Patents

Literature

482838results about "Semiconductor/solid-state device manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

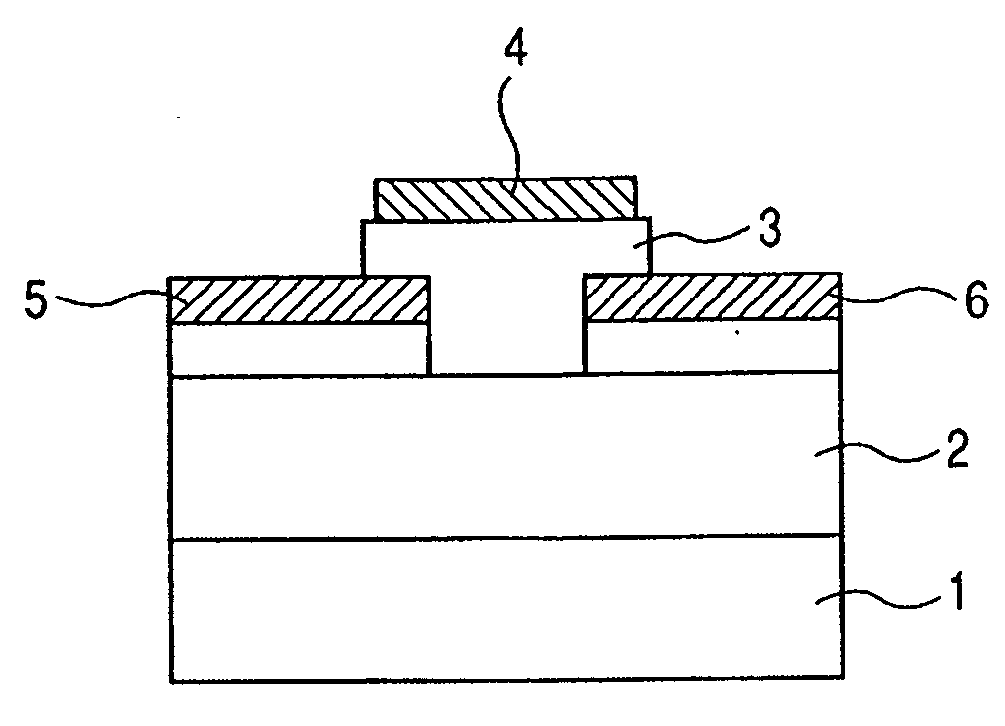

Amorphous Oxide And Thin Film Transistor

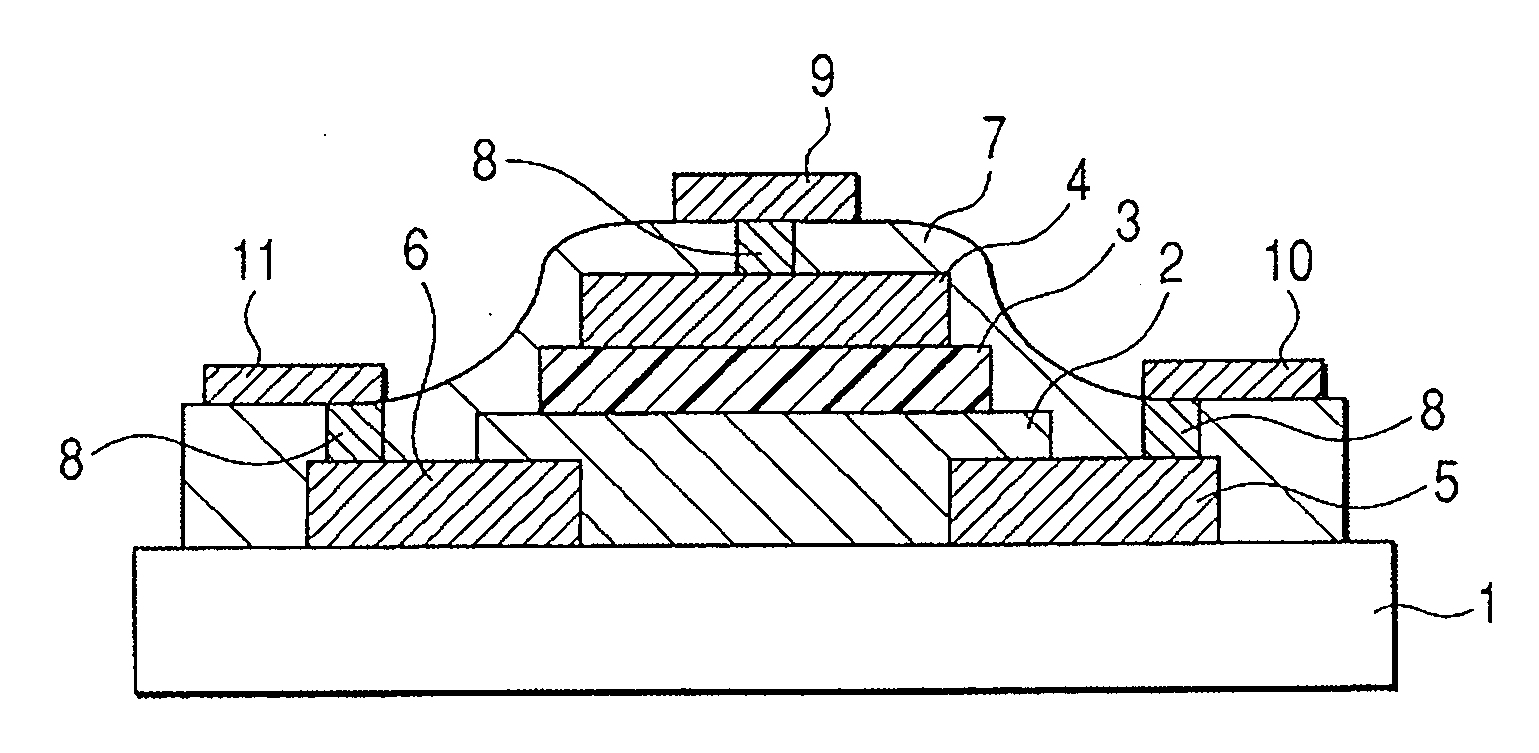

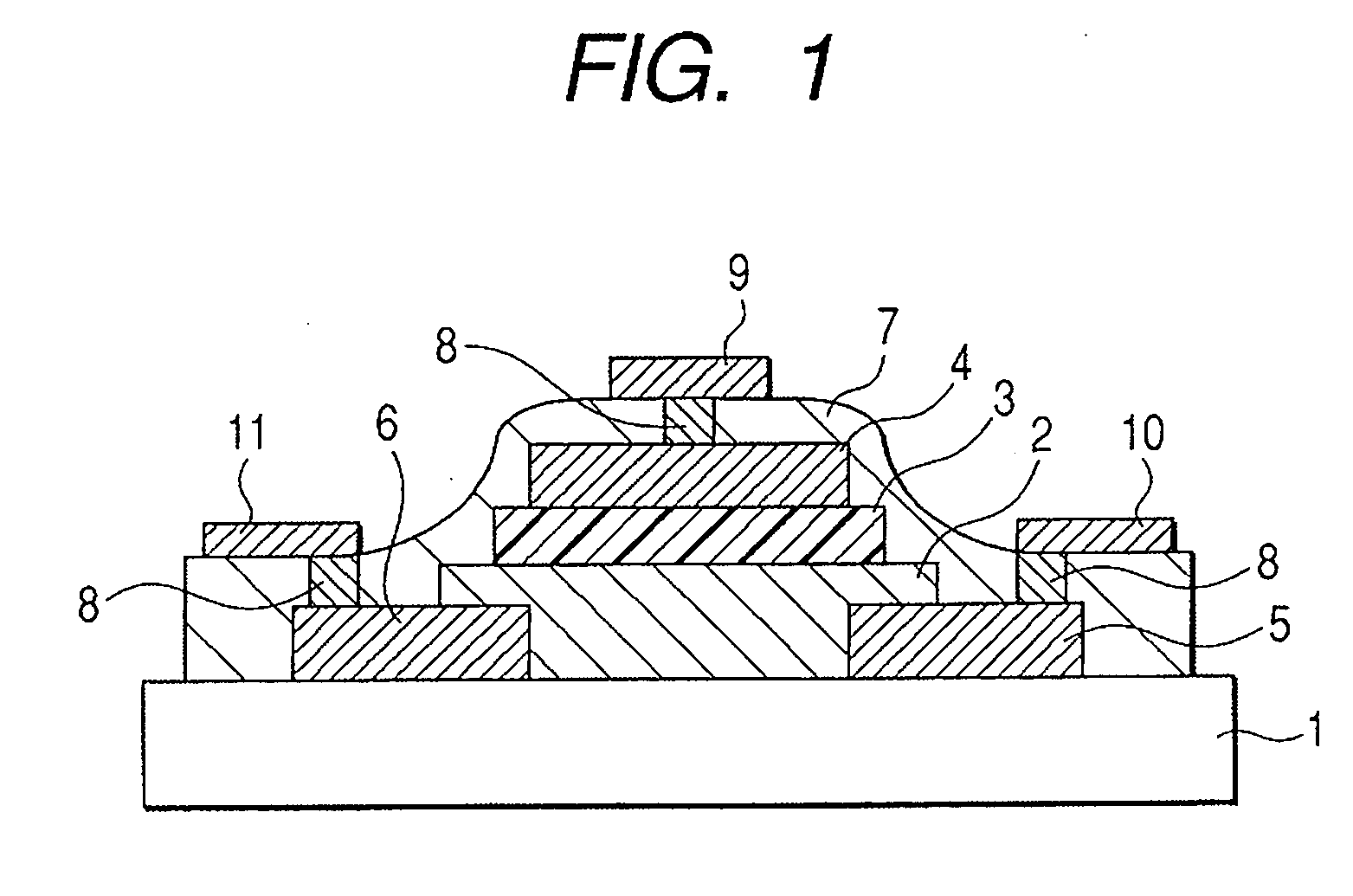

InactiveUS20070194379A1High ionicityGeneration of oxygen defects is less frequentTransistorVacuum evaporation coatingCharge carrierElectron

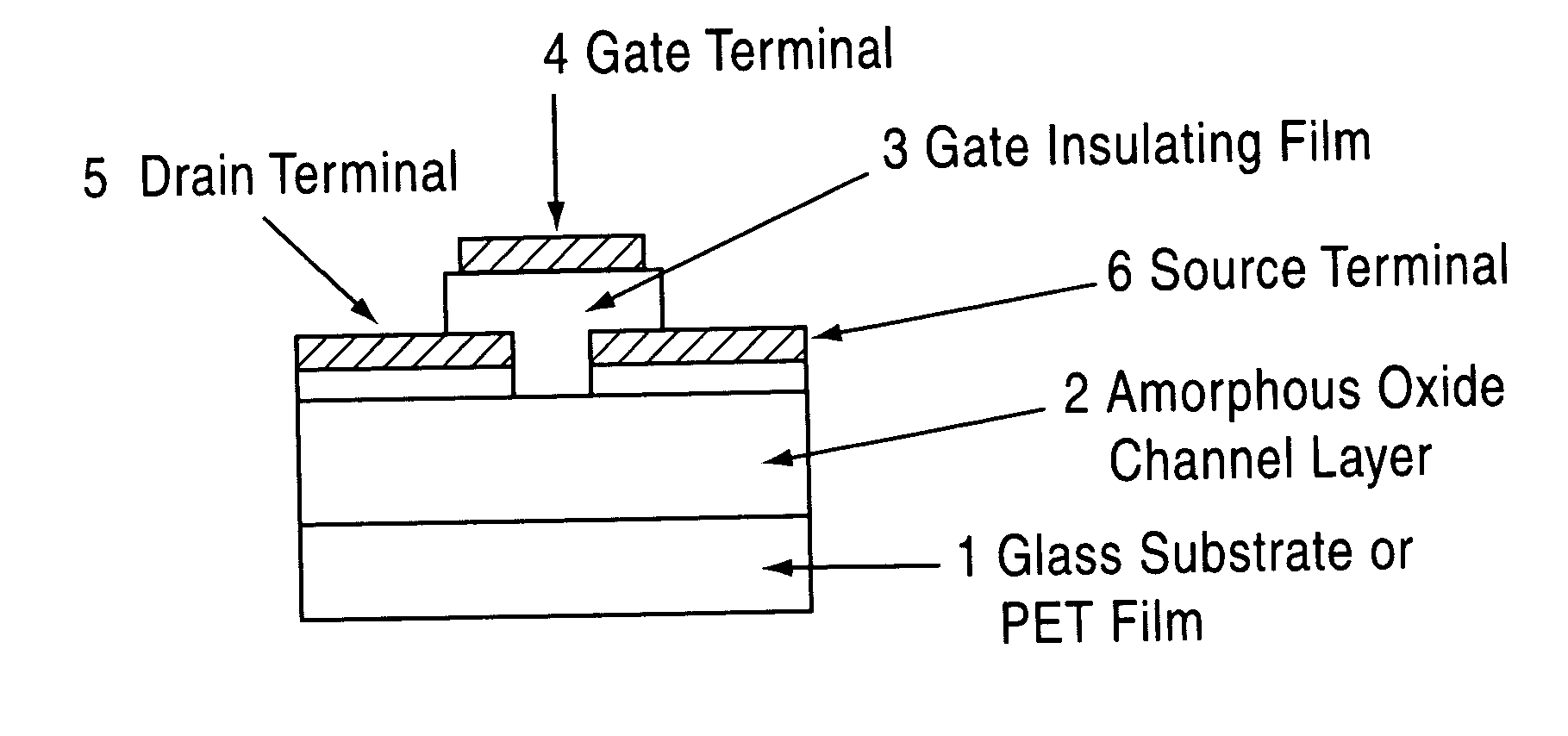

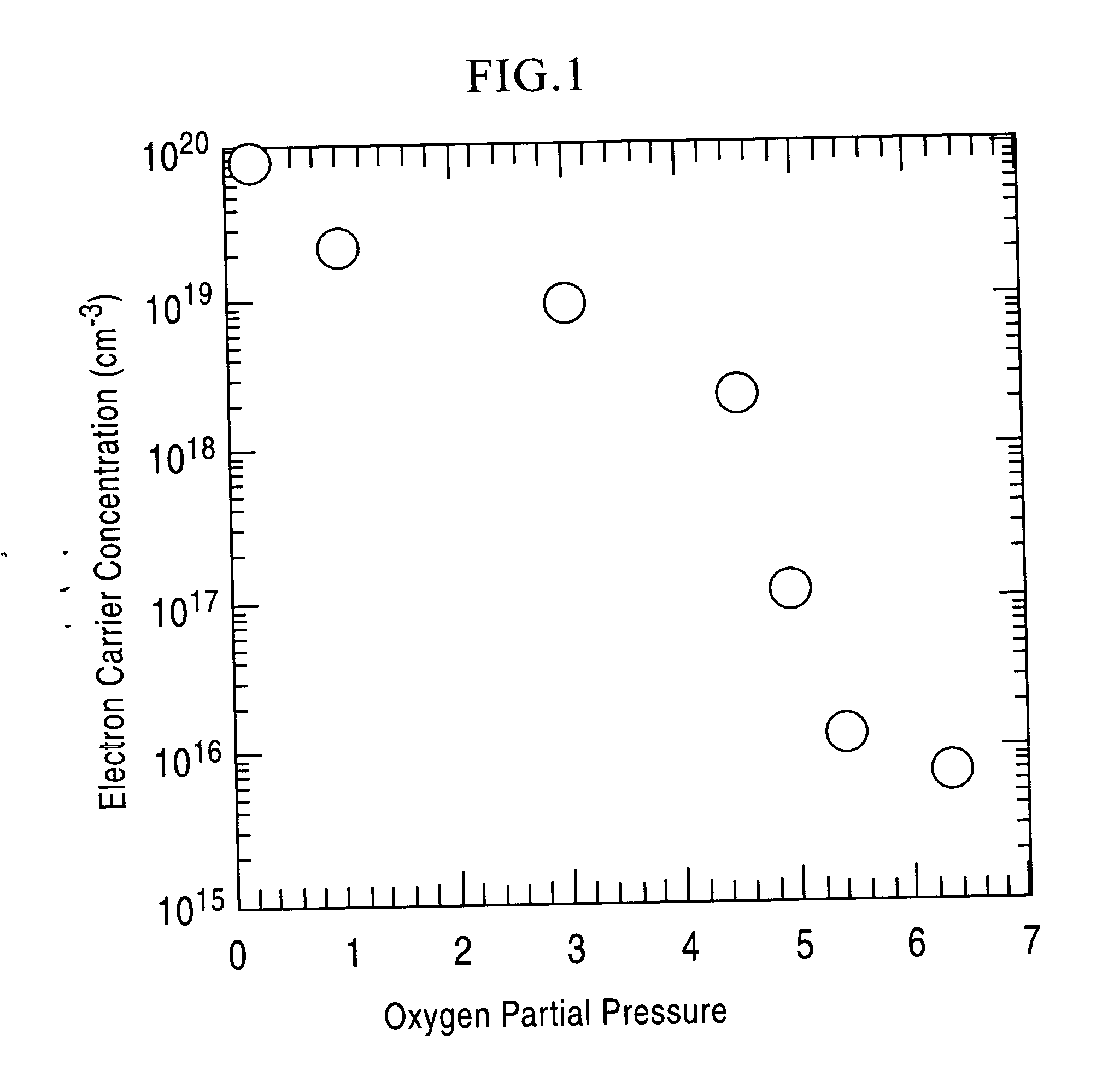

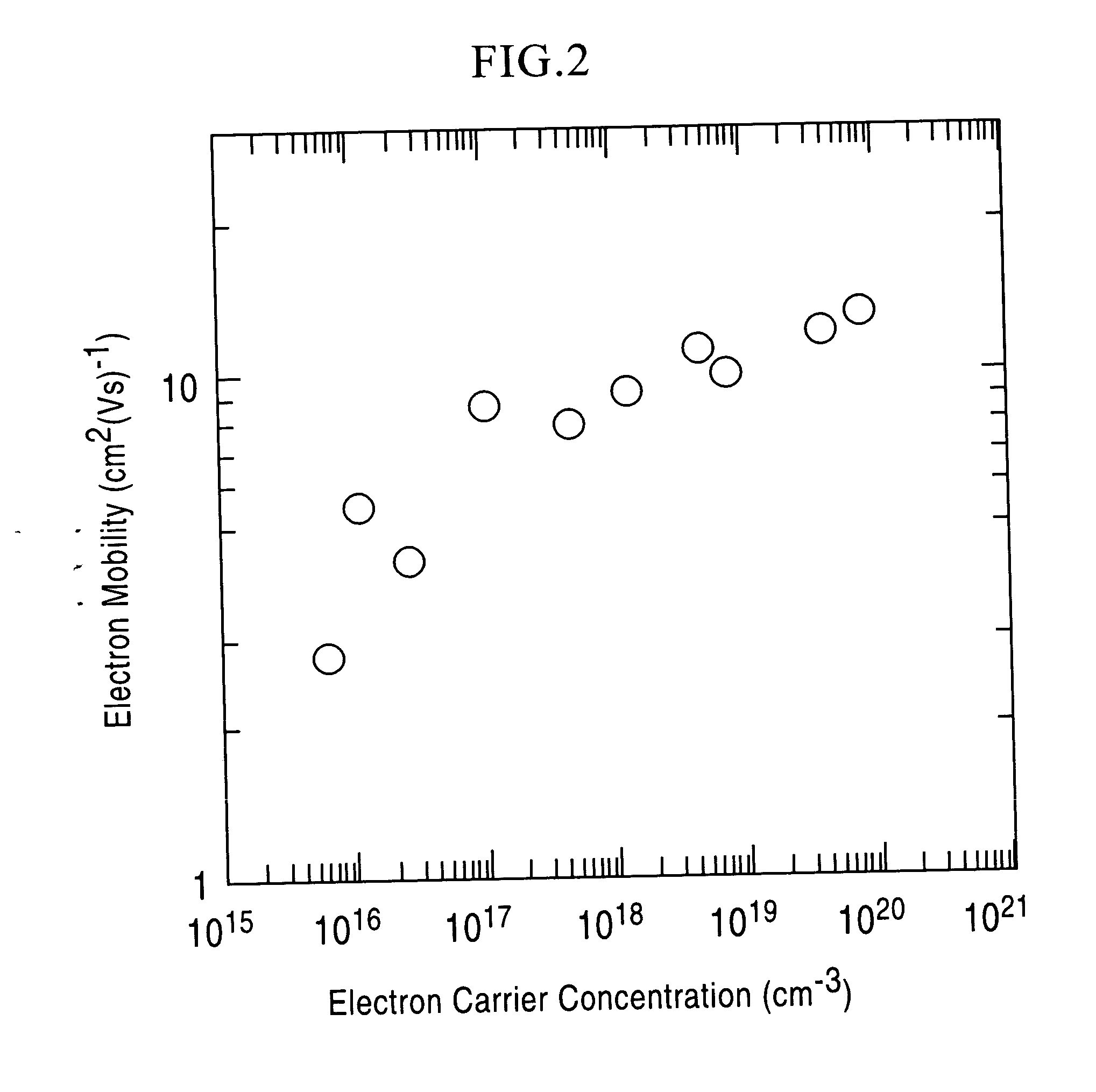

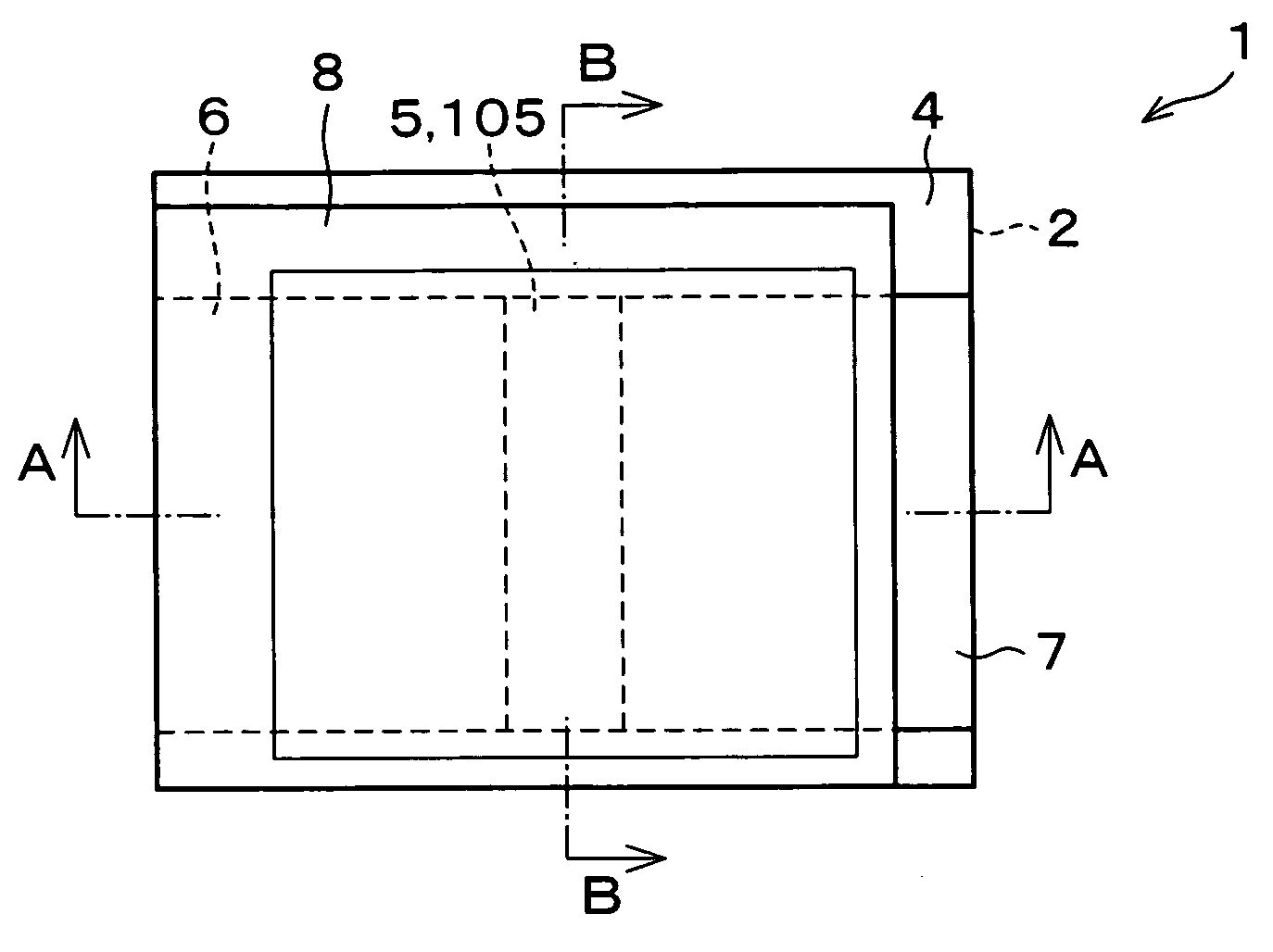

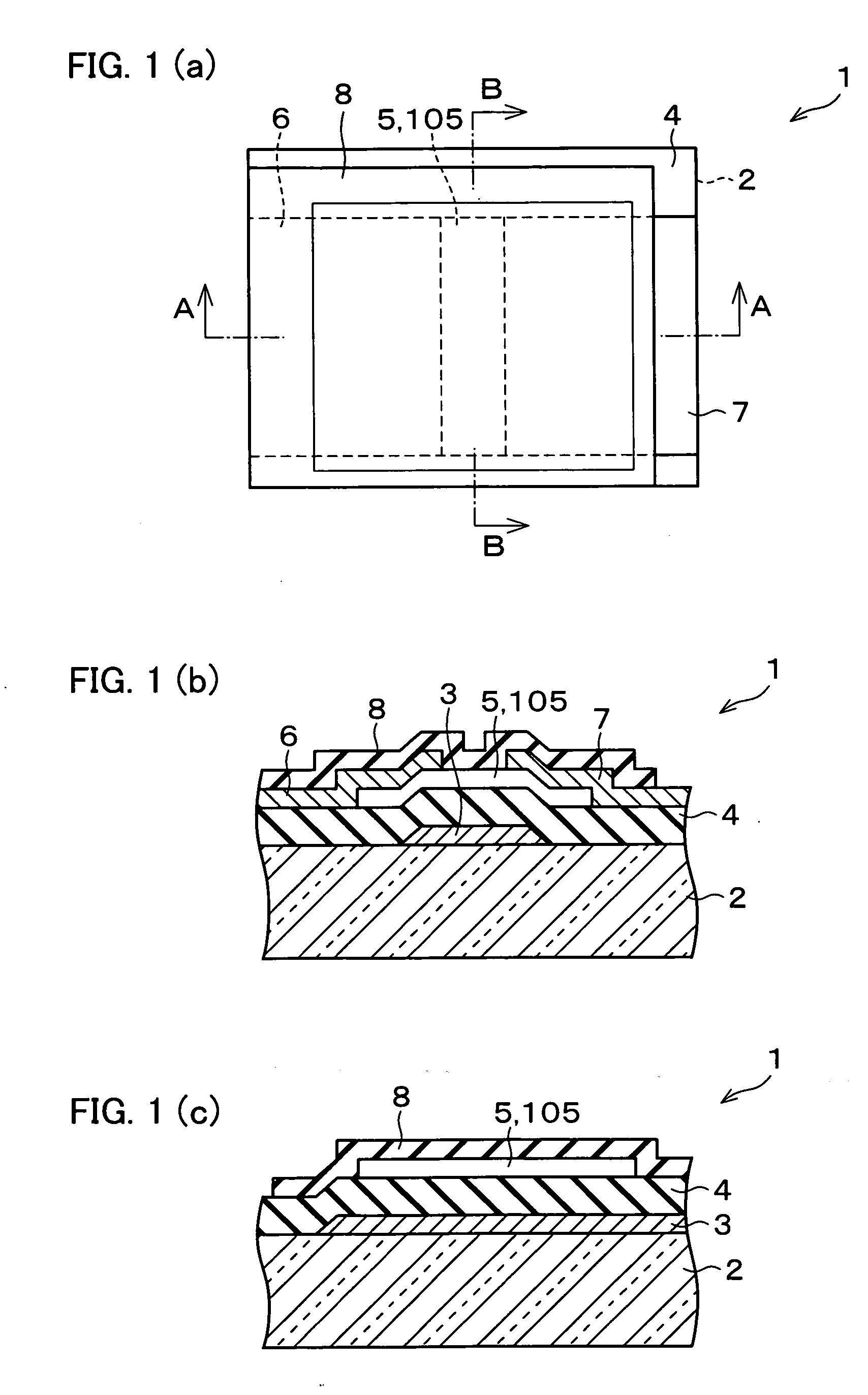

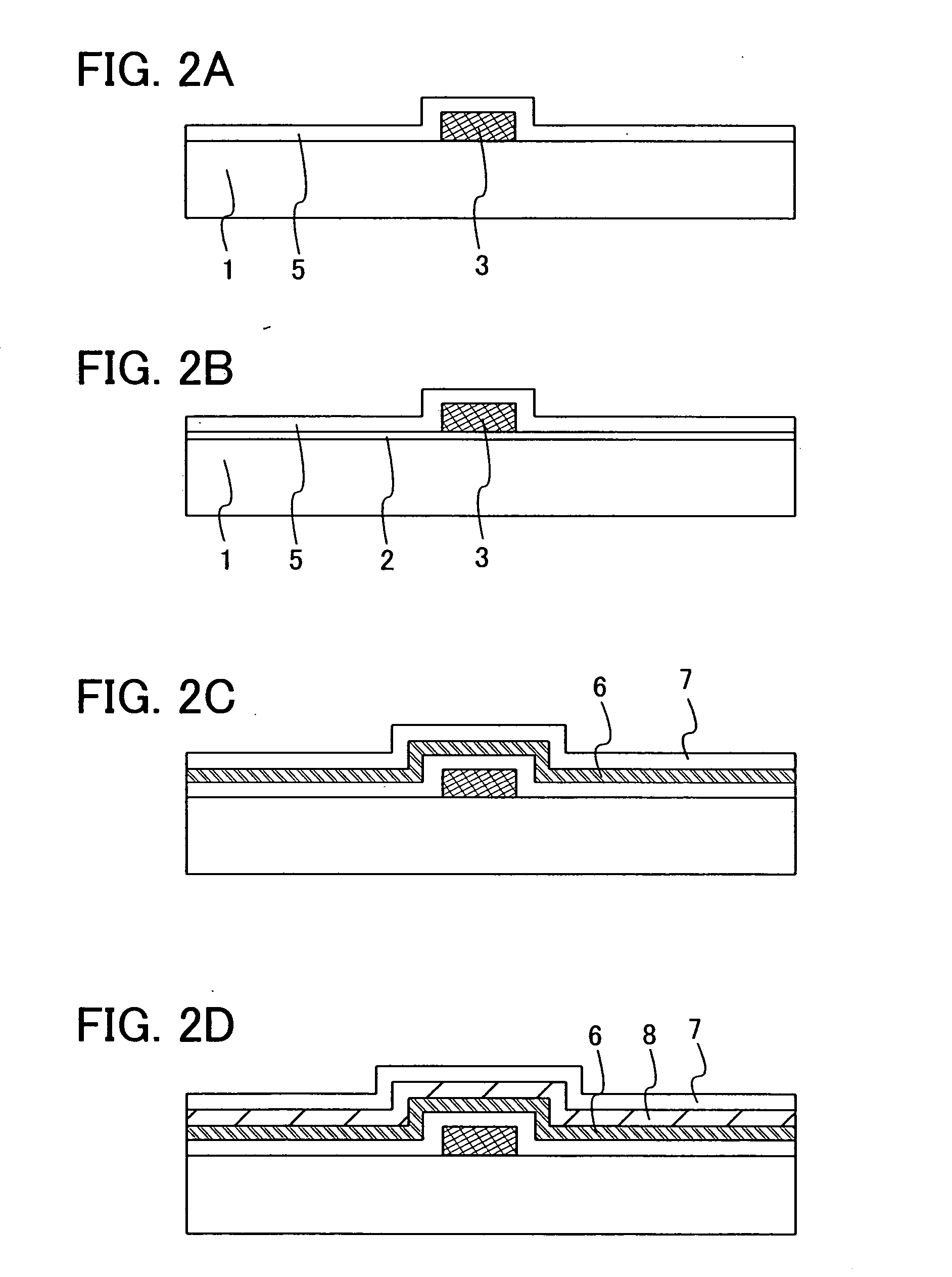

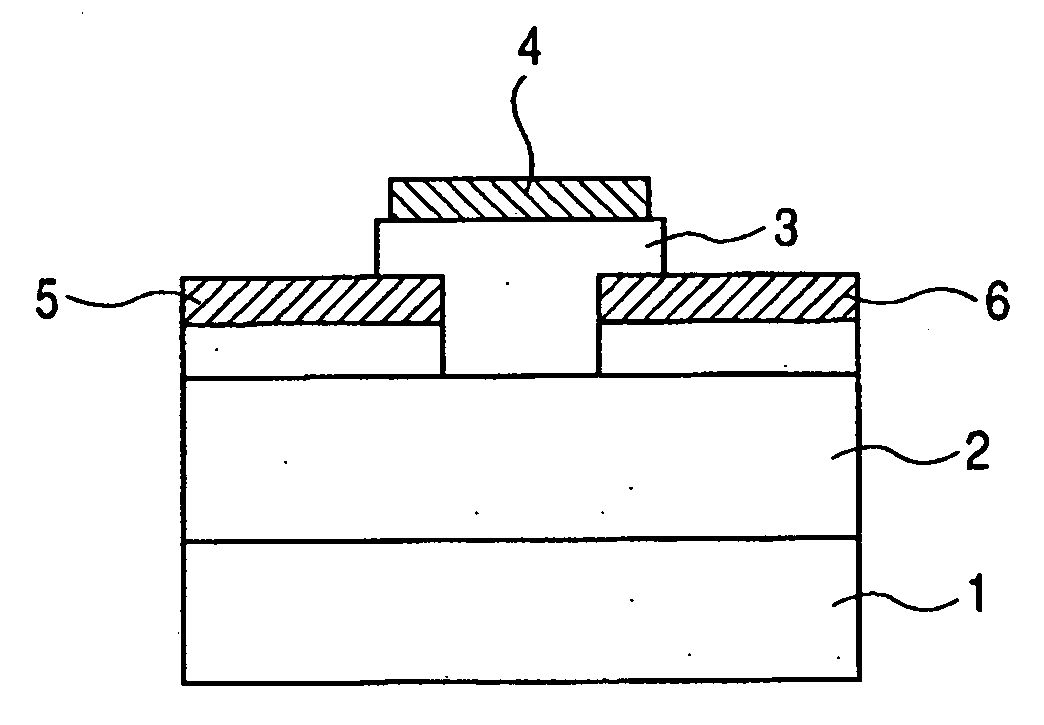

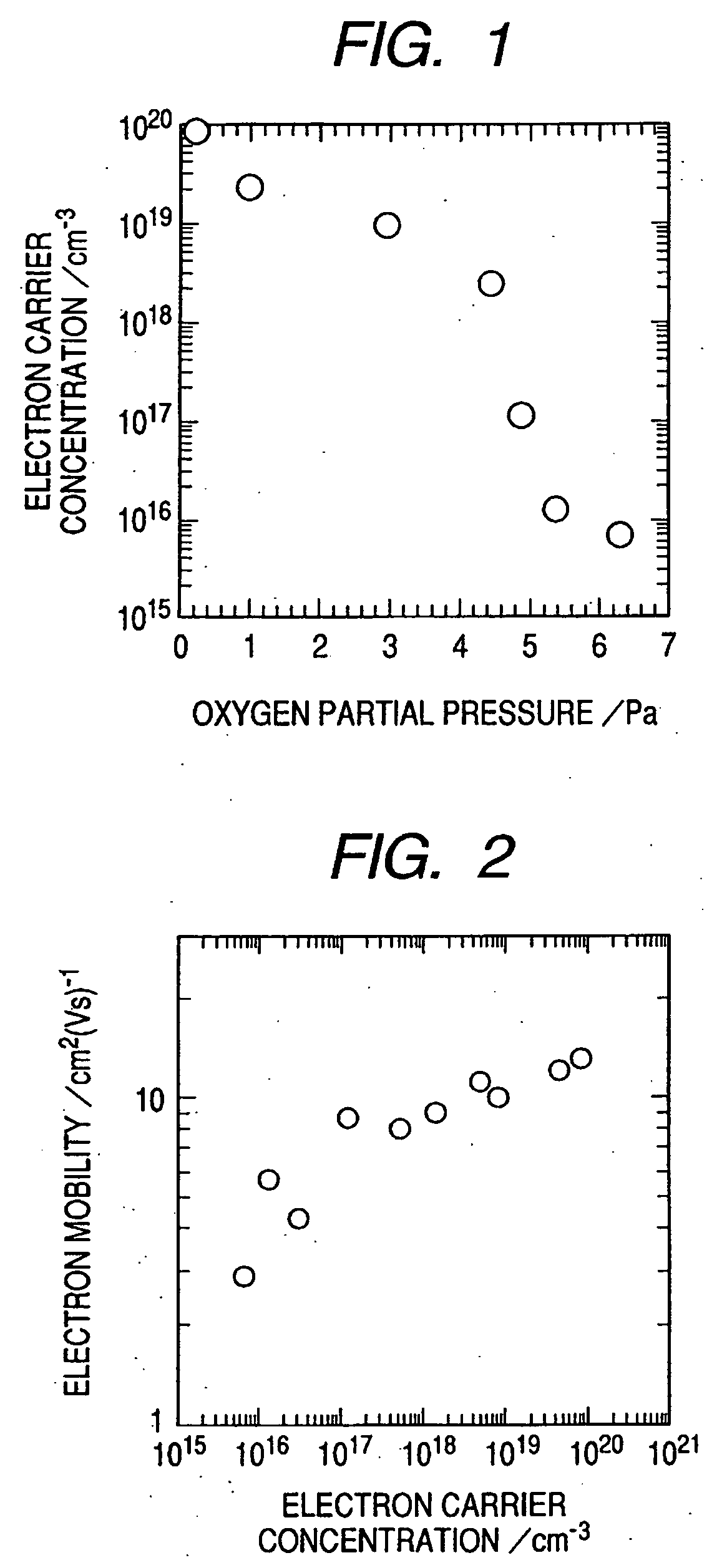

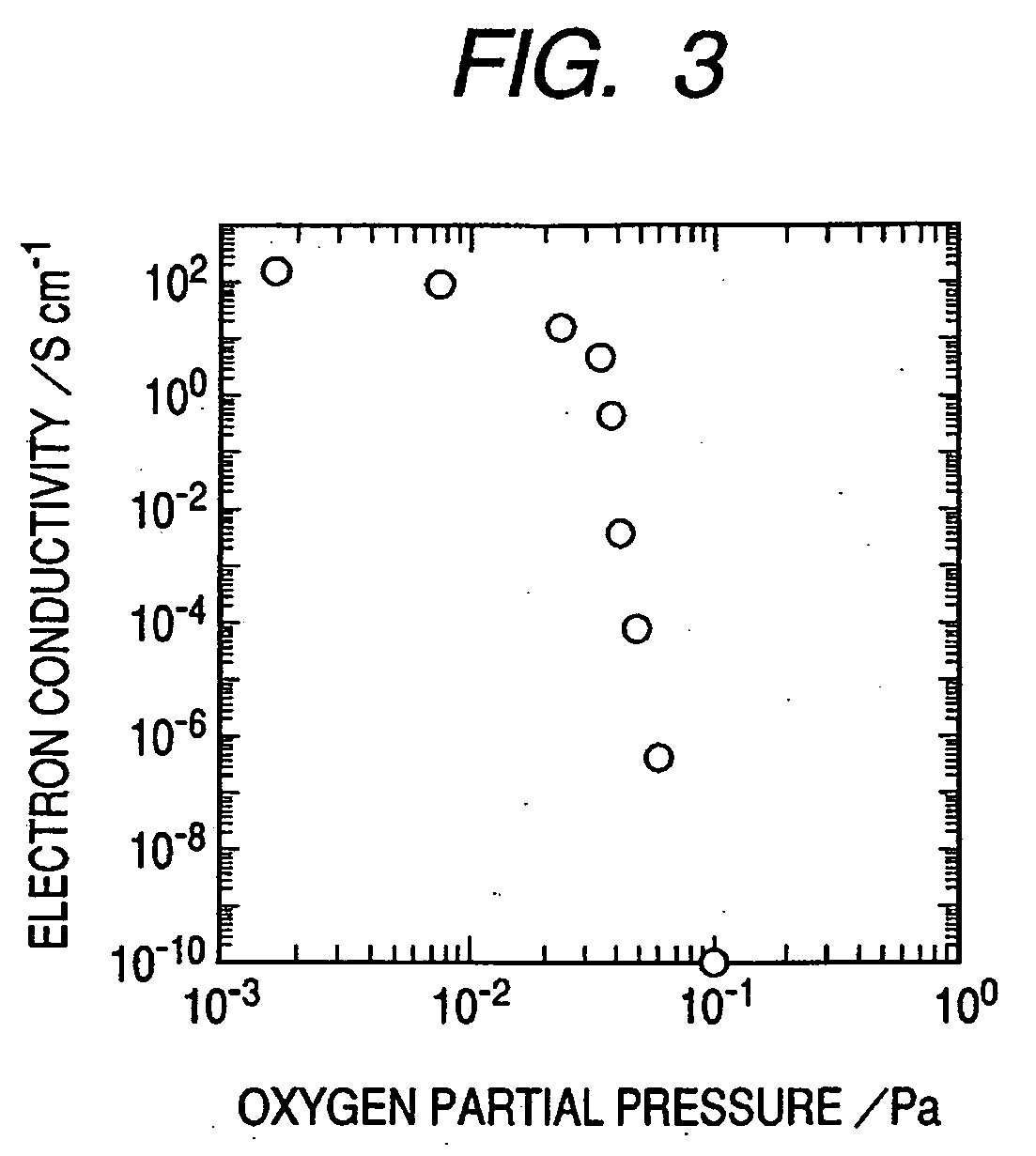

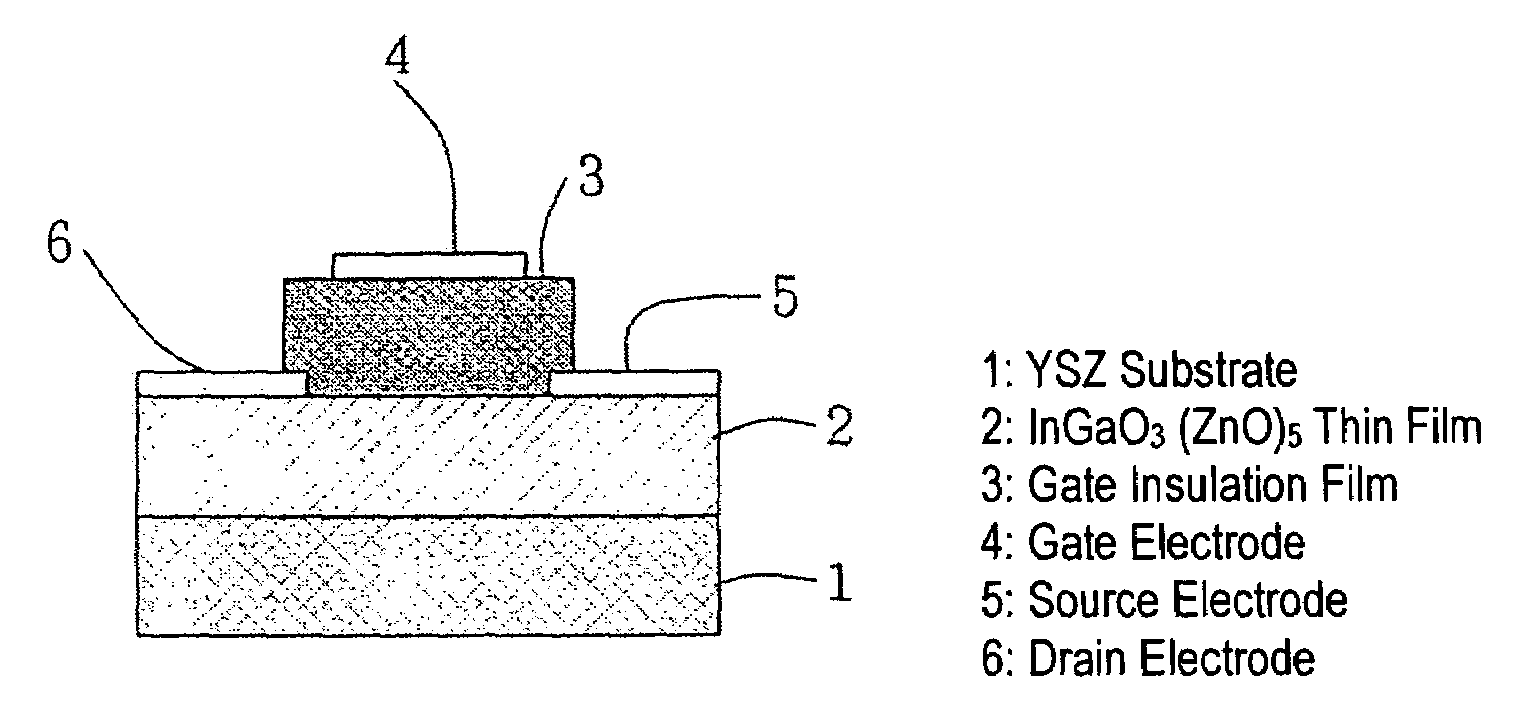

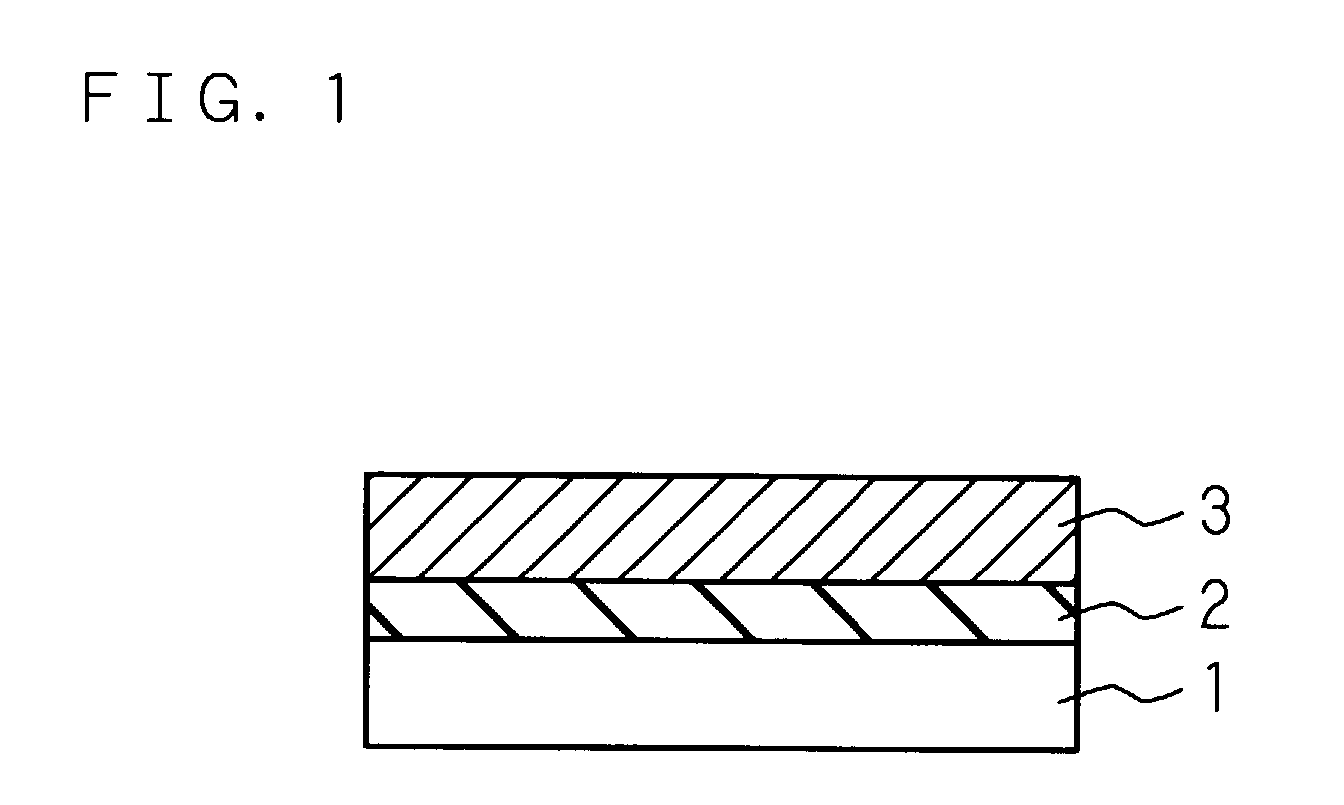

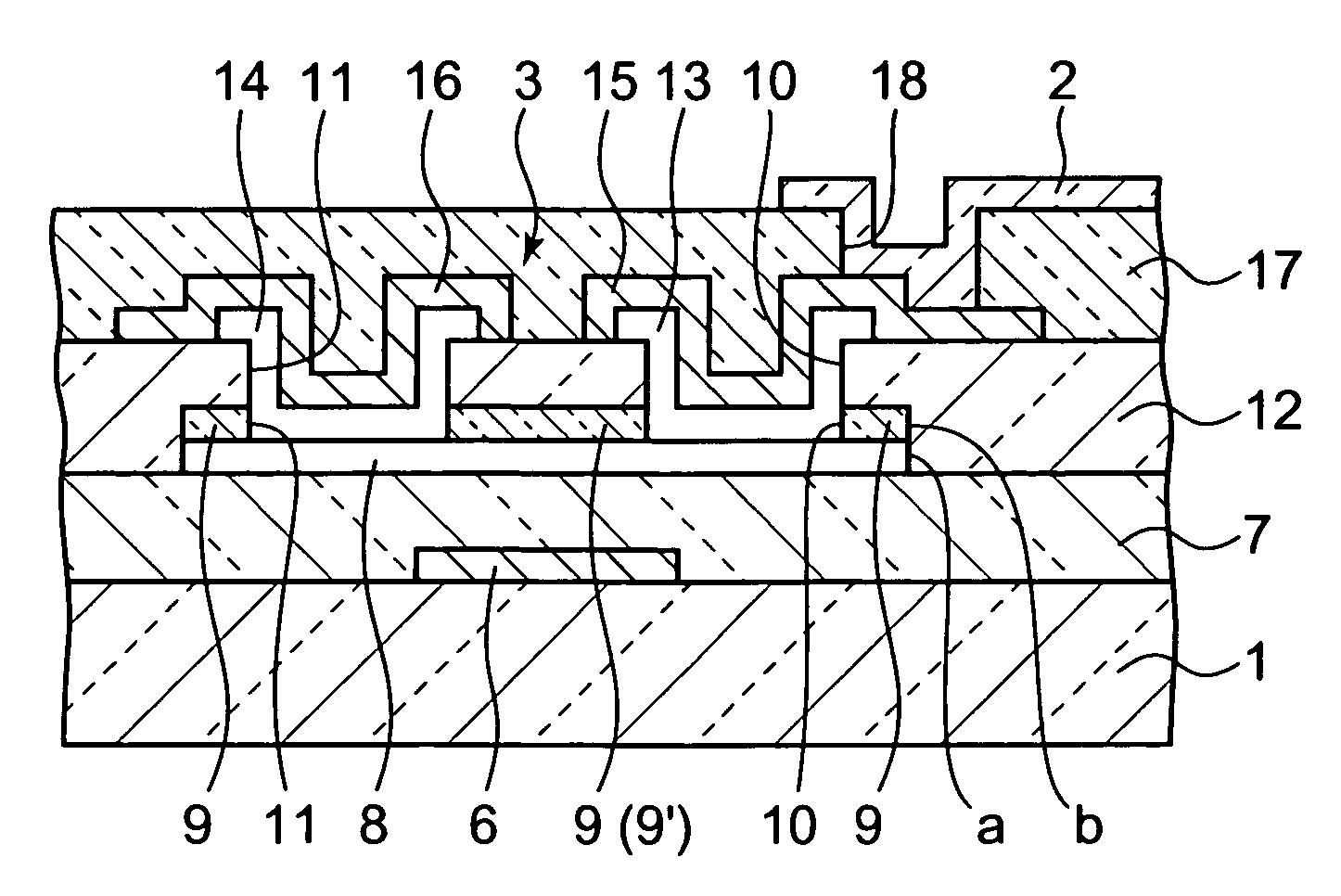

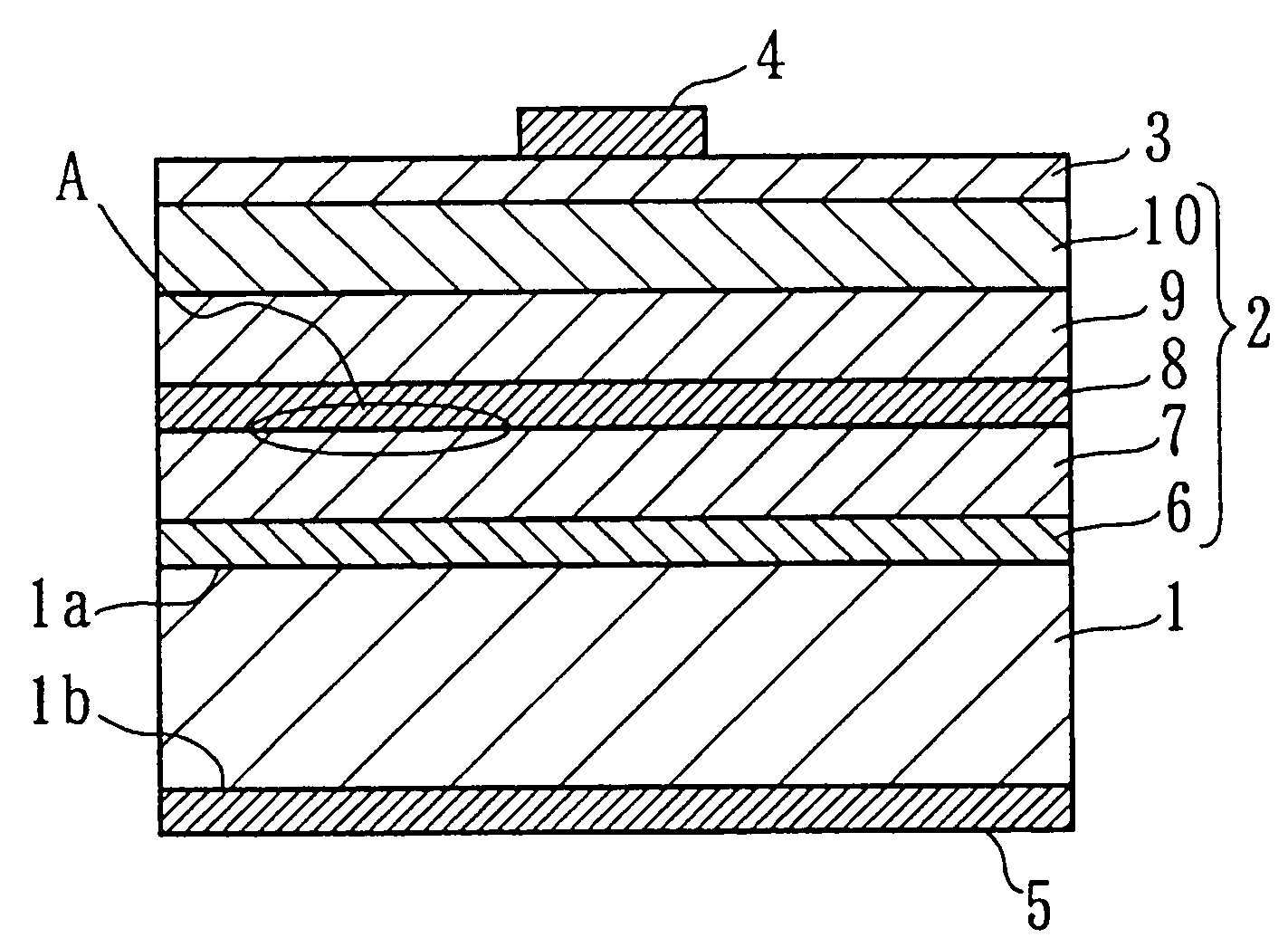

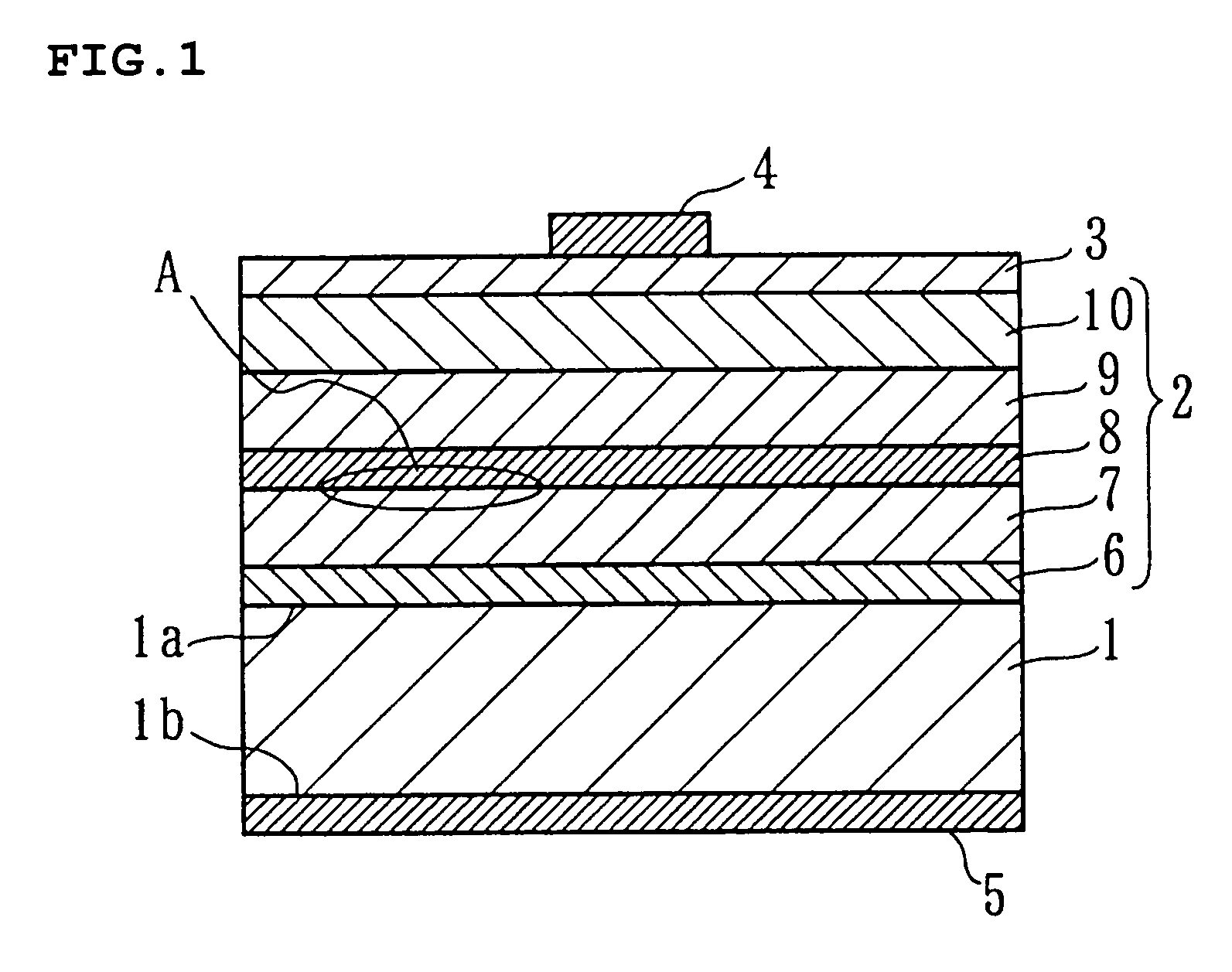

The present invention relates to an amorphous oxide and a thin film transistor using the amorphous oxide. In particular, the present invention provides an amorphous oxide having an electron carrier concentration less than 1018 / cm3, and a thin film transistor using such an amorphous oxide. In a thin film transistor having a source electrode 6, a drain electrode 5, a gate electrode 4, a gate insulating film 3, and a channel layer 2, an amorphous oxide having an electron carrier concentration less than 1018 / cm3 is used in the channel layer 2.

Owner:JAPAN SCI & TECH CORP

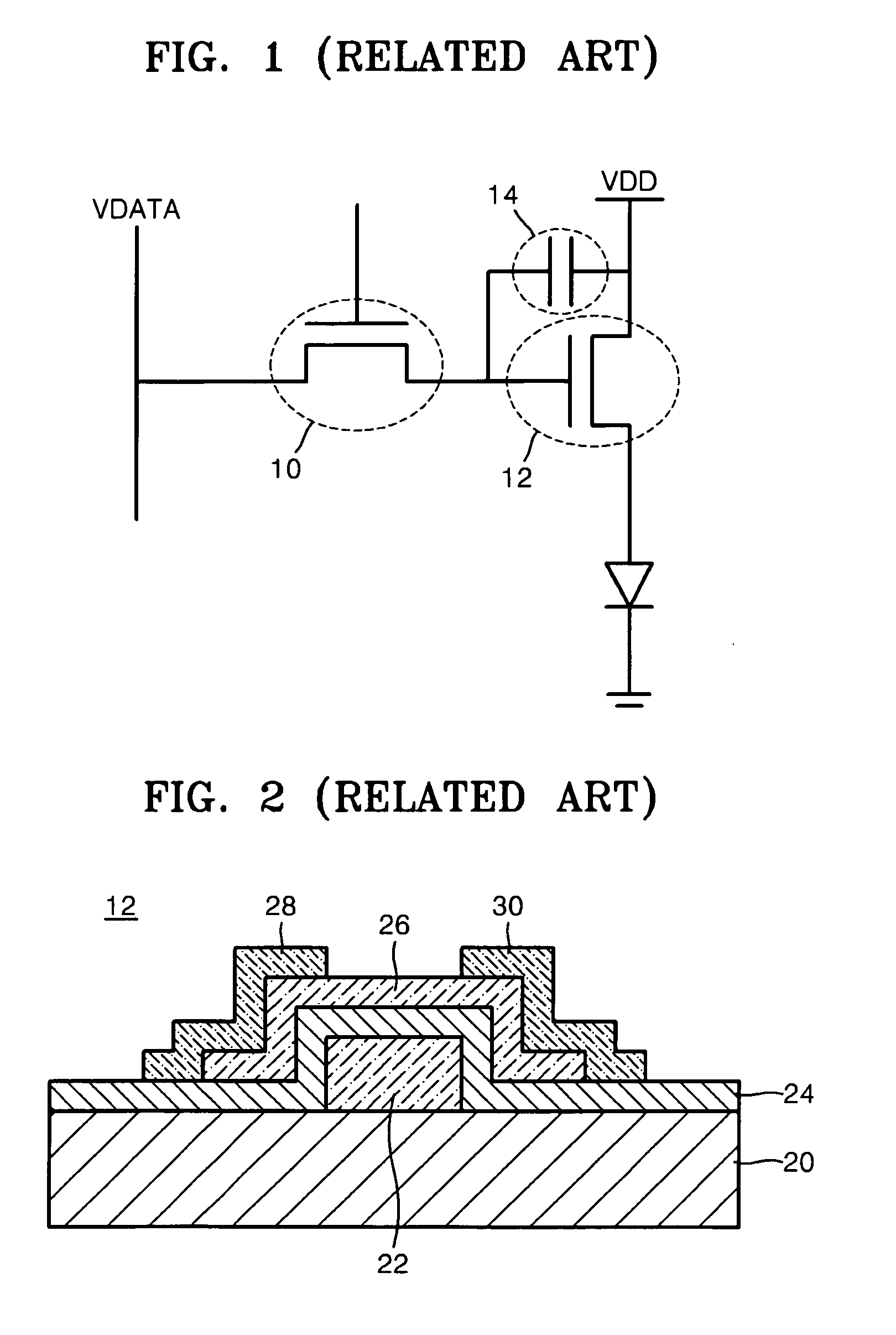

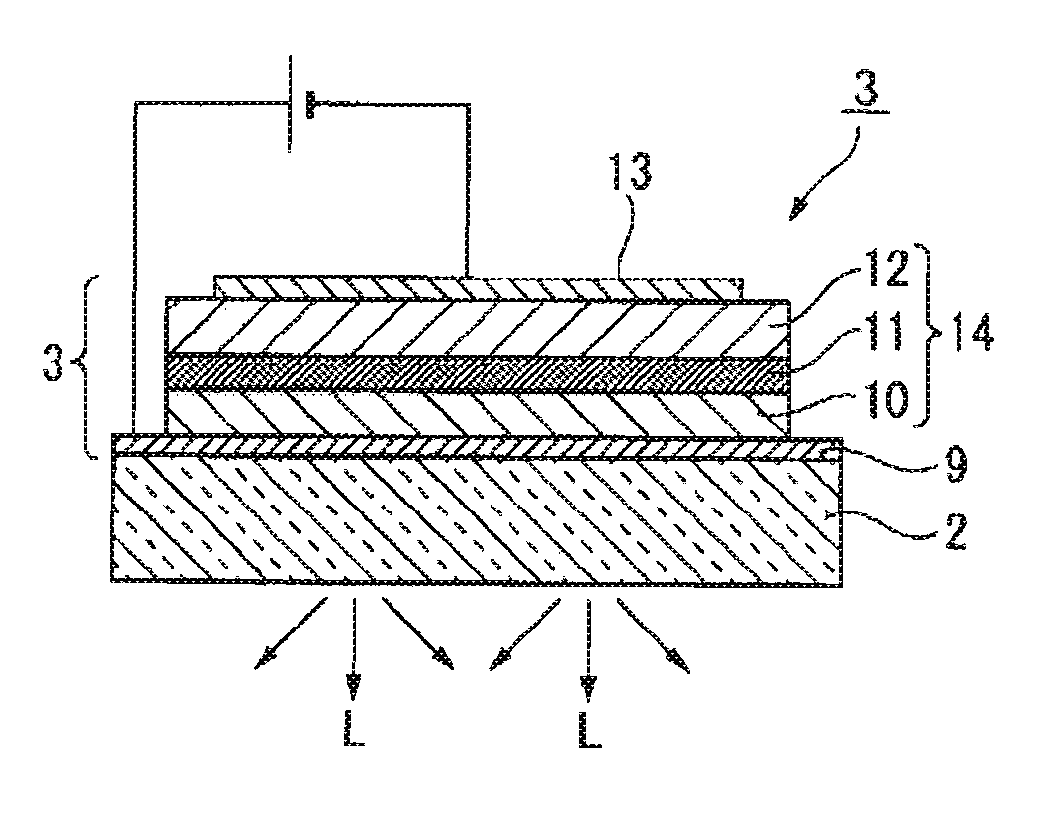

Semiconductor device, manufacturing method, and electronic device

ActiveUS20060244107A1Stabilize element propertyEasy to manufactureTransistorSemiconductor/solid-state device detailsSurface levelIntrinsic resistance

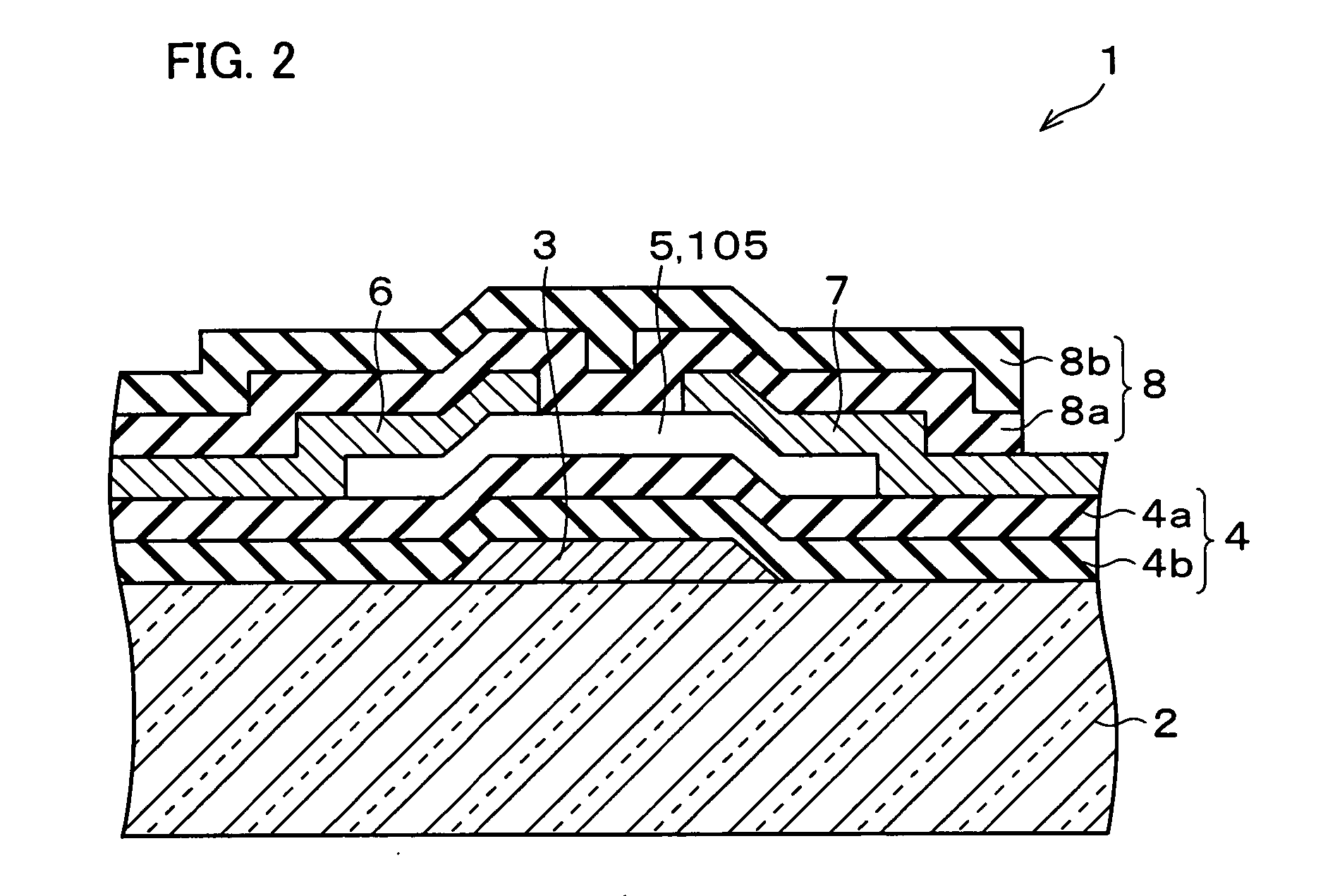

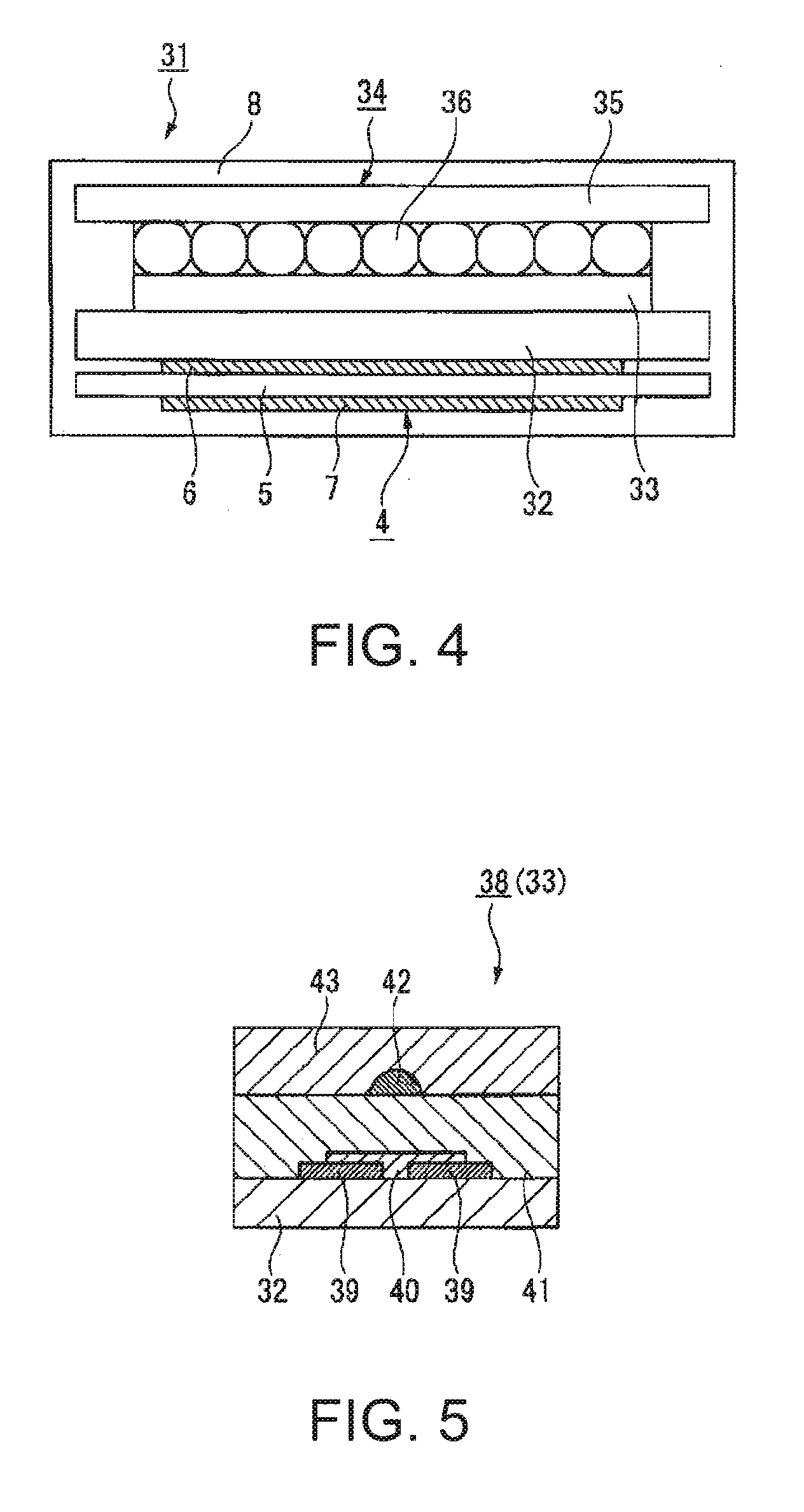

In a thin film transistor (1), a gate insulating layer (4) is formed on a gate electrode (3) formed on an insulating substrate (2). Formed on the gate insulating layer (4) is a semiconductor layer (5). Formed on the semiconductor layer (5) are a source electrode (6) and a drain electrode (7). A protective layer (8) covers them, so that the semiconductor layer (5) is blocked from an atmosphere. The semiconductor layer (5) (active layer) is made of, e.g., a semiconductor containing polycrystalline ZnO to which, e.g., a group V element is added. The protective layer (8) thus formed causes decrease of a surface level of the semiconductor layer (5). This eliminates a depletion layer spreading therewithin. Accordingly, the ZnO becomes an n-type semiconductor indicating an intrinsic resistance, with the result that too many free electrons are generated. However, the added element works on the ZnO as an accepter impurity, so that the free electrons are reduced. This decreases a gate voltage required for removal of the free electrons, so that the threshold voltage of the thin film transistor (1) becomes on the order of 0V. This allows practical use of a semiconductor device which has an active layer made of zinc oxide and which includes an protective layer for blocking the active layer from an atmosphere.

Owner:SHARP KK +2

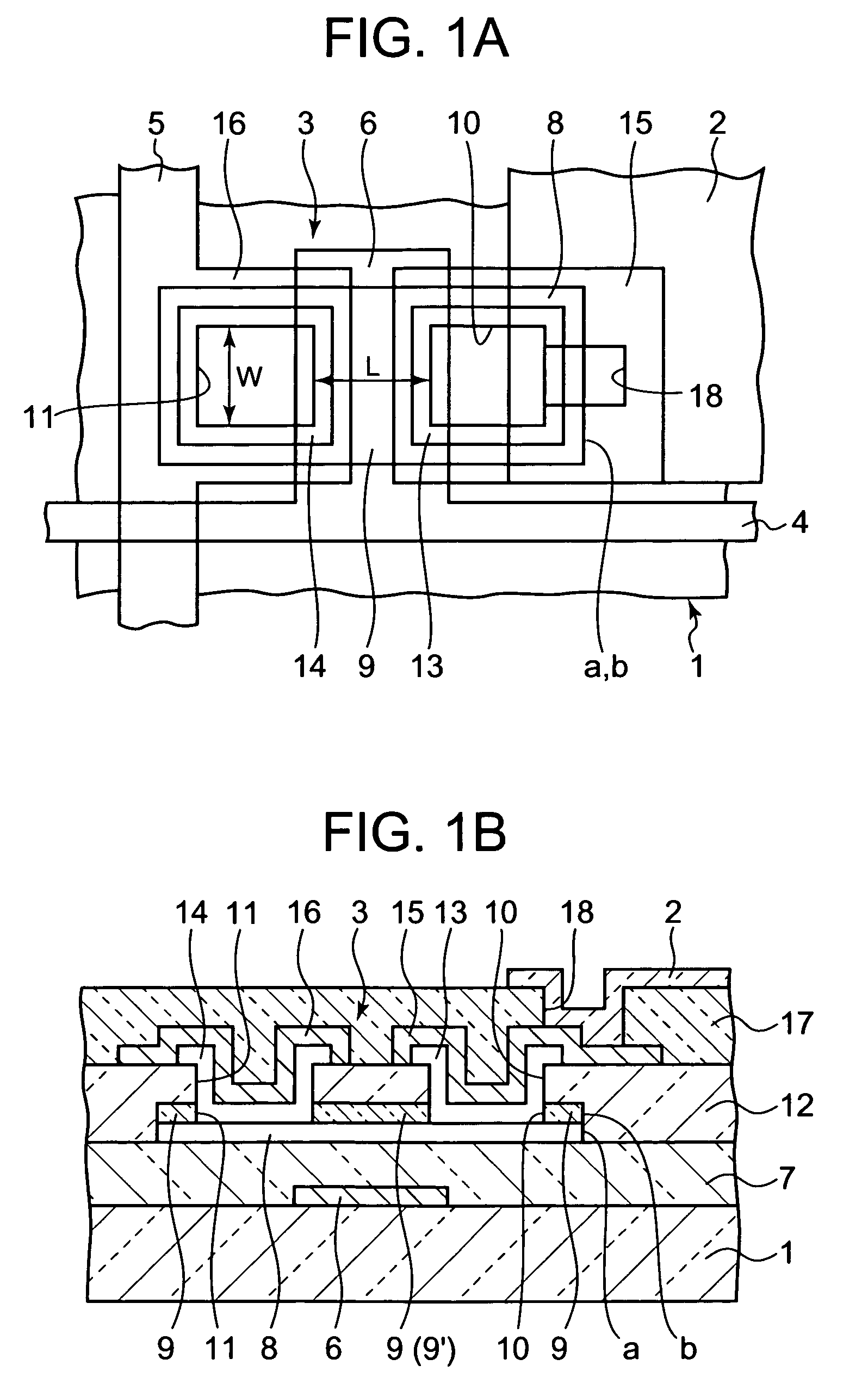

Semiconductor device and manufacturing method thereof

ActiveUS20070108446A1Low resistance of wireLower resistanceTransistorElectroluminescent light sourcesAlloySilicon oxide

To provide a semiconductor device in which a defect or fault is not generated and a manufacturing method thereof even if a ZnO semiconductor film is used and a ZnO film to which an n-type or p-type impurity is added is used for a source electrode and a drain electrode. The semiconductor device includes a gate insulating film formed by using a silicon oxide film or a silicon oxynitride film over a gate electrode, an Al film or an Al alloy film over the gate insulating film, a ZnO film to which an n-type or p-type impurity is added over the Al film or the Al alloy film, and a ZnO semiconductor film over the ZnO film to which an n-type or p-type impurity is added and the gate insulating film.

Owner:SEMICON ENERGY LAB CO LTD

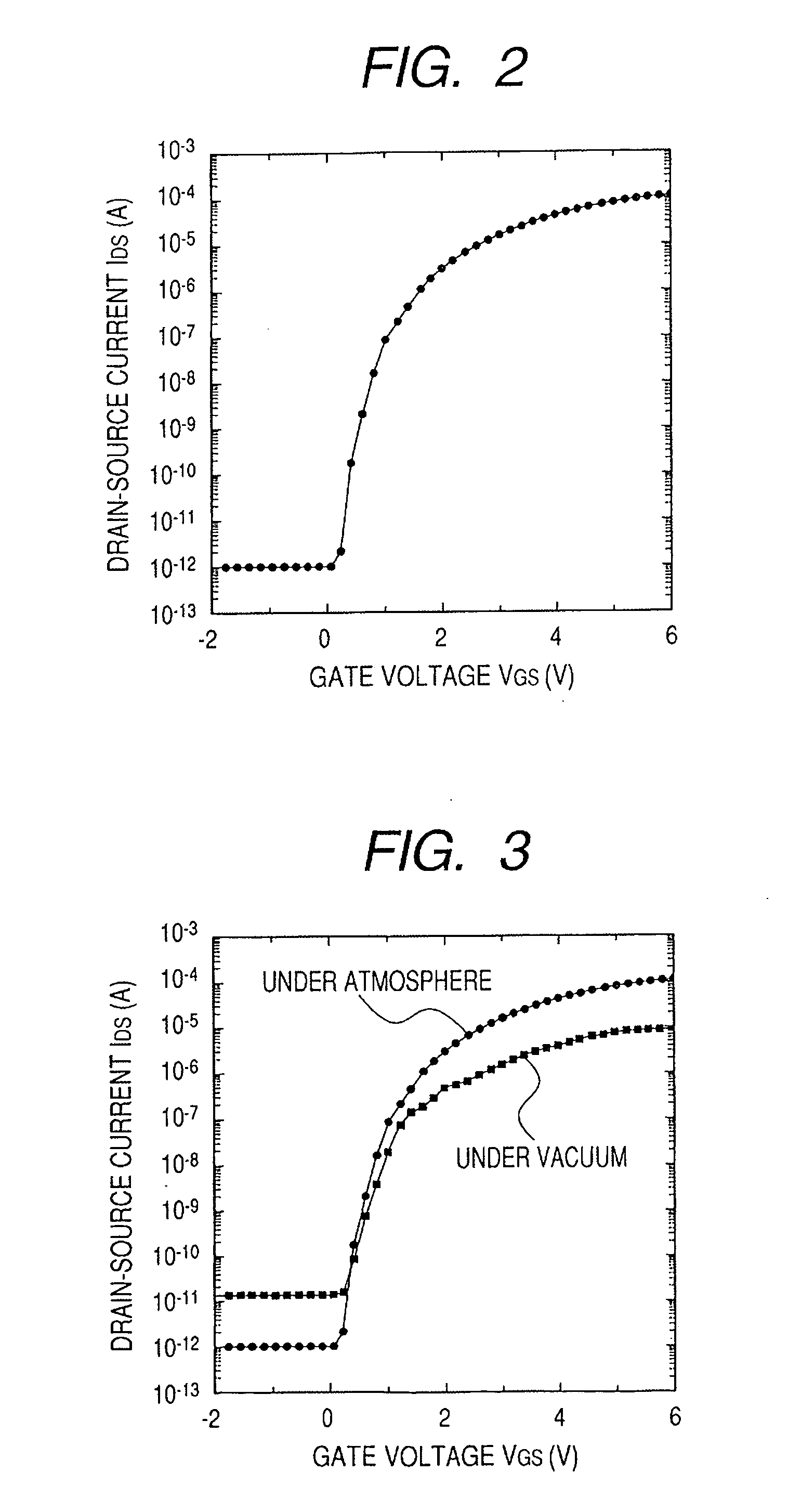

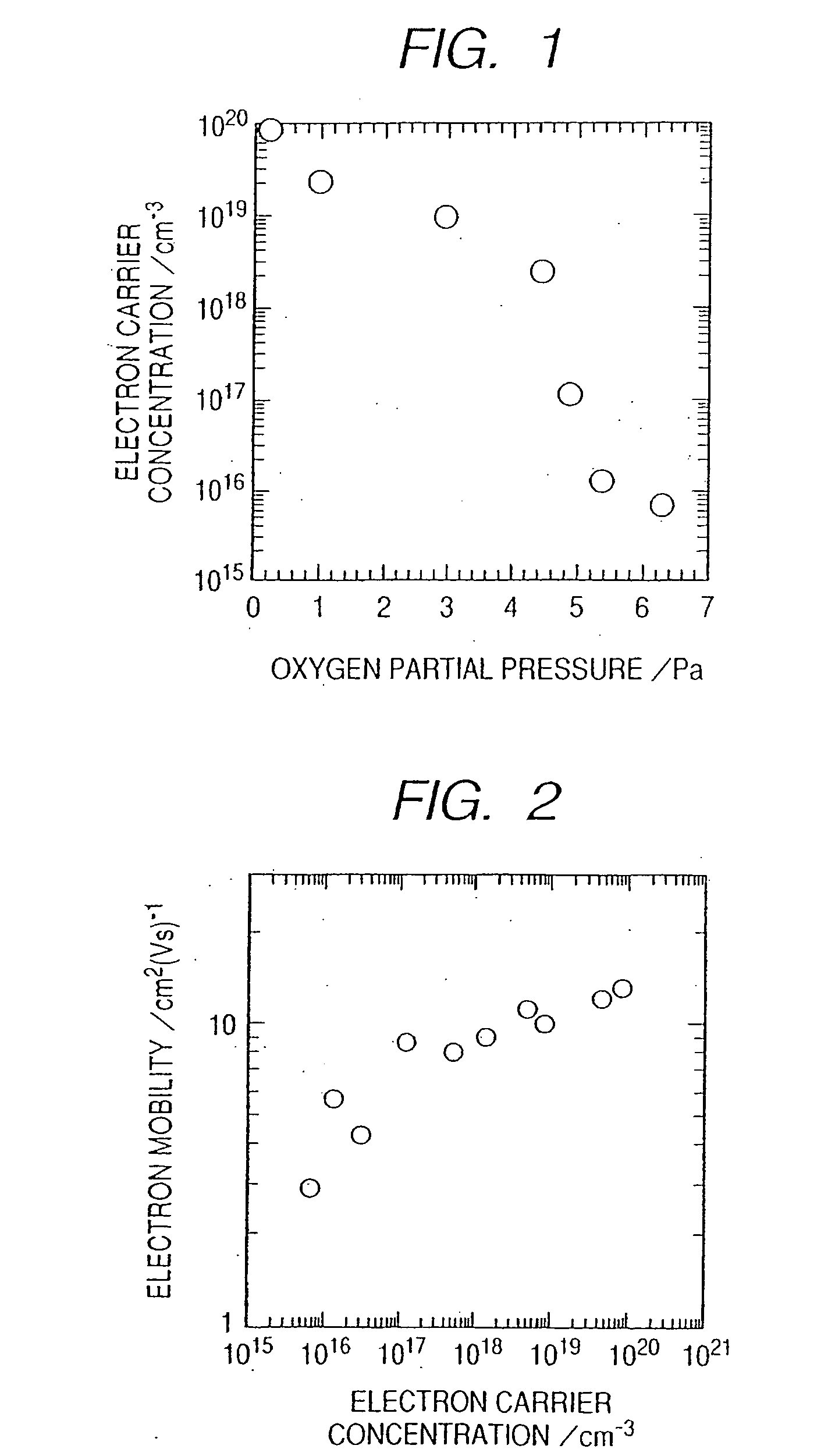

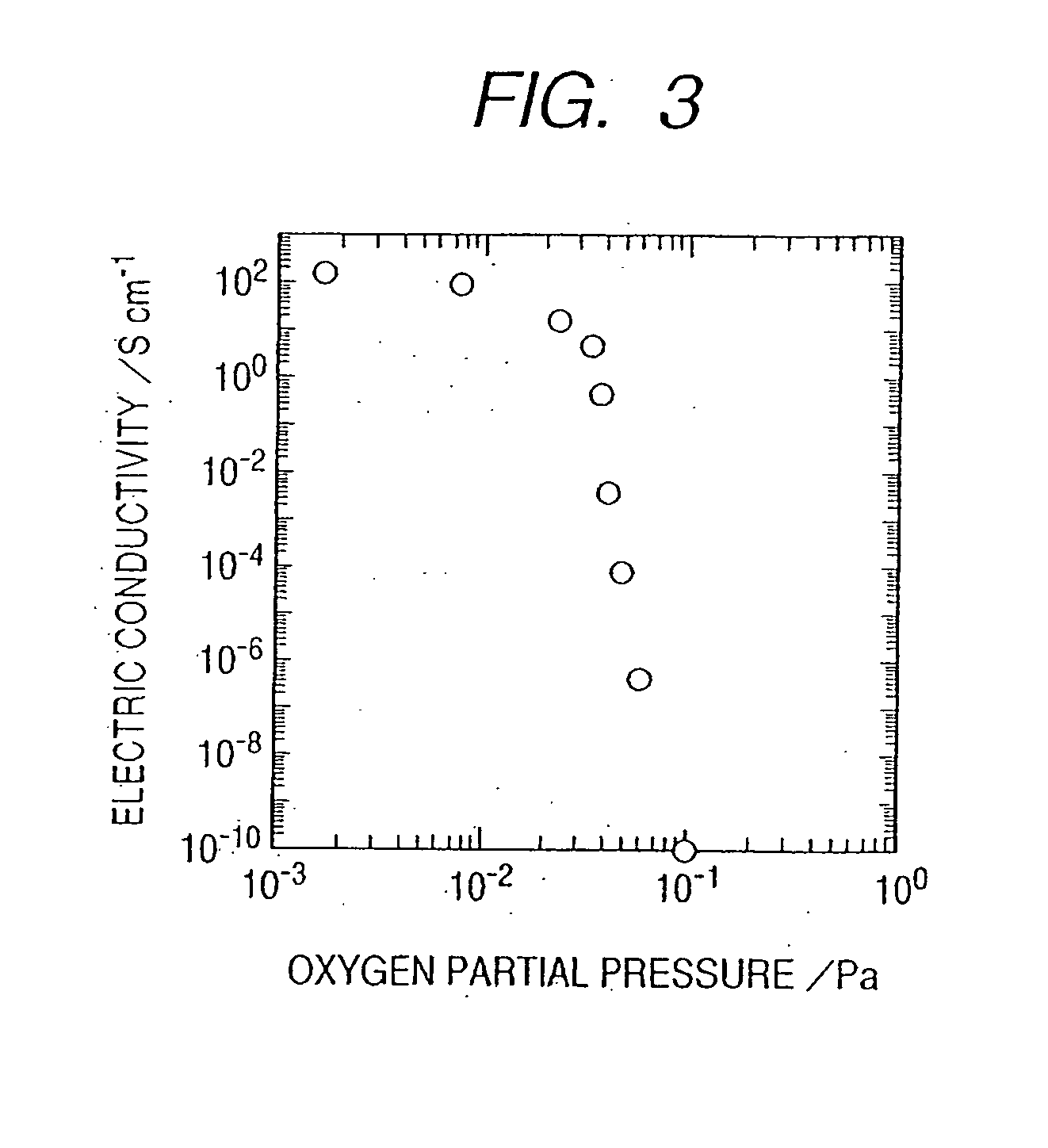

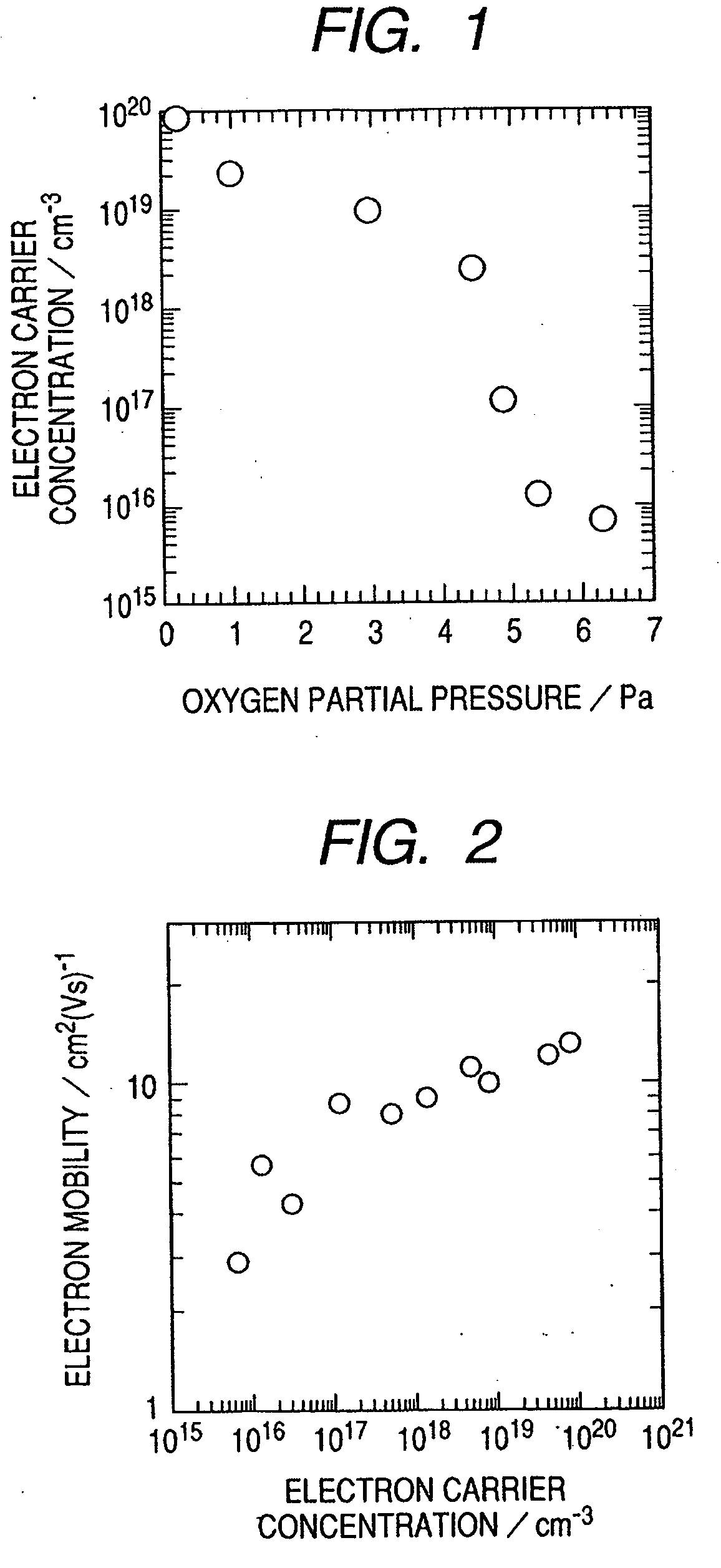

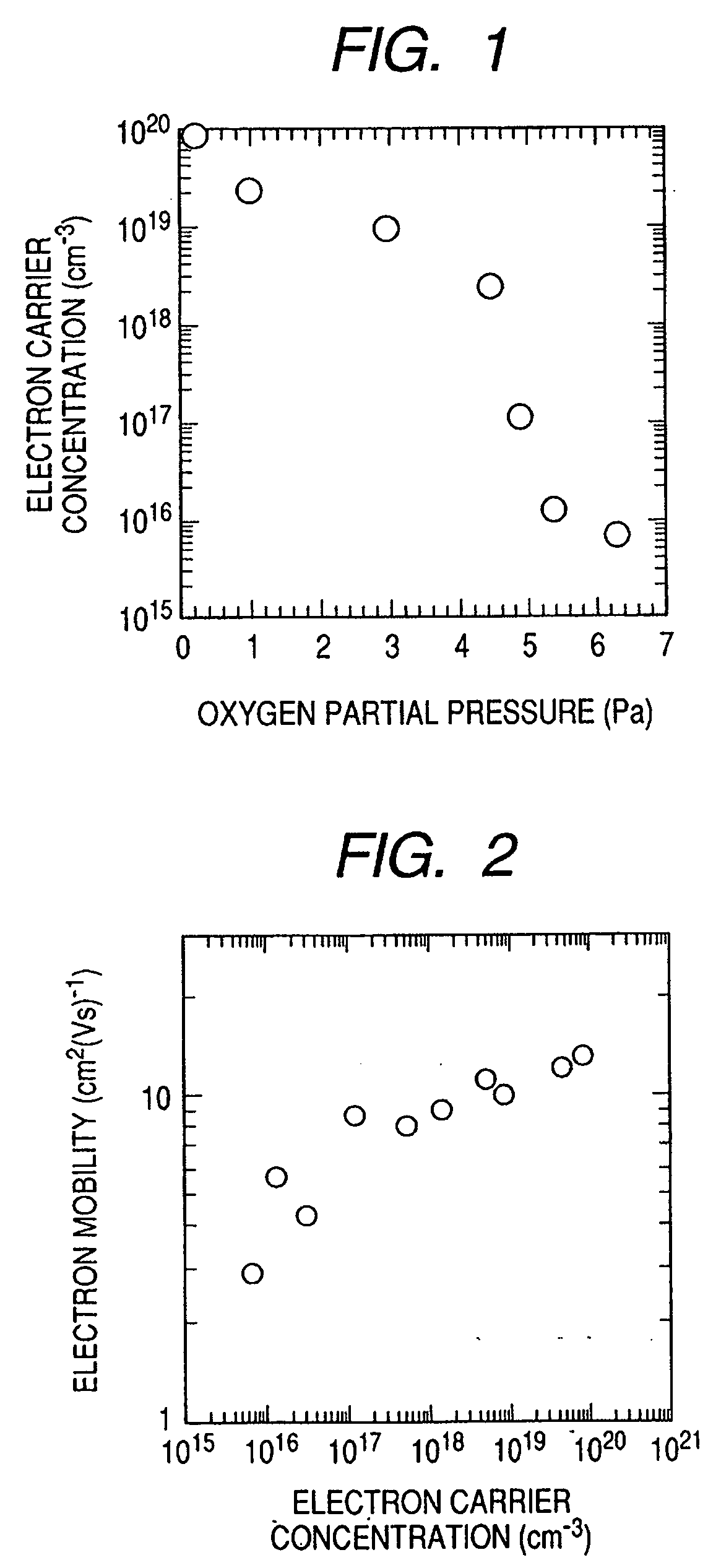

Amorphous oxide and field effect transistor

ActiveUS20060108636A1Reduced electron mobilityLow conductivitySolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorActive layer

A novel amorphous oxide applicable, for example, to an active layer of a TFT is provided. The amorphous oxide comprises microcrystals.

Owner:CANON KK +2

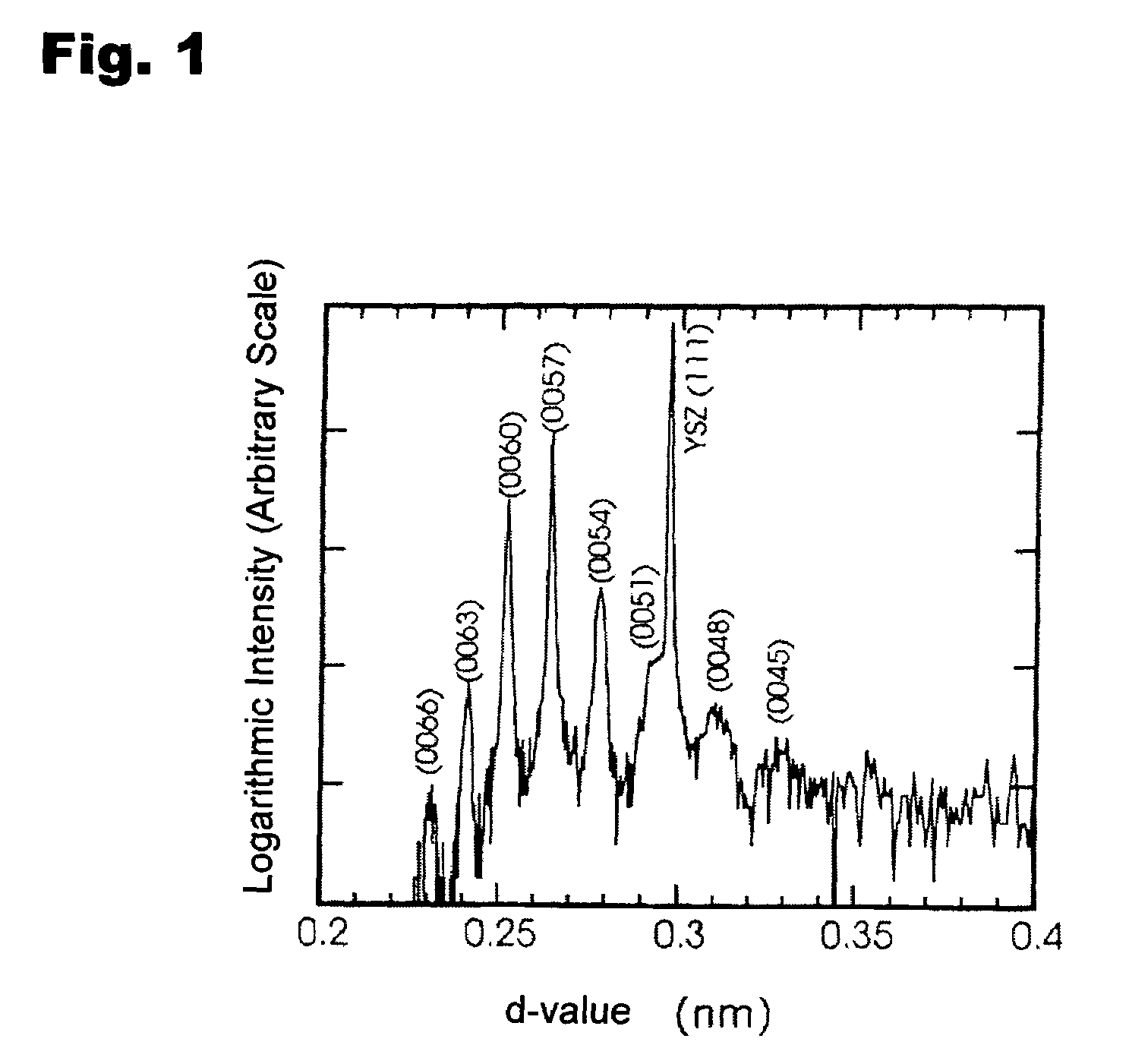

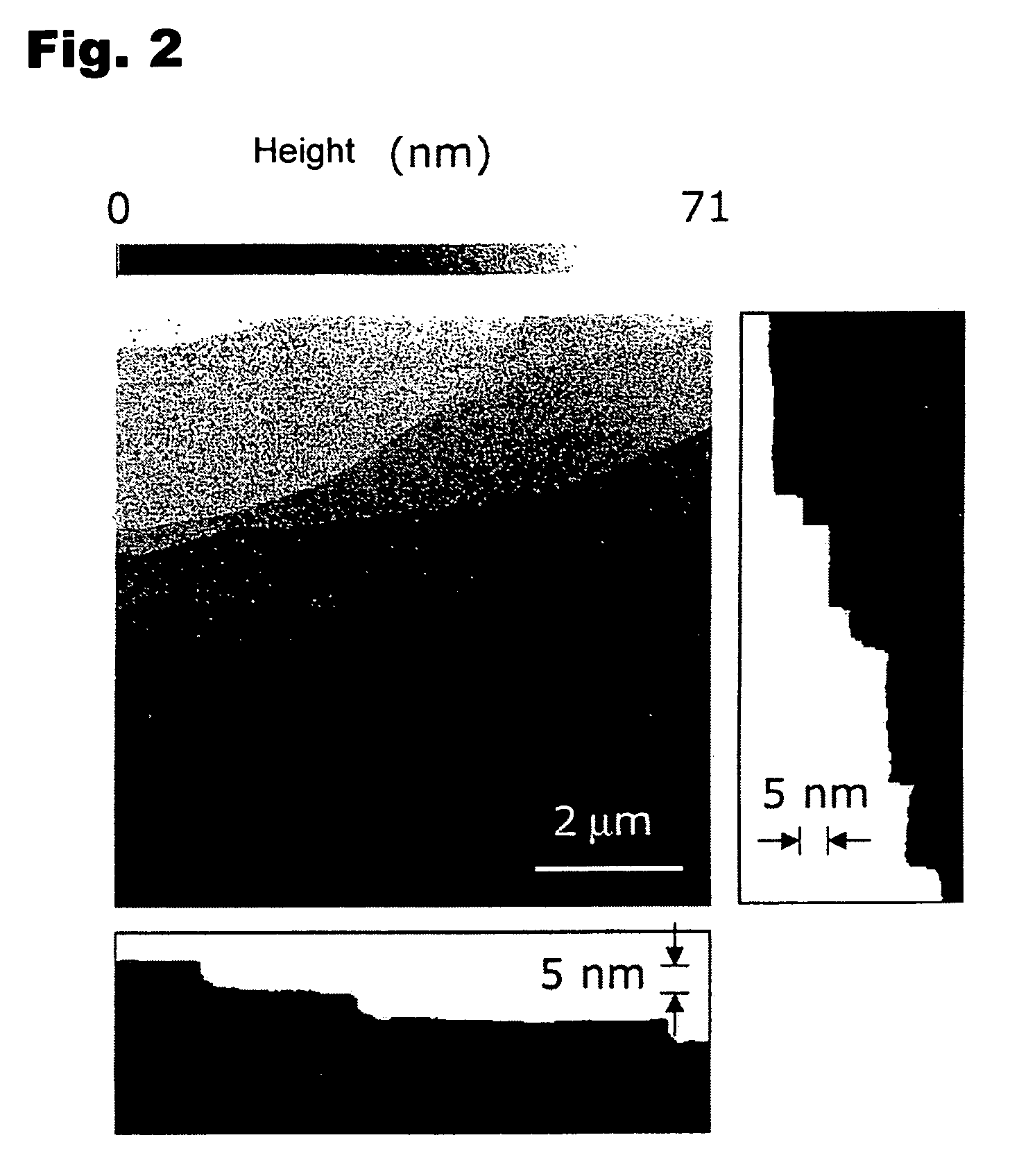

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS7061014B2Easy to controlSimple processTransistorPolycrystalline material growthSingle crystal substrateSingle crystal

Disclosed is a natural-superlattice homologous single-crystal thin film, which includes a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

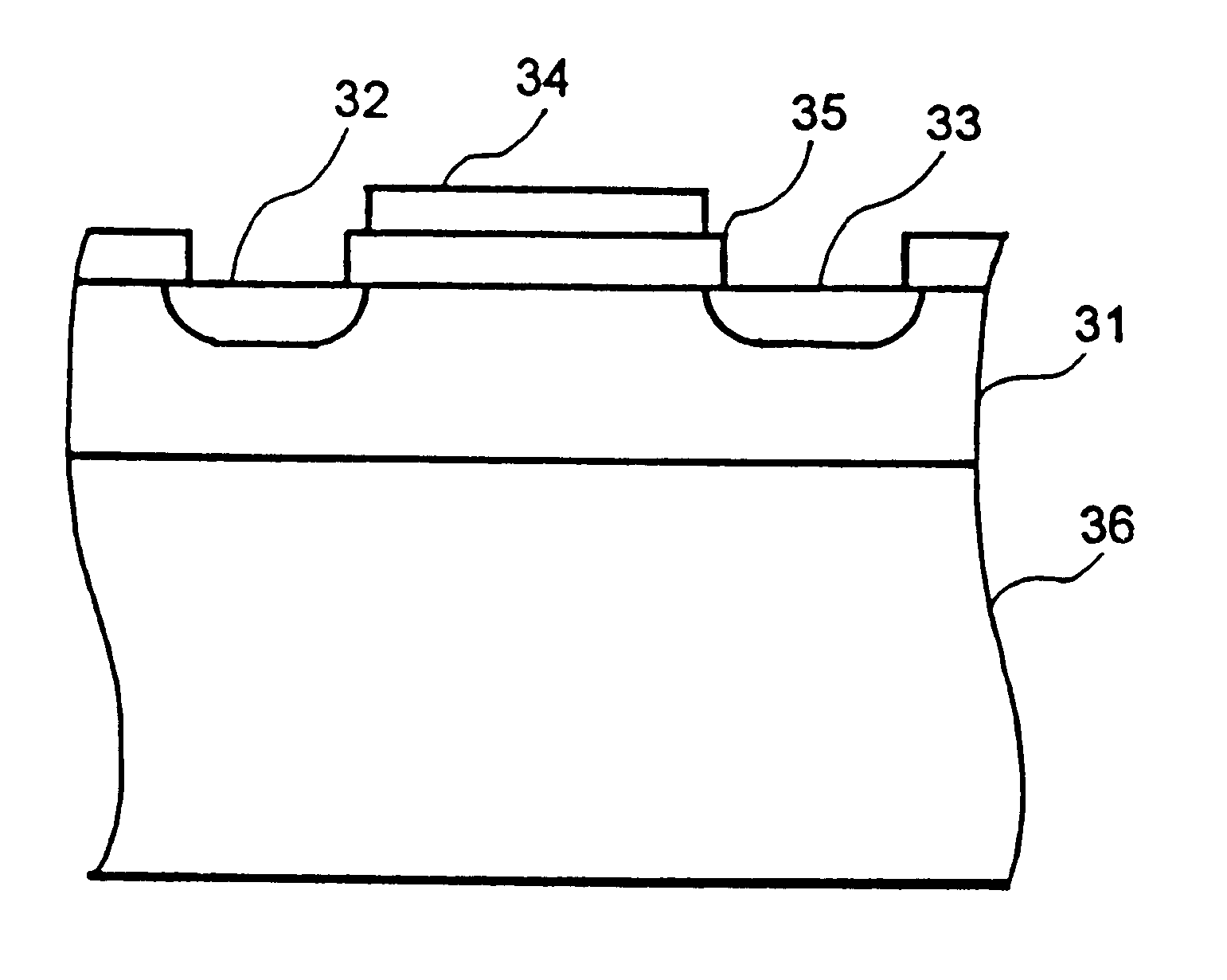

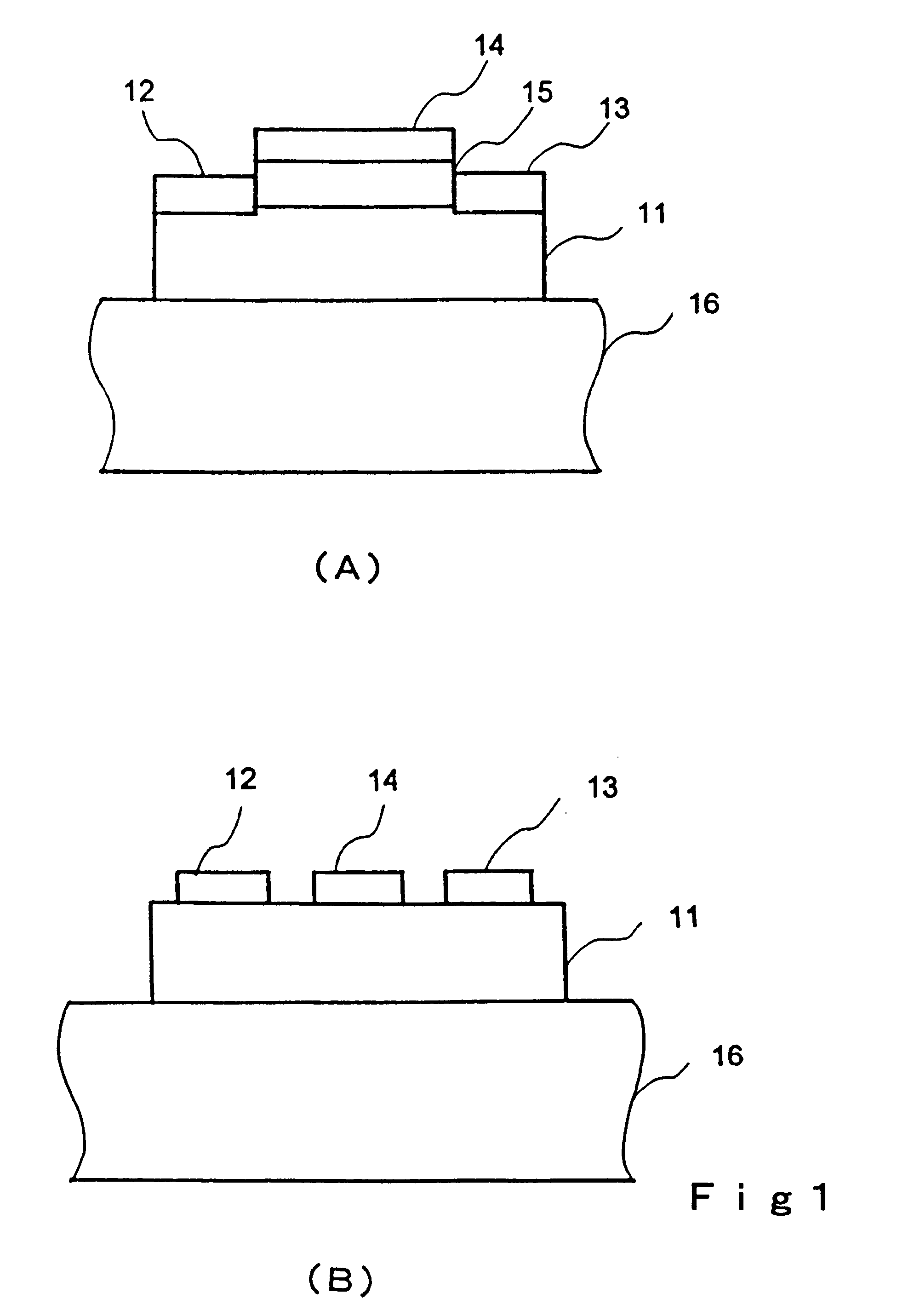

Transistor and semiconductor device

A transistor is provided, which is entirely and partially transparent by the use of a transparent channel layer made of zinc oxide or the like. A channel layer 11 formed of a transparent semiconductor such as zinc oxide ZnO. A transparent electrode is used for all of a source 12, a drain 13 and a gate 14, or a part of them. As the transparent electrode, a transparent conductive material such as conductive ZnO doped with, for example, group III elements is used. As a gate insulating layer 15, a transparent insulative material such as insulative ZnO doped with elements capable of taking a valence of one as a valence number or group V elements is used. If a substrate 16 must be transparent, for example, glass, sapphire, plastic or the like can be used as a transparent material.

Owner:JAPAN SCI & TECH CORP

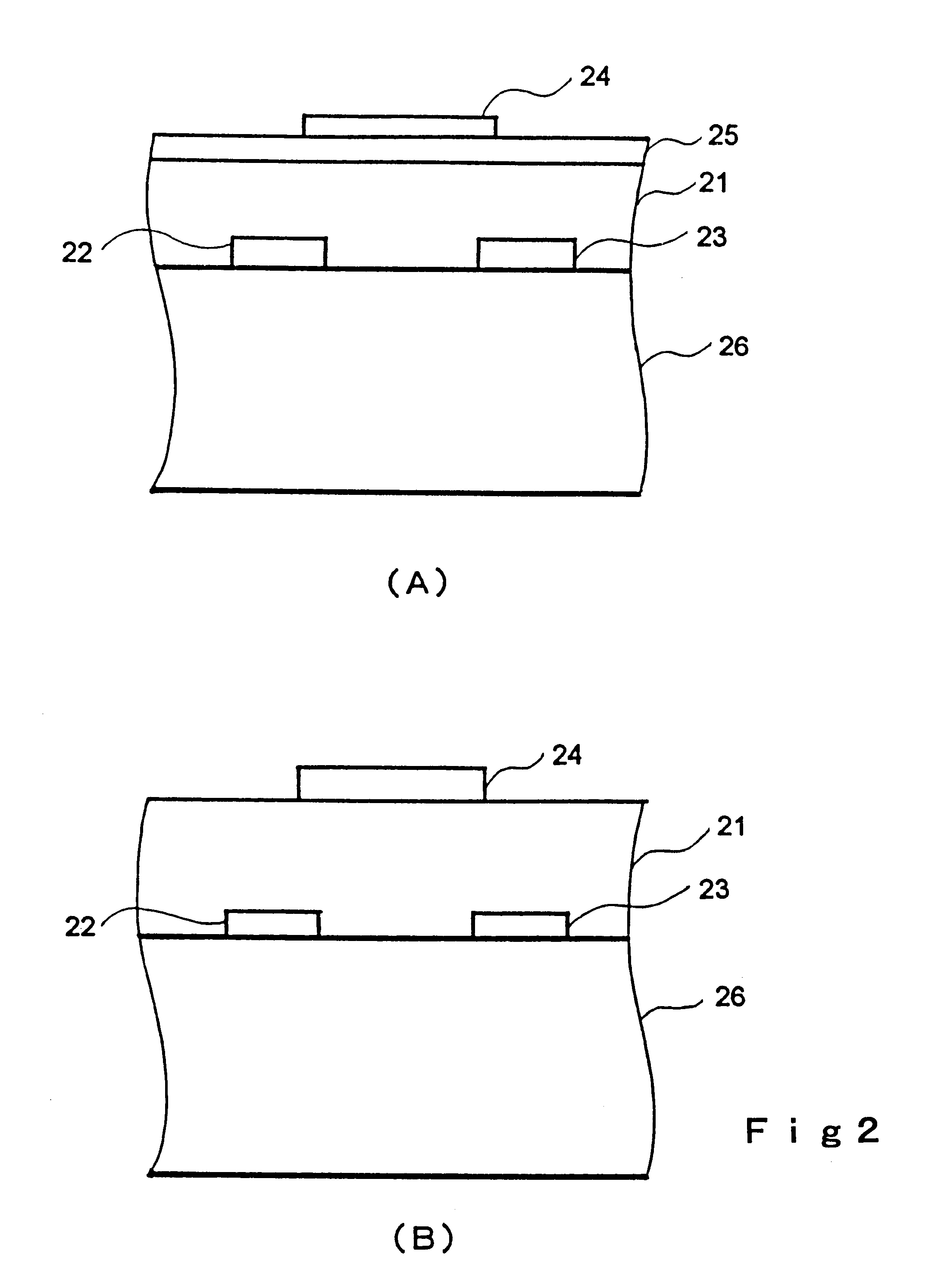

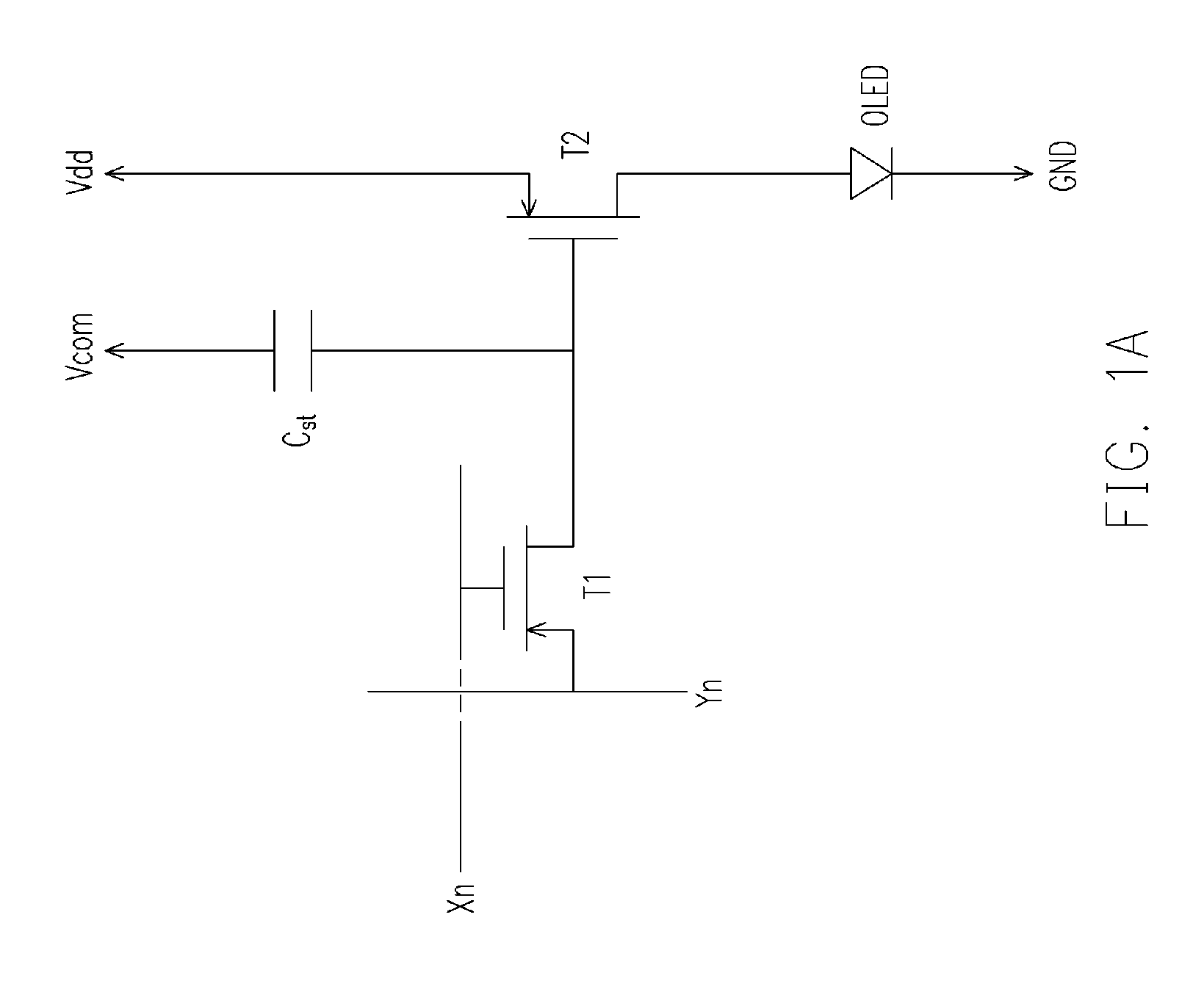

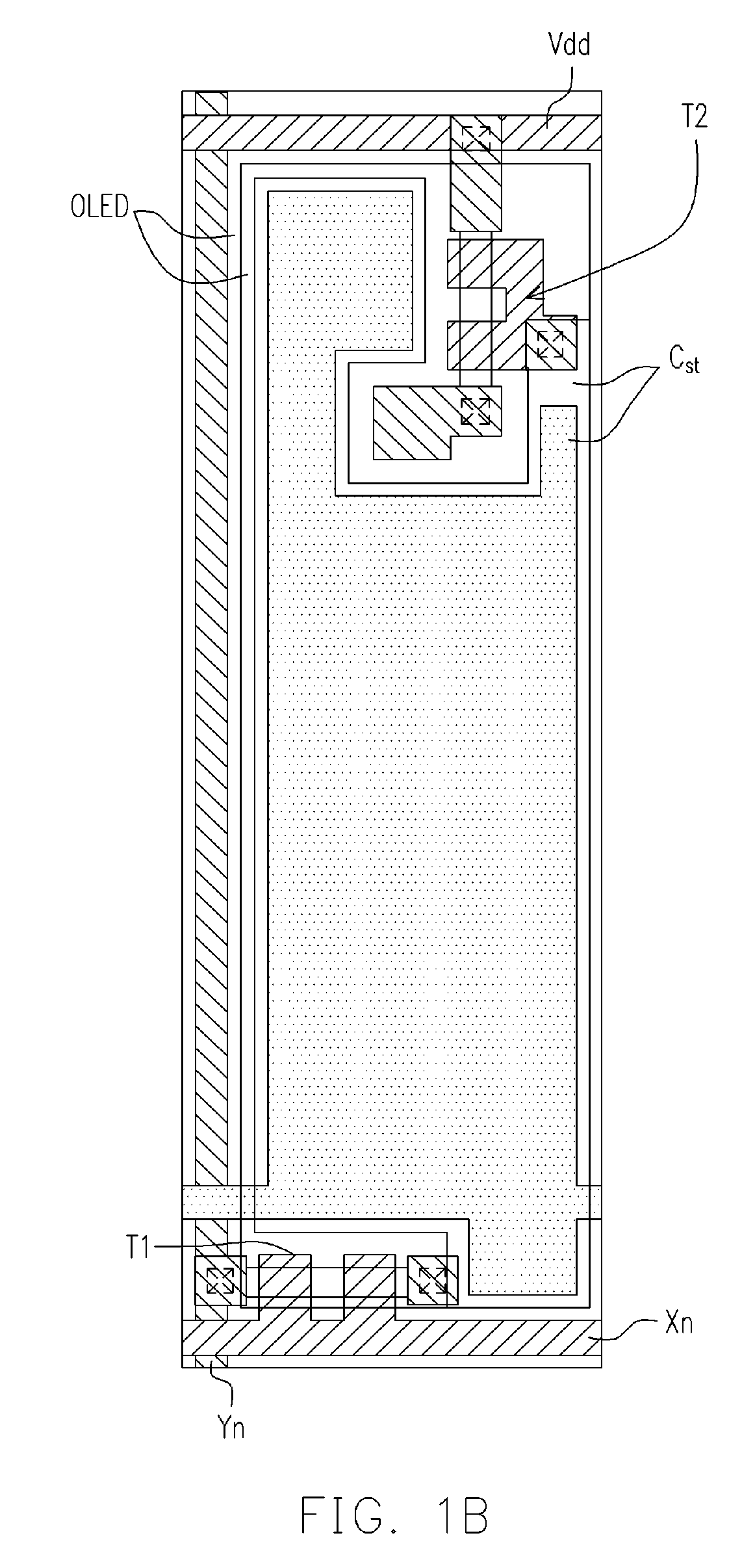

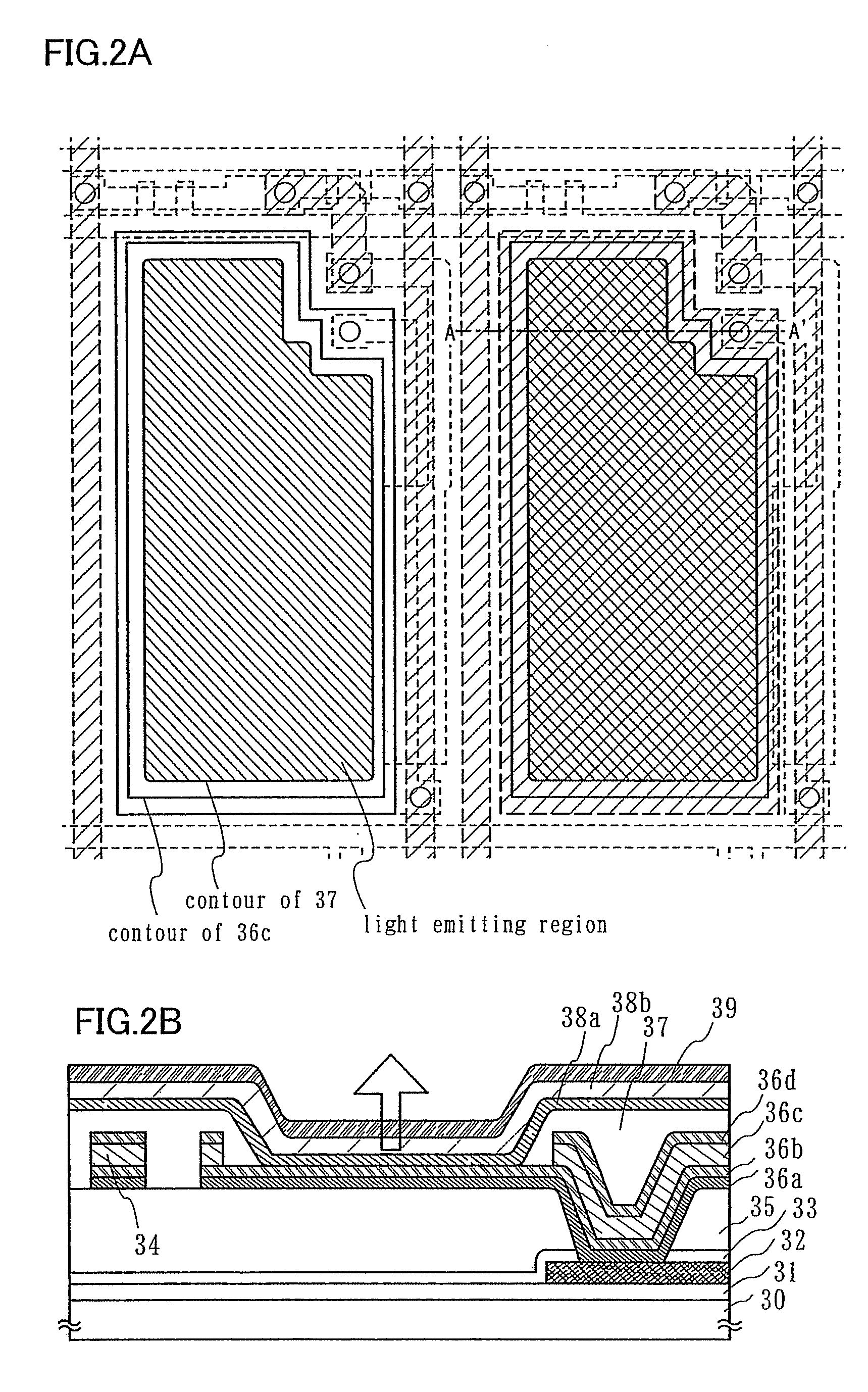

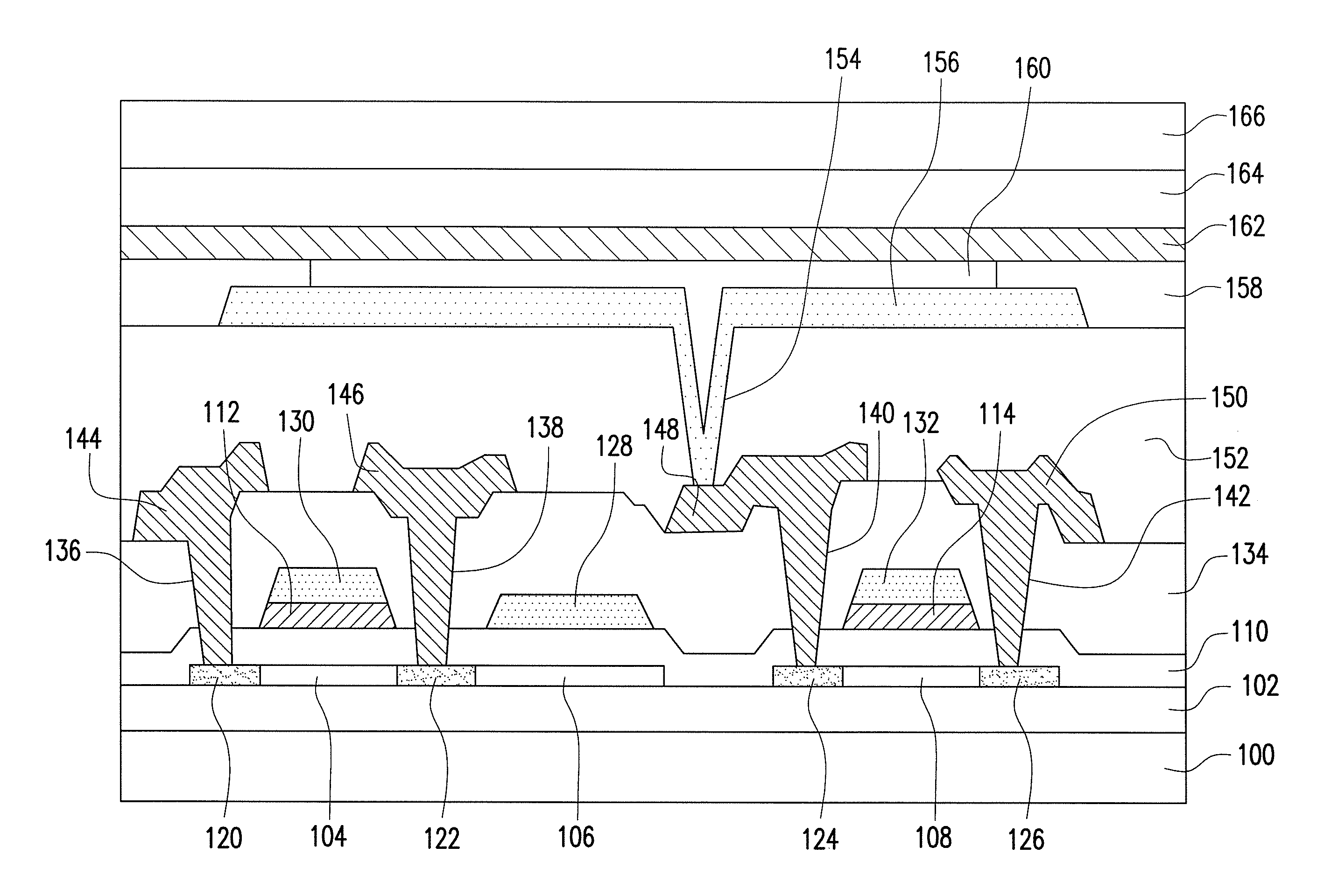

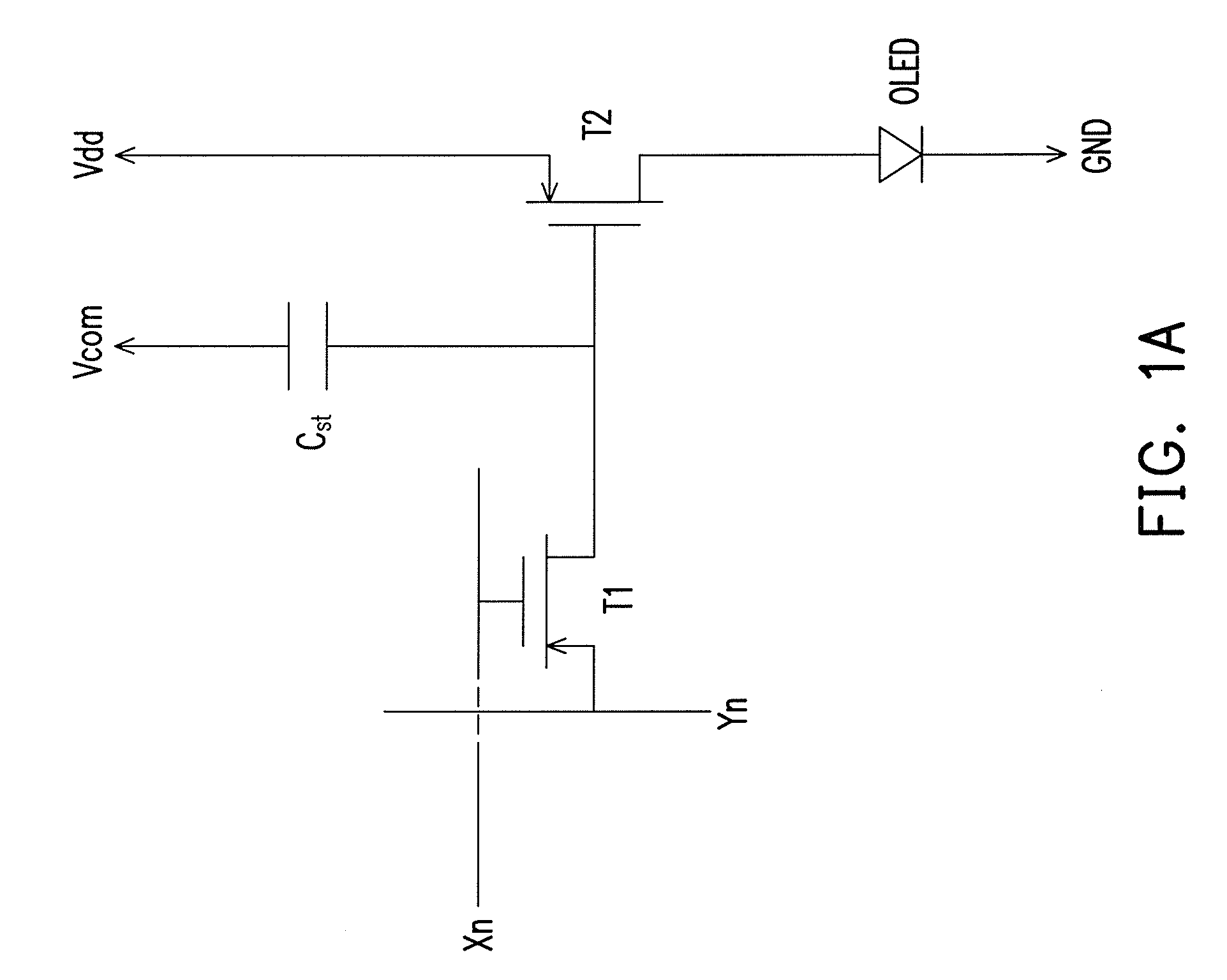

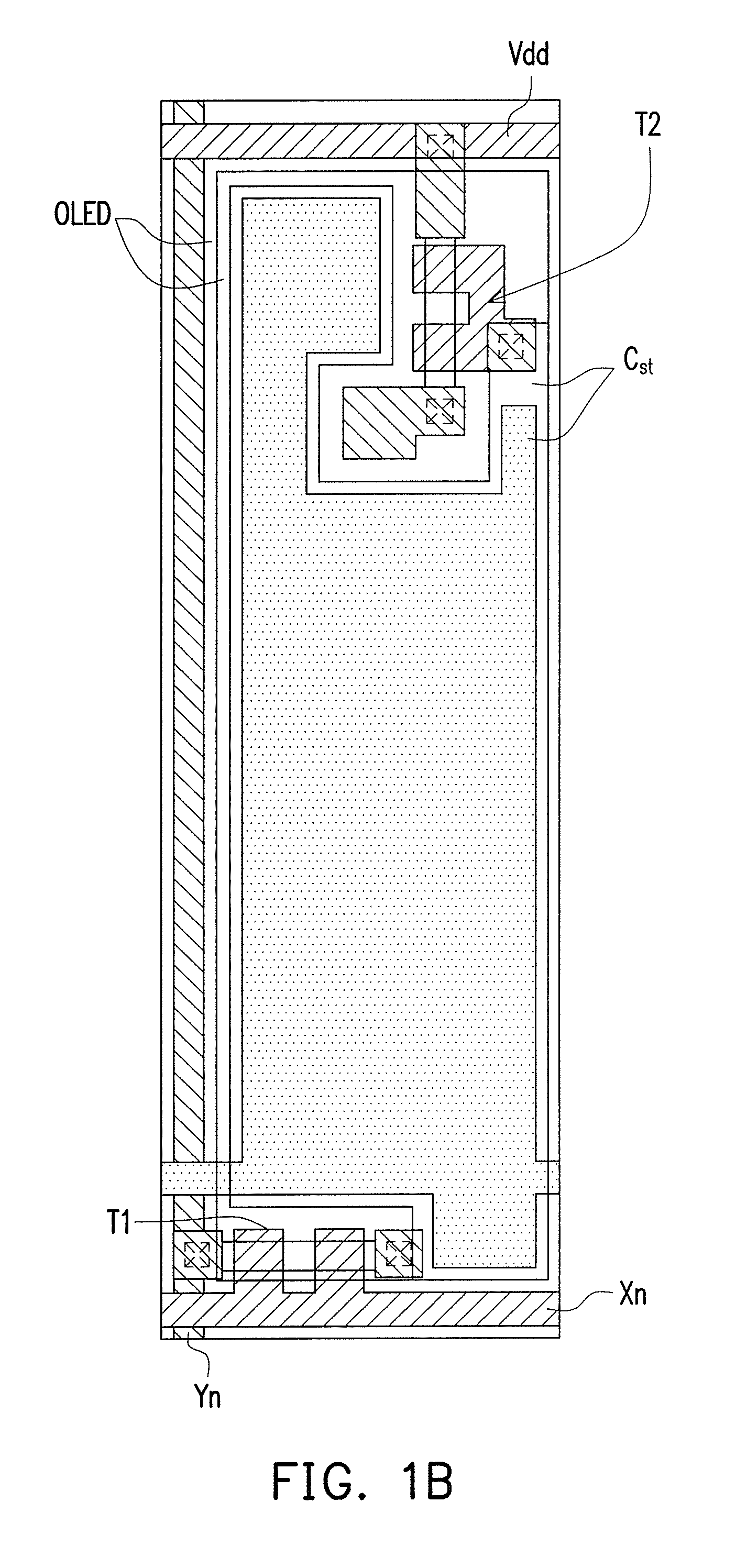

Pixel structure of active matrix organic light-emitting diode and method for fabricating the same

InactiveUS20070152217A1Improve pixel aperture ratioIncrease the aperture ratioSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceScan line

A pixel structure of an active matrix organic light-emitting diode (AMOLED) includes an organic light-emitting diode (OLED), a data line, at least one scan line, at least one switch thin film transistor (TFT), at least one driving TFT and at least one storage capacitor with two transparent electrodes. Since both the electrodes of the transparent storage capacitor are formed by transparent material, the aperture ratio of the pixel and the area of the capacitor largely increase and can reach 50%˜95% of a pixel area. Thus, the display quality of an AMOLED panel can be improved.

Owner:IND TECH RES INST

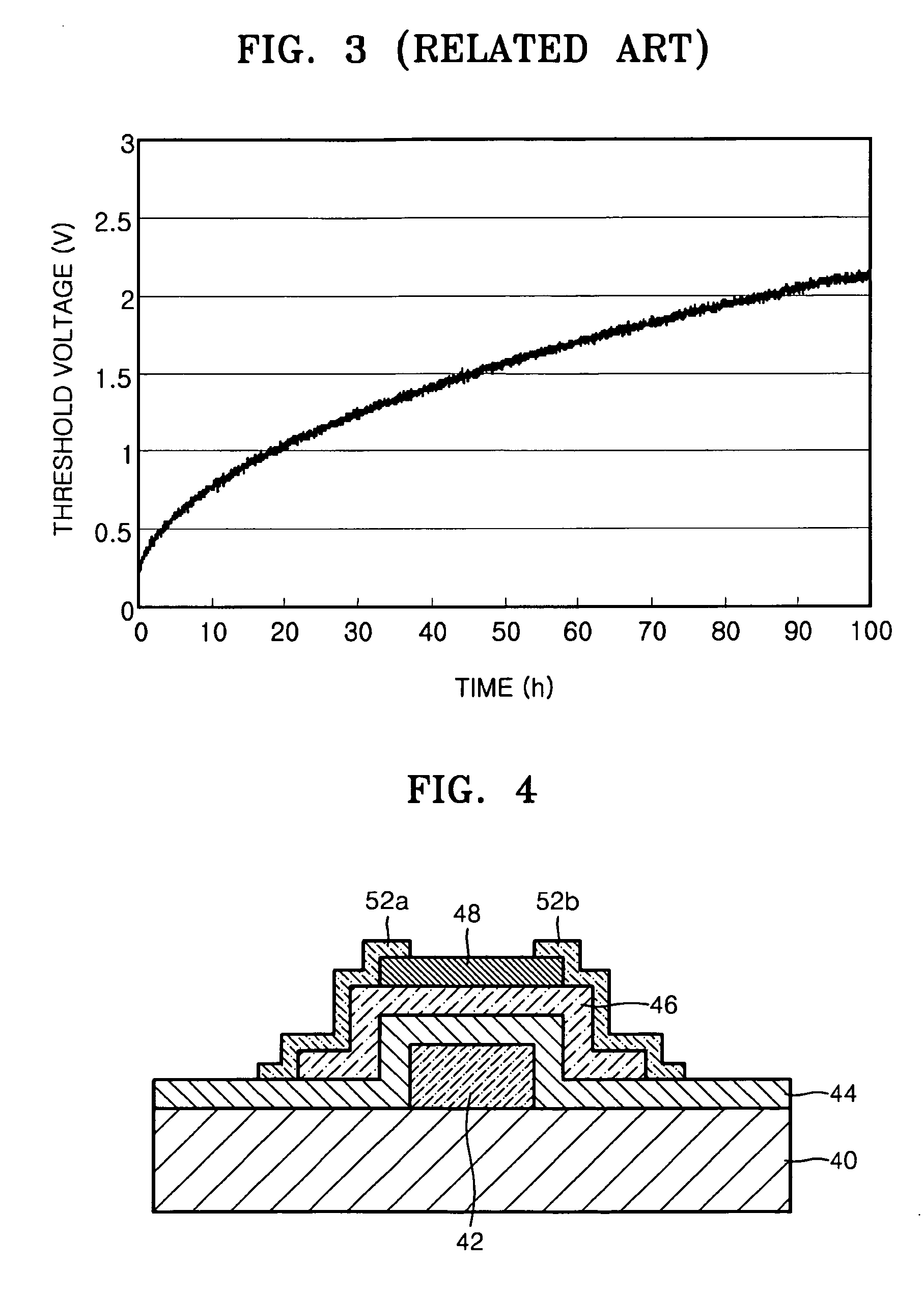

Oxide semiconductor thin film transistor and method of manufacturing the same

InactiveUS20070052025A1Improve reliabilityUnstability of may lessenSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Provided is a thin film transistor comprising a channel layer comprised of an oxide semiconductor containing In, M, Zn, and O, M including at least one selected from the group consisting of Ga, Al, and Fe. The channel layer is covered with a protective film.

Owner:CANON KK

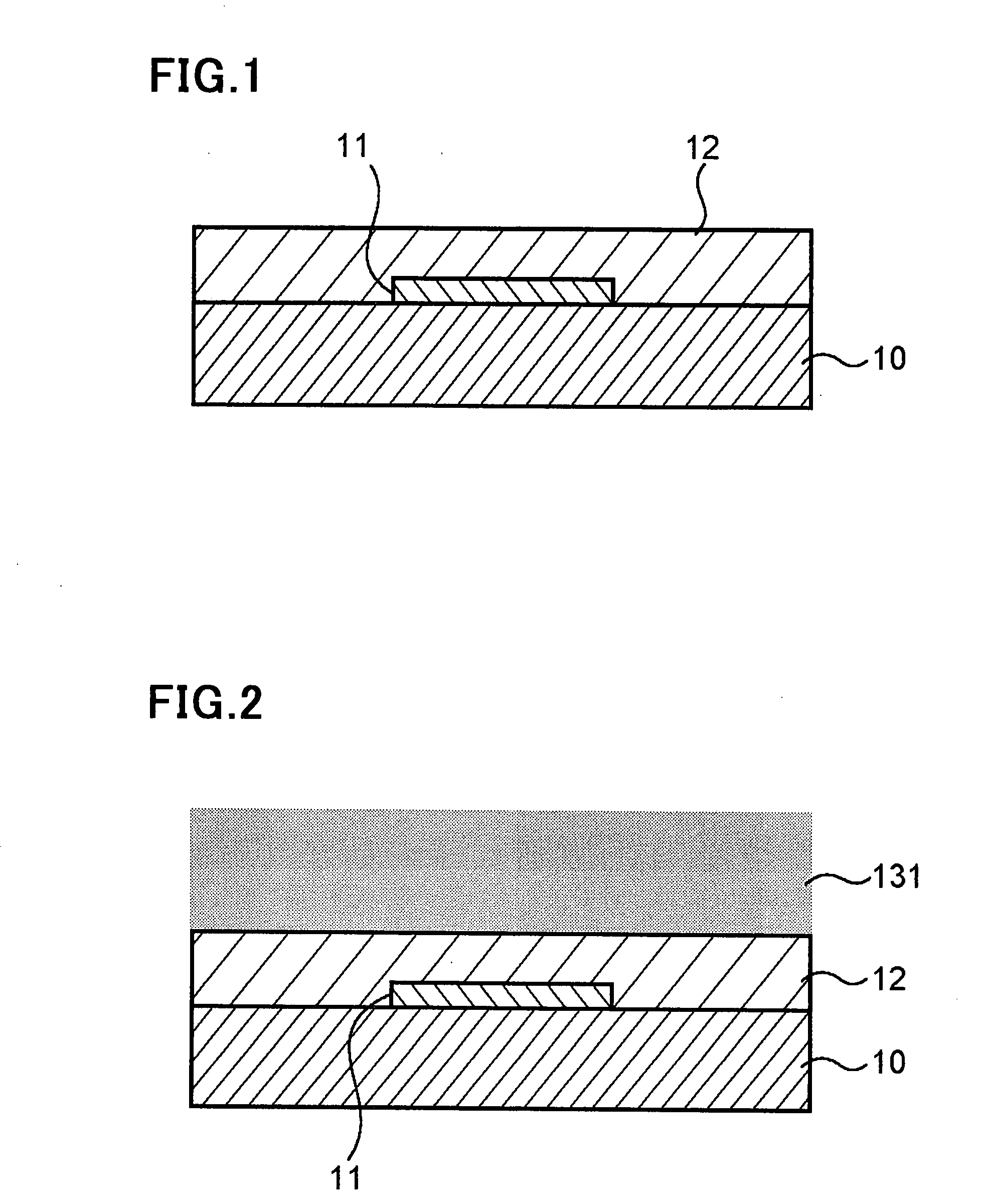

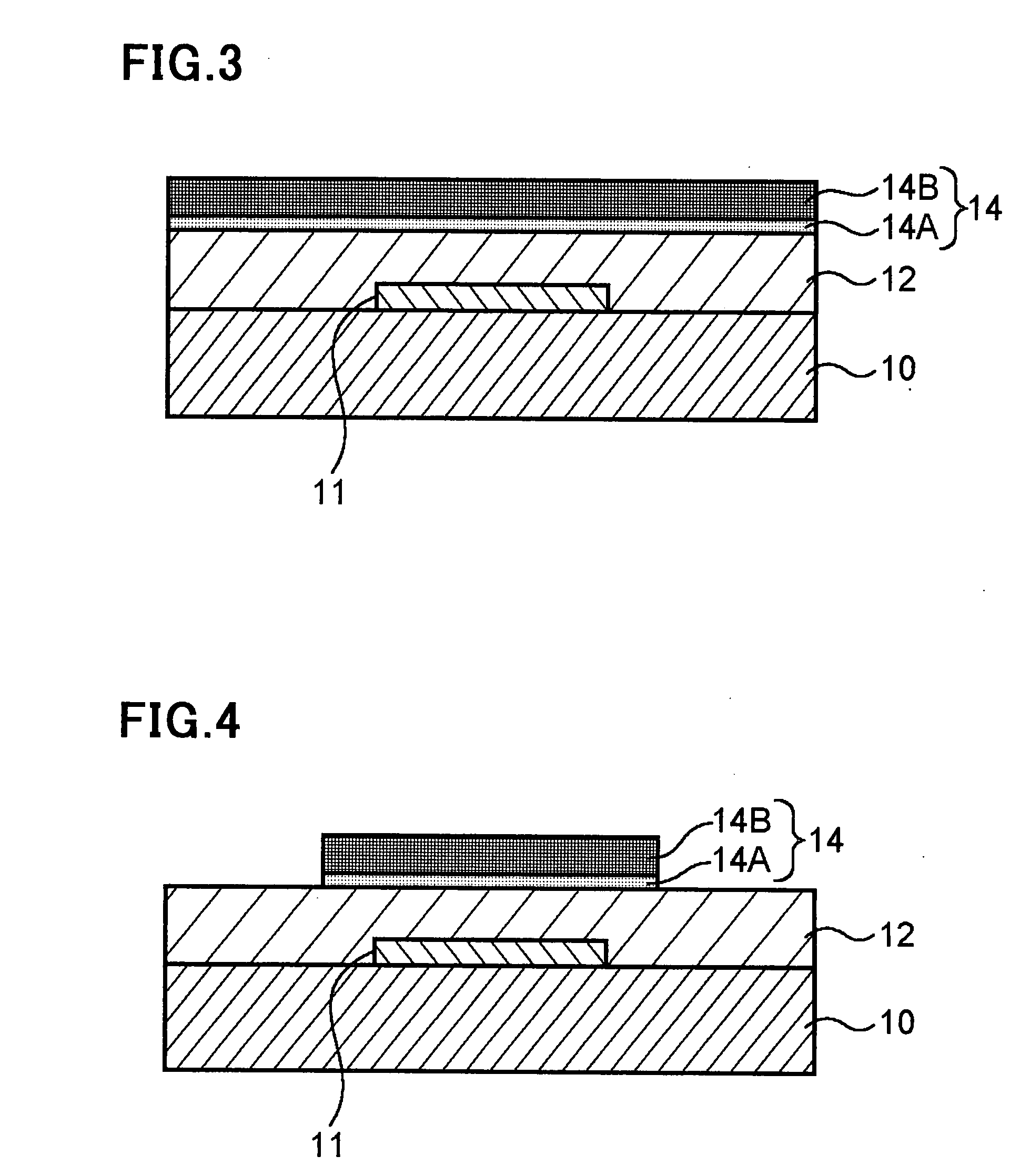

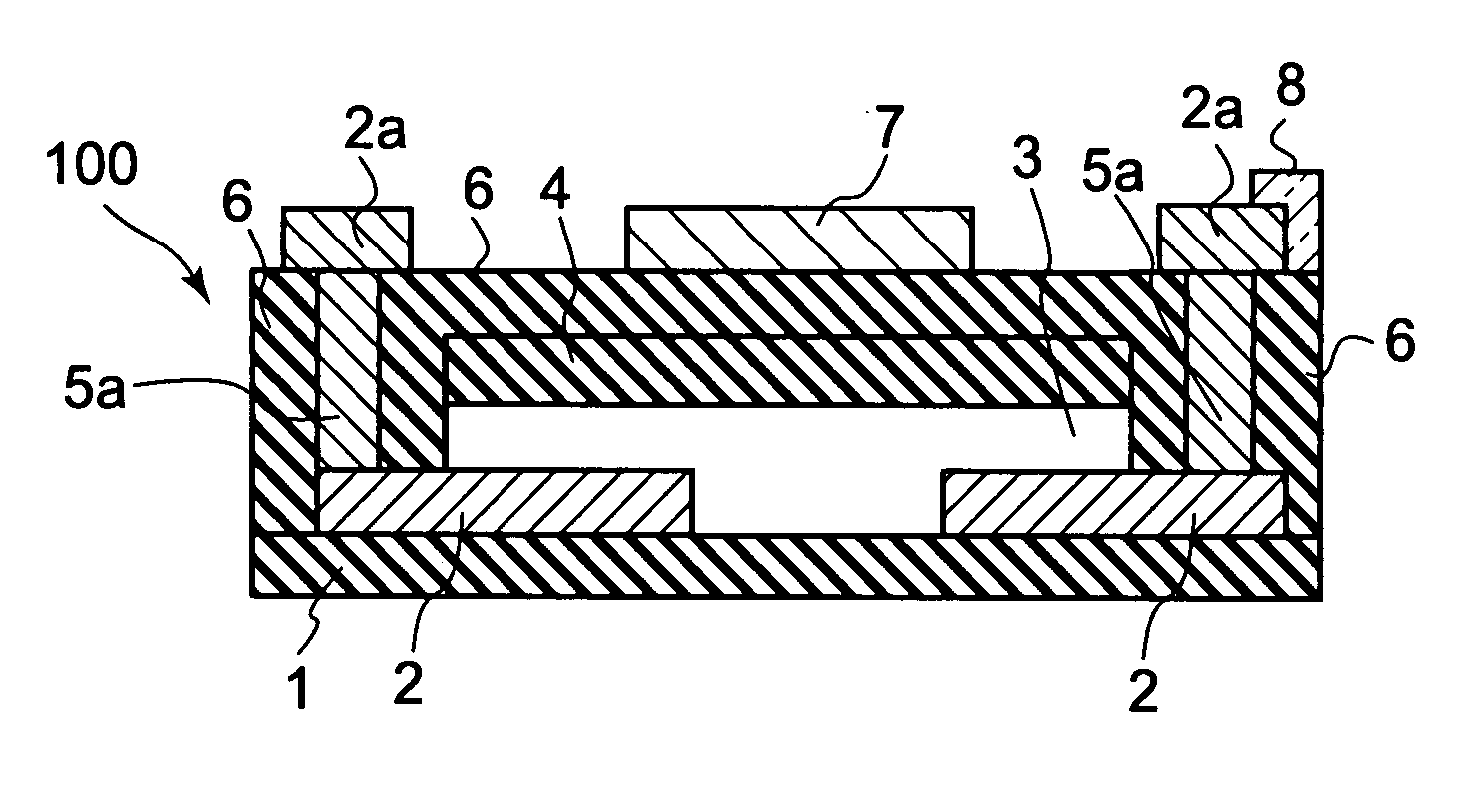

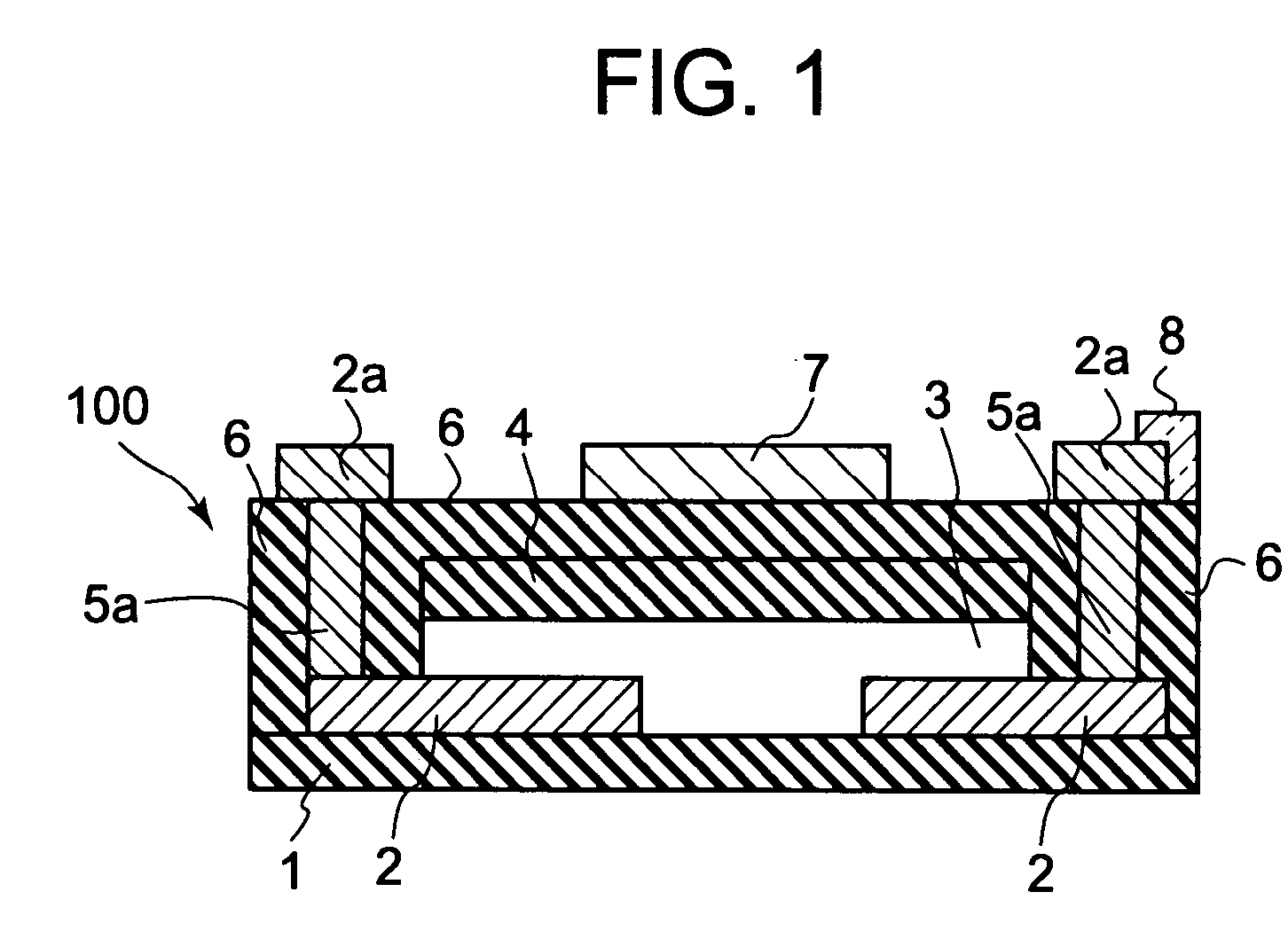

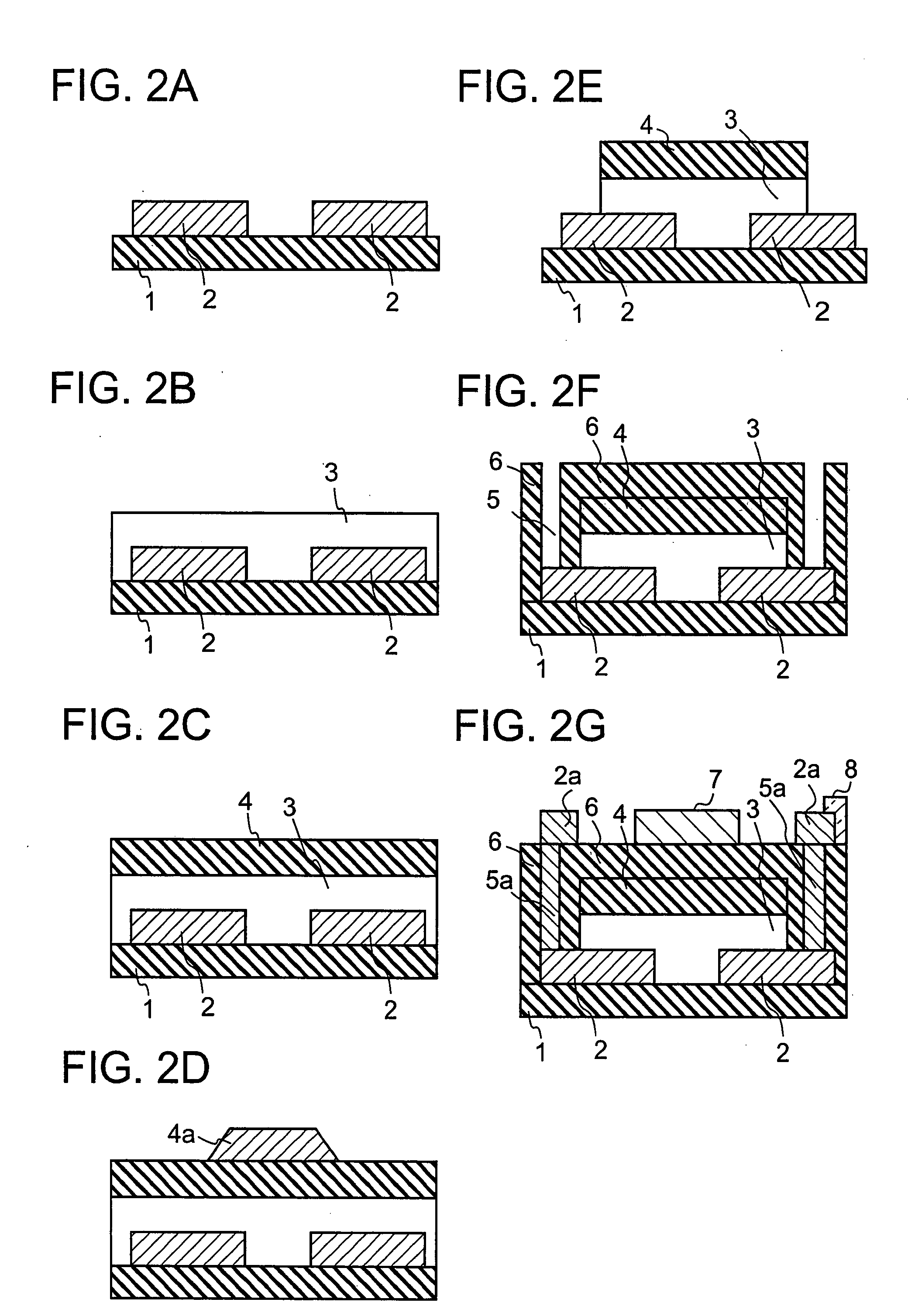

Thin-film device and method of fabricating the same

ActiveUS20080038882A1Low densityGood reproducibilitySemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxide

A thin-film device includes a first electrical insulator, an oxide-semiconductor film formed on the first electrical insulator, and a second electrical insulator formed on the oxide-semiconductor film, the oxide-semiconductor film defining an active layer. The oxide-semiconductor film is comprised of a first interface layer located at an interface with the first electrical insulating insulator, a second interface layer located at an interface with the second electrical insulator, and a bulk layer other than the first and second interface layers. A density of oxygen holes in at least one of the first and second interlayer layers is smaller than a density of oxygen holes in the bulk layer.

Owner:NEC LCD TECH CORP

Field effect transistor

ActiveUS20060113539A1Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

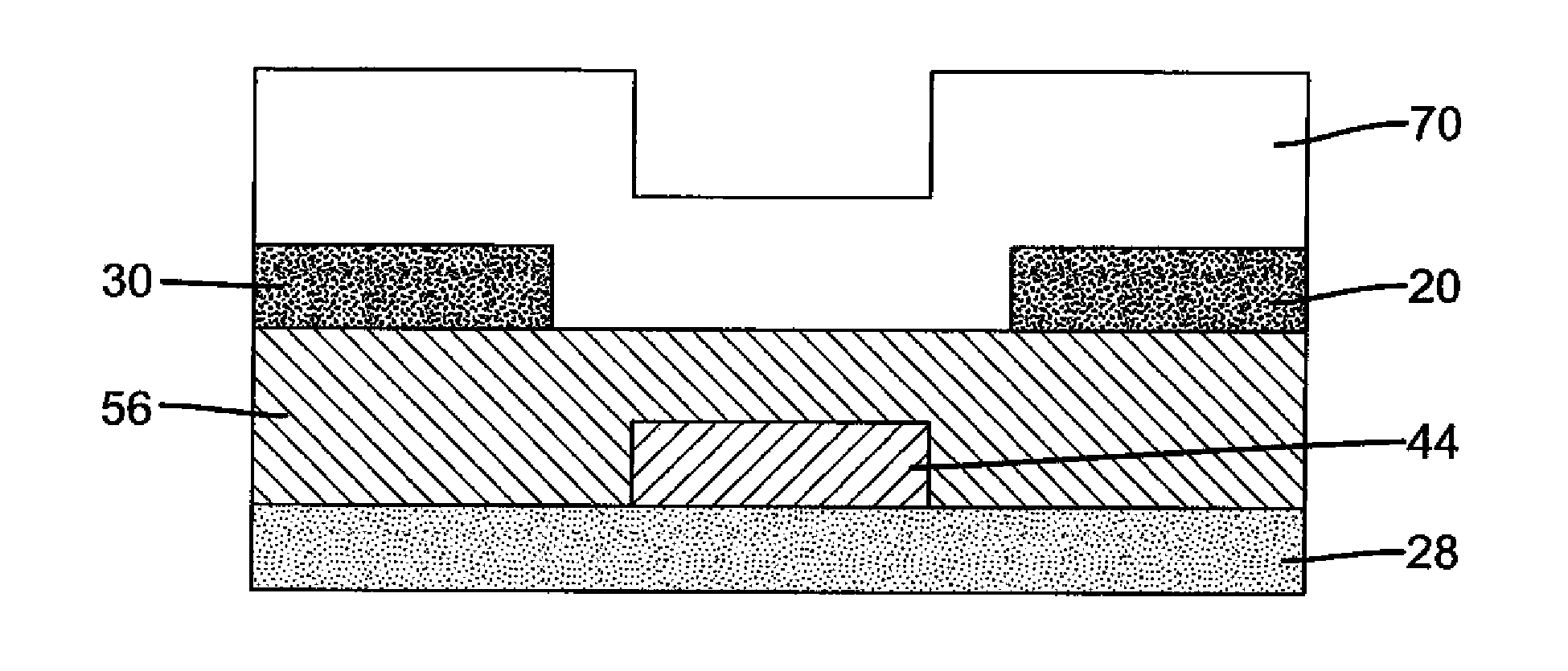

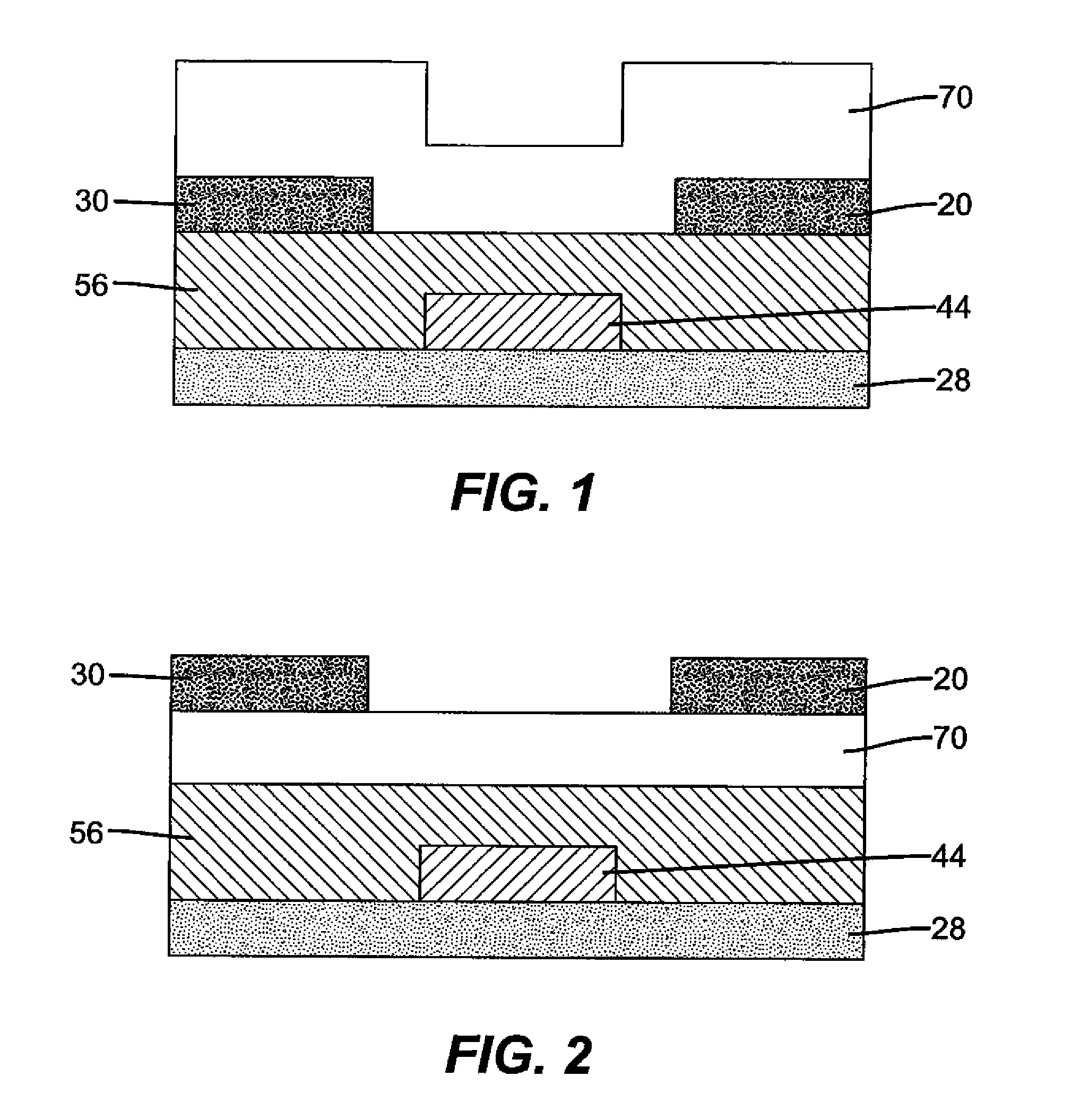

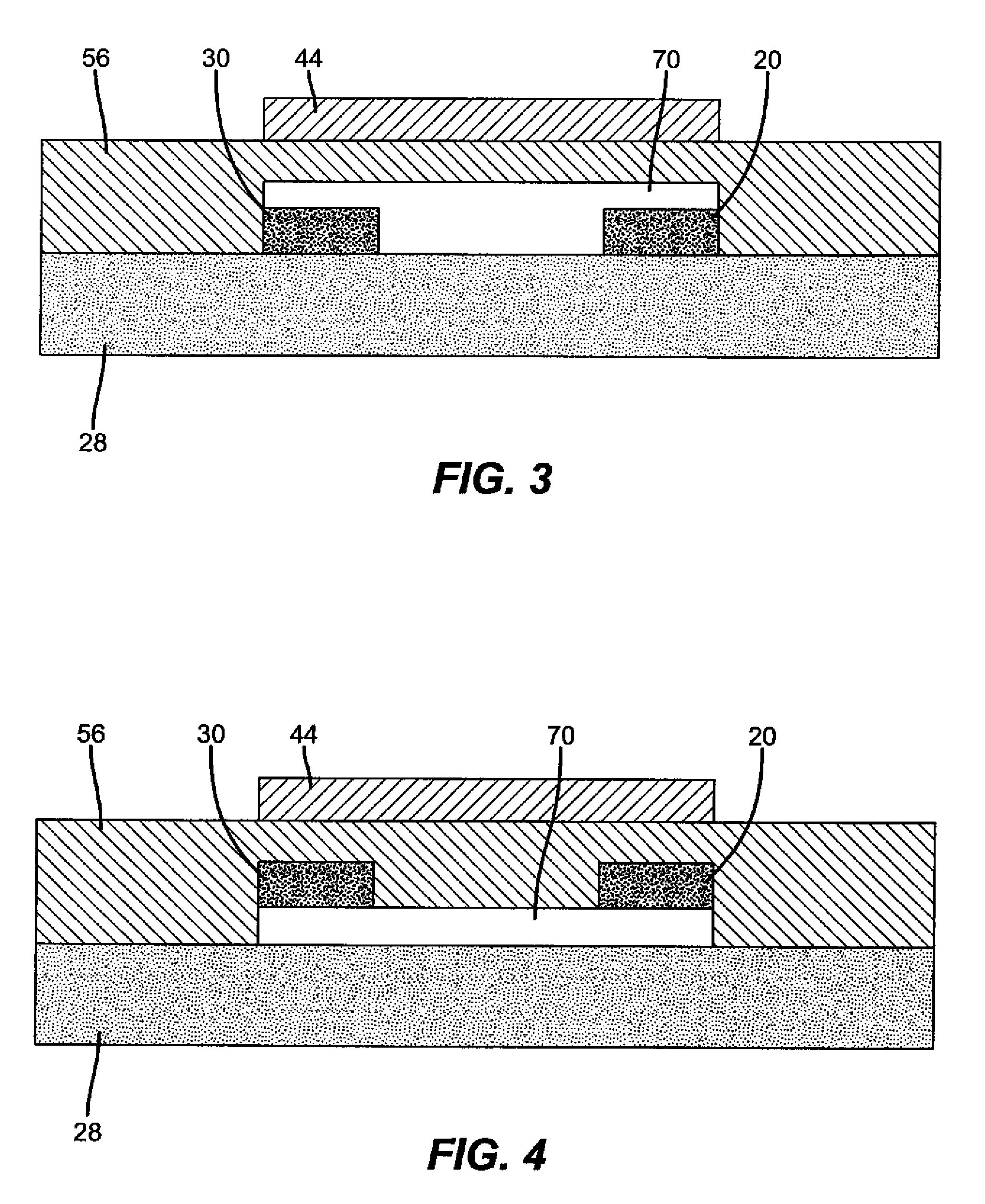

Transparent oxide semiconductor thin film transistors

This invention relates to novel, transparent oxide semiconductor thin film transistors (TFT's) and a process for making them.

Owner:SAMSUNG DISPLAY CO LTD

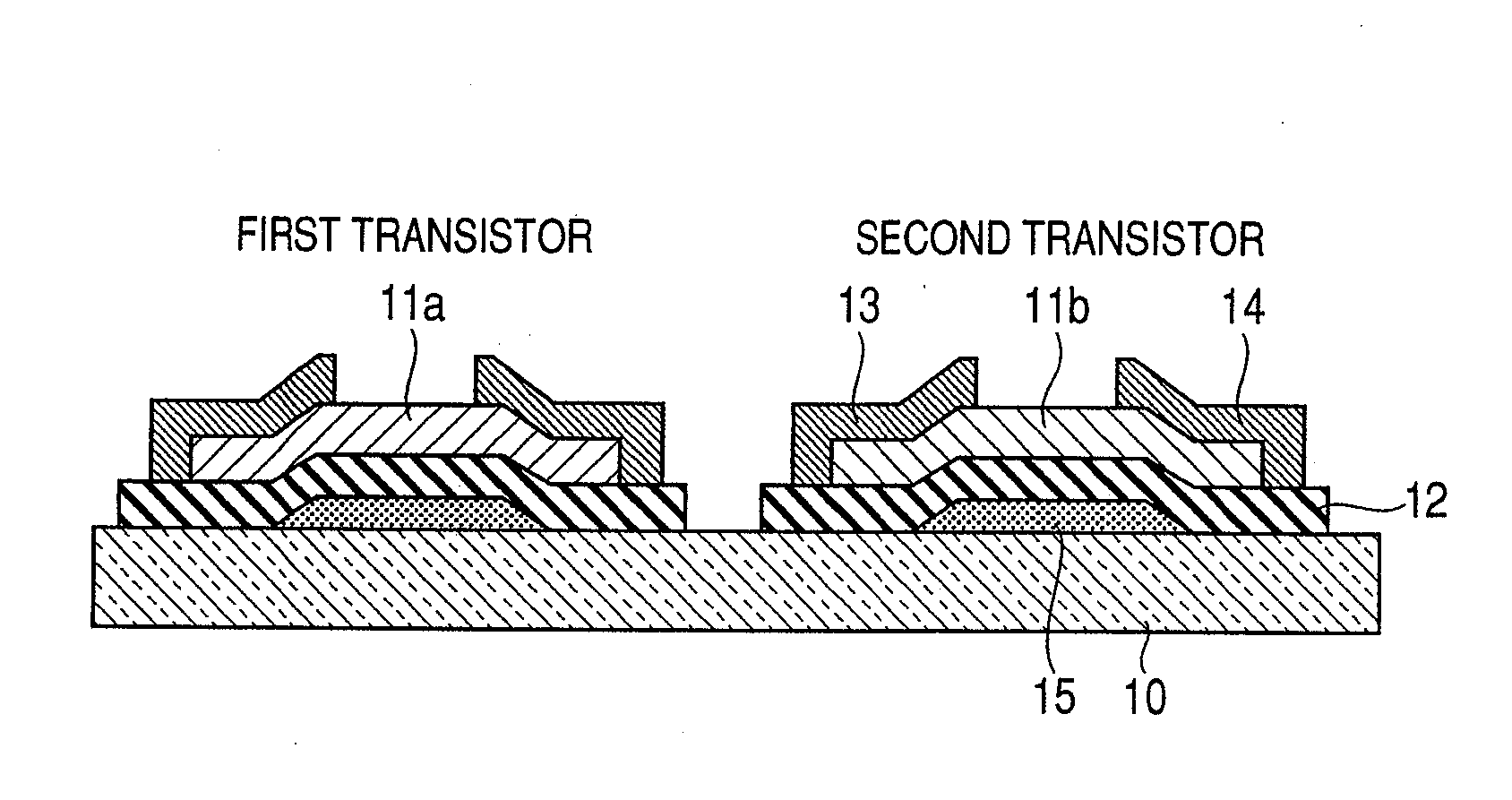

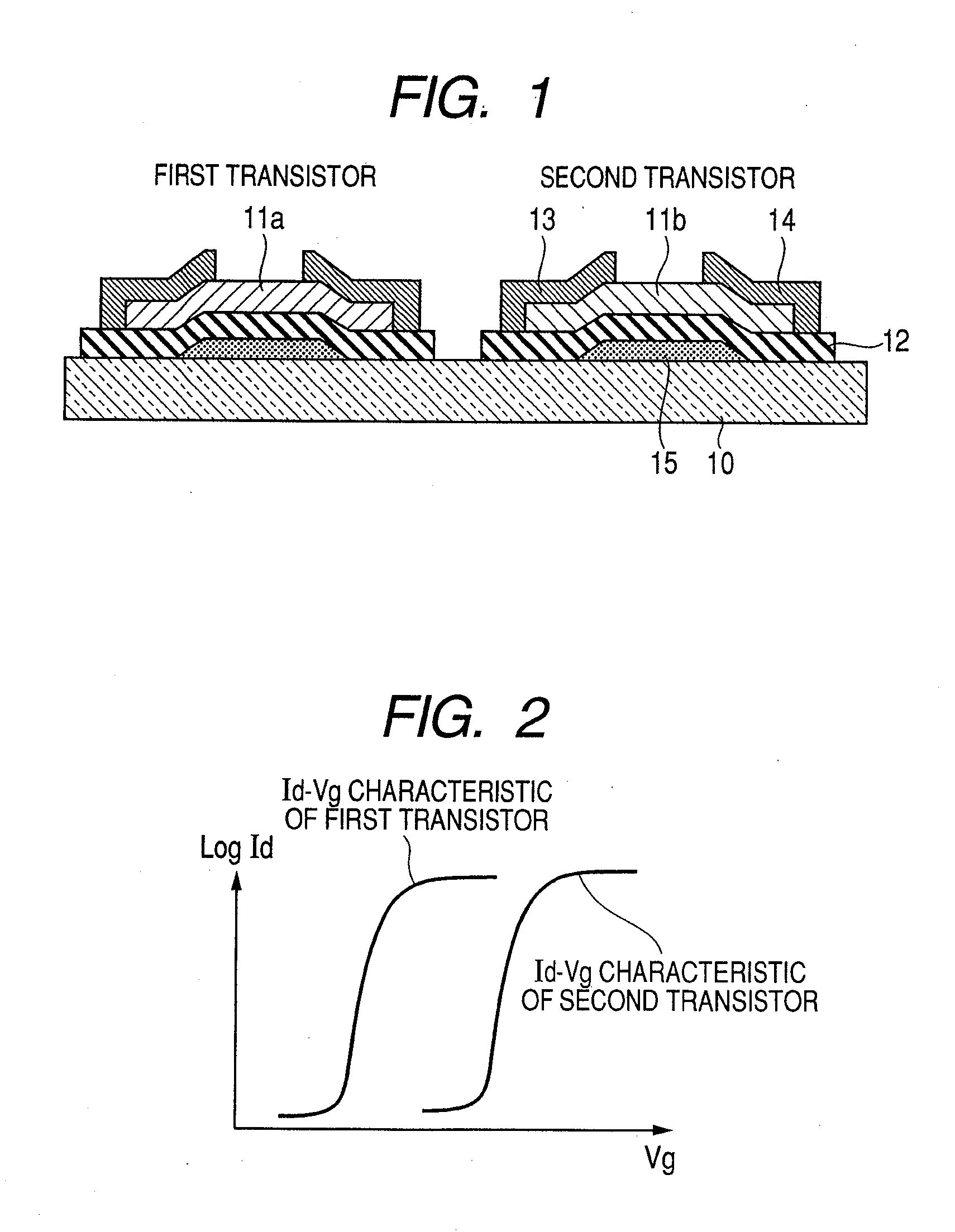

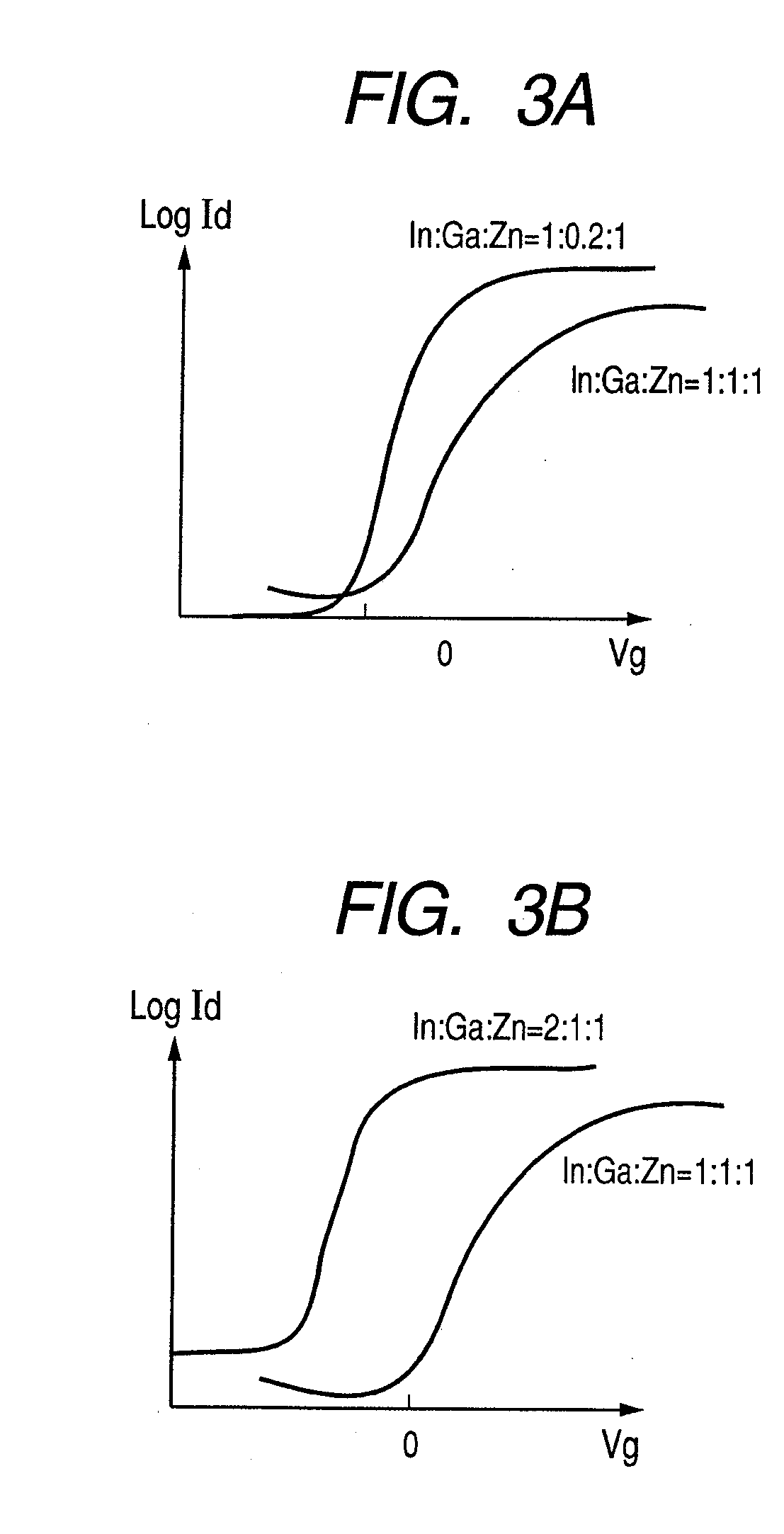

Semiconductor apparatus and method of manufacturing the same

InactiveUS20080073653A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

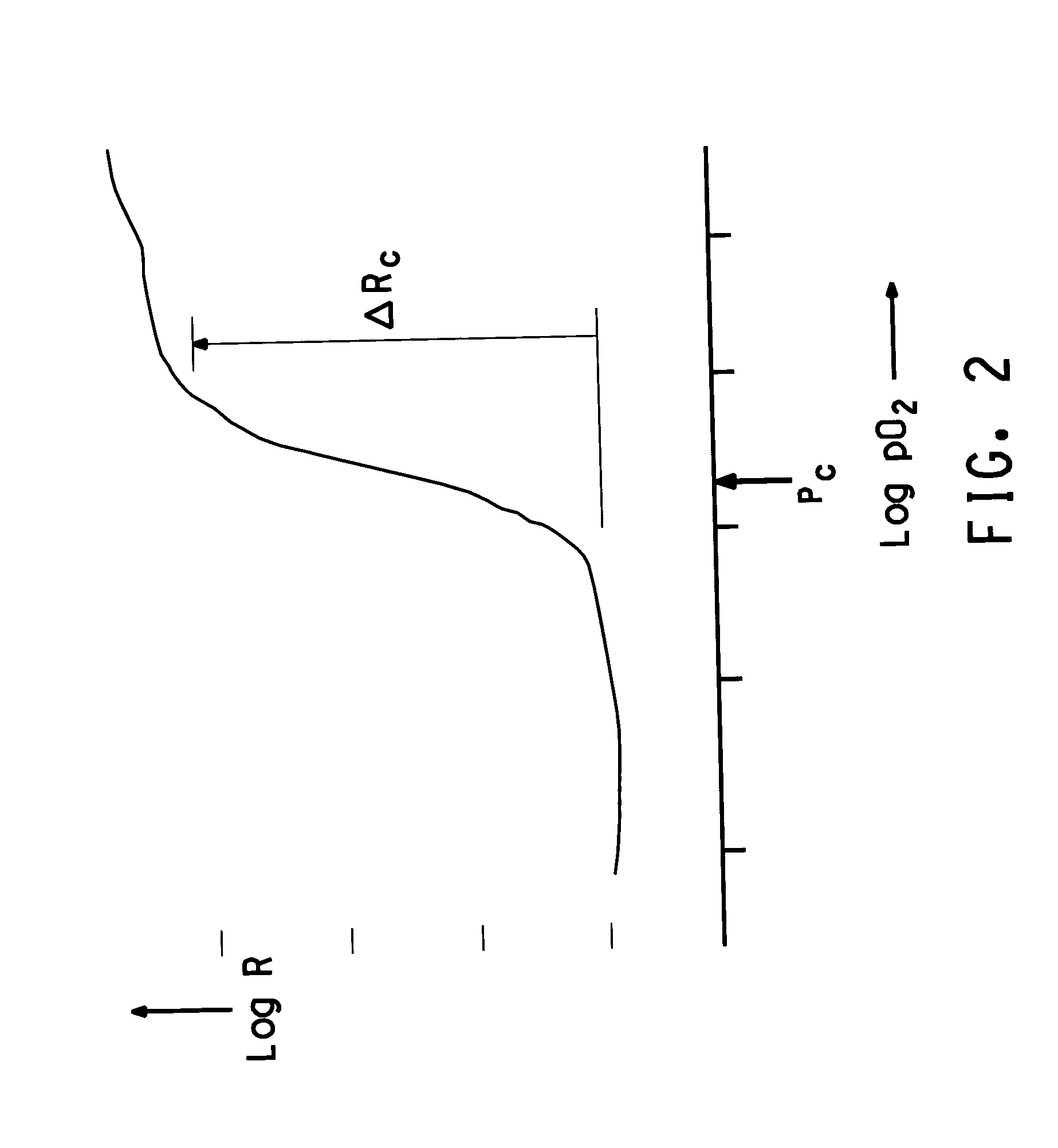

It is an object of the present invention to provide a technology of controlling a threshold voltage of a thin film transistor in which an amorphous oxide film is applied to a channel layer. There is provided a semiconductor apparatus including a plurality of kinds of transistors, each of the plurality of kinds of transistors including a channel layer made of an amorphous oxide containing a plurality of kinds of metal elements; and threshold voltages of the plurality of kinds of transistors are different from one another by changing an element ratio of the amorphous oxide.

Owner:CANON KK

Methods of making thin film transistors comprising zinc-oxide-based semiconductor materials and transistors made thereby

ActiveUS7402506B2NanoinformaticsSemiconductor/solid-state device manufacturingSemiconductor materialsZinc

A thin film transistor comprises a zinc-oxide-containing semiconductor material. Such transistors can further comprise spaced apart first and second contact means or electrodes in contact with said material. Further disclosed is a process for fabricating a thin film transistor device, wherein the substrate temperature is no more than 300° C. during fabrication.

Owner:EASTMAN KODAK CO

Field-effect transistor and method for manufacturing the same

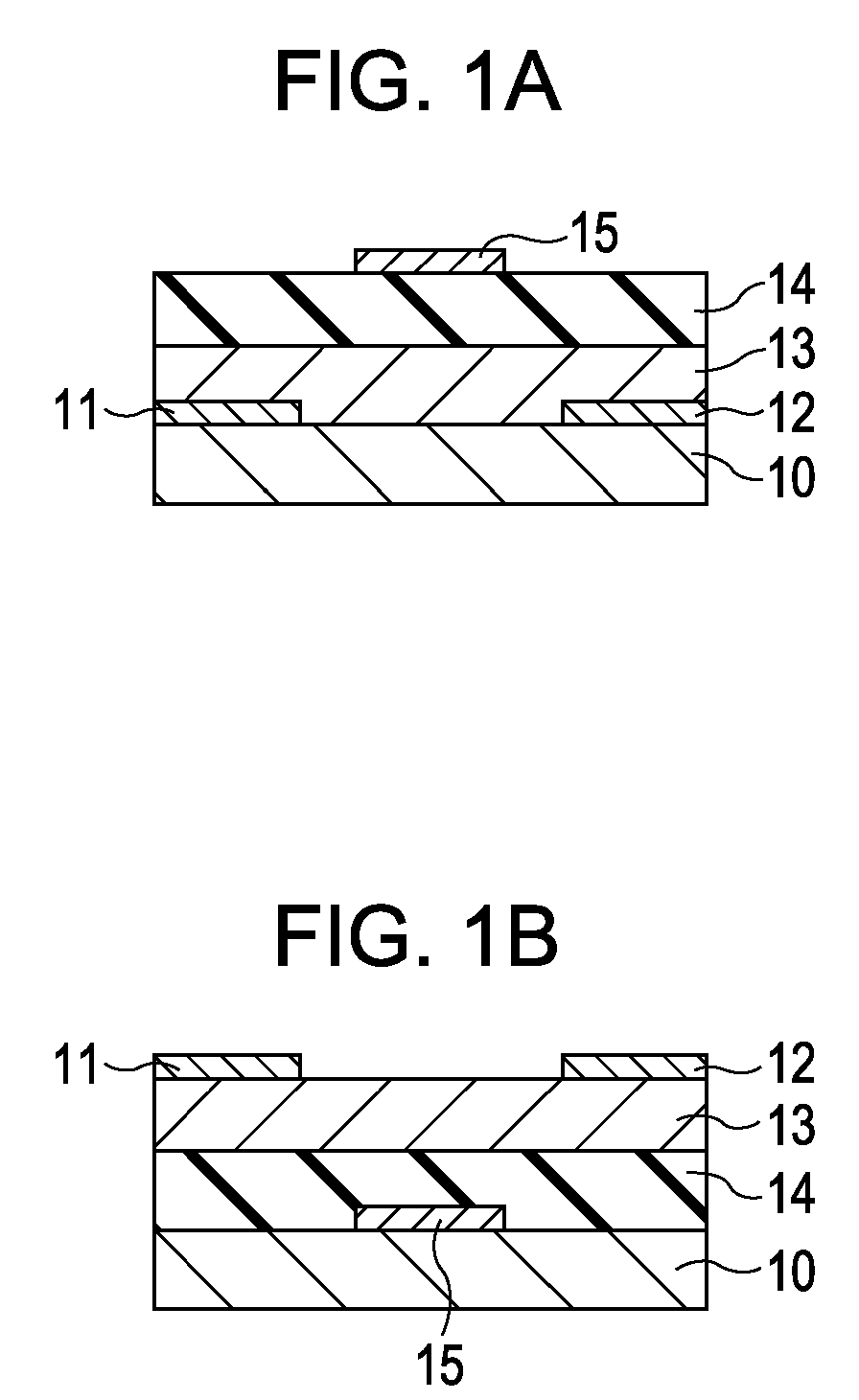

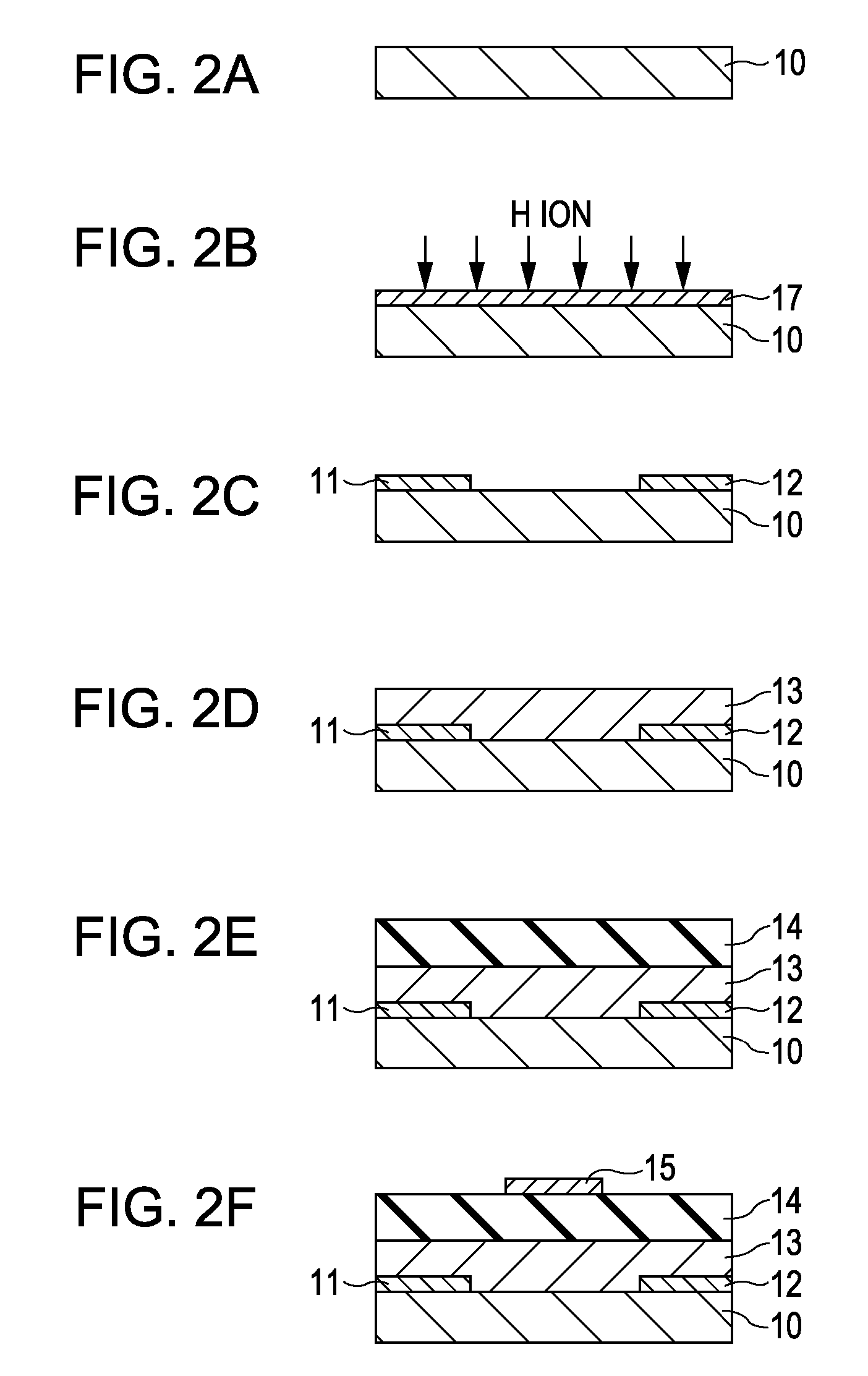

InactiveUS7411209B2Solid-state devicesSemiconductor/solid-state device manufacturingHydrogenField-effect transistor

A method for manufacturing a field-effect transistor includes the steps of forming a source electrode and a drain electrode each containing hydrogen or deuterium; forming an oxide semiconductor layer in which the electrical resistance is decreased if hydrogen or deuterium is added; and, causing hydrogen or deuterium to diffuse from the source electrode and the drain electrode to the oxide semiconductor layer.

Owner:CANON KK

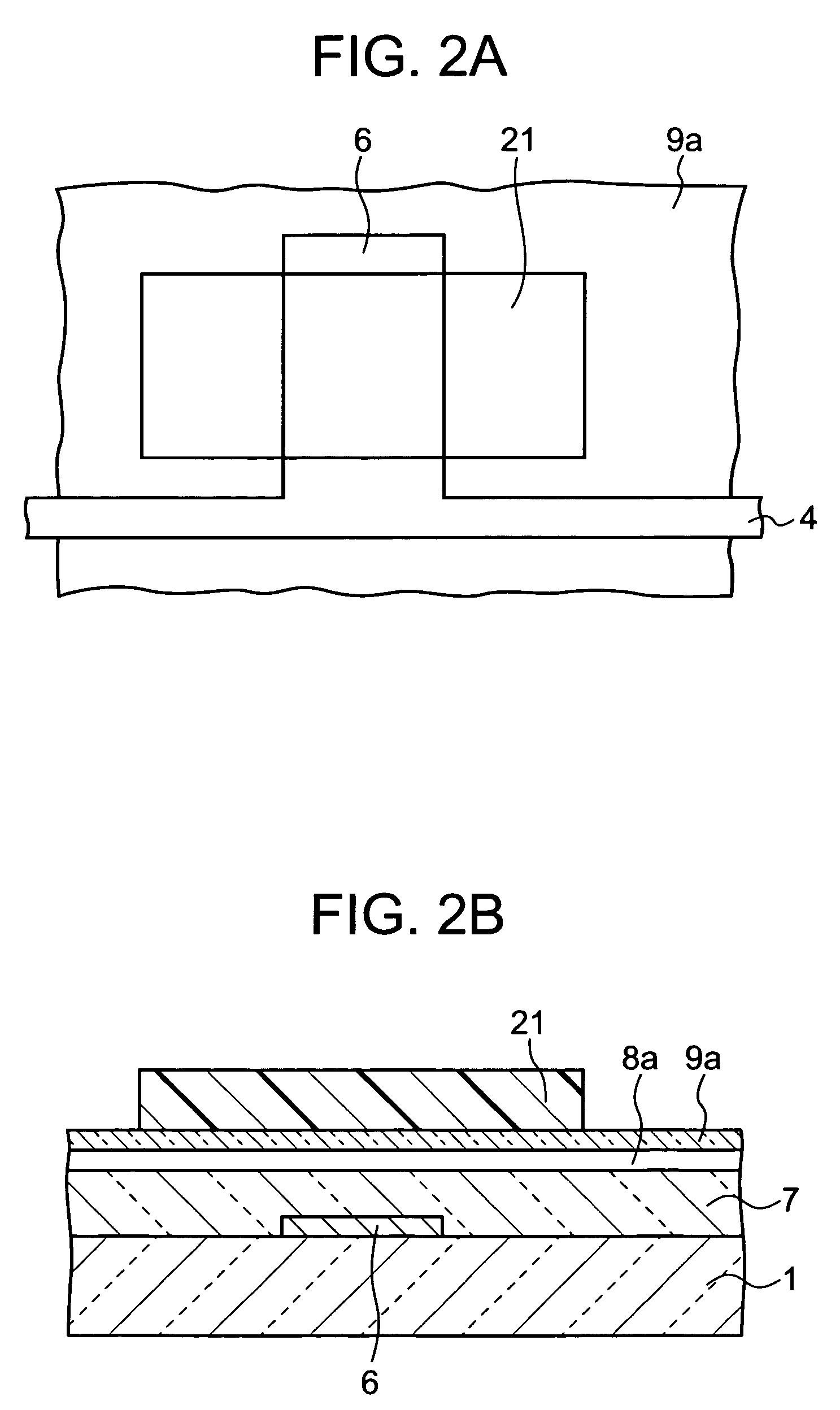

Light-emitting device

ActiveUS20060113549A1Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

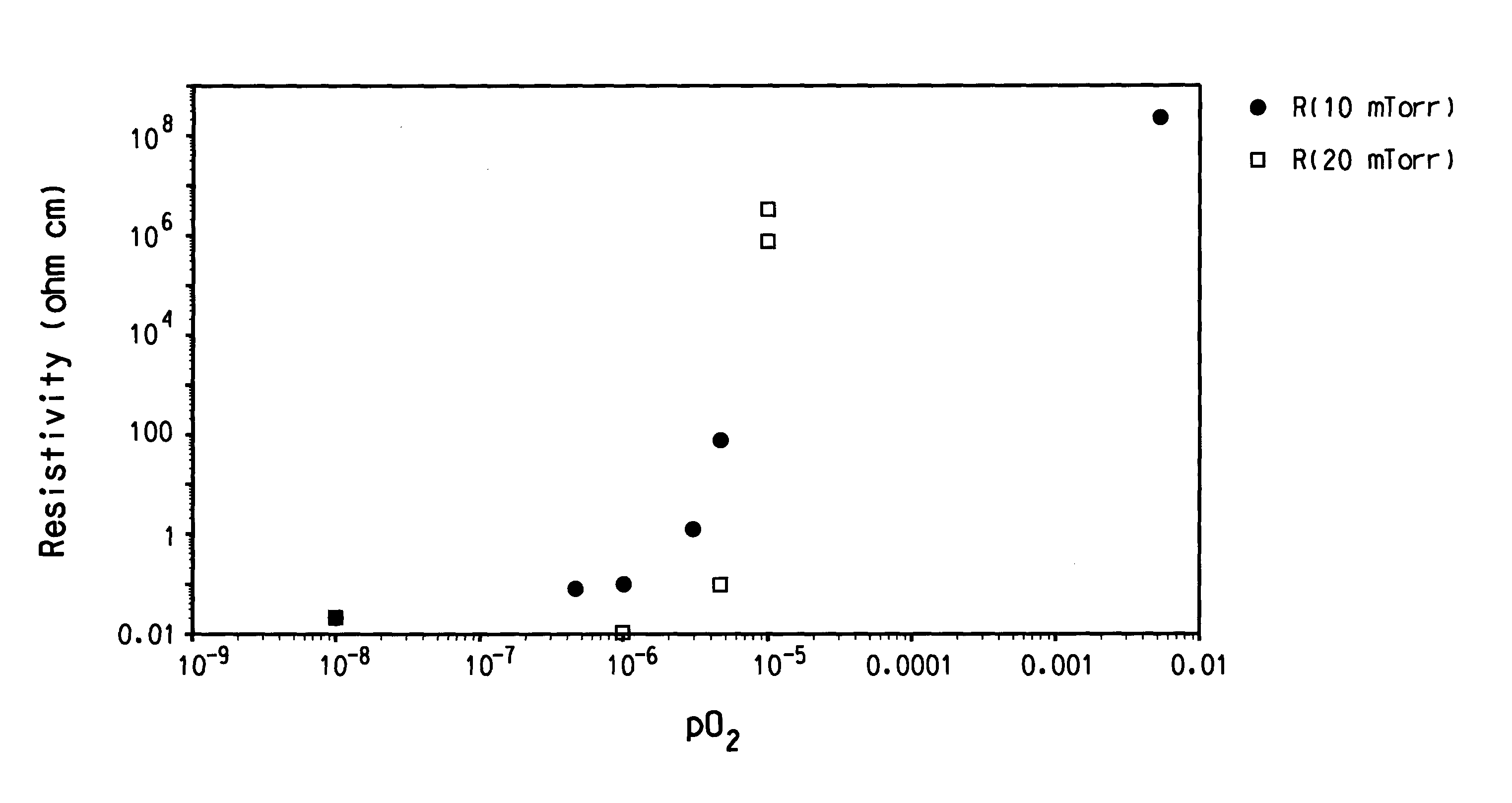

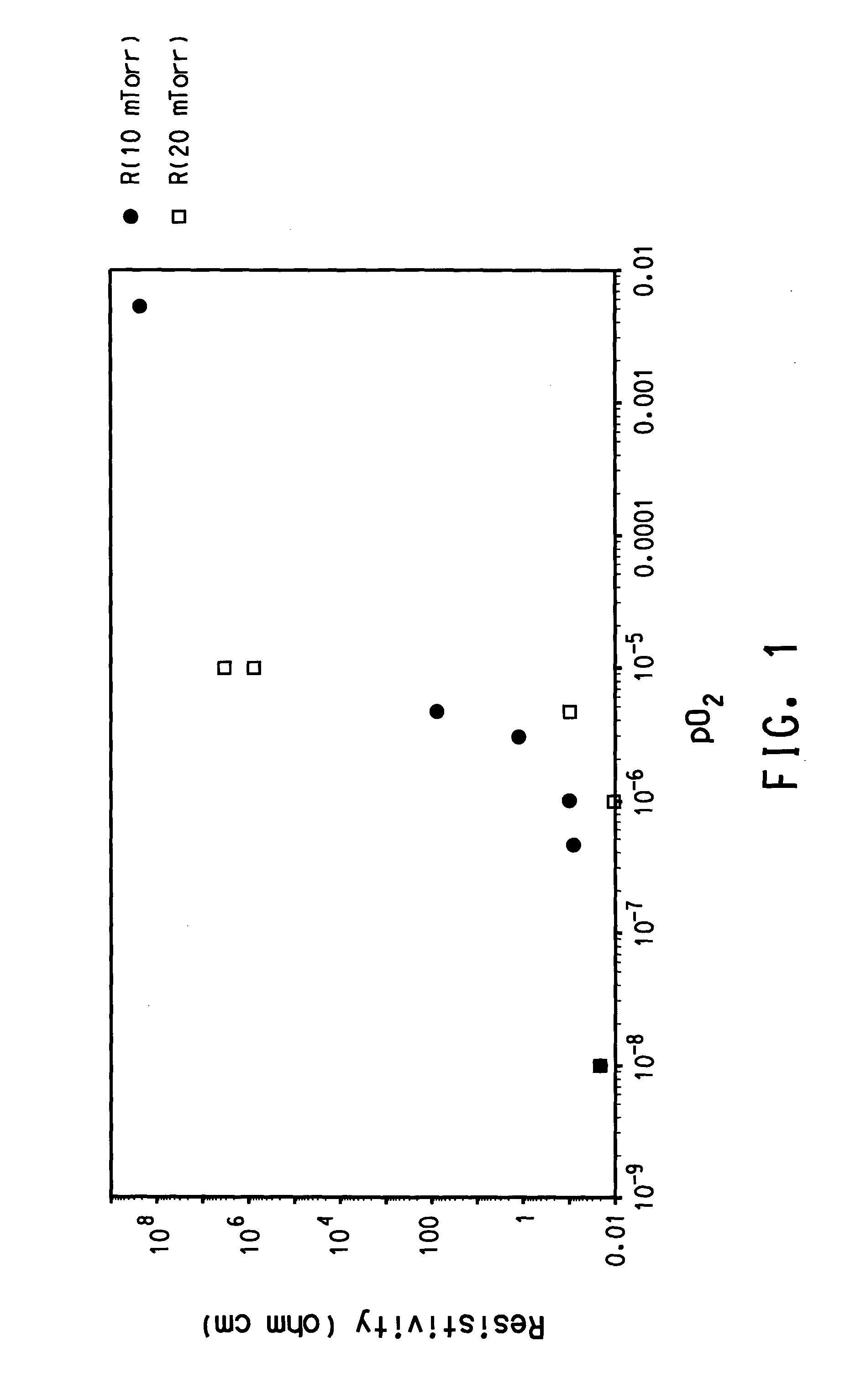

Method for forming ZnO film, method for forming ZnO semiconductor layer, method for fabricating semiconductor device, and semiconductor device

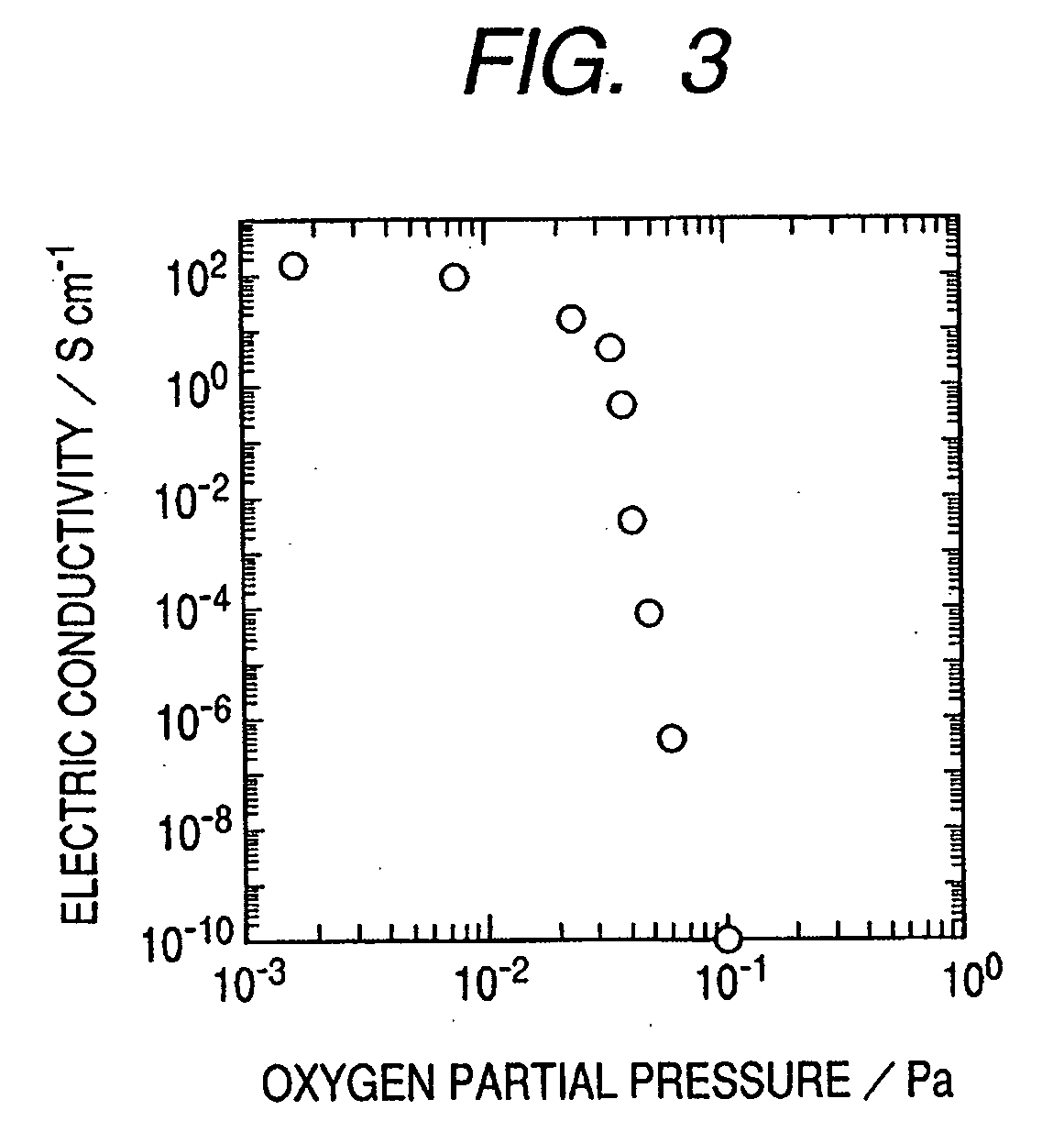

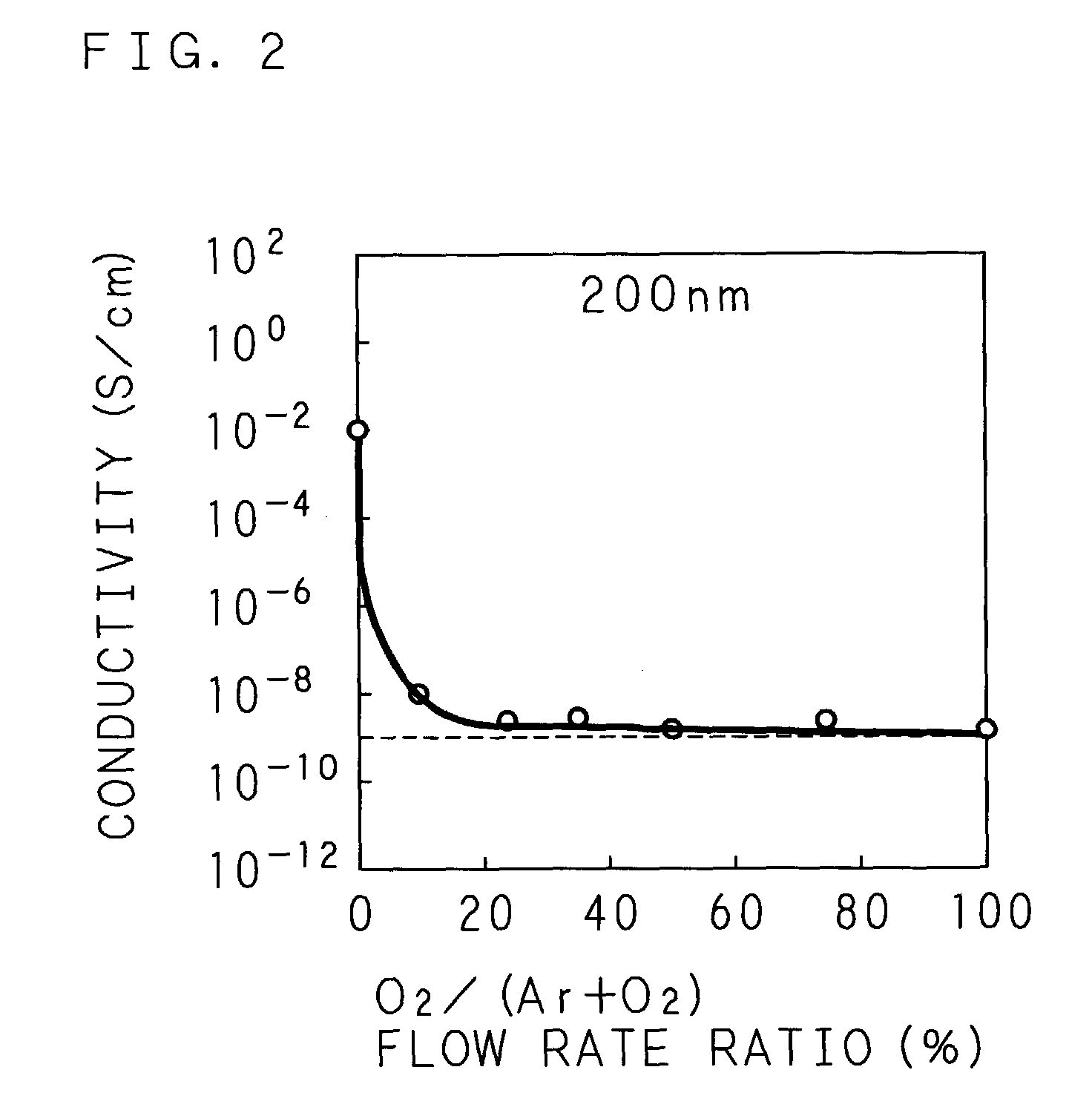

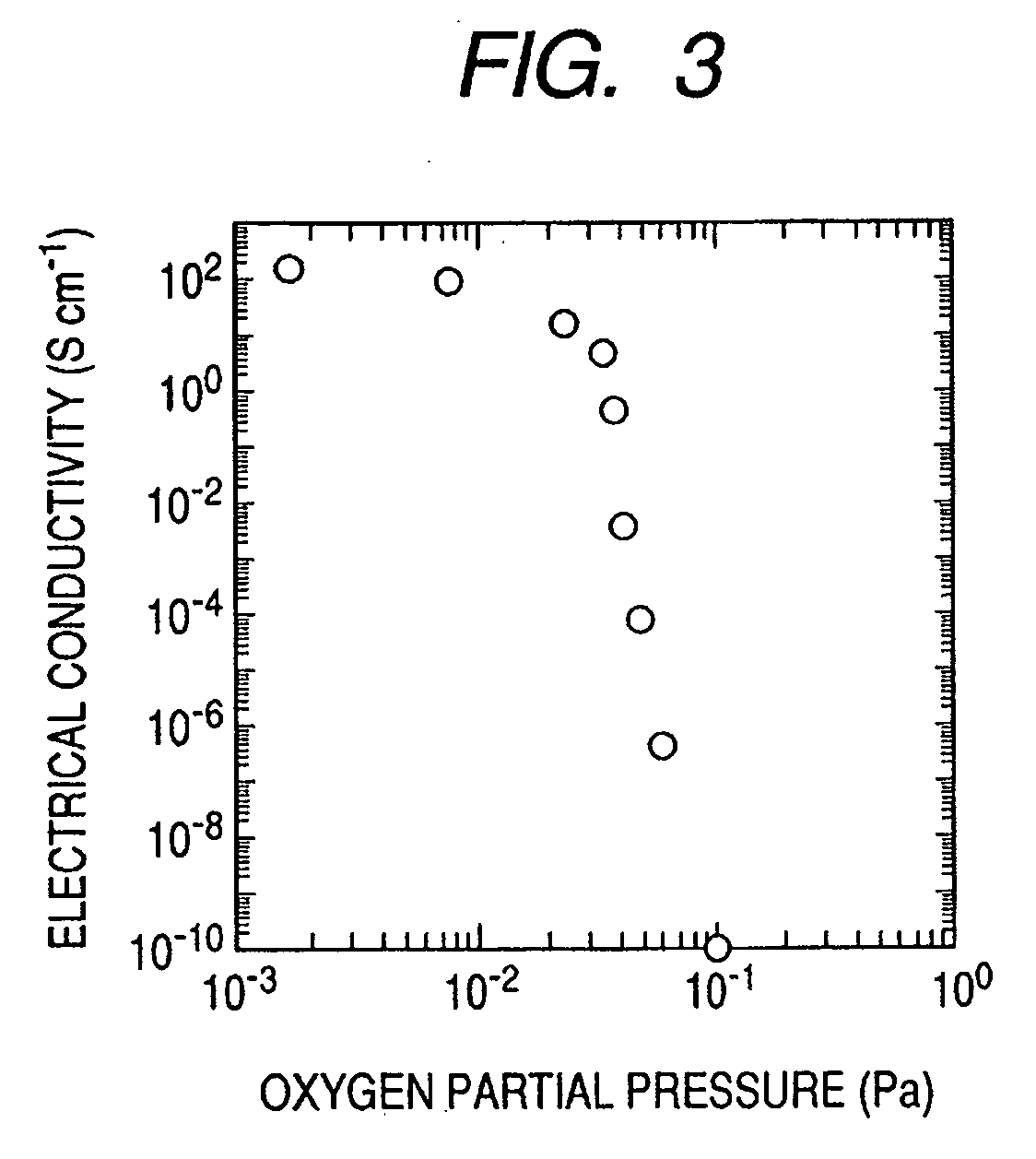

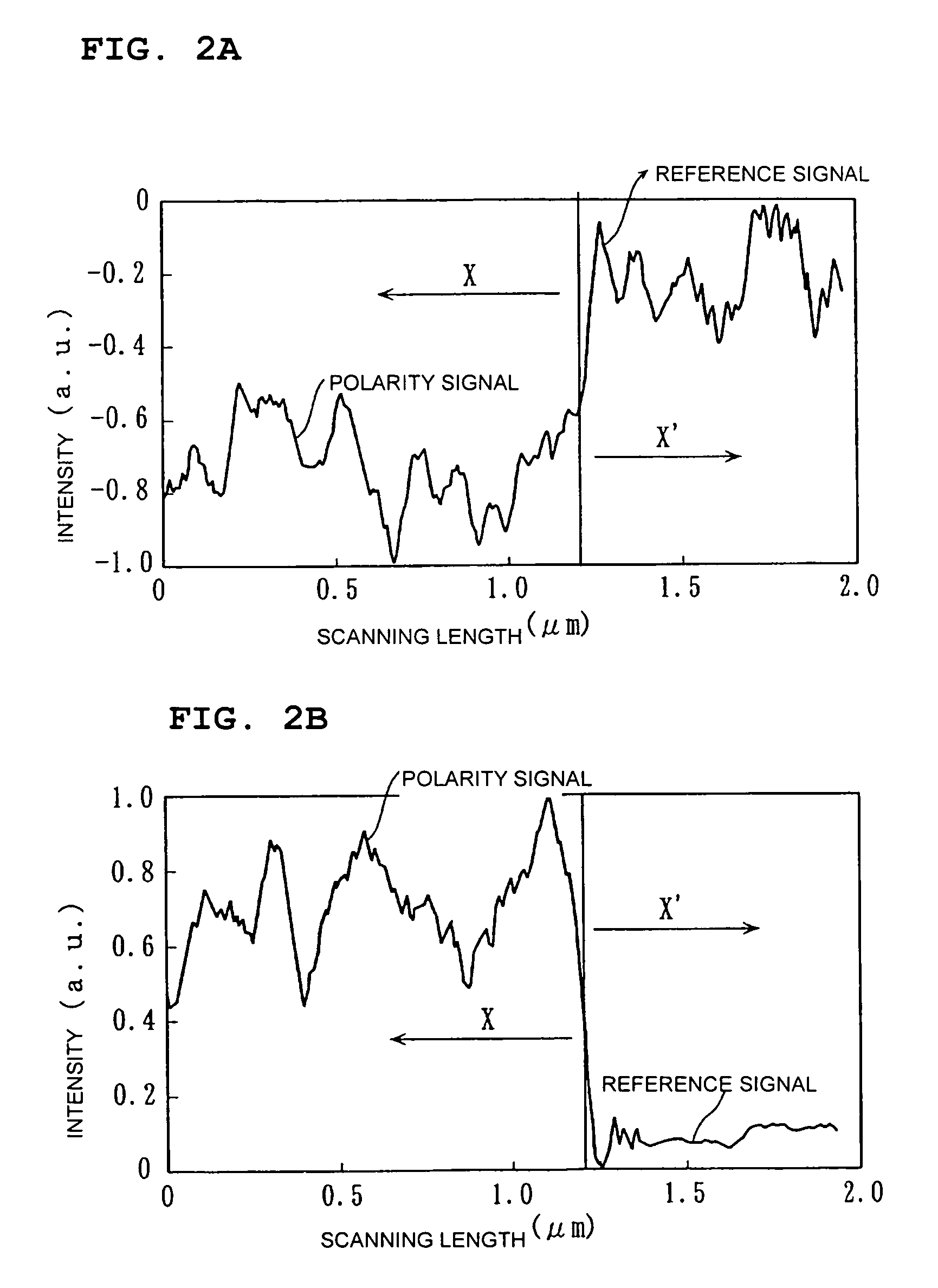

InactiveUS7049190B2High crystallinityLow costTransistorPolycrystalline material growthX-rayElectrical resistivity and conductivity

A ZnO buffer layer having an electric conductivity of 1×10−9 S / cm or lower or alternatively a ZnO buffer layer having a diffraction peak of a crystal face other than (002) and (004) in X-ray diffraction is formed on a substrate by sputtering. A ZnO semiconductor layer is formed on the ZnO buffer layer. The ZnO semiconductor layer is formed under the condition that the flow rate ratio of an oxygen gas in a sputtering gas is lower than that in the formation of the ZnO buffer layer.

Owner:SANYO ELECTRIC CO LTD

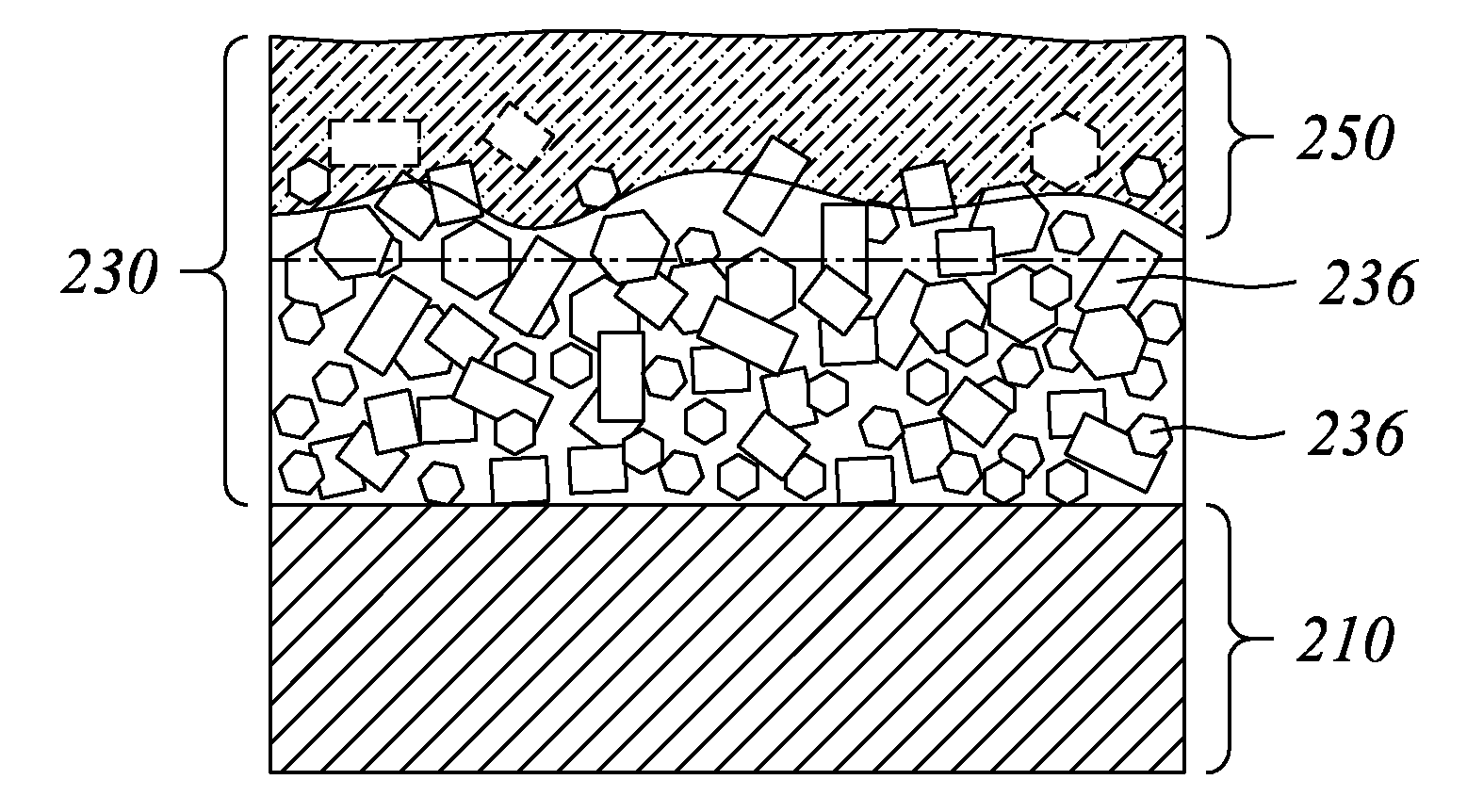

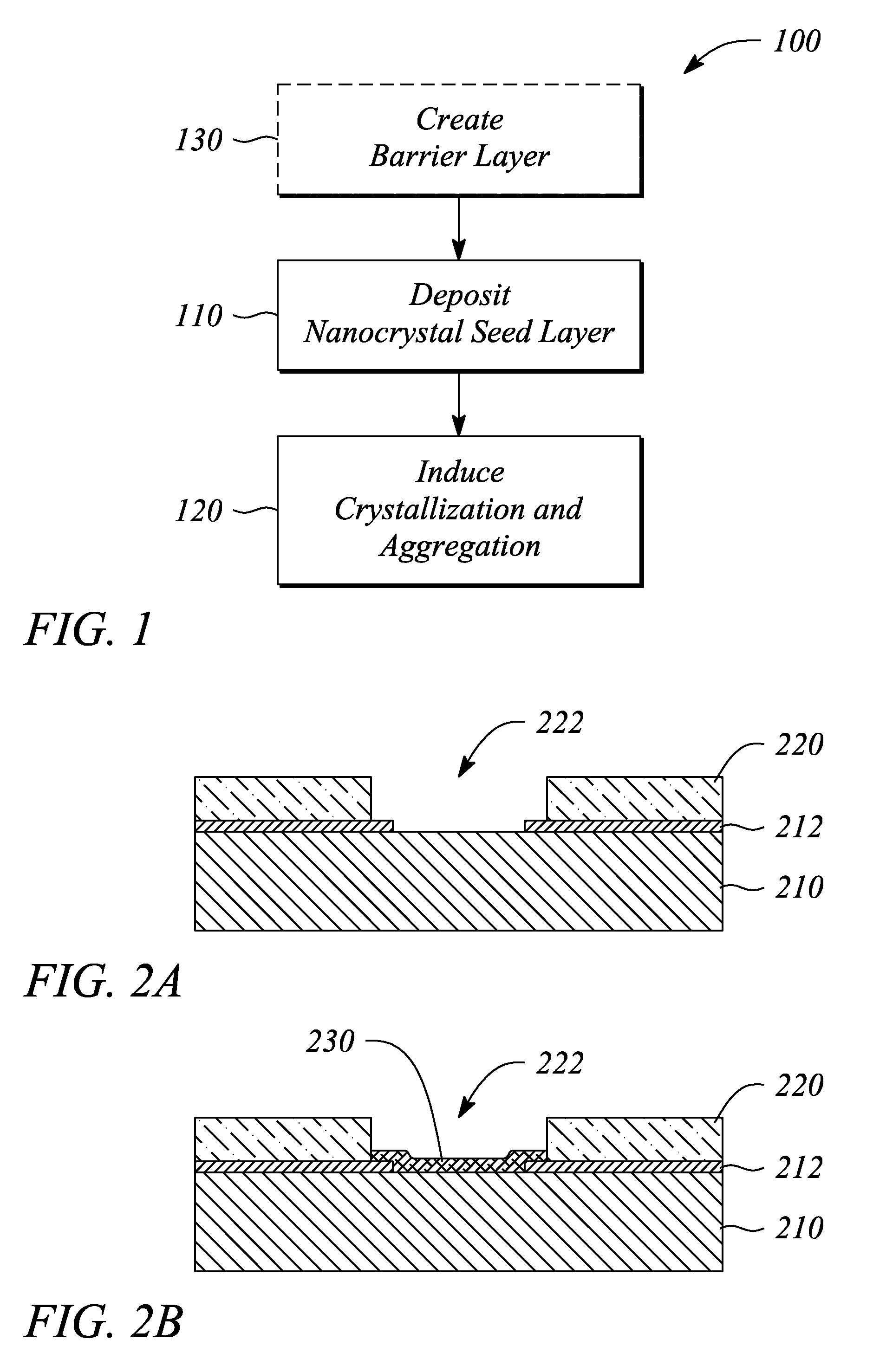

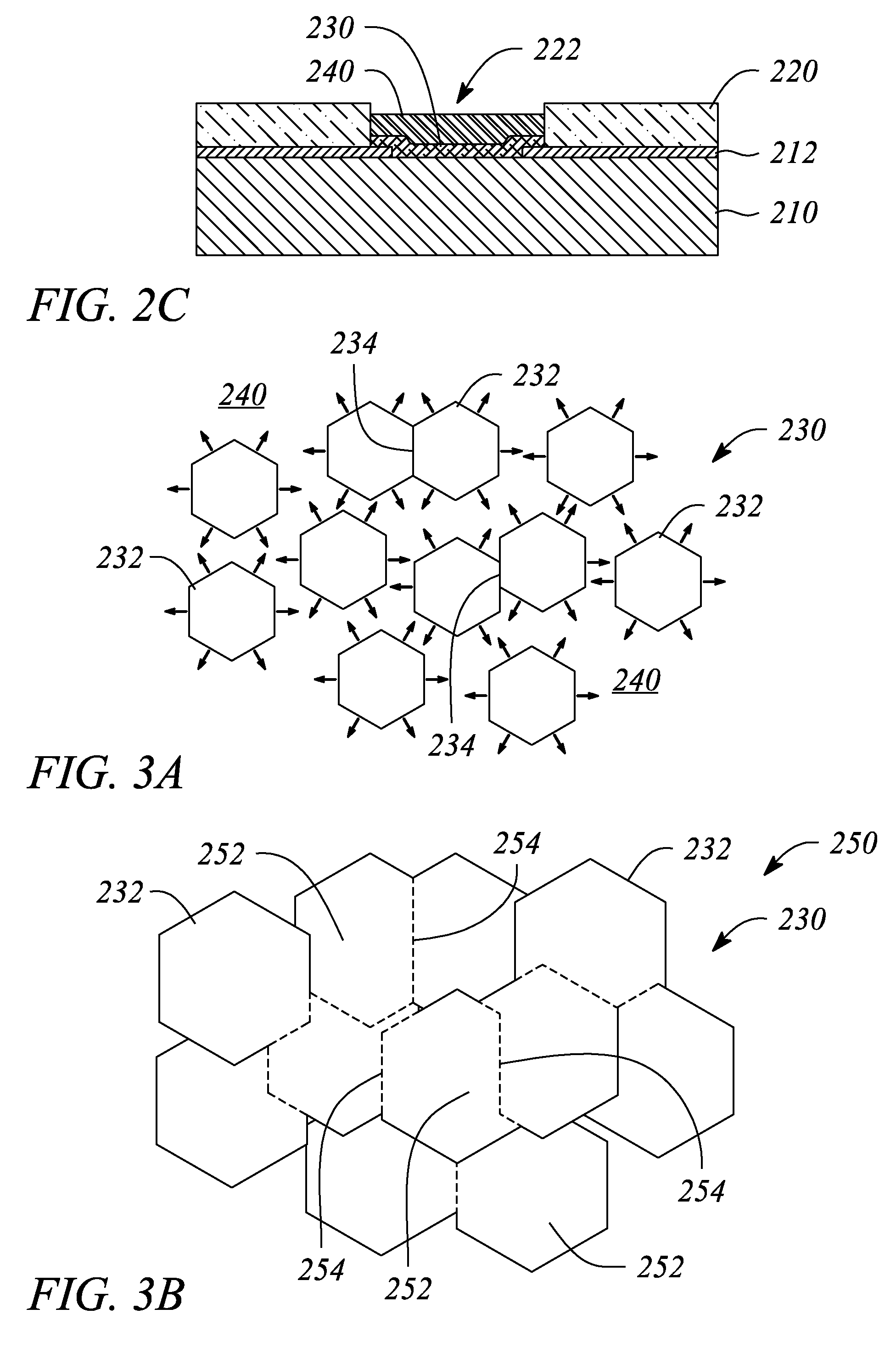

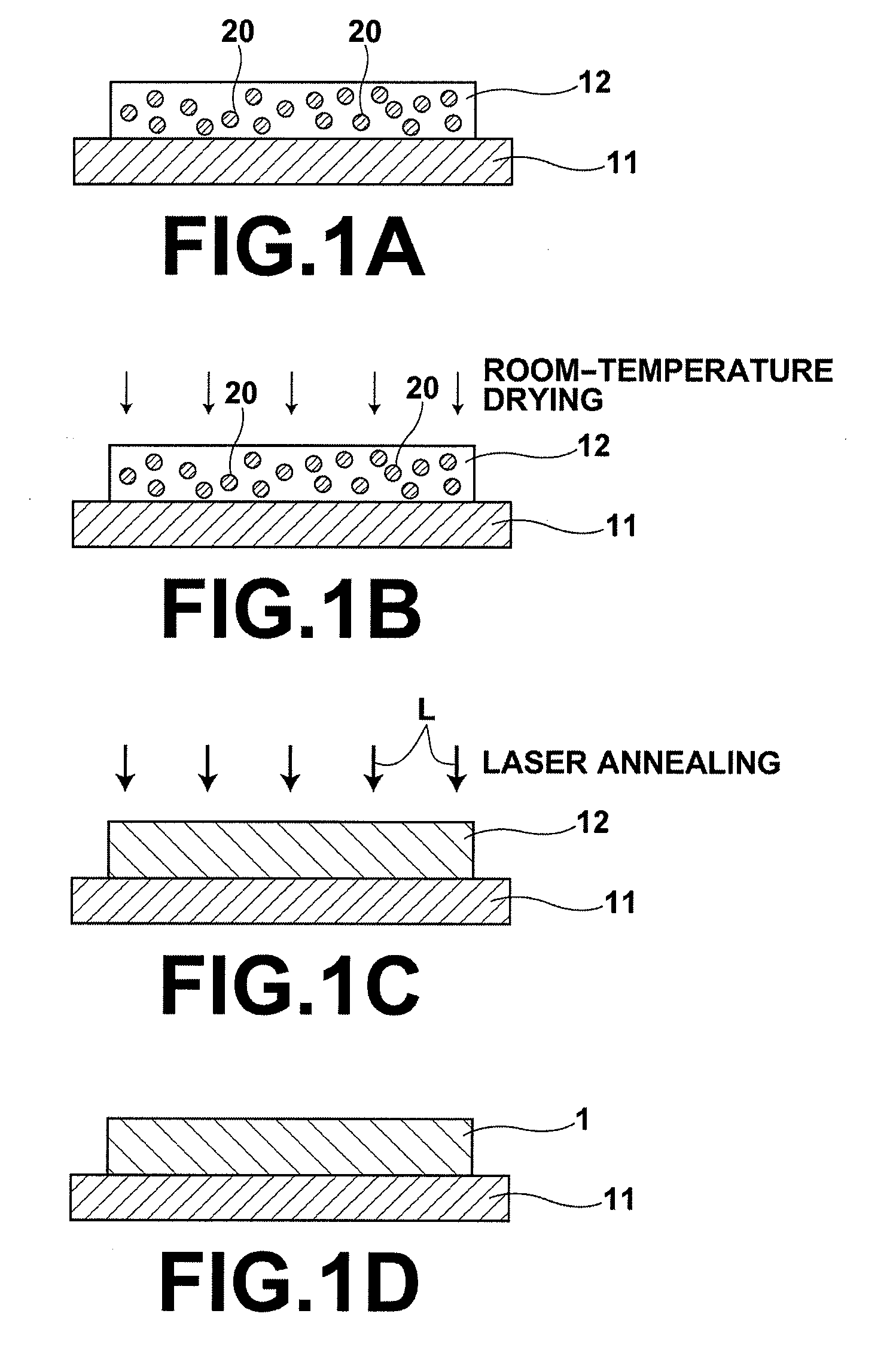

Fused nanocrystal thin film semiconductor and method

A thin film semiconductor and a method of its fabrication use induced crystallization and aggregation of a nanocrystal seed layer to form a merged-domain layer. The nanocrystal seed layer is deposited onto a substrate surface within a defined boundary. A reaction temperature below a boiling point of a reaction solution is employed. A thin film metal-oxide transistor and a method of its production employ the thin film semiconductor as a channel of the transistor. The merged-domain layer exhibits high carrier mobility.

Owner:HEWLETT PACKARD DEV CO LP

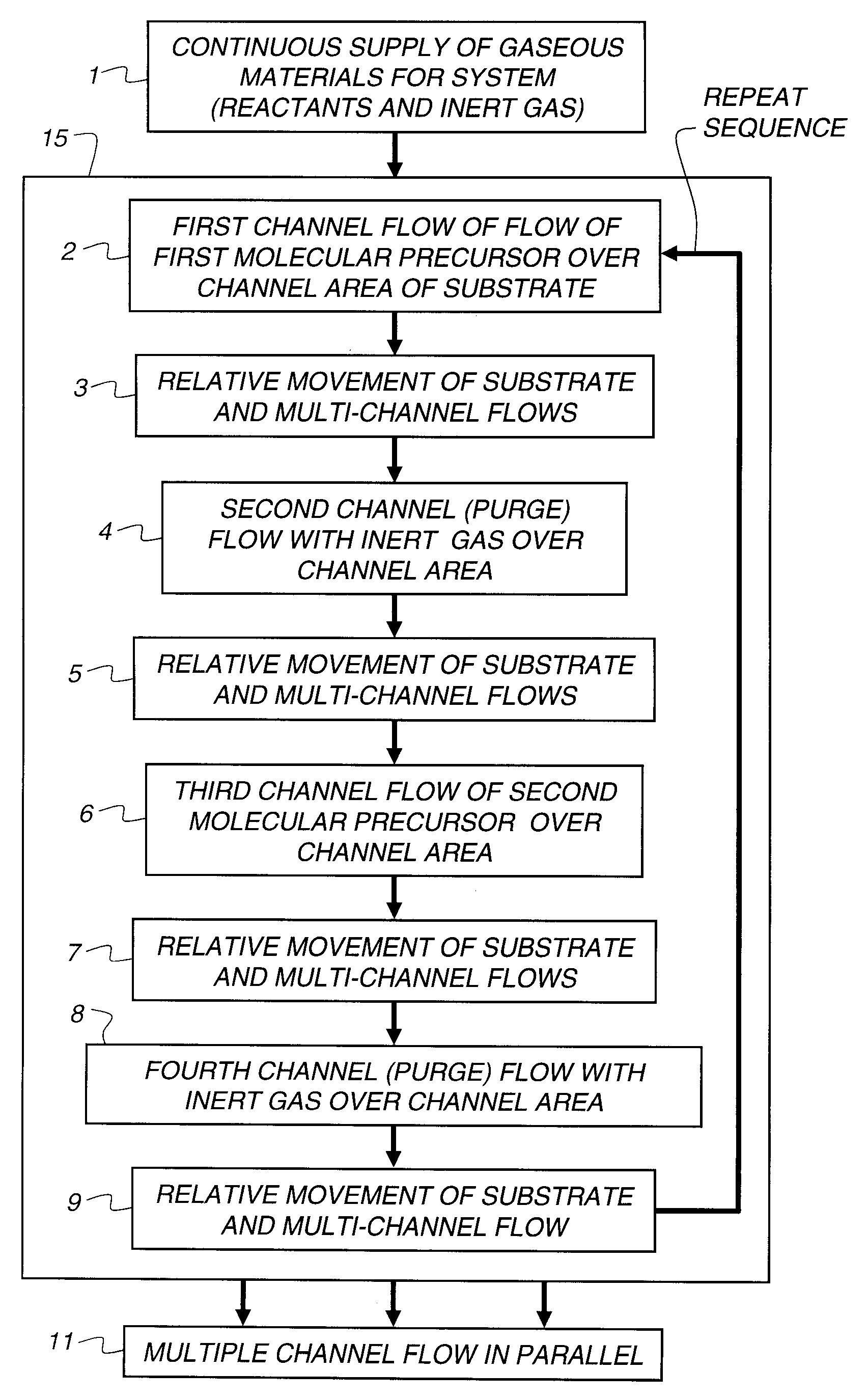

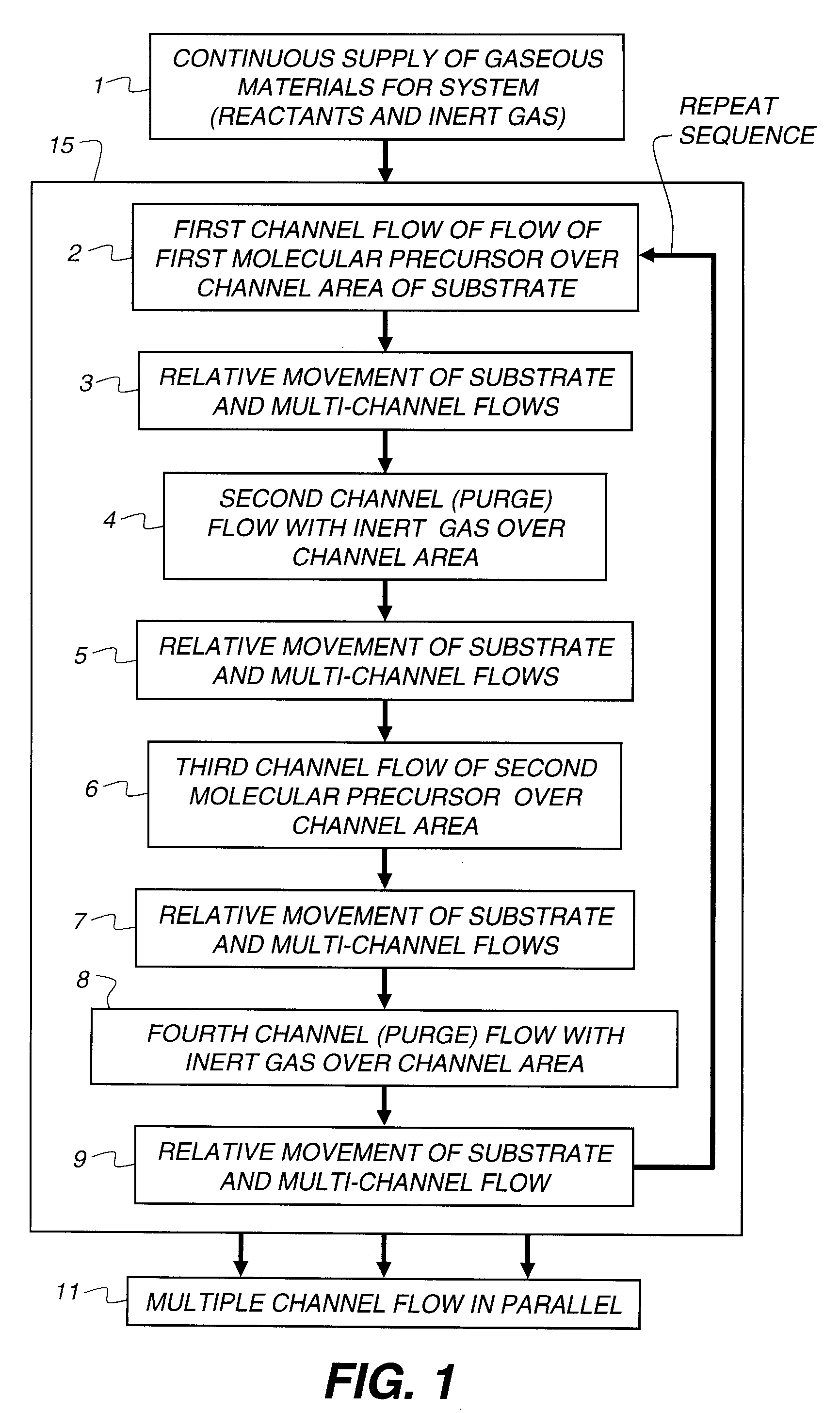

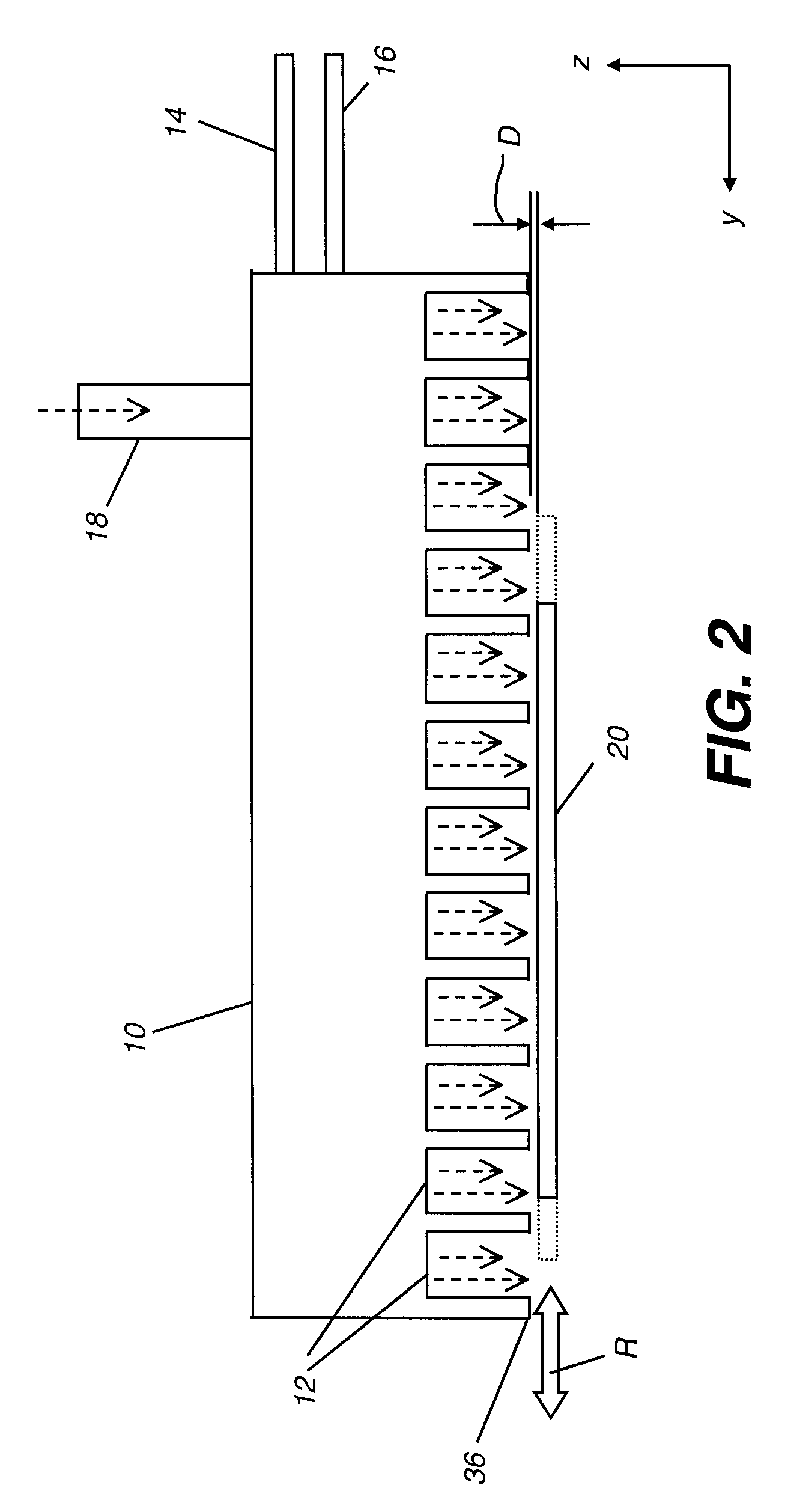

Process for atomic layer deposition

ActiveUS20080182358A1Suitable for processingAllowed to operateAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingZincAtomic layer deposition

The present invention relates to a process of making a zinc-oxide-based thin film semiconductor, for use in a transistor, comprising thin film deposition onto a substrate comprising providing a plurality of gaseous materials comprising at least first, second, and third gaseous materials, wherein the first gaseous material is a zinc-containing volatile material and the second gaseous material is reactive therewith such that when one of the first or second gaseous materials are on the surface of the substrate the other of the first or second gaseous materials will react to deposit a layer of material on the substrate and wherein the third gaseous material is inert with respect to reacting with the first or second gaseous materials.

Owner:EASTMAN KODAK CO

Sensor and image pickup device

ActiveUS20060108529A1Reduce distortion problemsLessen the burden on the bodySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsAmorphous oxide

A sensor for detecting a received electromagnetic wave comprising a first electrode, a second electrode and an amorphous oxide layer interposed between the first electrode and the second electrode.

Owner:CANON KK +2

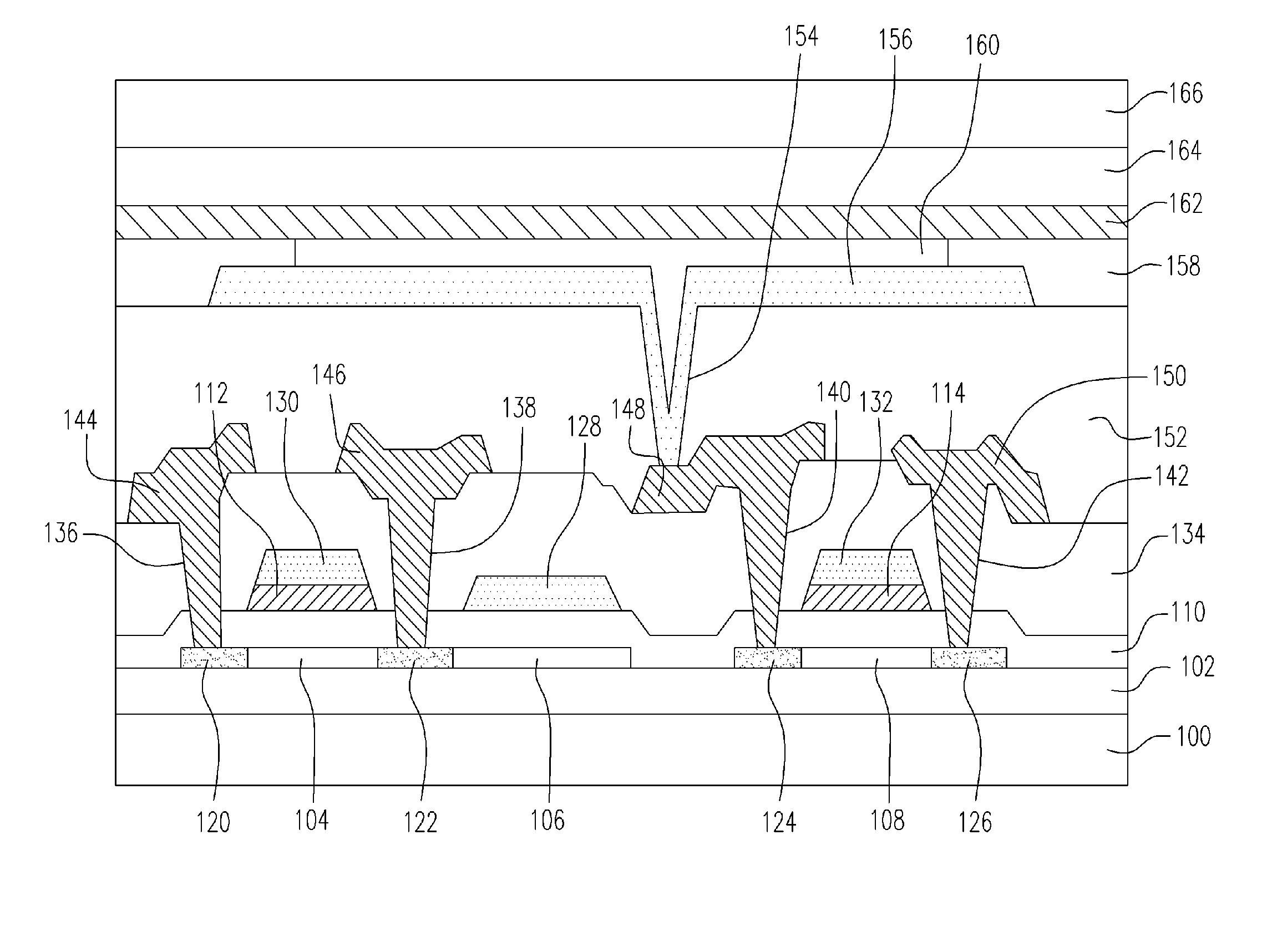

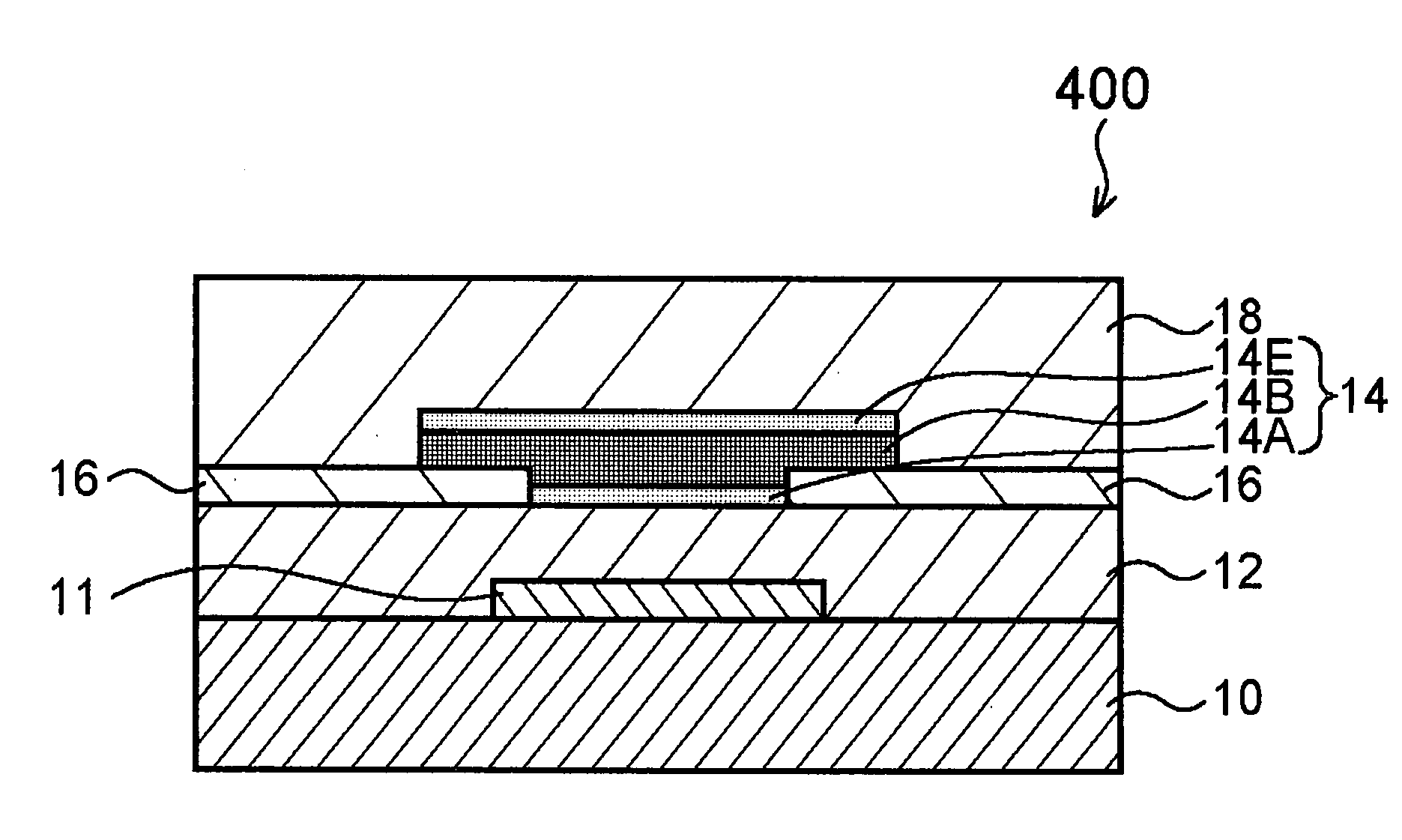

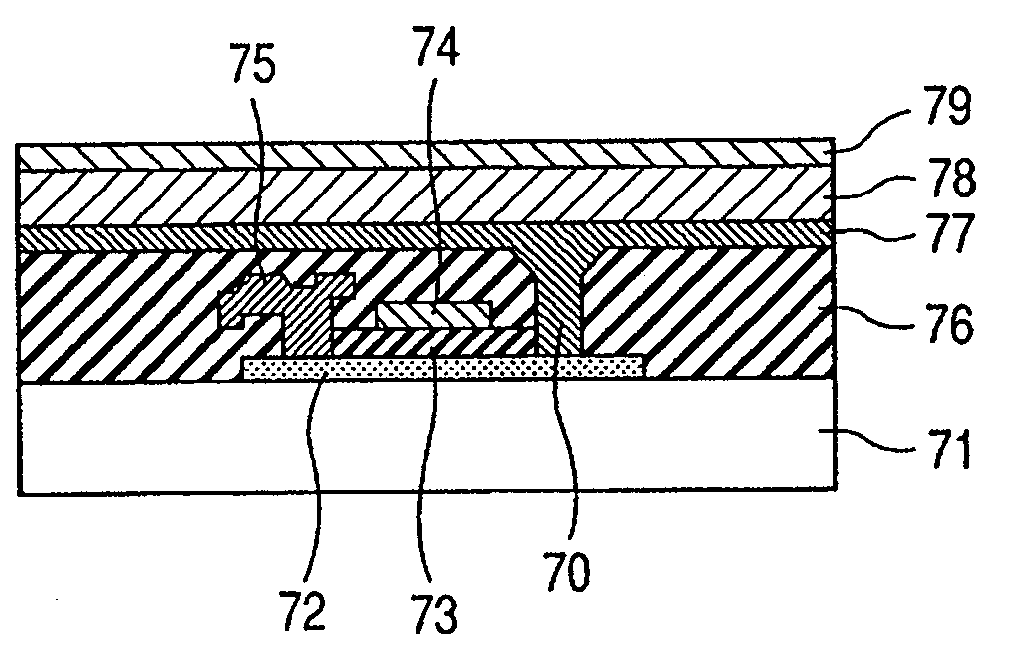

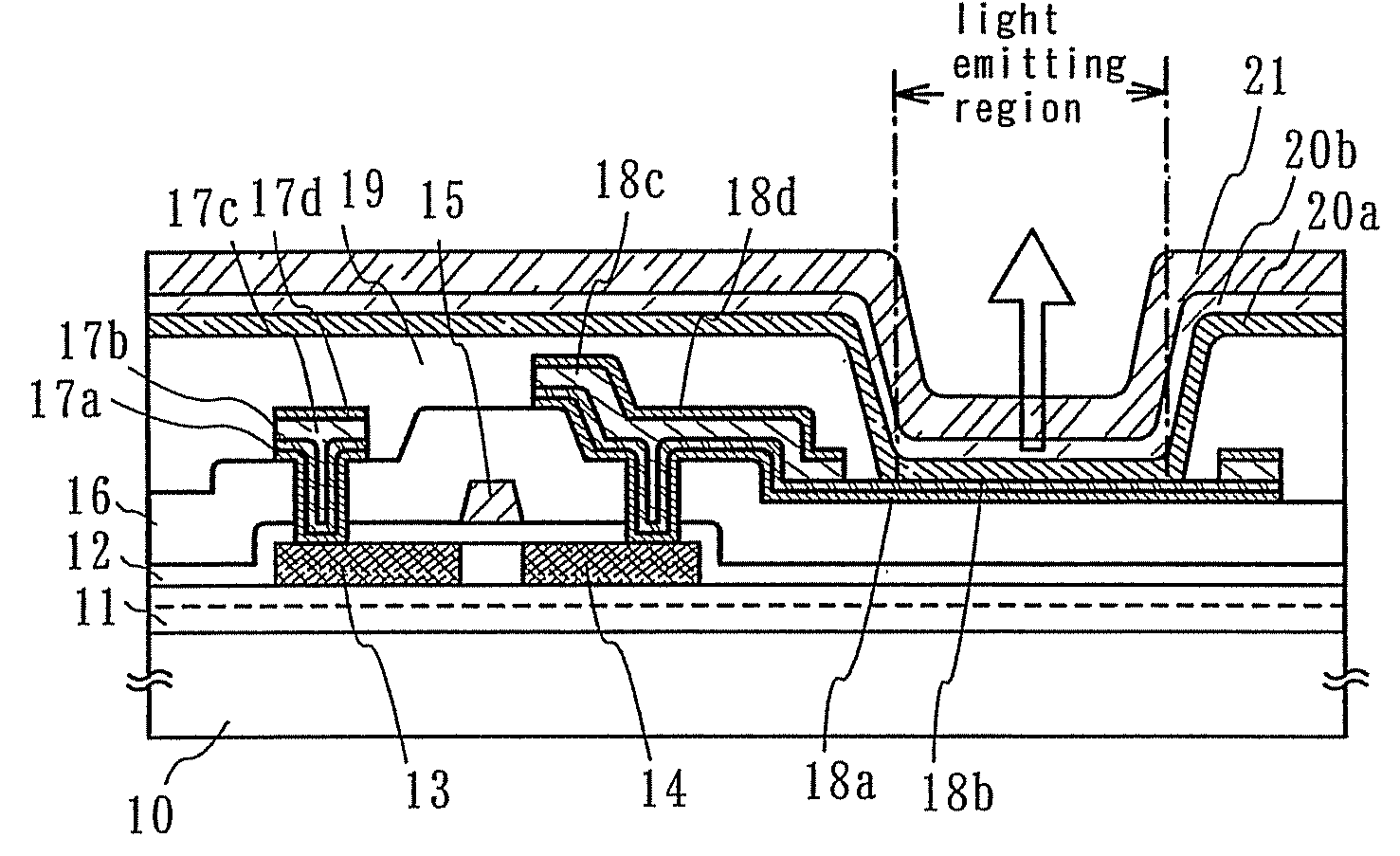

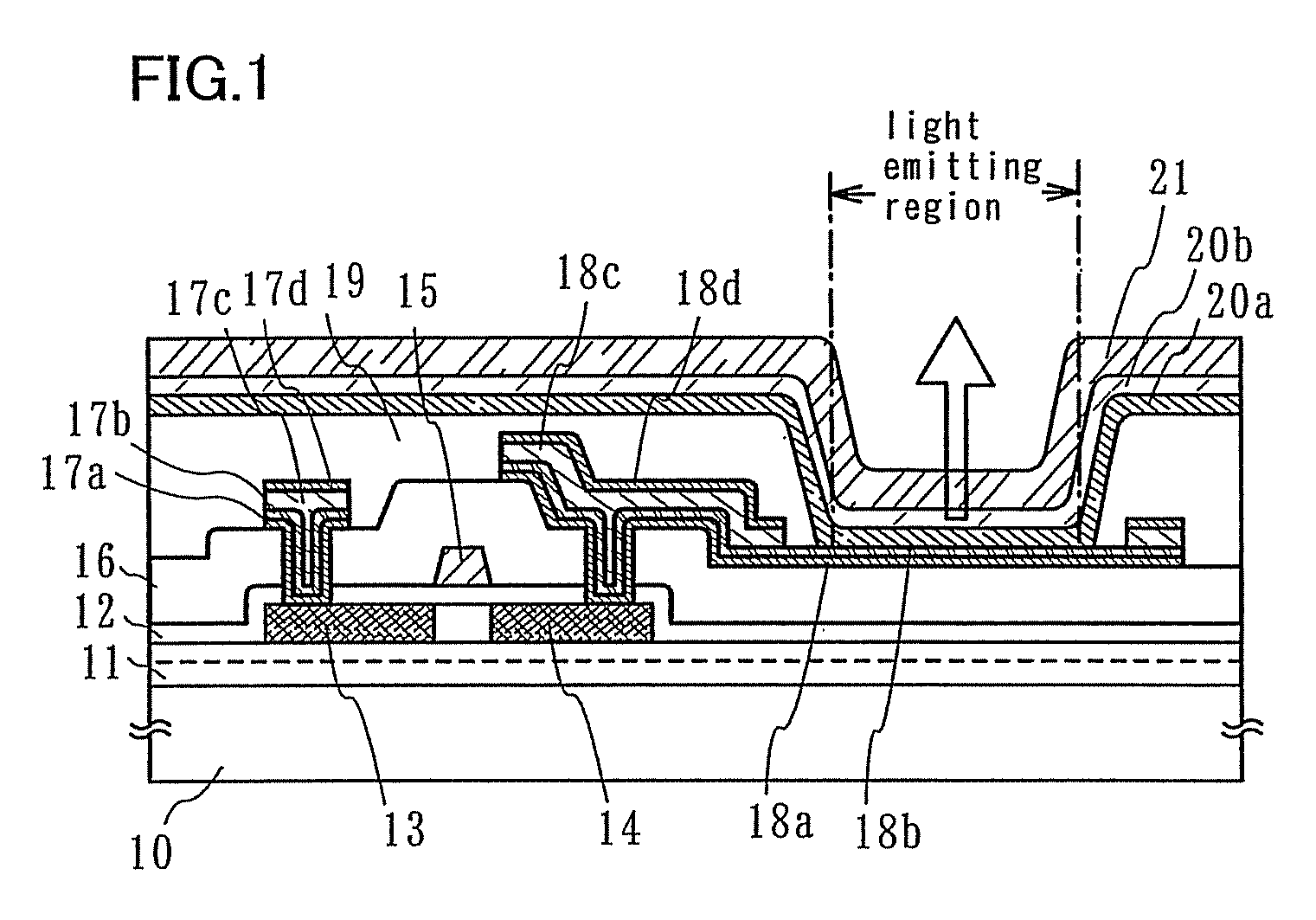

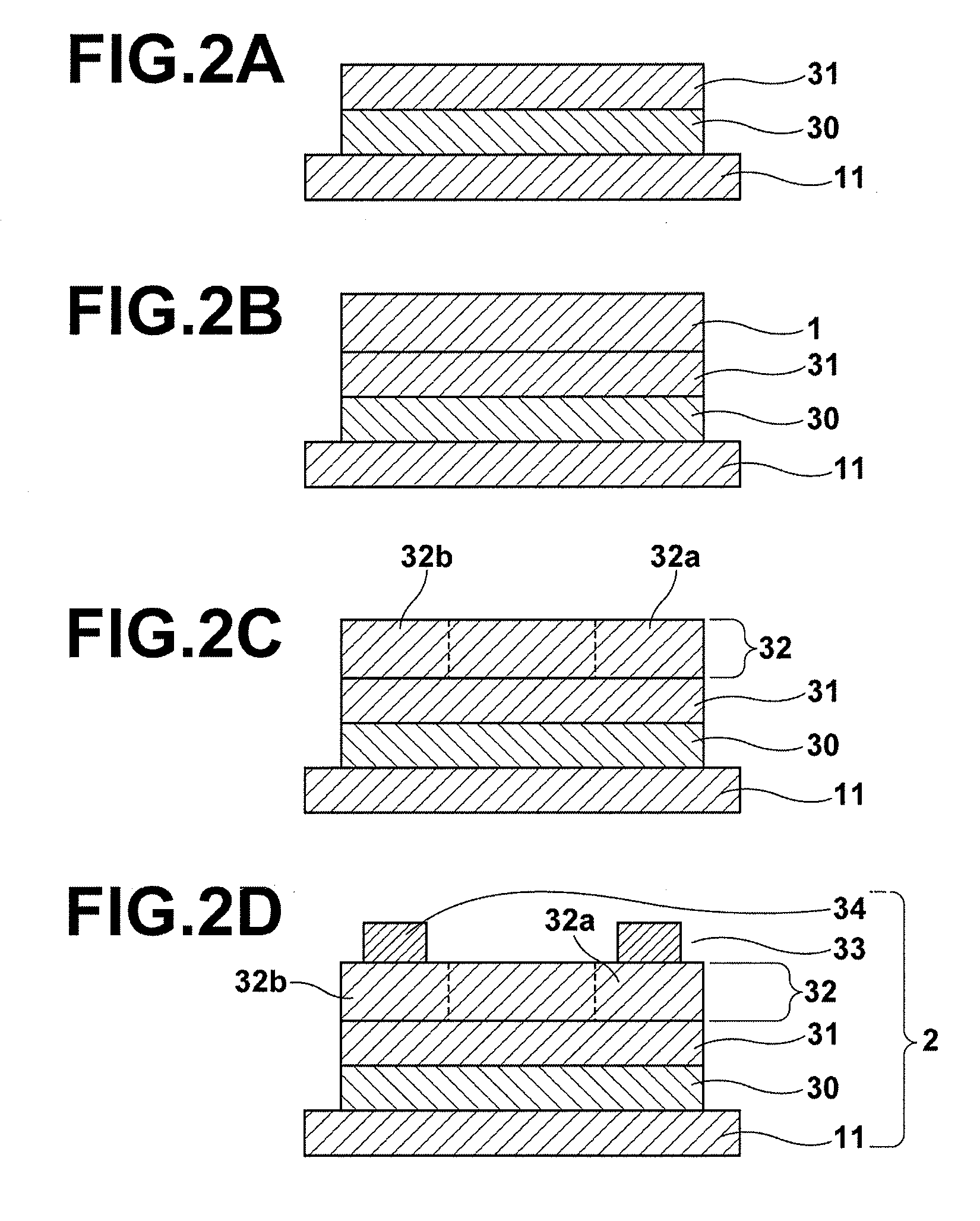

Semiconductor Device and Method for Manufacturing the Same

ActiveUS20090134399A1Good step coverageThin thicknessDischarge tube luminescnet screensElectroluminescent light sourcesActive matrixMetal electrodes

A manufacturing method of an active matrix light emitting device in which the active matrix light emitting device can be manufactured in a shorter time with high yield at low cost compared with conventional ones will be provided. It is a feature of the present invention that a layered structure is employed for a metal electrode which is formed in contact with or is electrically connected to a semiconductor layer of each TFT arranged in a pixel area of an active matrix light emitting device. Further, the metal electrode is partially etched and used as a first electrode of a light emitting element. A buffer layer, a layer containing an organic compound, and a second electrode layer are stacked over the first electrode.

Owner:SEMICON ENERGY LAB CO LTD

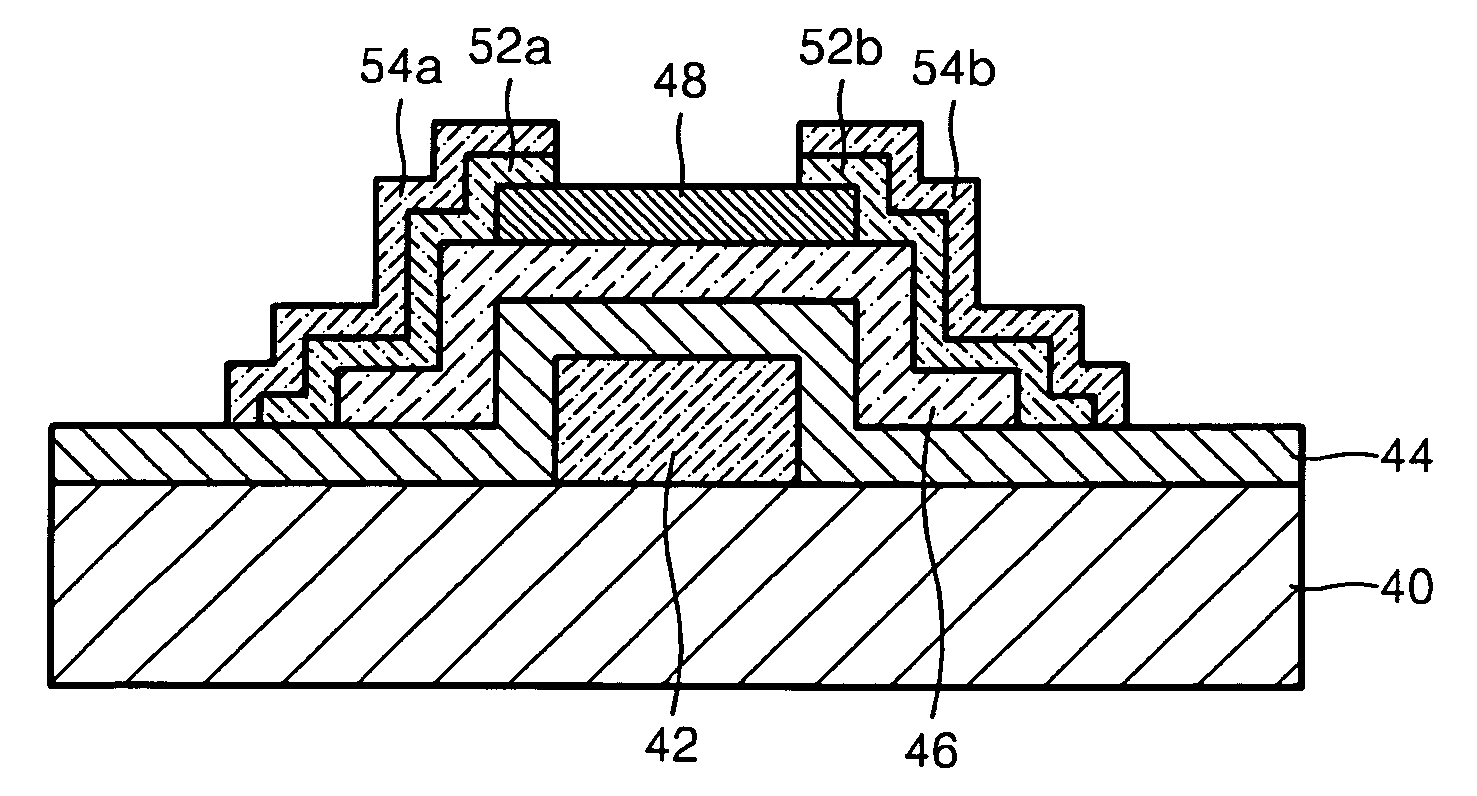

Thin film transistor, method of manufacturing the same, and flat panel display having the same

ActiveUS20080258141A1Improve stabilityUniform characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

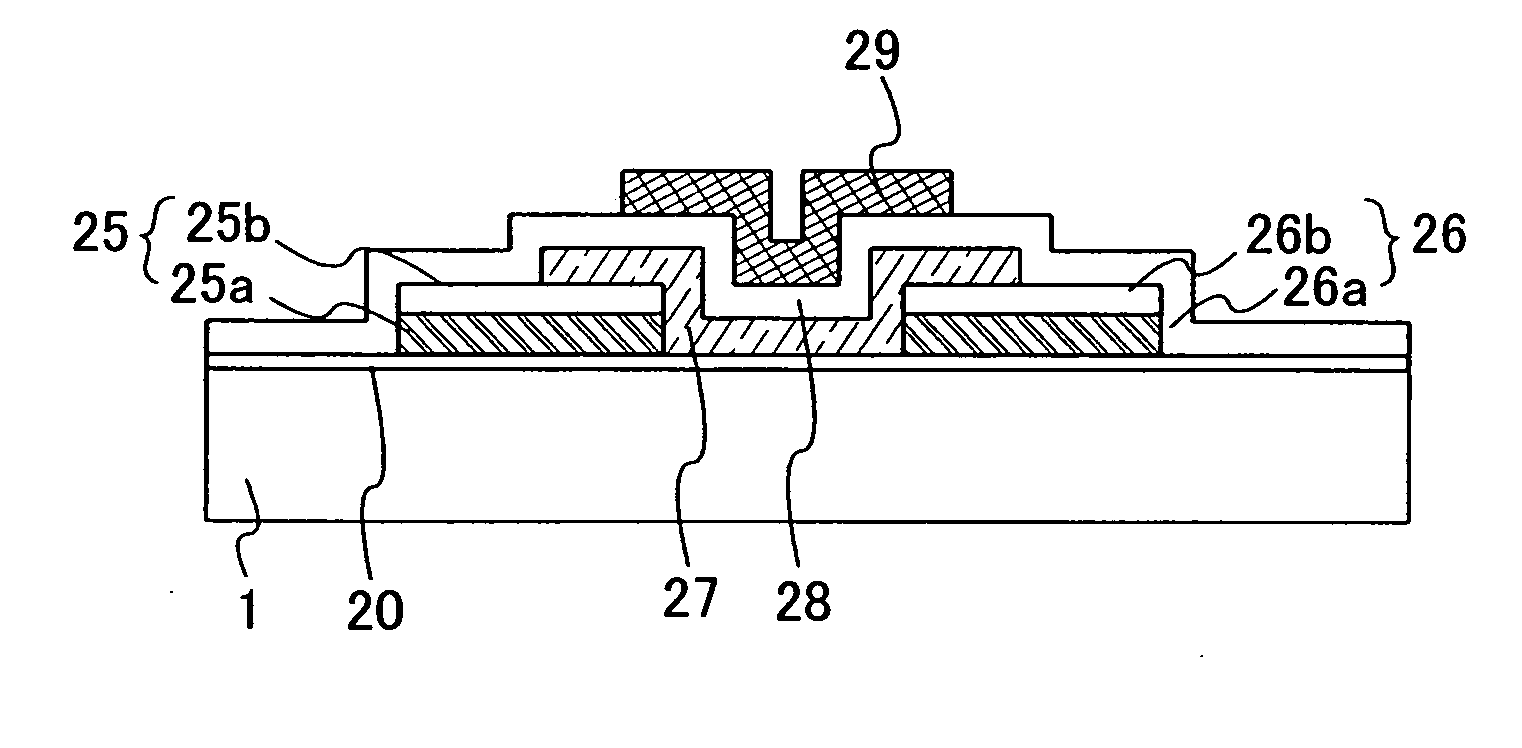

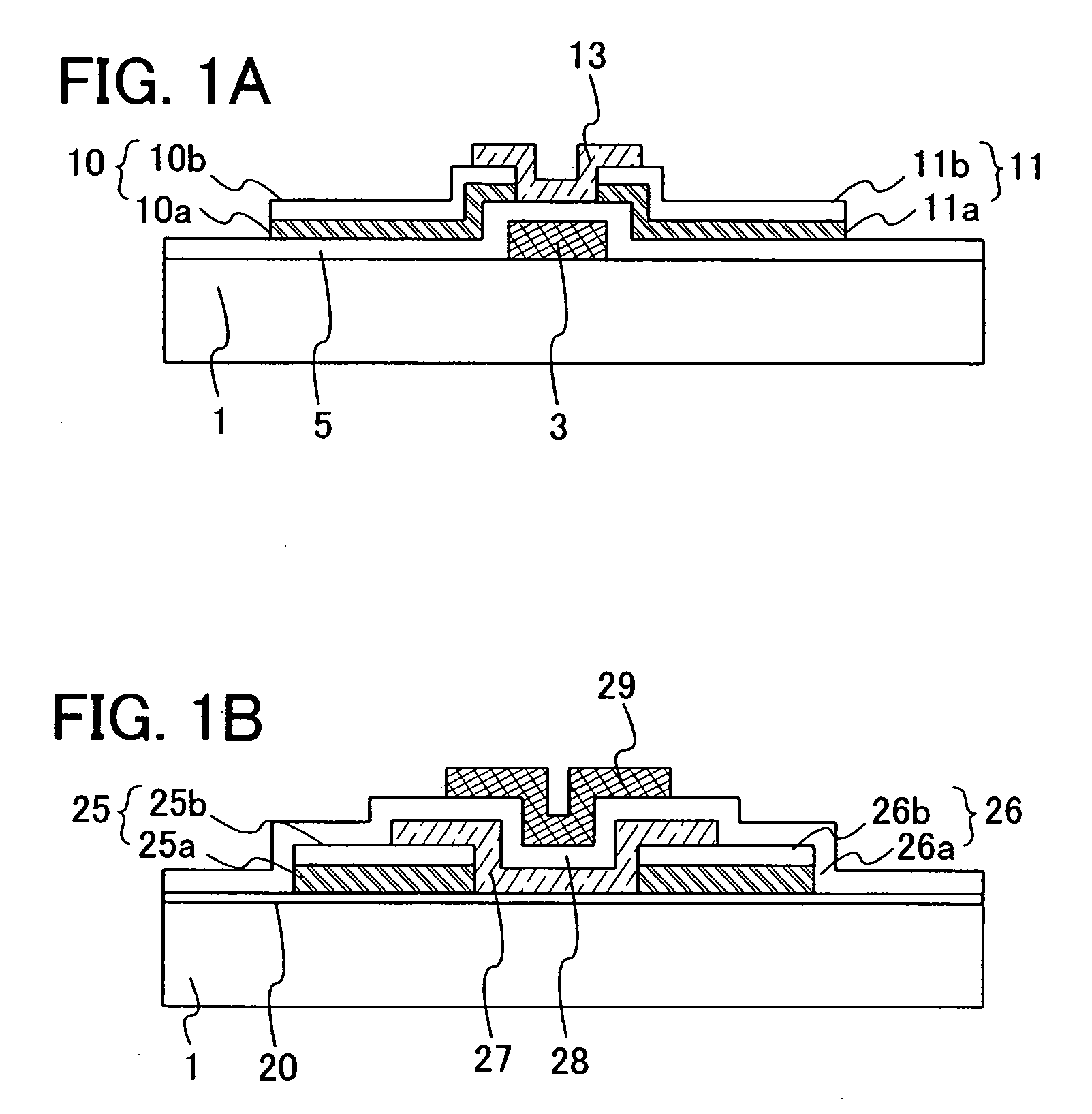

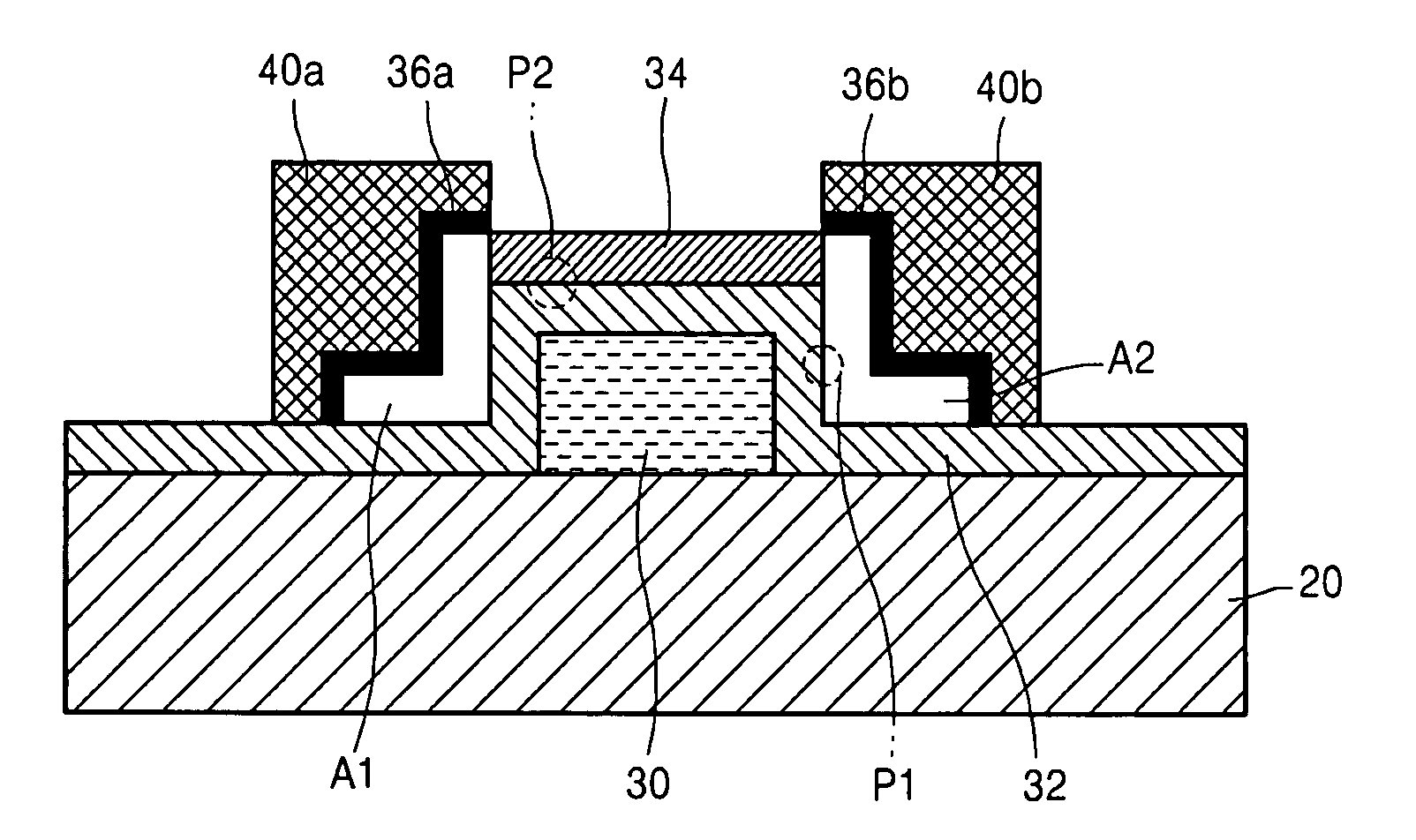

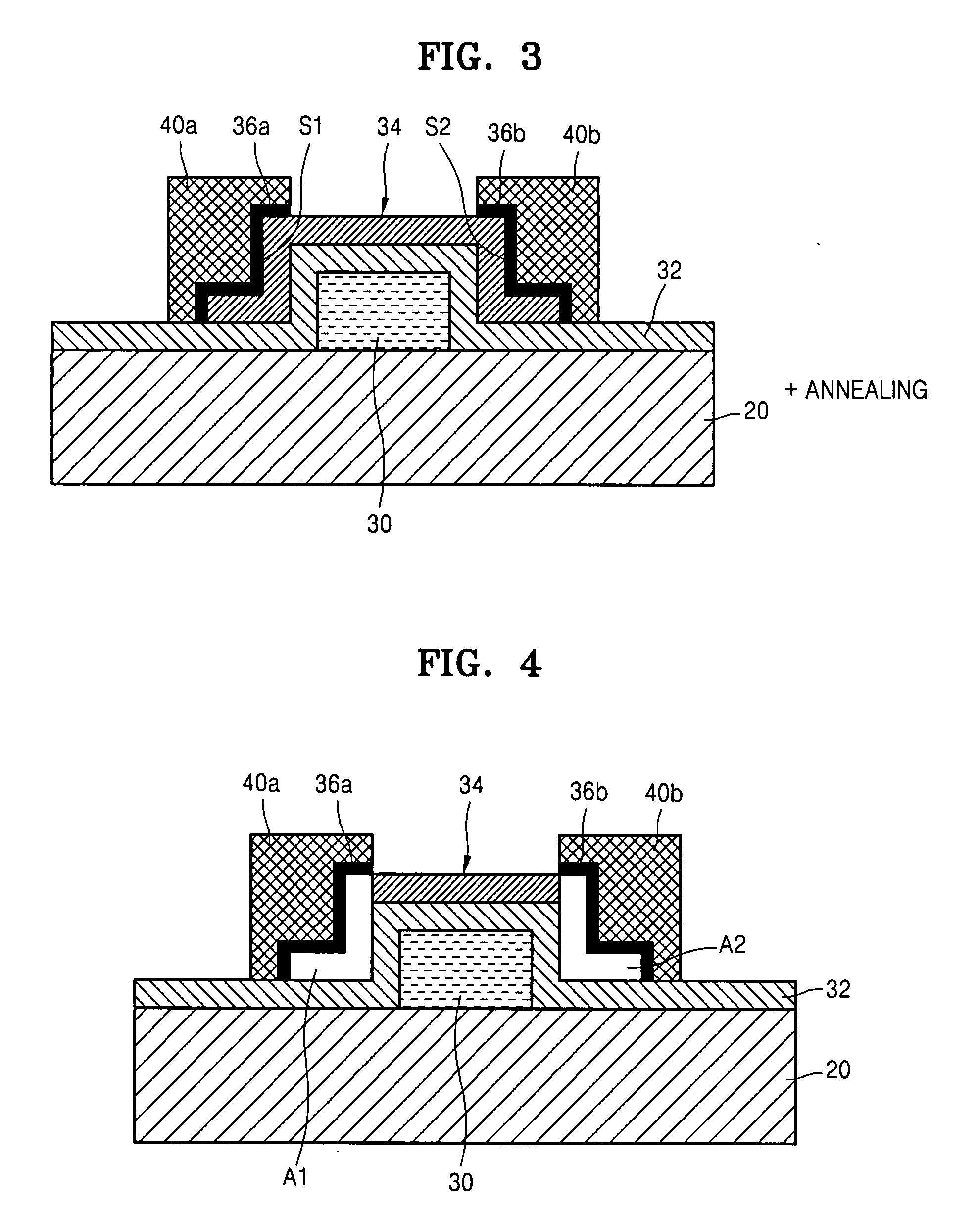

A thin film transistor (TFT), a method of manufacturing the TFT, and a flat panel display comprising the TFT are provided. The TFT includes a gate, a gate insulating layer that contacts the gate, a channel layer that contacts the gate insulating layer and faces the gate with the gate insulating layer therebetween, a source that contacts an end of the channel layer; and a drain that contacts an other end of the channel layer, wherein the channel layer is an amorphous oxide semiconductor layer, and each of the source and the drain is a conductive oxide layer comprising an oxide semiconductor layer having a conductive impurity in the oxide semiconductor layer. A low resistance metal layer can further be included on the source and drain. A driving circuit of a unit pixel of a flat panel display includes the TFT.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film transistor having an etching protection film and manufacturing method thereof

InactiveUS7385224B2Improve machining accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor thin films

A thin film transistor of the present invention includes a semiconductor thin film (8); a gate insulating film (7) formed on one surface of the semiconductor thin film (8); a gate electrode (6) formed to be opposite to the semiconductor thin film (8) through the gate insulating film (7); a source electrode (15) and a drain electrode (16) electrically connected to the semiconductor thin film (8); a source region; a drain region; and a channel region. The thin film transistor further includes an insulating film (9) formed on a peripheral portion corresponding to at least the source region and the drain region of the semiconductor thin film (8), and having a contact hole (10, 11) through which at least a part of each of the source region and the drain region is exposed wherein the source electrode (15) and the drain electrode (16) are connected to the semiconductor thin film (8) through the contact hole (10, 11).

Owner:CASIO COMPUTER CO LTD

Electronic device, organic electroluminescence device, and organic thin film semiconductor device

InactiveUS20080106191A1Easy to manufactureImprove reliabilityCellsDischarge tube luminescnet screensSolid state electrolyteElectrolysis

An electronic device includes a substrate, a functional element formed on the substrate, an electrolytic element provided on at least one of a side of the substrate on which the functional element is formed and a side of the substrate opposite to the side on which the functional element is formed, configured including a solid-state electrolyte layer and a pair of electrodes for holding the solid-state electrolyte layer in between, and capable of applying electrolysis to water, and a sealing member for sealing the functional element and the electrolytic element.

Owner:SEIKO EPSON CORP

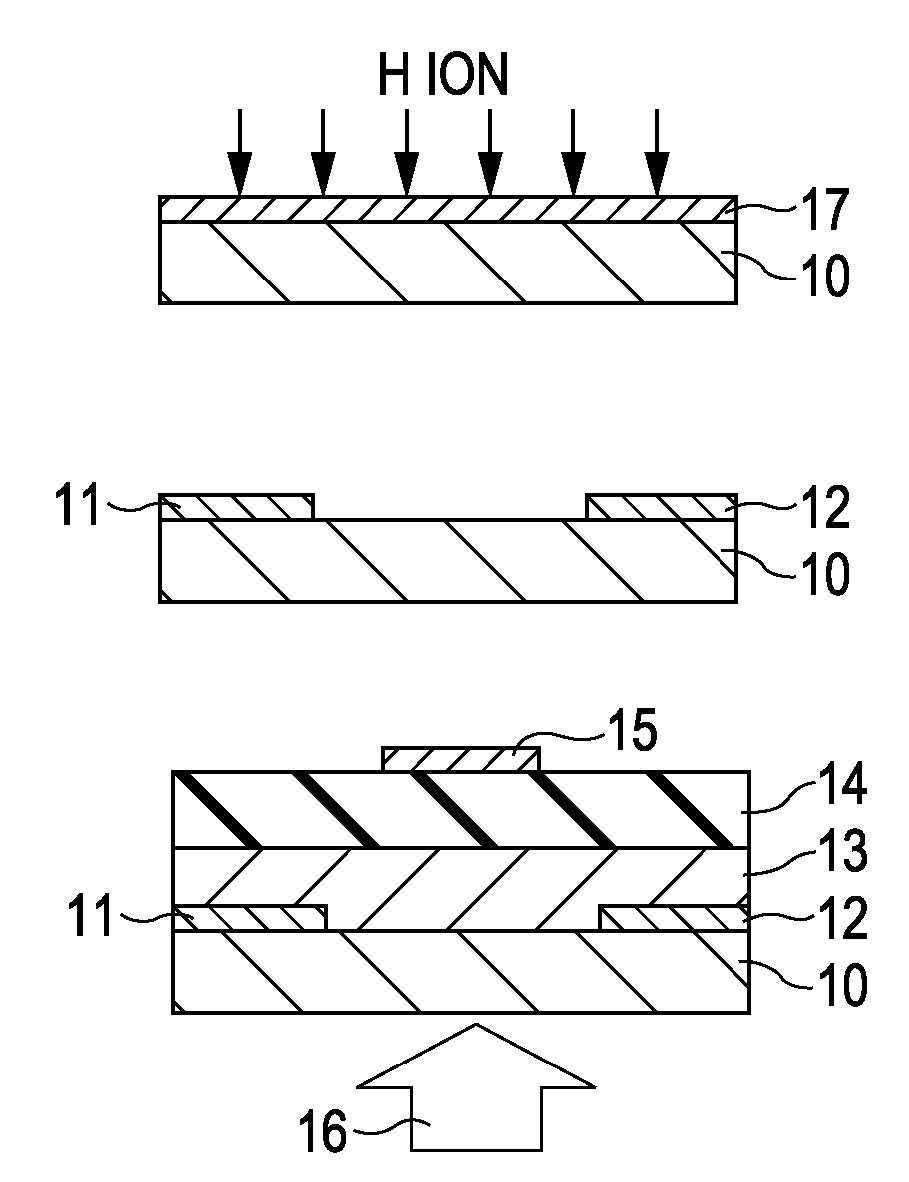

Thin film transistor including selectively crystallized channel layer and method of manufacturing the thin film transistor

ActiveUS20080258140A1Stable contact characteristicHigh carrier mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringIon implantation

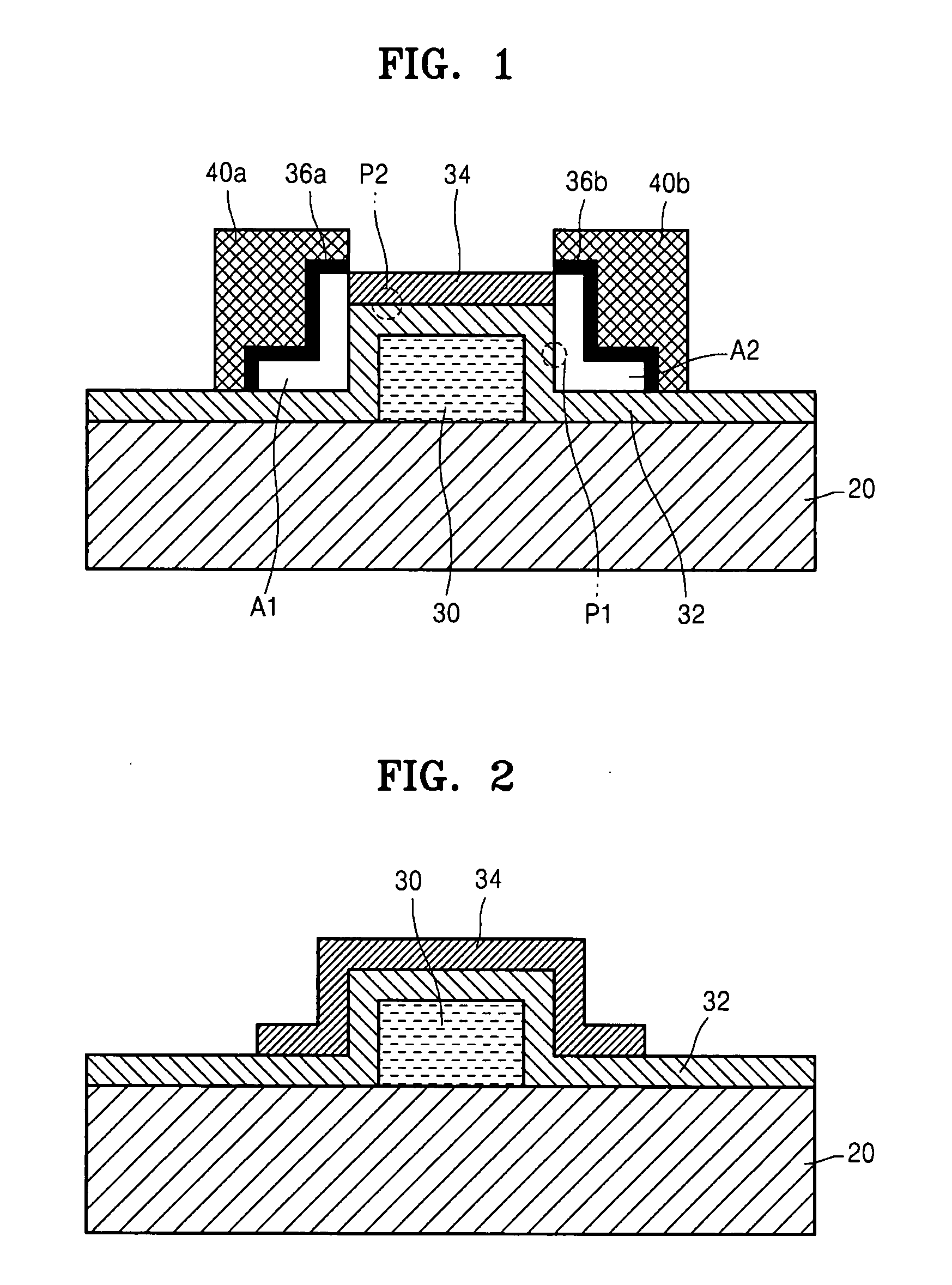

Provided are a thin film transistor (TFT) including a selectively crystallized channel layer, and a method of manufacturing the TFT. The TFT includes a gate, the channel layer, a source, and a drain. The channel layer is formed of an oxide semiconductor, and at least a portion of the channel layer contacting the source and the drain is crystallized. In the method of manufacturing the TFT, the channel layer is formed of an oxide semiconductor, and a metal component is injected into the channel layer so as to crystallize at least a portion of the channel layer contacting the source and the drain. The metal component can be injected into the channel layer by depositing and heat-treating a metal layer or by ion-implantation.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor device including active layer made of zinc oxide with controlled orientations and manufacturing method thereof

InactiveUS20070187678A1Improve heat resistanceImprove propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesZincActive layer

A semiconductor device includes an oxide semiconductor thin film layer primarily including zinc oxide having at least one orientation other than (002) orientation. The zinc oxide may have a mixed orientation including (002) orientation and (101) orientation. Alternatively, the zinc oxide may have a mixed orientation including (100) orientation and (101) orientation.

Owner:KOICHI IND PROMOTION CENT +1

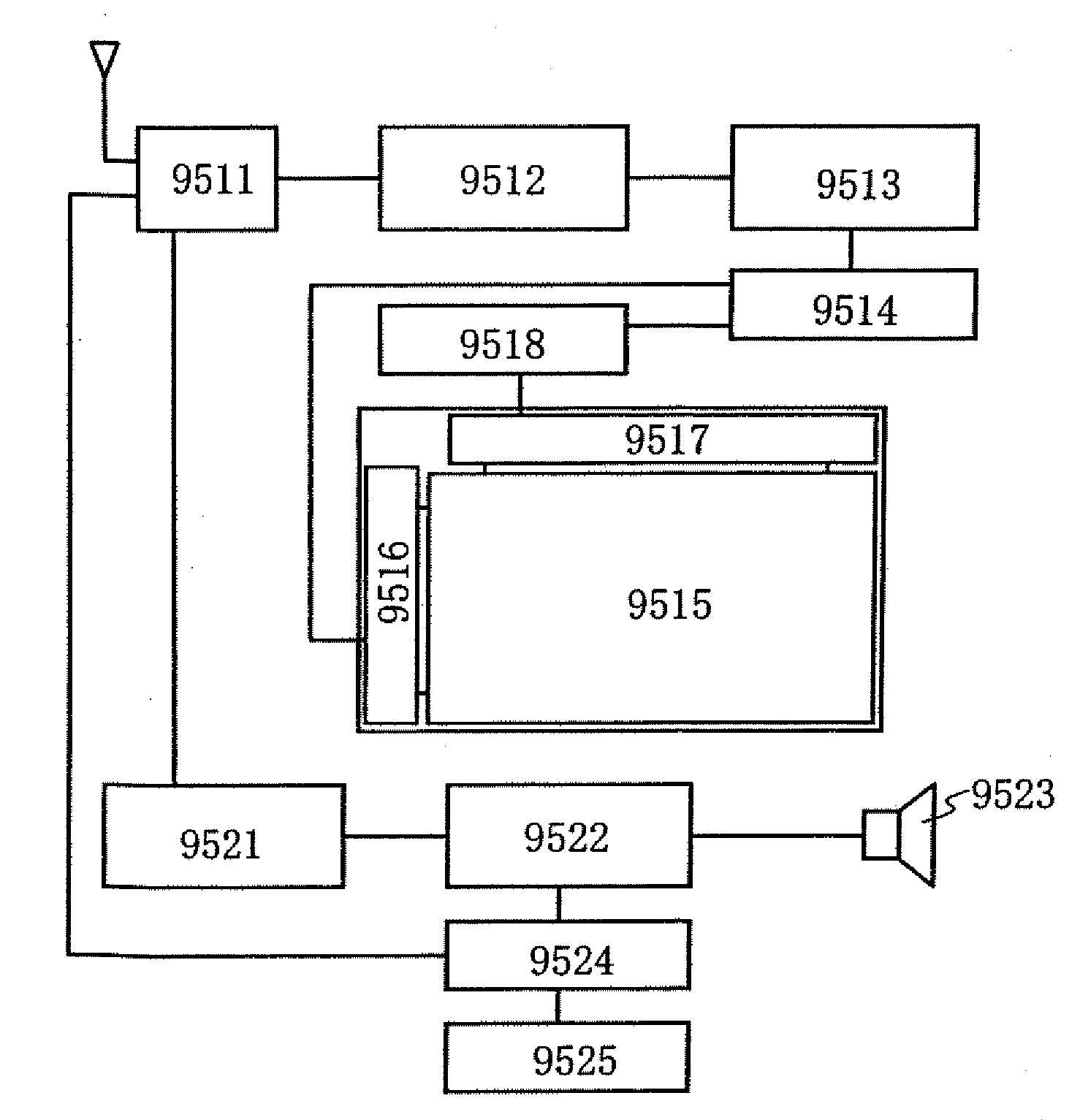

Semiconductor device and method for manufacturing the same, and electric device

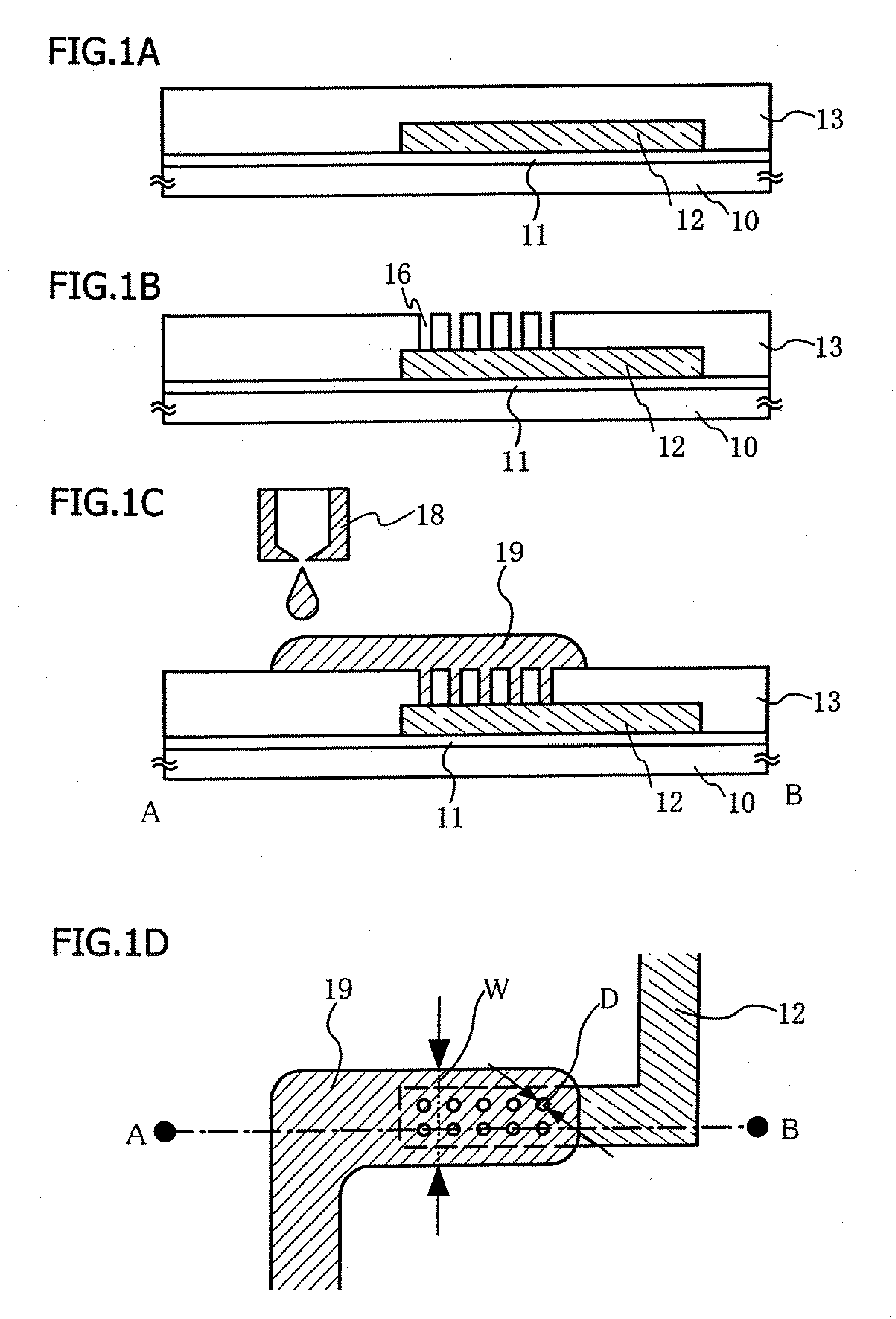

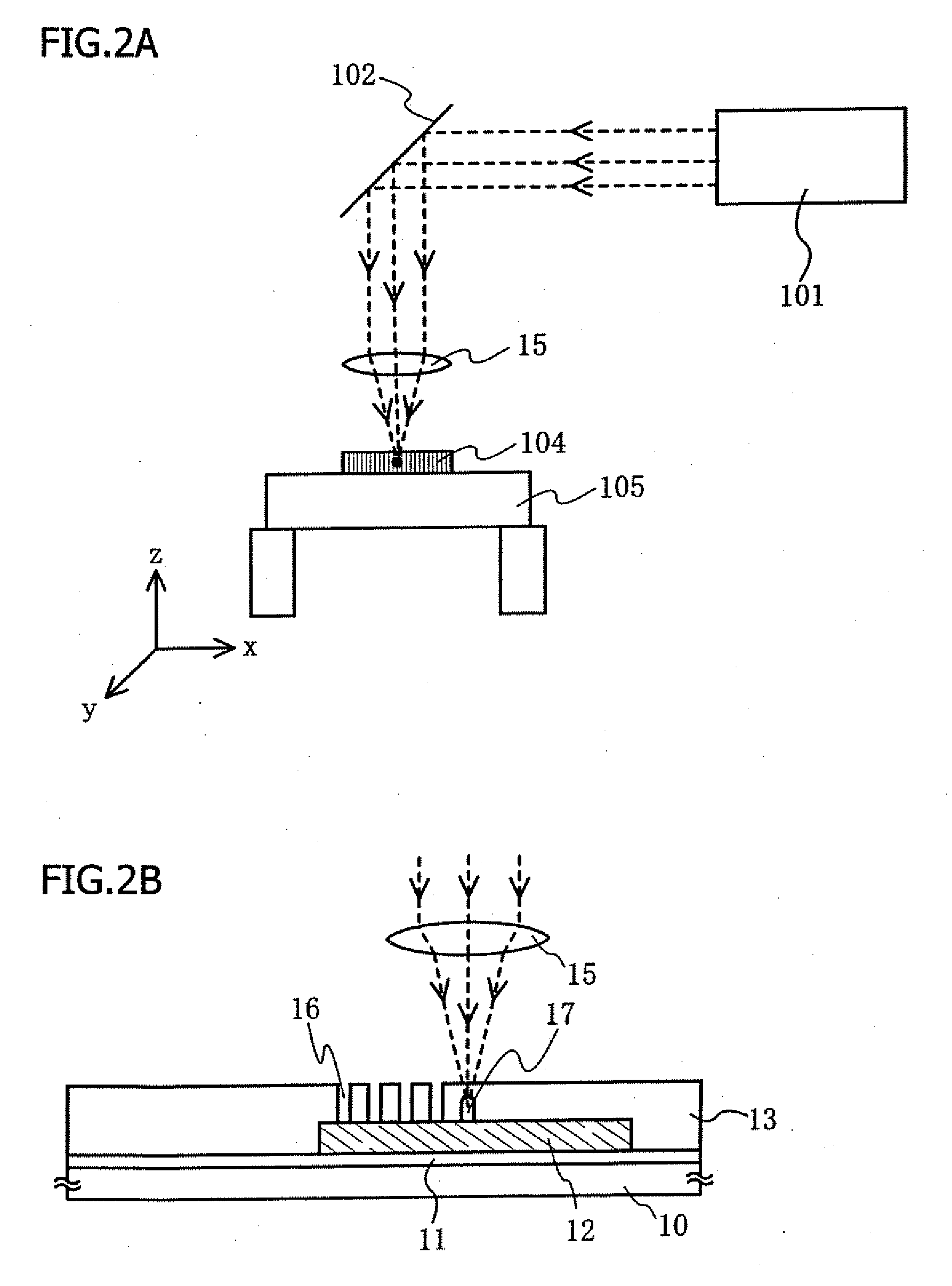

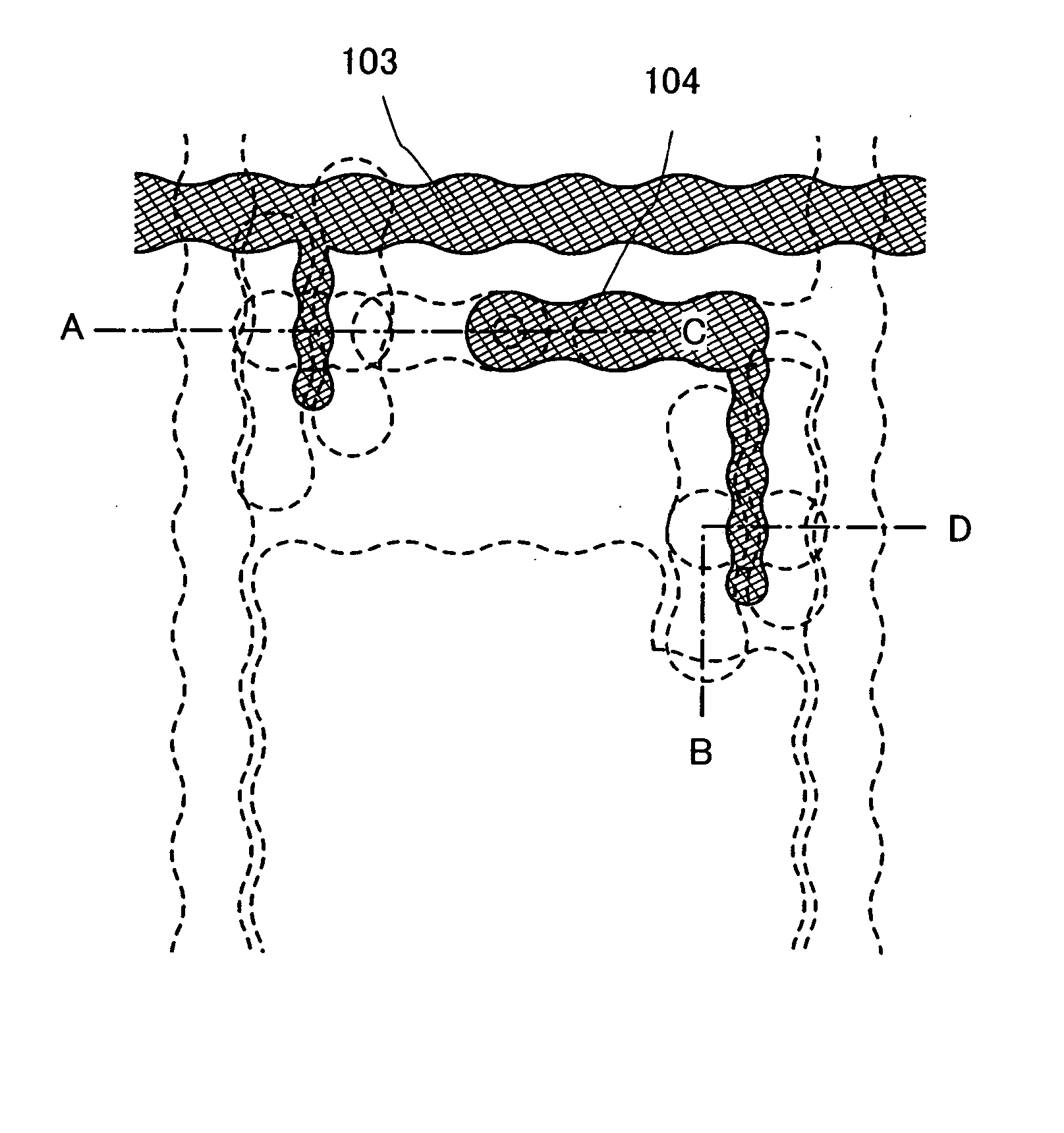

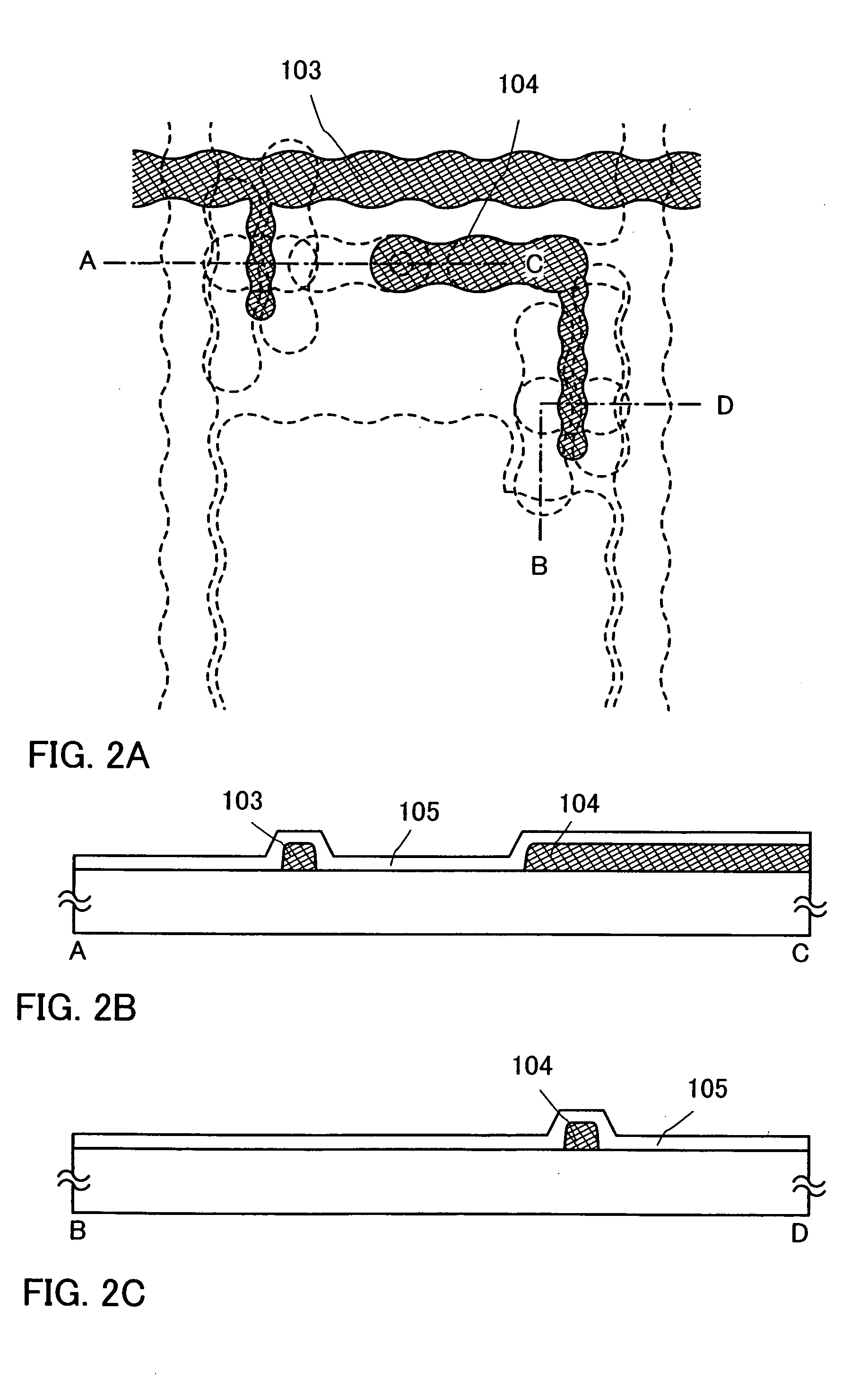

InactiveUS20090073325A1Simple stepsHighly integratedTransistorTelevision system detailsElectrical resistance and conductanceLongest Diameter

It is an object of the present invention to simplify steps needed to process a wiring in forming a multilayer wiring. In addition, when a droplet discharging technique or a nanoimprint technique is used to form a wiring in a contact hole having a comparatively long diameter, the wiring in accordance with the shape of the contact hole is formed, and the wiring portion of the contact hole is likely to have a depression compared with other portions. A penetrating opening is formed by irradiating a light-transmitting insulating film with laser light having high intensity and a pulse high in repetition frequency. A plurality of openings having a minute contact area is provided instead of forming one penetrating opening having a large contact area to have an even thickness of a wiring by reducing a partial depression and also to ensure contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

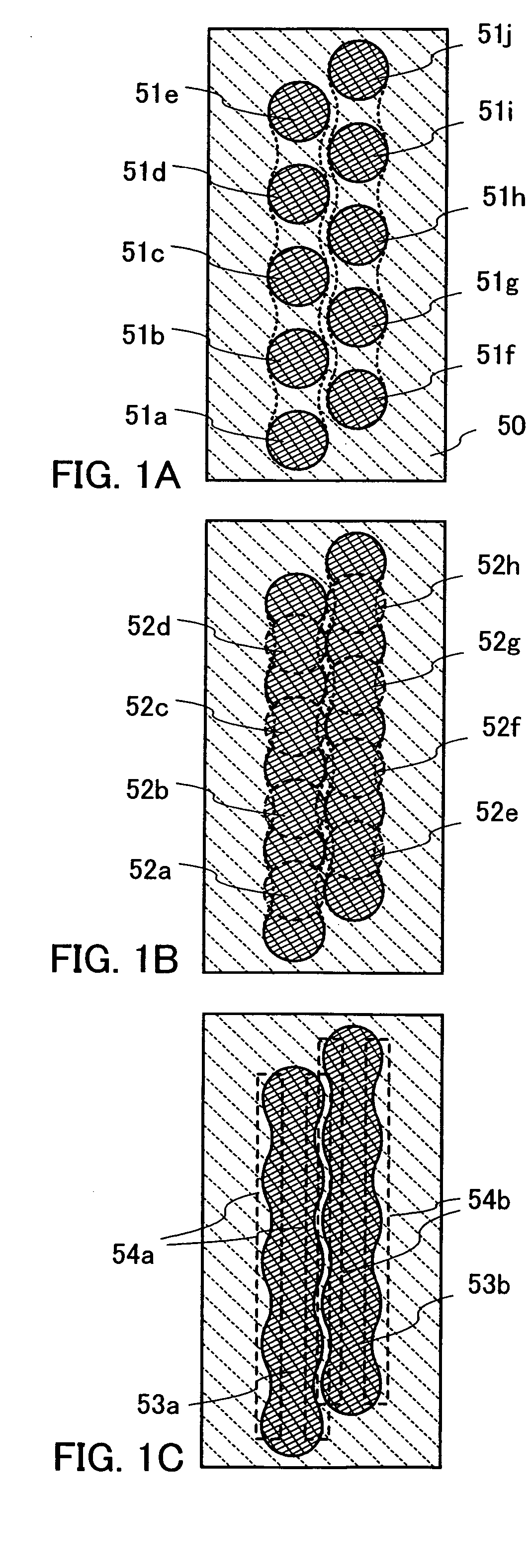

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060170111A1Stable formationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialShortest distance

Conductive layers having knots are adjacently formed with uniform distance therebetween. Droplets of the conductive layers are discharged to stagger centers of the droplets in a length direction of wirings so that the centers of the discharged droplets are not on the same line in a line width direction between the adjacent conductive layers. Since the centers of the droplets are staggered, parts of the conductive layers each having a widest line width (the widest width of knot) are not connected to each other, and the conductive layers can be formed adjacently with a shorter distance therebetween.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device in which zinc oxide is used as a semiconductor material and method for manufacturing the semiconductor device

ActiveUS7501293B2Improve surface smoothnessHigh crystallinityTransistorLaser detailsSemiconductor materialsDevice material

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer) primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrate. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

Method for fabricating pixel structure of active matrix organic light-emitting diode

ActiveUS20090068773A1Improve pixel aperture ratioIncrease the aperture ratioSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixScan line

Owner:IND TECH RES INST

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com