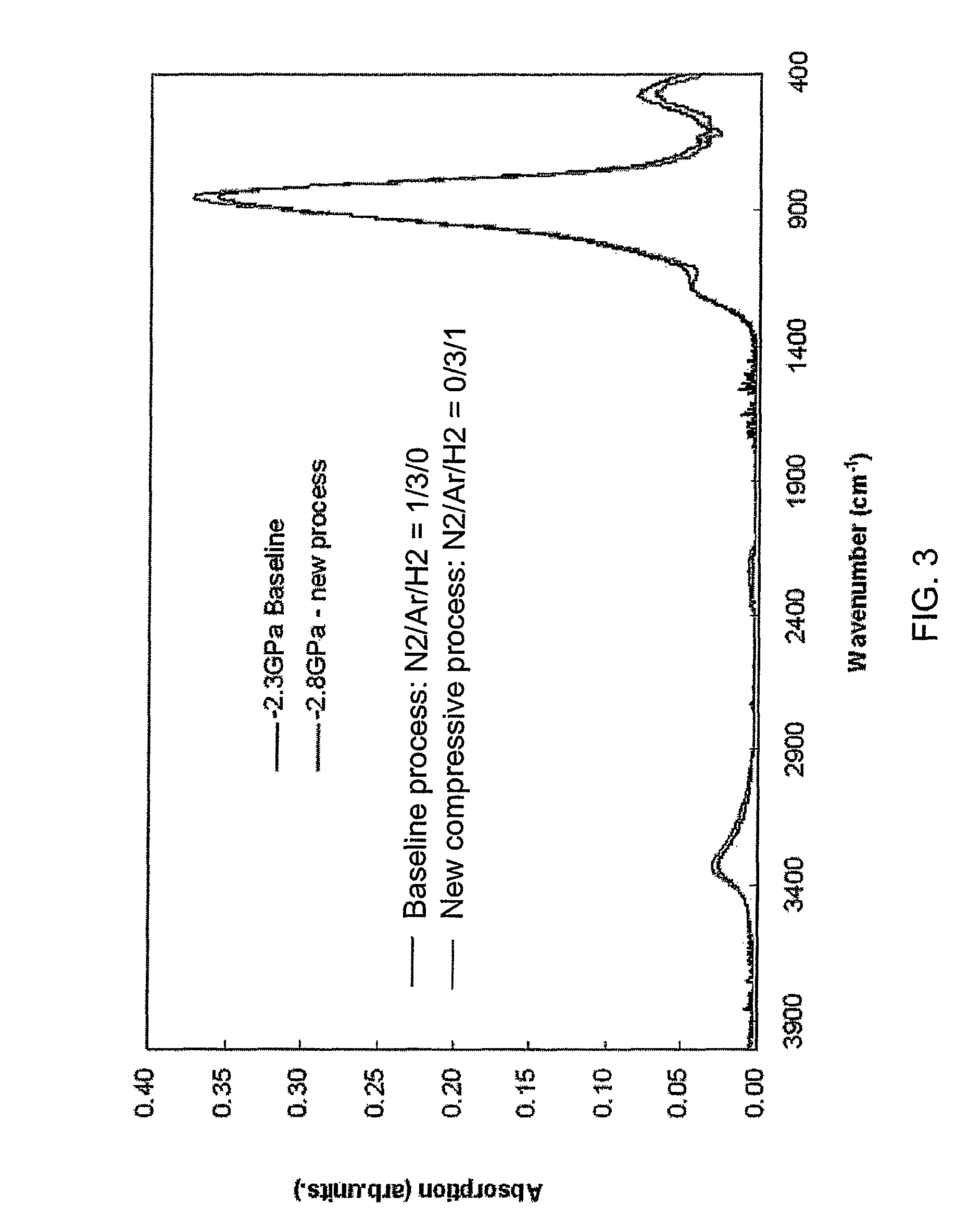

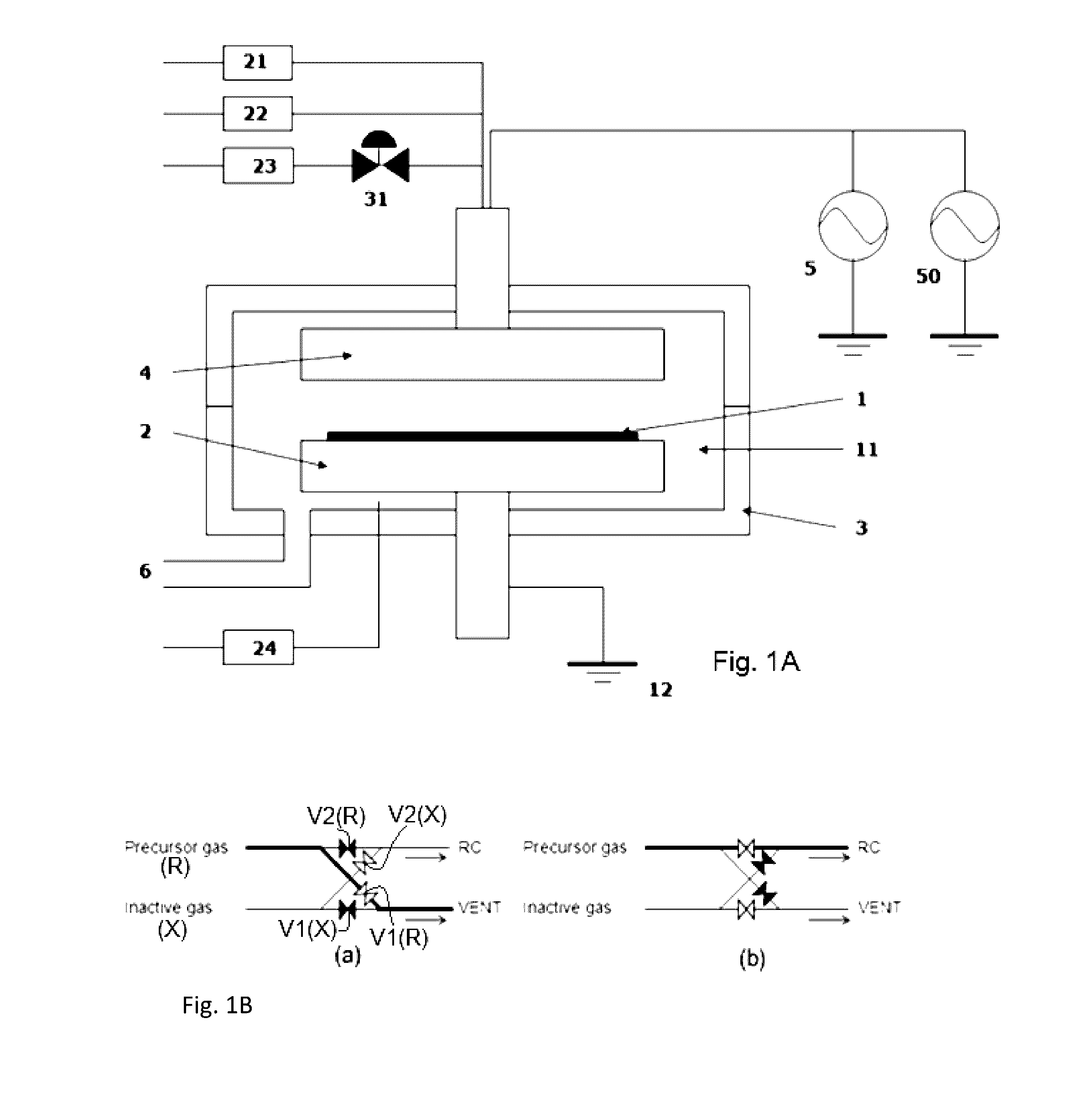

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

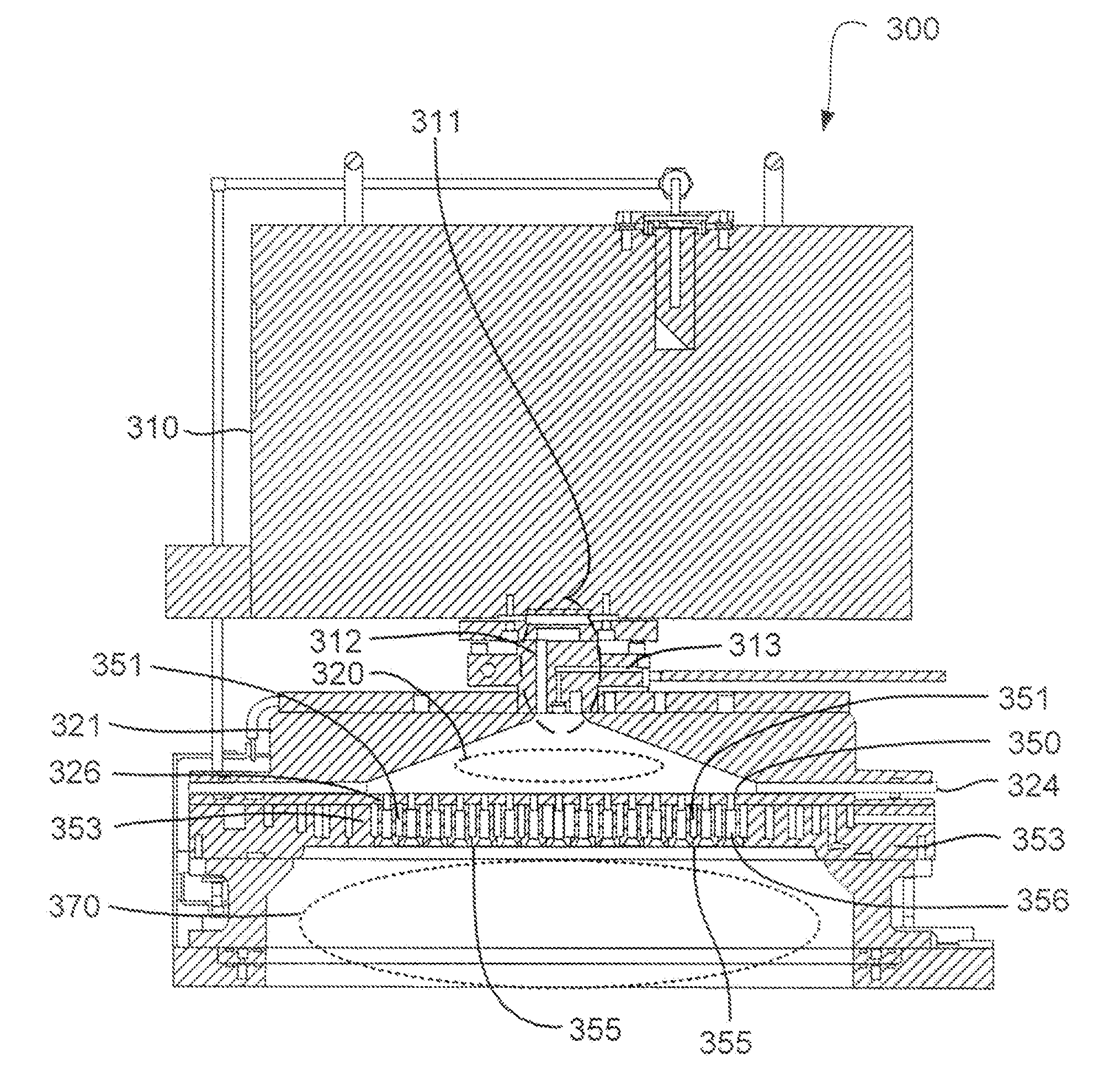

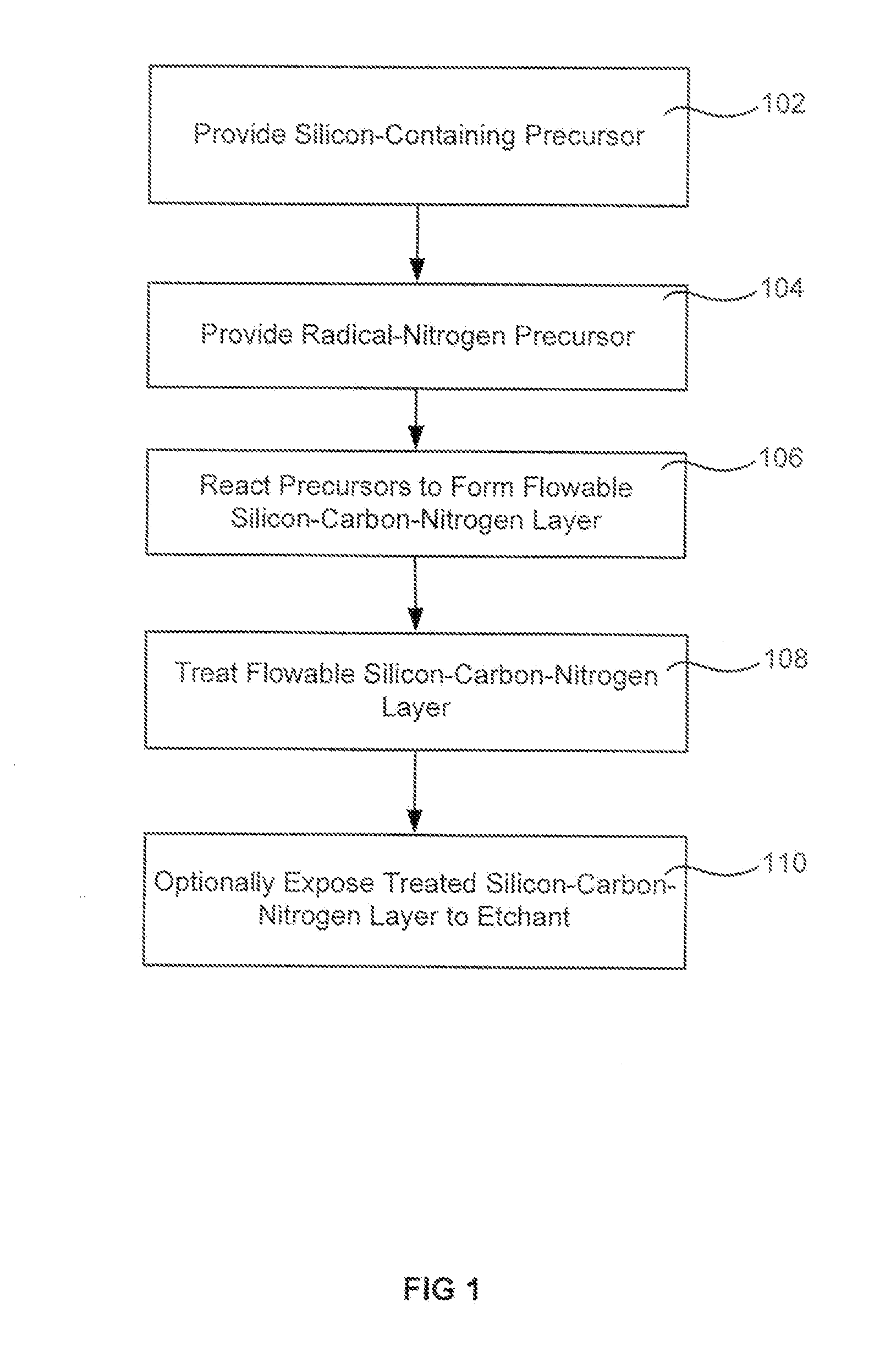

Flowable silicon-carbon-nitrogen layers for semiconductor processing

InactiveUS20130217240A1Reduce in quantityIncrease the number ofSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionDielectric layer

Methods are described for forming a dielectric layer on a semiconductor substrate. The methods may include providing a silicon-containing precursor and an energized nitrogen-containing precursor to a chemical vapor deposition chamber. The silicon-containing precursor and the energized nitrogen-containing precursor may be reacted in the chemical vapor deposition chamber to deposit a flowable silicon-carbon-nitrogen material on the substrate. The methods may further include treating the flowable silicon-carbon-nitrogen material to form the dielectric layer on the semiconductor substrate.

Owner:APPLIED MATERIALS INC

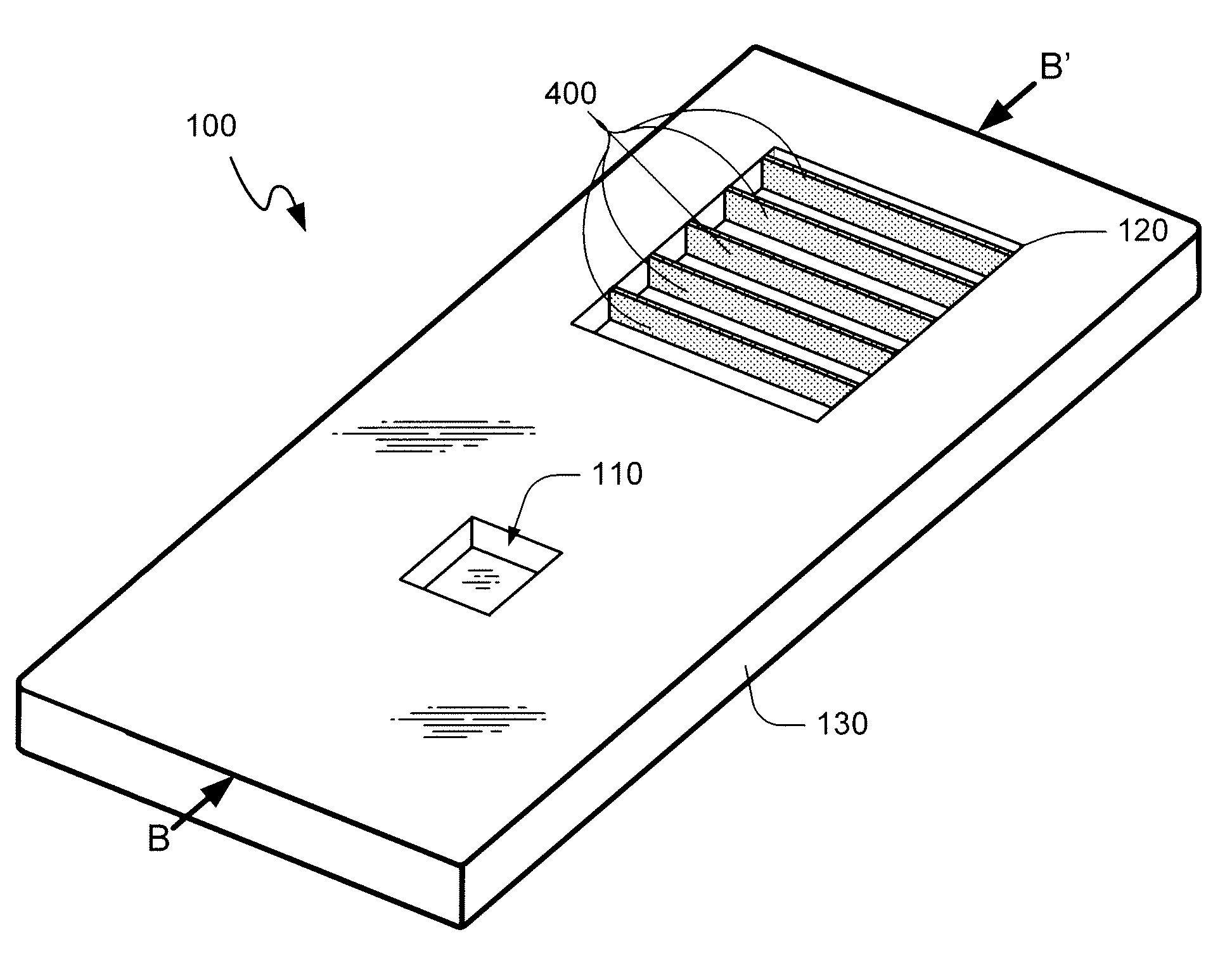

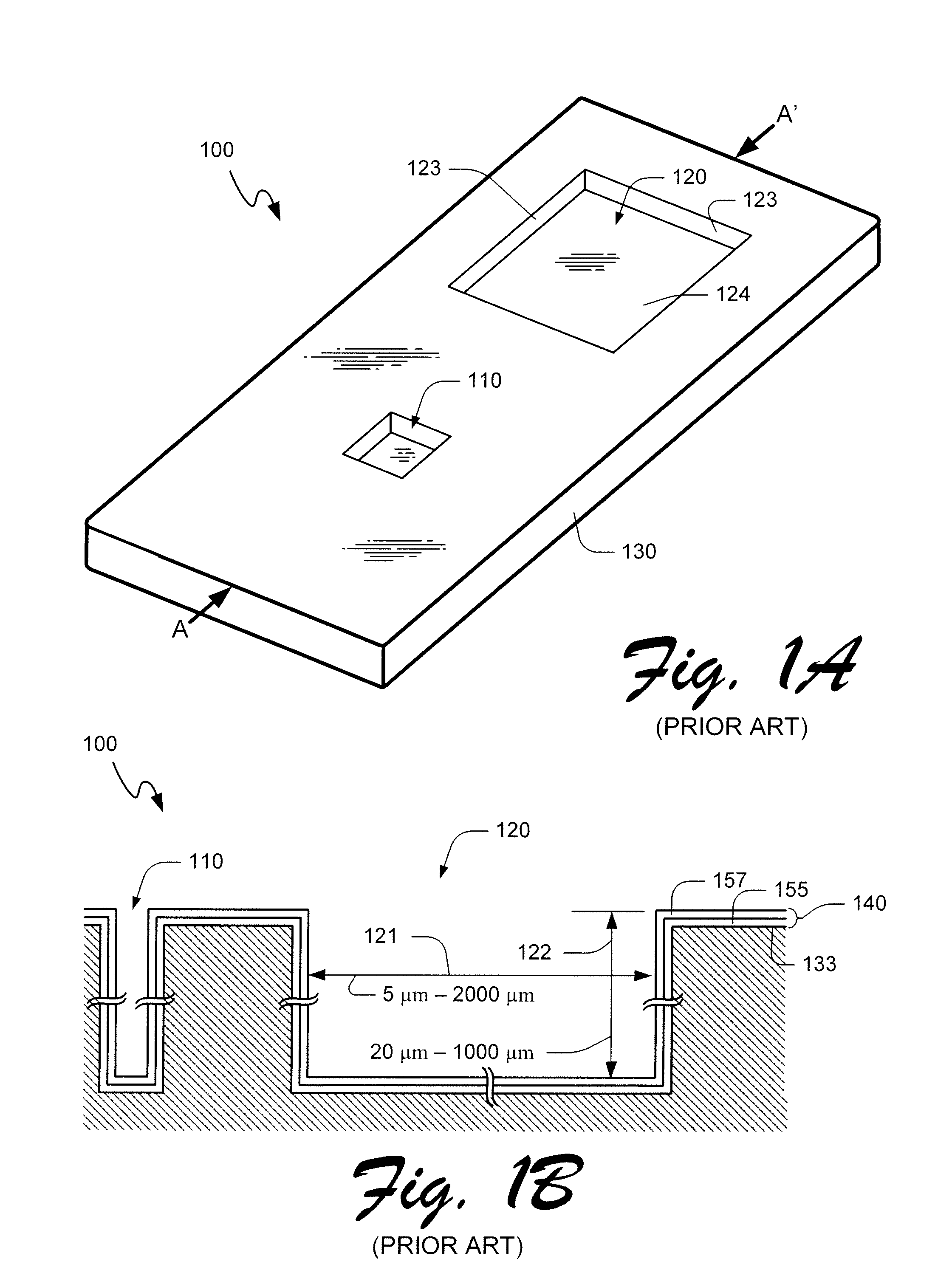

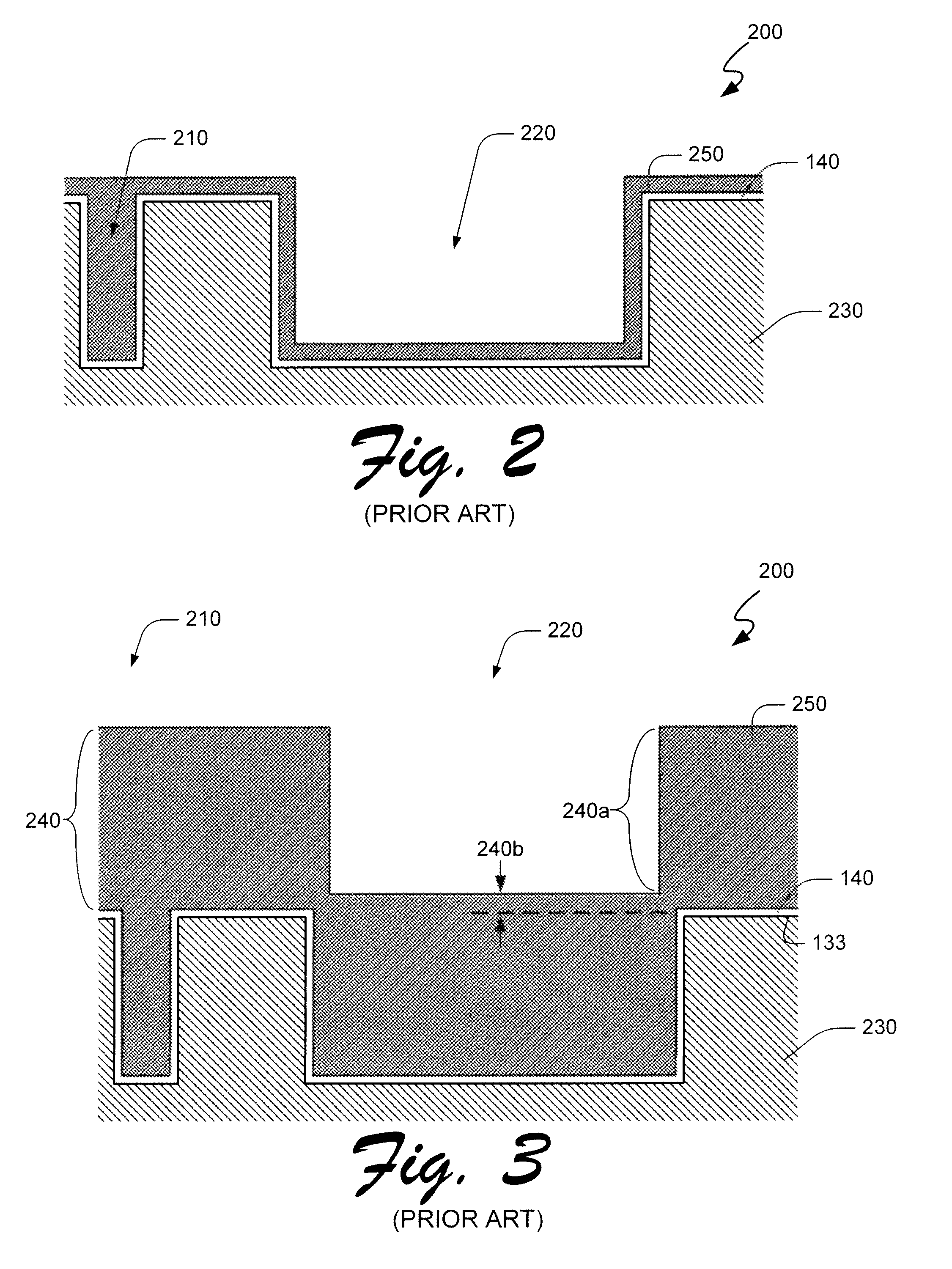

Method and apparatus for 3D interconnect

ActiveUS8076237B2Improve adhesionInhibited DiffusionSemiconductor/solid-state device detailsPrinted circuit aspectsConductive materialsEngineering

The present invention discloses methods for depositing a material, particularly a conductive material, in cavities of a substrate and forming bonding contacts or pads thereon. An intracavity structure may be utilized in conjunction with embodiments of the present invention to provide efficient filling of diverse cavities within the substrate. Also provided are embodiments for interconnection structures using filled cavities, along with electrically conductive or reactive structures which may include capacitors fabricated within a substrate.

Owner:ASM NUTOOL

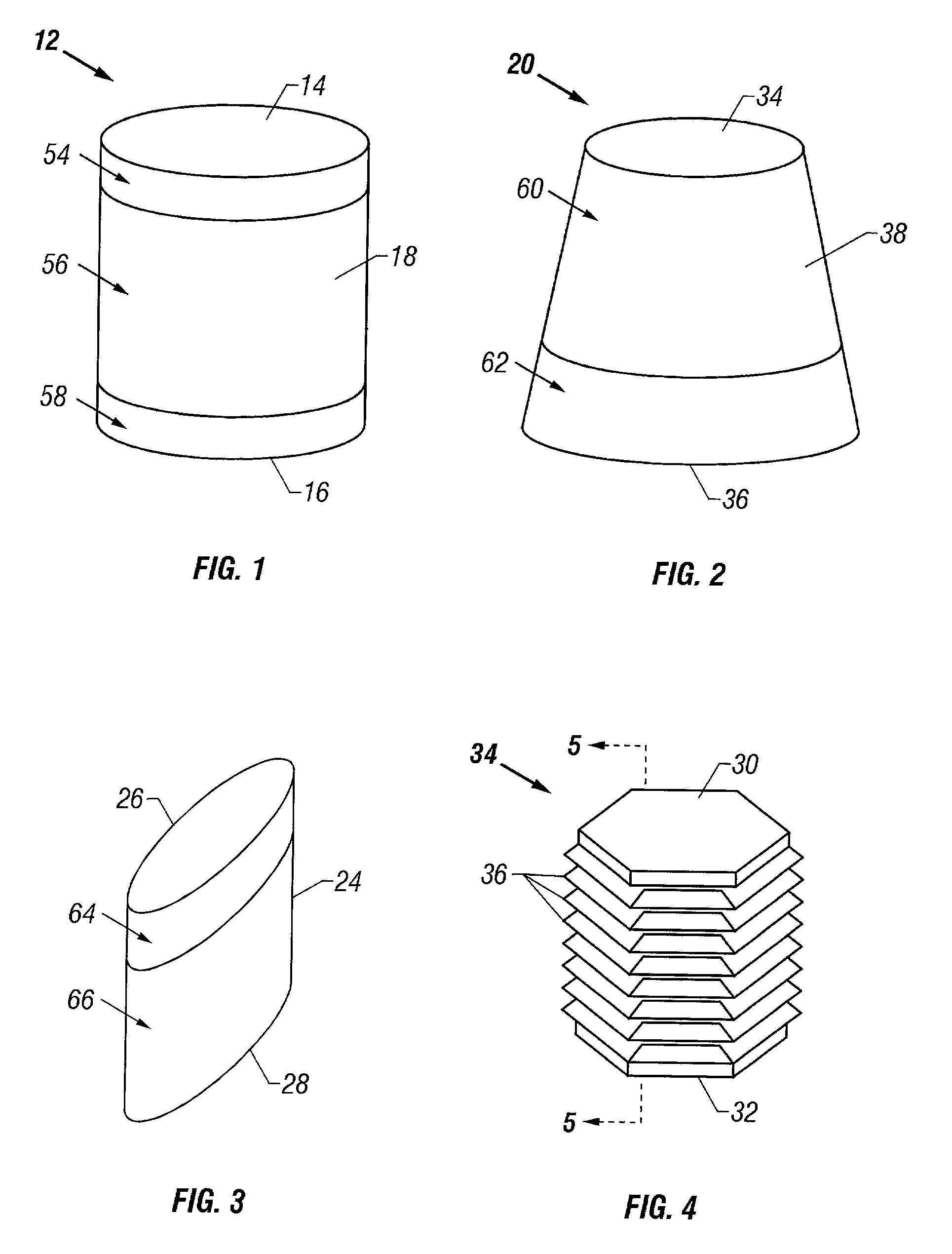

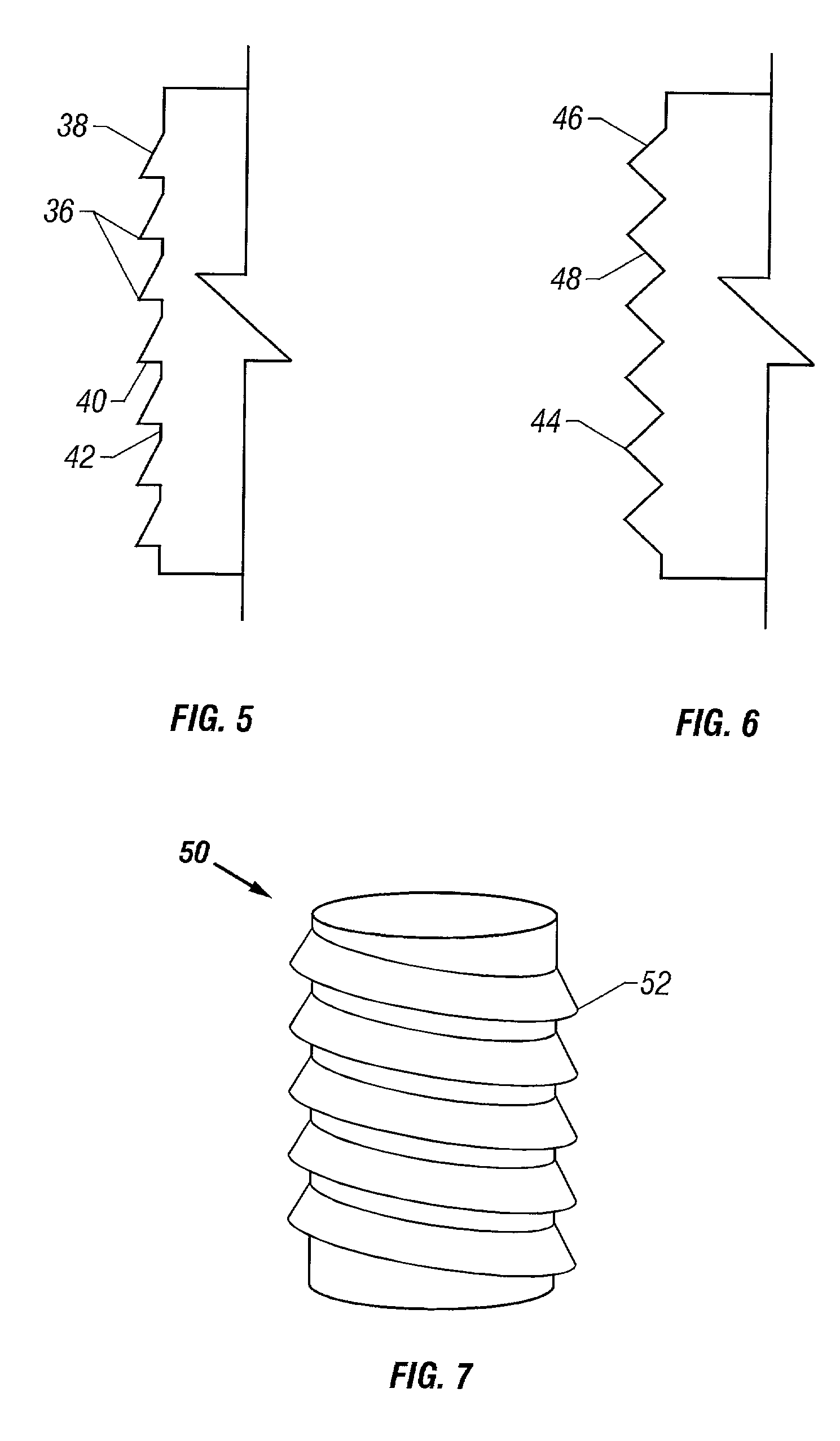

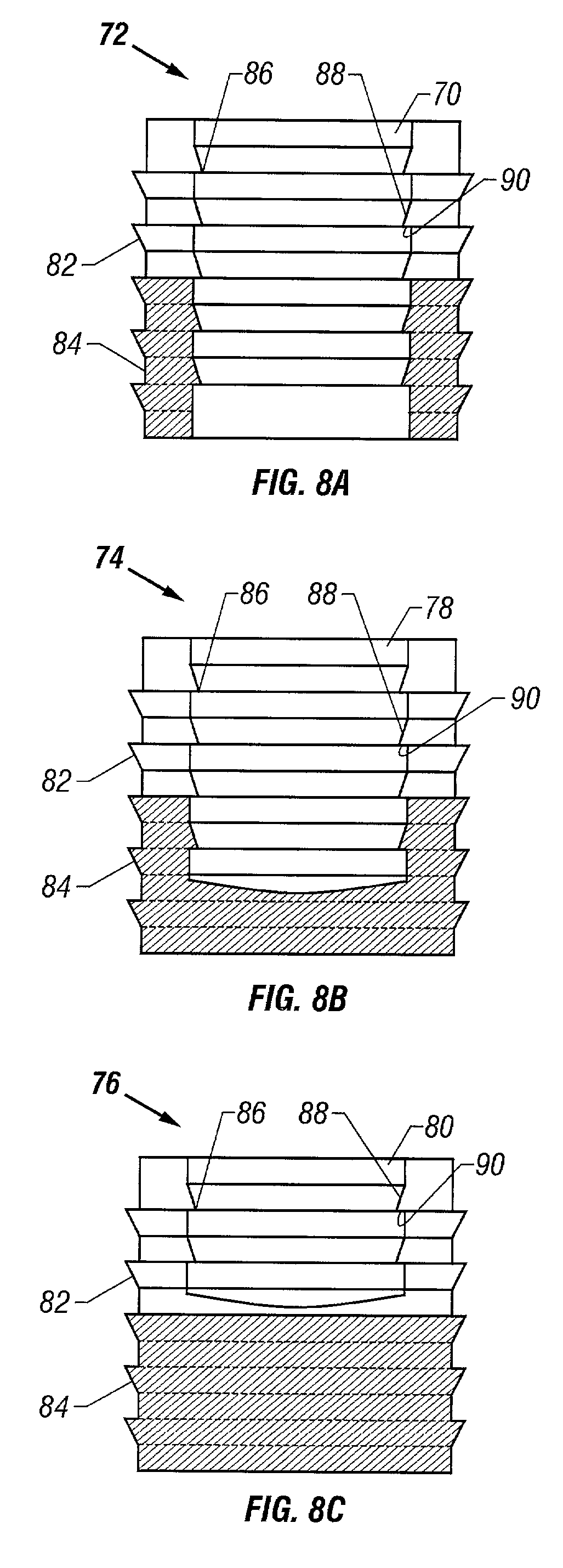

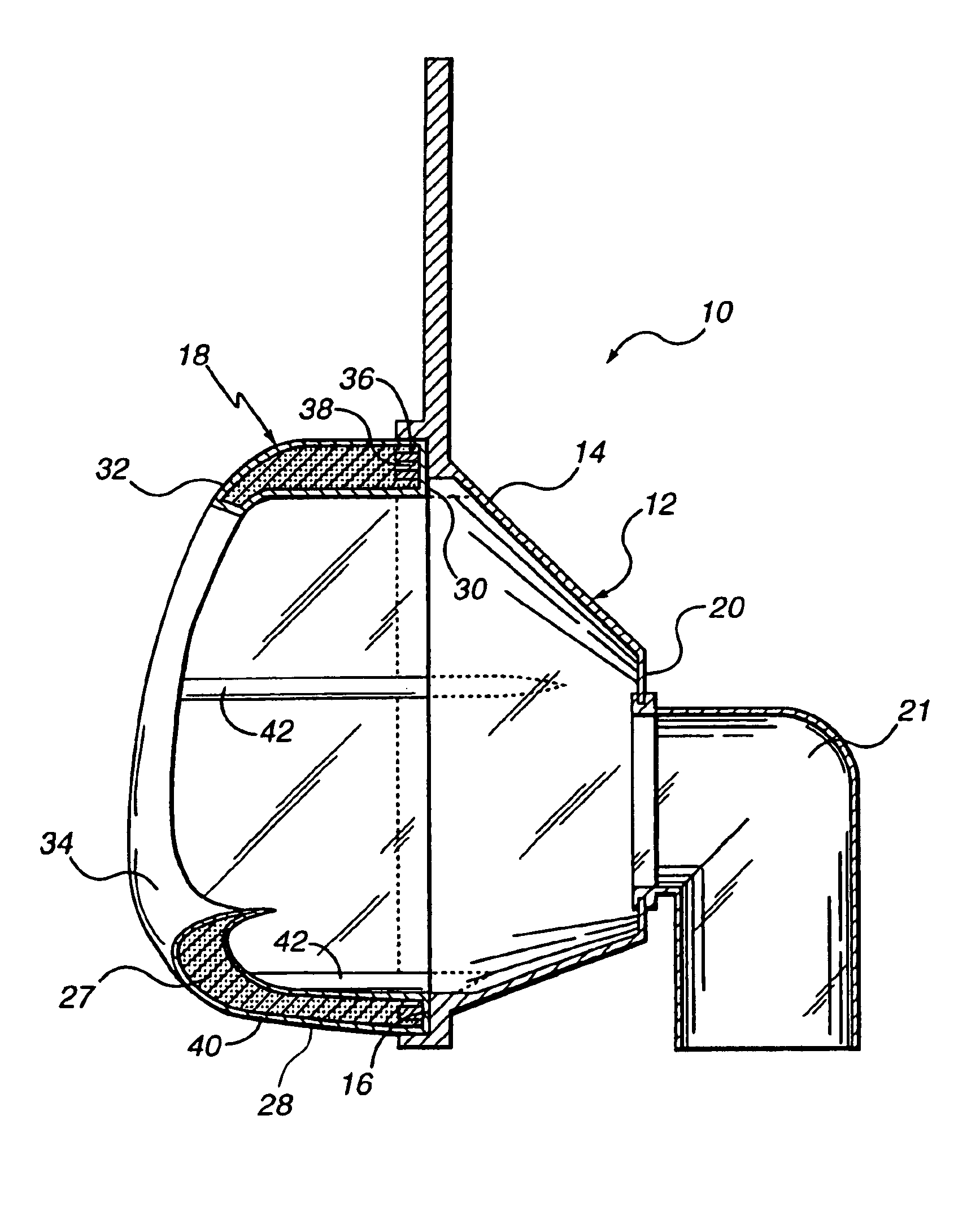

Cartilage repair plug

A cartilage plug, which is made from a biocompatible, artificial material, that is used to fill a void in natural cartilage that has been resected due to traumatic injury or chronic disease. Alternatively, the plug may be relied upon to anchor a flowable polymer to subchondral bone. The plug is prefabricatable in any size, shape, and contour and may be utilized either singly or in a plurality to fill any size void for any application. The plug may be formed of a laminated structure to match the physiological requirements of the repair site. A plurality of anchoring elements may share a single upper layer.

Owner:ABS

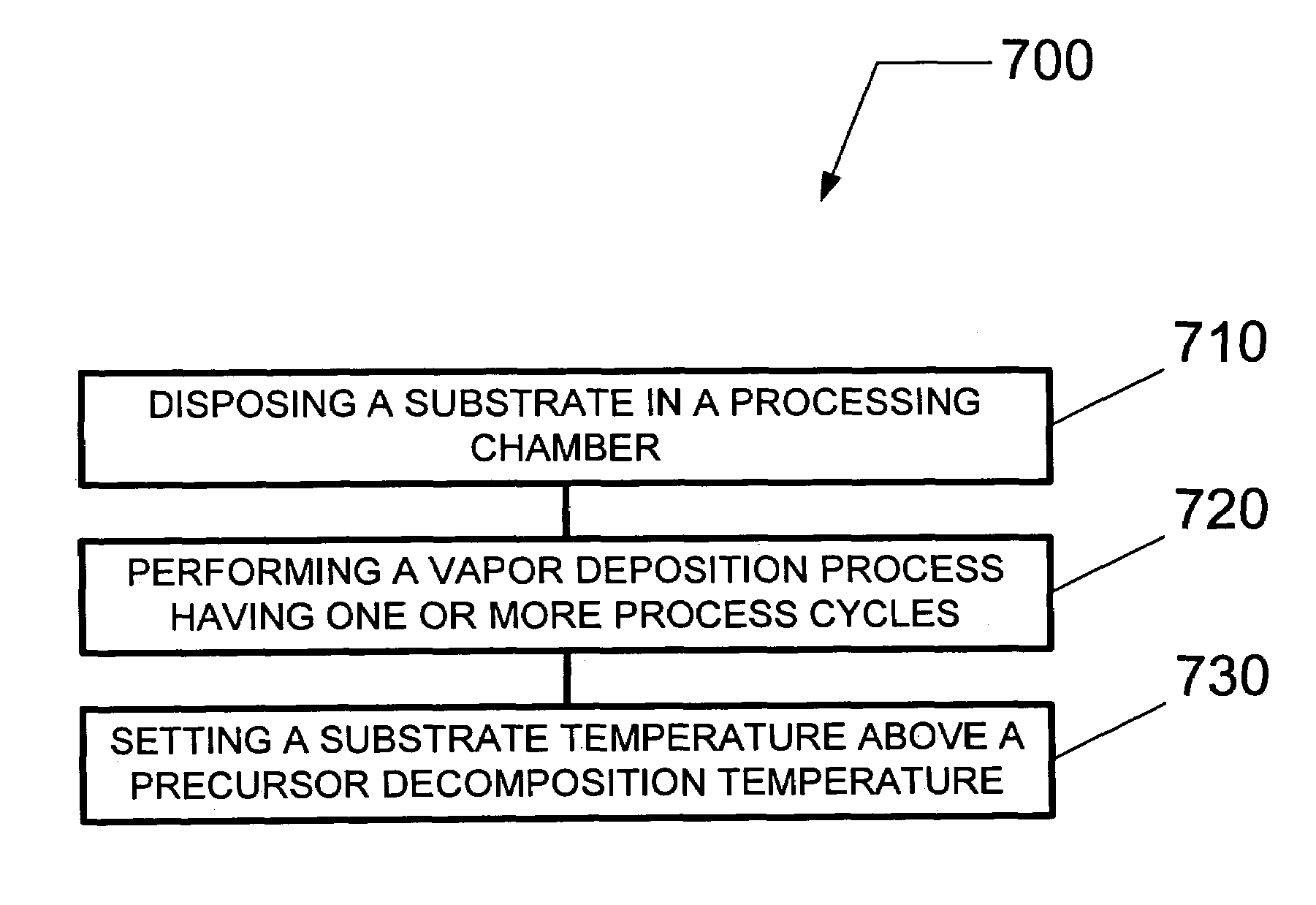

Method of forming a metal carbide or metal carbonitride film having improved adhesion

InactiveUS7645484B2Improve adhesionFacilitate depositionChemical vapor deposition coatingPlasma techniqueGas phaseDecomposition

A method for forming a metal carbide or metal carbonitride film on a substrate using a vapor deposition process. The method includes comprises introducing a first process material, such as a film precursor, to the substrate followed by introducing a second process material, such as a film reducing agent, to the substrate, whereby plasma can be formed during the introduction of the second process material in order to assist reduction of the first process material on the substrate. Additionally, the temperature of the substrate is elevated to a value approximately equal to or greater than the decomposition temperature of the first process material in order to improve adhesion properties for the metal carbide or metal carbonitride film.

Owner:TOKYO ELECTRON LTD

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

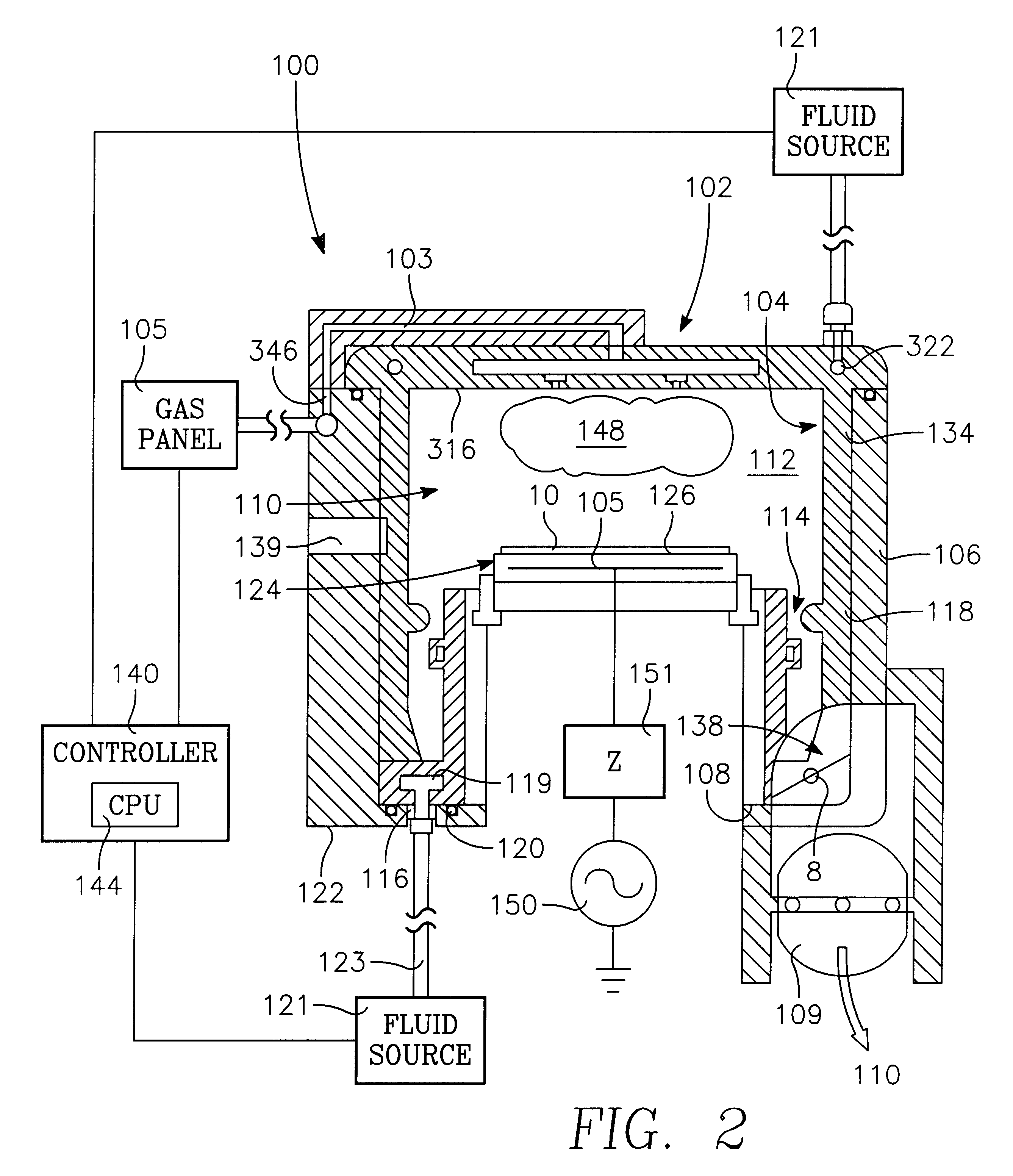

Etch method using a dielectric etch chamber with expanded process window

InactiveUS6403491B1Improve adhesionHigh rateElectric discharge tubesSolid-state devicesCapacitive couplingCapacitance

A method for etching a dielectric in a thermally controlled plasma etch chamber with an expanded processing window. The method is adapted to incorporate benefits of a the thermal control and high evacuation capability of the chamber. Etchent gases include hydrocarbons, oxygen and inert gas. Explanation is provided for enablling the use of hexafluoro-1,3-butadiene in a capacitively coupled etch plasma. The method is very useful for creating via, self aligned contacts, dual damascene, and other dielectric etch.

Owner:APPLIED MATERIALS INC

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

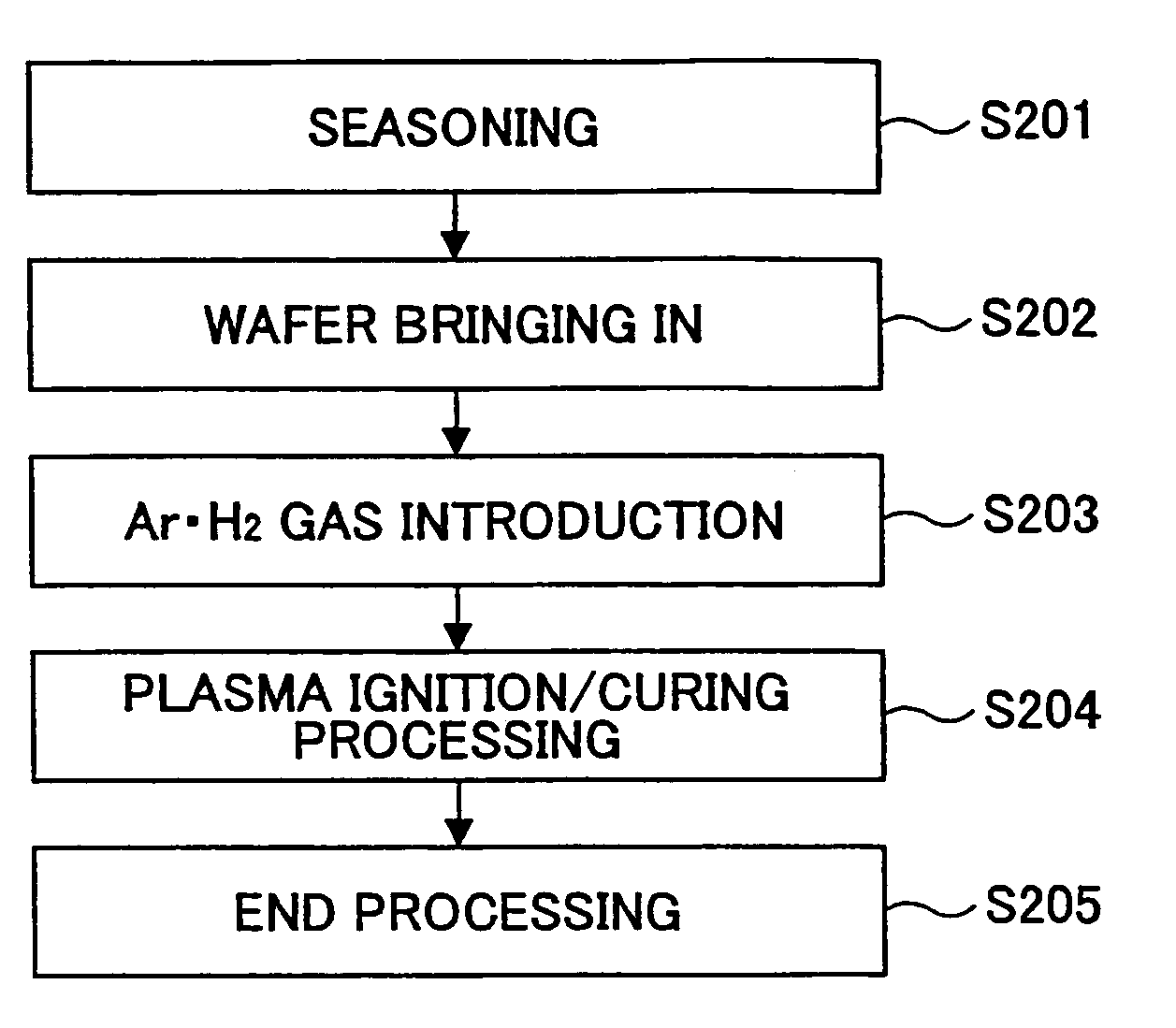

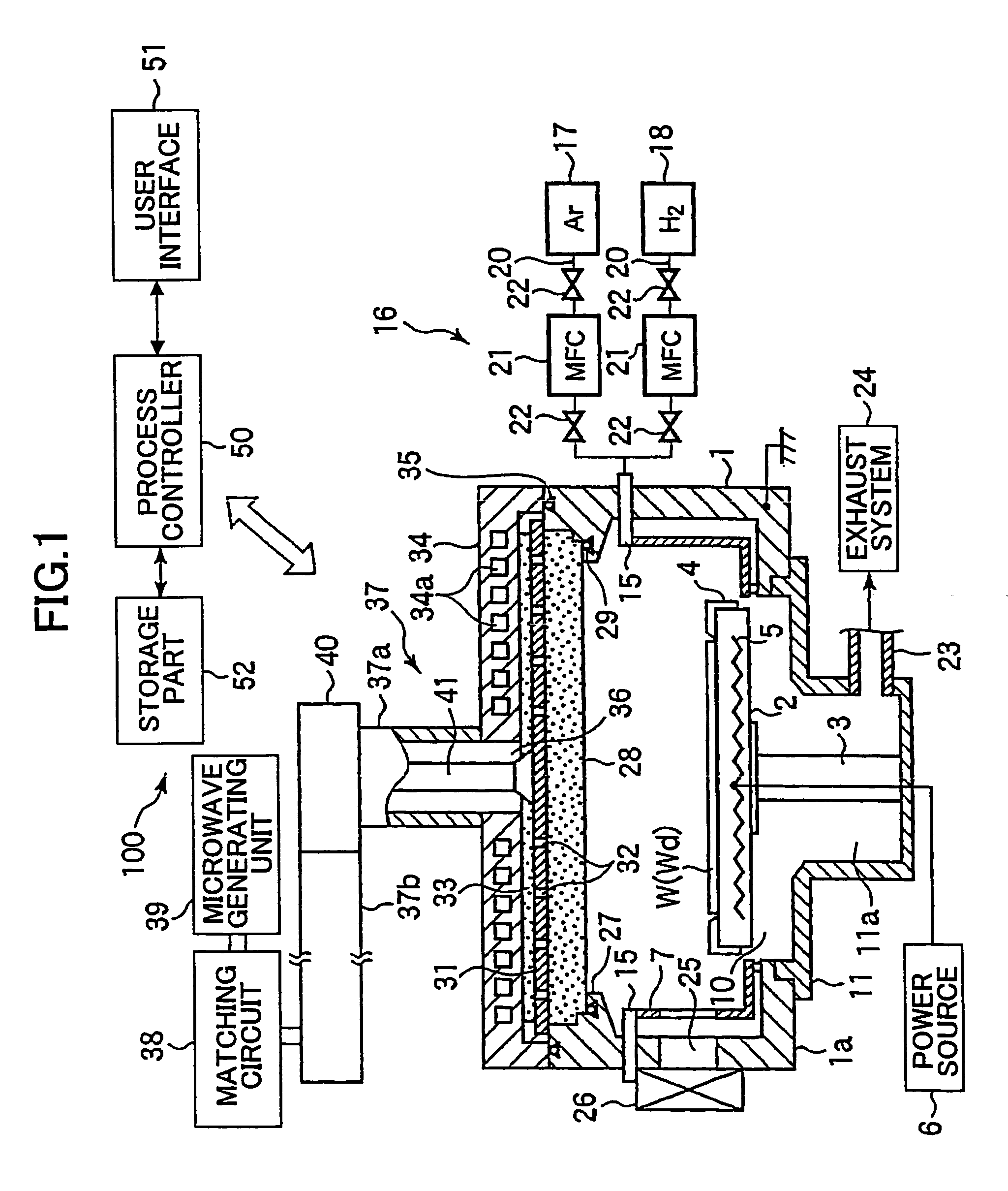

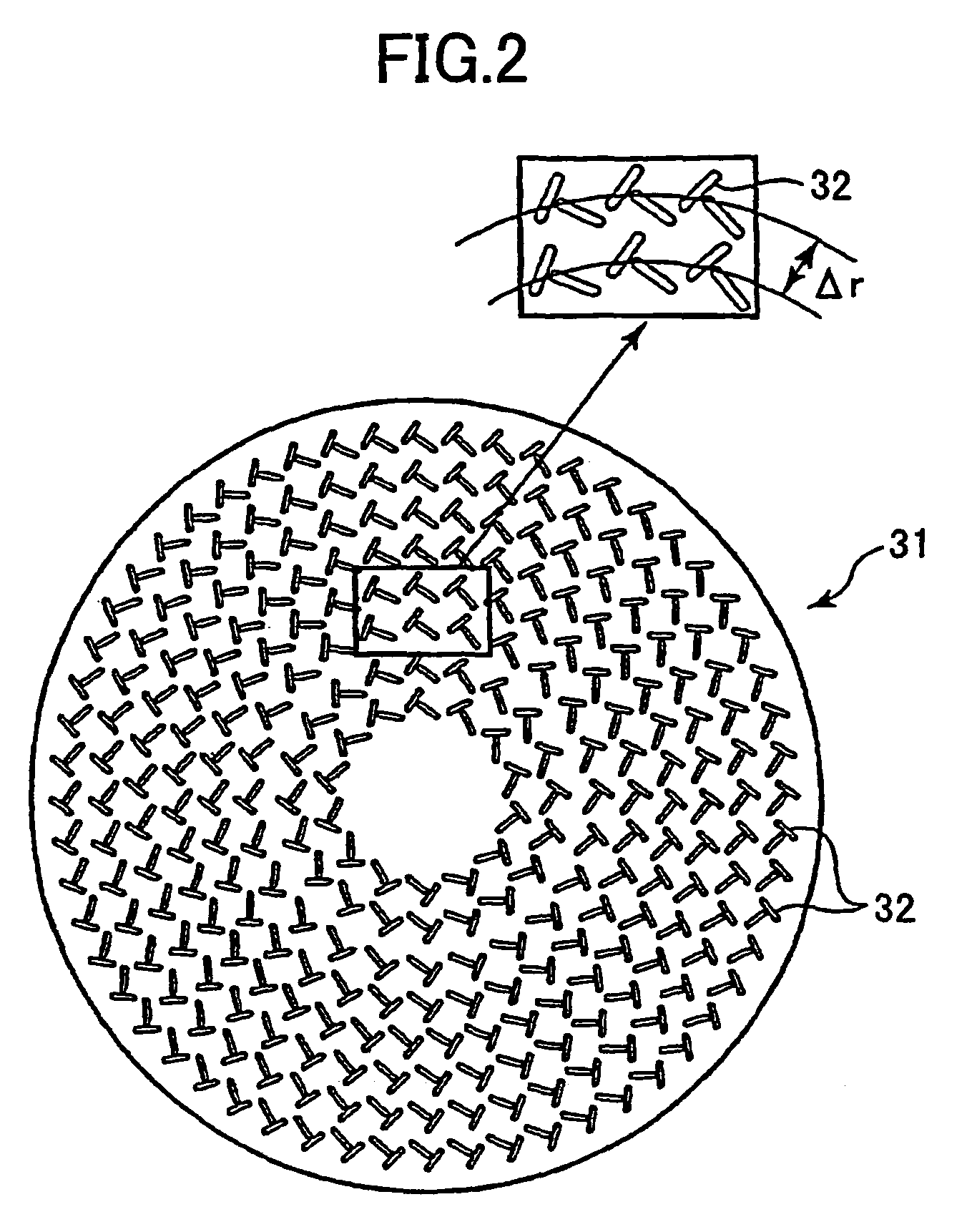

Plasma processing method and film forming method

InactiveUS7771796B2Low dielectric constantImprove adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenProduct gas

A plasma processing method of carrying out curing processing on a low dielectric constant film produced on a to-be-processed substrate by applying plasma thereto in a processing chamber of a plasma processing apparatus, includes the steps of: a) introducing, in the plasma processing chamber, a first gas having a function of stabilizing plasma and a second gas generating active hydrogen, and, after that; b) generating plasma, and carrying out curing processing on the low dielectric constant film.

Owner:TOKYO ELECTRON LTD

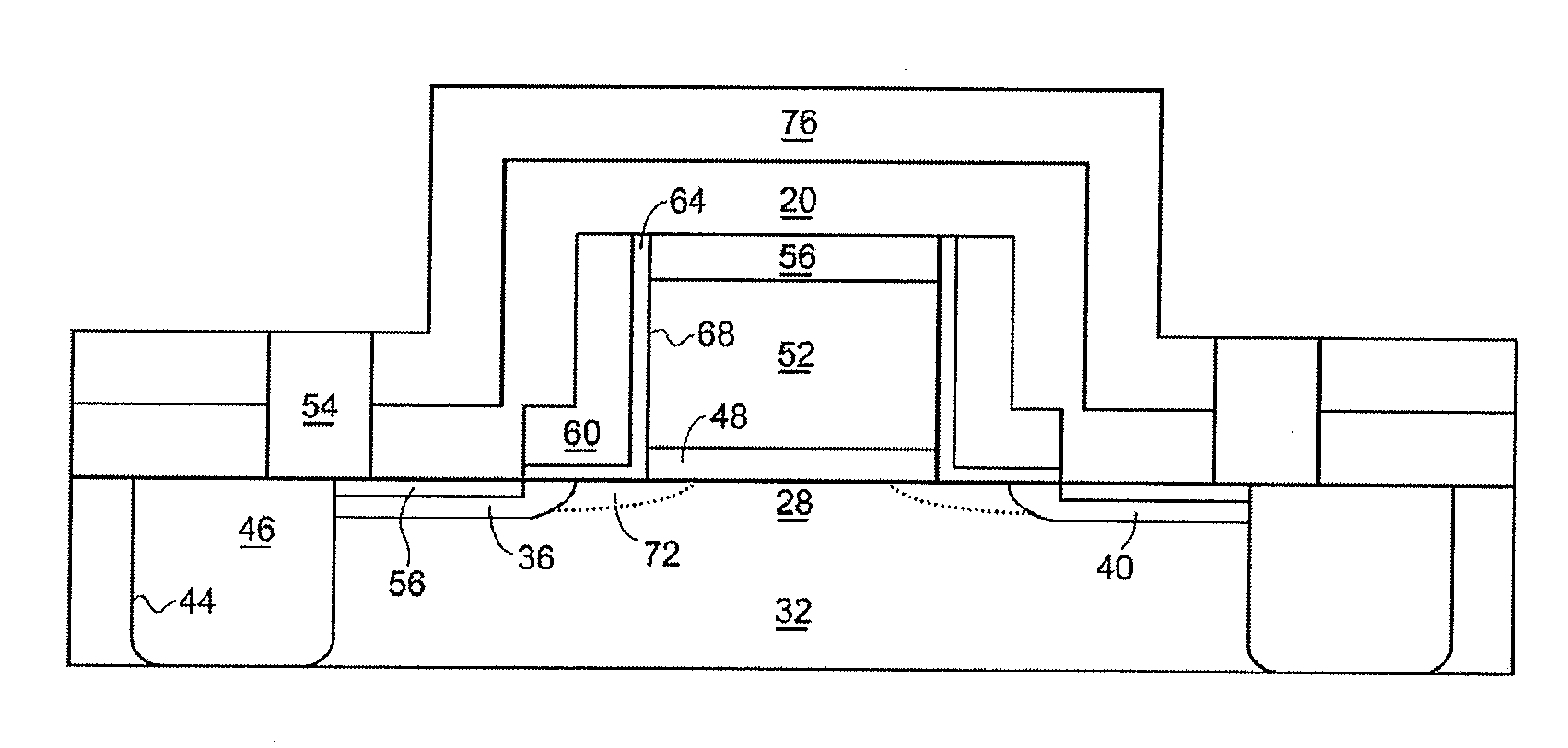

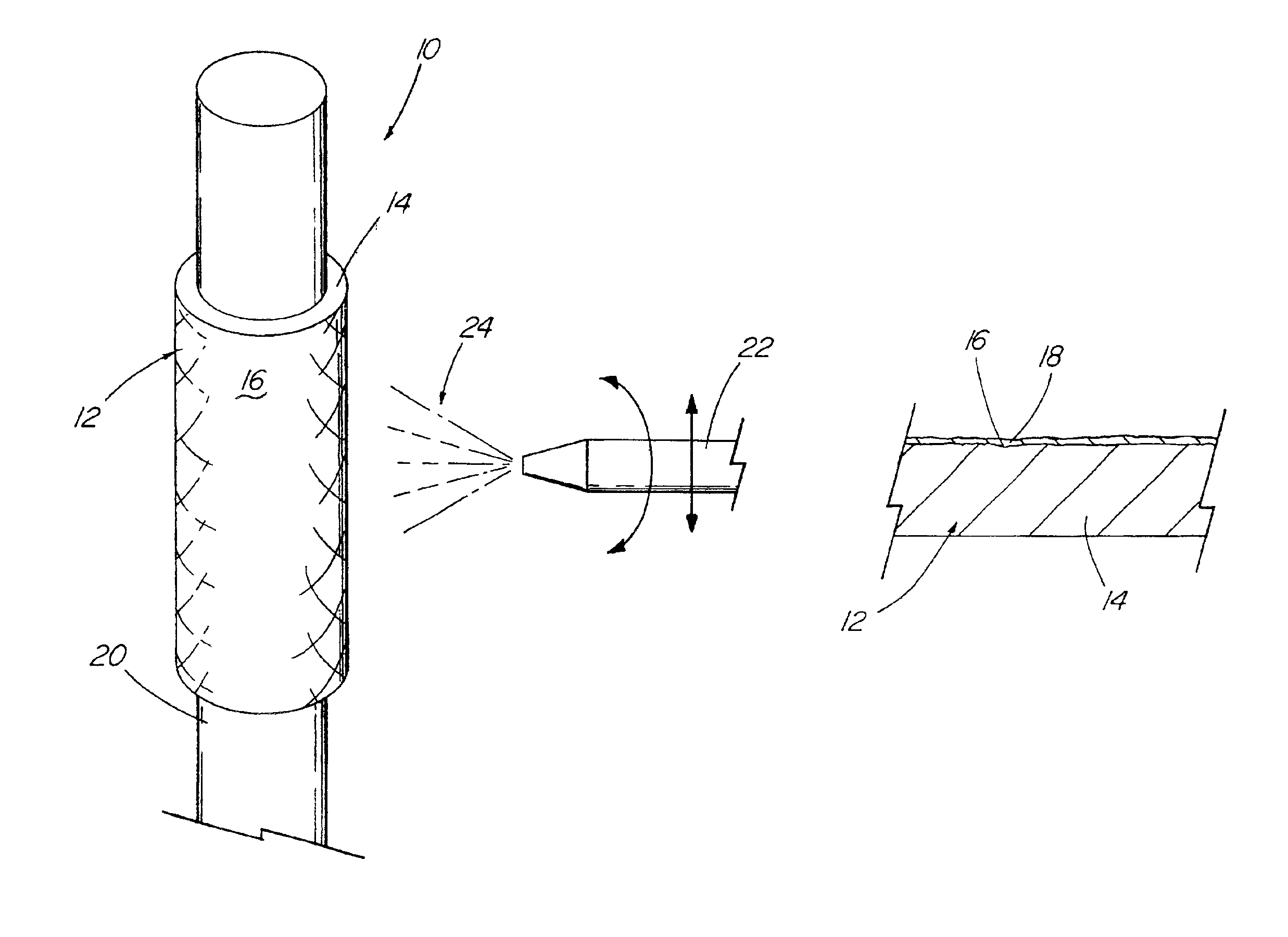

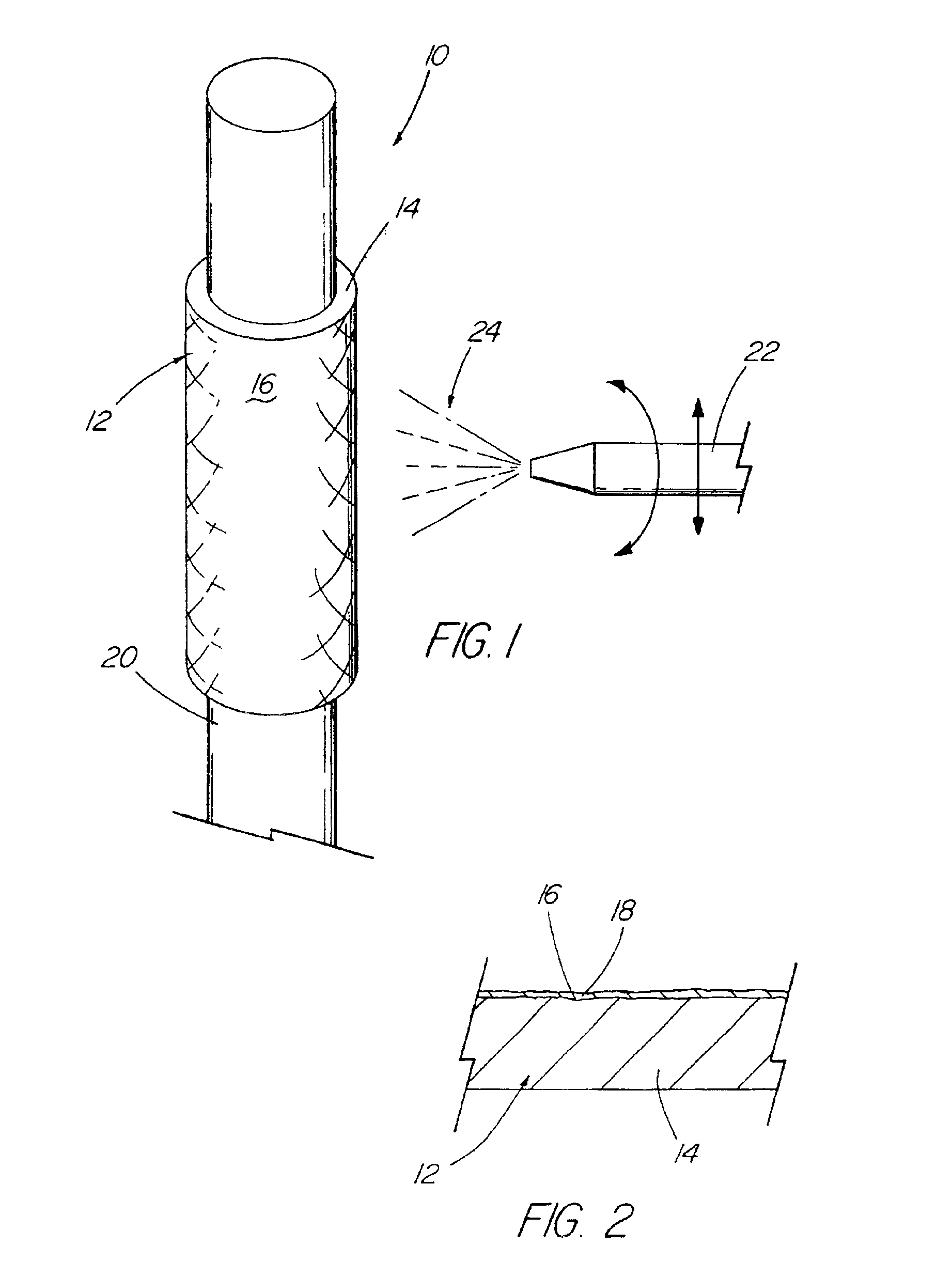

Coated implantable medical device

InactiveUS6918927B2Good worker safetyLow costOrganic active ingredientsSurgerySodium bicarbonateMedicine

A medical device (10) includes a structure (12) adapted for introduction into a patient, the structure (12) being formed of a preferably non-porous base material (14) having a roughened or textured surface (16). The structure (12) is conveniently configured as a vascular stent with a base material (14) of stainless steel, nitinol or another suitable material. The medical device (10) also includes a layer (18) of a bioactive material posited directly upon the roughened or textured surface (16) of the base material (14) of the structure (12). The surface (16) of the base material (14) is roughened or textured by etching or by abrasion with sodium bicarbonate or another suitable grit. A preferred roughened or textured surface (16) is thought to have a mean surface roughness of about 10 μin. (about 250 nm) and a surface roughness range between about 1 μin. and about 100 μin. (about 25 nm and about 2.5 μm). The particularly preferred use of sodium bicarbonate as the abrasive to provide roughness or texture to the surface (16) of the base material (14) of the structure (12) is additionally advantageous in the low toxicity of the sodium bicarbonate to production workers, the ease of product and waste cleanup, and the biocompatibility of any residual sodium bicarbonate.

Owner:COOK MEDICAL TECH LLC

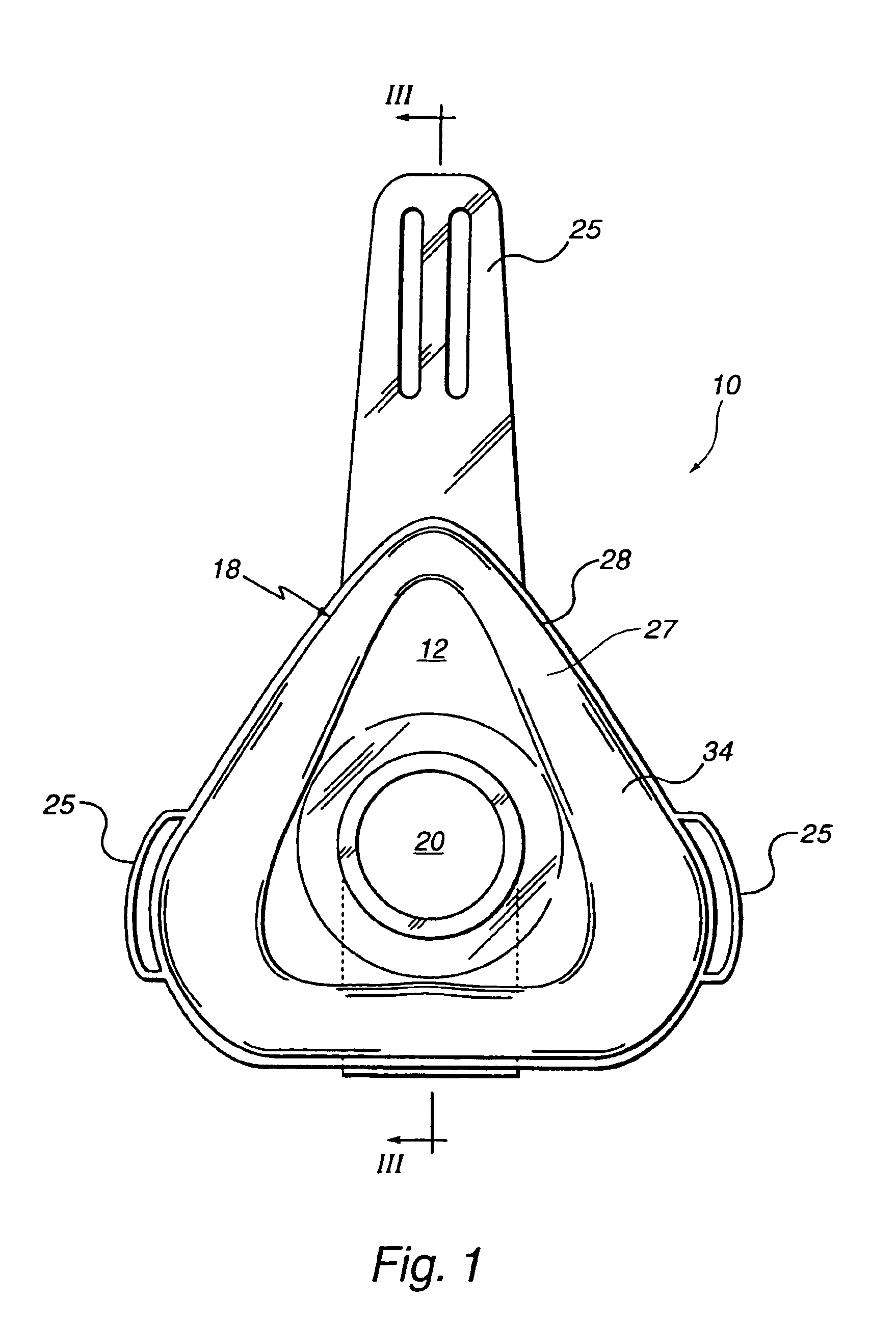

Customizable seal, mask with customizable seal and method of using such a seal

InactiveUS6895965B2Overcomes shortcomingReadily conformsRespiratory masksBreathing masksEngineeringMechanical engineering

A seal and a mask having a seal adapted for confronting engagement with a surface of a user to form an interface therewith. The seal includes a first portion defined by a gel substance and a second portion associated with the first portion. The second portion includes a selectively formable substance adapted to be molded from a first pattern into a second pattern and to retain the second pattern responsive to being so molded. The seal and mask having the seal is tailored to patient by causing the formable portion of the seal to be placed in a malleable state, applying the seal to the patient while the formable portion is in the malleable state, and causing the formable portion to be placed in a fixed state to retain a shape generally conforming to the portion of the patient underlying the seal.

Owner:RIC INVESTMENTS LLC

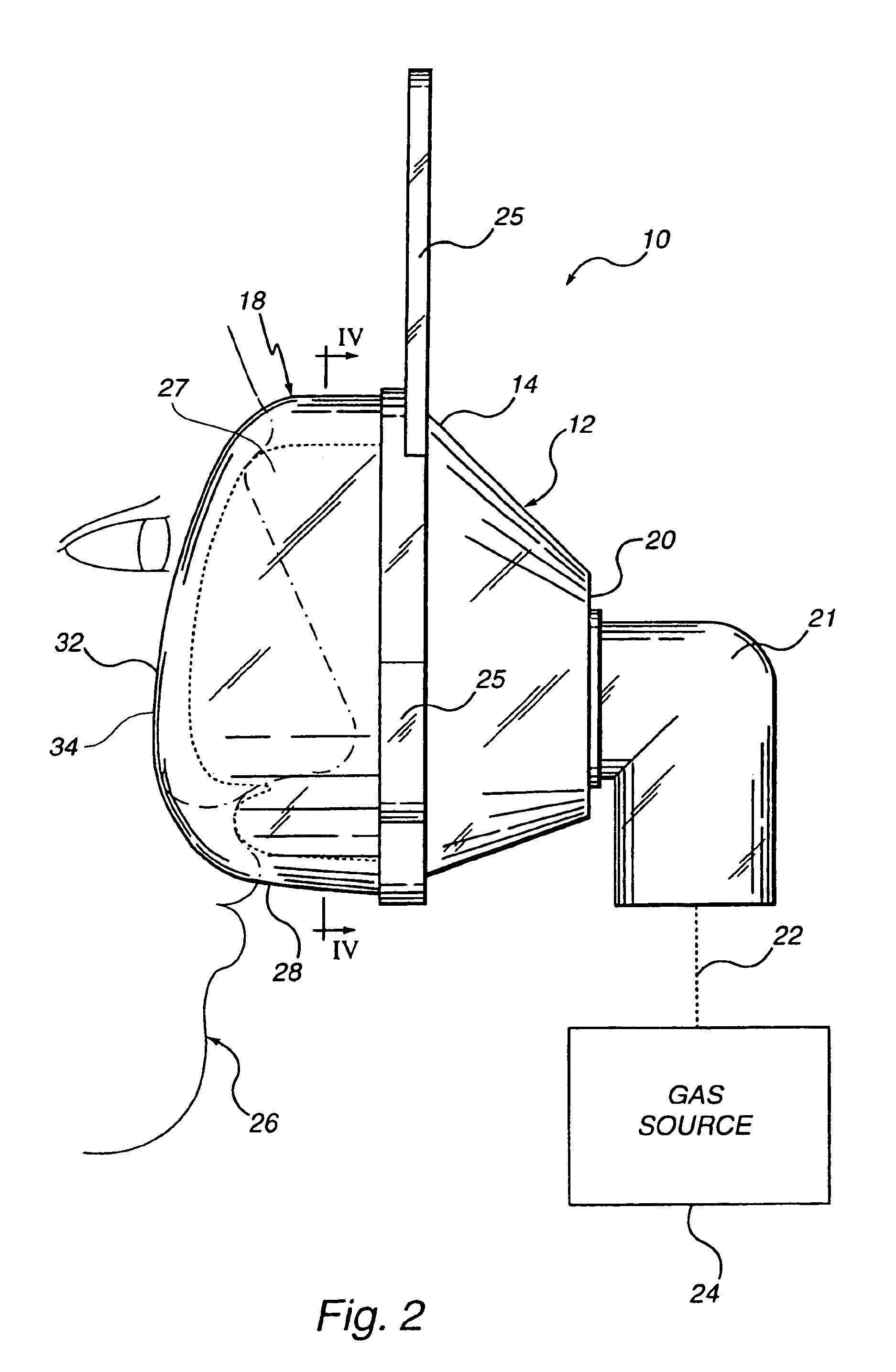

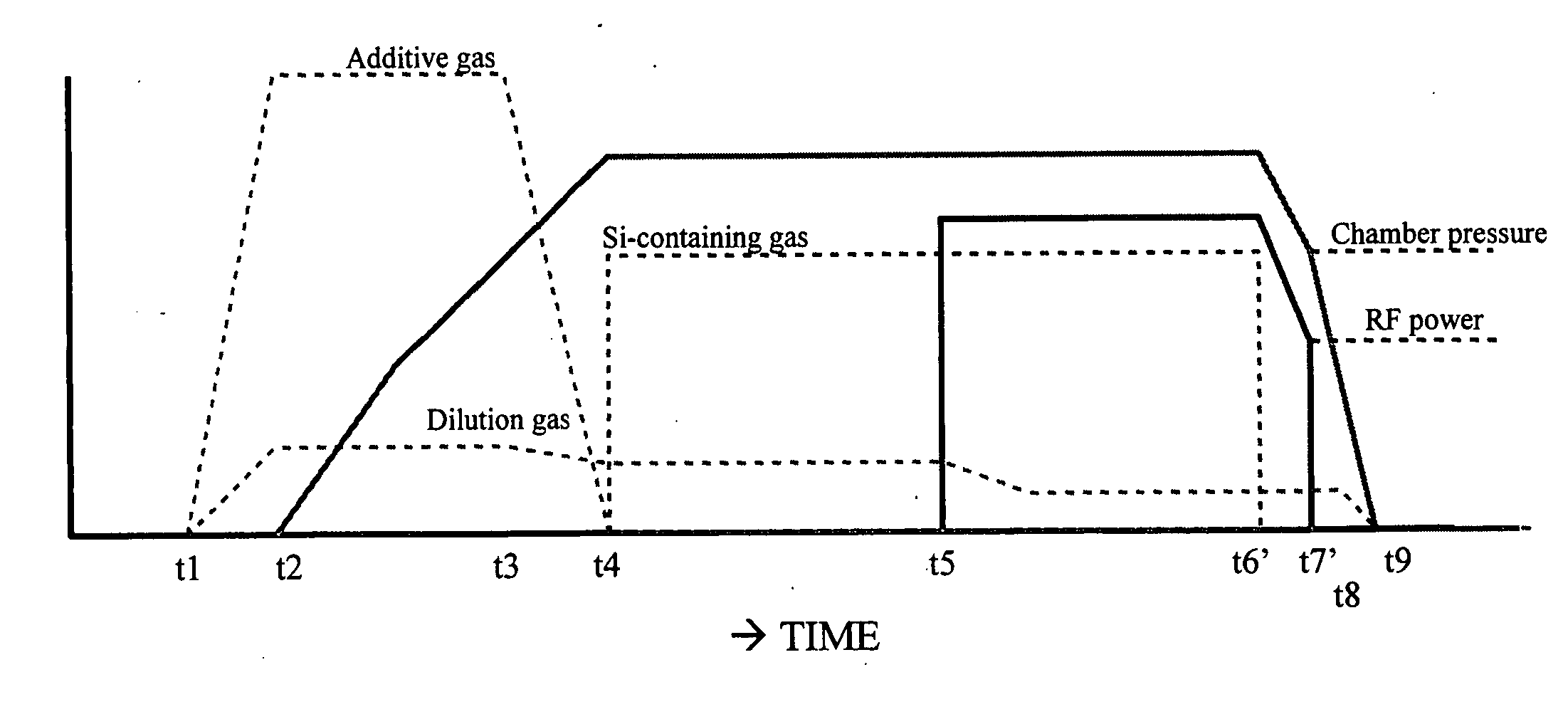

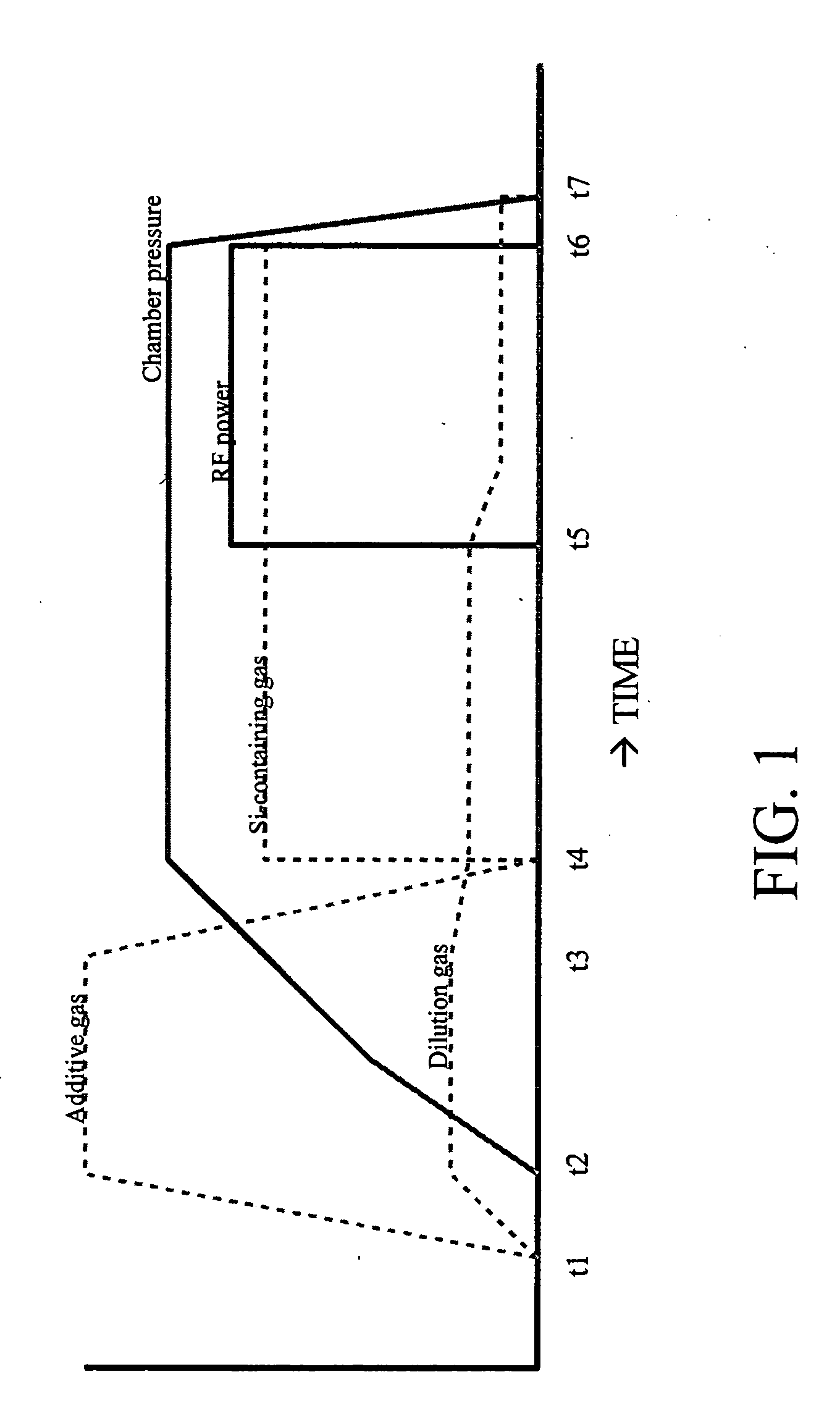

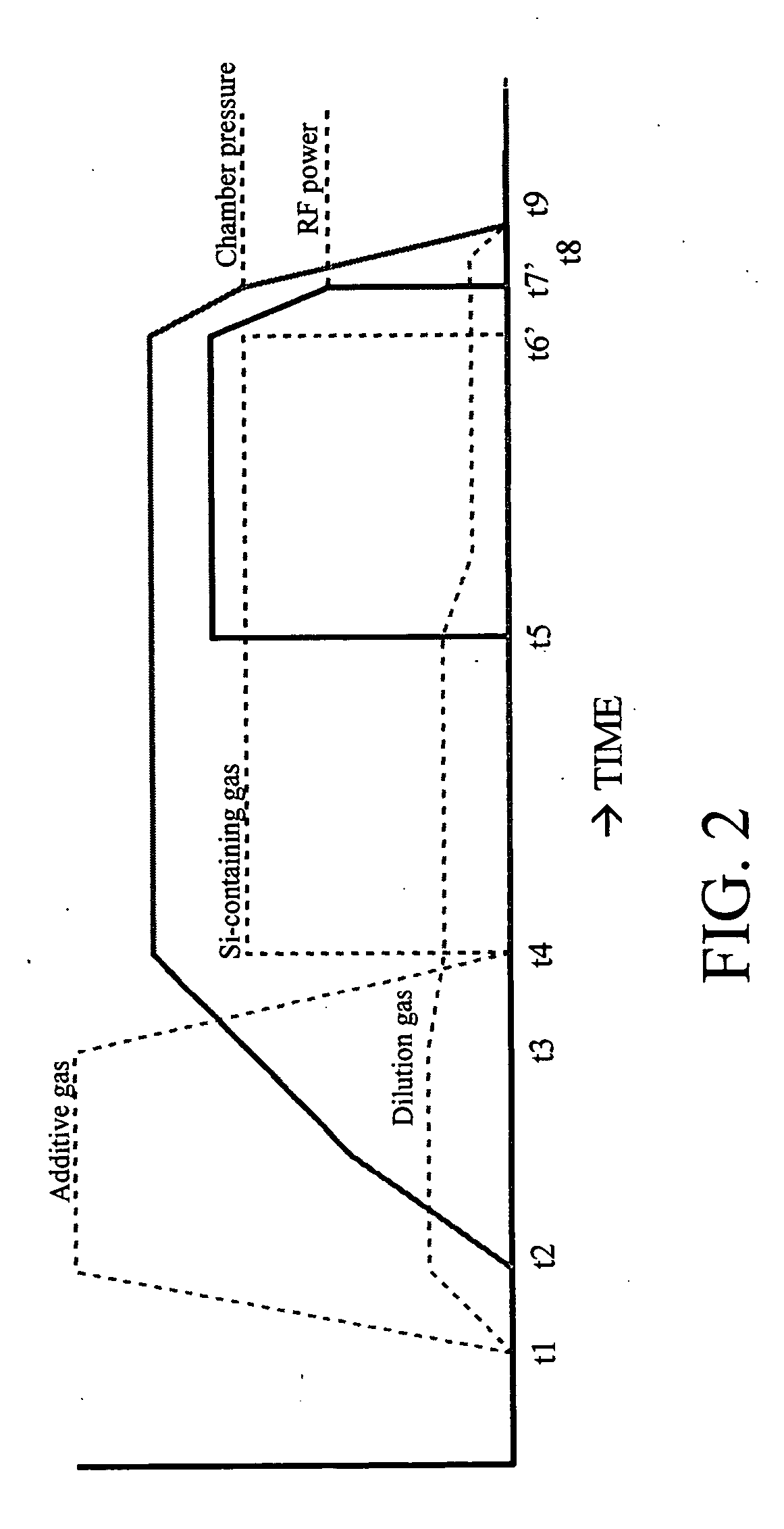

Method of forming thin film

ActiveUS20050048797A1Reduce plasma damageImprove adhesionSemiconductor/solid-state device manufacturingSolid state diffusion coatingRadio frequencyMechanics

A method for forming a thin film includes: supplying an additive gas, a dilution gas, and a silicon-containing source gas into a reaction chamber wherein a substrate is placed; forming a thin film on the substrate by plasma CVD under a given pressure with a given intensity of radio-frequency (RF) power from a first point in time to a second point in time; at the second point in time, stopping the supply of the silicon-containing source gas; and at the second point in time, beginning reducing but not stopping the RF power, and beginning reducing the pressure, wherein the reduction of the RF power and the reduction of the pressure are synchronized up to a third point in time.

Owner:ASM JAPAN

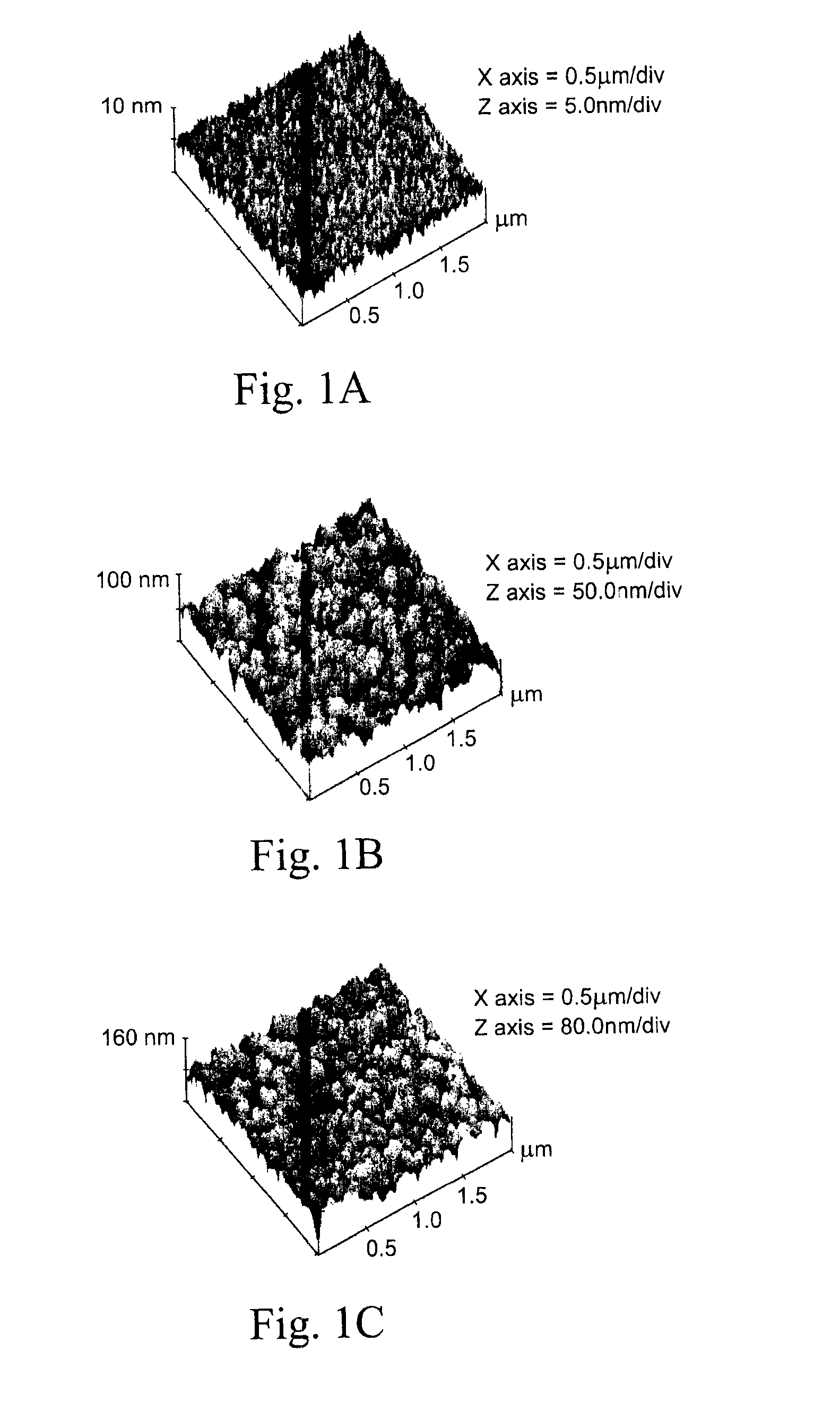

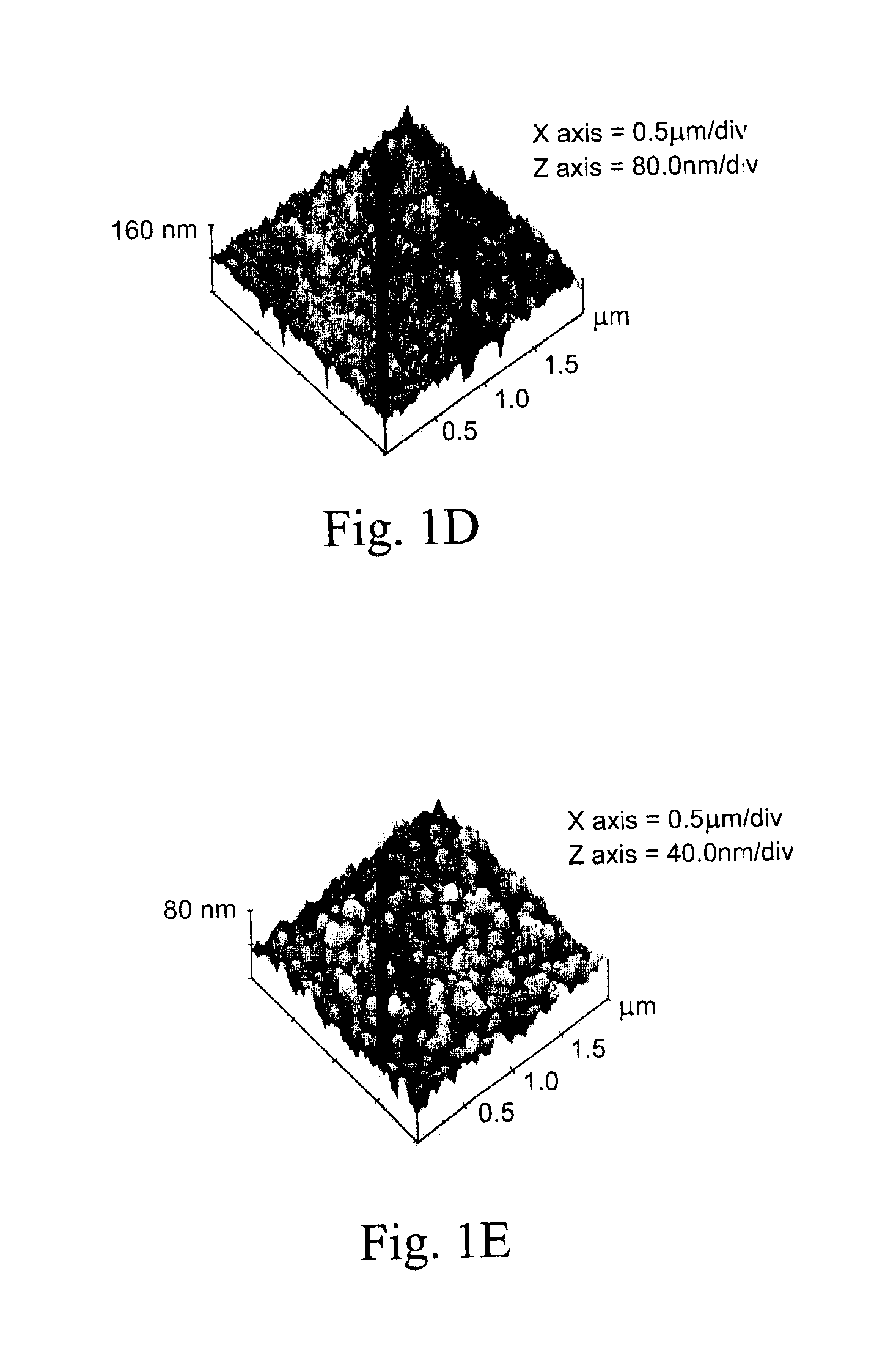

Method of preparing nano-structured surface coatings and coated articles

InactiveUS7892606B2Improve adhesionMore readily manufacturableMaterial nanotechnologyNanostructure manufactureCross-linkNano structuring

Owner:DSM IP ASSETS BV

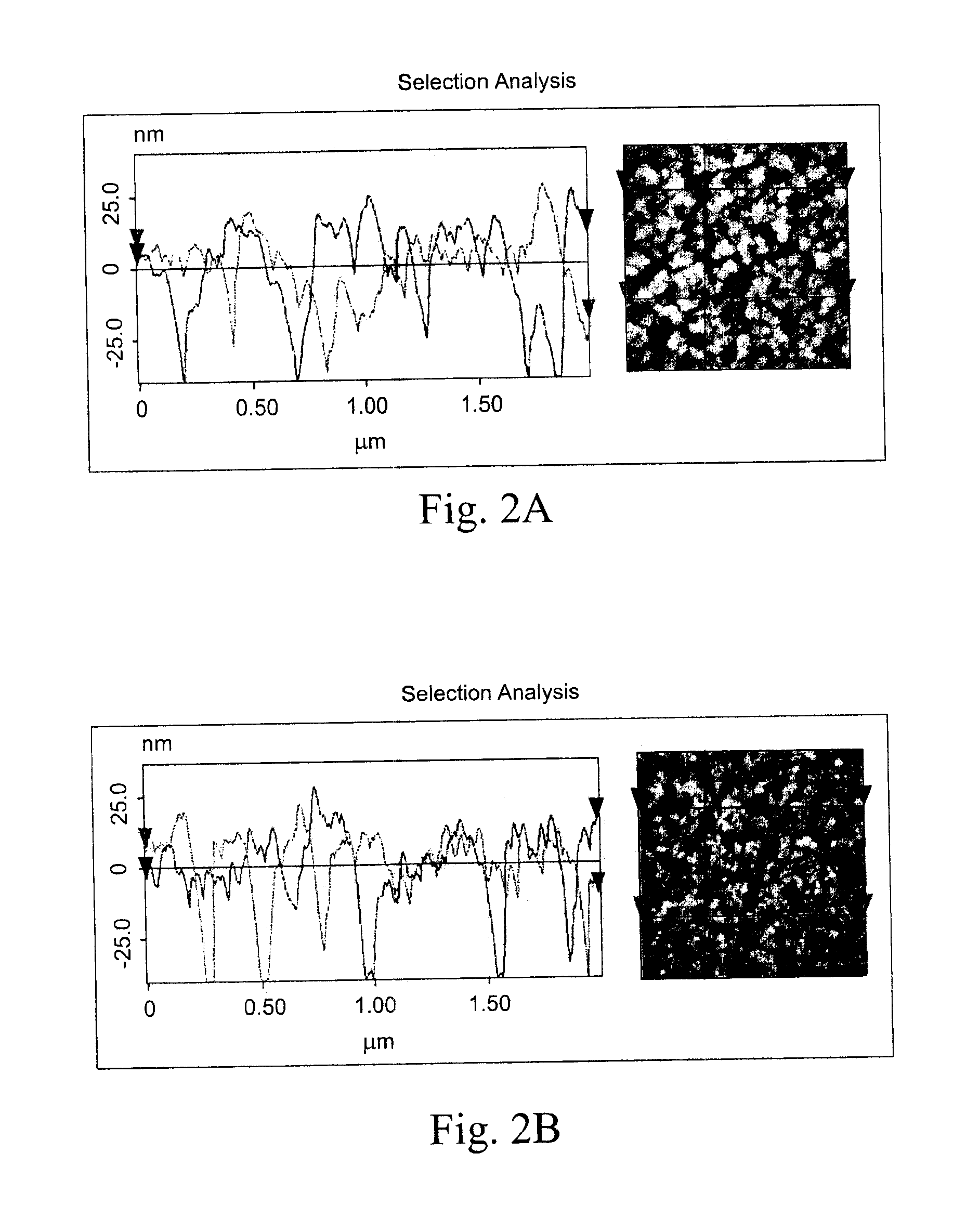

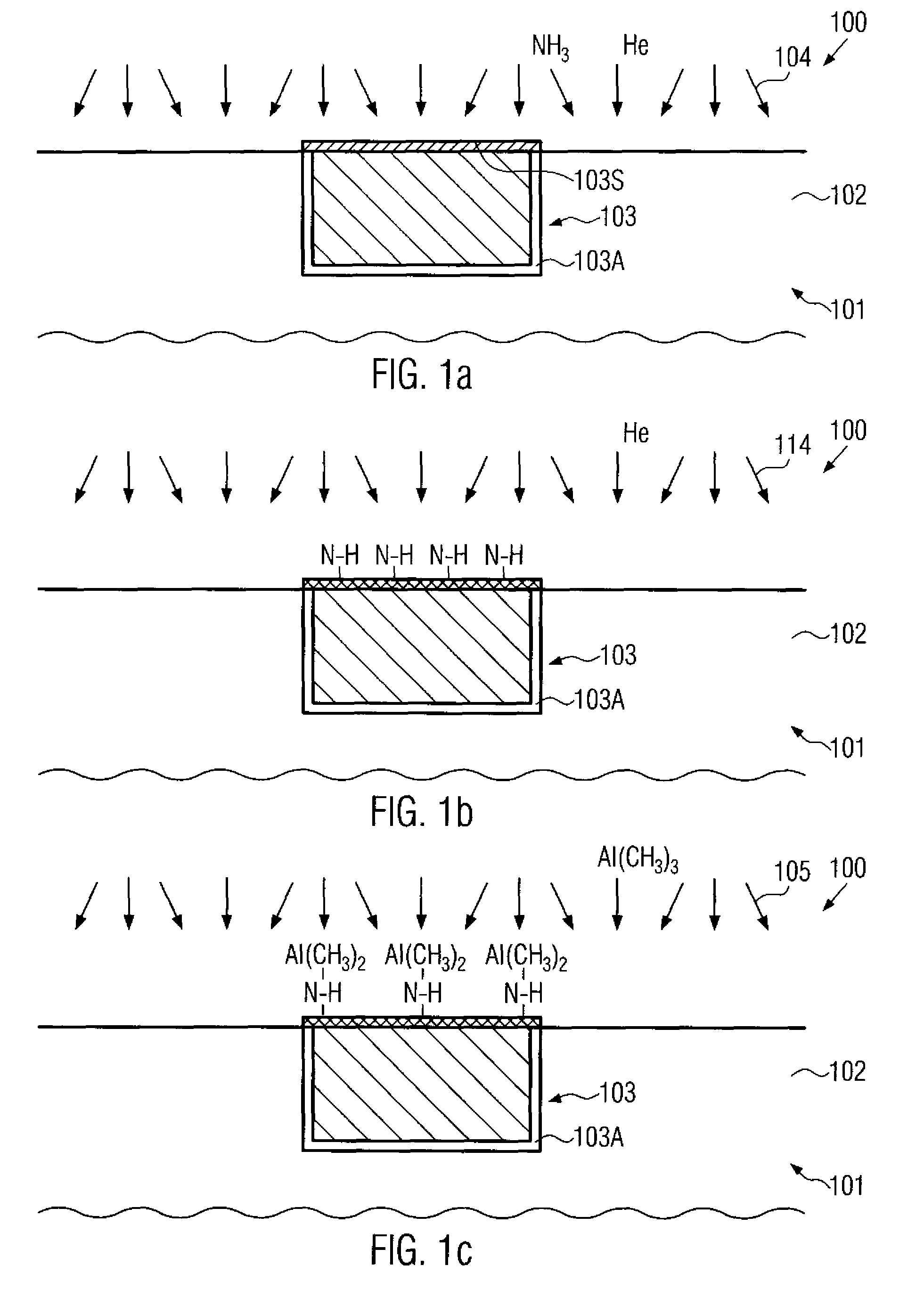

Method of manufracturing increasing reliability of copper-based metallization structures in a microstructure device by using aluminum nitride

ActiveUS7829460B2Reduce parasitic capacitanceEasy to controlSemiconductor/solid-state device detailsSolid-state devicesSelf limitingPermittivity

Owner:GLOBALFOUNDRIES U S INC

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS8138104B2Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

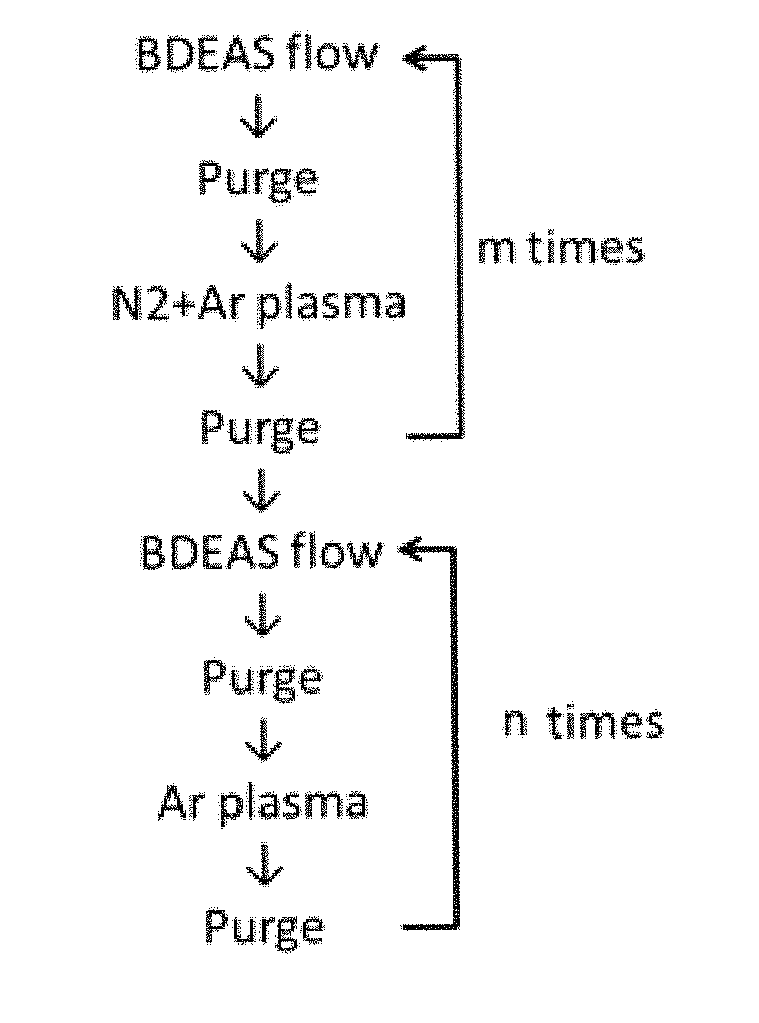

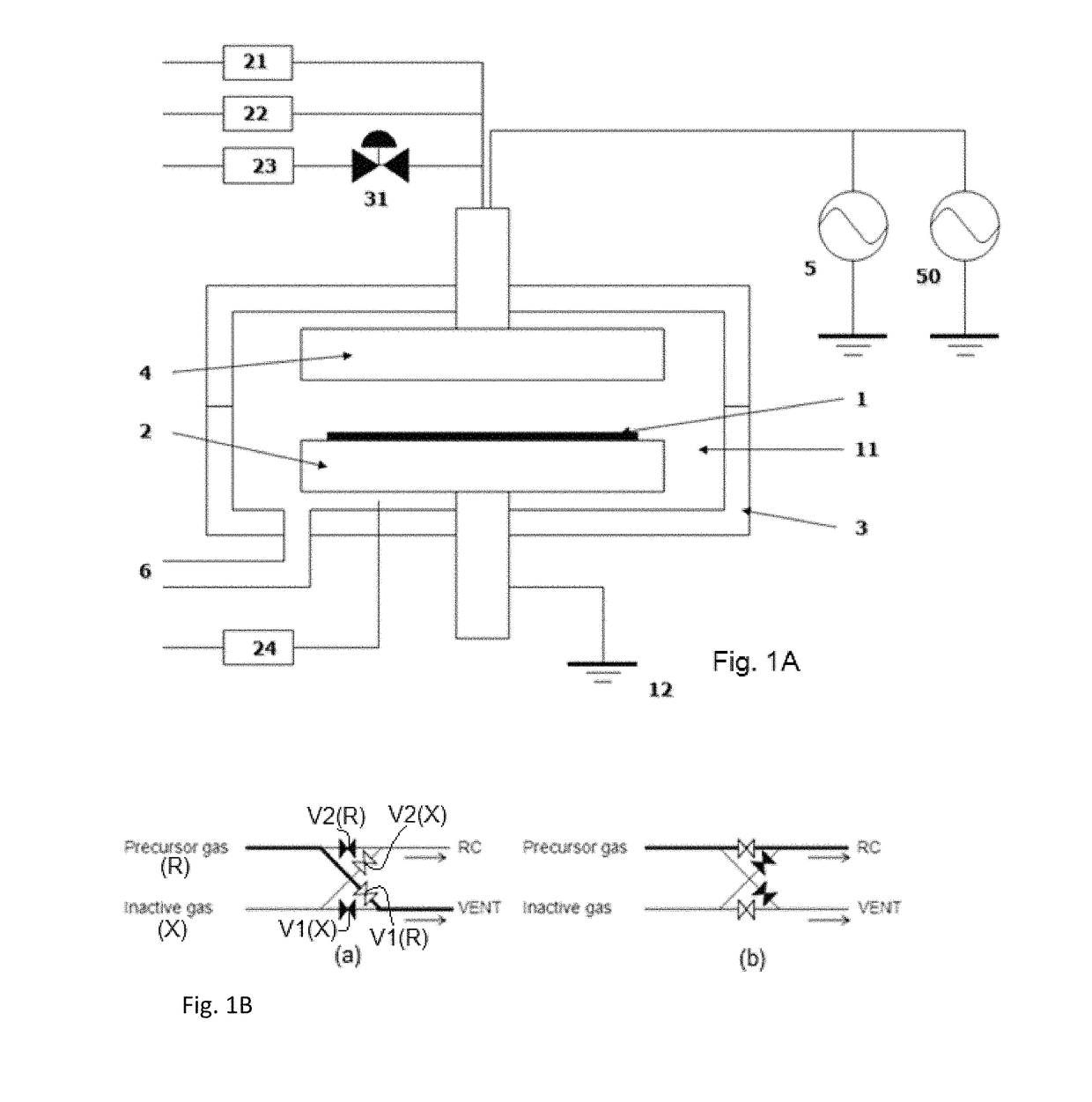

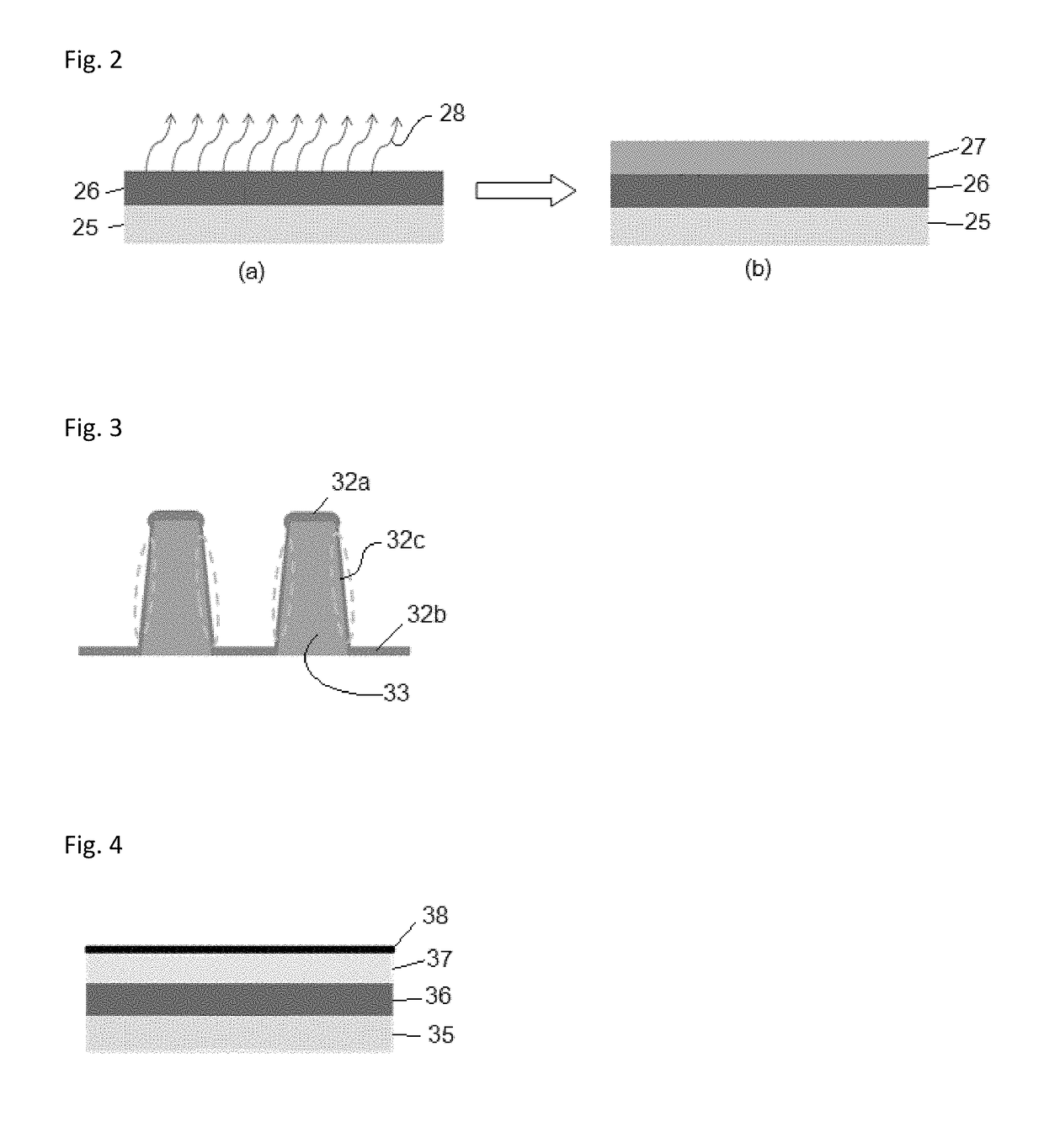

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS20170018477A1Improve concentrationGood chemical resistanceSemiconductor/solid-state device detailsSolid-state devicesNoble gasProtection layer

A method for protecting a layer includes: providing a substrate having a target layer and forming a protective layer on the target layer, said protective layer contacting and covering the target layer and containing a hydrocarbon-based layer constituting at least an upper part of the protective layer, which hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS9899291B2Improve concentrationGood chemical resistanceSemiconductor/solid-state device detailsSolid-state devicesNoble gasOptoelectronics

A method for protecting a layer includes: providing a substrate having a target layer and forming a protective layer on the target layer, said protective layer contacting and covering the target layer and containing a hydrocarbon-based layer constituting at least an upper part of the protective layer, which hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

Method for protecting layer by forming hydrocarbon-based extremely thin film

ActiveUS10043661B2Improve concentrationGood chemical resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasProtection layer

A method for protecting a layer includes: providing a substrate having a target layer; depositing a protective layer on the target layer, which protective layer contacts and covers the target layer and is constituted by a hydrocarbon-based layer; and depositing an oxide layer on the protective layer so that the protective layer in contact with the oxide layer is oxidized. The hydrocarbon-based layer is formed by plasma-enhanced atomic layer deposition (PEALD) using an alkylaminosilane precursor and a noble gas without a reactant.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com